c026e316096279148216f4b5aebcd59b.ppt

- Количество слайдов: 65

6 th Coal Summit Overland transportation of coal traversing difficult terrains. Presented by: Shri Sk. Nayak & Shri SK Grover Sunday, March 18, 2018 1

6 th Coal Summit Overland transportation of coal traversing difficult terrains. Presented by: Shri Sk. Nayak & Shri SK Grover Sunday, March 18, 2018 1

6 th Coal Summit AGENDA 1. Introduction. 2. Logistics, pros & cons. 3. Computer Modeling Techniques 4. Case Studies. 5. Conclusion. Sunday, March 18, 2018 2

6 th Coal Summit AGENDA 1. Introduction. 2. Logistics, pros & cons. 3. Computer Modeling Techniques 4. Case Studies. 5. Conclusion. Sunday, March 18, 2018 2

6 th Coal Summit SYNOPSIS • Transportation is a major cost to any coal producer / coal user. The next generation of coal users will have far more difficult transportation issues to address - as he may have to access the coal from far & more remote mines and/or traversing over difficult terrains. • The need to transport large volumes of coal over long distances - often leads to conflicts between economic necessities & environmental protections issues with different types of overland transportation solutions those are available today. • This paper sets out to explore three proven overland long distance transportation systems. 1) Belt Conveyor (BC), 2) Merry–Go–Round Rail (MGR), 3) Slurry Pipe Line (SPL). Sunday, March 18, 2018 3

6 th Coal Summit SYNOPSIS • Transportation is a major cost to any coal producer / coal user. The next generation of coal users will have far more difficult transportation issues to address - as he may have to access the coal from far & more remote mines and/or traversing over difficult terrains. • The need to transport large volumes of coal over long distances - often leads to conflicts between economic necessities & environmental protections issues with different types of overland transportation solutions those are available today. • This paper sets out to explore three proven overland long distance transportation systems. 1) Belt Conveyor (BC), 2) Merry–Go–Round Rail (MGR), 3) Slurry Pipe Line (SPL). Sunday, March 18, 2018 3

SYNOPSIS (Contd. ) 6 th Coal Summit An attempt to understand their value propositions, their logistics involved in selection processes and also to discuss and understand their ‘pros’ & ‘cons’ aspects, before an entrepreneur wishes to embark on selection of specific transportation systems suitable for his terrain. The writers amongst other issues will display a computer modeling tool developed specially to demonstrate one such system with its permutation and combinations which one has look, when demonstrating the selection of this particular system. Lastly – the writers have detailed some Case Studies carried out in the past to demonstrate the process for conducting such selection studies - beforehand, with cost analysis. Sunday, March 18, 2018 4

SYNOPSIS (Contd. ) 6 th Coal Summit An attempt to understand their value propositions, their logistics involved in selection processes and also to discuss and understand their ‘pros’ & ‘cons’ aspects, before an entrepreneur wishes to embark on selection of specific transportation systems suitable for his terrain. The writers amongst other issues will display a computer modeling tool developed specially to demonstrate one such system with its permutation and combinations which one has look, when demonstrating the selection of this particular system. Lastly – the writers have detailed some Case Studies carried out in the past to demonstrate the process for conducting such selection studies - beforehand, with cost analysis. Sunday, March 18, 2018 4

INTRODUCTION: 6 th Coal Summit We believe and appreciate there are ‘pros’ and ‘cons’ for each & every solutions. The first law of material handling is to look at the total system solutions, remove the blinkers on favoring a particular system and/or not to get biased towards any systems or what others have done in recent / past times and not to handle the bulk material ‘twice’. Transport Alternatives: Internationally Coal is traditionally transported in (-) 50 mm size (India being an exception as sometimes our mines deliver up to 300 mm or even more at the pit head) and delivered to power plants as solid fuel in the following listed transport alternatives. It is crushed to a very fine powder within the power plant and then fed to the boiler furnace. Sunday, March 18, 2018 5

INTRODUCTION: 6 th Coal Summit We believe and appreciate there are ‘pros’ and ‘cons’ for each & every solutions. The first law of material handling is to look at the total system solutions, remove the blinkers on favoring a particular system and/or not to get biased towards any systems or what others have done in recent / past times and not to handle the bulk material ‘twice’. Transport Alternatives: Internationally Coal is traditionally transported in (-) 50 mm size (India being an exception as sometimes our mines deliver up to 300 mm or even more at the pit head) and delivered to power plants as solid fuel in the following listed transport alternatives. It is crushed to a very fine powder within the power plant and then fed to the boiler furnace. Sunday, March 18, 2018 5

6 th Coal Summit We find that best known means of transporting large volumes of coal over long distances include following systems. 1. Trucking with its derivates like large capacity dumpers, trailer trains etc. , 2. Barges for inland river transportations etc. , (mostly prevalent in Indonesia) 3. Railways - short & long haul, side / bottom discharge, Merry-Go. Round etc. , 4. Belt Conveyors like trough, pipe, cable belt etc. , 5. Ropeways and now its latest development of Rope Conveyors etc. , 6. Slurry Pipe Lines. Sunday, March 18, 2018 6

6 th Coal Summit We find that best known means of transporting large volumes of coal over long distances include following systems. 1. Trucking with its derivates like large capacity dumpers, trailer trains etc. , 2. Barges for inland river transportations etc. , (mostly prevalent in Indonesia) 3. Railways - short & long haul, side / bottom discharge, Merry-Go. Round etc. , 4. Belt Conveyors like trough, pipe, cable belt etc. , 5. Ropeways and now its latest development of Rope Conveyors etc. , 6. Slurry Pipe Lines. Sunday, March 18, 2018 6

6 th Coal Summit In our presentation today - we have decided to limit our study to following three systems and have furnished the reasons as to their functional superiority of being continuous transportations modes over the others listed above which are either discontinuous modes or on costly modes. 1. Belt Conveyors like trough, pipe, cable belt etc. , 2. Rail transportations short & long haul, side / bottom discharge, Merry-Go-Round etc. , 3. Slurry Pipe Lines, Sunday, March 18, 2018 7

6 th Coal Summit In our presentation today - we have decided to limit our study to following three systems and have furnished the reasons as to their functional superiority of being continuous transportations modes over the others listed above which are either discontinuous modes or on costly modes. 1. Belt Conveyors like trough, pipe, cable belt etc. , 2. Rail transportations short & long haul, side / bottom discharge, Merry-Go-Round etc. , 3. Slurry Pipe Lines, Sunday, March 18, 2018 7

6 th Coal Summit Developments in conveyor design methods and technology have allowed conveyors to transverse rougher terrains through use of tighter radius bends of around 800 m to 2000 m. A number of different types of conveyors are available in the current market. Cable belts and ropeway conveyors have entered the market offering specific solutions to various “traditional” trough conveyor limitations such as horizontal curves, ground foot prints, conveying through rugged terrains etc. There is always a balance between Cable Belt Conveyors, Ropeway Conveyors & Rope mechanical requirements and the geometry of the conveyor route with a choice of putting more structural steel or carry out heavy earthworks conveyors – all use steel ropes cuts and fills requirements for the difficult terrains. With limitations on the horizontal and vertical curves – it may not be always possible to negotiate all obstacles such as mountains, roads and water courses like rivers, lakes and ponds etc. leading to additional costs in structures, bridges and earthworks. Sunday, March 18, 2018 8

6 th Coal Summit Developments in conveyor design methods and technology have allowed conveyors to transverse rougher terrains through use of tighter radius bends of around 800 m to 2000 m. A number of different types of conveyors are available in the current market. Cable belts and ropeway conveyors have entered the market offering specific solutions to various “traditional” trough conveyor limitations such as horizontal curves, ground foot prints, conveying through rugged terrains etc. There is always a balance between Cable Belt Conveyors, Ropeway Conveyors & Rope mechanical requirements and the geometry of the conveyor route with a choice of putting more structural steel or carry out heavy earthworks conveyors – all use steel ropes cuts and fills requirements for the difficult terrains. With limitations on the horizontal and vertical curves – it may not be always possible to negotiate all obstacles such as mountains, roads and water courses like rivers, lakes and ponds etc. leading to additional costs in structures, bridges and earthworks. Sunday, March 18, 2018 8

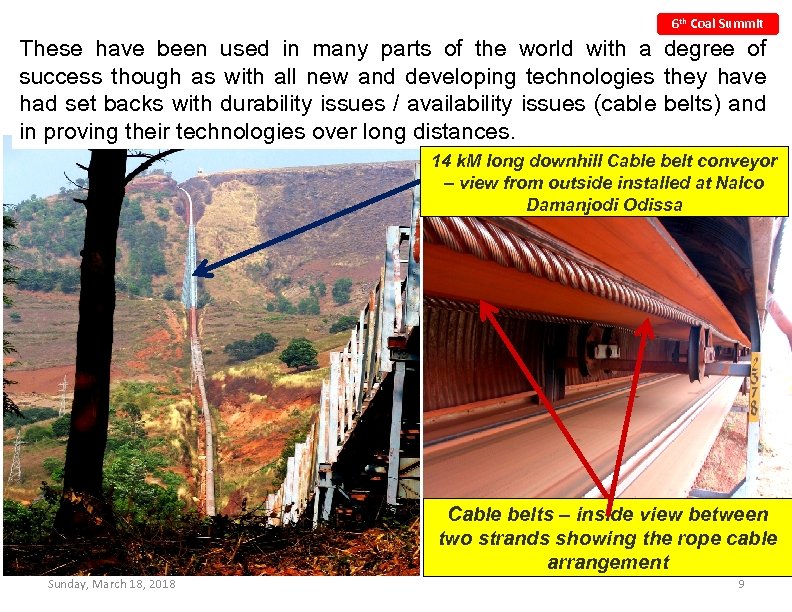

6 th Coal Summit These have been used in many parts of the world with a degree of success though as with all new and developing technologies they have had set backs with durability issues / availability issues (cable belts) and in proving their technologies over long distances. 14 k. M long downhill Cable belt conveyor – view from outside installed at Nalco Damanjodi Odissa Cable belts – inside view between two strands showing the rope cable arrangement Sunday, March 18, 2018 9

6 th Coal Summit These have been used in many parts of the world with a degree of success though as with all new and developing technologies they have had set backs with durability issues / availability issues (cable belts) and in proving their technologies over long distances. 14 k. M long downhill Cable belt conveyor – view from outside installed at Nalco Damanjodi Odissa Cable belts – inside view between two strands showing the rope cable arrangement Sunday, March 18, 2018 9

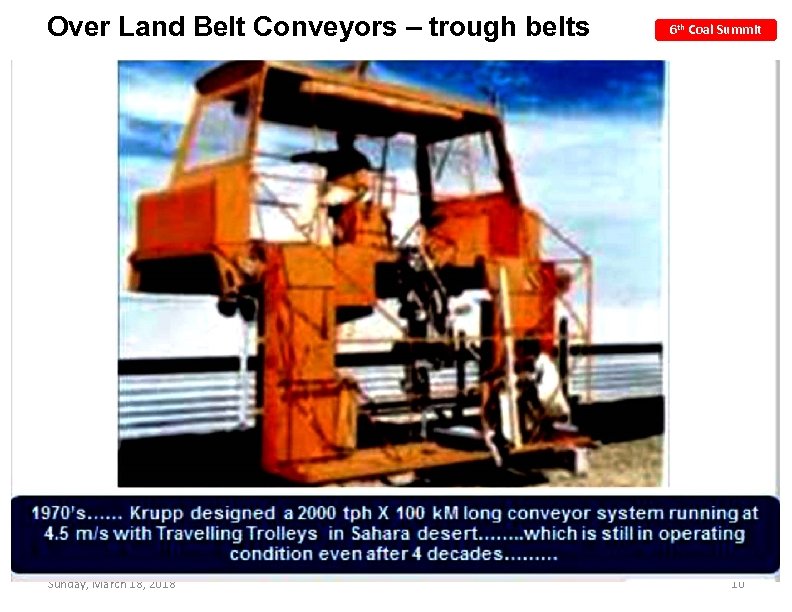

Over Land Belt Conveyors – trough belts Sunday, March 18, 2018 6 th Coal Summit 10

Over Land Belt Conveyors – trough belts Sunday, March 18, 2018 6 th Coal Summit 10

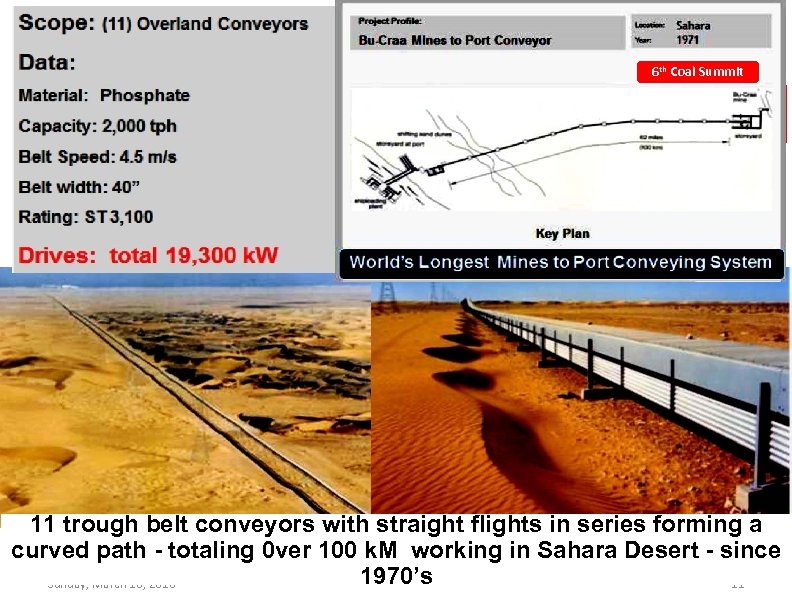

Port end 6 th Coal Summit Mines end 11 trough belt conveyors with straight flights in series forming a curved path - totaling 0 ver 100 k. M working in Sahara Desert - since 1970’s Sunday, March 18, 2018 11

Port end 6 th Coal Summit Mines end 11 trough belt conveyors with straight flights in series forming a curved path - totaling 0 ver 100 k. M working in Sahara Desert - since 1970’s Sunday, March 18, 2018 11

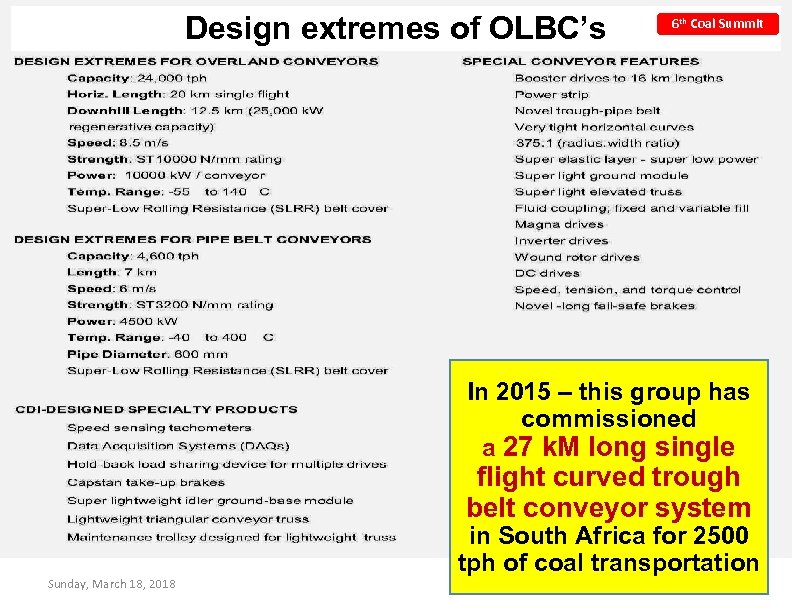

Design extremes of OLBC’s 6 th Coal Summit In 2015 – this group has commissioned a 27 k. M long single flight curved trough belt conveyor system Sunday, March 18, 2018 in South Africa for 2500 tph of coal transportation 12

Design extremes of OLBC’s 6 th Coal Summit In 2015 – this group has commissioned a 27 k. M long single flight curved trough belt conveyor system Sunday, March 18, 2018 in South Africa for 2500 tph of coal transportation 12

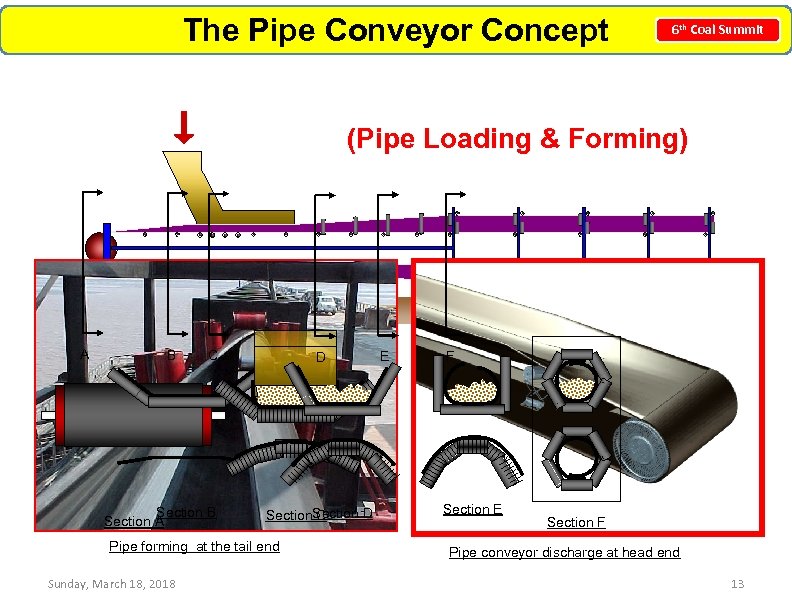

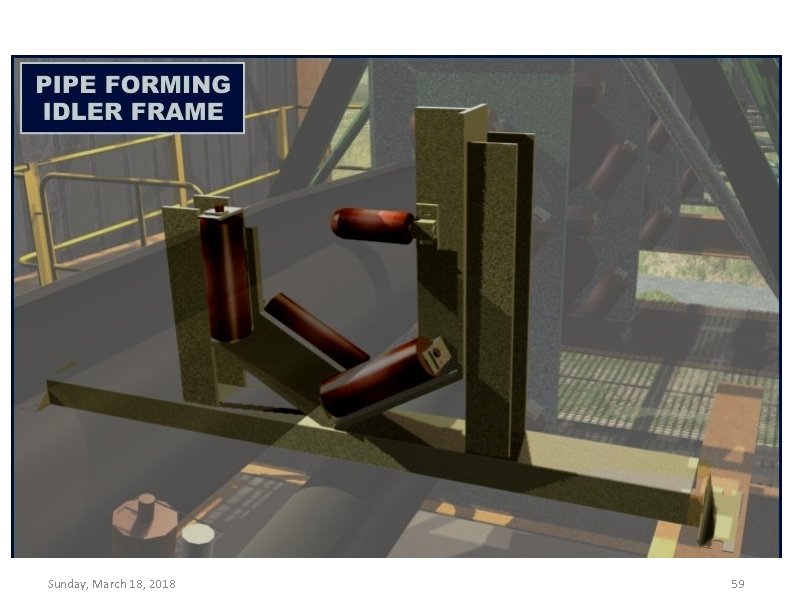

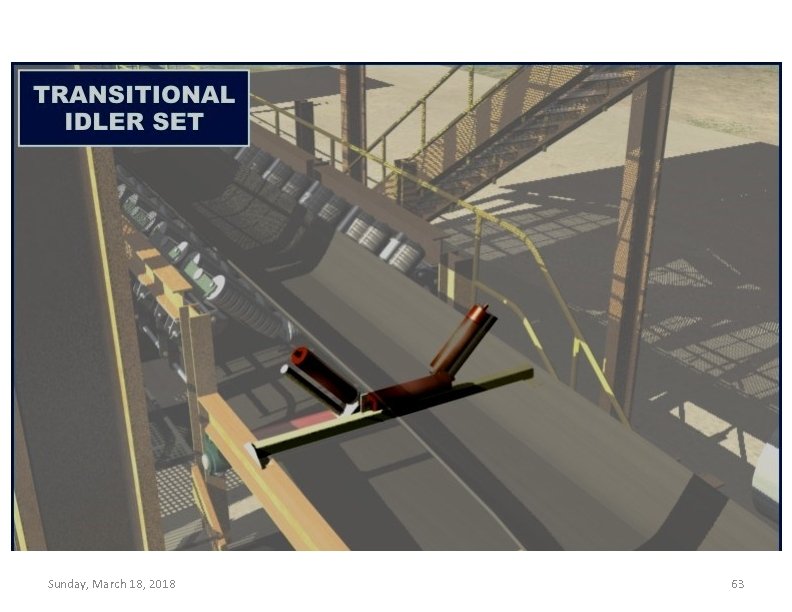

The Pipe Conveyor Concept 6 th Coal Summit (Pipe Loading & Forming) A B C Section B Section A D Section C Pipe forming at the tail end Sunday, March 18, 2018 E F Section E Section F Pipe conveyor discharge at head end 13

The Pipe Conveyor Concept 6 th Coal Summit (Pipe Loading & Forming) A B C Section B Section A D Section C Pipe forming at the tail end Sunday, March 18, 2018 E F Section E Section F Pipe conveyor discharge at head end 13

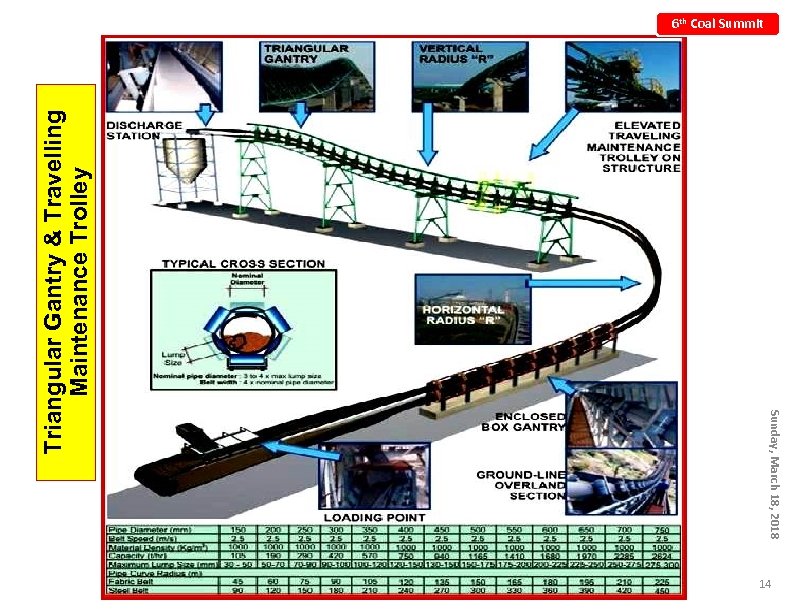

Sunday, March 18, 2018 Triangular Gantry & Travelling Maintenance Trolley 6 th Coal Summit 14

Sunday, March 18, 2018 Triangular Gantry & Travelling Maintenance Trolley 6 th Coal Summit 14

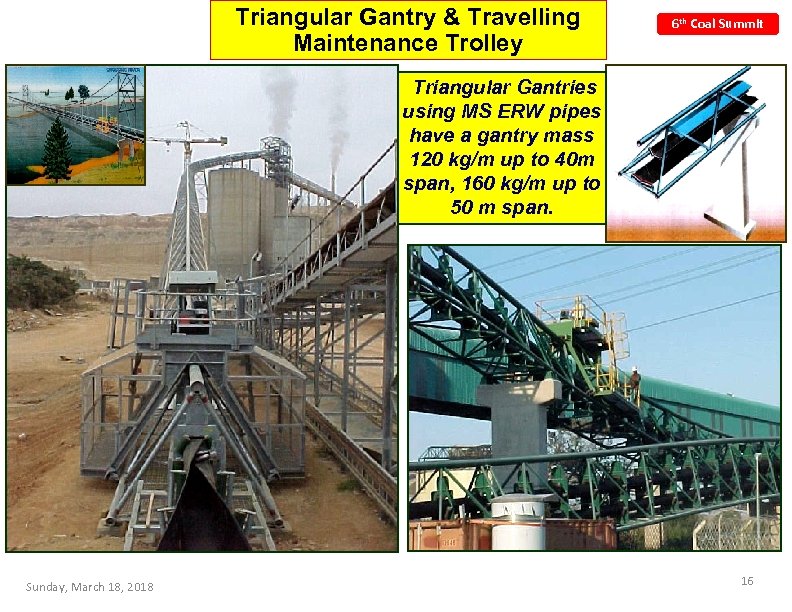

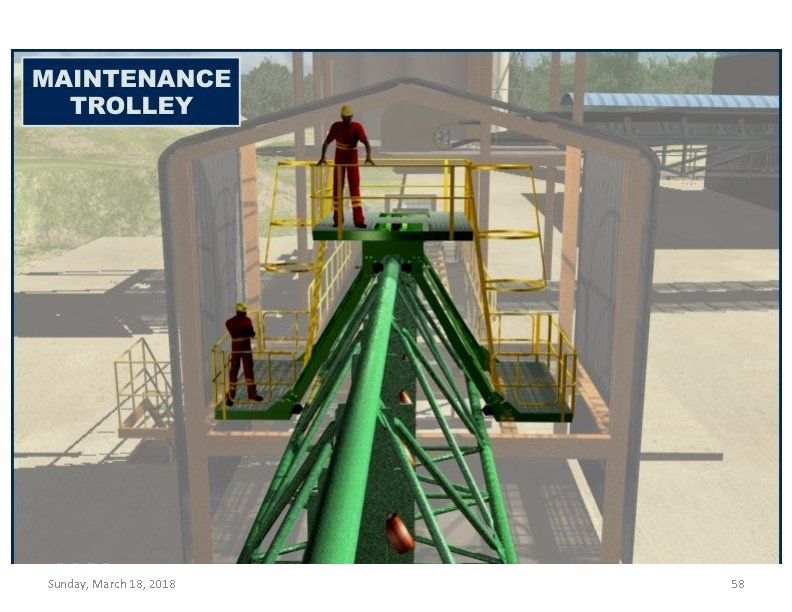

Triangular Gantry & Travelling Maintenance Trolley 6 th Coal Summit In Asia in particular – the social considerations play an important role in all Greenfield as well as ‘on going’ coal projects. From our experiences – the impact of transportation system on local communities needs to be considered. Haul roads are often adopted by the communities as a new access roads to & from their villages – causing safety concerns – when heavy duty haul trucks are sharing the road with light vehicle, motor cycles, bullock carts, hand carts and animals etc. In addition the villages tends to spring up adjacent to the road and people from outside the local area use roads to access the areas – causing potential social disturbances. Conveyors have the advantage that they can be constructed independent of the existing roads, or elevated above the ground and the roads / rails etc. There have been considerable improvements in the type of structural gantry that could be used to house the conveyors from traditional box type gantry to triangular gantry – where the structural weight per meter could be brought down by more than 50%. Sunday, March 18, 2018 15

Triangular Gantry & Travelling Maintenance Trolley 6 th Coal Summit In Asia in particular – the social considerations play an important role in all Greenfield as well as ‘on going’ coal projects. From our experiences – the impact of transportation system on local communities needs to be considered. Haul roads are often adopted by the communities as a new access roads to & from their villages – causing safety concerns – when heavy duty haul trucks are sharing the road with light vehicle, motor cycles, bullock carts, hand carts and animals etc. In addition the villages tends to spring up adjacent to the road and people from outside the local area use roads to access the areas – causing potential social disturbances. Conveyors have the advantage that they can be constructed independent of the existing roads, or elevated above the ground and the roads / rails etc. There have been considerable improvements in the type of structural gantry that could be used to house the conveyors from traditional box type gantry to triangular gantry – where the structural weight per meter could be brought down by more than 50%. Sunday, March 18, 2018 15

Triangular Gantry & Travelling Maintenance Trolley 6 th Coal Summit Triangular Gantries using MS ERW pipes have a gantry mass 120 kg/m up to 40 m span, 160 kg/m up to 50 m span. Sunday, March 18, 2018 16

Triangular Gantry & Travelling Maintenance Trolley 6 th Coal Summit Triangular Gantries using MS ERW pipes have a gantry mass 120 kg/m up to 40 m span, 160 kg/m up to 50 m span. Sunday, March 18, 2018 16

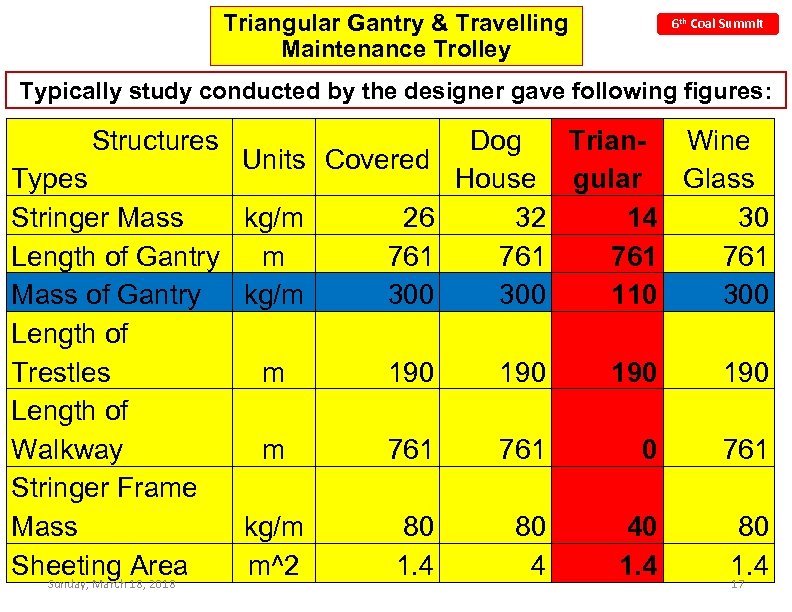

Triangular Gantry & Travelling Maintenance Trolley 6 th Coal Summit Typically study conducted by the designer gave following figures: Structures Units Covered Types Stringer Mass kg/m Length of Gantry m Mass of Gantry kg/m Length of Trestles m Length of Walkway m Stringer Frame Mass kg/m Sheeting Area m^2 Sunday, March 18, 2018 26 761 300 Dog Trian- Wine House gular Glass 32 14 30 761 761 300 110 300 190 190 761 80 1. 4 80 4 40 1. 4 80 1. 4 17

Triangular Gantry & Travelling Maintenance Trolley 6 th Coal Summit Typically study conducted by the designer gave following figures: Structures Units Covered Types Stringer Mass kg/m Length of Gantry m Mass of Gantry kg/m Length of Trestles m Length of Walkway m Stringer Frame Mass kg/m Sheeting Area m^2 Sunday, March 18, 2018 26 761 300 Dog Trian- Wine House gular Glass 32 14 30 761 761 300 110 300 190 190 761 80 1. 4 80 4 40 1. 4 80 1. 4 17

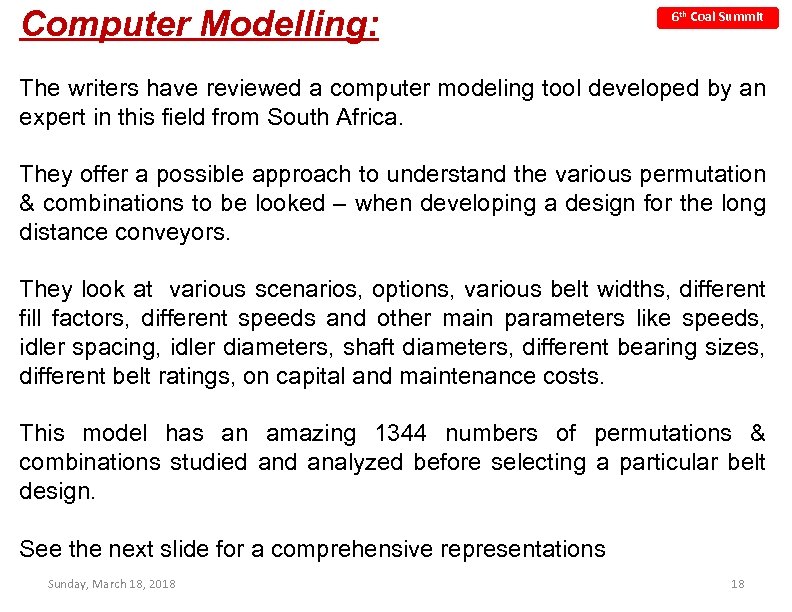

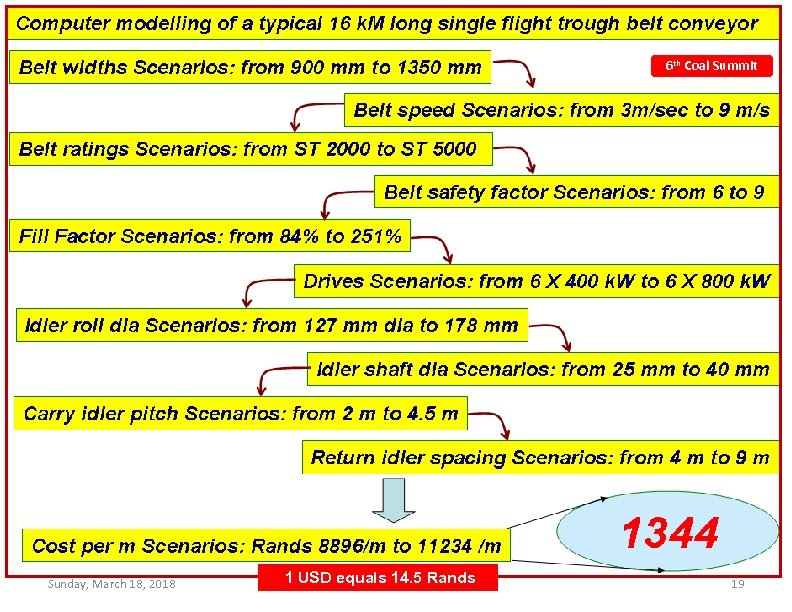

Computer Modelling: 6 th Coal Summit The writers have reviewed a computer modeling tool developed by an expert in this field from South Africa. They offer a possible approach to understand the various permutation & combinations to be looked – when developing a design for the long distance conveyors. They look at various scenarios, options, various belt widths, different fill factors, different speeds and other main parameters like speeds, idler spacing, idler diameters, shaft diameters, different bearing sizes, different belt ratings, on capital and maintenance costs. This model has an amazing 1344 numbers of permutations & combinations studied analyzed before selecting a particular belt design. See the next slide for a comprehensive representations Sunday, March 18, 2018 18

Computer Modelling: 6 th Coal Summit The writers have reviewed a computer modeling tool developed by an expert in this field from South Africa. They offer a possible approach to understand the various permutation & combinations to be looked – when developing a design for the long distance conveyors. They look at various scenarios, options, various belt widths, different fill factors, different speeds and other main parameters like speeds, idler spacing, idler diameters, shaft diameters, different bearing sizes, different belt ratings, on capital and maintenance costs. This model has an amazing 1344 numbers of permutations & combinations studied analyzed before selecting a particular belt design. See the next slide for a comprehensive representations Sunday, March 18, 2018 18

6 th Coal Summit Sunday, March 18, 2018 1 USD equals 14. 5 Rands 19

6 th Coal Summit Sunday, March 18, 2018 1 USD equals 14. 5 Rands 19

6 th Coal Summit Sunday, March 18, 2018 20

6 th Coal Summit Sunday, March 18, 2018 20

Rail Transportation Systems for coal 6 th Coal Summit In 1804 Richard Trevithick introduced the world to the steam driven railway engine, and almost immediately rail was recognized as a mass transport system. This was dramatically underlined in the late 1800's as then coal capital of the world, South Wales, switched from canal transport to rail. It was at this time that it became necessary to load coal into trains and of course the method of the day was to load them by hand. A loading rate of maybe 2 tonne per man hour being average and hence the ten tonne rail wagons of the day were invariably loaded by large teams of 14 men. Loading into static trains of wagons is a far cry from today's loading rates which can be as high as 7 000 tonnes per hour all done by one man from his control desk. All power stations across the globe had this system very much working for them and even today the rails carry a large amount of coal in Asia especially in India. In India CIL installed first Rapid Load out through Silo at Jayant Coal Mine. Sunday, March 18, 2018 21

Rail Transportation Systems for coal 6 th Coal Summit In 1804 Richard Trevithick introduced the world to the steam driven railway engine, and almost immediately rail was recognized as a mass transport system. This was dramatically underlined in the late 1800's as then coal capital of the world, South Wales, switched from canal transport to rail. It was at this time that it became necessary to load coal into trains and of course the method of the day was to load them by hand. A loading rate of maybe 2 tonne per man hour being average and hence the ten tonne rail wagons of the day were invariably loaded by large teams of 14 men. Loading into static trains of wagons is a far cry from today's loading rates which can be as high as 7 000 tonnes per hour all done by one man from his control desk. All power stations across the globe had this system very much working for them and even today the rails carry a large amount of coal in Asia especially in India. In India CIL installed first Rapid Load out through Silo at Jayant Coal Mine. Sunday, March 18, 2018 21

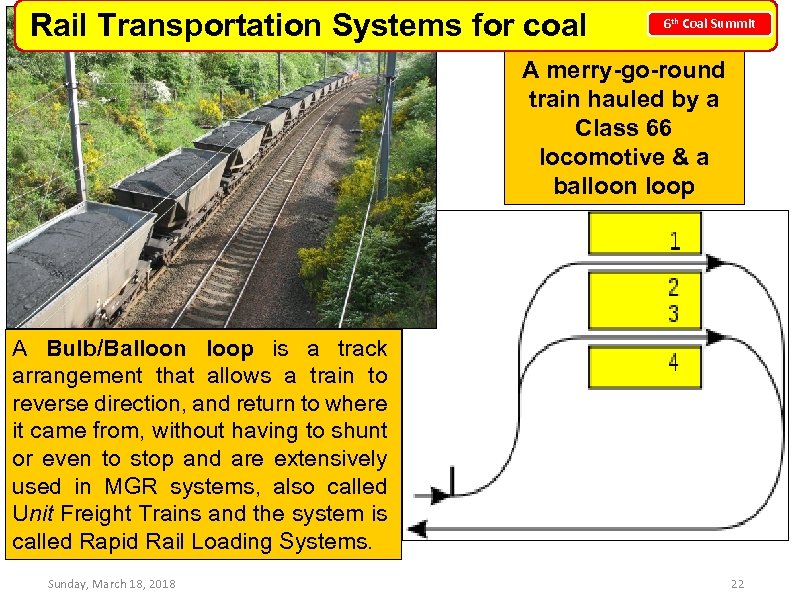

Rail Transportation Systems for coal 6 th Coal Summit A merry-go-round train hauled by a Class 66 locomotive & a balloon loop A Bulb/Balloon loop is a track arrangement that allows a train to reverse direction, and return to where it came from, without having to shunt or even to stop and are extensively used in MGR systems, also called Unit Freight Trains and the system is called Rapid Rail Loading Systems. Sunday, March 18, 2018 22

Rail Transportation Systems for coal 6 th Coal Summit A merry-go-round train hauled by a Class 66 locomotive & a balloon loop A Bulb/Balloon loop is a track arrangement that allows a train to reverse direction, and return to where it came from, without having to shunt or even to stop and are extensively used in MGR systems, also called Unit Freight Trains and the system is called Rapid Rail Loading Systems. Sunday, March 18, 2018 22

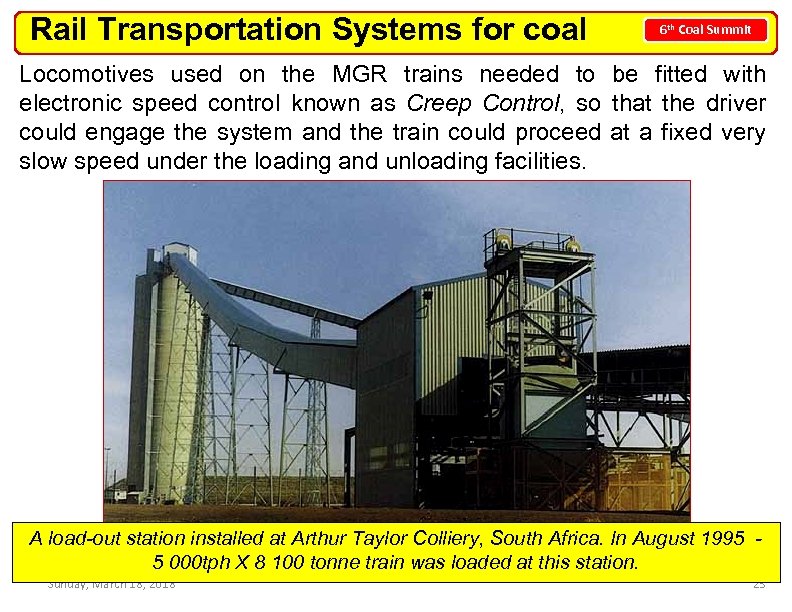

Rail Transportation Systems for coal 6 th Coal Summit Locomotives used on the MGR trains needed to be fitted with electronic speed control known as Creep Control, so that the driver could engage the system and the train could proceed at a fixed very slow speed under the loading and unloading facilities. A load-out station installed at Arthur Taylor Colliery, South Africa. In August 1995 5 000 tph X 8 100 tonne train was loaded at this station. Sunday, March 18, 2018 23

Rail Transportation Systems for coal 6 th Coal Summit Locomotives used on the MGR trains needed to be fitted with electronic speed control known as Creep Control, so that the driver could engage the system and the train could proceed at a fixed very slow speed under the loading and unloading facilities. A load-out station installed at Arthur Taylor Colliery, South Africa. In August 1995 5 000 tph X 8 100 tonne train was loaded at this station. Sunday, March 18, 2018 23

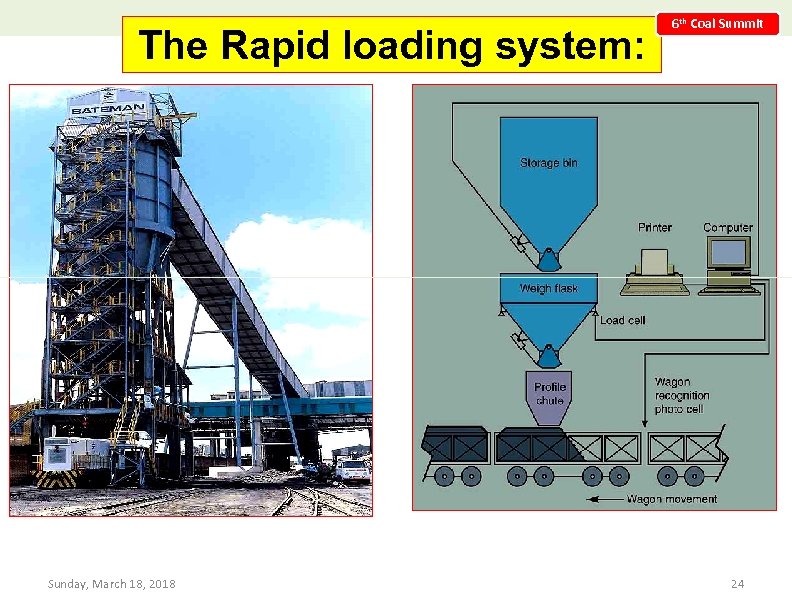

The Rapid loading system: 6 th Coal Summit Sunday, March 18, 2018 24

The Rapid loading system: 6 th Coal Summit Sunday, March 18, 2018 24

In India CIL installed first Rapid load out through Silo at Jayant mine for Singraule STPS of NTPC. Here the Coal was loaded into Bottom Discharge wagon of NTPC rake. Each wagon was loaded with 60 tes of coal in one minute & 30 wagons rake was loaded in 30 minutes. The wagons were weighed just after the load out. Based on experience of operators each wagon was loaded upto about 60 tes. In the second load Out System by CIL at Gevra mine for Korba STPS, the weighbridge was just under silo – load out & as when wagon contained 60 tes, the coal loading would stop. Here also rake of 34 wagons was loaded in about 34 minutes In Rajmahal mine of CIL for loading coal for Farakka & later for Kahalgaon STPS, there had been further improvement, each. Silo had two pre-weighed (60 tes each) hoppers and as pre-weighed quantity was discharged into wagon from one of the pre-weighed hopper, the second pre-weighed was getting filled with coal. In this way alternate pre-weighed hoppers keep on loading wagons in a rake. Being at long distance, each rake of Farakka has 54 wagons & rake is hauled by two locomotives. All the locomotives are fitted with creep control devise enabling loading & unloading of Coal with train in motion. Silo have capacity equivalent of rake capacity. Sunday, March 18, 2018 25

In India CIL installed first Rapid load out through Silo at Jayant mine for Singraule STPS of NTPC. Here the Coal was loaded into Bottom Discharge wagon of NTPC rake. Each wagon was loaded with 60 tes of coal in one minute & 30 wagons rake was loaded in 30 minutes. The wagons were weighed just after the load out. Based on experience of operators each wagon was loaded upto about 60 tes. In the second load Out System by CIL at Gevra mine for Korba STPS, the weighbridge was just under silo – load out & as when wagon contained 60 tes, the coal loading would stop. Here also rake of 34 wagons was loaded in about 34 minutes In Rajmahal mine of CIL for loading coal for Farakka & later for Kahalgaon STPS, there had been further improvement, each. Silo had two pre-weighed (60 tes each) hoppers and as pre-weighed quantity was discharged into wagon from one of the pre-weighed hopper, the second pre-weighed was getting filled with coal. In this way alternate pre-weighed hoppers keep on loading wagons in a rake. Being at long distance, each rake of Farakka has 54 wagons & rake is hauled by two locomotives. All the locomotives are fitted with creep control devise enabling loading & unloading of Coal with train in motion. Silo have capacity equivalent of rake capacity. Sunday, March 18, 2018 25

THE FUTURE: 6 th Coal Summit • To predict the future we must examine the problems of both the railway operator and the load out system operator. • Internationally railways are faced with increased demands on their lines and their rolling stock with the need to move more tonnage. One obvious method is to increase rolling stock but this increases costs and congestion. • The alternative is to increase wagon capacity, the United States for example between 1990 and 1994 average coal loads per wagon increased from 96, 67 to 102, 70 tonnes. The question is can the existing locomotives handle this increase, of for a 100 wagon train an additional 553 tonnes. • Here again some lead can be seen in the USA where the gross train mass is being reduced by the introduction of Aluminum wagons which offer tare savings of between 10 and 12%. In India also carrying capacity of wagons is being increased from 64 tes to 84 tes with reduction of tare weight also. Sunday, March 18, 2018 26

THE FUTURE: 6 th Coal Summit • To predict the future we must examine the problems of both the railway operator and the load out system operator. • Internationally railways are faced with increased demands on their lines and their rolling stock with the need to move more tonnage. One obvious method is to increase rolling stock but this increases costs and congestion. • The alternative is to increase wagon capacity, the United States for example between 1990 and 1994 average coal loads per wagon increased from 96, 67 to 102, 70 tonnes. The question is can the existing locomotives handle this increase, of for a 100 wagon train an additional 553 tonnes. • Here again some lead can be seen in the USA where the gross train mass is being reduced by the introduction of Aluminum wagons which offer tare savings of between 10 and 12%. In India also carrying capacity of wagons is being increased from 64 tes to 84 tes with reduction of tare weight also. Sunday, March 18, 2018 26

Slurry Pipe Lines: In this system Coal is crushed 0. 18 mm to 1. 80 mm (higher size particle high capex & opex) and conveyed through Pipe in slurry form at about 50% weight concentration. The positive displacement pumps are used with nominal velocity of 1. 9 to 2. 7 m/s. Depending upon length of haul and terrain, configuration of pumping stations is designed. In case of Test case of such studies by Videocon for its coal mines in Indonesia, a report was prepared for transporting 6 million tes of briquetted equivalent of 6 million tes/an of coal over 220 km long pipe line. The Capex and Opex (M $ USD) were estimated as $ 272 & $ 12. 1 respectively. The unit cost of briquette with 15% moisture from total moisture of about 34% worked out to $ 6. 60 per te. For long haul & large tonnage Slurry Pipe Line is good option. Sunday, March 18, 2018 27

Slurry Pipe Lines: In this system Coal is crushed 0. 18 mm to 1. 80 mm (higher size particle high capex & opex) and conveyed through Pipe in slurry form at about 50% weight concentration. The positive displacement pumps are used with nominal velocity of 1. 9 to 2. 7 m/s. Depending upon length of haul and terrain, configuration of pumping stations is designed. In case of Test case of such studies by Videocon for its coal mines in Indonesia, a report was prepared for transporting 6 million tes of briquetted equivalent of 6 million tes/an of coal over 220 km long pipe line. The Capex and Opex (M $ USD) were estimated as $ 272 & $ 12. 1 respectively. The unit cost of briquette with 15% moisture from total moisture of about 34% worked out to $ 6. 60 per te. For long haul & large tonnage Slurry Pipe Line is good option. Sunday, March 18, 2018 27

Long distance slurry pipe lines have been successfully used in transporting coal and way back in 1957 – the Ohio coal slurry pipe line in USA was the first to get commissioned for a distance of 174 km with multiple pumping stations to transport 1. 3 mtpy of coal. This was followed by the longest slurry pipe line in operation from 1970 till 2006 - the famous Black Mesa slurry pipe line. It was a 350 mm diameter X 450 km long slurry pipe line system with 4 pumping stations, designed to transport 5 mtpy of coal to a power plant in USA. In 2006 – this power plant was shut down due to permitting environmental issues and Black Mesa has stopped pumping coal slurry. Long distance slurry pipe lines are constructed using the cross country pipe line techniques that use the welded steel pipe that is buried under ground. Sunday, March 18, 2018 28

Long distance slurry pipe lines have been successfully used in transporting coal and way back in 1957 – the Ohio coal slurry pipe line in USA was the first to get commissioned for a distance of 174 km with multiple pumping stations to transport 1. 3 mtpy of coal. This was followed by the longest slurry pipe line in operation from 1970 till 2006 - the famous Black Mesa slurry pipe line. It was a 350 mm diameter X 450 km long slurry pipe line system with 4 pumping stations, designed to transport 5 mtpy of coal to a power plant in USA. In 2006 – this power plant was shut down due to permitting environmental issues and Black Mesa has stopped pumping coal slurry. Long distance slurry pipe lines are constructed using the cross country pipe line techniques that use the welded steel pipe that is buried under ground. Sunday, March 18, 2018 28

Sunday, March 18, 2018 29

Sunday, March 18, 2018 29

This requires that the pipe wall thickness should be sufficient to last for the life of the project, which could be 20 to 30 years. In order to achieve this, there should be no abrasion of the pipe steel due to slurry solids. The corrosion due to the slurries could also be controlled in order to achieve the desired life. Abrasion due to solids is controlled by using finely ground solids. The slurry concentration is kept high enough to prevent rapid settling of the solid particles. Use of finely ground solids, and high slurry concentration, allows use of transport velocities in the range up to 2 m/s. The friction loss for the slurry increases with an increase in velocity of flow. For coal – the slurry concentration could be as high as 65% and maximum particle size could be 1200 microns assuming the solid specific gravity @ 1. 4. Most of the other minerals are ideal application of this slurry pipe line transportation as the primary function of their beneficiation is crushing, grinding of the ore to a very fine size in order to achieve a good recovery. Sunday, March 18, 2018 30

This requires that the pipe wall thickness should be sufficient to last for the life of the project, which could be 20 to 30 years. In order to achieve this, there should be no abrasion of the pipe steel due to slurry solids. The corrosion due to the slurries could also be controlled in order to achieve the desired life. Abrasion due to solids is controlled by using finely ground solids. The slurry concentration is kept high enough to prevent rapid settling of the solid particles. Use of finely ground solids, and high slurry concentration, allows use of transport velocities in the range up to 2 m/s. The friction loss for the slurry increases with an increase in velocity of flow. For coal – the slurry concentration could be as high as 65% and maximum particle size could be 1200 microns assuming the solid specific gravity @ 1. 4. Most of the other minerals are ideal application of this slurry pipe line transportation as the primary function of their beneficiation is crushing, grinding of the ore to a very fine size in order to achieve a good recovery. Sunday, March 18, 2018 30

6 th Coal Summit More and more iron ore producers are going for this technology and even in India this idea was thought of and installed at Kudremukh Iron ore project way back 3 decades ago and recently one 267 k. M slurry pipe line has started working in the eastern coast for a 7 mtpy iron ore complex and another 271 k. M is under installation stage. Coal producers who wish to go for long distance transportation and those who wish to go for coal gasification projects should take the cue from these iron ore entrepreneurs. More and more iron ore producers are going for this technology and even in India this idea was thought of and installed at Kudremukh Iron ore project way back 3 decades ago and recently one 267 k. M slurry pipe line has started working in the eastern coast for a 7 mtpy iron ore complex and another 271 Km is under installation stage. Sunday, March 18, 2018 31

6 th Coal Summit More and more iron ore producers are going for this technology and even in India this idea was thought of and installed at Kudremukh Iron ore project way back 3 decades ago and recently one 267 k. M slurry pipe line has started working in the eastern coast for a 7 mtpy iron ore complex and another 271 k. M is under installation stage. Coal producers who wish to go for long distance transportation and those who wish to go for coal gasification projects should take the cue from these iron ore entrepreneurs. More and more iron ore producers are going for this technology and even in India this idea was thought of and installed at Kudremukh Iron ore project way back 3 decades ago and recently one 267 k. M slurry pipe line has started working in the eastern coast for a 7 mtpy iron ore complex and another 271 Km is under installation stage. Sunday, March 18, 2018 31

CONCLUSION: 6 th Coal Summit We have detailed several case studies on a subject which is dear to our heart. World wide - a lot has been detailed on the above three systems and we have only tried to bring out the fact that a new generation entrepreneur must be willing to take chances with the technology available and start looking at these with greater amount of ‘risk’ factor and those who have done have many times succeeded and gained from the same. We can furnish many examples of these entrepreneurial challenges taken by individuals and organization and we wish to table few of them. . . hereunder - as a part to support our paper and their case studies. Sunday, March 18, 2018 32

CONCLUSION: 6 th Coal Summit We have detailed several case studies on a subject which is dear to our heart. World wide - a lot has been detailed on the above three systems and we have only tried to bring out the fact that a new generation entrepreneur must be willing to take chances with the technology available and start looking at these with greater amount of ‘risk’ factor and those who have done have many times succeeded and gained from the same. We can furnish many examples of these entrepreneurial challenges taken by individuals and organization and we wish to table few of them. . . hereunder - as a part to support our paper and their case studies. Sunday, March 18, 2018 32

Belt Conveyors: 6 th Coal Summit The world spends about US $ 600 millions annually on new and replacement of belt conveyors for bulk material handling. US experience: Way back in 1980’s – open cut mines operator Homestake gold mines at Laad, South Dakota were planning to install 5 sections of trough belt forming a question mark route. A pipe conveyor solution provided a viable solution to transport gold ore in one single pass from tail end to head end. They did some investigations, saw some of the pipe conveyor installation and went for a 1920 m long single flight long distance conveyor – eliminating 5 transfer stations – resulting in a quiet, dust free, low maintenance cost operation compatible with a need to minimize the environmental impacts of mining in an urban area. This ‘first’ pipe conveyor installation in USA – the longest at that time in 1987 - has achieved availability factor of 94% after overcoming teething issues and in June 1989 it was available 100% of the time. Sunday, March 18, 2018 33

Belt Conveyors: 6 th Coal Summit The world spends about US $ 600 millions annually on new and replacement of belt conveyors for bulk material handling. US experience: Way back in 1980’s – open cut mines operator Homestake gold mines at Laad, South Dakota were planning to install 5 sections of trough belt forming a question mark route. A pipe conveyor solution provided a viable solution to transport gold ore in one single pass from tail end to head end. They did some investigations, saw some of the pipe conveyor installation and went for a 1920 m long single flight long distance conveyor – eliminating 5 transfer stations – resulting in a quiet, dust free, low maintenance cost operation compatible with a need to minimize the environmental impacts of mining in an urban area. This ‘first’ pipe conveyor installation in USA – the longest at that time in 1987 - has achieved availability factor of 94% after overcoming teething issues and in June 1989 it was available 100% of the time. Sunday, March 18, 2018 33

6 th Coal Summit Recently – an Indian company has installed and commissioned an 800 tph X 17 k. M long X 59 m uphill single flight trough belt connecting a limestone mine located in India to a cement plant located in Bangladesh – literally connecting two countries. The 17 k. M conveyor route is: 1. First 1. 50 km in extremely hilly terrain with tail end in the limestone quarry in Meghalaya, India, 2. Balance 5. 50 k. M in plains up to the Bangladesh border, 3. Rest 10 km generally on plains from India border to Cement plant located at Noarai Chhatak, Bangladesh. 4. On the way it crosses numerous rivers, waterways, and roads – necessitating 12 bridges, and bridge spans vary between 40 m to 100 m. The recent experiences of installing longer and longer conveyors has established the fact that conveying of coal over longer and longer distances is a viable solution to reduce the transportation cost per tonne per kilometre. Sunday, March 18, 2018 34

6 th Coal Summit Recently – an Indian company has installed and commissioned an 800 tph X 17 k. M long X 59 m uphill single flight trough belt connecting a limestone mine located in India to a cement plant located in Bangladesh – literally connecting two countries. The 17 k. M conveyor route is: 1. First 1. 50 km in extremely hilly terrain with tail end in the limestone quarry in Meghalaya, India, 2. Balance 5. 50 k. M in plains up to the Bangladesh border, 3. Rest 10 km generally on plains from India border to Cement plant located at Noarai Chhatak, Bangladesh. 4. On the way it crosses numerous rivers, waterways, and roads – necessitating 12 bridges, and bridge spans vary between 40 m to 100 m. The recent experiences of installing longer and longer conveyors has established the fact that conveying of coal over longer and longer distances is a viable solution to reduce the transportation cost per tonne per kilometre. Sunday, March 18, 2018 34

6 th Coal Summit Rail Transportation System MGR: A well-designed rapid load out system is one of the most trouble free plants in any mine system. If the loading and unloading issues are sorted out properly – there is no reason why a Rail MGR could not be installed and transportation cost per tonne per k. M can be reduced to increase the profits. Sunday, March 18, 2018 35

6 th Coal Summit Rail Transportation System MGR: A well-designed rapid load out system is one of the most trouble free plants in any mine system. If the loading and unloading issues are sorted out properly – there is no reason why a Rail MGR could not be installed and transportation cost per tonne per k. M can be reduced to increase the profits. Sunday, March 18, 2018 35

Slurry Pipe Lines: Slurry pipe lines have lower environmental impact and are not affected by weather or traffic congestions. The OPEX costs are much lower to comparable long distance transport systems. Because of low OPEX costs component, the transportation costs increase is moderate even during periods of high inflation. Slurry pipe lines need large amount of water. Slurry preparation and dewatering costs become part of overall costs. In the recent times, the interest to use coal for gasification has increased. The coal gasification process generally requires coal that is finely ground and in slurry form and there is no need to dry the coal. Thus it could be good to look at this form of coal transportation for this application. Sunday, March 18, 2018 36

Slurry Pipe Lines: Slurry pipe lines have lower environmental impact and are not affected by weather or traffic congestions. The OPEX costs are much lower to comparable long distance transport systems. Because of low OPEX costs component, the transportation costs increase is moderate even during periods of high inflation. Slurry pipe lines need large amount of water. Slurry preparation and dewatering costs become part of overall costs. In the recent times, the interest to use coal for gasification has increased. The coal gasification process generally requires coal that is finely ground and in slurry form and there is no need to dry the coal. Thus it could be good to look at this form of coal transportation for this application. Sunday, March 18, 2018 36

SUMMING UP: 1. Slurry pipe lines & MGR can go where Belt conveyors can not go. 2. Like wise Belt conveyor can go where slurry pipe lines and MGR’s can not go. 3. Like wise MGR’s can go where slurry pipe lines and belt conveyors can or can not go. Combination of Multi model transport system may be need of Future Sunday, March 18, 2018 37

SUMMING UP: 1. Slurry pipe lines & MGR can go where Belt conveyors can not go. 2. Like wise Belt conveyor can go where slurry pipe lines and MGR’s can not go. 3. Like wise MGR’s can go where slurry pipe lines and belt conveyors can or can not go. Combination of Multi model transport system may be need of Future Sunday, March 18, 2018 37

Finally –it goes to a proverb: 6 th Coal Summit Prepare the horses for the courses and select a horse which is most appropriate for the course… Like may be slurry pipe line is best for one project, may be belt conveyor may be ideal for another project and may be rail system will suit the long term needs of third project. Our sincere thanks to 6 th Coal Summit organizers for giving us this opportunity to express our thoughts. Sunday, March 18, 2018 38

Finally –it goes to a proverb: 6 th Coal Summit Prepare the horses for the courses and select a horse which is most appropriate for the course… Like may be slurry pipe line is best for one project, may be belt conveyor may be ideal for another project and may be rail system will suit the long term needs of third project. Our sincere thanks to 6 th Coal Summit organizers for giving us this opportunity to express our thoughts. Sunday, March 18, 2018 38

6 th Coal Summit ACKNOWLEDGEMENTS We wish to thank Mr. Phil Staples, Republic of South Africa for his valuable support and the following technical papers and their Authors and the organizations. BIBLIOGRAPHY 1. The Use of Slurry Pipelines for Cost Effective Transportation of Minerals, by Mr. Ramesh L Gandhi & Steven A Young, Pipeline Systems Inc. , USA – Paper presented at 2 nd Coal Mining Operations & Economics, Singapore Dec, 2007. 2. Achieving cost reduction in mine pit to port transportation, by Mr. Dale Ewart, Associate, PT Connell Wagner Indonesia -– Paper presented at 2 nd Coal Mining Operations & Economics, Singapore Dec, 2007. 3. Coal – Long distance bulk transport, by Mr. AP Wild for Eskom Management, RSA. 4. Rapid Rail Load Out Systems – Past, present & Future by A E W Fletcher, RSA in his presentation made at Belt Con 9 Conference in RSA in 1997. 5. The Homestake Pipe Conveyor by Mr. Charles F Langdon, Open Cut Mines Superintendent, Homestake mines, Lead, South Dakota for his paper presented at The American Mining Convention ’ 89, San Francisco, California on 20 th Sept, 1989. 6. The Challenge of Creating a 17 Km Belt Conveyor for the Lafarge Surma Cement Plant by Mr. Kumar Vikram and Mr. Pabak Mukhopadhyay, India – published in Vol. 26 (2006) No. 4 of Bulk Solids Handling Magazine. 7. Courtesy of the management of m/s Conveyor Dynamics Inc. USA through our earlier associations 8. Courtesy of the management of m/s Thyssen. Krupp India through our earlier associations 9. Courtesy of the management of m/s FL Smidth India through our earlier associations. END OF PAPER Sunday, March 18, 2018 39

6 th Coal Summit ACKNOWLEDGEMENTS We wish to thank Mr. Phil Staples, Republic of South Africa for his valuable support and the following technical papers and their Authors and the organizations. BIBLIOGRAPHY 1. The Use of Slurry Pipelines for Cost Effective Transportation of Minerals, by Mr. Ramesh L Gandhi & Steven A Young, Pipeline Systems Inc. , USA – Paper presented at 2 nd Coal Mining Operations & Economics, Singapore Dec, 2007. 2. Achieving cost reduction in mine pit to port transportation, by Mr. Dale Ewart, Associate, PT Connell Wagner Indonesia -– Paper presented at 2 nd Coal Mining Operations & Economics, Singapore Dec, 2007. 3. Coal – Long distance bulk transport, by Mr. AP Wild for Eskom Management, RSA. 4. Rapid Rail Load Out Systems – Past, present & Future by A E W Fletcher, RSA in his presentation made at Belt Con 9 Conference in RSA in 1997. 5. The Homestake Pipe Conveyor by Mr. Charles F Langdon, Open Cut Mines Superintendent, Homestake mines, Lead, South Dakota for his paper presented at The American Mining Convention ’ 89, San Francisco, California on 20 th Sept, 1989. 6. The Challenge of Creating a 17 Km Belt Conveyor for the Lafarge Surma Cement Plant by Mr. Kumar Vikram and Mr. Pabak Mukhopadhyay, India – published in Vol. 26 (2006) No. 4 of Bulk Solids Handling Magazine. 7. Courtesy of the management of m/s Conveyor Dynamics Inc. USA through our earlier associations 8. Courtesy of the management of m/s Thyssen. Krupp India through our earlier associations 9. Courtesy of the management of m/s FL Smidth India through our earlier associations. END OF PAPER Sunday, March 18, 2018 39

Sunday, March 18, 2018 40

Sunday, March 18, 2018 40

Sunday, March 18, 2018 41

Sunday, March 18, 2018 41

Sunday, March 18, 2018 42

Sunday, March 18, 2018 42

Sunday, March 18, 2018 43

Sunday, March 18, 2018 43

Sunday, March 18, 2018 44

Sunday, March 18, 2018 44

Sunday, March 18, 2018 45

Sunday, March 18, 2018 45

Sunday, March 18, 2018 46

Sunday, March 18, 2018 46

Sunday, March 18, 2018 47

Sunday, March 18, 2018 47

Sunday, March 18, 2018 48

Sunday, March 18, 2018 48

Sunday, March 18, 2018 49

Sunday, March 18, 2018 49

Sunday, March 18, 2018 50

Sunday, March 18, 2018 50

Sunday, March 18, 2018 51

Sunday, March 18, 2018 51

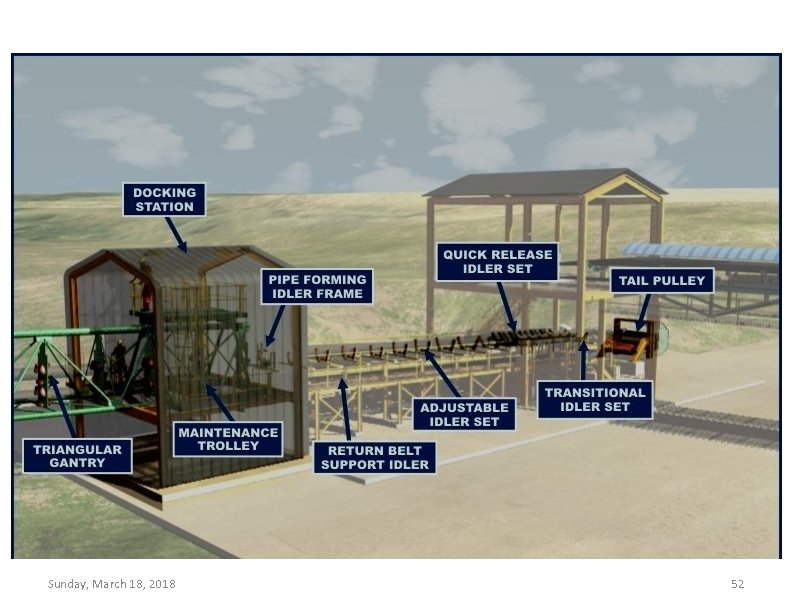

Sunday, March 18, 2018 52

Sunday, March 18, 2018 52

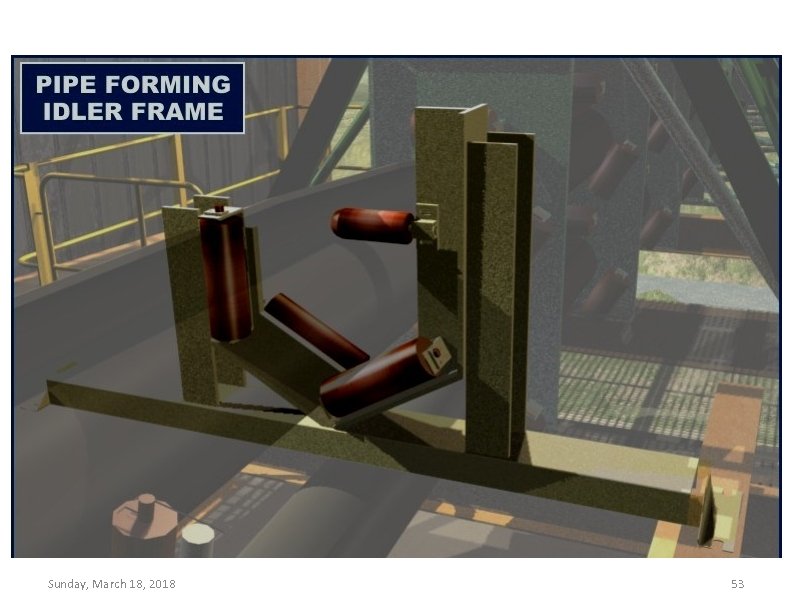

Sunday, March 18, 2018 53

Sunday, March 18, 2018 53

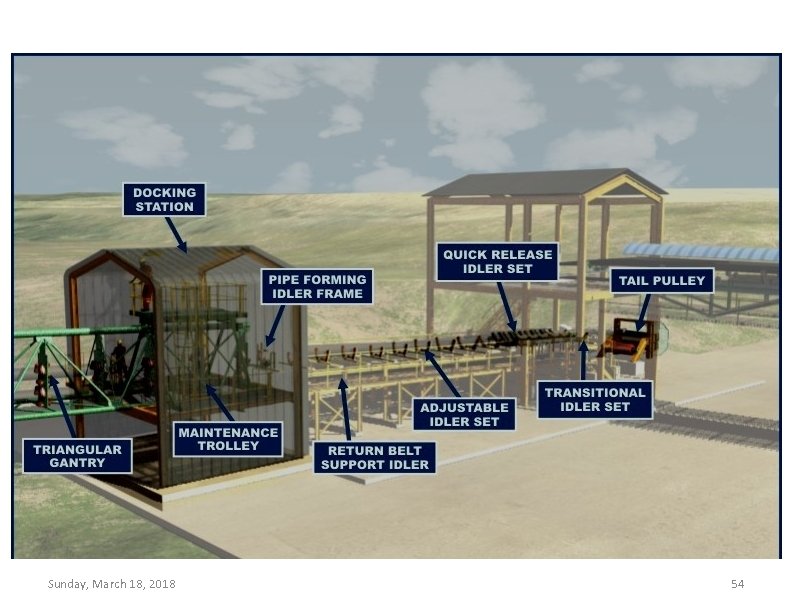

Sunday, March 18, 2018 54

Sunday, March 18, 2018 54

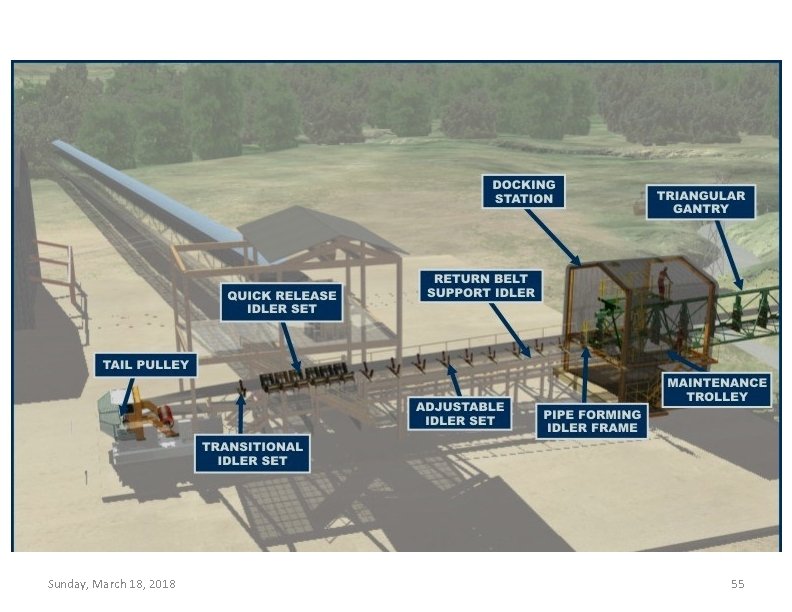

Sunday, March 18, 2018 55

Sunday, March 18, 2018 55

Sunday, March 18, 2018 56

Sunday, March 18, 2018 56

Sunday, March 18, 2018 57

Sunday, March 18, 2018 57

Sunday, March 18, 2018 58

Sunday, March 18, 2018 58

Sunday, March 18, 2018 59

Sunday, March 18, 2018 59

Sunday, March 18, 2018 60

Sunday, March 18, 2018 60

Sunday, March 18, 2018 61

Sunday, March 18, 2018 61

Sunday, March 18, 2018 62

Sunday, March 18, 2018 62

Sunday, March 18, 2018 63

Sunday, March 18, 2018 63

Sunday, March 18, 2018 64

Sunday, March 18, 2018 64

Thank You Sunday, March 18, 2018 65

Thank You Sunday, March 18, 2018 65