5S Implementation plan WUAST.pptx

- Количество слайдов: 7

5 S in WUAST Problems: q. Not enough available rooms to provide training q 5 S Checklists are bad q. Audits are planned 1

5 S Implementation on WUAST 2015 The Quality Connection

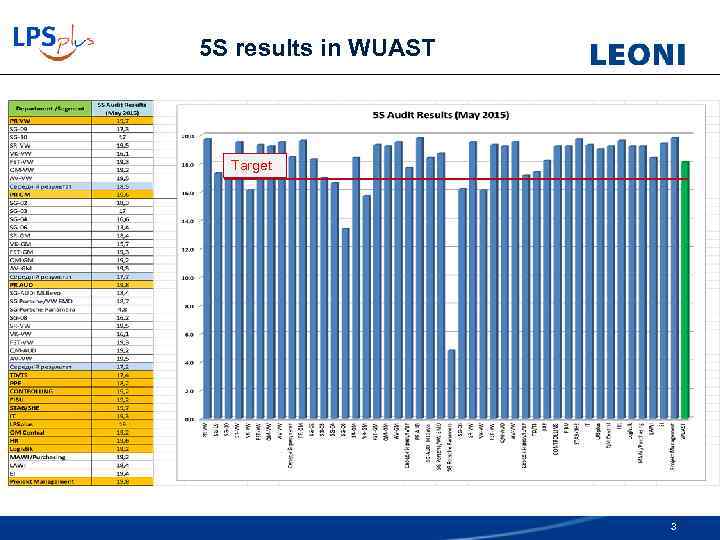

5 S results in WUAST Target 3

5 S trainings in WUAST 5 S Training Plan 2015. xlsx All employees – 6278 19% 81% 22% 88% 26% 74% 4

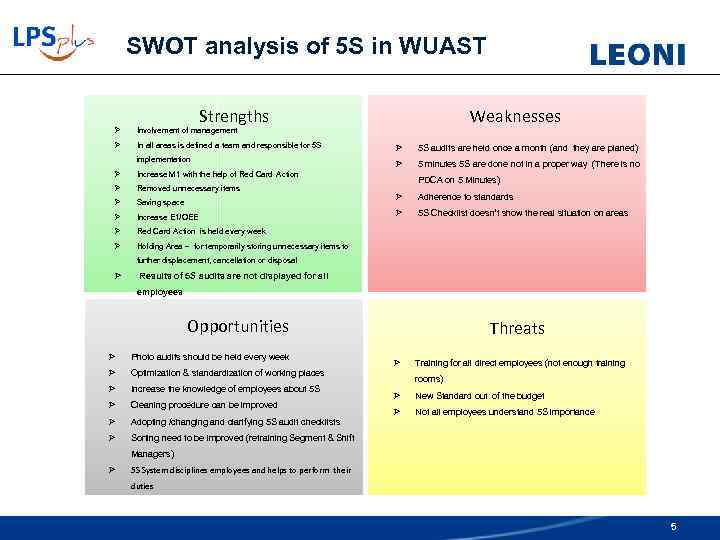

SWOT analysis of 5 S in WUAST Strengths Weaknesses Ø Involvement of management Ø In all areas is defined a team and responsible for 5 S Ø 5 S audits are held once a month (and they are planed) implementation Ø 5 minutes 5 S are done not in a proper way (There is no Ø Increase M 1 with the help of Red Card Action Ø Removed unnecessary items Ø Saving space Ø Increase E 1/OEE Ø Red Card Action is held every week Ø Holding Area – for temporarily storing unnecessary items to PDCA on 5 Minutes) Ø Adherence to standards Ø 5 S Checklist doesn’t show the real situation on areas further displacement, cancellation or disposal Ø Results of 5 S audits are not displayed for all employees Opportunities Ø Photo audits should be held every week Ø Optimization & standardization of working places Ø Increase the knowledge of employees about 5 S Ø Cleaning procedure can be improved Ø Adopting /changing and clarifying 5 S audit checklists Ø Threats Sorting need to be improved (retraining Segment & Shift Ø Training for all direct employees (not enough training rooms) Ø New Standard out of the budget Ø Not all employees understand 5 S importance Managers) Ø 5 S System disciplines employees and helps to perform their duties 5

Our actions q We discussed in the LPSplus department the problem of Planed Audit and suggested to organize additional Audit. It was agreed by Top Managers. Top Manager is responsible for it conducting. q As 5 S Checklist was contained of too many questions it was difficult for Top Manager to be present on Audit if he (she) has many small lines. A lot of questions were unneeded. We have already proposed our new version of a checklist (the same for production & office). q 5 S Training has already done and in CW 27 HR trainers will be taught. In CW 28 the Training Plan will be agreed with Managers of all department. q The 5 S Board has already designed where the standard and best team from each BU and office will be showed 6

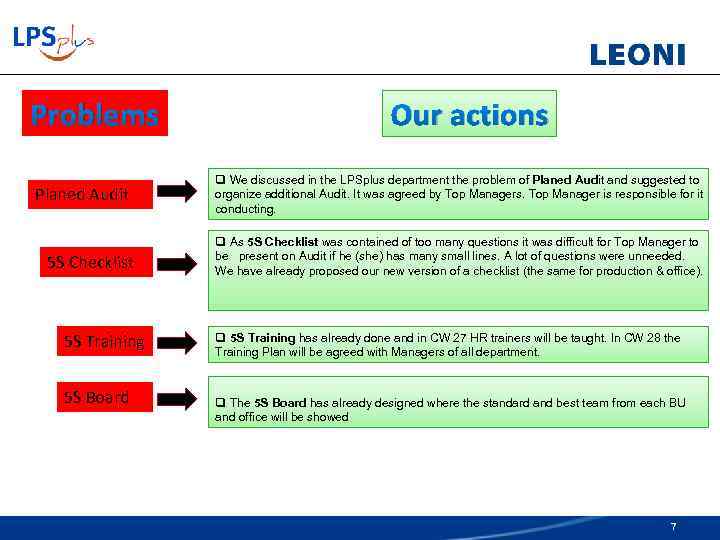

Problems Planed Audit 5 S Checklist 5 S Training 5 S Board Our actions q We discussed in the LPSplus department the problem of Planed Audit and suggested to organize additional Audit. It was agreed by Top Managers. Top Manager is responsible for it conducting. q As 5 S Checklist was contained of too many questions it was difficult for Top Manager to be present on Audit if he (she) has many small lines. A lot of questions were unneeded. We have already proposed our new version of a checklist (the same for production & office). q 5 S Training has already done and in CW 27 HR trainers will be taught. In CW 28 the Training Plan will be agreed with Managers of all department. q The 5 S Board has already designed where the standard and best team from each BU and office will be showed 7

5S Implementation plan WUAST.pptx