b7506d2756a40d41d27ee489889be725.ppt

- Количество слайдов: 20

5 -S: Housekeeping to improve efficiency and productivity to maintain safety and cleanliness to maintain good control over the processes to maintain the good product quality

5 -S: Housekeeping to improve efficiency and productivity to maintain safety and cleanliness to maintain good control over the processes to maintain the good product quality

5 -S Ø SEIRI sorting/segregating Ø SEITON self arrangement/arranging Ø SEISO spic and span (neat and clean) Ø SEIKETSU standardization Ø SHITSUKE self discipline

5 -S Ø SEIRI sorting/segregating Ø SEITON self arrangement/arranging Ø SEISO spic and span (neat and clean) Ø SEIKETSU standardization Ø SHITSUKE self discipline

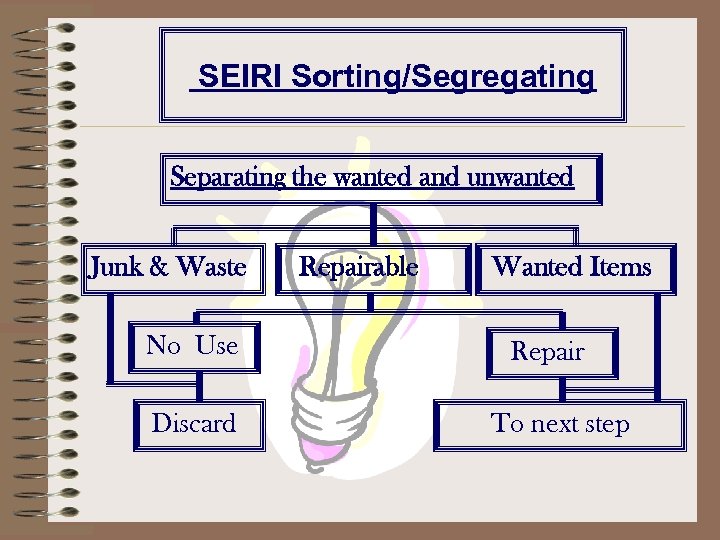

SEIRI Sorting/Segregating Separating the wanted and unwanted Junk & Waste No Use Discard Repairable Wanted Items Repair To next step

SEIRI Sorting/Segregating Separating the wanted and unwanted Junk & Waste No Use Discard Repairable Wanted Items Repair To next step

SEIRI Sorting/Segregating While doing Seiri keep in mind : üHow often things are used. ü What is the life if the material. ü Cost of the material ü Be sure to throw the things, otherwise you may repent.

SEIRI Sorting/Segregating While doing Seiri keep in mind : üHow often things are used. ü What is the life if the material. ü Cost of the material ü Be sure to throw the things, otherwise you may repent.

SEIRI Sorting/Segregating Consequences of not following SEIRI: • The wanted is hard to find, when required. • More space is demanded. • Unwanted items cause misidentification. • Misidentification causes errors in operation. • Maintenance cost of the equipments increases.

SEIRI Sorting/Segregating Consequences of not following SEIRI: • The wanted is hard to find, when required. • More space is demanded. • Unwanted items cause misidentification. • Misidentification causes errors in operation. • Maintenance cost of the equipments increases.

SEITON self arrangement/arranging Identifying places to arrange things and placing them in proper order for prompt usage. “A place for every thing and everything in its place. ” place

SEITON self arrangement/arranging Identifying places to arrange things and placing them in proper order for prompt usage. “A place for every thing and everything in its place. ” place

SEITON self arrangement/arranging While doing Seiton keep in mind : üThe right location where things will be used. üFIFO (First in First out) arrangement. üLabeling of the area and the equipment is very important. üKeep proper gaps between two things to avoid confusion.

SEITON self arrangement/arranging While doing Seiton keep in mind : üThe right location where things will be used. üFIFO (First in First out) arrangement. üLabeling of the area and the equipment is very important. üKeep proper gaps between two things to avoid confusion.

SEITON self arrangement/arranging Consequences of not following SEITON: • Things are seldom available when needed • Items get lost • Items get mixed up • Visual control not possible • Failure to achieve targets

SEITON self arrangement/arranging Consequences of not following SEITON: • Things are seldom available when needed • Items get lost • Items get mixed up • Visual control not possible • Failure to achieve targets

SEITON & VISUAL CONTROL • Good SEITON includes use of labels signs, indications, display, cautions • Use of labels signs, indications, display, cautions highlights difference between normality and abnormality. • Non - users of the equipments also become aware of its use and precautions.

SEITON & VISUAL CONTROL • Good SEITON includes use of labels signs, indications, display, cautions • Use of labels signs, indications, display, cautions highlights difference between normality and abnormality. • Non - users of the equipments also become aware of its use and precautions.

SEISO Spic and Span (Neat and Clean) Sweep your workplace thoroughly so that there is no dust/dirt/scrap anywhere. The area should say “ Who I’m” and its neatness should give you a natural welcome.

SEISO Spic and Span (Neat and Clean) Sweep your workplace thoroughly so that there is no dust/dirt/scrap anywhere. The area should say “ Who I’m” and its neatness should give you a natural welcome.

SEISO Spic and Span (Neat and Clean) While doing Seiso keep in mind : üCleaning should be done regularly. üUse the best cleaning agent. üAll the nooks and corners should be cleaned. üKeep all the labels intact. üAll the labels should correct, visible and legible to all.

SEISO Spic and Span (Neat and Clean) While doing Seiso keep in mind : üCleaning should be done regularly. üUse the best cleaning agent. üAll the nooks and corners should be cleaned. üKeep all the labels intact. üAll the labels should correct, visible and legible to all.

Spic and Span (Neat and Clean) Consequences of not practicing SEISO: • • Performance of machines deteriorates The quality / aesthetic quality deteriorates Dirty place is unpleasant and hazardous to health. Sends uncaring and irresponsible message to the team members and society at large. • People working at dirty areas are generally found to have low desire to excel and their motivation level is low.

Spic and Span (Neat and Clean) Consequences of not practicing SEISO: • • Performance of machines deteriorates The quality / aesthetic quality deteriorates Dirty place is unpleasant and hazardous to health. Sends uncaring and irresponsible message to the team members and society at large. • People working at dirty areas are generally found to have low desire to excel and their motivation level is low.

SEIKETSU (standardization) • Always aim at maintaining the standard level of cleanliness, hygiene and visual control. • Keep all the 4 M’s ( Man. , Machine, Material and Method) intact, a lapse in any one of them will make you loose the rest of the three

SEIKETSU (standardization) • Always aim at maintaining the standard level of cleanliness, hygiene and visual control. • Keep all the 4 M’s ( Man. , Machine, Material and Method) intact, a lapse in any one of them will make you loose the rest of the three

SEIKETSU (standardization) While doing Seiketsu keep in mind : üThe standards should be arrived at unanimously. üAlways keep the standards flexible to changes and improvements. üStandards should be known to all and displayed.

SEIKETSU (standardization) While doing Seiketsu keep in mind : üThe standards should be arrived at unanimously. üAlways keep the standards flexible to changes and improvements. üStandards should be known to all and displayed.

s. Ei. KEts. U (standardization) ØConsequences of not following Seiketsu : • Dual standards yield multiple results. • Multiple results lead to conflicts and confusions. • Rework increases the basic cost of the finished product without any value addition

s. Ei. KEts. U (standardization) ØConsequences of not following Seiketsu : • Dual standards yield multiple results. • Multiple results lead to conflicts and confusions. • Rework increases the basic cost of the finished product without any value addition

SEIKETSU (standardization) Ø The Essence of Seiketsu – It is the proof that 3 -S (SEIRI, SEITON, SEISO) are being religiously carried out. – It is the barometer which indicates the control level based on the 5 -S of all the workers.

SEIKETSU (standardization) Ø The Essence of Seiketsu – It is the proof that 3 -S (SEIRI, SEITON, SEISO) are being religiously carried out. – It is the barometer which indicates the control level based on the 5 -S of all the workers.

SHITSUKE (Self-Discipline) • If you are disciplined. : – Rules will always be followed. – Laid down targets will be achieved. – Improvements will be promoted. – The no. of defects will be reduced. – The cost will not increase.

SHITSUKE (Self-Discipline) • If you are disciplined. : – Rules will always be followed. – Laid down targets will be achieved. – Improvements will be promoted. – The no. of defects will be reduced. – The cost will not increase.

SHITSUKE (Self-Discipline) ØHow to practice SHITSUKE • Train all team members on 4 -S • Correct wrong practices on the spot • Punctuality is the backbone of 5 S • Follow work instructions.

SHITSUKE (Self-Discipline) ØHow to practice SHITSUKE • Train all team members on 4 -S • Correct wrong practices on the spot • Punctuality is the backbone of 5 S • Follow work instructions.

think locally act globally

think locally act globally

5 - S HOUSE KEEPING Following 5 S will help you : Maintain good product quality. Improve your efficiency and productivity Maintain good control over the processes Ensure safety and cleanliness.

5 - S HOUSE KEEPING Following 5 S will help you : Maintain good product quality. Improve your efficiency and productivity Maintain good control over the processes Ensure safety and cleanliness.