41856c5a4a81f6f5792c09049a44ba35.ppt

- Количество слайдов: 27

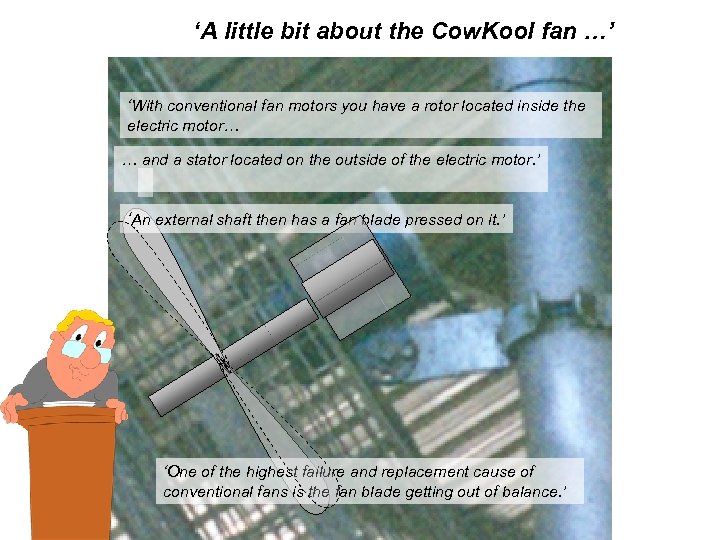

‘A little bit about the Cow. Kool fan …’ ‘With conventional fan motors you have a rotor located inside the electric motor… … and a stator located on the outside of the electric motor. ’ ‘An external shaft then has a fan blade pressed on it. ’ ‘One of the highest failure and replacement cause of conventional fans is the fan blade getting out of balance. ’

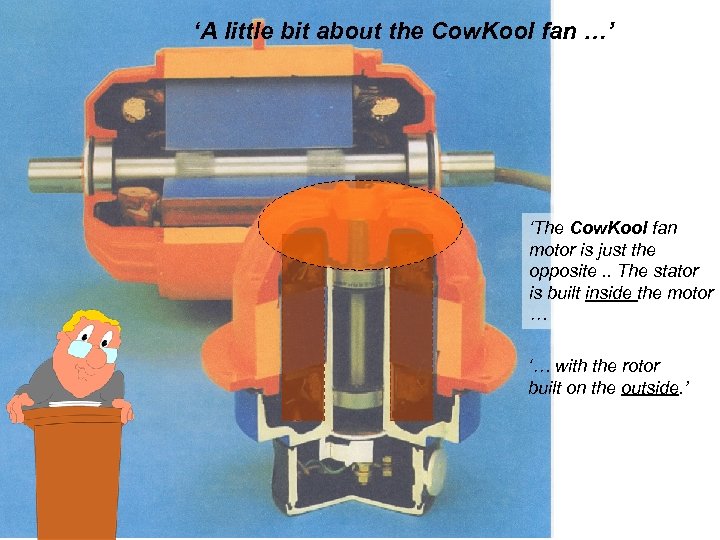

‘A little bit about the Cow. Kool fan …’ ‘The Cow. Kool fan motor is just the opposite. . The stator is built inside the motor … ‘… with the rotor built on the outside. ’

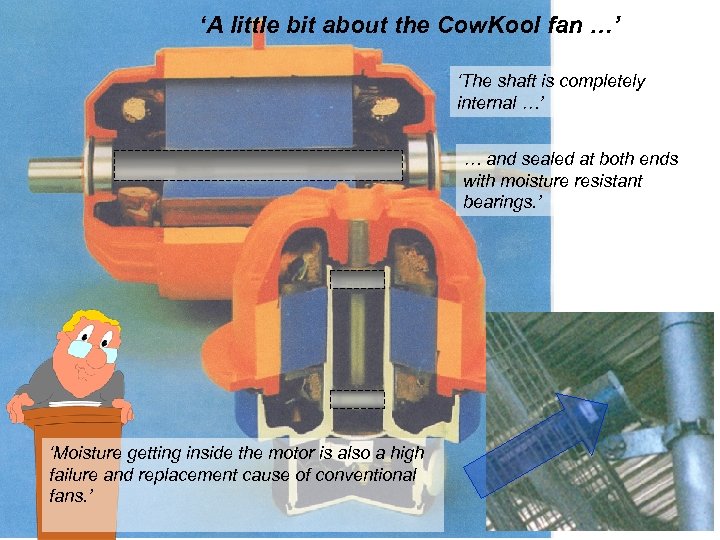

‘A little bit about the Cow. Kool fan …’ ‘The shaft is completely internal …’ … and sealed at both ends with moisture resistant bearings. ’ ‘Moisture getting inside the motor is also a high failure and replacement cause of conventional fans. ’

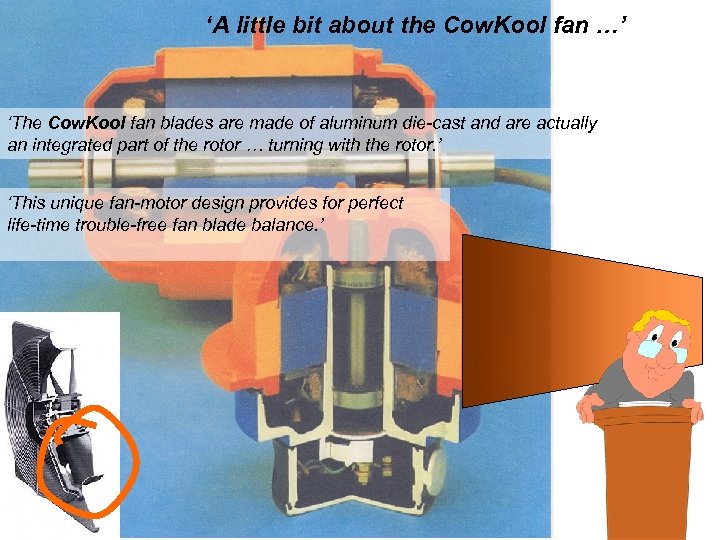

‘A little bit about the Cow. Kool fan …’ ‘The Cow. Kool fan blades are made of aluminum die-cast and are actually an integrated part of the rotor … turning with the rotor. ’ ‘This unique fan-motor design provides for perfect life-time trouble-free fan blade balance. ’

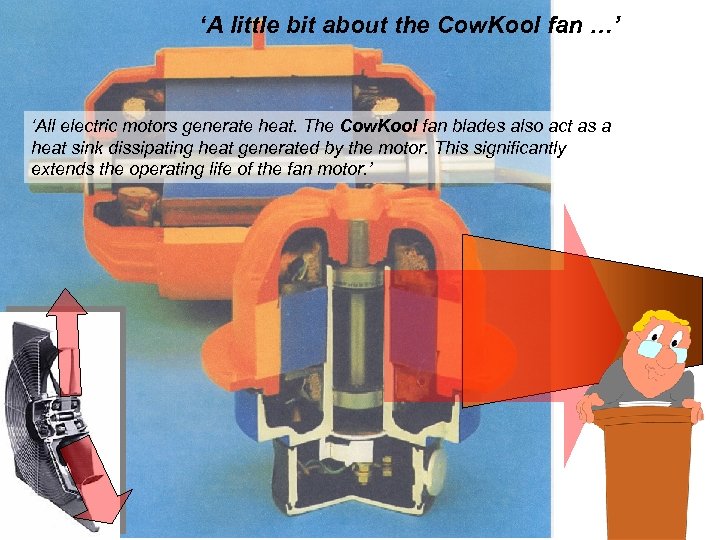

‘A little bit about the Cow. Kool fan …’ ‘All electric motors generate heat. The Cow. Kool fan blades also act as a heat sink dissipating heat generated by the motor. This significantly extends the operating life of the fan motor. ’

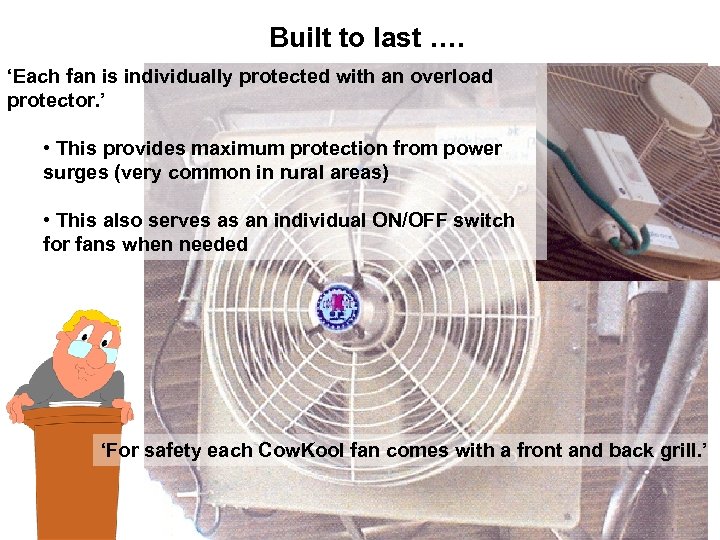

Built to last …. ‘Each fan is individually protected with an overload protector. ’ • This provides maximum protection from power surges (very common in rural areas) • This also serves as an individual ON/OFF switch for fans when needed ‘For safety each Cow. Kool fan comes with a front and back grill. ’

Built to last …. ‘The Cow. Kool fans are by far the best fans that I’ve seen on the market. I’ve had my fans installed over 32 years with very little problems. ’ Isac Gal Kibbutz Ashdot Yaakov Ichud Israel

Built to last …. ‘I’ve had my Cow. Kool fans in now for 20 years. I’m now rebuilding all of the barns and will stay with the Cow. Kool System. My summer time milk production is the same as my winter time production. I’d recommend this system to any dairyman. ’ Uri Gil Kibbutz Bachan, Israel

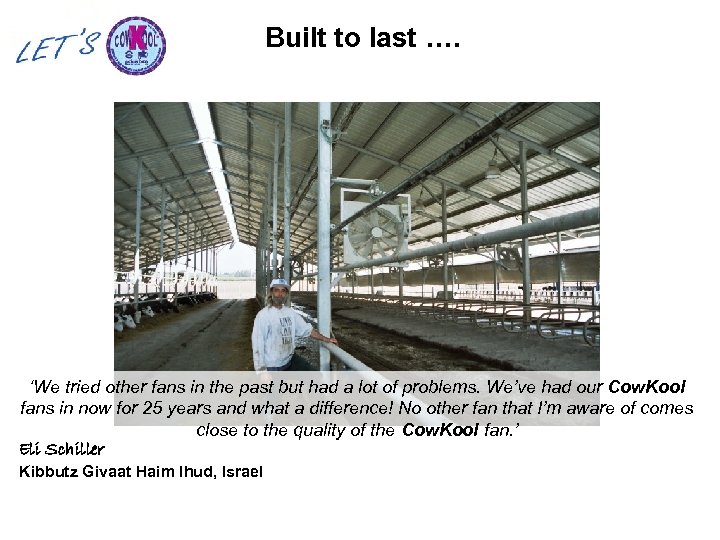

Built to last …. ‘We tried other fans in the past but had a lot of problems. We’ve had our Cow. Kool fans in now for 25 years and what a difference! No other fan that I’m aware of comes close to the quality of the Cow. Kool fan. ’ Eli Schiller Kibbutz Givaat Haim Ihud, Israel

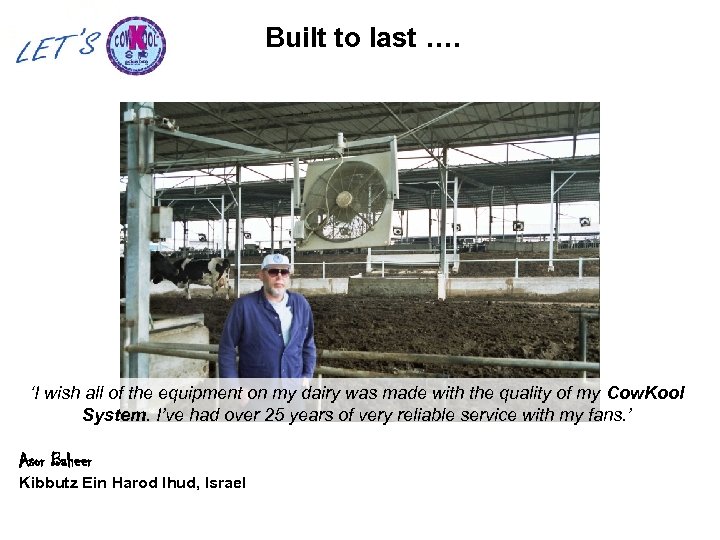

Built to last …. ‘I wish all of the equipment on my dairy was made with the quality of my Cow. Kool System. I’ve had over 25 years of very reliable service with my fans. ’ Asor Baheer Kibbutz Ein Harod Ihud, Israel

Built to last …. Mr. Ossi Dayan, Israel Cow. Kool fans installed 32 years

Built to last …. System The Cow. Kool fans are backed by a 3 -year factory warranty

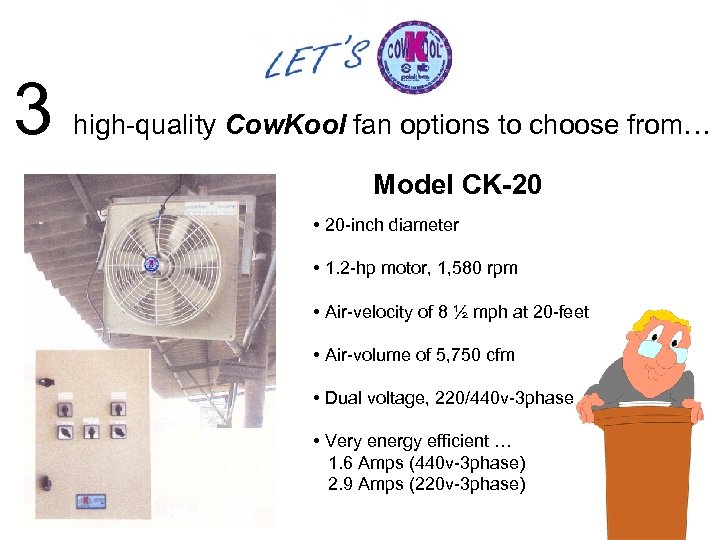

3 high-quality Cow. Kool fan options to choose from… Model CK-20 • 20 -inch diameter • 1. 2 -hp motor, 1, 580 rpm • Air-velocity of 8 ½ mph at 20 -feet • Air-volume of 5, 750 cfm • Dual voltage, 220/440 v-3 phase • Very energy efficient … 1. 6 Amps (440 v-3 phase) 2. 9 Amps (220 v-3 phase)

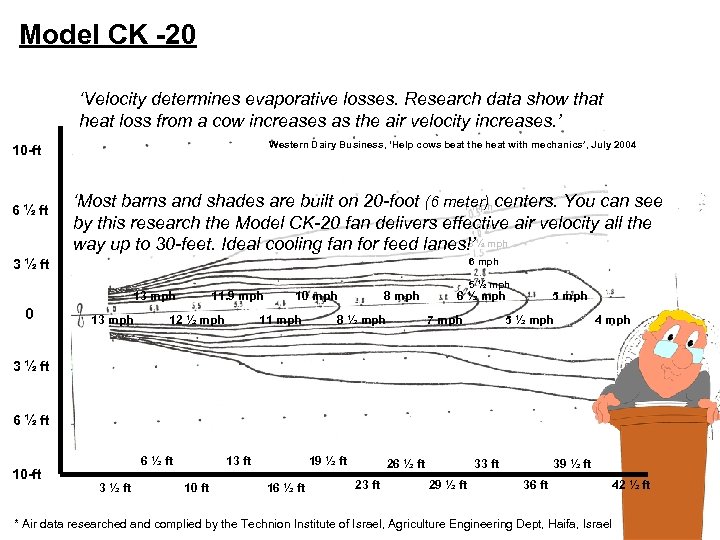

Model CK -20 ‘Velocity determines evaporative losses. Research data show that heat loss from a cow increases as the air velocity increases. ’ Western Dairy Business, ‘Help cows beat the heat with mechanics’, July 2004 10 -ft 6 ½ ft ‘Most barns and shades are built on 20 -foot (6 meter) centers. You can see 1 mph by this research the Model CK-20 fan delivers effective air velocity all the 2 mph 3 way up to 30 -feet. Ideal cooling fan for feed lanes!’ ½ mph 6 mph 3 ½ ft 13 mph 0 13 mph 11. 9 mph 12 ½ mph 10 mph 11 mph 8 ½ mph 5 mph 6 ½ mph 5 ½ mph 7 mph 4 mph 3 ½ ft 6 ½ ft 10 -ft 6 ½ ft 3 ½ ft 13 ft 10 ft 19 ½ ft 16 ½ ft 23 ft 33 ft 29 ½ ft 36 ft 42 ½ ft * Air data researched and complied by the Technion Institute of Israel, Agriculture Engineering Dept, Haifa, Israel

‘Biting flies cost you money! In addition to cooling cows the high-speed air velocity of the Cow. Kool fans also provide very effective protection from annoying flies. ’ 1. 6 km/hr 3. 2 km/hr 5. 6 km/hr 9. 7 km/hr 19 km/hr 20 km/hr 16 km/hr 17. 7 km/hr 12. 9 km/hr 13. 7 km/hr 8. 9 km/hr 10. 5 km/hr 11. 3 km/hr

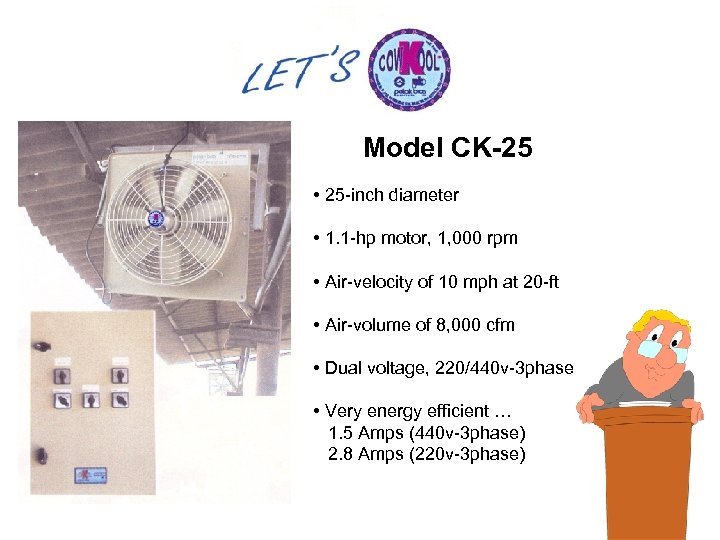

Model CK-25 • 25 -inch diameter • 1. 1 -hp motor, 1, 000 rpm • Air-velocity of 10 mph at 20 -ft • Air-volume of 8, 000 cfm • Dual voltage, 220/440 v-3 phase • Very energy efficient … 1. 5 Amps (440 v-3 phase) 2. 8 Amps (220 v-3 phase)

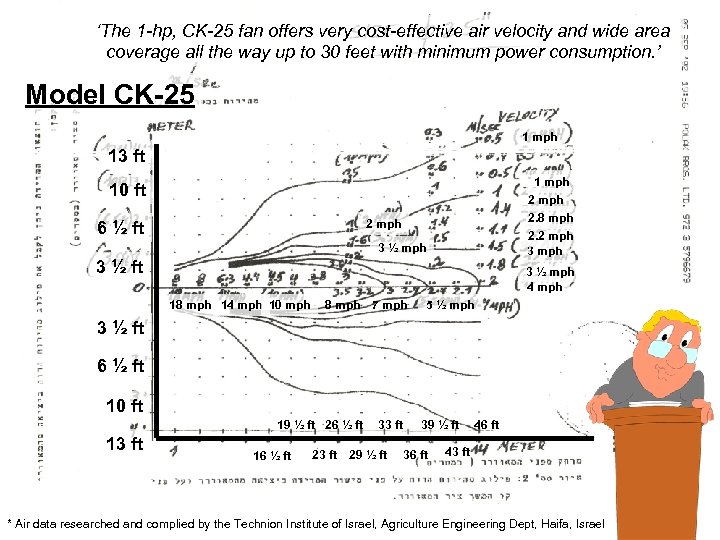

‘The 1 -hp, CK-25 fan offers very cost-effective air velocity and wide area coverage all the way up to 30 feet with minimum power consumption. ’ Model CK-25 1 mph 13 ft 1 mph 2. 8 mph 2. 2 mph 3 mph 10 ft 2 mph 6 ½ ft 3 ½ mph 3 ½ ft 3 ½ mph 4 mph 18 mph 14 mph 10 mph 8 mph 7 mph 5 ½ mph 3 ½ ft 6 ½ ft 10 ft 19 ½ ft 26 ½ ft 13 ft 16 ½ ft 23 ft 33 ft 29 ½ ft 36 ft 43 ft * Air data researched and complied by the Technion Institute of Israel, Agriculture Engineering Dept, Haifa, Israel

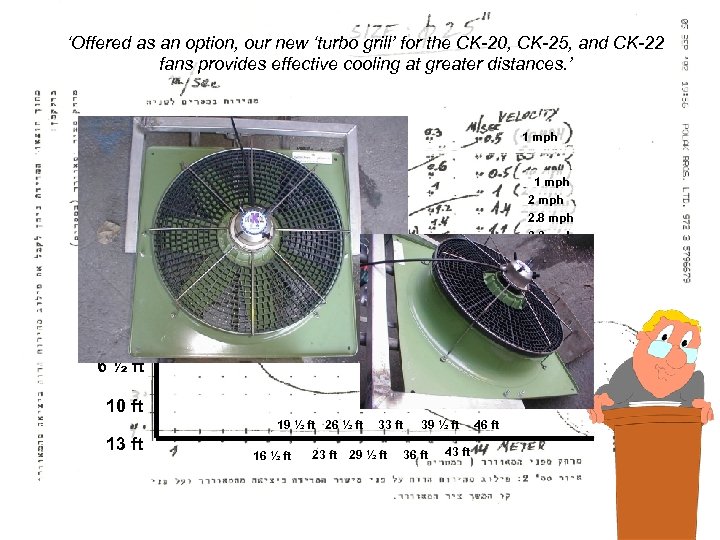

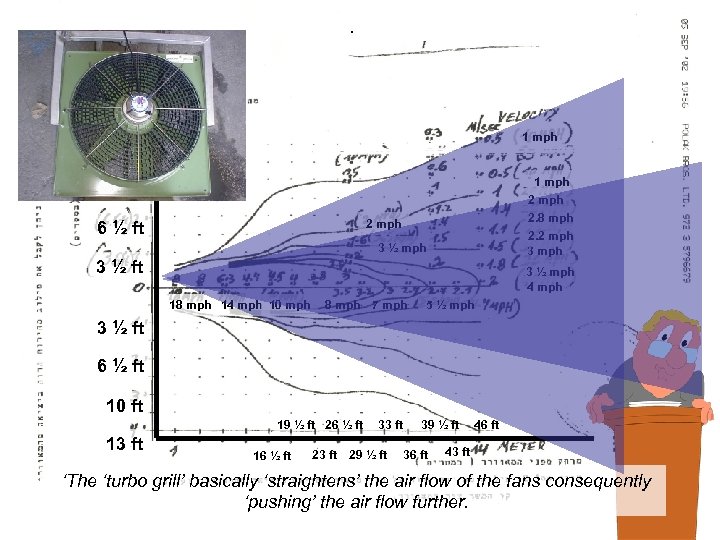

‘Offered as an option, our new ‘turbo grill’ for the CK-20, CK-25, and CK-22 fans provides effective cooling at greater distances. ’ 1 mph 13 ft 1 mph 2. 8 mph 2. 2 mph 3 mph 10 ft 2 mph 6 ½ ft 3 ½ mph 3 ½ ft 3 ½ mph 4 mph 18 mph 14 mph 10 mph 8 mph 7 mph 5 ½ mph 3 ½ ft 6 ½ ft 10 ft 19 ½ ft 26 ½ ft 13 ft 16 ½ ft 23 ft 33 ft 29 ½ ft 36 ft 43 ft 46 ft

. 1 mph 13 ft 1 mph 2. 8 mph 2. 2 mph 3 mph 10 ft 2 mph 6 ½ ft 3 ½ mph 3 ½ ft 3 ½ mph 4 mph 18 mph 14 mph 10 mph 8 mph 7 mph 5 ½ mph 3 ½ ft 6 ½ ft 10 ft 19 ½ ft 26 ½ ft 13 ft 16 ½ ft 23 ft 33 ft 29 ½ ft 36 ft 43 ft ‘The ‘turbo grill’ basically ‘straightens’ the air flow of the fans consequently ‘pushing’ the air flow further.

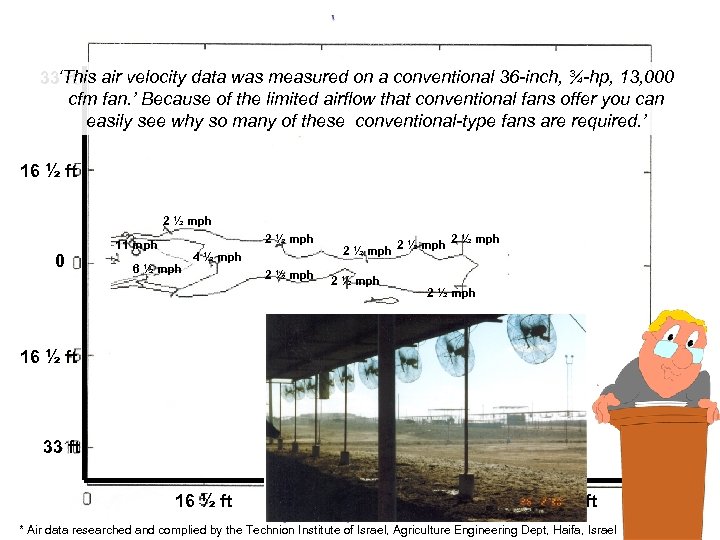

33‘This air velocity data was measured on a conventional 36 -inch, ¾-hp, 13, 000 ft cfm fan. ’ Because of the limited airflow that conventional fans offer you can easily see why so many of these conventional-type fans are required. ’ 16 ½ ft 2 ½ mph 0 2 ½ mph 11 mph 6 ½ mph 2 ½ mph 4 ½ mph 2 ½ mph 16 ½ ft 33 ft 49 ft 65 ½ ft * Air data researched and complied by the Technion Institute of Israel, Agriculture Engineering Dept, Haifa, Israel

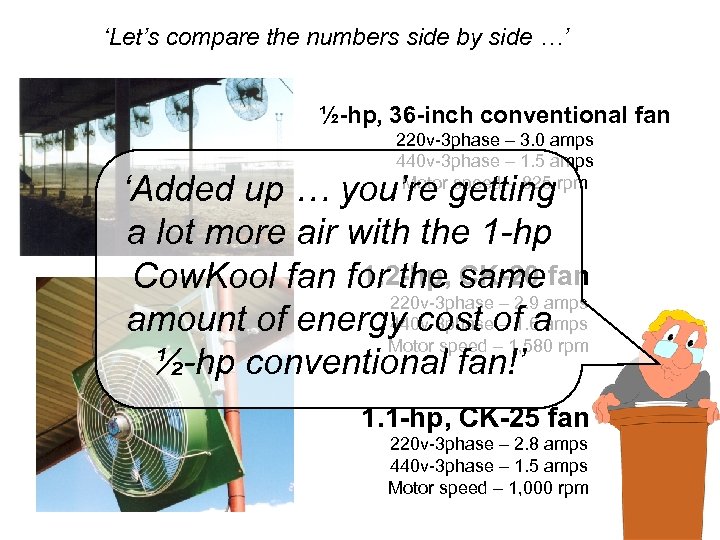

‘Let’s compare the numbers side by side …’ ½-hp, 36 -inch conventional fan 220 v-3 phase – 3. 0 amps 440 v-3 phase – 1. 5 amps Motor speed – 825 rpm ‘Added up … you’re getting a lot more air with the 1 -hp 1. 2 -hp, CK-20 fan Cow. Kool fan for the same 220 v-3 phase – 2. 9 amps 440 v-3 phase – 1. 6 amps amount of energy cost of a Motor speed – 1, 580 rpm ½-hp conventional fan!’ 1. 1 -hp, CK-25 fan 220 v-3 phase – 2. 8 amps 440 v-3 phase – 1. 5 amps Motor speed – 1, 000 rpm

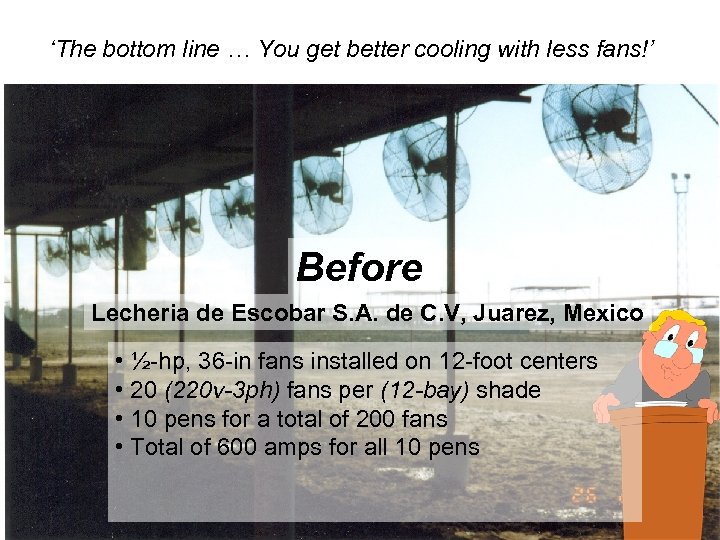

‘The bottom line … You get better cooling with less fans!’ Before Lecheria de Escobar S. A. de C. V, Juarez, Mexico • ½-hp, 36 -in fans installed on 12 -foot centers • 20 (220 v-3 ph) fans per (12 -bay) shade • 10 pens for a total of 200 fans • Total of 600 amps for all 10 pens

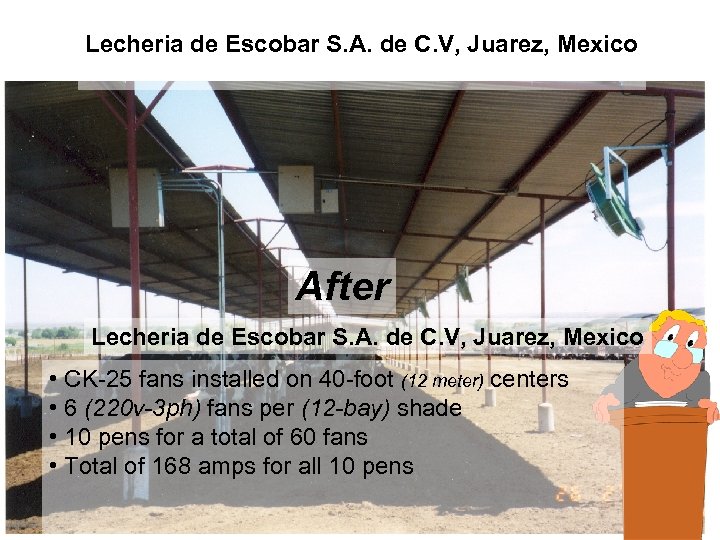

Lecheria de Escobar S. A. de C. V, Juarez, Mexico After Lecheria de Escobar S. A. de C. V, Juarez, Mexico • CK-25 fans installed on 40 -foot (12 meter) centers • 6 (220 v-3 ph) fans per (12 -bay) shade • 10 pens for a total of 60 fans • Total of 168 amps for all 10 pens

‘This saves in equipment costs … … and energy costs!’

‘What do they have to say about the Cow. Kool System? ’ ‘ALL IS GOING WELL. We are 2. 3 liters (5 lbs) over last year and we’ve had three weeks over 104 F every day. ’ August, 2005 Dr Jorge Montemayor, General Manager Lecheria de Escobar S. A. de C. V, Juarez, Mexico

41856c5a4a81f6f5792c09049a44ba35.ppt