882df8dd2cfcdadcc7522cd9d0b03880.ppt

- Количество слайдов: 57

A BATCH POLYSTYRENE REACTOR RUNAWAY: A CASE HISTORY BY RONALD J. WILLEY, Ph. D. PE. NORTHEASTERN UNIVERSITY PREPARED FOR SACHE A PRODUCT OF THE CCPS-AICHE NEW YORK, NEW YORK 2000 1

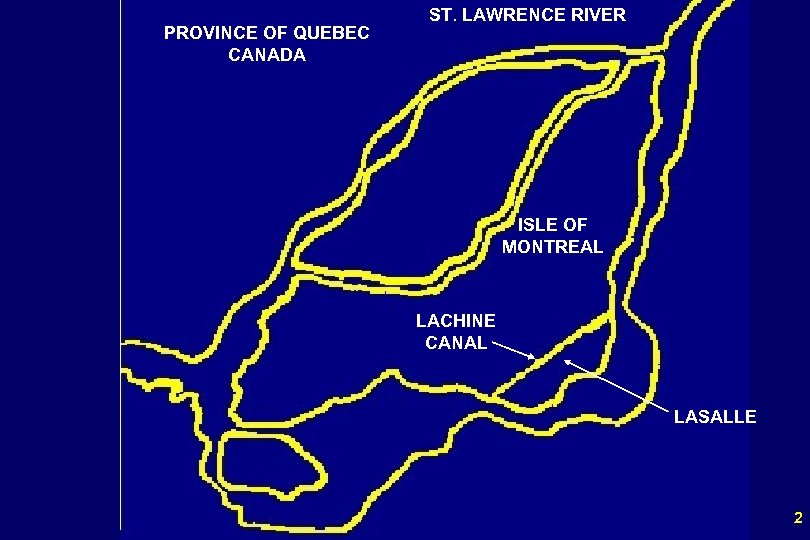

PROVINCE OF QUEBEC CANADA ST. LAWRENCE RIVER ISLE OF MONTREAL LACHINE CANAL LASALLE 2

3

4

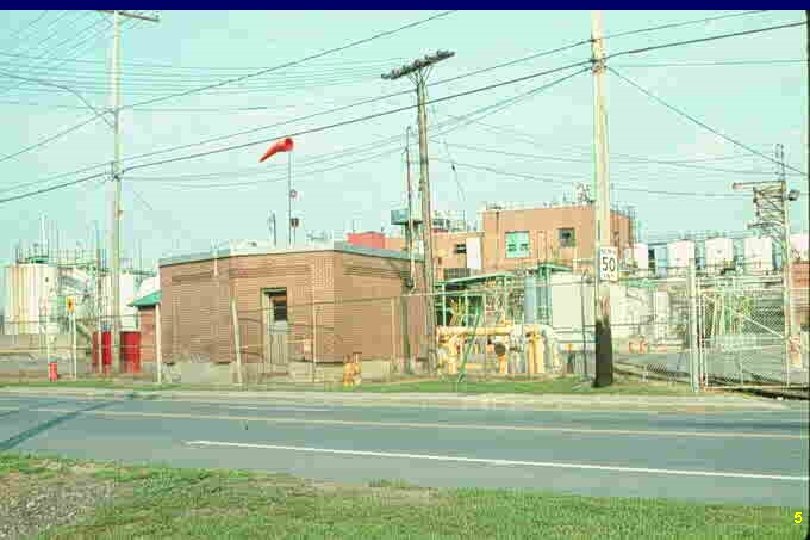

5

6

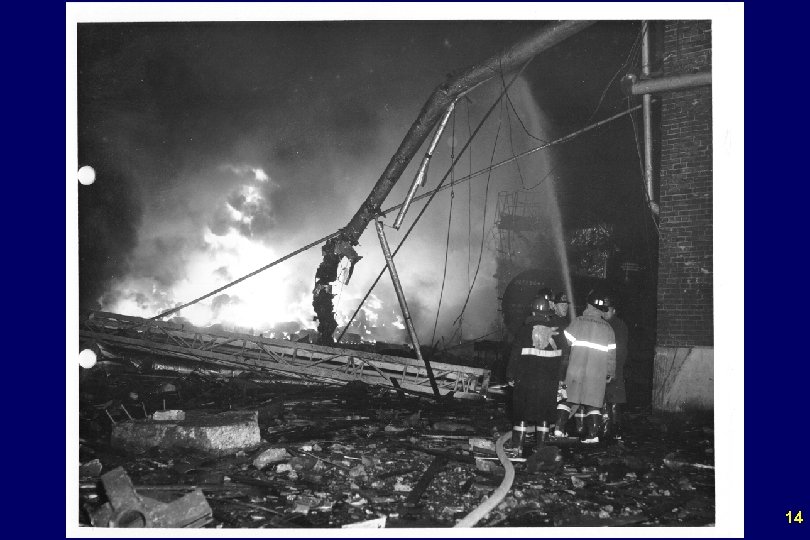

THE ACCIDENT OCTOBER 13, 1966 LATE EVENING INITIAL EVENT STYRENE VAPOR COMBUSTION 7

8

9

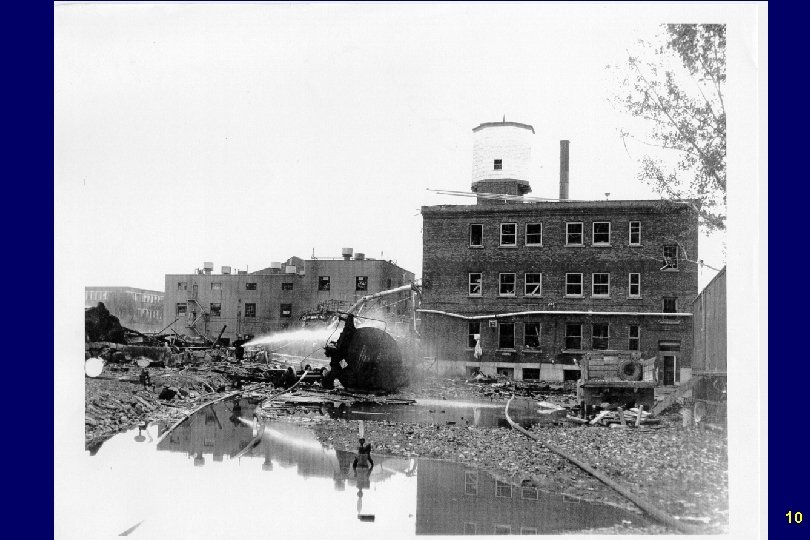

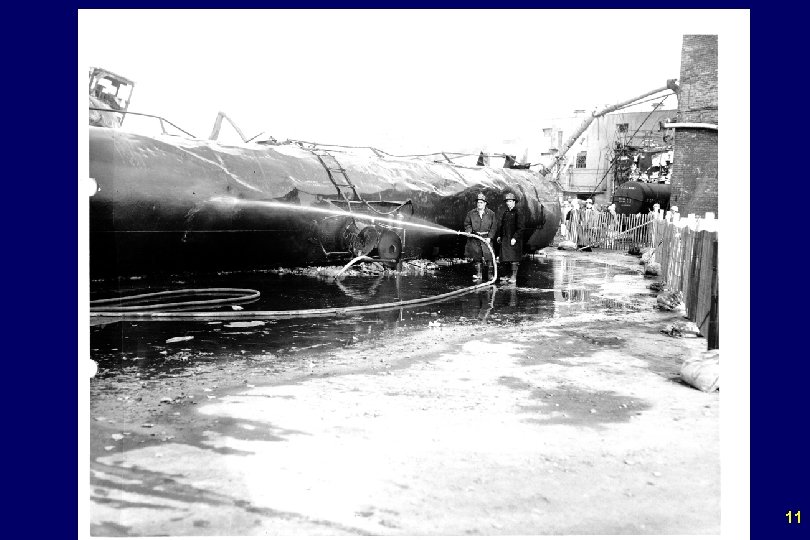

10

11

12

13

14

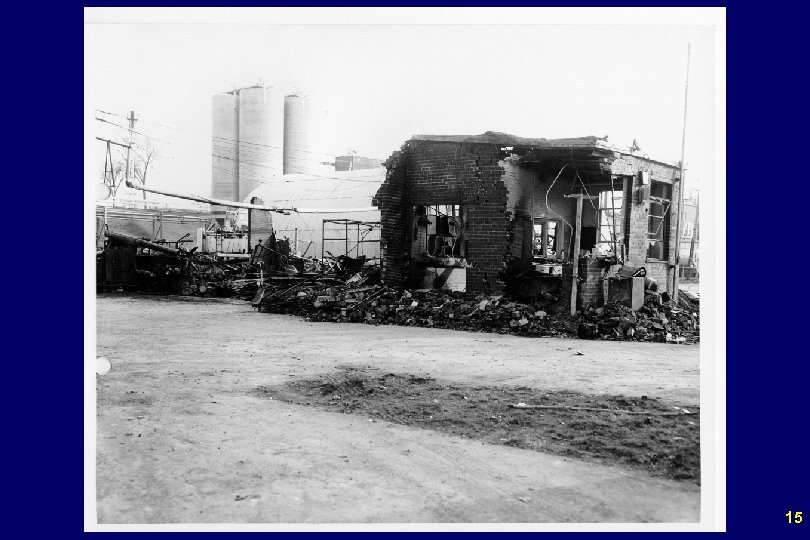

15

16

BACKGROUND 17

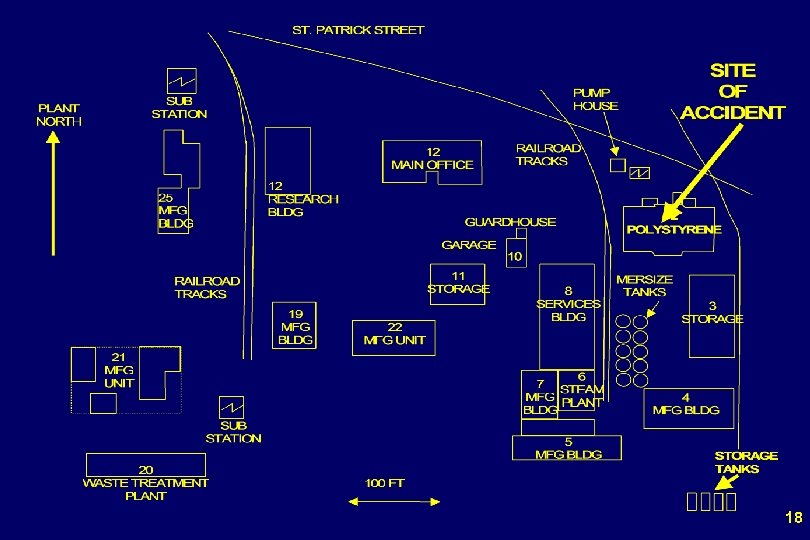

18

5 POLYMERIZATION REACTORS IN THE BUILDING 2 REACTORS WERE USED FOR THE PROCESS DESCRIBED BELOW 19

PHYSICAL PROPERTIES OF STYRENE CH=CH 2 · MOLECULAR WEIGHT 104. 5 · BOILING POINT 145 C · FREEZING POINT -30. 6 C · FLASH POINT 31 C · AUTOIGNITION TEMPERATURE 490 C 20

ADDITIONAL PROPERTIES OF STYRENE FLAMMABLE LIMITS IN AIR (VOL%) 1. 1 TO 6. 1 OSHA PEL 50 PPM WILL POLYMERIZE AT ROOM TEMPERATURE IF UNINHIBITED HEAT OF POLYMERIZATION 74. 5 MJ/KMOL CP, HEAT CAPACITY 1. 69 J/G 21

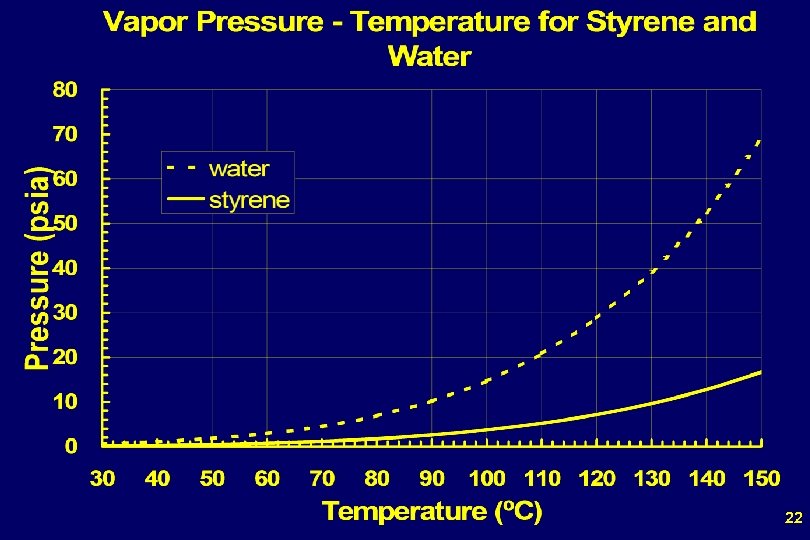

22

ARRHENIUS EQUATION k A Ea R T Rate constant Pre-exponential constant Activation energy Gas Constant Absolute temperature 23

24

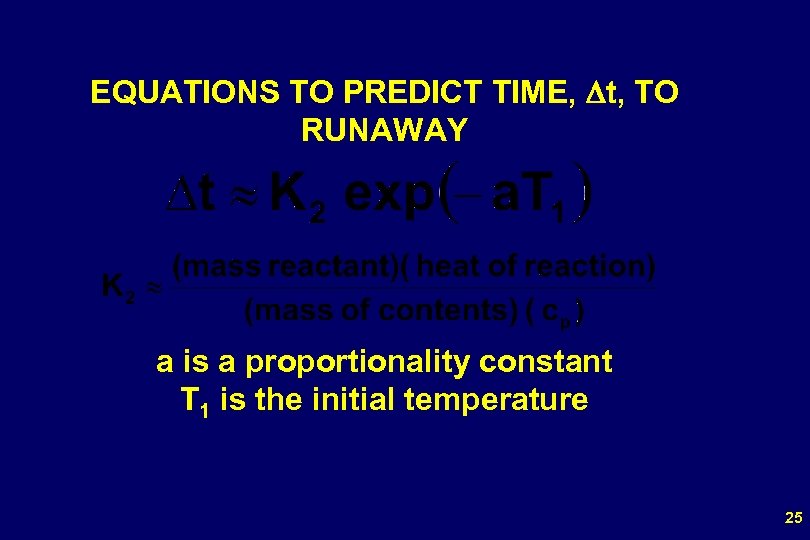

EQUATIONS TO PREDICT TIME, Dt, TO RUNAWAY a is a proportionality constant T 1 is the initial temperature 25

TIME, D t, MINUTES ADIABATIC TEMPERATURE RISE OF CATALYZED STYRENE (HYPOTHETICAL EXAMPLE) from Boyle 100 o At ~130 C, 10 MIN TO RUNAWAY 10 1 0. 1 100 150 200 o BATCH TEMPERATURE, C 26

STYRENE POLYMERIZATION METHODS ANIONIC POLYMERIZATION CATIONIC POLYMERIZATION FREE RADICAL POLYMERIZATION ZIEGLER NATTA POLYMERIZATION 27

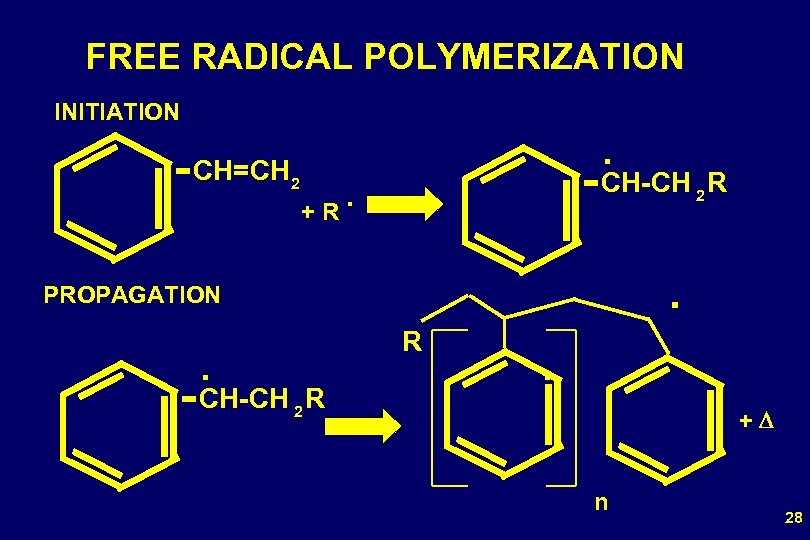

FREE RADICAL POLYMERIZATION INITIATION CH=CH 2 . CH-CH R 2 . + R . PROPAGATION . CH-CH R 2 R . + D n 28

STYRENE TO POLYSTYRENE BATCH PROCESS 1. LOAD THE REACTOR WITH STYRENE 2. ADD POLYMERIZATION CATALYST 3. HEAT TO 95°C 4. HOLD FOR 2 TO 8 HOURS 29

STYRENE TO POLYSTYRENE BATCH PROCESS CONTINUED 5. TRANSFER TO FORMING UNIT AT ABOUT 75% CONVERSION 6. OPEN FORMING UNIT AFTER FULL CONVERSION. REMOVE PS BLOCK 7. CRUSH PS BLOCK 8. TRANSFER SOLIDS TO EXTRUDER 30

31

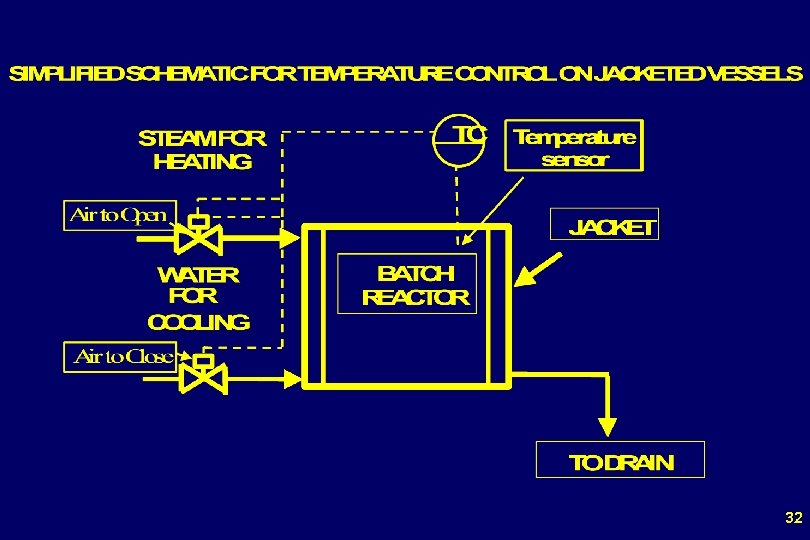

32

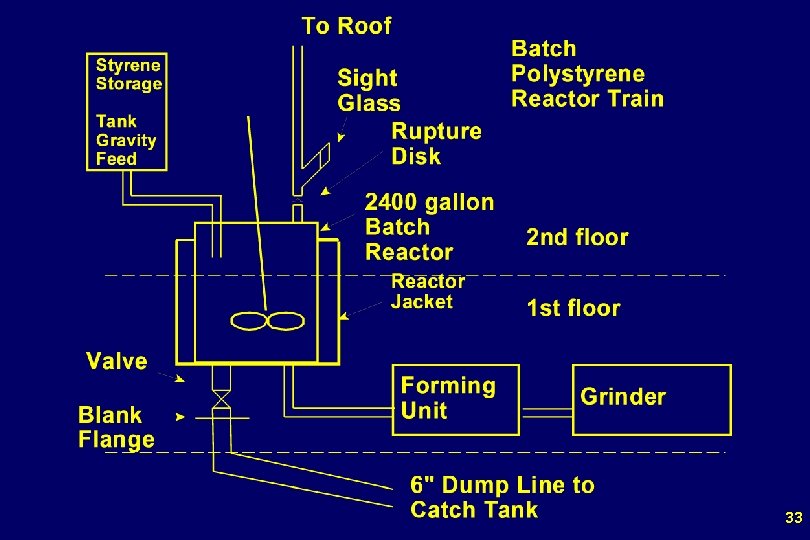

33

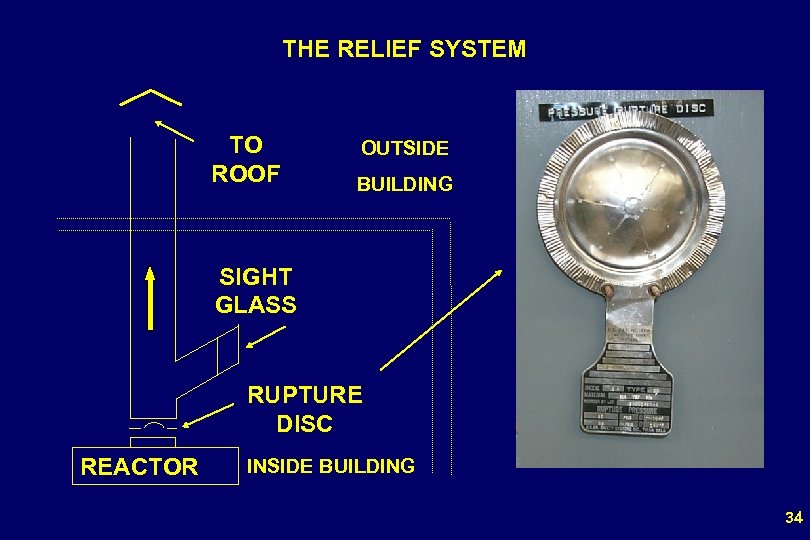

THE RELIEF SYSTEM TO ROOF OUTSIDE BUILDING SIGHT GLASS RUPTURE DISC REACTOR INSIDE BUILDING 34

TIME LINE EARLY IN THE DAY OF EXPLOSION TIME NOTE 2: 30 19: 40 21: 15 POLYMER A PRODUCED STARTED POLYMER B BATCH LOADED MATERIAL STARTED HEATING HEATED TO 92°C 35

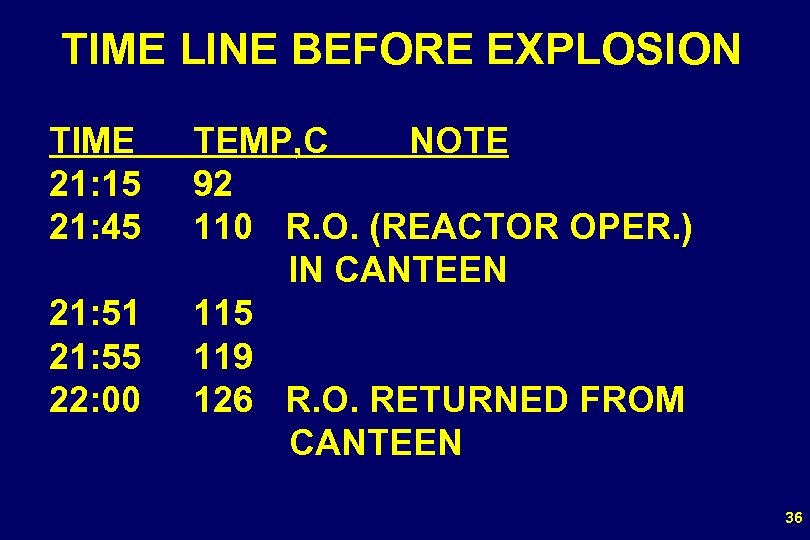

TIME LINE BEFORE EXPLOSION TIME TEMP, C NOTE 21: 15 92 21: 45 110 R. O. (REACTOR OPER. ) IN CANTEEN 21: 51 115 21: 55 119 22: 00 126 R. O. RETURNED FROM CANTEEN 36

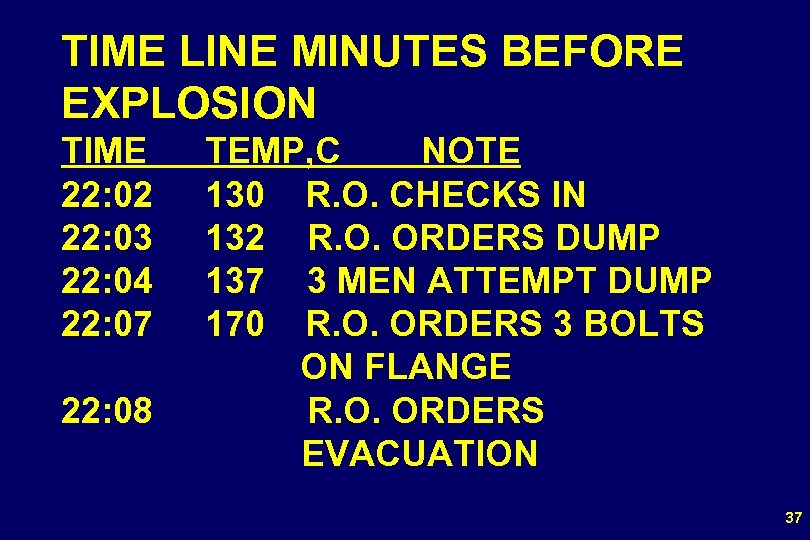

TIME LINE MINUTES BEFORE EXPLOSION TIME TEMP, C NOTE 22: 02 130 R. O. CHECKS IN 22: 03 132 R. O. ORDERS DUMP 22: 04 137 3 MEN ATTEMPT DUMP 22: 07 170 R. O. ORDERS 3 BOLTS ON FLANGE 22: 08 R. O. ORDERS EVACUATION 37

38

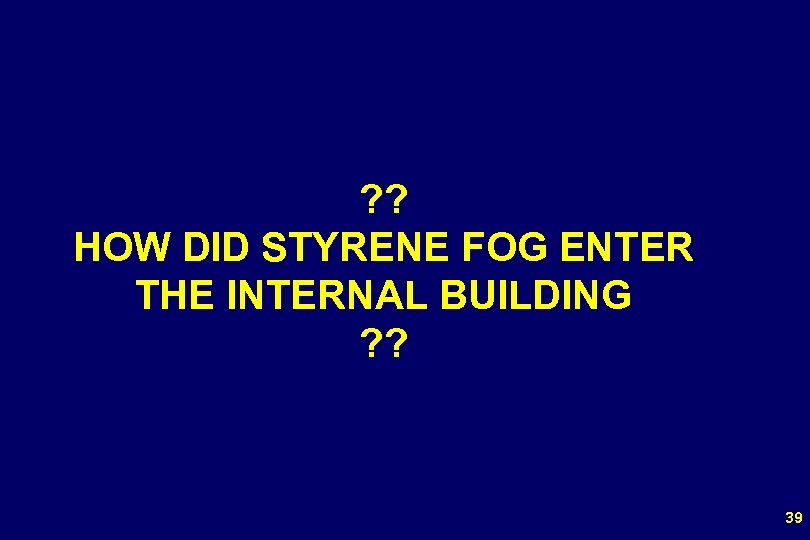

? ? HOW DID STYRENE FOG ENTER THE INTERNAL BUILDING ? ? 39

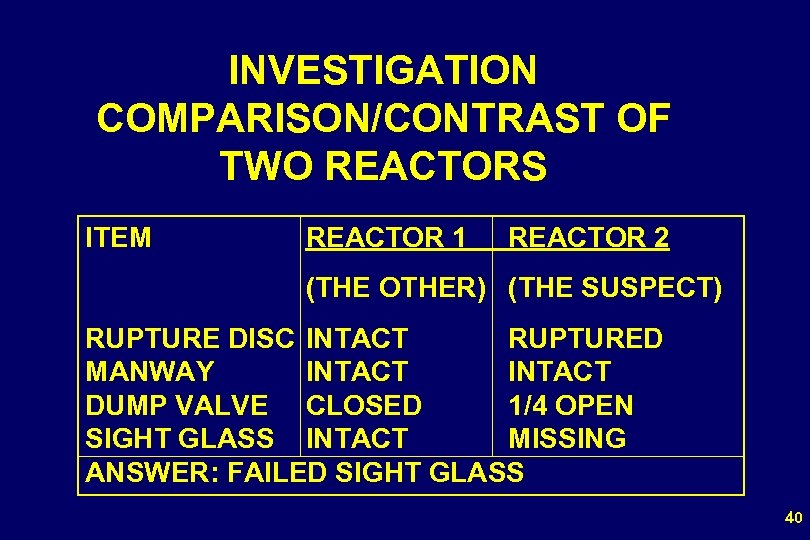

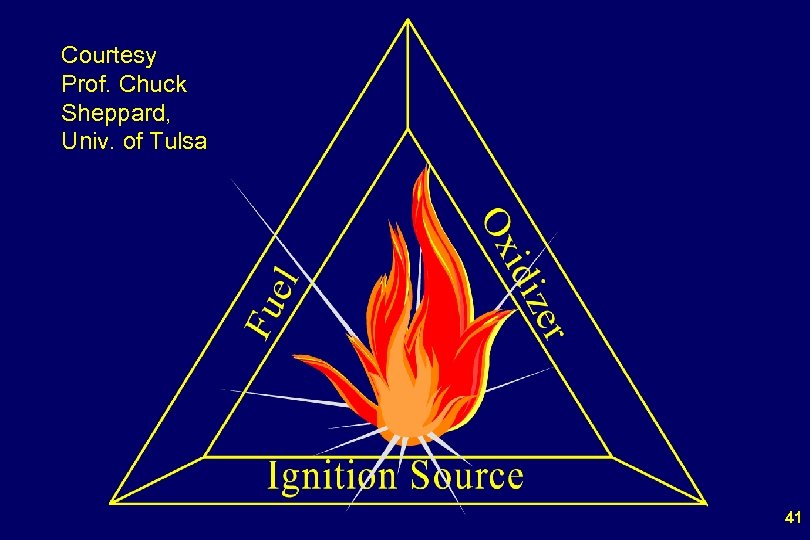

INVESTIGATION COMPARISON/CONTRAST OF TWO REACTORS ITEM REACTOR 1 REACTOR 2 (THE OTHER) (THE SUSPECT) RUPTURE DISC INTACT RUPTURED MANWAY INTACT DUMP VALVE CLOSED 1/4 OPEN SIGHT GLASS INTACT MISSING ANSWER: FAILED SIGHT GLASS 40

Courtesy Prof. Chuck Sheppard, Univ. of Tulsa 41

A CONFINED SPACE EXPLOSION 42

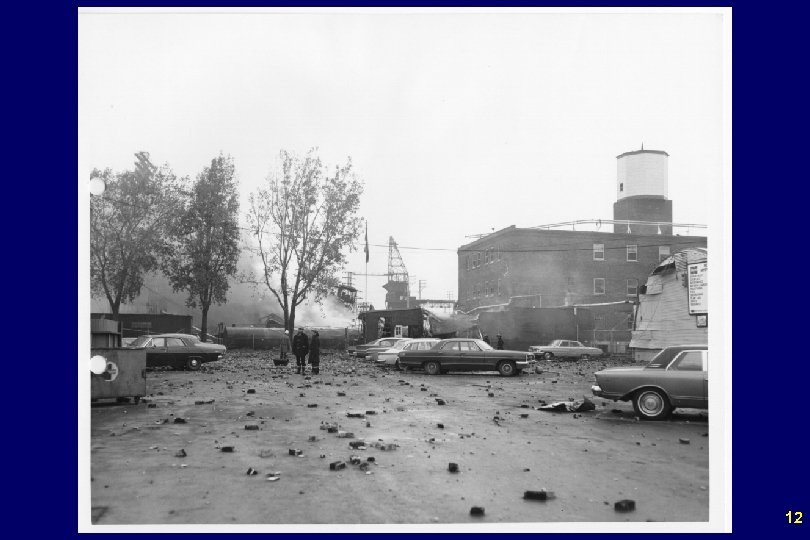

EXTENT OF EXPLOSION 11 PEOPLE KILLED 130 TON CAR OF VINYL CHLORIDE TIPPED OVER GUARDHOUSE DESTROYED BRICKS FOUND 400 FEET AWAY 43

TNT EQUIVALENT BASED ON THE ESTIMATED OVERPRESSURES AND AMOUNT OF STYRENE RELEASED BEFORE THE INITIAL COMBUSTION THE COMBUSTION WAS AS IF 6. 6 TONS OF TNT EXPLODED AT ONCE 44

45

FIRE PROTECTION SYSTEMS SPRINKLER SYSTEMS FIRE WATER PUMPS FIRE RATED WALLS AND BARRIERS 46

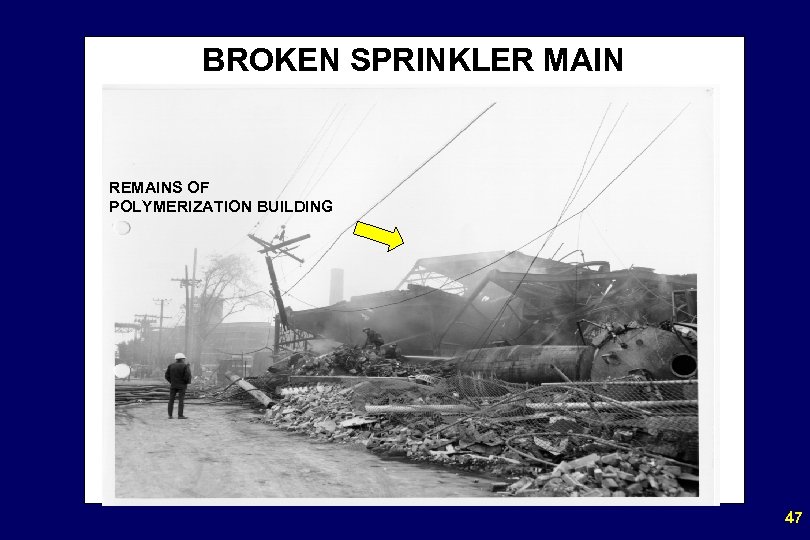

BROKEN SPRINKLER MAIN REMAINS OF POLYMERIZATION BUILDING 47

48

PROPERTY DAMAGE SUMMARY POLYSTYRENE BUILDING DESTROYED BUILDINGS 1, 4, 5, 8, &12 SUFFERED FIRE AND WATER DAMAGE PUMP HOUSE DESTROYED SEVERAL AUTOMOBILES DAMAGED 49

INVESTIGATION SEARCH FOR THE ROOT CAUSE PRINCIPAL CAUSE – RUNAWAY REACTION CAUSED A PRESSURE BUILDUP INSIDE A REACTOR THAT SUBSEQUENTLY RELIEVED. ALL MATERIAL RELIEVED SHOULD HAVE EXITED BUILDING THROUGH ROOF VENT. 50

TESTIMONY STYRENE VAPOR INSIDE PS BUILDING WHY? FAILED SIGHT GLASS ABOVE RUPTURE DISK 51

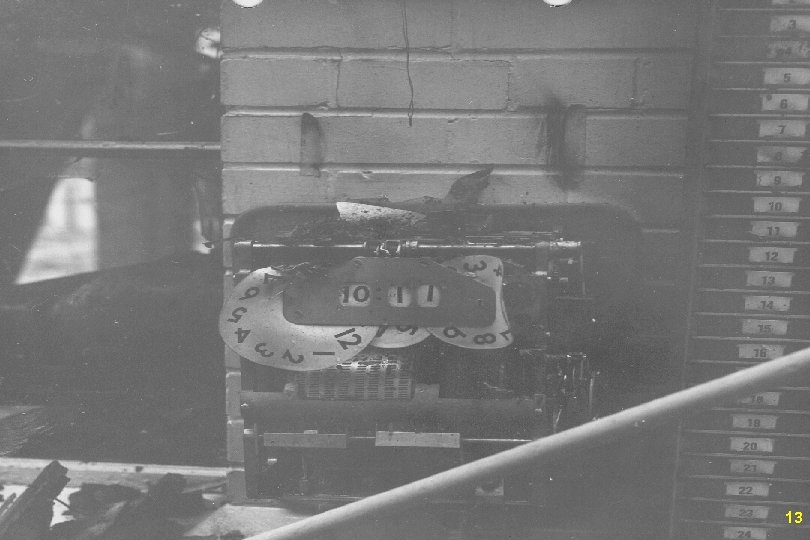

POSSIBLE IGNITION SOURCE ARCING MOTOR? HOT SURFACES? ELECTROSTATIC DISCHARGE? 52

WHY DID THE REACTION RUN AWAY? WRONG CAM ON THE RECORDER? OR THE PENS STUCK? 53

LESSONS LEARNED MAINTAIN CRITICAL PROCESS EQUIPMENT INSTALL AUDIBLE ALARMS CENTRALIZE CONTROL OF BATCH OPERATIONS ELIMINATE SIGHT GLASS VIEWPORTS FROM RELIEF LINES HAVE SEMI-AUTOMATED DISCHARGE SYSTEMS (REMOTE DUMP VALVE) 54

BROADER LESSONS LEARNED USE DOW FIRE AND EXPLOSION INDEX FOR SPACING OF PROCESS EQUIPMENT STORAGE TANKS, AND TANK CAR KEEP UPDATED DISASTER CONTROL PLANS 55

OTHER LESSONS LEARNED REDUNDANT PROCESS CONTROL EQUIPMENT LOCATION OF EMERGENCY POWER AND FIRE PROTECTION FAIL SAFE VALVES ON STORAGE TANKS 56

ACKNOWLEDGEMENT DR. WALT HOWARD LASALLE FIRE DEPARTMENT MR. ROBERT GUERARD MR. JOHN PAUL LACOURSIERE SACHE COMMITTEE 57

882df8dd2cfcdadcc7522cd9d0b03880.ppt