fb820f5b54c5764b6f7661729201572b.ppt

- Количество слайдов: 30

A Seminar on MEMS (Microelectromechanical Systems) Growing in a Shrinking World 1

A Seminar on MEMS (Microelectromechanical Systems) Growing in a Shrinking World 1

CONTENTS • INTRODUCTION • MICROMACHINING PROCESSES • MICROSENSORS AND MICROACTUATORS • MEMS DEVICES AND APPLICATIONS • FUTURE PROSPECTS • CONCLUSION 2

CONTENTS • INTRODUCTION • MICROMACHINING PROCESSES • MICROSENSORS AND MICROACTUATORS • MEMS DEVICES AND APPLICATIONS • FUTURE PROSPECTS • CONCLUSION 2

INTRODUCTION 3

INTRODUCTION 3

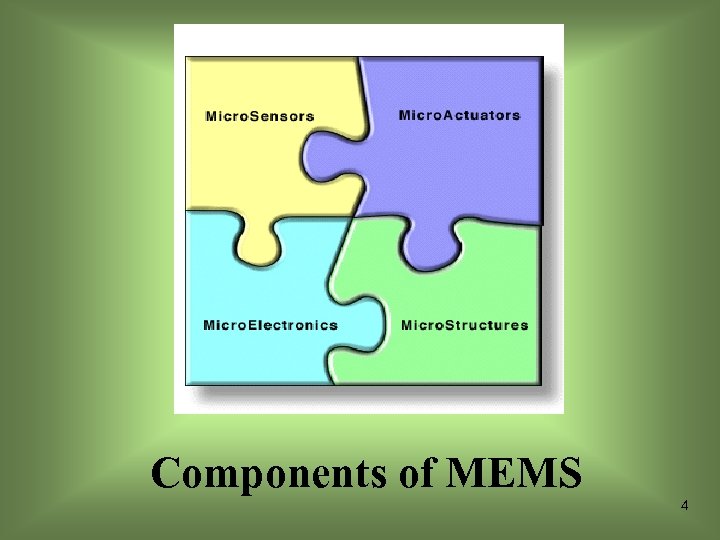

Components of MEMS 4

Components of MEMS 4

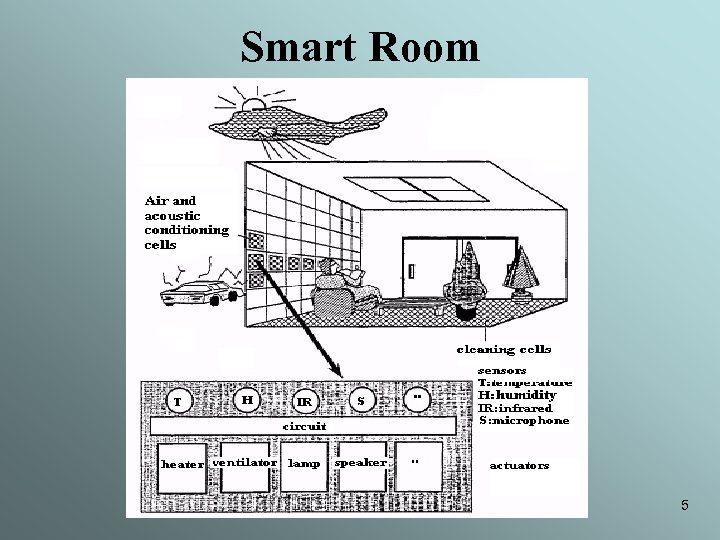

Smart Room 5

Smart Room 5

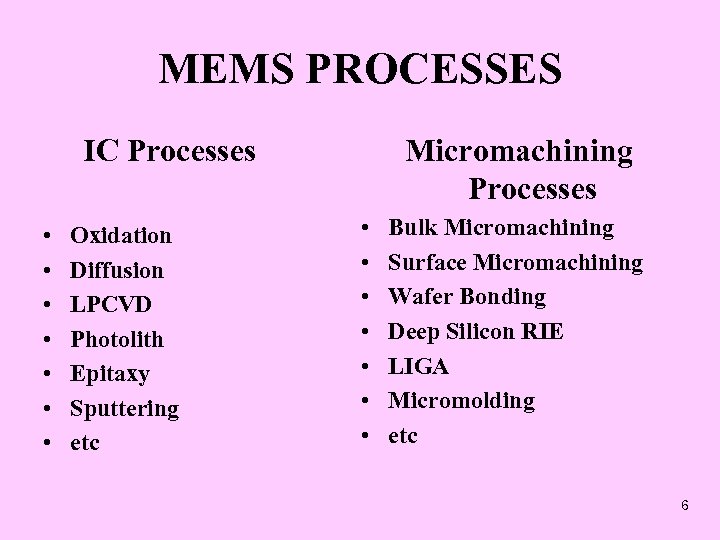

MEMS PROCESSES IC Processes • • Oxidation Diffusion LPCVD Photolith Epitaxy Sputtering etc Micromachining Processes • • Bulk Micromachining Surface Micromachining Wafer Bonding Deep Silicon RIE LIGA Micromolding etc 6

MEMS PROCESSES IC Processes • • Oxidation Diffusion LPCVD Photolith Epitaxy Sputtering etc Micromachining Processes • • Bulk Micromachining Surface Micromachining Wafer Bonding Deep Silicon RIE LIGA Micromolding etc 6

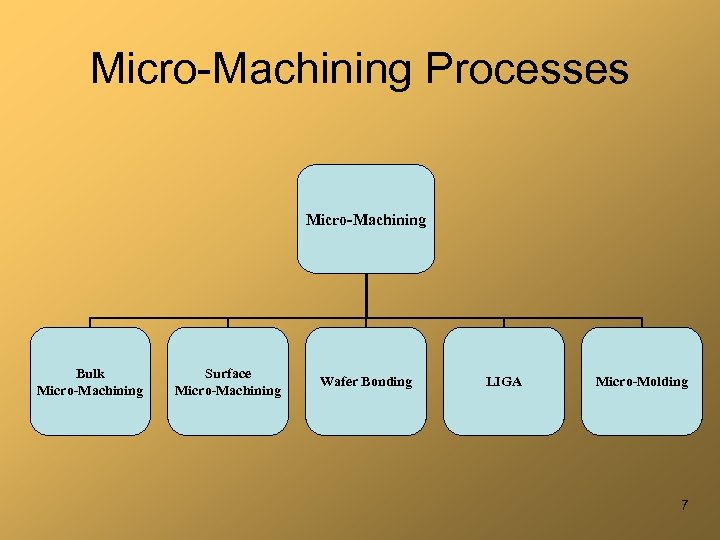

Micro-Machining Processes Micro-Machining Bulk Micro-Machining Surface Micro-Machining Wafer Bonding LIGA Micro-Molding 7

Micro-Machining Processes Micro-Machining Bulk Micro-Machining Surface Micro-Machining Wafer Bonding LIGA Micro-Molding 7

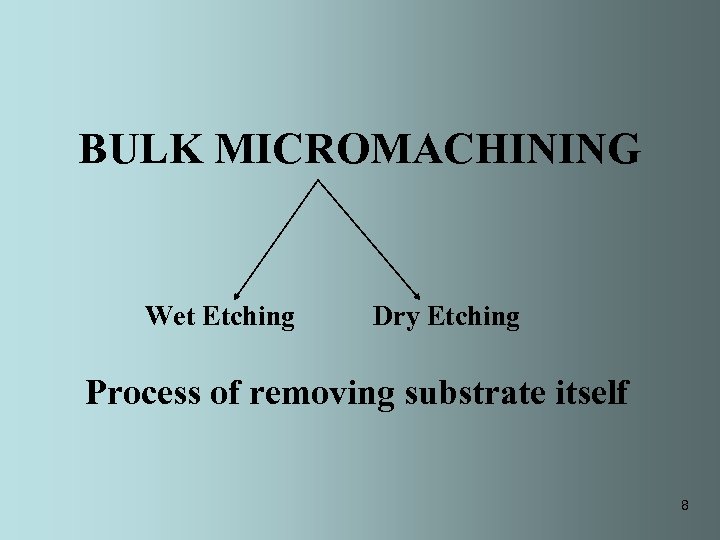

BULK MICROMACHINING Wet Etching Dry Etching Process of removing substrate itself 8

BULK MICROMACHINING Wet Etching Dry Etching Process of removing substrate itself 8

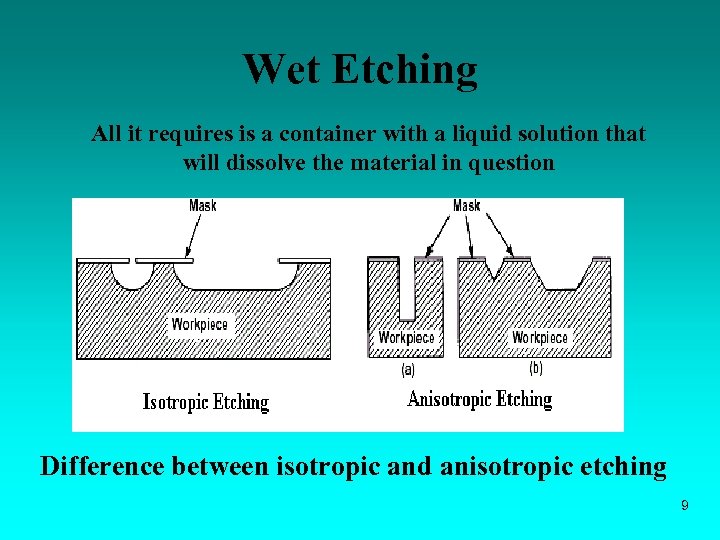

Wet Etching All it requires is a container with a liquid solution that will dissolve the material in question Difference between isotropic and anisotropic etching 9

Wet Etching All it requires is a container with a liquid solution that will dissolve the material in question Difference between isotropic and anisotropic etching 9

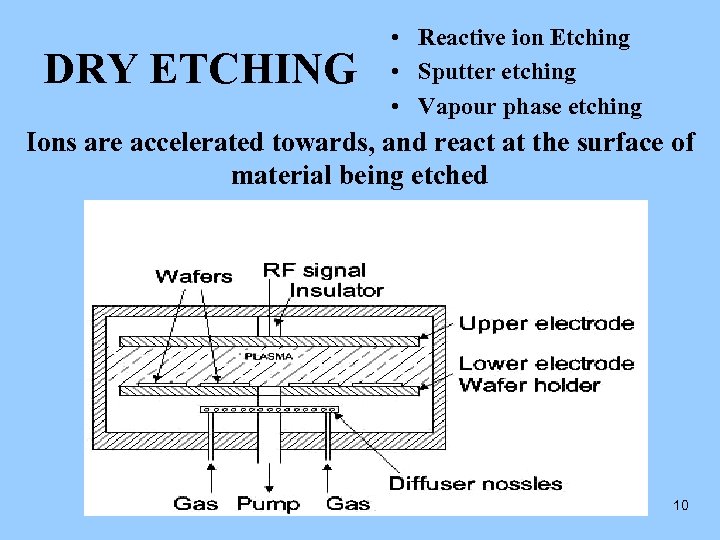

DRY ETCHING • Reactive ion Etching • Sputter etching • Vapour phase etching Ions are accelerated towards, and react at the surface of material being etched 10

DRY ETCHING • Reactive ion Etching • Sputter etching • Vapour phase etching Ions are accelerated towards, and react at the surface of material being etched 10

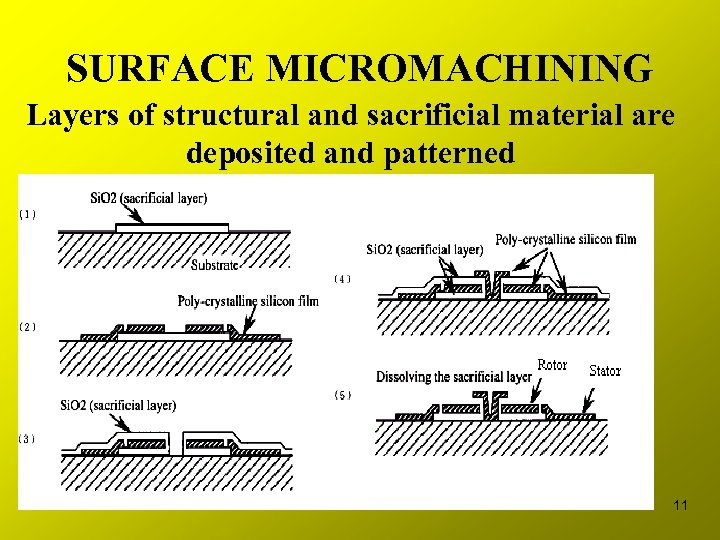

SURFACE MICROMACHINING Layers of structural and sacrificial material are deposited and patterned 11

SURFACE MICROMACHINING Layers of structural and sacrificial material are deposited and patterned 11

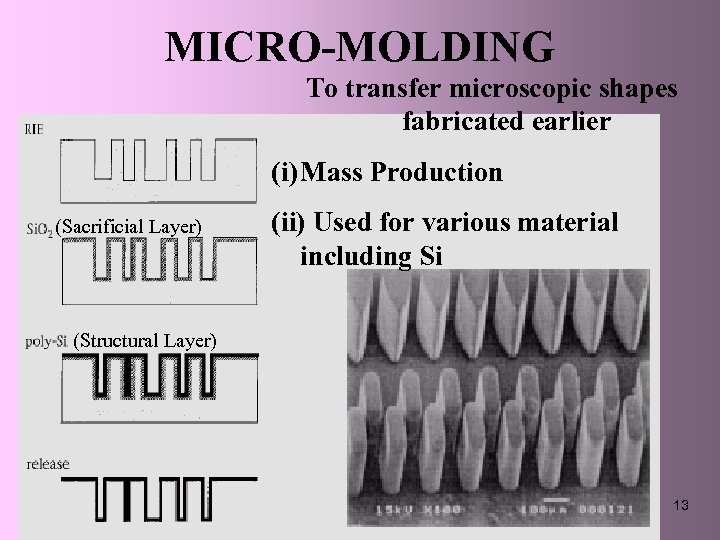

MICRO-MOLDING To transfer microscopic shapes fabricated earlier (i) Mass Production (Sacrificial Layer) (ii) Used for various material including Si (Structural Layer) 13

MICRO-MOLDING To transfer microscopic shapes fabricated earlier (i) Mass Production (Sacrificial Layer) (ii) Used for various material including Si (Structural Layer) 13

Micro Sensors and Micro Actuators 14

Micro Sensors and Micro Actuators 14

Micro Sensors • • Mechanical Sensors Thermal Sensors Radiation Sensors Magnetic Sensors 15

Micro Sensors • • Mechanical Sensors Thermal Sensors Radiation Sensors Magnetic Sensors 15

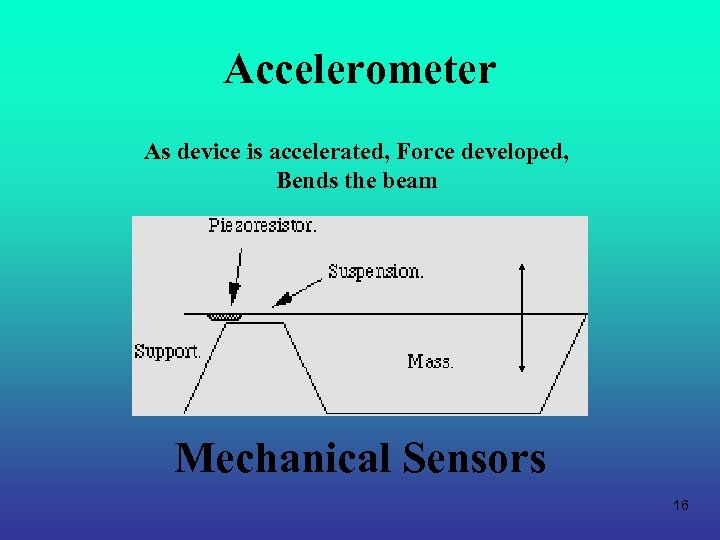

Accelerometer As device is accelerated, Force developed, Bends the beam Mechanical Sensors 16

Accelerometer As device is accelerated, Force developed, Bends the beam Mechanical Sensors 16

RADIATION SENSOR • PHOTO-DIODE • Reversed Biased p-n junction diode • As light falls; charge carriers are generated and more current flows in the circuit 17

RADIATION SENSOR • PHOTO-DIODE • Reversed Biased p-n junction diode • As light falls; charge carriers are generated and more current flows in the circuit 17

Micro Actuators • • • Electrostatic actuators Magnetic actuators Piezoelectric actuators Hydraulic actuators Thermal actuators 18

Micro Actuators • • • Electrostatic actuators Magnetic actuators Piezoelectric actuators Hydraulic actuators Thermal actuators 18

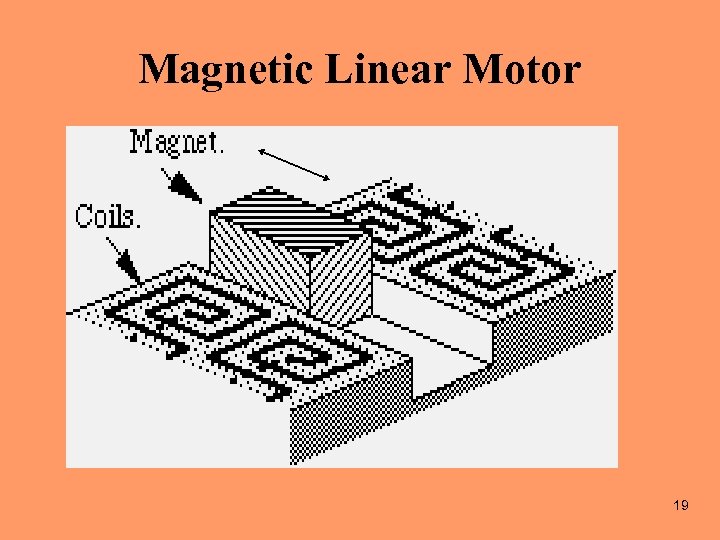

Magnetic Linear Motor 19

Magnetic Linear Motor 19

MEMS Devices and Applications 21

MEMS Devices and Applications 21

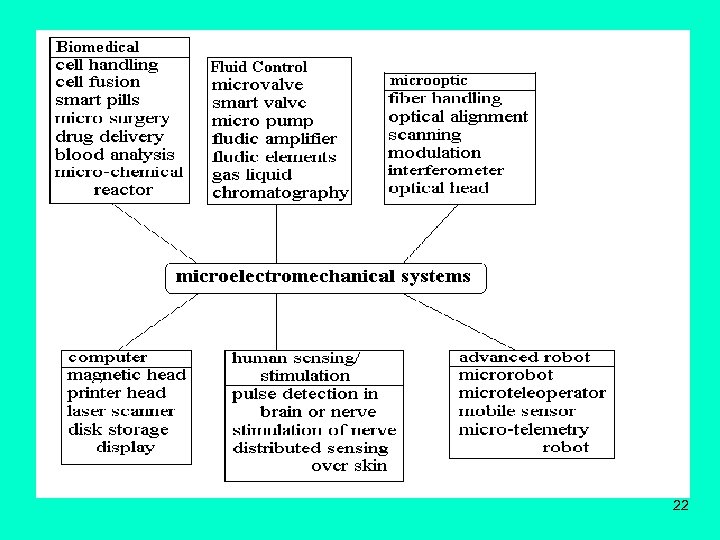

22

22

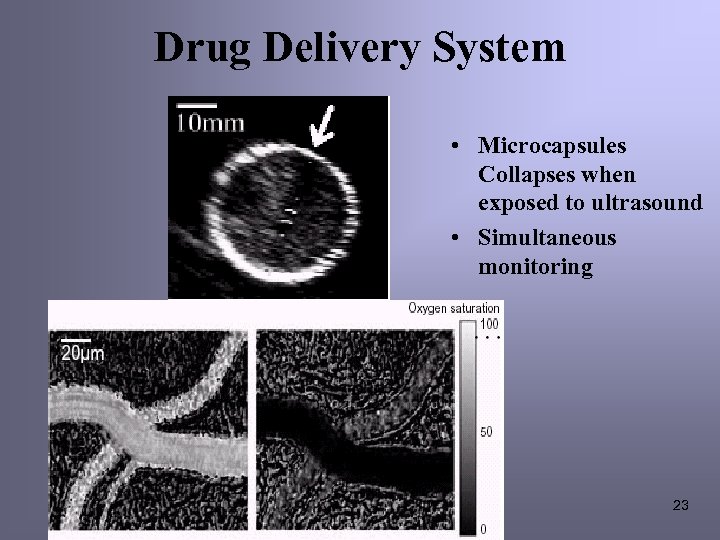

Drug Delivery System • Microcapsules Collapses when exposed to ultrasound • Simultaneous monitoring 23

Drug Delivery System • Microcapsules Collapses when exposed to ultrasound • Simultaneous monitoring 23

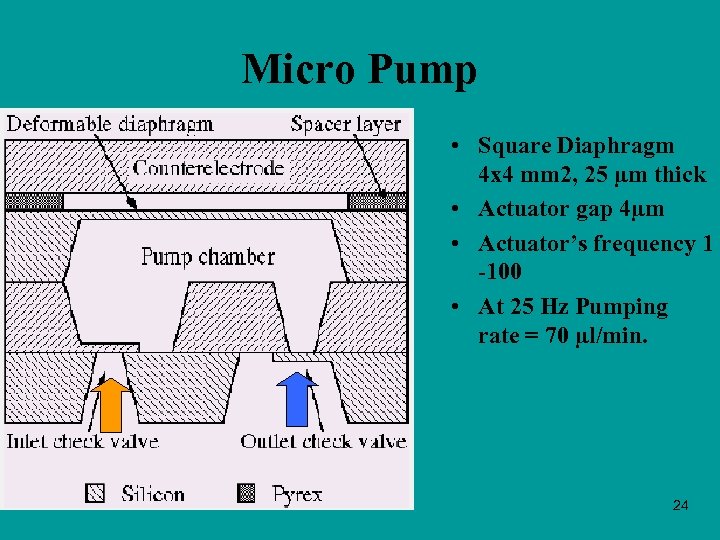

Micro Pump • Square Diaphragm 4 x 4 mm 2, 25 µm thick • Actuator gap 4µm • Actuator’s frequency 1 -100 • At 25 Hz Pumping rate = 70 µl/min. 24

Micro Pump • Square Diaphragm 4 x 4 mm 2, 25 µm thick • Actuator gap 4µm • Actuator’s frequency 1 -100 • At 25 Hz Pumping rate = 70 µl/min. 24

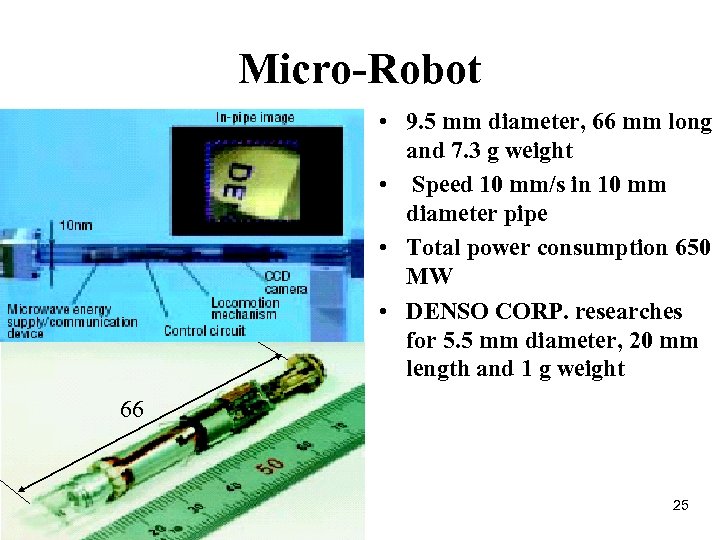

Micro-Robot • 9. 5 mm diameter, 66 mm long and 7. 3 g weight • Speed 10 mm/s in 10 mm diameter pipe • Total power consumption 650 MW • DENSO CORP. researches for 5. 5 mm diameter, 20 mm length and 1 g weight 66 25

Micro-Robot • 9. 5 mm diameter, 66 mm long and 7. 3 g weight • Speed 10 mm/s in 10 mm diameter pipe • Total power consumption 650 MW • DENSO CORP. researches for 5. 5 mm diameter, 20 mm length and 1 g weight 66 25

Future Prospects 27

Future Prospects 27

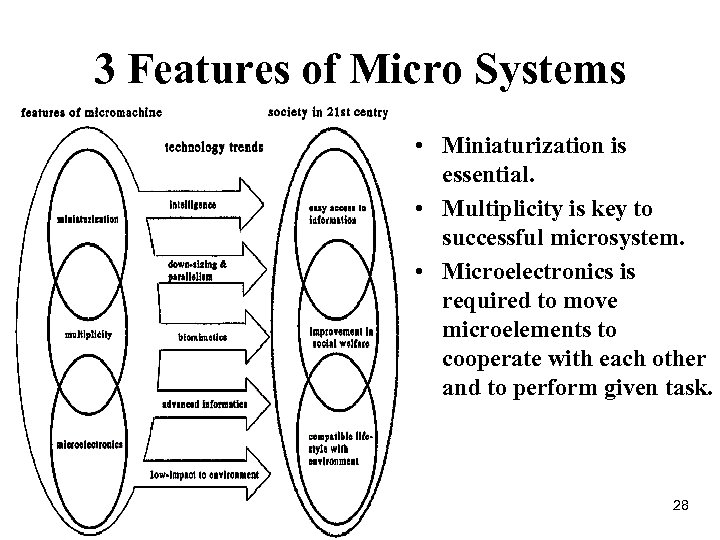

3 Features of Micro Systems • Miniaturization is essential. • Multiplicity is key to successful microsystem. • Microelectronics is required to move microelements to cooperate with each other and to perform given task. 28

3 Features of Micro Systems • Miniaturization is essential. • Multiplicity is key to successful microsystem. • Microelectronics is required to move microelements to cooperate with each other and to perform given task. 28

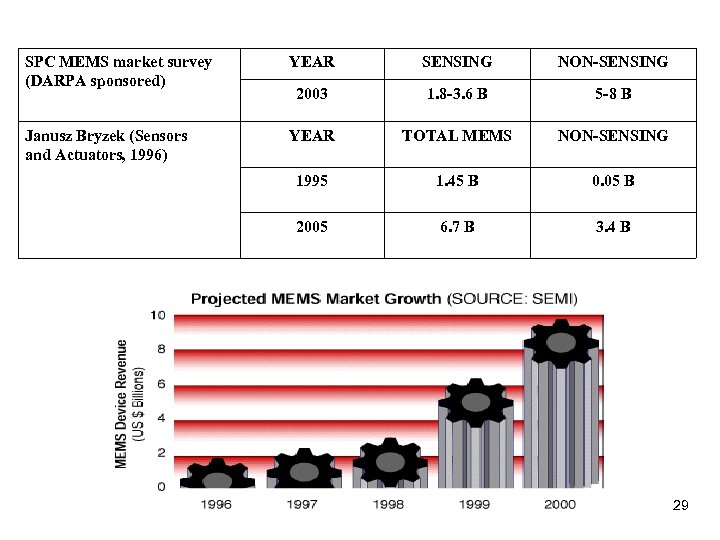

SPC MEMS market survey (DARPA sponsored) YEAR SENSING NON-SENSING 2003 1. 8 -3. 6 B 5 -8 B Janusz Bryzek (Sensors and Actuators, 1996) YEAR TOTAL MEMS NON-SENSING 1995 1. 45 B 0. 05 B 2005 6. 7 B 3. 4 B 29

SPC MEMS market survey (DARPA sponsored) YEAR SENSING NON-SENSING 2003 1. 8 -3. 6 B 5 -8 B Janusz Bryzek (Sensors and Actuators, 1996) YEAR TOTAL MEMS NON-SENSING 1995 1. 45 B 0. 05 B 2005 6. 7 B 3. 4 B 29

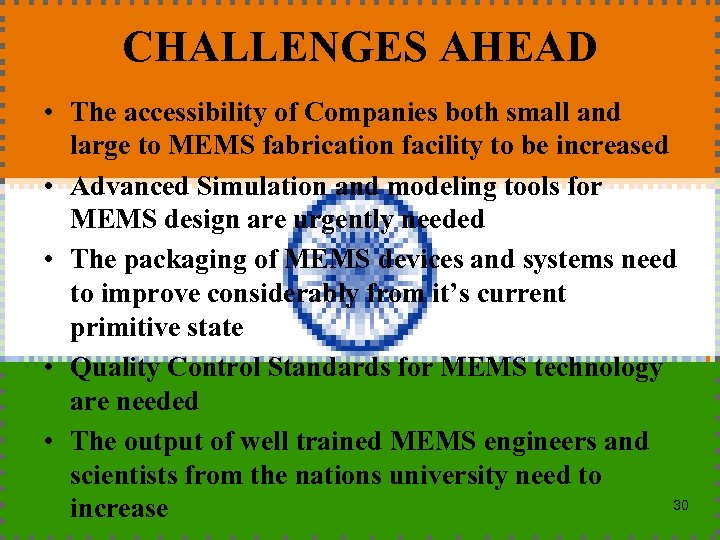

CHALLENGES AHEAD • The accessibility of Companies both small and large to MEMS fabrication facility to be increased • Advanced Simulation and modeling tools for MEMS design are urgently needed • The packaging of MEMS devices and systems need to improve considerably from it’s current primitive state • Quality Control Standards for MEMS technology are needed • The output of well trained MEMS engineers and scientists from the nations university need to 30 increase

CHALLENGES AHEAD • The accessibility of Companies both small and large to MEMS fabrication facility to be increased • Advanced Simulation and modeling tools for MEMS design are urgently needed • The packaging of MEMS devices and systems need to improve considerably from it’s current primitive state • Quality Control Standards for MEMS technology are needed • The output of well trained MEMS engineers and scientists from the nations university need to 30 increase

CONCLUSIONS MEMS have been emerging as a new technology in the past decade. They will continue to develop as an independent technology in the future, while their techniques continue to disperse to other technological fields. The strategy being proven successful in developing MEMS is: according to the features of the micromachining, attention has been paid to develop MEMS devices that communicate with the outside world through non contact signals, i. e. , electrical, magnetic and optical signals. MEMS will have profound impact on the future society. It is necessary to continue and enhance research activities in both fundamental and application related area. Fusion of knowledge in different disciplines is essential for well balanced accelerated growth of the technology. I believe since, MEMS is a nascent and synergistic technology, many new applications will emerge, expanding the markets beyond that which is currently identified or known. 31

CONCLUSIONS MEMS have been emerging as a new technology in the past decade. They will continue to develop as an independent technology in the future, while their techniques continue to disperse to other technological fields. The strategy being proven successful in developing MEMS is: according to the features of the micromachining, attention has been paid to develop MEMS devices that communicate with the outside world through non contact signals, i. e. , electrical, magnetic and optical signals. MEMS will have profound impact on the future society. It is necessary to continue and enhance research activities in both fundamental and application related area. Fusion of knowledge in different disciplines is essential for well balanced accelerated growth of the technology. I believe since, MEMS is a nascent and synergistic technology, many new applications will emerge, expanding the markets beyond that which is currently identified or known. 31

REFERENCES 1) Hiroyuki Fujita, Future of actuators and microsystems, Sensors and Actuators, A 56 (1996) 105111. 2) Minhang Bao, Weiyuan Wang, Future of microelectromechanical systems (MEMS), Sensors and Actuators, A 56 (1996) 135 -141. 3) Janusz Bryzek, Impact of MEMS technology on society, Sensors and Actuators, A 56 (1996) 1 -9. 4) Wayne P. Liu, George H. Brodie, A demonstration of MEMS-based active turbulence transitioning, International Journal of Heat and Fluid Flow, 21 (2000) 297 -303. 5) Mehran Mehregany and Andrew S. Dewa, Introduction to MICROELECTROMECHANICAL SYSTEMS AND THE MULTIUSER MEMS PROCESSES, Part I, MEMS OVERVIEW, Electronics Design Center, Cleveland OH. 6) Mehran Mehregany and Andrew S. Dewa, Introduction to MICROELECTROMECHANICAL SYSTEMS AND THE MULTIUSER MEMS PROCESSES, Part II, SURFACE MICROMACHINING TECHNOLOGY, Electronics Design Center, Cleveland OH 7) Kohji Masuda, Norihiko Tateishi, Eizen Kimura, and Ken Ishihara, Ultrasound DDS using Microcapsules and Visualization of Oxygen Saturation Levels in Microcirculations, MICROMACHINE No. 37, October 19, 2001. 8) Professor Kazuo Sato, Introductory Course, Latest Micromachining Technology – Part 1. MICROMACHINE No. 33, February 2000. 9) Professor Kazuo Sato, Introductory Course, Latest Micromachining Technology – Part 4. MICROMACHINE No. 34, February 2001. 10) http: //home. earthlink. net/ 11) http: //www. dbanks. demon. co. uk/ 12) http: //www. mems-exchange. org/ 32

REFERENCES 1) Hiroyuki Fujita, Future of actuators and microsystems, Sensors and Actuators, A 56 (1996) 105111. 2) Minhang Bao, Weiyuan Wang, Future of microelectromechanical systems (MEMS), Sensors and Actuators, A 56 (1996) 135 -141. 3) Janusz Bryzek, Impact of MEMS technology on society, Sensors and Actuators, A 56 (1996) 1 -9. 4) Wayne P. Liu, George H. Brodie, A demonstration of MEMS-based active turbulence transitioning, International Journal of Heat and Fluid Flow, 21 (2000) 297 -303. 5) Mehran Mehregany and Andrew S. Dewa, Introduction to MICROELECTROMECHANICAL SYSTEMS AND THE MULTIUSER MEMS PROCESSES, Part I, MEMS OVERVIEW, Electronics Design Center, Cleveland OH. 6) Mehran Mehregany and Andrew S. Dewa, Introduction to MICROELECTROMECHANICAL SYSTEMS AND THE MULTIUSER MEMS PROCESSES, Part II, SURFACE MICROMACHINING TECHNOLOGY, Electronics Design Center, Cleveland OH 7) Kohji Masuda, Norihiko Tateishi, Eizen Kimura, and Ken Ishihara, Ultrasound DDS using Microcapsules and Visualization of Oxygen Saturation Levels in Microcirculations, MICROMACHINE No. 37, October 19, 2001. 8) Professor Kazuo Sato, Introductory Course, Latest Micromachining Technology – Part 1. MICROMACHINE No. 33, February 2000. 9) Professor Kazuo Sato, Introductory Course, Latest Micromachining Technology – Part 4. MICROMACHINE No. 34, February 2001. 10) http: //home. earthlink. net/ 11) http: //www. dbanks. demon. co. uk/ 12) http: //www. mems-exchange. org/ 32

Thank You 33

Thank You 33