c692ccc27c1a7c11d179187e7907e22b.ppt

- Количество слайдов: 31

A Fast Chopping System for High Intensity Linac Beams F. Caspers, T. Kroyer CERN-AB-RF E. Mahner CERN-AT-VAC CARE’ 06 Frascati, November 15 – 17, 2006 CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 1

A Fast Chopping System for High Intensity Linac Beams F. Caspers, T. Kroyer CERN-AB-RF E. Mahner CERN-AT-VAC CARE’ 06 Frascati, November 15 – 17, 2006 CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 1

n n Layout Technical requirements n u Contents Modifications in 2005 n u Status by September 2006 Evolution of the SPL chopper Measurements & tests n n n u Coverage factor n n u Electrical properties Vacuum & leak test Heat transfer test Measurement Simulation Remaining jobs CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 2

n n Layout Technical requirements n u Contents Modifications in 2005 n u Status by September 2006 Evolution of the SPL chopper Measurements & tests n n n u Coverage factor n n u Electrical properties Vacuum & leak test Heat transfer test Measurement Simulation Remaining jobs CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 2

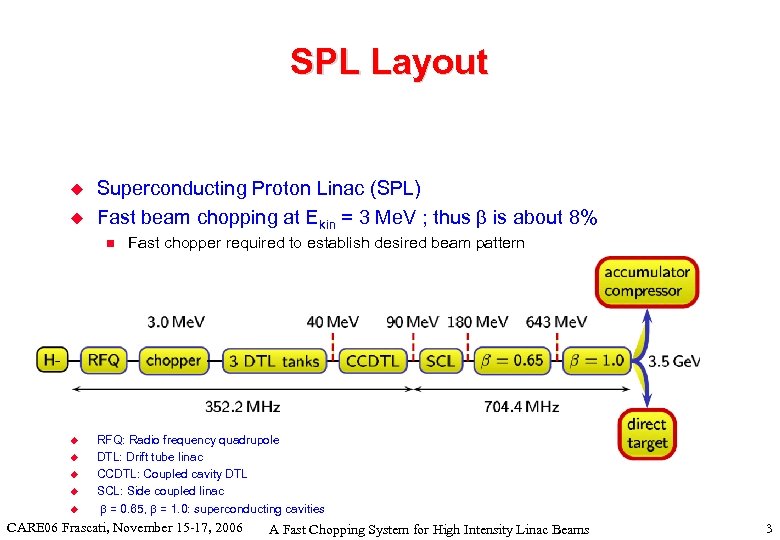

SPL Layout u u Superconducting Proton Linac (SPL) Fast beam chopping at Ekin = 3 Me. V ; thus is about 8% n u u u Fast chopper required to establish desired beam pattern RFQ: Radio frequency quadrupole DTL: Drift tube linac CCDTL: Coupled cavity DTL SCL: Side coupled linac = 0. 65, = 1. 0: superconducting cavities CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 3

SPL Layout u u Superconducting Proton Linac (SPL) Fast beam chopping at Ekin = 3 Me. V ; thus is about 8% n u u u Fast chopper required to establish desired beam pattern RFQ: Radio frequency quadrupole DTL: Drift tube linac CCDTL: Coupled cavity DTL SCL: Side coupled linac = 0. 65, = 1. 0: superconducting cavities CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 3

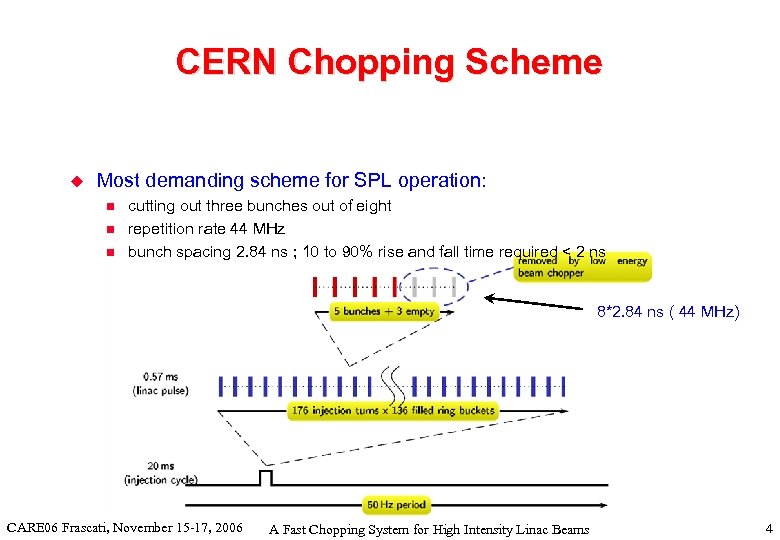

CERN Chopping Scheme u Most demanding scheme for SPL operation: n n n cutting out three bunches out of eight repetition rate 44 MHz bunch spacing 2. 84 ns ; 10 to 90% rise and fall time required < 2 ns 8*2. 84 ns ( 44 MHz) CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 4

CERN Chopping Scheme u Most demanding scheme for SPL operation: n n n cutting out three bunches out of eight repetition rate 44 MHz bunch spacing 2. 84 ns ; 10 to 90% rise and fall time required < 2 ns 8*2. 84 ns ( 44 MHz) CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 4

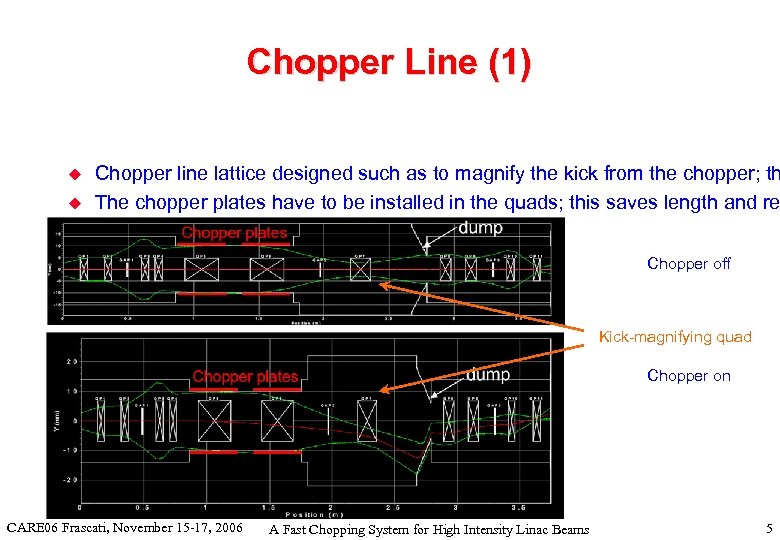

Chopper Line (1) u u Chopper line lattice designed such as to magnify the kick from the chopper; th The chopper plates have to be installed in the quads; this saves length and re Chopper off Kick-magnifying quad Chopper on CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 5

Chopper Line (1) u u Chopper line lattice designed such as to magnify the kick from the chopper; th The chopper plates have to be installed in the quads; this saves length and re Chopper off Kick-magnifying quad Chopper on CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 5

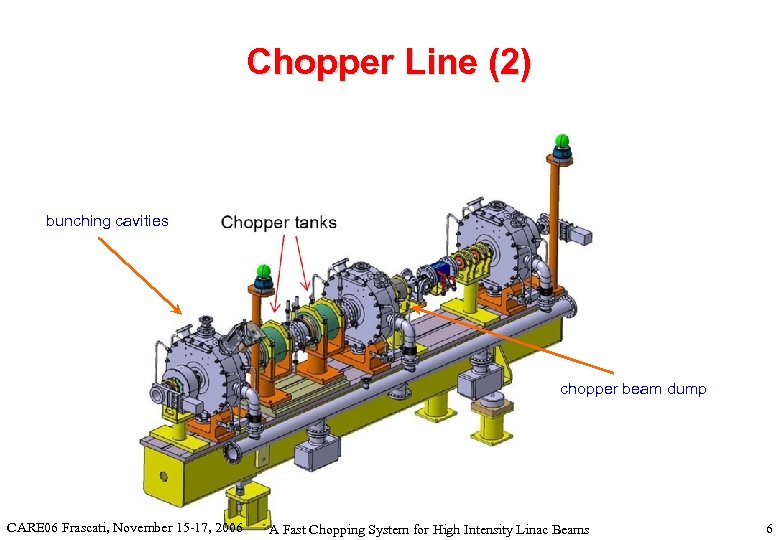

Chopper Line (2) bunching cavities chopper beam dump CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 6

Chopper Line (2) bunching cavities chopper beam dump CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 6

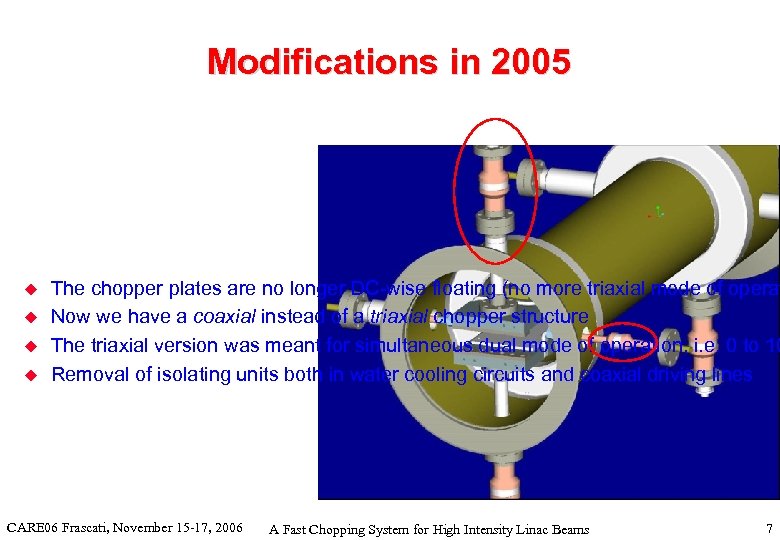

Modifications in 2005 u u The chopper plates are no longer DC-wise floating (no more triaxial mode of operat Now we have a coaxial instead of a triaxial chopper structure The triaxial version was meant for simultaneous dual mode of operation, i. e. 0 to 10 Removal of isolating units both in water cooling circuits and coaxial driving lines CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 7

Modifications in 2005 u u The chopper plates are no longer DC-wise floating (no more triaxial mode of operat Now we have a coaxial instead of a triaxial chopper structure The triaxial version was meant for simultaneous dual mode of operation, i. e. 0 to 10 Removal of isolating units both in water cooling circuits and coaxial driving lines CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 7

Meander lines u u u Initially samples of the meander lines were produced at CERN While all parameters were basically ok (electrical, vacuum), reproducibility of c After the accomplished proof of principle with CERN technology, a supplier tha Kyocera was eager to enter in a cooperation with CERN and willing to adapt th The plate that was recently furnished compared well in all aspects with the be CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 8

Meander lines u u u Initially samples of the meander lines were produced at CERN While all parameters were basically ok (electrical, vacuum), reproducibility of c After the accomplished proof of principle with CERN technology, a supplier tha Kyocera was eager to enter in a cooperation with CERN and willing to adapt th The plate that was recently furnished compared well in all aspects with the be CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 8

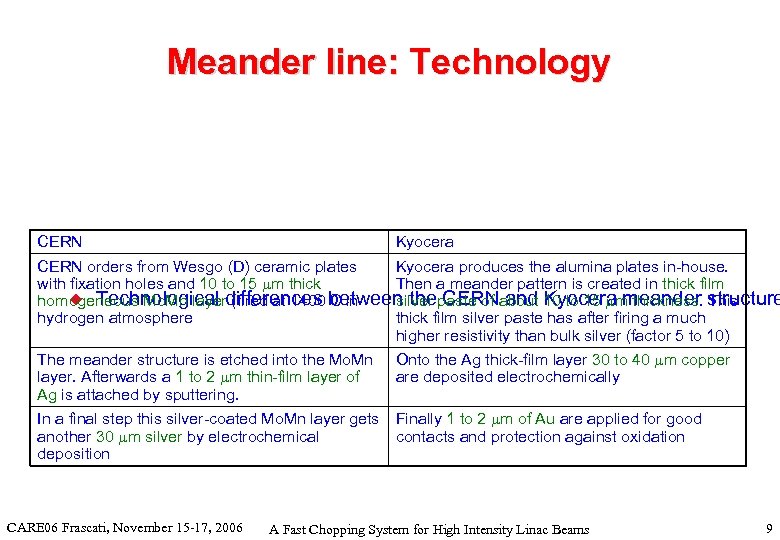

Meander line: Technology CERN Kyocera CERN orders from Wesgo (D) ceramic plates Kyocera produces the alumina plates in-house. with fixation holes and 10 to 15 m thick Then a meander pattern is created in thick film u Technological (fired at 1400 C in homogeneous Mo. Mn layerdifferences between thepaste of about 10 to 15 m thickness. structure silver CERN and Kyocera meander This hydrogen atmosphere thick film silver paste has after firing a much higher resistivity than bulk silver (factor 5 to 10) The meander structure is etched into the Mo. Mn layer. Afterwards a 1 to 2 m thin-film layer of Ag is attached by sputtering. Onto the Ag thick-film layer 30 to 40 m copper are deposited electrochemically In a final step this silver-coated Mo. Mn layer gets Finally 1 to 2 m of Au are applied for good another 30 m silver by electrochemical contacts and protection against oxidation deposition CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 9

Meander line: Technology CERN Kyocera CERN orders from Wesgo (D) ceramic plates Kyocera produces the alumina plates in-house. with fixation holes and 10 to 15 m thick Then a meander pattern is created in thick film u Technological (fired at 1400 C in homogeneous Mo. Mn layerdifferences between thepaste of about 10 to 15 m thickness. structure silver CERN and Kyocera meander This hydrogen atmosphere thick film silver paste has after firing a much higher resistivity than bulk silver (factor 5 to 10) The meander structure is etched into the Mo. Mn layer. Afterwards a 1 to 2 m thin-film layer of Ag is attached by sputtering. Onto the Ag thick-film layer 30 to 40 m copper are deposited electrochemically In a final step this silver-coated Mo. Mn layer gets Finally 1 to 2 m of Au are applied for good another 30 m silver by electrochemical contacts and protection against oxidation deposition CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 9

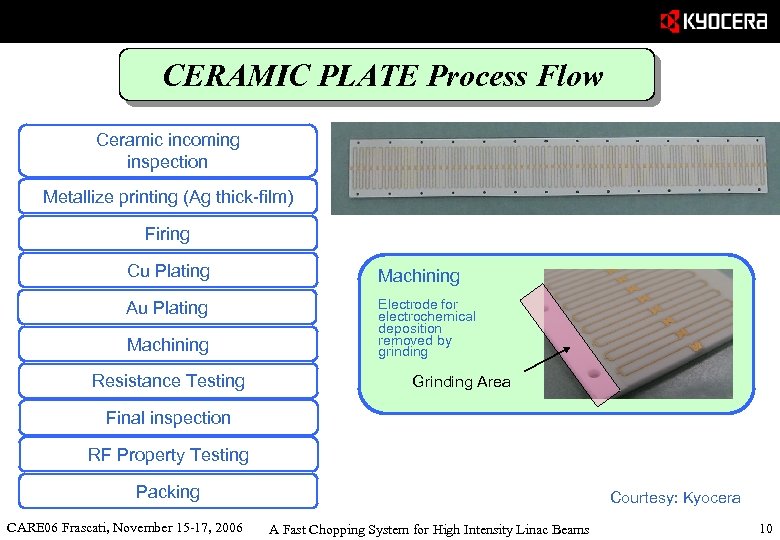

CERAMIC PLATE Process Flow Ceramic incoming inspection Metallize printing (Ag thick-film) Firing Cu Plating Machining Au Plating Electrode for electrochemical deposition removed by grinding Machining Resistance Testing Grinding Area Final inspection RF Property Testing Packing CARE 06 Frascati, November 15 -17, 2006 Courtesy: Kyocera A Fast Chopping System for High Intensity Linac Beams 10

CERAMIC PLATE Process Flow Ceramic incoming inspection Metallize printing (Ag thick-film) Firing Cu Plating Machining Au Plating Electrode for electrochemical deposition removed by grinding Machining Resistance Testing Grinding Area Final inspection RF Property Testing Packing CARE 06 Frascati, November 15 -17, 2006 Courtesy: Kyocera A Fast Chopping System for High Intensity Linac Beams 10

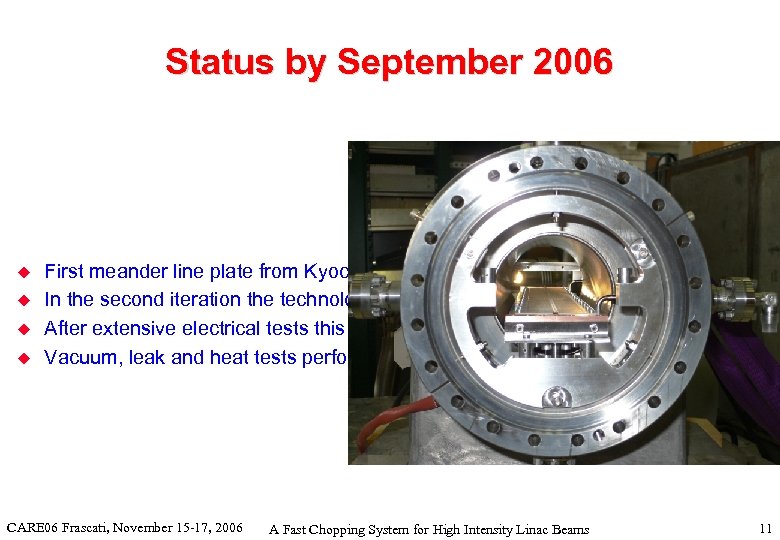

Status by September 2006 u u First meander line plate from Kyocera were received in June 2006 but it turned out t In the second iteration the technological parameters were properly adjusted and the After extensive electrical tests this single plate was installed in the chopper tank Vacuum, leak and heat tests performed successfully CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 11

Status by September 2006 u u First meander line plate from Kyocera were received in June 2006 but it turned out t In the second iteration the technological parameters were properly adjusted and the After extensive electrical tests this single plate was installed in the chopper tank Vacuum, leak and heat tests performed successfully CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 11

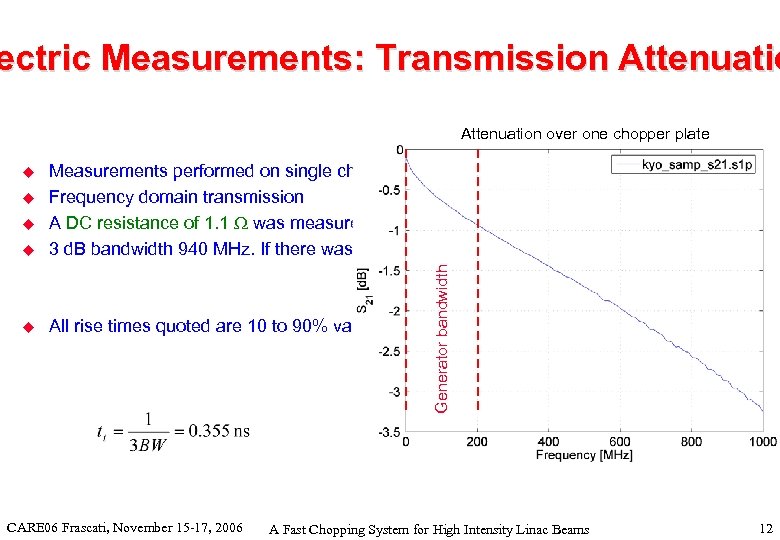

ectric Measurements: Transmission Attenuation over one chopper plate u All rise times quoted are 10 to 90% values u u CARE 06 Frascati, November 15 -17, 2006 Generator bandwidth u Measurements performed on single chopper plate with an image plane 10 mm above the line Frequency domain transmission A DC resistance of 1. 1 was measured, which agrees very well with the low-frequency limit 3 d. B bandwidth 940 MHz. If there was no phase distortion the rise time would be u A Fast Chopping System for High Intensity Linac Beams 12

ectric Measurements: Transmission Attenuation over one chopper plate u All rise times quoted are 10 to 90% values u u CARE 06 Frascati, November 15 -17, 2006 Generator bandwidth u Measurements performed on single chopper plate with an image plane 10 mm above the line Frequency domain transmission A DC resistance of 1. 1 was measured, which agrees very well with the low-frequency limit 3 d. B bandwidth 940 MHz. If there was no phase distortion the rise time would be u A Fast Chopping System for High Intensity Linac Beams 12

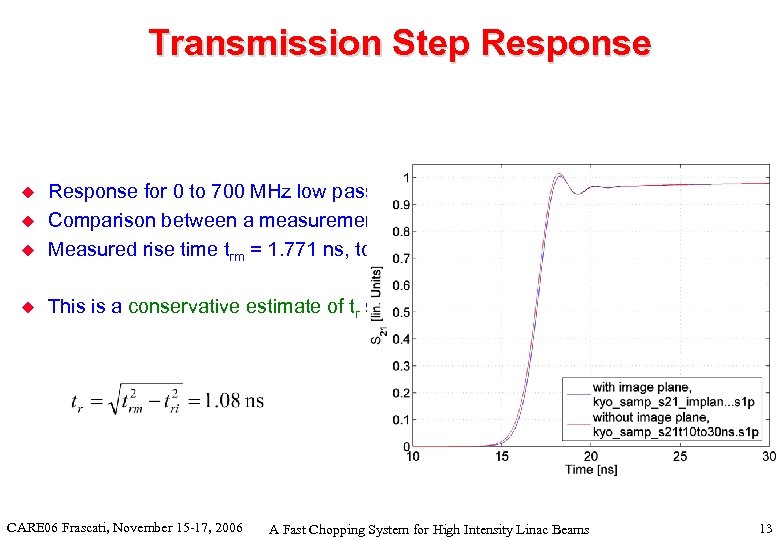

Transmission Step Response u Response for 0 to 700 MHz low pass step function (Kaiser Bessel weighting functio Comparison between a measurement with and without the image plane. Due to the Measured rise time trm = 1. 771 ns, to be compared with tri = 1. 407 ns of input pulse; u This is a conservative estimate of tr since the tti is rather short and we get into the h u u CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 13

Transmission Step Response u Response for 0 to 700 MHz low pass step function (Kaiser Bessel weighting functio Comparison between a measurement with and without the image plane. Due to the Measured rise time trm = 1. 771 ns, to be compared with tri = 1. 407 ns of input pulse; u This is a conservative estimate of tr since the tti is rather short and we get into the h u u CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 13

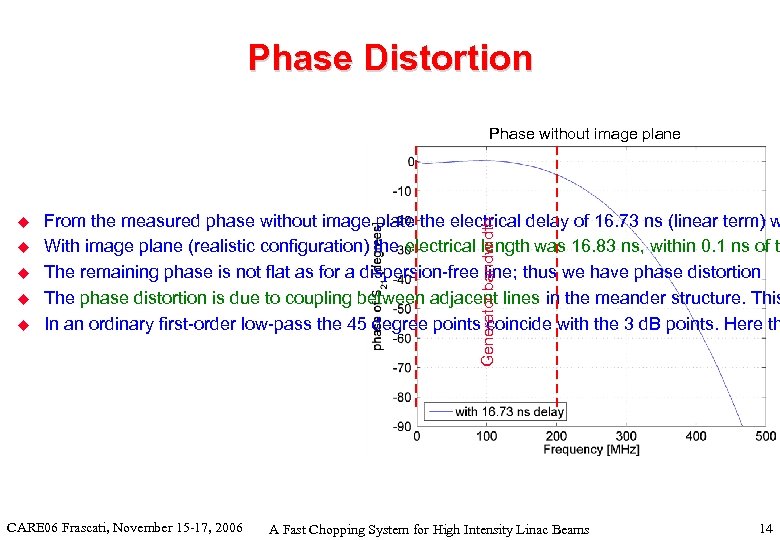

Phase Distortion Phase without image plane u u From the measured phase without image plate the electrical delay of 16. 73 ns (linear term) w With image plane (realistic configuration) the electrical length was 16. 83 ns, within 0. 1 ns of t The remaining phase is not flat as for a dispersion-free line; thus we have phase distortion The phase distortion is due to coupling between adjacent lines in the meander structure. This In an ordinary first-order low-pass the 45 degree points coincide with the 3 d. B points. Here th CARE 06 Frascati, November 15 -17, 2006 Generator bandwidth u A Fast Chopping System for High Intensity Linac Beams 14

Phase Distortion Phase without image plane u u From the measured phase without image plate the electrical delay of 16. 73 ns (linear term) w With image plane (realistic configuration) the electrical length was 16. 83 ns, within 0. 1 ns of t The remaining phase is not flat as for a dispersion-free line; thus we have phase distortion The phase distortion is due to coupling between adjacent lines in the meander structure. This In an ordinary first-order low-pass the 45 degree points coincide with the 3 d. B points. Here th CARE 06 Frascati, November 15 -17, 2006 Generator bandwidth u A Fast Chopping System for High Intensity Linac Beams 14

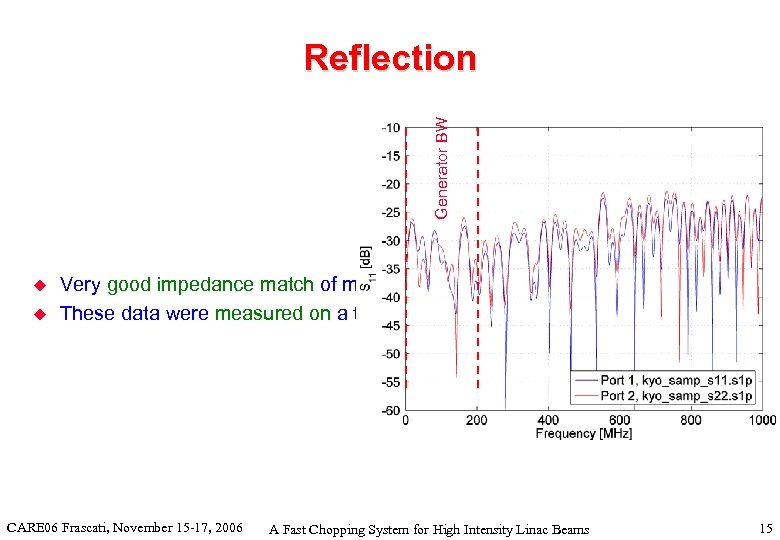

Generator BW Reflection u u Very good impedance match of meander line to 50 : reflection in frequency dom These data were measured on a test jig consisting of a single plate with SMA conn CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 15

Generator BW Reflection u u Very good impedance match of meander line to 50 : reflection in frequency dom These data were measured on a test jig consisting of a single plate with SMA conn CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 15

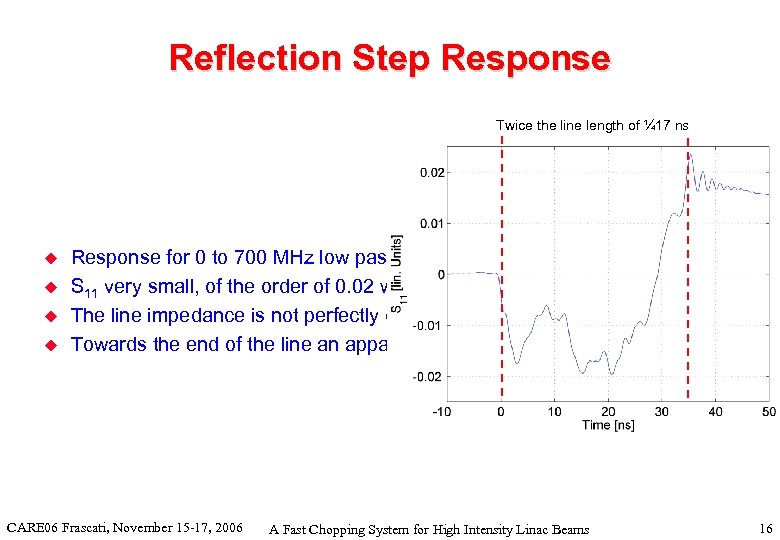

Reflection Step Response Twice the line length of ¼ 17 ns u u Response for 0 to 700 MHz low pass step function S 11 very small, of the order of 0. 02 which is another indication of good match The line impedance is not perfectly constant over the meander length as can be Towards the end of the line an apparent increase in line impedance can be seen CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 16

Reflection Step Response Twice the line length of ¼ 17 ns u u Response for 0 to 700 MHz low pass step function S 11 very small, of the order of 0. 02 which is another indication of good match The line impedance is not perfectly constant over the meander length as can be Towards the end of the line an apparent increase in line impedance can be seen CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 16

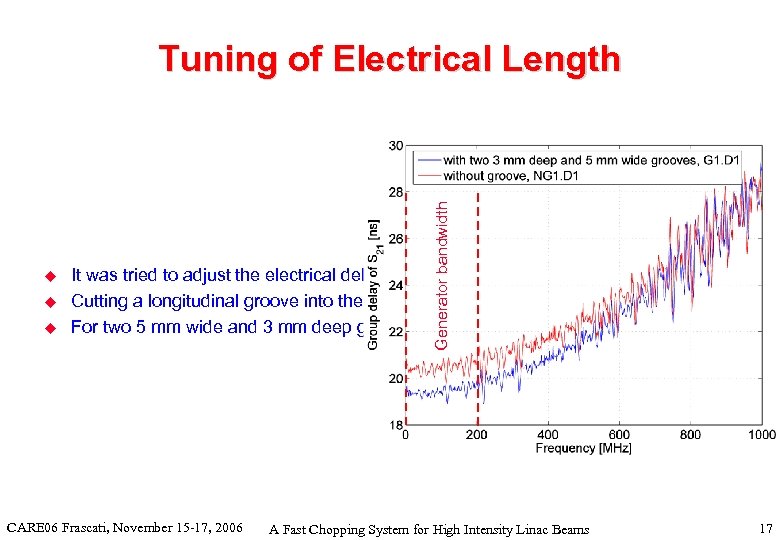

u u u Generator bandwidth Tuning of Electrical Length It was tried to adjust the electrical delay of a chopper plate by modifying the metal ground Cutting a longitudinal groove into the ground plane reduces the effective e and thus increa For two 5 mm wide and 3 mm deep grooves a 5% decrease in the electrical length was fo CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 17

u u u Generator bandwidth Tuning of Electrical Length It was tried to adjust the electrical delay of a chopper plate by modifying the metal ground Cutting a longitudinal groove into the ground plane reduces the effective e and thus increa For two 5 mm wide and 3 mm deep grooves a 5% decrease in the electrical length was fo CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 17

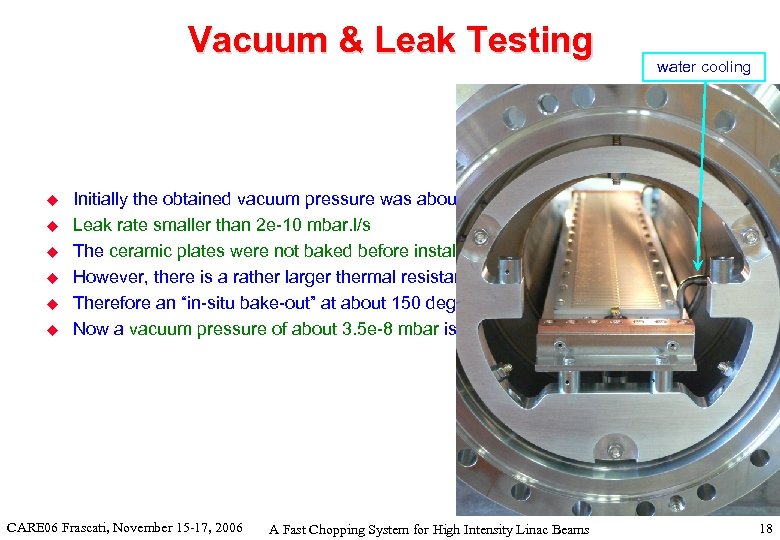

Vacuum & Leak Testing u u u water cooling Initially the obtained vacuum pressure was about 1. 5 e-7 mbar Leak rate smaller than 2 e-10 mbar. l/s The ceramic plates were not baked before installation and the entire tank cannot be bake However, there is a rather larger thermal resistance between the ceramic plate and its alu Therefore an “in-situ bake-out” at about 150 degrees C was possible by passing current th Now a vacuum pressure of about 3. 5 e-8 mbar is reached, which is within specs for the ch CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 18

Vacuum & Leak Testing u u u water cooling Initially the obtained vacuum pressure was about 1. 5 e-7 mbar Leak rate smaller than 2 e-10 mbar. l/s The ceramic plates were not baked before installation and the entire tank cannot be bake However, there is a rather larger thermal resistance between the ceramic plate and its alu Therefore an “in-situ bake-out” at about 150 degrees C was possible by passing current th Now a vacuum pressure of about 3. 5 e-8 mbar is reached, which is within specs for the ch CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 18

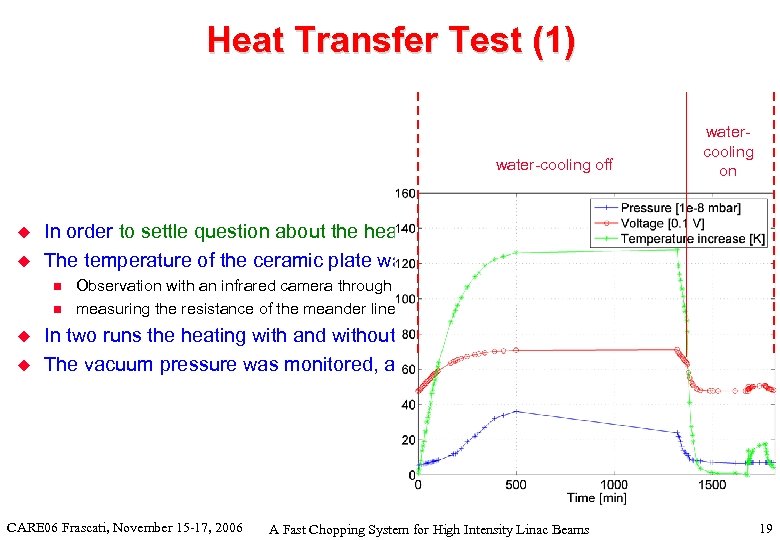

Heat Transfer Test (1) water-cooling off u u In order to settle question about the heat contact between the ceramic plates and th The temperature of the ceramic plate was monitored in two ways, by n n u u watercooling on Observation with an infrared camera through a window at one end of the tank measuring the resistance of the meander line, knowing that the resistivities of the Cu, Ag and Au all In two runs the heating with and without water cooling was measured The vacuum pressure was monitored, as well CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 19

Heat Transfer Test (1) water-cooling off u u In order to settle question about the heat contact between the ceramic plates and th The temperature of the ceramic plate was monitored in two ways, by n n u u watercooling on Observation with an infrared camera through a window at one end of the tank measuring the resistance of the meander line, knowing that the resistivities of the Cu, Ag and Au all In two runs the heating with and without water cooling was measured The vacuum pressure was monitored, as well CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 19

Heat Transfer Test (2) u The device under test… CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 20

Heat Transfer Test (2) u The device under test… CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 20

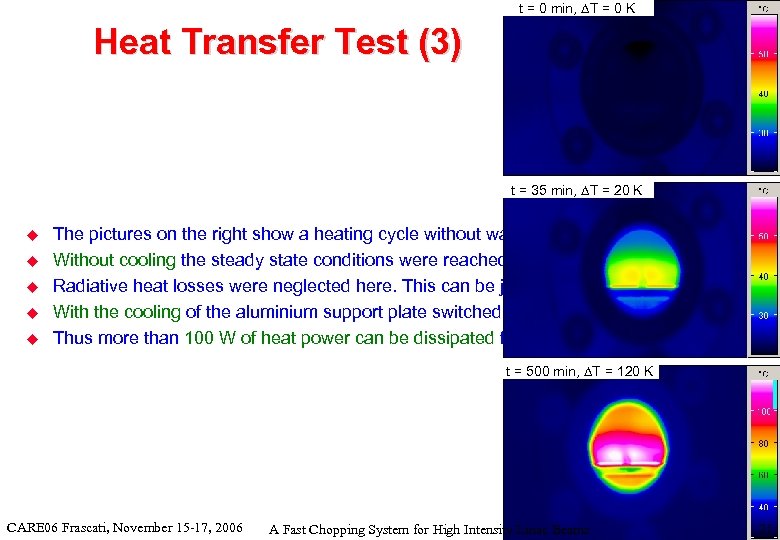

t = 0 min, T = 0 K Heat Transfer Test (3) t = 35 min, T = 20 K u u u The pictures on the right show a heating cycle without water cooling (Note the change in sca Without cooling the steady state conditions were reached at a temperature difference T = 1 Radiative heat losses were neglected here. This can be justified by the fact that inner surfac With the cooling of the aluminium support plate switched on, the steady state T decreases Thus more than 100 W of heat power can be dissipated for an operation temperature 100 K t = 500 min, T = 120 K CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 21

t = 0 min, T = 0 K Heat Transfer Test (3) t = 35 min, T = 20 K u u u The pictures on the right show a heating cycle without water cooling (Note the change in sca Without cooling the steady state conditions were reached at a temperature difference T = 1 Radiative heat losses were neglected here. This can be justified by the fact that inner surfac With the cooling of the aluminium support plate switched on, the steady state T decreases Thus more than 100 W of heat power can be dissipated for an operation temperature 100 K t = 500 min, T = 120 K CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 21

High Voltage Testing u u The chopper must be able to stand the 500 V pulses on the plates High voltage testing showed that a single chopper plate can stand at least 2 k. V to CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 22

High Voltage Testing u u The chopper must be able to stand the 500 V pulses on the plates High voltage testing showed that a single chopper plate can stand at least 2 k. V to CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 22

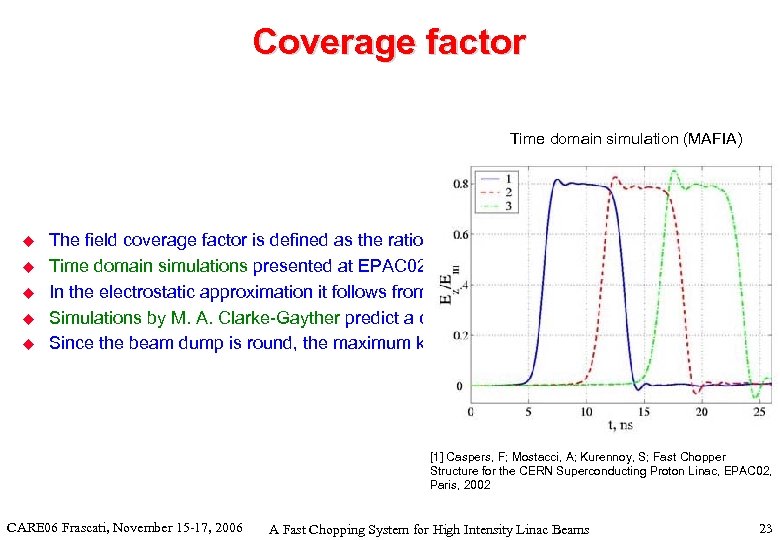

Coverage factor Time domain simulation (MAFIA) u u u The field coverage factor is defined as the ratio of the deflecting electric field on the beam pa Time domain simulations presented at EPAC 02 predict a coverage factor of 0. 8 in the center In the electrostatic approximation it follows from Gauss’s law that the vertical electric field int Simulations by M. A. Clarke-Gayther predict a coverage factor of 0. 78 in the center of the ch Since the beam dump is round, the maximum kick field is needed in the center of the structu [1] Caspers, F; Mostacci, A; Kurennoy, S; Fast Chopper Structure for the CERN Superconducting Proton Linac, EPAC 02, Paris, 2002 CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 23

Coverage factor Time domain simulation (MAFIA) u u u The field coverage factor is defined as the ratio of the deflecting electric field on the beam pa Time domain simulations presented at EPAC 02 predict a coverage factor of 0. 8 in the center In the electrostatic approximation it follows from Gauss’s law that the vertical electric field int Simulations by M. A. Clarke-Gayther predict a coverage factor of 0. 78 in the center of the ch Since the beam dump is round, the maximum kick field is needed in the center of the structu [1] Caspers, F; Mostacci, A; Kurennoy, S; Fast Chopper Structure for the CERN Superconducting Proton Linac, EPAC 02, Paris, 2002 CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 23

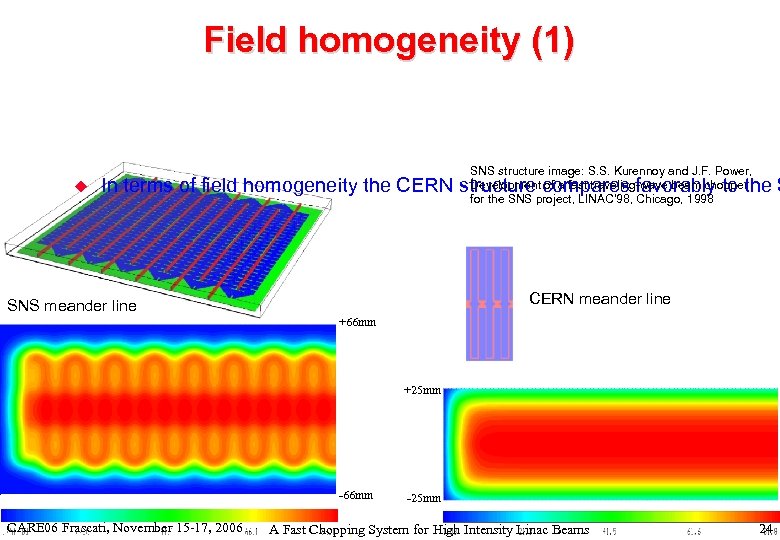

Field homogeneity (1) u SNS structure image: S. S. Kurennoy and J. F. Power, Development of a fast traveling-wave beam chopper for the SNS project, LINAC’ 98, Chicago, 1998 In terms of field homogeneity the CERN structure compares favorably to the S CERN meander line SNS meander line +66 mm +25 mm -66 mm CARE 06 Frascati, November 15 -17, 2006 -25 mm A Fast Chopping System for High Intensity Linac Beams 24

Field homogeneity (1) u SNS structure image: S. S. Kurennoy and J. F. Power, Development of a fast traveling-wave beam chopper for the SNS project, LINAC’ 98, Chicago, 1998 In terms of field homogeneity the CERN structure compares favorably to the S CERN meander line SNS meander line +66 mm +25 mm -66 mm CARE 06 Frascati, November 15 -17, 2006 -25 mm A Fast Chopping System for High Intensity Linac Beams 24

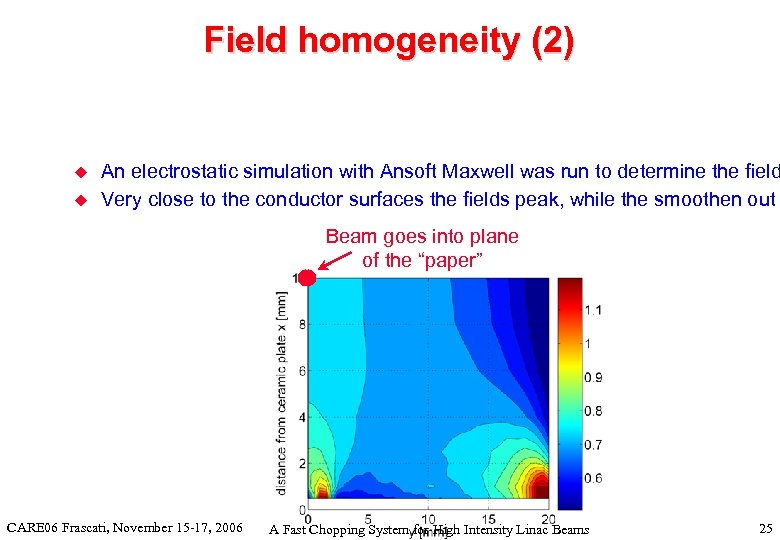

Field homogeneity (2) u u An electrostatic simulation with Ansoft Maxwell was run to determine the field Very close to the conductor surfaces the fields peak, while the smoothen out Beam goes into plane of the “paper” CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 25

Field homogeneity (2) u u An electrostatic simulation with Ansoft Maxwell was run to determine the field Very close to the conductor surfaces the fields peak, while the smoothen out Beam goes into plane of the “paper” CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 25

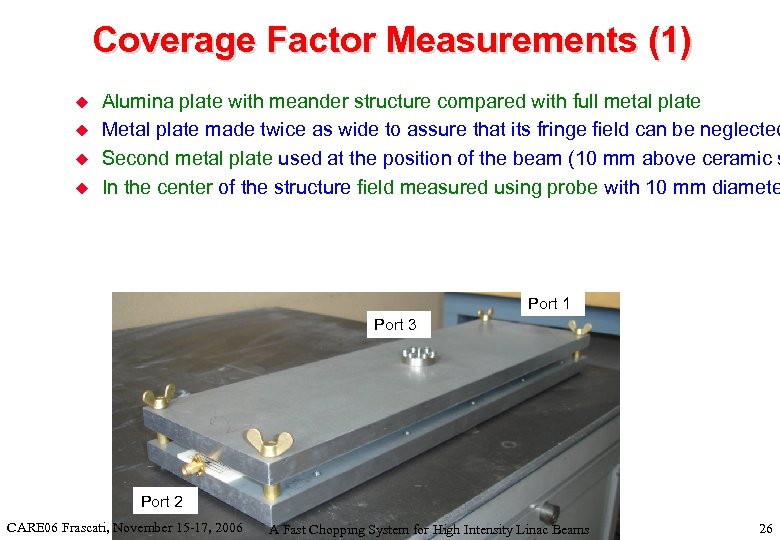

Coverage Factor Measurements (1) u u Alumina plate with meander structure compared with full metal plate Metal plate made twice as wide to assure that its fringe field can be neglected Second metal plate used at the position of the beam (10 mm above ceramic s In the center of the structure field measured using probe with 10 mm diamete Port 1 Port 3 Port 2 CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 26

Coverage Factor Measurements (1) u u Alumina plate with meander structure compared with full metal plate Metal plate made twice as wide to assure that its fringe field can be neglected Second metal plate used at the position of the beam (10 mm above ceramic s In the center of the structure field measured using probe with 10 mm diamete Port 1 Port 3 Port 2 CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 26

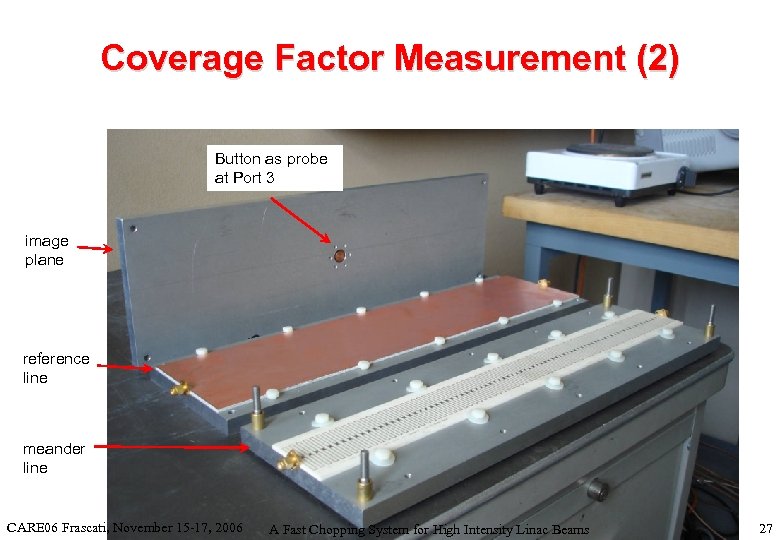

Coverage Factor Measurement (2) Button as probe at Port 3 image plane reference line meander line CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 27

Coverage Factor Measurement (2) Button as probe at Port 3 image plane reference line meander line CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 27

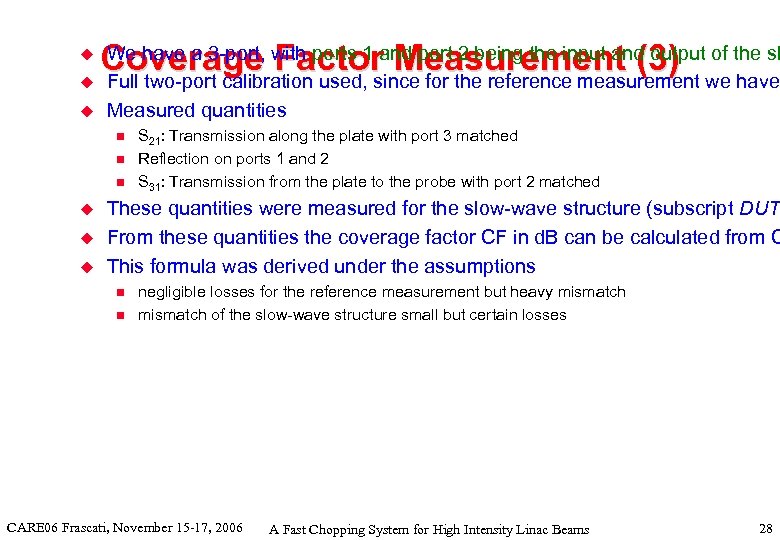

We have a 3 -port, Coverage with ports 1 and port 2 being the input and output of the sl Factor Measurement (3) u Full two-port calibration used, since for the reference measurement we have u u Measured quantities n n n u u u S 21: Transmission along the plate with port 3 matched Reflection on ports 1 and 2 S 31: Transmission from the plate to the probe with port 2 matched These quantities were measured for the slow-wave structure (subscript DUT From these quantities the coverage factor CF in d. B can be calculated from C This formula was derived under the assumptions n n negligible losses for the reference measurement but heavy mismatch of the slow-wave structure small but certain losses CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 28

We have a 3 -port, Coverage with ports 1 and port 2 being the input and output of the sl Factor Measurement (3) u Full two-port calibration used, since for the reference measurement we have u u Measured quantities n n n u u u S 21: Transmission along the plate with port 3 matched Reflection on ports 1 and 2 S 31: Transmission from the plate to the probe with port 2 matched These quantities were measured for the slow-wave structure (subscript DUT From these quantities the coverage factor CF in d. B can be calculated from C This formula was derived under the assumptions n n negligible losses for the reference measurement but heavy mismatch of the slow-wave structure small but certain losses CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 28

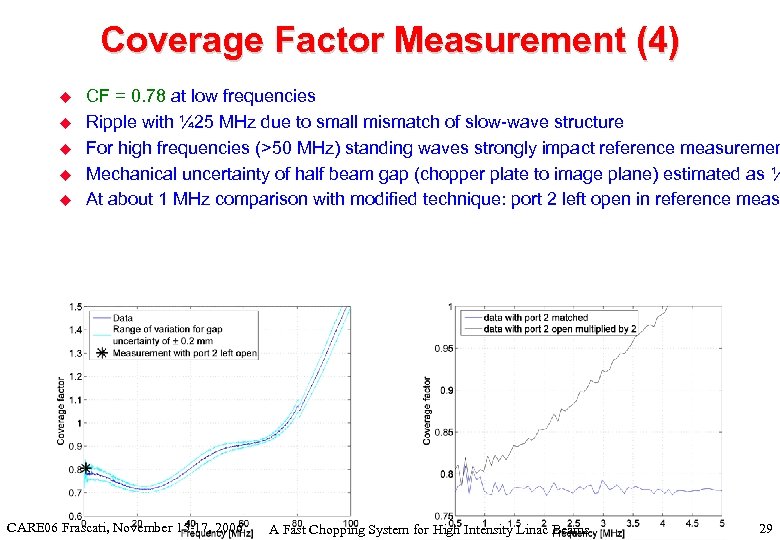

Coverage Factor Measurement (4) u u u CF = 0. 78 at low frequencies Ripple with ¼ 25 MHz due to small mismatch of slow-wave structure For high frequencies (>50 MHz) standing waves strongly impact reference measuremen Mechanical uncertainty of half beam gap (chopper plate to image plane) estimated as ¼ At about 1 MHz comparison with modified technique: port 2 left open in reference measu CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 29

Coverage Factor Measurement (4) u u u CF = 0. 78 at low frequencies Ripple with ¼ 25 MHz due to small mismatch of slow-wave structure For high frequencies (>50 MHz) standing waves strongly impact reference measuremen Mechanical uncertainty of half beam gap (chopper plate to image plane) estimated as ¼ At about 1 MHz comparison with modified technique: port 2 left open in reference measu CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 29

Remaining Jobs u u u Final assembly of both chopper tanks including outgassing, leakage and ele Power test with new pulser Test with beam n n u Static: A DC voltage applied at the plates, 50 termination removed Dynamic test with pulser Whatever else you can suggest or dream up. . . CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 30

Remaining Jobs u u u Final assembly of both chopper tanks including outgassing, leakage and ele Power test with new pulser Test with beam n n u Static: A DC voltage applied at the plates, 50 termination removed Dynamic test with pulser Whatever else you can suggest or dream up. . . CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 30

Acknowledgements u u We would like to thank the AB-RF workshops for assembling the tank, F. W Thanks to R. Garoby and T. Linnecar for support CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 31

Acknowledgements u u We would like to thank the AB-RF workshops for assembling the tank, F. W Thanks to R. Garoby and T. Linnecar for support CARE 06 Frascati, November 15 -17, 2006 A Fast Chopping System for High Intensity Linac Beams 31