FundamNano StructurFuel Technol.ppt

- Количество слайдов: 37

9 th International Colloquium «Fuels-Conventional and Future Energy for Automobiles » 15 -17, January 2013 Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I Bauman Moscow State Technical University Moscow, Russia E-mail: deulin@bmstu. ru, ikonnikova@mail. ru

9 th International Colloquium «Fuels-Conventional and Future Energy for Automobiles » 15 -17, January 2013 Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I Bauman Moscow State Technical University Moscow, Russia E-mail: deulin@bmstu. ru, ikonnikova@mail. ru

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The fundamentals describe so called “dry friction” process and are actual for different technologies: -Mechanisms work in atmosphere and in vacuum -Cutting processes in metal working -Rolling processes in metal working -Gas transportation in pipe line tubes - Traditional milling technologies -Nuclear technologies and hydrogen isotopes accumulation - Nano structured fuel technology , based on the renewable sources Physical fundamentals of all these technologies are joint

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The fundamentals describe so called “dry friction” process and are actual for different technologies: -Mechanisms work in atmosphere and in vacuum -Cutting processes in metal working -Rolling processes in metal working -Gas transportation in pipe line tubes - Traditional milling technologies -Nuclear technologies and hydrogen isotopes accumulation - Nano structured fuel technology , based on the renewable sources Physical fundamentals of all these technologies are joint

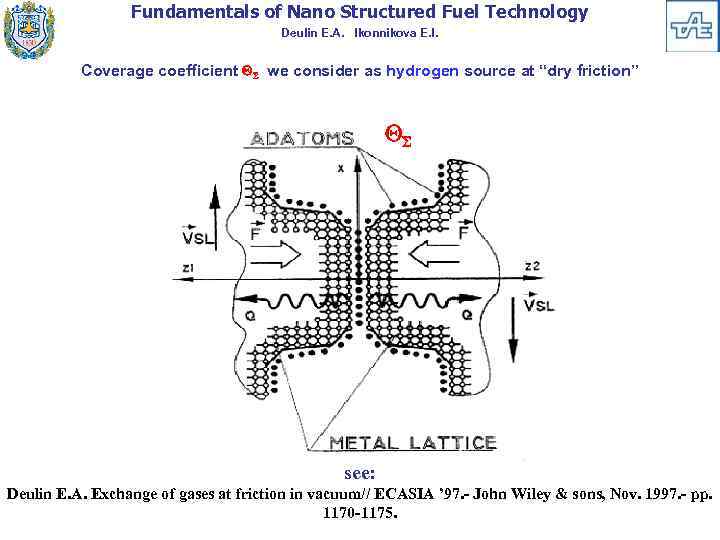

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Coverage coefficient we consider as hydrogen source at “dry friction” see: Deulin E. A. Exchange of gases at friction in vacuum// ECASIA ’ 97. - John Wiley & sons, Nov. 1997. - pp. 1170 -1175.

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Coverage coefficient we consider as hydrogen source at “dry friction” see: Deulin E. A. Exchange of gases at friction in vacuum// ECASIA ’ 97. - John Wiley & sons, Nov. 1997. - pp. 1170 -1175.

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The fundamental position of patented technology : Coverage coefficient is a source of hydrogen into the particles of patented fuel. -sorbed water molecules dissociate into H and OH parts on the surfaces in first monolayer of coverage -hydrogen isotopes atoms dissolute into the solids under action adhesion energy -H atoms concentration on the surfaces is 100 -300 times more then in solid particles -”double sorption” (coverage 1 with coverage 2 contacting ) is exothermal process and leads to heat on the surfaces appearing -” double desorption” as endothermic process based on friction force transformation into next (sorption process) [2] Deulin E. A. Exchange of gases at friction in vacuum// ECASIA ’ 97. - John Wiley & sons, Nov. 1997. - pp. 1170 -1175. Deulin E. A The method of nano structured fuel manufacturing Patent RF № 2 444 561 C 1 dated. 10. 03. 2012

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The fundamental position of patented technology : Coverage coefficient is a source of hydrogen into the particles of patented fuel. -sorbed water molecules dissociate into H and OH parts on the surfaces in first monolayer of coverage -hydrogen isotopes atoms dissolute into the solids under action adhesion energy -H atoms concentration on the surfaces is 100 -300 times more then in solid particles -”double sorption” (coverage 1 with coverage 2 contacting ) is exothermal process and leads to heat on the surfaces appearing -” double desorption” as endothermic process based on friction force transformation into next (sorption process) [2] Deulin E. A. Exchange of gases at friction in vacuum// ECASIA ’ 97. - John Wiley & sons, Nov. 1997. - pp. 1170 -1175. Deulin E. A The method of nano structured fuel manufacturing Patent RF № 2 444 561 C 1 dated. 10. 03. 2012

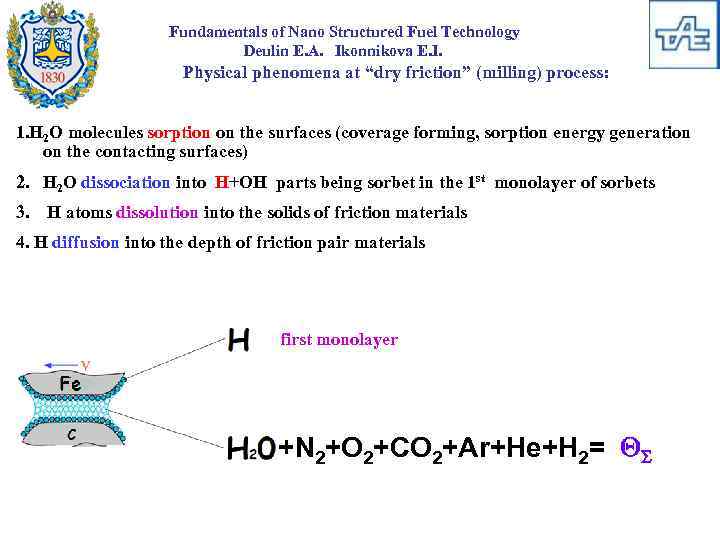

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Physical phenomena at “dry friction” (milling) process: 1. Н 2 О molecules sorption on the surfaces (coverage forming, sorption energy generation on the contacting surfaces) 2. Н 2 О dissociation into Н+ОН parts being sorbet in the 1 st monolayer of sorbets 3. Н atoms dissolution into the solids of friction materials 4. Н diffusion into the depth of friction pair materials first monolayer +N 2+O 2+CO 2+Ar+He+H 2=

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Physical phenomena at “dry friction” (milling) process: 1. Н 2 О molecules sorption on the surfaces (coverage forming, sorption energy generation on the contacting surfaces) 2. Н 2 О dissociation into Н+ОН parts being sorbet in the 1 st monolayer of sorbets 3. Н atoms dissolution into the solids of friction materials 4. Н diffusion into the depth of friction pair materials first monolayer +N 2+O 2+CO 2+Ar+He+H 2=

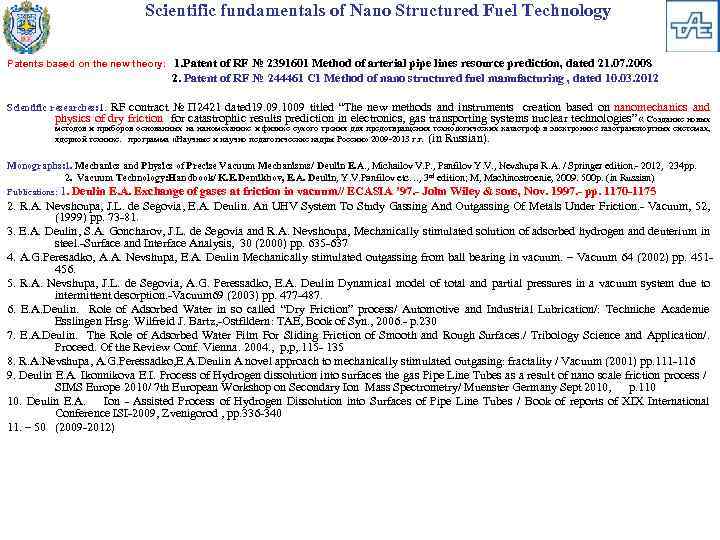

Scientific fundamentals of Nano Structured Fuel Technology Patents based on the new theory: 1. Patent of RF № 2391601 Method of arterial pipe lines resource prediction, dated 21. 07. 2008 2. Patent of RF № 244461 С 1 Method of nano structured fuel manufacturing , dated 10. 03. 2012 RF contract № П 2421 dated 19. 09. 1009 titled “The new methods and instruments creation based on nanomechanics and physics of dry friction for catastrophic results prediction in electronics, gas transporting systems nuclear technologies” « Cоздание новых Scientific researches: 1. методов и приборов основанных на наномеханике и физике сухого трения для предотвращения технологических катастроф в электронике газотранспортных системах, ядерной технике. программа «Научные и научно педагогические кадры России» 2009 -2013 г. г. (in Russian). Monographs: 1. Mechanics and Physics of Precise Vacuum Mechanisms/ Deulin E. A. , Michailov V. P. , Panfilov Y. V. , Nevshupa R. A. / Springer edition. - 2012, 234 pp. 2. Vacuum Technology: Handbook/ K. E. Demikhov, E. A. Deulin, Y. V. Panfilov etc…, 3 rd edition; M, Machinostroenie, 2009. 500 p. (in Russian) Publications: 1. Deulin E. A. Exchange of gases at friction in vacuum// ECASIA ’ 97. - John Wiley & sons, Nov. 1997. - pp. 1170 -1175 2. R. A. Nevshoupa, J. L. de Segovia, E. A. Deulin. An UHV System To Study Gassing And Outgassing Of Metals Under Friction. - Vacuum, 52, (1999) pp. 73 -81. 3. E. A. Deulin, S. A. Goncharov, J. L. de Segovia and R. A. Nevshoupa, Mechanically stimulated solution of adsorbed hydrogen and deuterium in steel. -Surface and Interface Analysis, 30 (2000) pp. 635 -637 4. A. G. Peresadko, A. A. Nevshupa, E. A. Deulin Mechanically stimulated outgassing from ball bearing in vacuum. – Vacuum 64 (2002) pp. 451456. 5. R. A. Nevshupa, J. L. de Segovia, A. G. Peressadko, E. A. Deulin Dynamical model of total and partial pressures in a vacuum system due to intermittent desorption. -Vacuum 69 (2003) pp. 477 -487. 6. E. A. Deulin. Role of Adsorbed Water in so called “Dry Friction” process/ Automotive and Industrial Lubrication/: Techniche Academie Esslingen Hrsg: Wilfreid J. Bartz, -Ostfildern: TAE, Book of Syn. , 2006. - p. 230 7. E. A. Deulin. The Role of Adsorbed Water Film For Sliding Friction of Smooth and Rough Surfaces. / Tribology Science and Application/. Proceed. Of the Review Conf. Vienna. 2004. , p, p, . 115 - 135 8. R. A. Nevshupa, A. G. Peressadko, E. A. Deulin A novel approach to mechanically stimulated outgasing: fractality / Vacuum (2001) pp. 111 -116 9. Deulin E. A. Ikonnikova E. I. Process of Hydrogen dissolution into surfaces the gas Pipe Line Tubes as a result of nano scale friction process / SIMS Europe 2010/ 7 th European Workshop on Secondary Ion Mass Spectrometry/ Muenster Germany Sept 2010, p. 110 10. Deulin E. A. Ion - Assisted Process of Hydrogen Dissolution into Surfaces of Pipe Line Tubes / Book of reports of XIX International Conference ISI-2009, Zvenigorod , pp. 336 -340 11. – 50 (2009 -2012)

Scientific fundamentals of Nano Structured Fuel Technology Patents based on the new theory: 1. Patent of RF № 2391601 Method of arterial pipe lines resource prediction, dated 21. 07. 2008 2. Patent of RF № 244461 С 1 Method of nano structured fuel manufacturing , dated 10. 03. 2012 RF contract № П 2421 dated 19. 09. 1009 titled “The new methods and instruments creation based on nanomechanics and physics of dry friction for catastrophic results prediction in electronics, gas transporting systems nuclear technologies” « Cоздание новых Scientific researches: 1. методов и приборов основанных на наномеханике и физике сухого трения для предотвращения технологических катастроф в электронике газотранспортных системах, ядерной технике. программа «Научные и научно педагогические кадры России» 2009 -2013 г. г. (in Russian). Monographs: 1. Mechanics and Physics of Precise Vacuum Mechanisms/ Deulin E. A. , Michailov V. P. , Panfilov Y. V. , Nevshupa R. A. / Springer edition. - 2012, 234 pp. 2. Vacuum Technology: Handbook/ K. E. Demikhov, E. A. Deulin, Y. V. Panfilov etc…, 3 rd edition; M, Machinostroenie, 2009. 500 p. (in Russian) Publications: 1. Deulin E. A. Exchange of gases at friction in vacuum// ECASIA ’ 97. - John Wiley & sons, Nov. 1997. - pp. 1170 -1175 2. R. A. Nevshoupa, J. L. de Segovia, E. A. Deulin. An UHV System To Study Gassing And Outgassing Of Metals Under Friction. - Vacuum, 52, (1999) pp. 73 -81. 3. E. A. Deulin, S. A. Goncharov, J. L. de Segovia and R. A. Nevshoupa, Mechanically stimulated solution of adsorbed hydrogen and deuterium in steel. -Surface and Interface Analysis, 30 (2000) pp. 635 -637 4. A. G. Peresadko, A. A. Nevshupa, E. A. Deulin Mechanically stimulated outgassing from ball bearing in vacuum. – Vacuum 64 (2002) pp. 451456. 5. R. A. Nevshupa, J. L. de Segovia, A. G. Peressadko, E. A. Deulin Dynamical model of total and partial pressures in a vacuum system due to intermittent desorption. -Vacuum 69 (2003) pp. 477 -487. 6. E. A. Deulin. Role of Adsorbed Water in so called “Dry Friction” process/ Automotive and Industrial Lubrication/: Techniche Academie Esslingen Hrsg: Wilfreid J. Bartz, -Ostfildern: TAE, Book of Syn. , 2006. - p. 230 7. E. A. Deulin. The Role of Adsorbed Water Film For Sliding Friction of Smooth and Rough Surfaces. / Tribology Science and Application/. Proceed. Of the Review Conf. Vienna. 2004. , p, p, . 115 - 135 8. R. A. Nevshupa, A. G. Peressadko, E. A. Deulin A novel approach to mechanically stimulated outgasing: fractality / Vacuum (2001) pp. 111 -116 9. Deulin E. A. Ikonnikova E. I. Process of Hydrogen dissolution into surfaces the gas Pipe Line Tubes as a result of nano scale friction process / SIMS Europe 2010/ 7 th European Workshop on Secondary Ion Mass Spectrometry/ Muenster Germany Sept 2010, p. 110 10. Deulin E. A. Ion - Assisted Process of Hydrogen Dissolution into Surfaces of Pipe Line Tubes / Book of reports of XIX International Conference ISI-2009, Zvenigorod , pp. 336 -340 11. – 50 (2009 -2012)

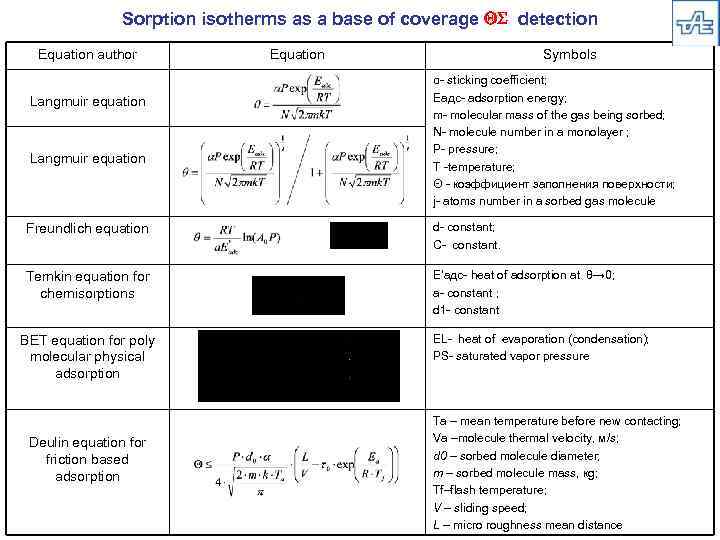

Sorption isotherms as a base of coverage detection Equation author Langmuir equation Equation Symbols α- sticking coefficient; Еадс- adsorption energy; m- molecular mass of the gas being sorbed; N- molecule number in a monolayer ; Р- pressure; Т -temperature; Θ - коэффициент заполнения поверхности; j- atoms number in a sorbed gas molecule Freundlich equation d- constant; С- constant. Temkin equation for chemisorptions E’адс- heat of adsorption at θ→ 0; а- constant ; d 1 - constant BET equation for poly molecular physical adsorption Deulin equation for friction based adsorption ЕL- heat of evaporation (condensation); РS- saturated vapor pressure Та – mean temperature before new contacting; Va –molecule thermal velocity, м/s; d 0 – sorbed molecule diameter; m – sorbed molecule mass, кg; Tf–flash temperature; V – sliding speed; L – micro roughness mean distance

Sorption isotherms as a base of coverage detection Equation author Langmuir equation Equation Symbols α- sticking coefficient; Еадс- adsorption energy; m- molecular mass of the gas being sorbed; N- molecule number in a monolayer ; Р- pressure; Т -temperature; Θ - коэффициент заполнения поверхности; j- atoms number in a sorbed gas molecule Freundlich equation d- constant; С- constant. Temkin equation for chemisorptions E’адс- heat of adsorption at θ→ 0; а- constant ; d 1 - constant BET equation for poly molecular physical adsorption Deulin equation for friction based adsorption ЕL- heat of evaporation (condensation); РS- saturated vapor pressure Та – mean temperature before new contacting; Va –molecule thermal velocity, м/s; d 0 – sorbed molecule diameter; m – sorbed molecule mass, кg; Tf–flash temperature; V – sliding speed; L – micro roughness mean distance

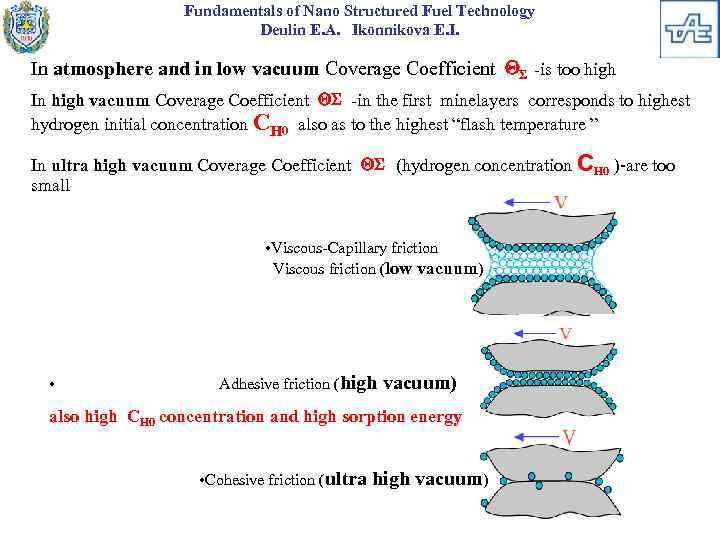

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. In atmosphere and in low vacuum Coverage Coefficient -is too high In high vacuum Coverage Coefficient -in the first minelayers corresponds to highest hydrogen initial concentration CH 0 also as to the highest “flash temperature ” In ultra high vacuum Coverage Coefficient (hydrogen concentration CH 0 )-are too small • Viscous-Capillary friction Viscous friction (low vacuum) • Adhesive friction (high vacuum) also high CH 0 concentration and high sorption energy • Cohesive friction (ultra high vacuum)

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. In atmosphere and in low vacuum Coverage Coefficient -is too high In high vacuum Coverage Coefficient -in the first minelayers corresponds to highest hydrogen initial concentration CH 0 also as to the highest “flash temperature ” In ultra high vacuum Coverage Coefficient (hydrogen concentration CH 0 )-are too small • Viscous-Capillary friction Viscous friction (low vacuum) • Adhesive friction (high vacuum) also high CH 0 concentration and high sorption energy • Cohesive friction (ultra high vacuum)

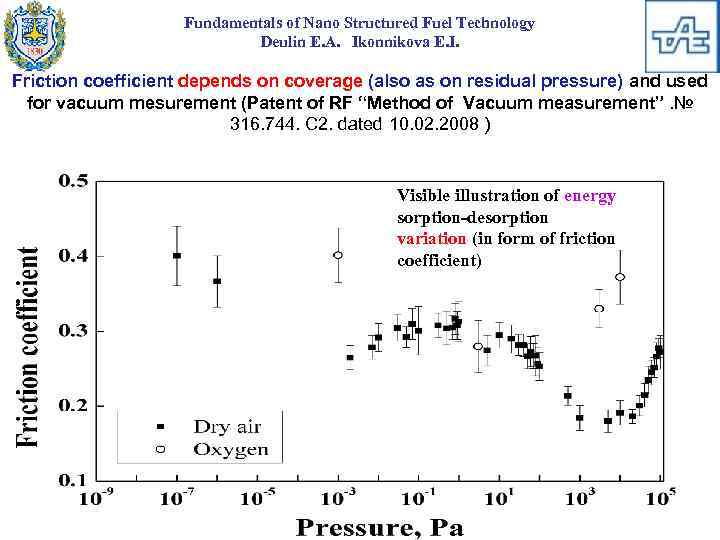

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Friction coefficient depends on coverage (also as on residual pressure) and used for vacuum mesurement (Patent of RF “Мethod of Vacuum measurement”. № 316. 744. С 2. dated 10. 02. 2008 ) Visible illustration of energy sorption-desorption variation (in form of friction coefficient)

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Friction coefficient depends on coverage (also as on residual pressure) and used for vacuum mesurement (Patent of RF “Мethod of Vacuum measurement”. № 316. 744. С 2. dated 10. 02. 2008 ) Visible illustration of energy sorption-desorption variation (in form of friction coefficient)

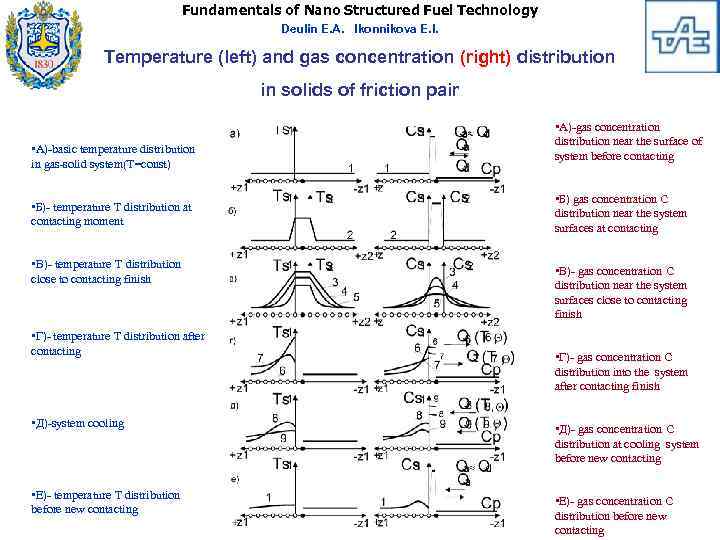

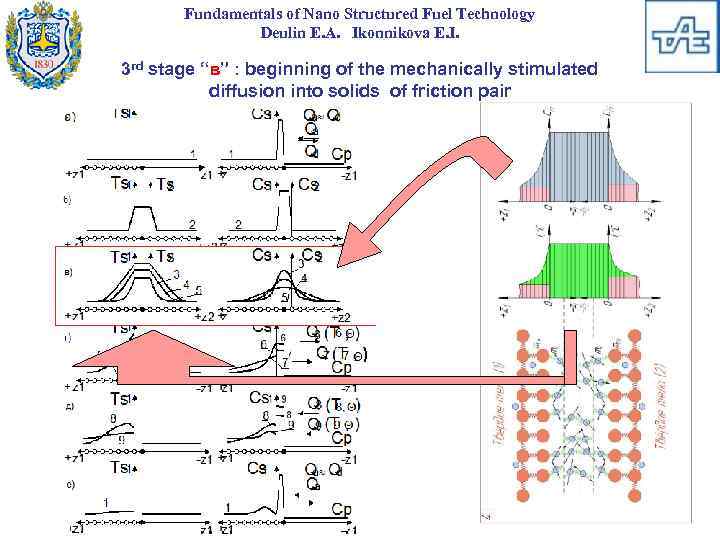

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Temperature (left) and gas concentration (right) distribution in solids of friction pair • А)-basic temperature distribution in gas-solid system(Т=const) • Б)- temperature Т distribution at contacting moment • В)- temperature Т distribution close to contacting finish • Г)- temperature Т distribution after contacting • Д)-system cooling • Е)- temperature Т distribution before new contacting • А)-gas concentration distribution near the surface of system before contacting • Б) gas concentration С distribution near the system surfaces at contacting • В)- gas concentration С distribution near the system surfaces close to contacting finish • Г)- gas concentration С distribution into the system after contacting finish • Д)- gas concentration С distribution at cooling system before new contacting • Е)- gas concentration С distribution before new contacting

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Temperature (left) and gas concentration (right) distribution in solids of friction pair • А)-basic temperature distribution in gas-solid system(Т=const) • Б)- temperature Т distribution at contacting moment • В)- temperature Т distribution close to contacting finish • Г)- temperature Т distribution after contacting • Д)-system cooling • Е)- temperature Т distribution before new contacting • А)-gas concentration distribution near the surface of system before contacting • Б) gas concentration С distribution near the system surfaces at contacting • В)- gas concentration С distribution near the system surfaces close to contacting finish • Г)- gas concentration С distribution into the system after contacting finish • Д)- gas concentration С distribution at cooling system before new contacting • Е)- gas concentration С distribution before new contacting

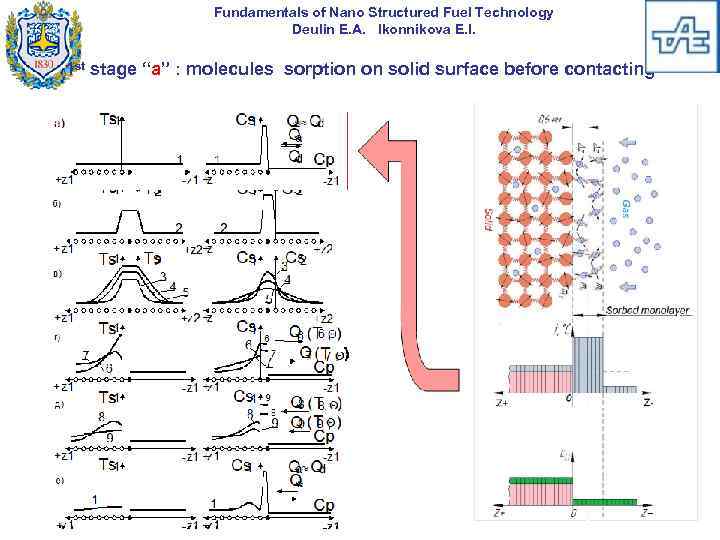

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 1 st stage “a” : molecules sorption on solid surface before contacting

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 1 st stage “a” : molecules sorption on solid surface before contacting

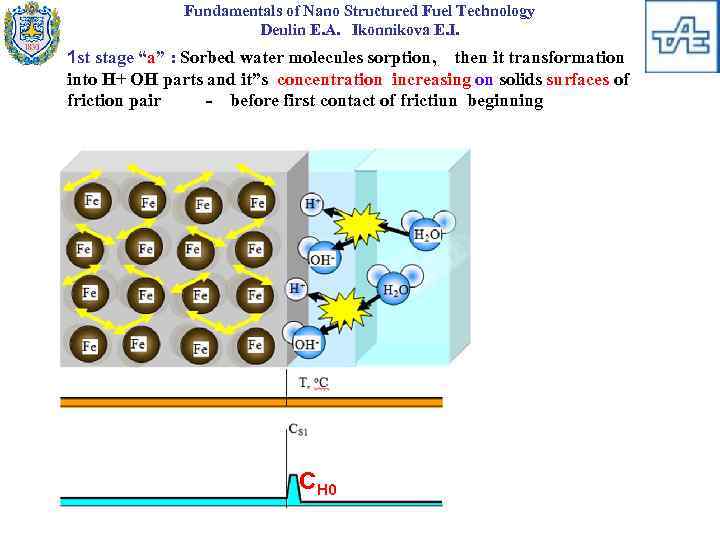

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 1 st stage “a” : Sorbed water molecules sorption, then it transformation into H+ OH parts and it”s concentration increasing on solids surfaces of friction pair - before first contact of frictiun beginning CH 0

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 1 st stage “a” : Sorbed water molecules sorption, then it transformation into H+ OH parts and it”s concentration increasing on solids surfaces of friction pair - before first contact of frictiun beginning CH 0

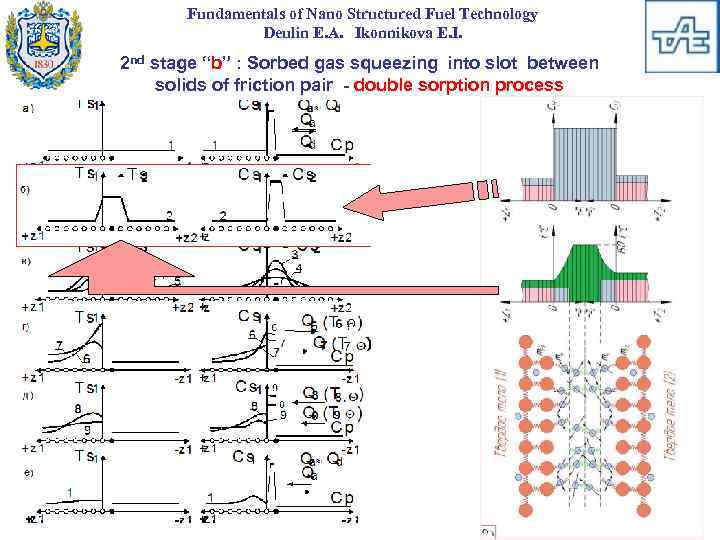

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 2 nd stage “b” : Sorbed gas squeezing into slot between solids of friction pair - double sorption process

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 2 nd stage “b” : Sorbed gas squeezing into slot between solids of friction pair - double sorption process

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 3 rd stage “в” : beginning of the mechanically stimulated diffusion into solids of friction pair

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 3 rd stage “в” : beginning of the mechanically stimulated diffusion into solids of friction pair

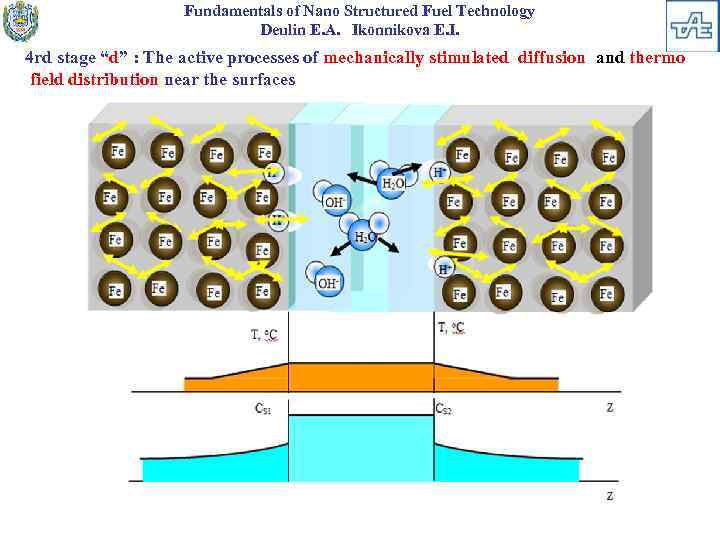

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 4 rd stage “d” : The active processes of mechanically stimulated diffusion and thermo field distribution near the surfaces

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 4 rd stage “d” : The active processes of mechanically stimulated diffusion and thermo field distribution near the surfaces

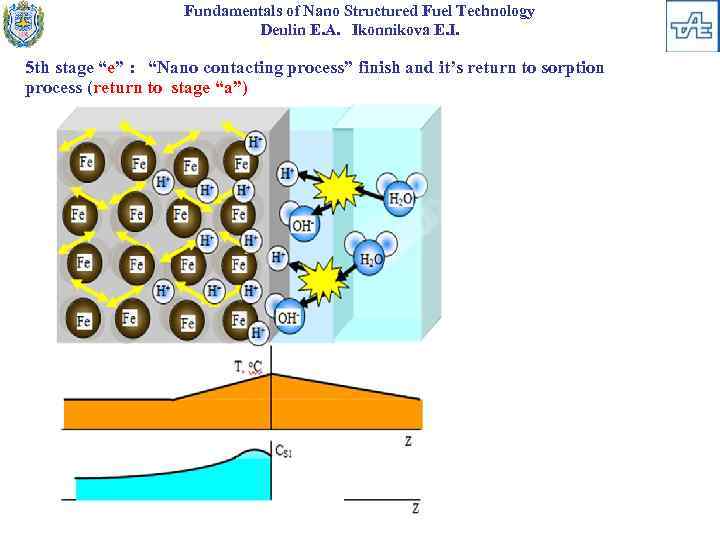

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 5 th stage “e” : “Nano contacting process” finish and it’s return to sorption process (return to stage “a”)

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. 5 th stage “e” : “Nano contacting process” finish and it’s return to sorption process (return to stage “a”)

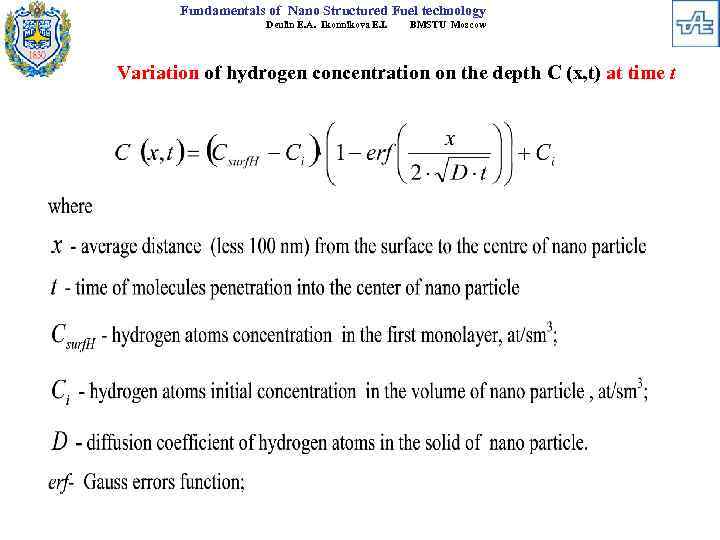

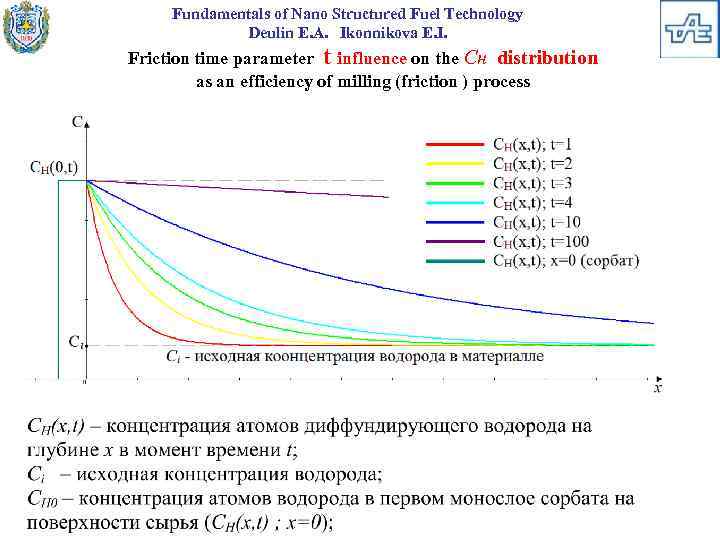

Fundamentals of Nano Structured Fuel technology Deulin E. A. Ikonnikova E. I. BMSTU Moscow Variation of hydrogen concentration on the depth С (x, t) at time t

Fundamentals of Nano Structured Fuel technology Deulin E. A. Ikonnikova E. I. BMSTU Moscow Variation of hydrogen concentration on the depth С (x, t) at time t

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Friction time parameter t influence on the Сн distribution as an efficiency of milling (friction ) process

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Friction time parameter t influence on the Сн distribution as an efficiency of milling (friction ) process

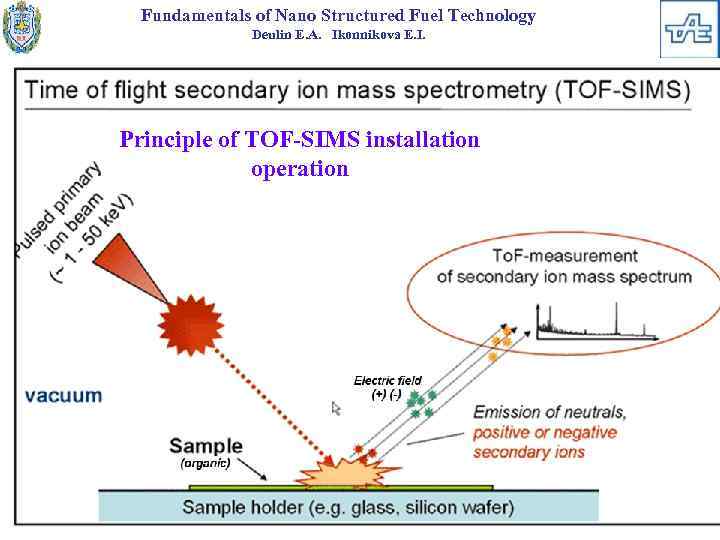

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Principle of TOF-SIMS installation operation

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Principle of TOF-SIMS installation operation

The view of TOF-SIMS installation operation

The view of TOF-SIMS installation operation

analysis: 1 - Coil 3 -Cutter 2 -Diamond 4 -Tooth

analysis: 1 - Coil 3 -Cutter 2 -Diamond 4 -Tooth

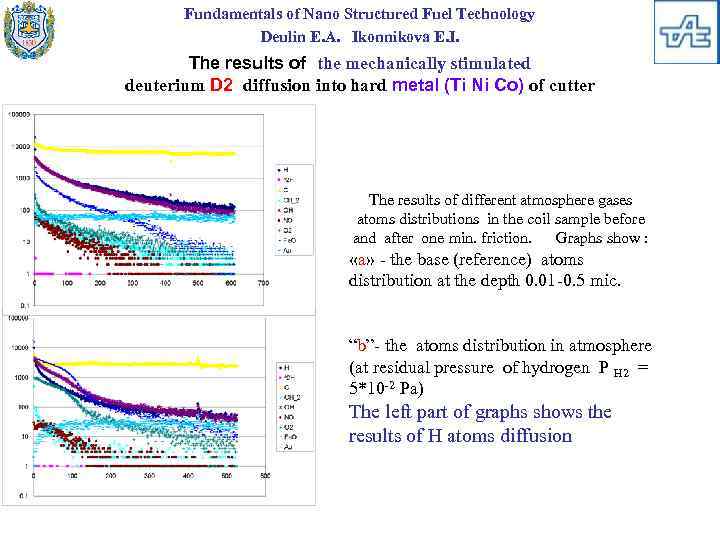

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The results of the mechanically stimulated deuterium D 2 diffusion into hard metal (Ti Ni Co) of cutter The results of different atmosphere gases atoms distributions in the coil sample before and after one min. friction. Graphs show : «a» - the base (reference) atoms distribution at the depth 0. 01 -0. 5 mic. “b”- the atoms distribution in atmosphere (at residual pressure of hydrogen P H 2 = 5*10 -2 Pa) The left part of graphs shows the results of H atoms diffusion

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The results of the mechanically stimulated deuterium D 2 diffusion into hard metal (Ti Ni Co) of cutter The results of different atmosphere gases atoms distributions in the coil sample before and after one min. friction. Graphs show : «a» - the base (reference) atoms distribution at the depth 0. 01 -0. 5 mic. “b”- the atoms distribution in atmosphere (at residual pressure of hydrogen P H 2 = 5*10 -2 Pa) The left part of graphs shows the results of H atoms diffusion

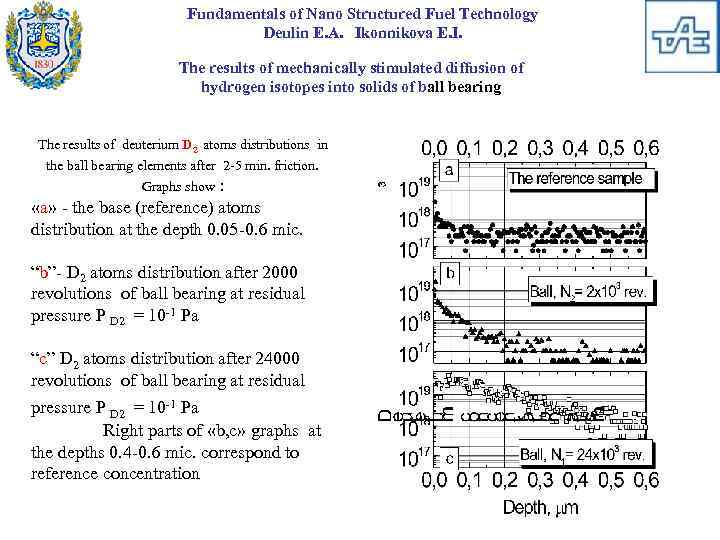

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The results of mechanically stimulated diffusion of hydrogen isotopes into solids of ball bearing The results of deuterium D 2 atoms distributions in the ball bearing elements after 2 -5 min. friction. : «a» - the base (reference) atoms distribution at the depth 0. 05 -0. 6 mic. Graphs show “b”- D 2 atoms distribution after 2000 revolutions of ball bearing at residual pressure P D 2 = 10 -1 Pa “c” D 2 atoms distribution after 24000 revolutions of ball bearing at residual pressure P D 2 = 10 -1 Pa Right parts of «b, c» graphs at the depths 0. 4 -0. 6 mic. correspond to reference concentration

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The results of mechanically stimulated diffusion of hydrogen isotopes into solids of ball bearing The results of deuterium D 2 atoms distributions in the ball bearing elements after 2 -5 min. friction. : «a» - the base (reference) atoms distribution at the depth 0. 05 -0. 6 mic. Graphs show “b”- D 2 atoms distribution after 2000 revolutions of ball bearing at residual pressure P D 2 = 10 -1 Pa “c” D 2 atoms distribution after 24000 revolutions of ball bearing at residual pressure P D 2 = 10 -1 Pa Right parts of «b, c» graphs at the depths 0. 4 -0. 6 mic. correspond to reference concentration

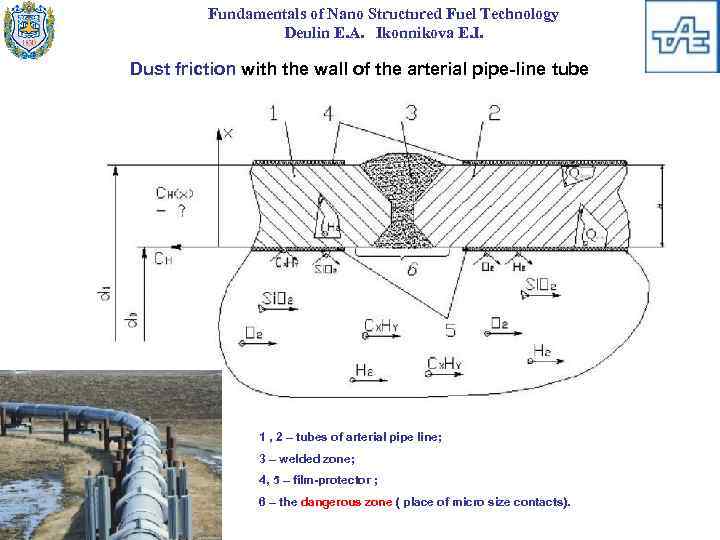

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Dust friction with the wall of the arterial pipe-line tube 1 , 2 – tubes of arterial pipe line; 3 – welded zone; 4, 5 – film-protector ; 6 – the dangerous zone ( place of micro size contacts).

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Dust friction with the wall of the arterial pipe-line tube 1 , 2 – tubes of arterial pipe line; 3 – welded zone; 4, 5 – film-protector ; 6 – the dangerous zone ( place of micro size contacts).

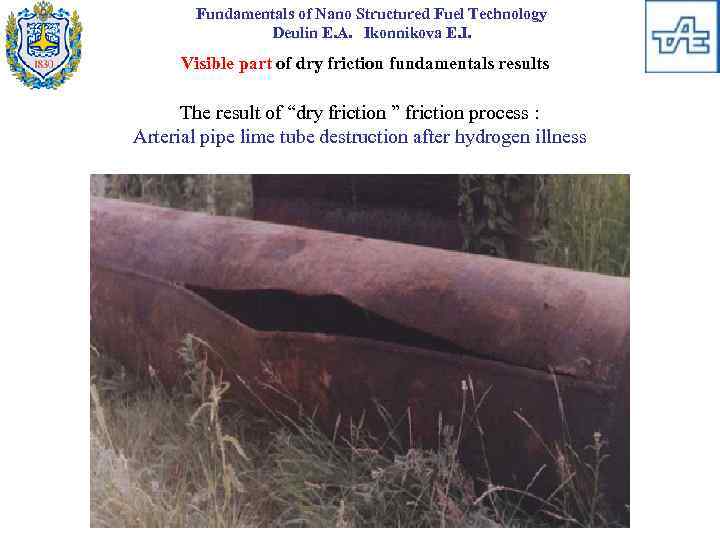

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Visible part of dry friction fundamentals results The result of “dry friction ” friction process : Arterial pipe lime tube destruction after hydrogen illness

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Visible part of dry friction fundamentals results The result of “dry friction ” friction process : Arterial pipe lime tube destruction after hydrogen illness

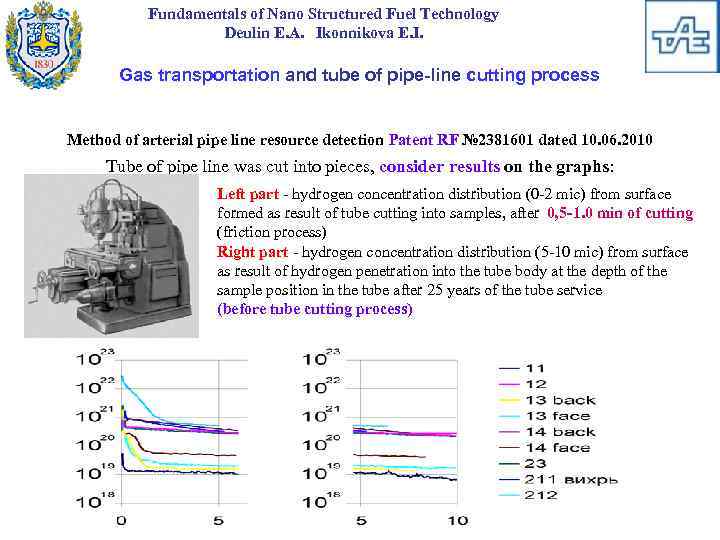

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Gas transportation and tube of pipe-line cutting process Method of arterial pipe line resource detection Patent RF № 2381601 dated 10. 06. 2010 Tube of pipe line was cut into pieces, consider results on the graphs: Left part - hydrogen concentration distribution (0 -2 mic) from surface formed as result of tube cutting into samples, after 0, 5 -1. 0 min of cutting (friction process) Right part - hydrogen concentration distribution (5 -10 mic) from surface as result of hydrogen penetration into the tube body at the depth of the sample position in the tube after 25 years of the tube service (before tube cutting process)

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Gas transportation and tube of pipe-line cutting process Method of arterial pipe line resource detection Patent RF № 2381601 dated 10. 06. 2010 Tube of pipe line was cut into pieces, consider results on the graphs: Left part - hydrogen concentration distribution (0 -2 mic) from surface formed as result of tube cutting into samples, after 0, 5 -1. 0 min of cutting (friction process) Right part - hydrogen concentration distribution (5 -10 mic) from surface as result of hydrogen penetration into the tube body at the depth of the sample position in the tube after 25 years of the tube service (before tube cutting process)

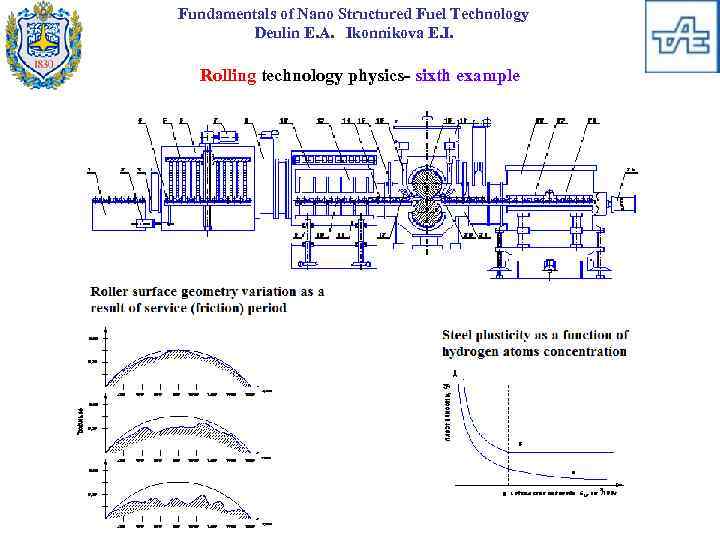

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Rolling technology physics- sixth example

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Rolling technology physics- sixth example

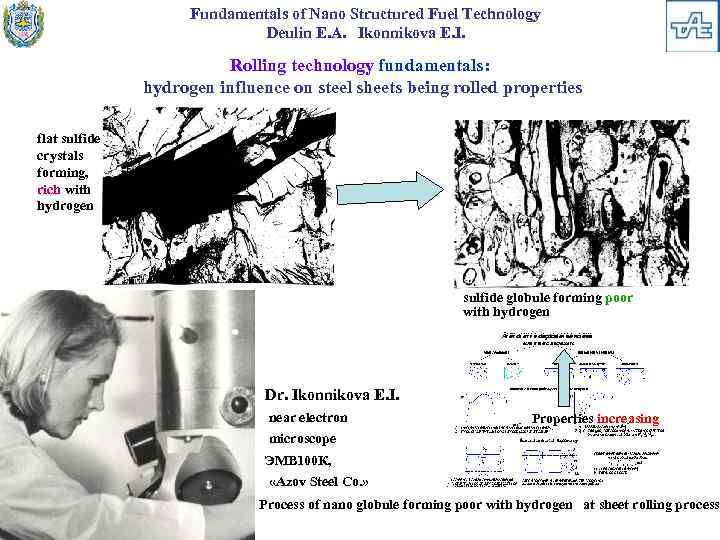

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Rolling technology fundamentals: hydrogen influence on steel sheets being rolled properties flat sulfide crystals forming, rich with hydrogen sulfide globule forming poor with hydrogen Dr. Ikonnikova E. I. near electron Properties increasing microscope ЭМВ 100 К, «Azov Steel Co. » Process of nano globule forming poor with hydrogen at sheet rolling process,

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Rolling technology fundamentals: hydrogen influence on steel sheets being rolled properties flat sulfide crystals forming, rich with hydrogen sulfide globule forming poor with hydrogen Dr. Ikonnikova E. I. near electron Properties increasing microscope ЭМВ 100 К, «Azov Steel Co. » Process of nano globule forming poor with hydrogen at sheet rolling process,

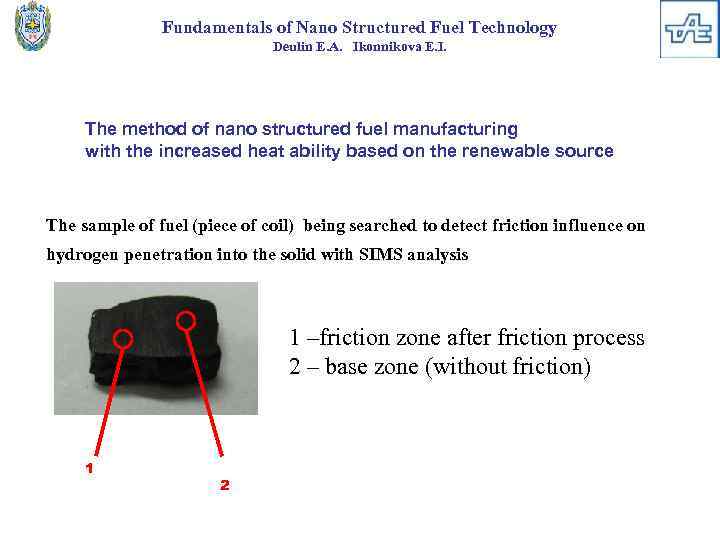

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The method of nano structured fuel manufacturing with the increased heat ability based on the renewable source The sample of fuel (piece of coil) being searched to detect friction influence on hydrogen penetration into the solid with SIMS analysis 1 –friction zone after friction process 2 – base zone (without friction) 1 2

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The method of nano structured fuel manufacturing with the increased heat ability based on the renewable source The sample of fuel (piece of coil) being searched to detect friction influence on hydrogen penetration into the solid with SIMS analysis 1 –friction zone after friction process 2 – base zone (without friction) 1 2

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The results of the mechanically stimulated diffusion of hydrogen H and deuterium D diffusion into coil after friction(T=30 sec) С(HT) С(H 0) С(DT) С(D 0)

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The results of the mechanically stimulated diffusion of hydrogen H and deuterium D diffusion into coil after friction(T=30 sec) С(HT) С(H 0) С(DT) С(D 0)

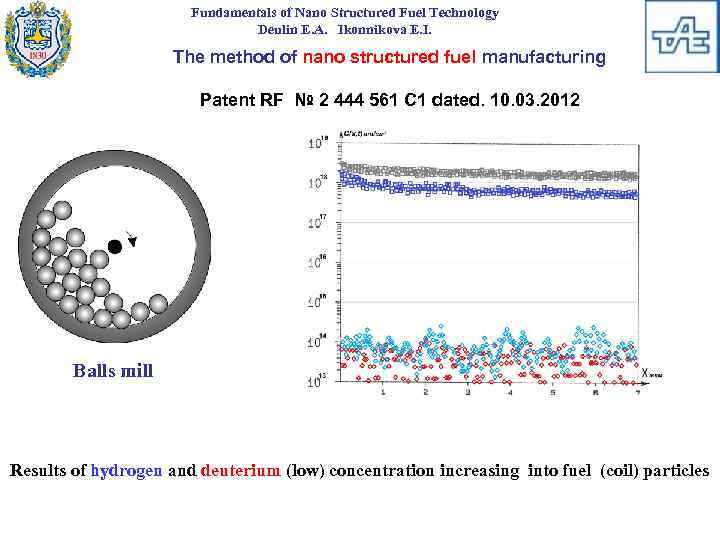

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The method of nano structured fuel manufacturing Patent RF № 2 444 561 C 1 dated. 10. 03. 2012 Balls mill Results of hydrogen and deuterium (low) concentration increasing into fuel (coil) particles

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The method of nano structured fuel manufacturing Patent RF № 2 444 561 C 1 dated. 10. 03. 2012 Balls mill Results of hydrogen and deuterium (low) concentration increasing into fuel (coil) particles

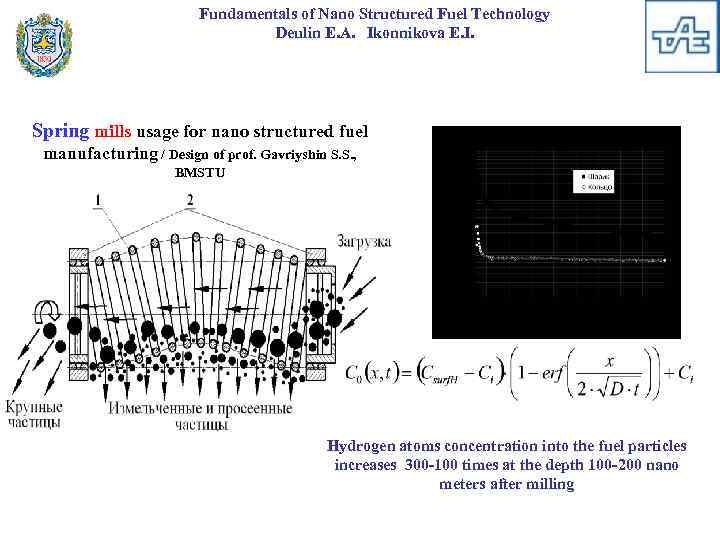

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Spring mills usage for nano structured fuel manufacturing / Design of prof. Gavriyshin S. S. , BMSTU Hydrogen atoms concentration into the fuel particles increases 300 -100 times at the depth 100 -200 nano meters after milling

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Spring mills usage for nano structured fuel manufacturing / Design of prof. Gavriyshin S. S. , BMSTU Hydrogen atoms concentration into the fuel particles increases 300 -100 times at the depth 100 -200 nano meters after milling

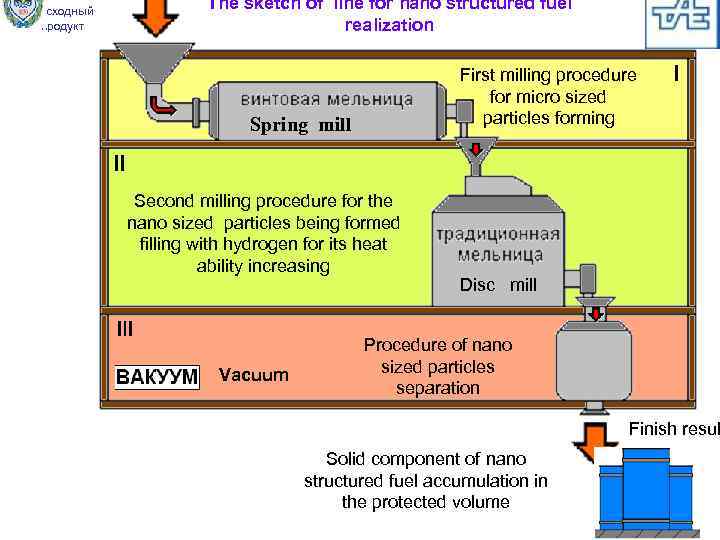

Исходный продукт The sketch of line for nano structured fuel realization First milling procedure for micro sized particles forming Spring mill Second milling procedure for the nano sized particles being formed filling with hydrogen for its heat ability increasing Vacuum Disc mill Procedure of nano sized particles separation Finish resul Solid component of nano structured fuel accumulation in the protected volume

Исходный продукт The sketch of line for nano structured fuel realization First milling procedure for micro sized particles forming Spring mill Second milling procedure for the nano sized particles being formed filling with hydrogen for its heat ability increasing Vacuum Disc mill Procedure of nano sized particles separation Finish resul Solid component of nano structured fuel accumulation in the protected volume

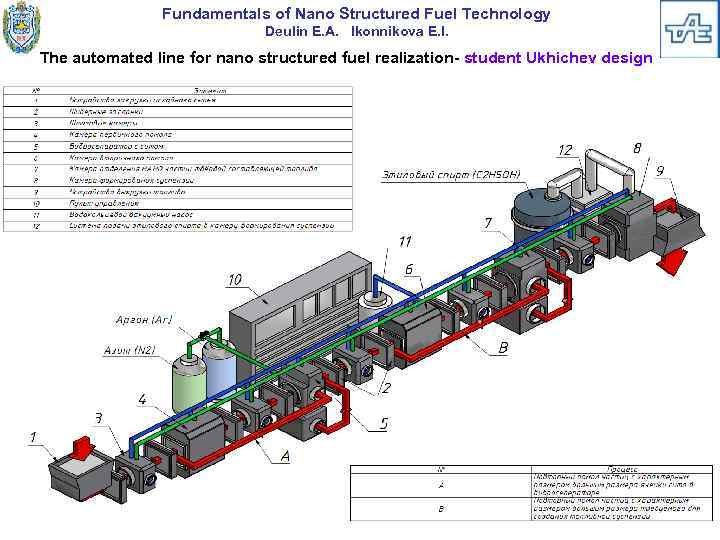

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The automated line for nano structured fuel realization- student Ukhichev design

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. The automated line for nano structured fuel realization- student Ukhichev design

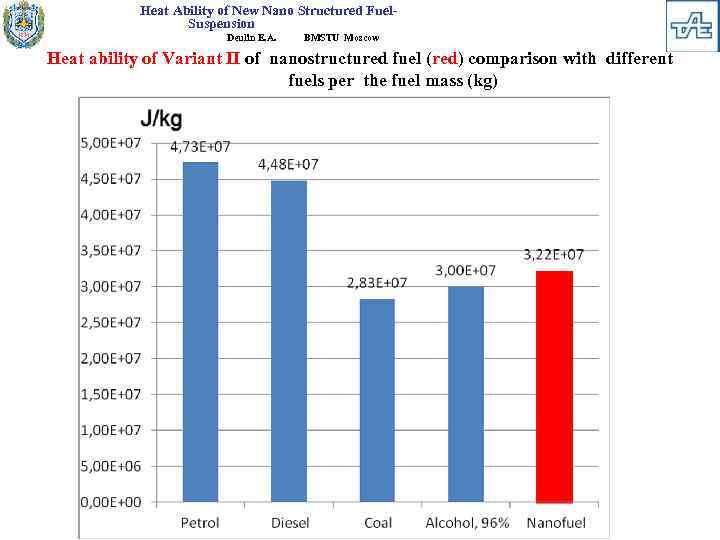

Heat Ability of New Nano Structured Fuel. Suspension Deulin E. A. BMSTU Moscow Heat ability of Variant II of nanostructured fuel (red) comparison with different fuels per the fuel mass (kg)

Heat Ability of New Nano Structured Fuel. Suspension Deulin E. A. BMSTU Moscow Heat ability of Variant II of nanostructured fuel (red) comparison with different fuels per the fuel mass (kg)

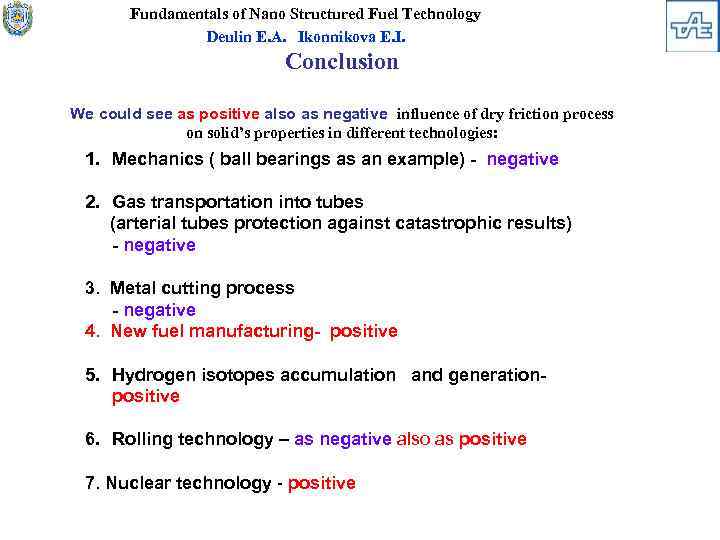

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Conclusion We could see as positive also as negative influence of dry friction process on solid’s properties in different technologies: 1. Mechanics ( ball bearings as an example) - negative 2. Gas transportation into tubes (arterial tubes protection against catastrophic results) - negative 3. Metal cutting process - negative 4. New fuel manufacturing- positive 5. Hydrogen isotopes accumulation and generationpositive 6. Rolling technology – as negative also as positive 7. Nuclear technology - positive

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. Conclusion We could see as positive also as negative influence of dry friction process on solid’s properties in different technologies: 1. Mechanics ( ball bearings as an example) - negative 2. Gas transportation into tubes (arterial tubes protection against catastrophic results) - negative 3. Metal cutting process - negative 4. New fuel manufacturing- positive 5. Hydrogen isotopes accumulation and generationpositive 6. Rolling technology – as negative also as positive 7. Nuclear technology - positive

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. As we can see fundamentals of “ dry friction” process may be useful in different technologies: 1. Mechanics 2. Gas transportation into tubes (arterial tubes protection against catastrophic results) 3. Metal cutting process 4. New fuel manufacturing 5. Hydrogen isotopes accumulation and generation 6. Rolling technology 7. Nuclear technology Thank you for attention !

Fundamentals of Nano Structured Fuel Technology Deulin E. A. Ikonnikova E. I. As we can see fundamentals of “ dry friction” process may be useful in different technologies: 1. Mechanics 2. Gas transportation into tubes (arterial tubes protection against catastrophic results) 3. Metal cutting process 4. New fuel manufacturing 5. Hydrogen isotopes accumulation and generation 6. Rolling technology 7. Nuclear technology Thank you for attention !