6ad54316e1c4a2990116437b893940e9.ppt

- Количество слайдов: 6

50 Hz Stainless steel Vertical multistage centrifugal pumps Sego Industrial Co. , Ltd.

50 Hz Stainless steel Vertical multistage centrifugal pumps Sego Industrial Co. , Ltd.

SEGO PUMP Vertical multistage centrifugal ■Product Introduction ■Product range The SM & SMS pump is a non-self-priming, vertical multistage centrifugal pump. The pumps are available with a flange type motors. Pump type SM, SMS The SM & SMS pumps are suitable for a variety of applications from pumping of potable water to pumping of chemicals. The pumps are therefore used in a wide variety of pumping systems where the performance and material of the pump meet specific demands. The SM & SMS pumps consist materials of stainless steel on all parts. The SM & SMS pumps have sanitation & durability. The SM & SMS pumps are vertical multistage centrifugal pumps. The In-line design enables the pump to be installed in a horizontal one-pipe system where the suction and discharge port are in the same horizontal plane and have the same pipe dimensions. This design provides a more compact pump design and pipe-work. SM 15 02 A V Nominal flow rate(㎥/h) Number of Impellers A : Oval Flange V : F. K. M(Viton) ■Operating range - Ambient Temperature : Max +40℃ (Locate 1, 000 m above sea level requires a reduction) - Approval liquid temperature : -20℃ ~ +120℃ - Location : No exist on non-corrosive and explosive gas The SM & SMS pumps come with various pump sizes and various numbers of stages to provide the flow and the pressure required. or steam The SM & SMS pumps consist of two parts the moor and the pump unit. The motor on SM & SMS pump is IEC standard. (see on the upper) - Minimum inlet pressure : NPSH Min. +0. 5 m -Rotation : Counter. Clock. Wise ■Analysis of 3 D current flow designs ■Pipe-work connection SM & SMS 1, 3, 5 models support to Oval Flange type 2 D Impeller 3 D Impeller Support to High performance and high efficiency through analysis of 3 D current flow Oval Flange Round Flange Chamber

SEGO PUMP Vertical multistage centrifugal ■Product Introduction ■Product range The SM & SMS pump is a non-self-priming, vertical multistage centrifugal pump. The pumps are available with a flange type motors. Pump type SM, SMS The SM & SMS pumps are suitable for a variety of applications from pumping of potable water to pumping of chemicals. The pumps are therefore used in a wide variety of pumping systems where the performance and material of the pump meet specific demands. The SM & SMS pumps consist materials of stainless steel on all parts. The SM & SMS pumps have sanitation & durability. The SM & SMS pumps are vertical multistage centrifugal pumps. The In-line design enables the pump to be installed in a horizontal one-pipe system where the suction and discharge port are in the same horizontal plane and have the same pipe dimensions. This design provides a more compact pump design and pipe-work. SM 15 02 A V Nominal flow rate(㎥/h) Number of Impellers A : Oval Flange V : F. K. M(Viton) ■Operating range - Ambient Temperature : Max +40℃ (Locate 1, 000 m above sea level requires a reduction) - Approval liquid temperature : -20℃ ~ +120℃ - Location : No exist on non-corrosive and explosive gas The SM & SMS pumps come with various pump sizes and various numbers of stages to provide the flow and the pressure required. or steam The SM & SMS pumps consist of two parts the moor and the pump unit. The motor on SM & SMS pump is IEC standard. (see on the upper) - Minimum inlet pressure : NPSH Min. +0. 5 m -Rotation : Counter. Clock. Wise ■Analysis of 3 D current flow designs ■Pipe-work connection SM & SMS 1, 3, 5 models support to Oval Flange type 2 D Impeller 3 D Impeller Support to High performance and high efficiency through analysis of 3 D current flow Oval Flange Round Flange Chamber

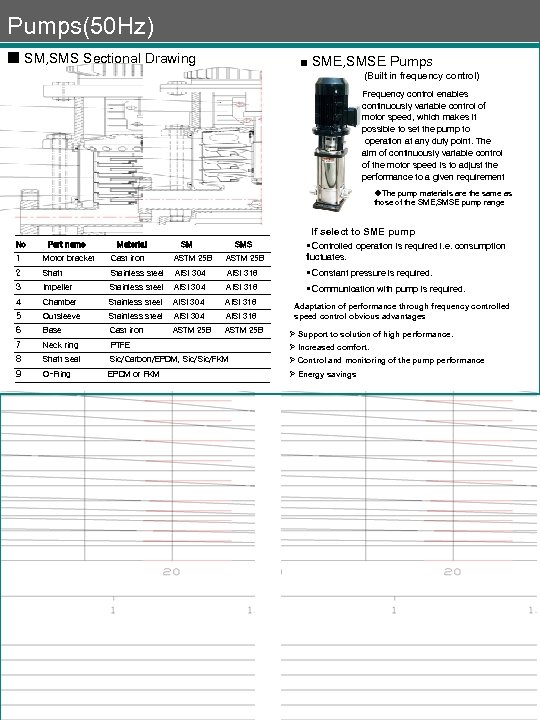

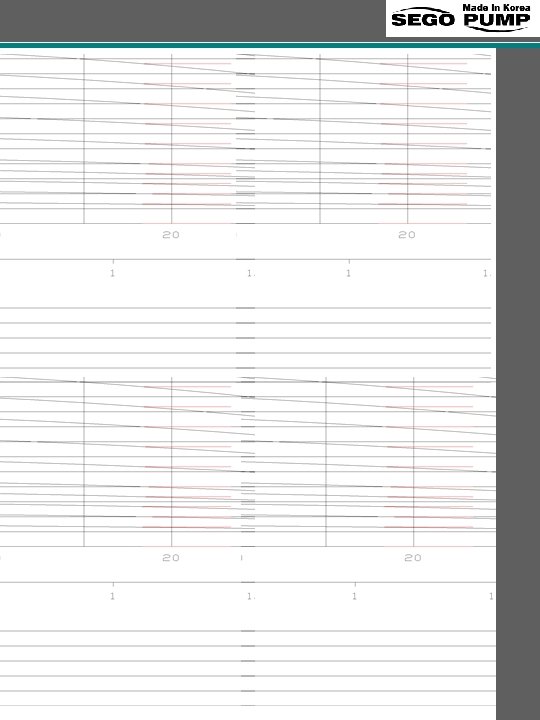

Pumps(50 Hz) ■ SM, SMS Sectional Drawing ■ SME, SMSE Pumps (Built in frequency control) Frequency control enables continuously variable control of motor speed, which makes it possible to set the pump to operation at any duty point. The aim of continuously variable control of the motor speed is to adjust the performance to a given requirement u. The pump materials are the same as those of the SME, SMSE pump range If select to SME pump No Part name Material SM SMS § Controlled operation is required i. e. consumption 1 Motor bracket Cast iron ASTM 25 B fluctuates. 2 Shaft Stainless steel AISI 304 AISI 316 § Constant pressure is required. 3 Impeller Stainless steel AISI 304 AISI 316 § Communication with pump is required. 4 Chamber Stainless steel AISI 304 AISI 316 5 Outsleeve Stainless steel AISI 304 AISI 316 6 Base Cast iron ASTM 25 B 7 Neck ring PTFE Ø Increased comfort. 8 Shaft seal Sic/Carbon/EPDM, Sic/FKM Ø Control and monitoring of the pump performance 9 O-Ring EPDM or FKM Ø Energy savings Adaptation of performance through frequency controlled speed control obvious advantages Ø Support to solution of high performance.

Pumps(50 Hz) ■ SM, SMS Sectional Drawing ■ SME, SMSE Pumps (Built in frequency control) Frequency control enables continuously variable control of motor speed, which makes it possible to set the pump to operation at any duty point. The aim of continuously variable control of the motor speed is to adjust the performance to a given requirement u. The pump materials are the same as those of the SME, SMSE pump range If select to SME pump No Part name Material SM SMS § Controlled operation is required i. e. consumption 1 Motor bracket Cast iron ASTM 25 B fluctuates. 2 Shaft Stainless steel AISI 304 AISI 316 § Constant pressure is required. 3 Impeller Stainless steel AISI 304 AISI 316 § Communication with pump is required. 4 Chamber Stainless steel AISI 304 AISI 316 5 Outsleeve Stainless steel AISI 304 AISI 316 6 Base Cast iron ASTM 25 B 7 Neck ring PTFE Ø Increased comfort. 8 Shaft seal Sic/Carbon/EPDM, Sic/FKM Ø Control and monitoring of the pump performance 9 O-Ring EPDM or FKM Ø Energy savings Adaptation of performance through frequency controlled speed control obvious advantages Ø Support to solution of high performance.

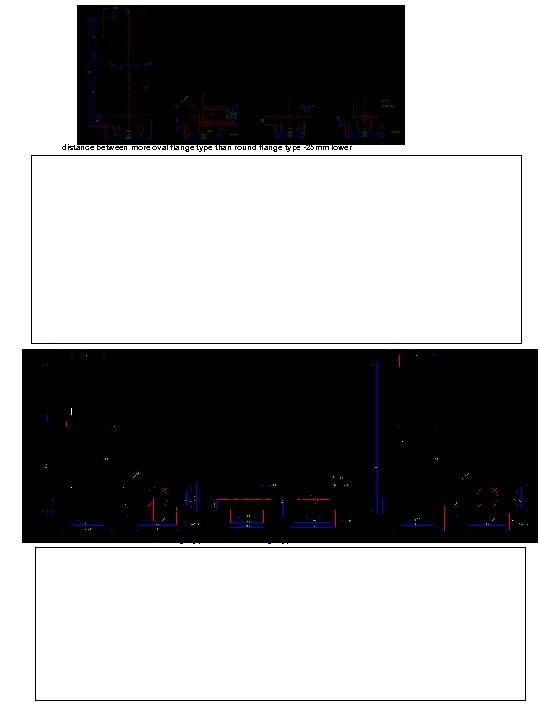

distance between more oval flange type than round flange type -25 mm lower

distance between more oval flange type than round flange type -25 mm lower

ISO 9001/ISO 14001 www. segopump. co. kr Applications Selection Chart (50 Hz) -- water supply Application ● Distribution from waterworks ● Pressure boosting in mains ● Pressure boosting in high-rise buildings, hotel, etc ● Pressure boosting for industrial water supply -- Industrial Application ● washing and cleaning systems ● Boiler feed and condensate systems ● Fire fighting systems ● Cooling and Air-conditioning systems (refrigerants) ● Process water systems ● Liquid transfer in machine tools (cooling lubricants) ● Transfer of oils and alcohols systems ● Transfer of acids and alkalies systems ● Transfer of glycol and coolants -- Water treatment Application ● Ultra-filtration systems ● Distillation systems ● Separators ● Supply for swimming fool systems -- Irrigation Application ● Field irrigation (flooding) ● Sprinkler irrigation ● Drip-feed irrigation Sego Industrial Co. , Ltd. 65 -25, Sosabon-dong, Sosa-gu, Bucheon-si, Gyeonggi-do, Korea Tel: 82 -32 -345 -2611, Fax: 82 -32 -345 -1355

ISO 9001/ISO 14001 www. segopump. co. kr Applications Selection Chart (50 Hz) -- water supply Application ● Distribution from waterworks ● Pressure boosting in mains ● Pressure boosting in high-rise buildings, hotel, etc ● Pressure boosting for industrial water supply -- Industrial Application ● washing and cleaning systems ● Boiler feed and condensate systems ● Fire fighting systems ● Cooling and Air-conditioning systems (refrigerants) ● Process water systems ● Liquid transfer in machine tools (cooling lubricants) ● Transfer of oils and alcohols systems ● Transfer of acids and alkalies systems ● Transfer of glycol and coolants -- Water treatment Application ● Ultra-filtration systems ● Distillation systems ● Separators ● Supply for swimming fool systems -- Irrigation Application ● Field irrigation (flooding) ● Sprinkler irrigation ● Drip-feed irrigation Sego Industrial Co. , Ltd. 65 -25, Sosabon-dong, Sosa-gu, Bucheon-si, Gyeonggi-do, Korea Tel: 82 -32 -345 -2611, Fax: 82 -32 -345 -1355