3a599cfbcd6c65c27604c214fa7a5498.ppt

- Количество слайдов: 31

A first introduction of……. . - a subsidiary of SAS - MEMBER OF THE SAS GROUP

The Content…. . MEMBER OF THE SAS GROUP 1 Ramp. Snake - Background and History 2 Ramp. Snake - Our Vision and Mission 3 Ramp. Snake - Safety 4 Ramp. Snake - Systems Today 5 Ramp. Snake - The product – functionality and benefit

Background and history MEMBER OF THE SAS GROUP • Loading/unloading of narrow body aircraft is hard work causing problems for the people involved (shoulders, knees, backs) Workload per man per shift Average 5. 5 tons, summer > 9 tons • Not much has been done in this area in comparison with cabin, cockpit, etc. • Occupational Health and Safety issues are on top of the agenda in Scandinavia, UK (HSE) and the USA (OSHA). – The authorities demand improvements of work conditions in this area. SAS agrees. Max lifting in the cargo hold 1. 5 tons. Legislation shortly! • SAS + The union starts a joint study in early 1998 in co-operation with an external design company, CPH Industrial Design

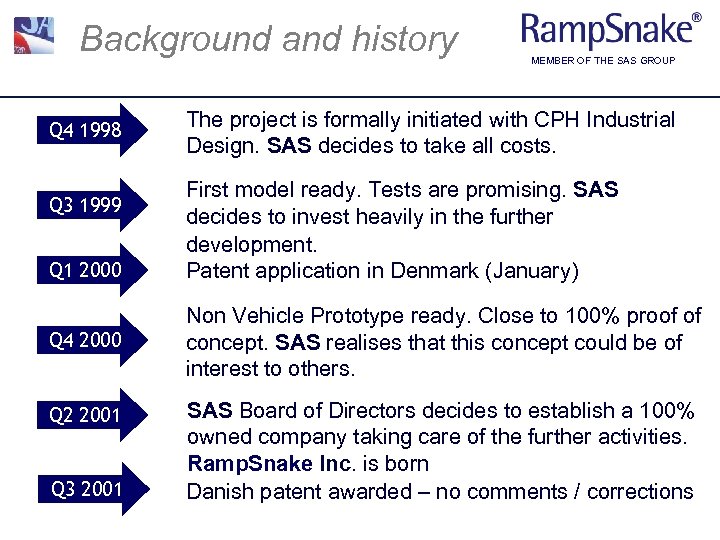

Background and history Q 4 1998 Q 3 1999 Q 1 2000 Q 4 2000 Q 2 2001 Q 3 2001 MEMBER OF THE SAS GROUP The project is formally initiated with CPH Industrial Design. SAS decides to take all costs. First model ready. Tests are promising. SAS decides to invest heavily in the further development. Patent application in Denmark (January) Non Vehicle Prototype ready. Close to 100% proof of concept. SAS realises that this concept could be of interest to others. SAS Board of Directors decides to establish a 100% owned company taking care of the further activities. Ramp. Snake Inc. is born Danish patent awarded – no comments / corrections

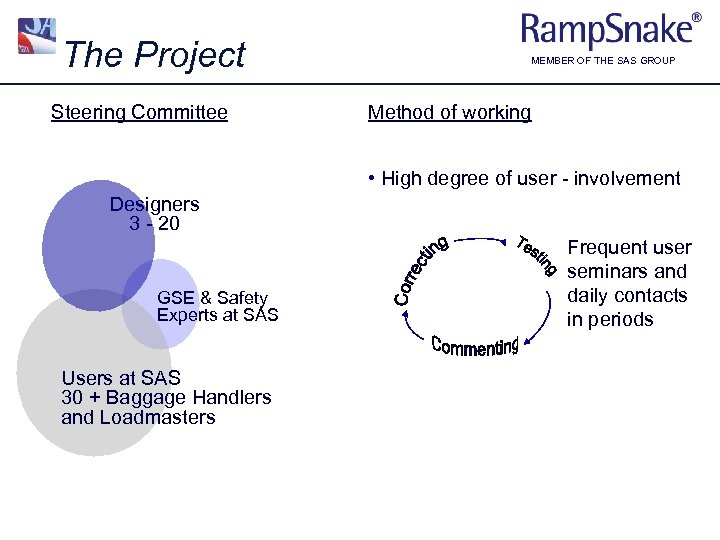

The Project Steering Committee MEMBER OF THE SAS GROUP Method of working • High degree of user - involvement Designers 3 - 20 GSE & Safety Experts at SAS Users at SAS 30 + Baggage Handlers and Loadmasters Frequent user seminars and daily contacts in periods

SAS Case Study MEMBER OF THE SAS GROUP • Environmental and Occupational Safety & Health • Aircraft damages • Delayed and lost bags • Baggage-loading/ Turn-around-times • Manpower savings • Aircraft in-plane systems & ground support equipment reductions • Employer moral obligations • Legislation for weight limitations in respect of manual handling • Taking these parameters in account – it was found out that…… • . . one single Ramp. Snake would save more than USD 140. 000

The “Vision and design and provide To develop, Mission” Philosophy MEMBER OF THE SAS GROUP User Driven Ground Support Equipment for enhancing the working environment - inside aircraft cargo compartments - on the ramp - beside the aircraft - in the baggage sorting room MEMBER OF THE SAS GROUP

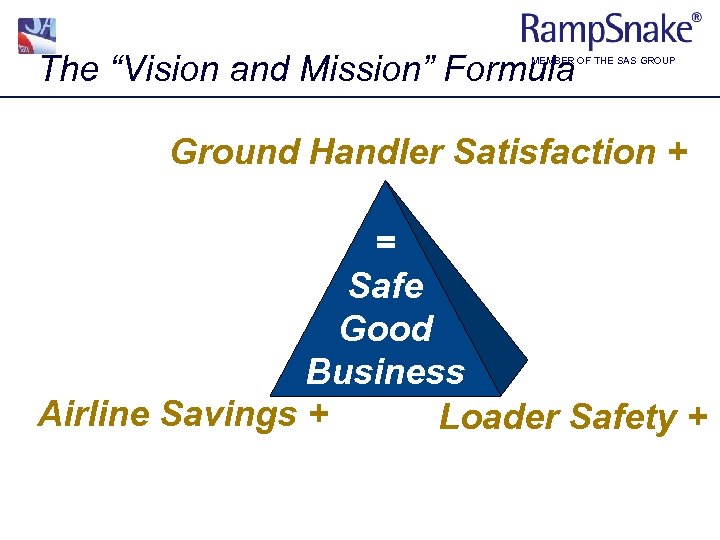

The “Vision and Mission” Formula MEMBER OF THE SAS GROUP Ground Handler Satisfaction + = Safe Good Business Airline Savings + Loader Safety +

A very costly exercise MEMBER OF THE SAS GROUP Manual handling of baggage and cargo accounts for 46% of the $3, 000, 000 USD incident and accident costs burdening the commercial aviation industry. ( HSE - Health & Safety Executive - Research, UK) $1. 5 Billion Pain

A $1. 5 Billion Impact On Profits MEMBER OF THE SAS GROUP The four most hazardous working areas in respect of manual handling in the Aviation Industry. Ê Inside aircraft cargo compartments Ê On the ramp by the baggage cart Ê In the baggage sorting area Ê At the check-in desk (The Americas)

A $1. 5 Billion Impact On Profits MEMBER OF THE SAS GROUP According to an ARTEX survey of 32 major companies worldwide who employ baggage handlers, the three highest risks for injury are: (ARTEX - The Air Transport Section within the US National Safety Council) Stacking bags inside narrow-body aircraft Pushing bags in narrow-body aircraft Transferring baggage directly into narrow-body aircraft

Industry bottle necks & threats MEMBER OF THE SAS GROUP The ever-increasing pressure from carriers and alliances to shorten turn-around-times is impacting to keep up with loading times? Problems on how you perform Lost and delayed baggage and cargo? Missed transfers? Increased damage to the aircraft and ground equipment? Too much loading equipment. In the aircraft and on the ground? Escalation of back-injuries. Increased workers compensation costs? MEMBER OF TH SAS GROUP

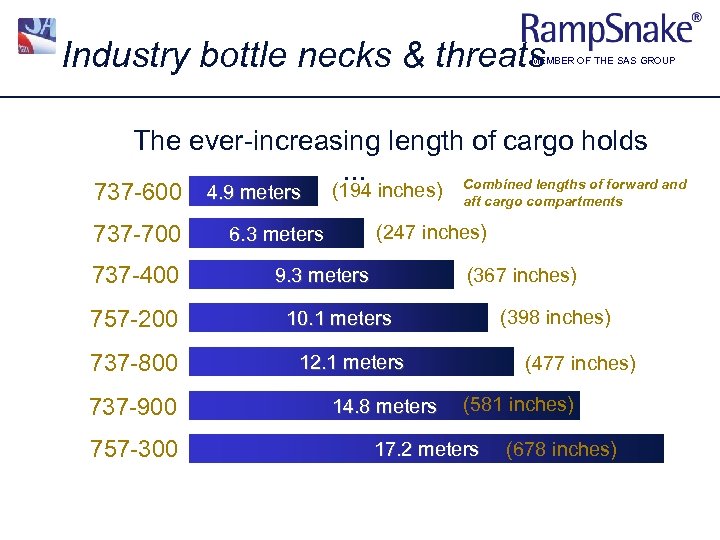

Industry bottle necks & threats MEMBER OF THE SAS GROUP The ever-increasing length of cargo holds. . . Combined lengths of forward and 737 -600 737 -700 737 -400 757 -200 737 -800 737 -900 757 -300 4. 9 meters (194 inches) aft cargo compartments (247 inches) 6. 3 meters (367 inches) 9. 3 meters (398 inches) 10. 1 meters 12. 1 meters 14. 8 meters (477 inches) (581 inches) 17. 2 meters (678 inches)

IATA Airport Handling Manual MEMBER OF THE SAS GROUP Manual handling of baggage and material is the primary cause of personnel injuries and workers compensation premiums. This is in addition to causing damage to the baggage, material and aircraft.

Systems Yesterday MEMBER OF THE SAS GROUP Working in a coal mine 1754 The Human Manual Loading System

Systems Today MEMBER OF THE SAS GROUP Working in a narrow body aircraft 2002 The Human Manual Loading System

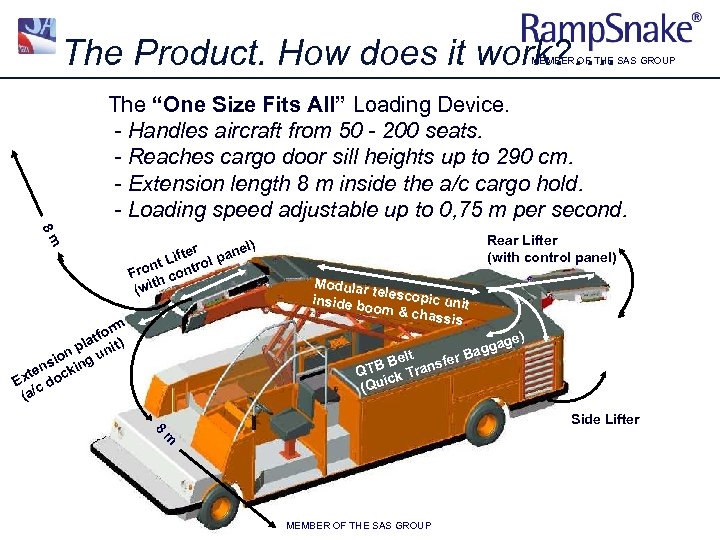

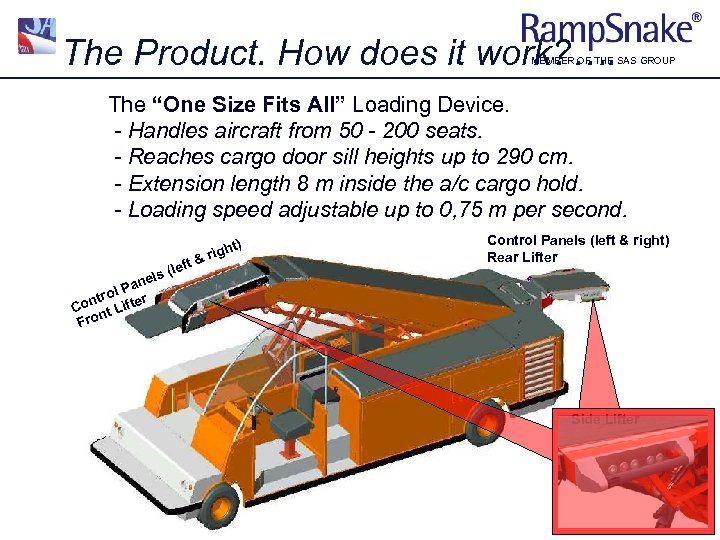

The Product. How does it work? …. MEMBER OF THE SAS GROUP The “One Size Fits All” Loading Device. - Handles aircraft from 50 - 200 seats. - Reaches cargo door sill heights up to 290 cm. - Extension length 8 m inside the a/c cargo hold. - Loading speed adjustable up to 0, 75 m per second. 8 m Rear Lifter (with control panel) l) ane fter t Li trol p n Fro con h (wit rm tfo ) la t n p uni o si ng ten ocki Ex c d (a/ Modular te inside b lescopic unit oom & c hassis ge) gga r Ba elt B B ransfe QT k T ic (Qu Side Lifter 8 m MEMBER OF THE SAS GROUP

The Product. How does it work? …. MEMBER OF THE SAS GROUP The “One Size Fits All” Loading Device. - Handles aircraft from 50 - 200 seats. - Reaches cargo door sill heights up to 290 cm. - Extension length 8 m inside the a/c cargo hold. - Loading speed adjustable up to 0, 75 m per second. ls ( ane l. P ntro ifter Co t L n Fro left t) righ & Control Panels (left & right) Rear Lifter Side Lifter

Who will benefit Airframe Manufacturers Airports - Authorities Ground Handlers / Loaders MEMBER OF THE SAS GROUP Airlines Safety forums IATA, ARTEX, EAGOSH etc

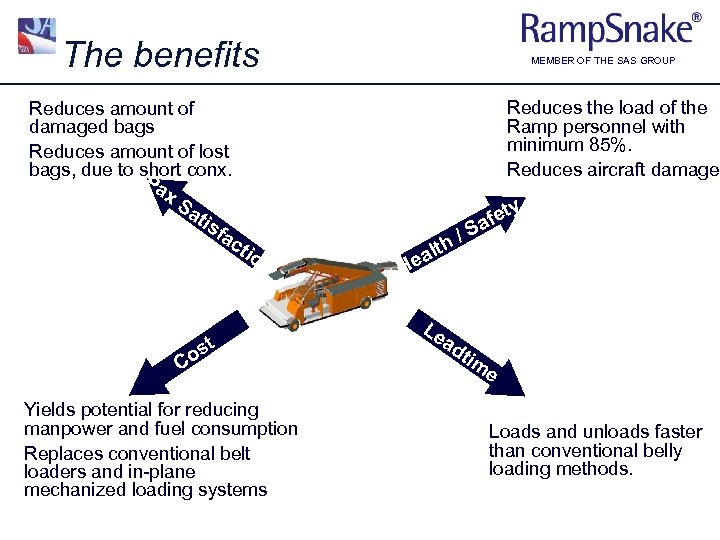

The benefits MEMBER OF THE SAS GROUP Reduces the load of the Ramp personnel with minimum 85%. Reduces aircraft damages Reduces amount of damaged bags Reduces amount of lost bags, due to short conx. P ax Sa tis y fa ct io n t os C Yields potential for reducing manpower and fuel consumption Replaces conventional belt loaders and in-plane mechanized loading systems h alt He Le a t afe /S dt im e Loads and unloads faster than conventional belly loading methods.

Ready to go…. MEMBER OF THE SAS GROUP

Talk Of The Town MEMBER OF THE SAS GROUP ”I have seen the Ramp. Snake in operation at Copenhagen Airport – an amazing technical wonder, that eliminates the occupational lifting hazards when loading and offloading aircraft. Arbeidstilsynet (Danish OSHA) has for many years now been focused on this particular environmental occupational problem. With the introduction of Ramp. Snake, this problem will soon be a thing of the past. The Ramp. Snake Project is an example of how tough legislative demands to improve the working environment, can bring about innovative technical solutions” H. Elo Petersen, Executive VP – Arbejdstilsynet OSHA) (Danish

Talk Of The Town MEMBER OF THE SAS GROUP "After nearly 3 months of testing in snow, rain and foul winter weather in Copenhagen all I can say is: No aircraft damages and no delays due to Ramp. Snake. It is surprisingly easy to handle and has been well received among the super users, who regard it as a very effective tool for reducing the load on their shoulders. " John Gronemann, Manager SAS Ramp Operations Copenhagen Airport

Talk Of The Town MEMBER OF THE SAS GROUP "Ramp. Snake is a success! Ramp. Snake has been tested for some months now, and has proven to be a great success. Vi are really looking forward to receiving more of them. Within 2 years, we will have all units (approx. 150 units in all Scandinavia) which are aimed for KRB (Copenhagen Airport). This will cut down the workload by 75%. It will be marvellous being able to say goodbye to many work related injuries. ” Press Information from The Workers Union at SAS

Talk Of The Town MEMBER OF THE SAS GROUP "Rampsnake is so very revolutionary that I believe there will be many skeptics and they are the people who will need the most convincing. The potential market for it is huge, especially in areas of the world that has sound and effective OS & H legislation Norman Hogwood Ground Safety Investigator Air New Zealand

Talk Of The Town MEMBER OF THE SAS GROUP ”I have been in the airline industry for 21 years and in the safety field for the last 8 years. I can say that I have never seen a more revolutionary product related to ramp safety in those 21 years. ” Pat Karol Manager, Corporate Safety and Compliance Delta Air Lines

Talk Of The Town MEMBER OF THE SAS GROUP "It is high time that something is happening in the industry with regards to bulk loading/handling. Judging by the sound of your product it appears you will not be needing much encouragement as you have hit it right on the nail. Well done. " John Mashava Manager Ground Safety South African Airways

Talk Of The Town MEMBER OF THE SAS GROUP "I am totally convinced it will bring a great break-through within our industry. I already informed my board about this project. So I do hope to ask for a presentation for our boardpeople in the very near future as there is also quite an interest to be one of your first (or the first) customer in Germany and Spain. " Michael Lindhof Station Manager FRA Acciona Airport services

Talk Of The Town MEMBER OF THE SAS GROUP "If the Ramp. Snake holds up to work on the ramp I feel we have a solution to the ergonomics issues for narrow body planes. " Bill Carlyon Safety, Health & Environmental Affairs Boeing Commercial Aviation Services

Talk Of The Town MEMBER OF THE SAS GROUP "The concept of the Ramp Snake has been elusive for many years and I am glad to hear that somebody has finally come up with a workable solution. This is very interesting. We've all talked about the need for such a beast. ” Craig Reisacker Air Rap - (Airbus US Consultant)

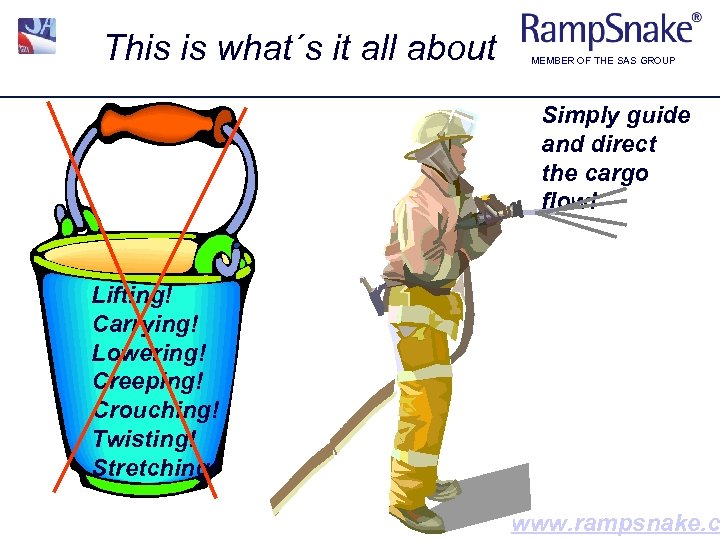

This is what´s it all about MEMBER OF THE SAS GROUP Simply guide and direct the cargo flow! Lifting! Carrying! Lowering! Creeping! Crouching! Twisting! Stretching! www. rampsnake. c

3a599cfbcd6c65c27604c214fa7a5498.ppt