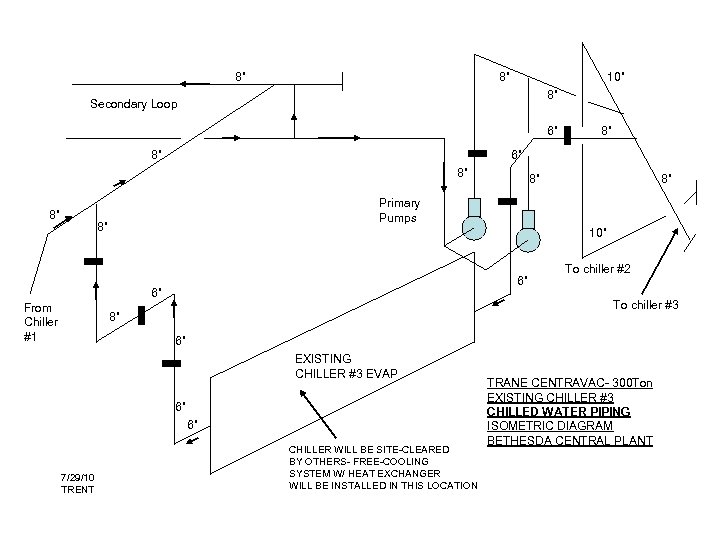

8” 8” 10” 8” Secondary Loop 6” 8” 8” Primary Pumps 8” 10” 6” 6” From Chiller #1 8” To chiller #2 To chiller #3 8” 6” EXISTING CHILLER #3 EVAP 6” 6” 7/29/10 TRENT CHILLER WILL BE SITE-CLEARED BY OTHERS- FREE-COOLING SYSTEM W/ HEAT EXCHANGER WILL BE INSTALLED IN THIS LOCATION TRANE CENTRAVAC- 300 Ton EXISTING CHILLER #3 CHILLED WATER PIPING ISOMETRIC DIAGRAM BETHESDA CENTRAL PLANT

8” 8” 10” 8” Secondary Loop 6” 8” 8” Primary Pumps 8” 10” 6” 6” From Chiller #1 8” To chiller #2 To chiller #3 8” 6” EXISTING CHILLER #3 EVAP 6” 6” 7/29/10 TRENT CHILLER WILL BE SITE-CLEARED BY OTHERS- FREE-COOLING SYSTEM W/ HEAT EXCHANGER WILL BE INSTALLED IN THIS LOCATION TRANE CENTRAVAC- 300 Ton EXISTING CHILLER #3 CHILLED WATER PIPING ISOMETRIC DIAGRAM BETHESDA CENTRAL PLANT

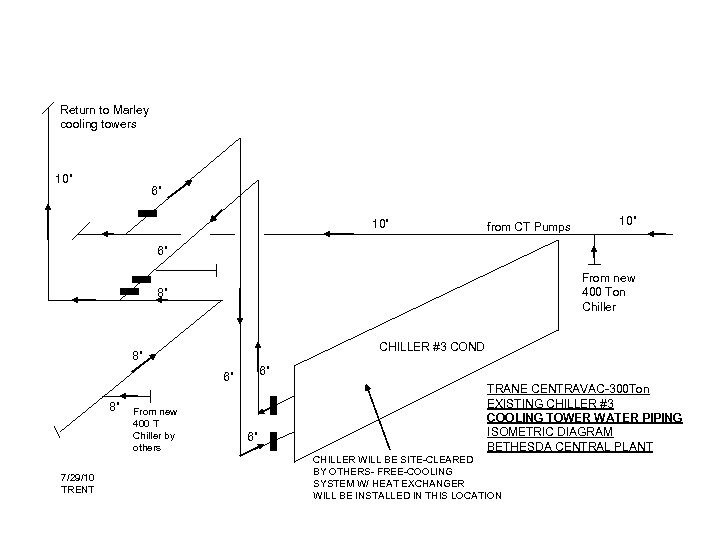

Return to Marley cooling towers 10” 6” 10” from CT Pumps 10” 6” From new 400 Ton Chiller 8” CHILLER #3 COND 8” 6” 6” 8” 7/29/10 TRENT From new 400 T Chiller by others 6” TRANE CENTRAVAC-300 Ton EXISTING CHILLER #3 COOLING TOWER WATER PIPING ISOMETRIC DIAGRAM BETHESDA CENTRAL PLANT CHILLER WILL BE SITE-CLEARED BY OTHERS- FREE-COOLING SYSTEM W/ HEAT EXCHANGER WILL BE INSTALLED IN THIS LOCATION

Return to Marley cooling towers 10” 6” 10” from CT Pumps 10” 6” From new 400 Ton Chiller 8” CHILLER #3 COND 8” 6” 6” 8” 7/29/10 TRENT From new 400 T Chiller by others 6” TRANE CENTRAVAC-300 Ton EXISTING CHILLER #3 COOLING TOWER WATER PIPING ISOMETRIC DIAGRAM BETHESDA CENTRAL PLANT CHILLER WILL BE SITE-CLEARED BY OTHERS- FREE-COOLING SYSTEM W/ HEAT EXCHANGER WILL BE INSTALLED IN THIS LOCATION

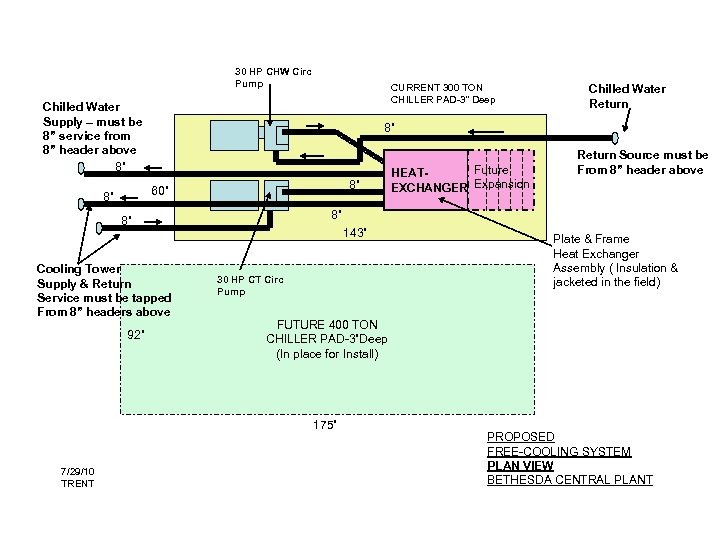

30 HP CHW Circ Pump CURRENT 300 TON CHILLER PAD-3” Deep Chilled Water Supply – must be 8” service from 8” header above 8” 8” 8” 60” 8” Cooling Tower Supply & Return Service must be tapped From 8” headers above 143” 30 HP CT Circ Pump Plate & Frame Heat Exchanger Assembly ( Insulation & jacketed in the field) FUTURE 400 TON CHILLER PAD-3”Deep (In place for Install) 175” 7/29/10 TRENT Future HEATEXCHANGER Expansion Return Source must be From 8” header above 8” 8” 92” Chilled Water Return PROPOSED FREE-COOLING SYSTEM PLAN VIEW BETHESDA CENTRAL PLANT

30 HP CHW Circ Pump CURRENT 300 TON CHILLER PAD-3” Deep Chilled Water Supply – must be 8” service from 8” header above 8” 8” 8” 60” 8” Cooling Tower Supply & Return Service must be tapped From 8” headers above 143” 30 HP CT Circ Pump Plate & Frame Heat Exchanger Assembly ( Insulation & jacketed in the field) FUTURE 400 TON CHILLER PAD-3”Deep (In place for Install) 175” 7/29/10 TRENT Future HEATEXCHANGER Expansion Return Source must be From 8” header above 8” 8” 92” Chilled Water Return PROPOSED FREE-COOLING SYSTEM PLAN VIEW BETHESDA CENTRAL PLANT

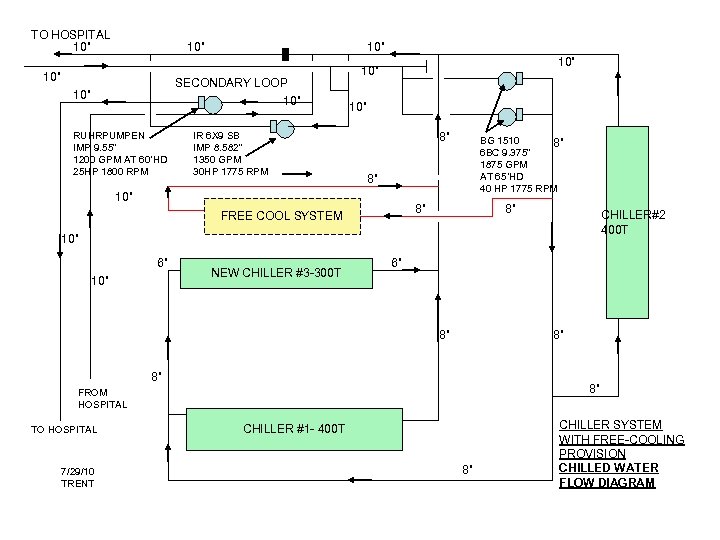

TO HOSPITAL 10” 10” SECONDARY LOOP 10” RUHRPUMPEN IMP 9. 55” 1200 GPM AT 60’HD 25 HP 1800 RPM IR 6 X 9 SB IMP 8. 582” 1350 GPM 30 HP 1775 RPM 10” 10” 8” BG 1510 8” 6 BC 9. 375” 1875 GPM AT 65’HD 40 HP 1775 RPM 8” 10” 8” FREE COOL SYSTEM 8” CHILLER#2 400 T 10” 6” 10” NEW CHILLER #3 -300 T 6” 8” 8” FROM HOSPITAL TO HOSPITAL 7/29/10 TRENT CHILLER #1 - 400 T 8” CHILLER SYSTEM WITH FREE-COOLING PROVISION CHILLED WATER FLOW DIAGRAM

TO HOSPITAL 10” 10” SECONDARY LOOP 10” RUHRPUMPEN IMP 9. 55” 1200 GPM AT 60’HD 25 HP 1800 RPM IR 6 X 9 SB IMP 8. 582” 1350 GPM 30 HP 1775 RPM 10” 10” 8” BG 1510 8” 6 BC 9. 375” 1875 GPM AT 65’HD 40 HP 1775 RPM 8” 10” 8” FREE COOL SYSTEM 8” CHILLER#2 400 T 10” 6” 10” NEW CHILLER #3 -300 T 6” 8” 8” FROM HOSPITAL TO HOSPITAL 7/29/10 TRENT CHILLER #1 - 400 T 8” CHILLER SYSTEM WITH FREE-COOLING PROVISION CHILLED WATER FLOW DIAGRAM

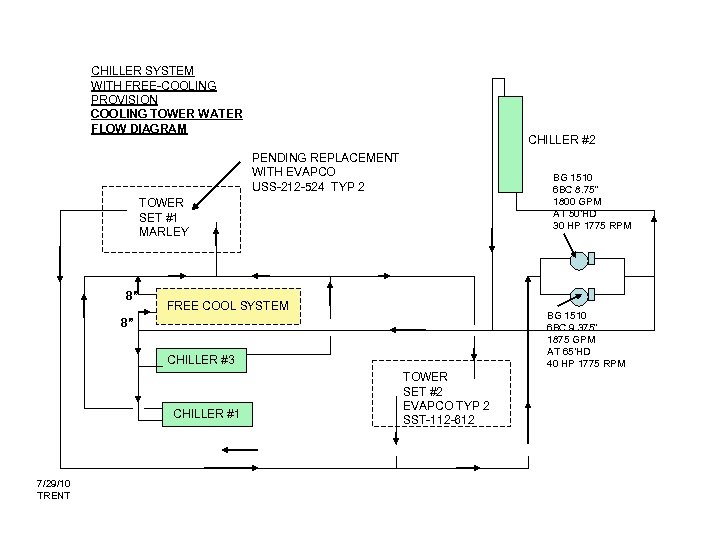

CHILLER SYSTEM WITH FREE-COOLING PROVISION COOLING TOWER WATER FLOW DIAGRAM CHILLER #2 PENDING REPLACEMENT WITH EVAPCO USS-212 -524 TYP 2 BG 1510 6 BC 8. 75” 1800 GPM AT 50’HD 30 HP 1775 RPM TOWER SET #1 MARLEY 8” FREE COOL SYSTEM BG 1510 6 BC 9. 375” 1875 GPM AT 65’HD 40 HP 1775 RPM 8” CHILLER #3 CHILLER #1 7/29/10 TRENT TOWER SET #2 EVAPCO TYP 2 SST-112 -612

CHILLER SYSTEM WITH FREE-COOLING PROVISION COOLING TOWER WATER FLOW DIAGRAM CHILLER #2 PENDING REPLACEMENT WITH EVAPCO USS-212 -524 TYP 2 BG 1510 6 BC 8. 75” 1800 GPM AT 50’HD 30 HP 1775 RPM TOWER SET #1 MARLEY 8” FREE COOL SYSTEM BG 1510 6 BC 9. 375” 1875 GPM AT 65’HD 40 HP 1775 RPM 8” CHILLER #3 CHILLER #1 7/29/10 TRENT TOWER SET #2 EVAPCO TYP 2 SST-112 -612

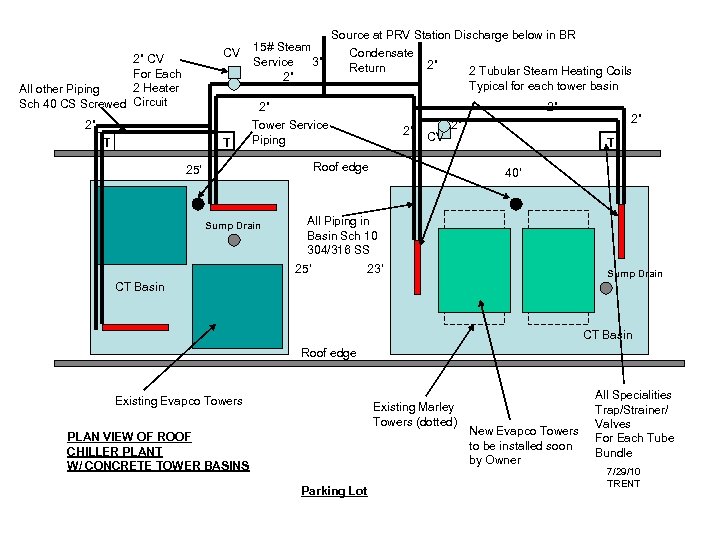

CV 2” CV For Each 2 Heater All other Piping Sch 40 CS Screwed Circuit 2” T T 15# Steam Service 3” 2” Source at PRV Station Discharge below in BR Condensate 2” Return 2 Tubular Steam Heating Coils Typical for each tower basin 2” Tower Service Piping 2” 2” CV Roof edge 25’ Sump Drain 2” 2” T 40’ All Piping in Basin Sch 10 304/316 SS 25’ 23’ Sump Drain CT Basin Roof edge Existing Evapco Towers Existing Marley Towers (dotted) PLAN VIEW OF ROOF CHILLER PLANT W/ CONCRETE TOWER BASINS Parking Lot New Evapco Towers to be installed soon by Owner All Specialities Trap/Strainer/ Valves For Each Tube Bundle 7/29/10 TRENT

CV 2” CV For Each 2 Heater All other Piping Sch 40 CS Screwed Circuit 2” T T 15# Steam Service 3” 2” Source at PRV Station Discharge below in BR Condensate 2” Return 2 Tubular Steam Heating Coils Typical for each tower basin 2” Tower Service Piping 2” 2” CV Roof edge 25’ Sump Drain 2” 2” T 40’ All Piping in Basin Sch 10 304/316 SS 25’ 23’ Sump Drain CT Basin Roof edge Existing Evapco Towers Existing Marley Towers (dotted) PLAN VIEW OF ROOF CHILLER PLANT W/ CONCRETE TOWER BASINS Parking Lot New Evapco Towers to be installed soon by Owner All Specialities Trap/Strainer/ Valves For Each Tube Bundle 7/29/10 TRENT