b9e38b8e118dec8986456fda65eedad2.ppt

- Количество слайдов: 25

![a member of the IGM-group [ Hot wire - narrow gap welding ] Z. a member of the IGM-group [ Hot wire - narrow gap welding ] Z.](https://present5.com/presentation/b9e38b8e118dec8986456fda65eedad2/image-1.jpg)

a member of the IGM-group [ Hot wire - narrow gap welding ] Z. I. du Bois Briand 2, rue Paul Beaupère F 44300 NANTES FRANCE Hot wire rev 3 1

Hot wire narrow gap welding a member of the IGM-group Hot wire welding with narrow gap preparation permits : Increase of productivity up to a factor of 9 compared to standard TIG welding Maintain the best affordable quality produced by the TIG process 2

Hot wire narrow gap welding a member of the IGM-group Other advantages of the TIG hot wire process: Can be used on root, filling and finish passes As the TIG process, the TIG HW offers the great advantage to control separately the energy in the arc and the quantity of metal in the weld pool: • easy to control the starting and down slope stages • control of welding energy permits to weld delicate materials as duplex, super duplex, titanium… • fusion operations for repair are simplified 3

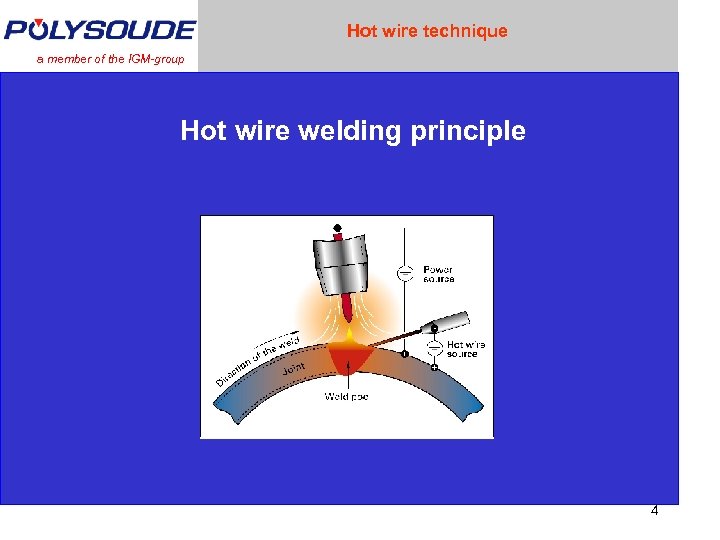

Hot wire technique a member of the IGM-group Hot wire welding principle 4

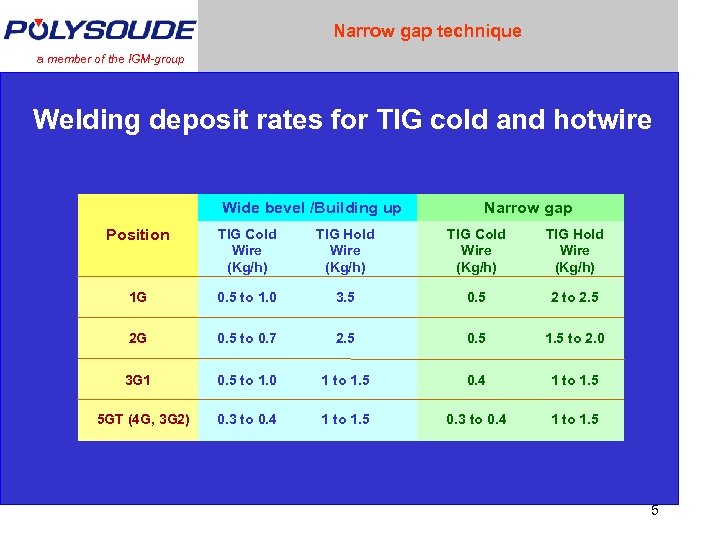

Narrow gap technique a member of the IGM-group Welding deposit rates for TIG cold and hotwire Wide bevel /Building up Narrow gap Position TIG Cold Wire (Kg/h) TIG Hold Wire (Kg/h) 1 G 0. 5 to 1. 0 3. 5 0. 5 2 to 2. 5 2 G 0. 5 to 0. 7 2. 5 0. 5 1. 5 to 2. 0 3 G 1 0. 5 to 1. 0 1 to 1. 5 0. 4 1 to 1. 5 0. 3 to 0. 4 1 to 1. 5 5 GT (4 G, 3 G 2) 5

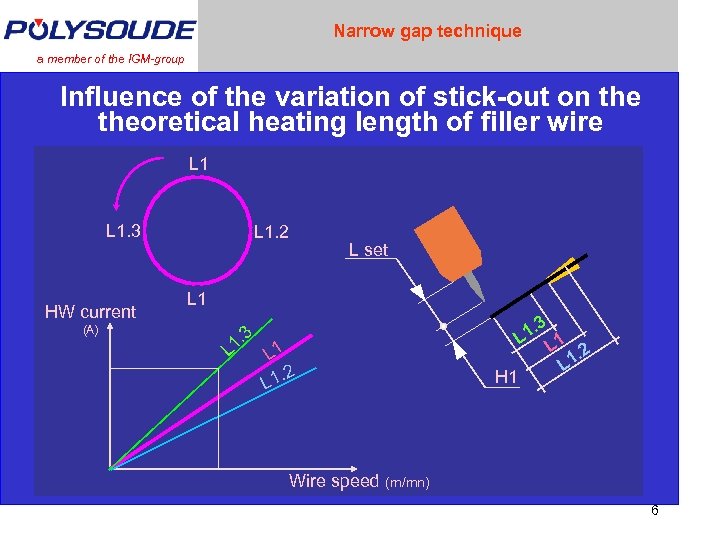

Narrow gap technique a member of the IGM-group Influence of the variation of stick-out on theoretical heating length of filler wire L 1. 3 HW current L 1. 2 L set L 1 (A) L 3 1. L 1 2 L 1. 3 1 L L. 2 L 1 H 1 Wire speed (m/mn) 6

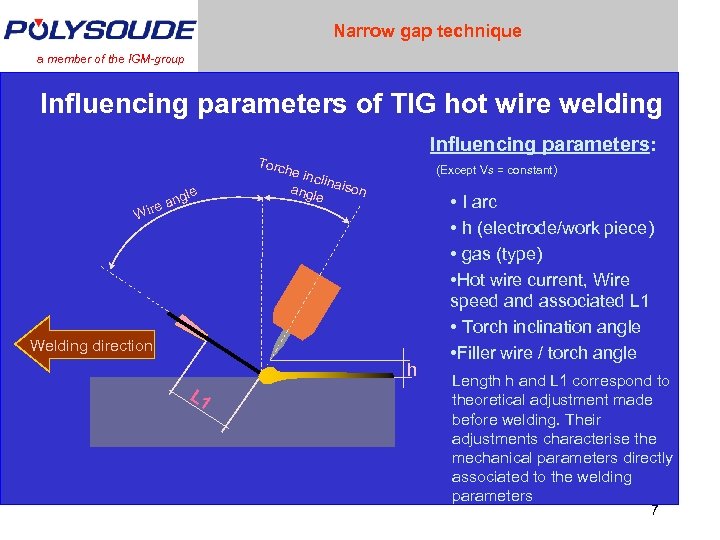

Narrow gap technique a member of the IGM-group Influencing parameters of TIG hot wire welding Torc le ang ire W Influencing parameters: he in clin angl aison e (Except Vs = constant) Welding direction h L 1 • I arc • h (electrode/work piece) • gas (type) • Hot wire current, Wire speed and associated L 1 • Torch inclination angle • Filler wire / torch angle Length h and L 1 correspond to theoretical adjustment made before welding. Their adjustments characterise the mechanical parameters directly associated to the welding parameters 7

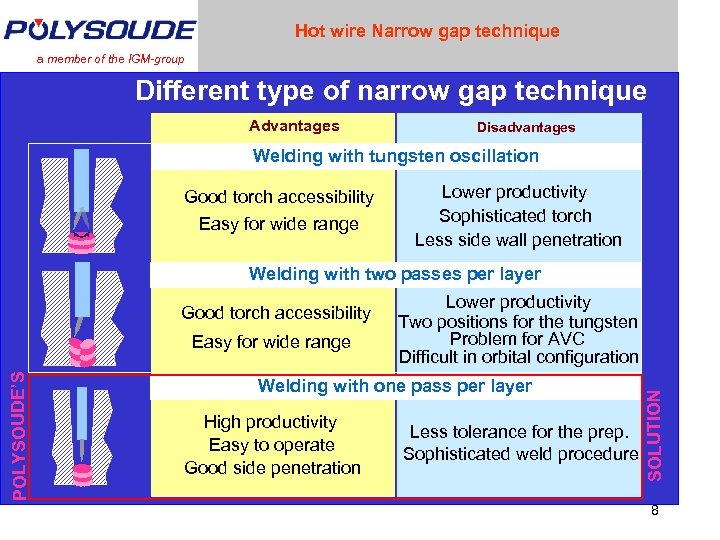

Hot wire Narrow gap technique a member of the IGM-group Different type of narrow gap technique Advantages Disadvantages Welding with tungsten oscillation Good torch accessibility Easy for wide range Lower productivity Sophisticated torch Less side wall penetration Welding with two passes per layer POLYSOUDE’S Easy for wide range Lower productivity Two positions for the tungsten Problem for AVC Difficult in orbital configuration Welding with one pass per layer High productivity Easy to operate Good side penetration Less tolerance for the prep. Sophisticated weld procedure SOLUTION Good torch accessibility 8

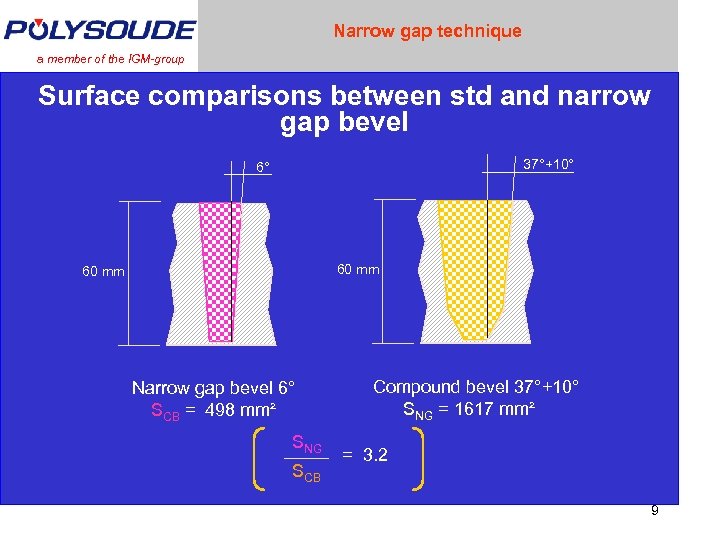

Narrow gap technique a member of the IGM-group Surface comparisons between std and narrow gap bevel 37°+10° 6° 60 mm Narrow gap bevel 6° SCB = 498 mm² SNG SCB Compound bevel 37°+10° SNG = 1617 mm² = 3. 2 9

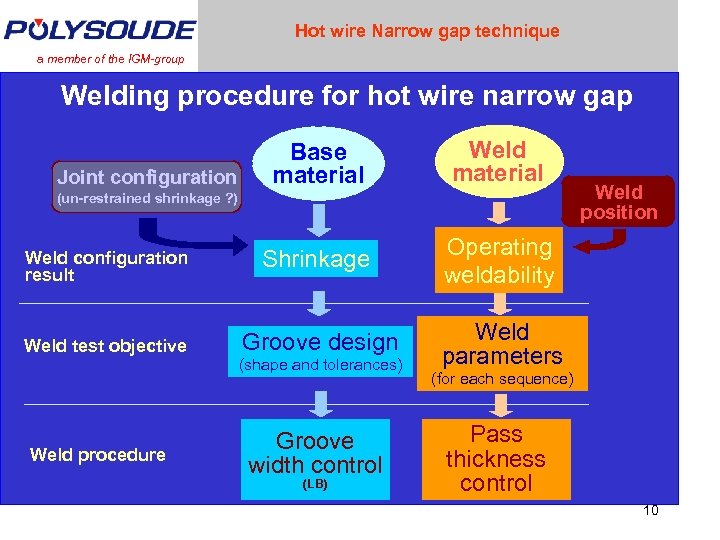

Hot wire Narrow gap technique a member of the IGM-group Welding procedure for hot wire narrow gap Base material Weld configuration result Shrinkage Operating weldability Weld test objective Groove design Weld parameters Joint configuration (un-restrained shrinkage ? ) Weld procedure (shape and tolerances) Groove width control (LB) Weld position (for each sequence) Pass thickness control 10

Narrow gap technique a member of the IGM-group Definition of the bevel design LB LB LB “LB” must be constant for the complete weld For orbital and fixed station welding: 7. 5 mm < LB < 10 mm The groove angle is adjusted according to thickness, material and welding parameters 11

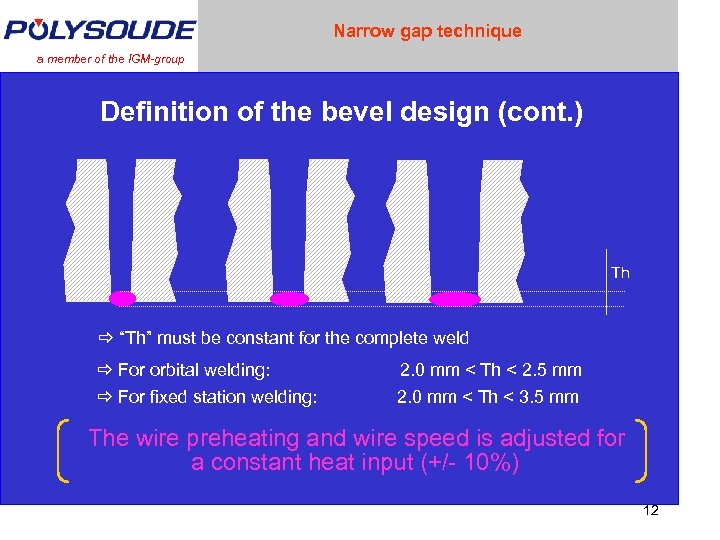

Narrow gap technique a member of the IGM-group Definition of the bevel design (cont. ) Th “Th” must be constant for the complete weld For orbital welding: For fixed station welding: 2. 0 mm < Th < 2. 5 mm 2. 0 mm < Th < 3. 5 mm The wire preheating and wire speed is adjusted for a constant heat input (+/- 10%) 12

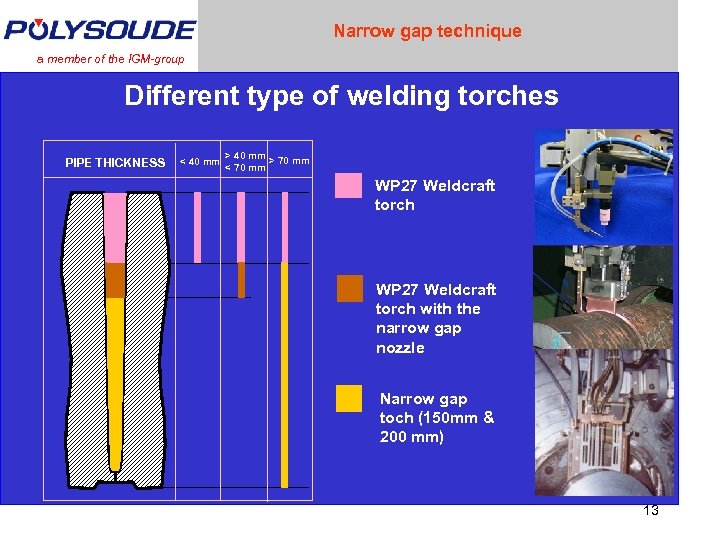

Narrow gap technique a member of the IGM-group Different type of welding torches PIPE THICKNESS < 40 mm > 70 mm < 70 mm WP 27 Weldcraft torch with the narrow gap nozzle Narrow gap toch (150 mm & 200 mm) 13

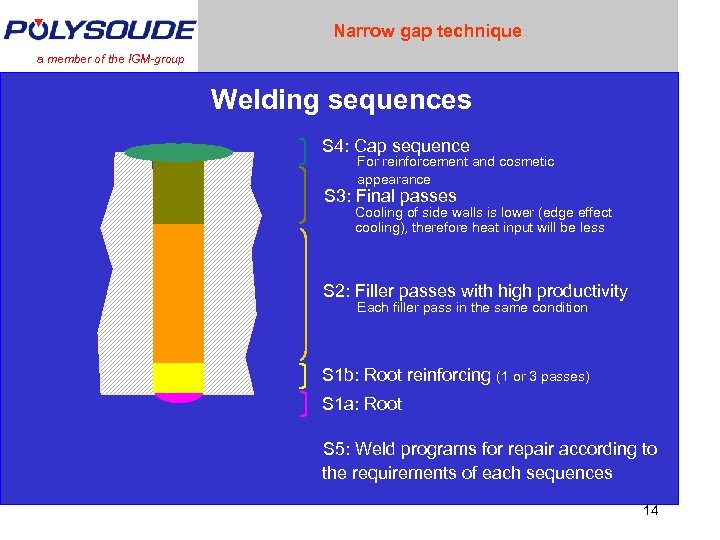

Narrow gap technique a member of the IGM-group Welding sequences S 4: Cap sequence For reinforcement and cosmetic appearance S 3: Final passes Cooling of side walls is lower (edge effect cooling), therefore heat input will be less S 2: Filler passes with high productivity Each filler pass in the same condition S 1 b: Root reinforcing (1 or 3 passes) S 1 a: Root S 5: Weld programs for repair according to the requirements of each sequences 14

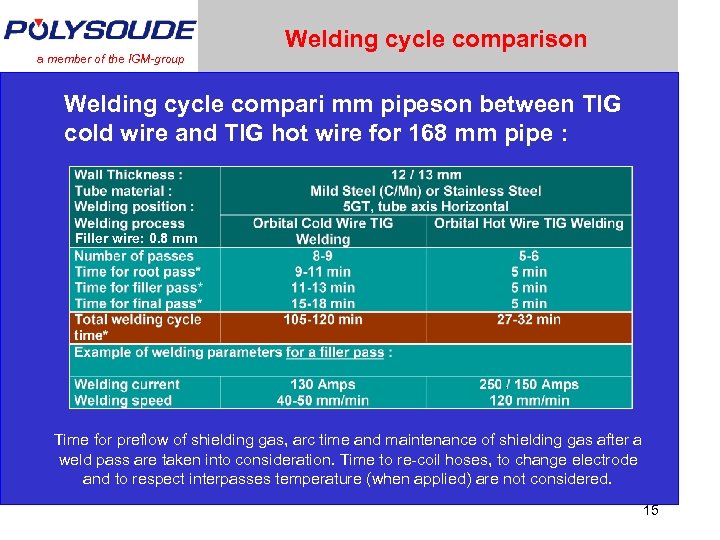

Welding cycle comparison a member of the IGM-group Welding cycle compari mm pipeson between TIG cold wire and TIG hot wire for 168 mm pipe : Filler wire: 0. 8 mm Time for preflow of shielding gas, arc time and maintenance of shielding gas after a weld pass are taken into consideration. Time to re-coil hoses, to change electrode and to respect interpasses temperature (when applied) are not considered. 15

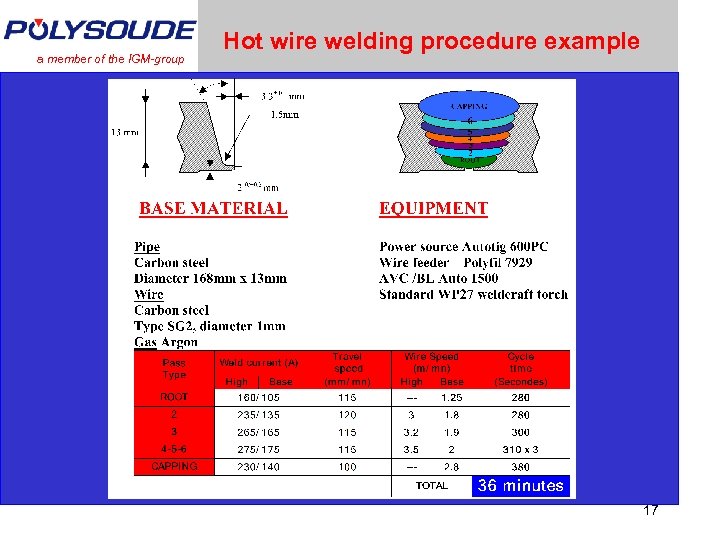

a member of the IGM-group Hot wire welding procedure example 17

Narrow gap TIG welding a member of the IGM-group Application examples 18

Narrow gap TIG welding a member of the IGM-group TOSHIBA on site Orbital TIG Hot wire welding Narrow gap (5 GT) Carbon steel STPG 38 508 x 50 mm 356 x 54 mm 24 layers 19

Narrow gap TIG welding a member of the IGM-group TOSHIBA on site (cont. ) 20

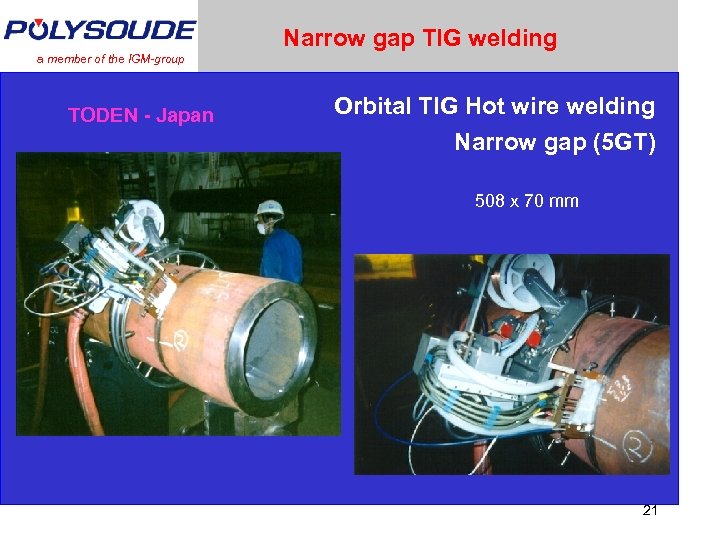

Narrow gap TIG welding a member of the IGM-group TODEN - Japan Orbital TIG Hot wire welding Narrow gap (5 GT) 508 x 70 mm 21

Narrow gap TIG welding a member of the IGM-group HOLMING WORKS FINLAND Fix station TIG Hot wire welding Narrow gap Carbon steel 280 x 100 mm 460 x 85 mm 22

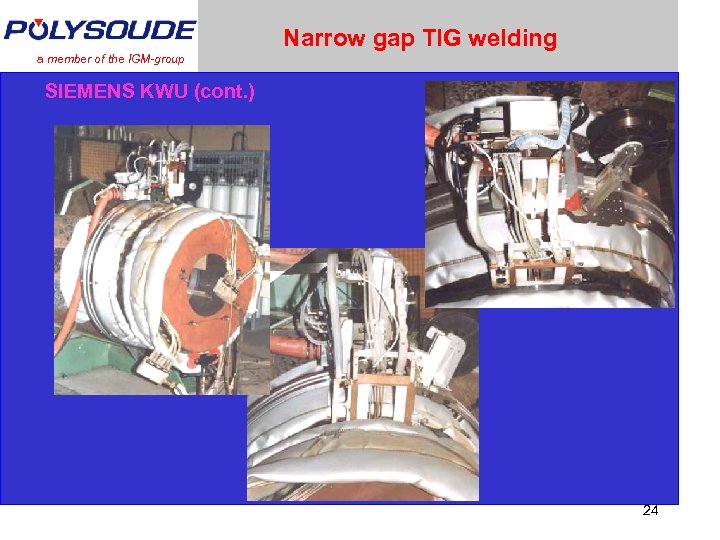

Narrow gap TIG welding a member of the IGM-group SIEMENS KWU Orbital TIG Hot wire welding Narrow gap 180 mm Application: 250 bars / 600°C = X 10 Cr. Mo. VNb 91 = 700 mm x 180 mm = Position 5 GT = Total arc time: 40 hours 23

Narrow gap TIG welding a member of the IGM-group SIEMENS KWU (cont. ) 24

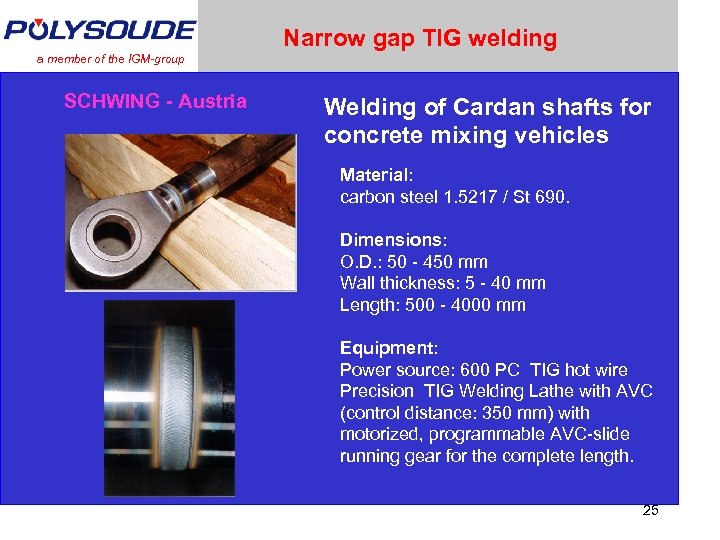

Narrow gap TIG welding a member of the IGM-group SCHWING - Austria Welding of Cardan shafts for concrete mixing vehicles Material: carbon steel 1. 5217 / St 690. Dimensions: O. D. : 50 - 450 mm Wall thickness: 5 - 40 mm Length: 500 - 4000 mm Equipment: Power source: 600 PC TIG hot wire Precision TIG Welding Lathe with AVC (control distance: 350 mm) with motorized, programmable AVC-slide running gear for the complete length. 25

a member of the IGM-group Narrow gap hot wire TIG welding: The solution for the best Quality with the highest productivity level ! 26

b9e38b8e118dec8986456fda65eedad2.ppt