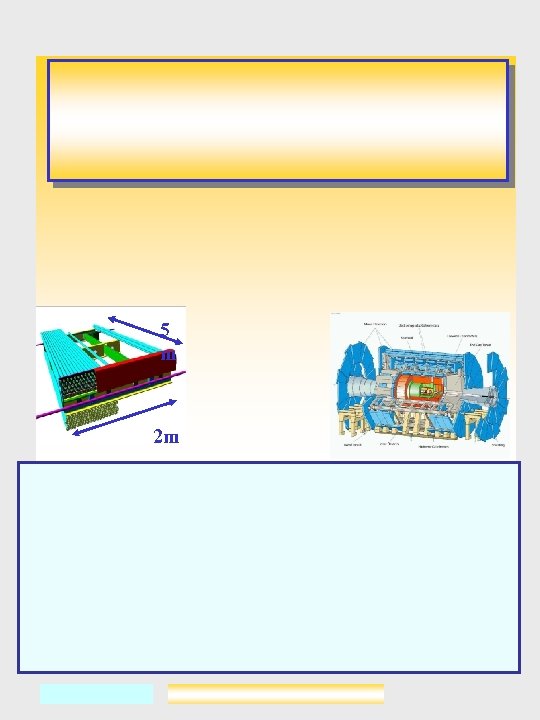

5 m 2 m

5 m 2 m

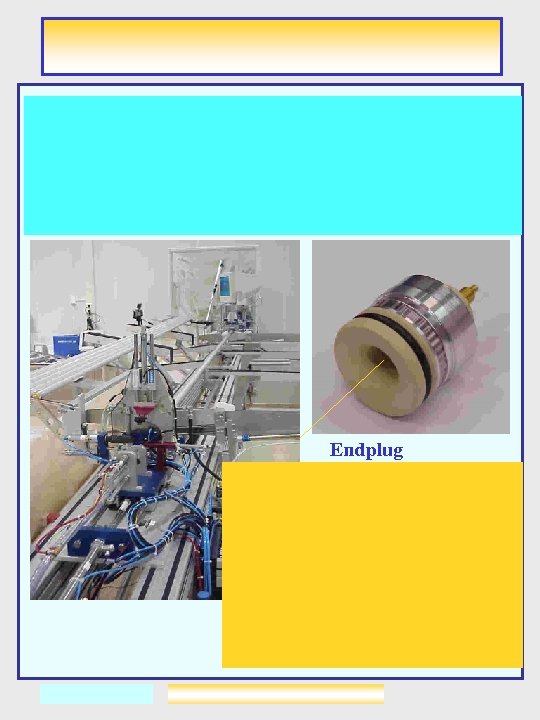

Endplug

Endplug

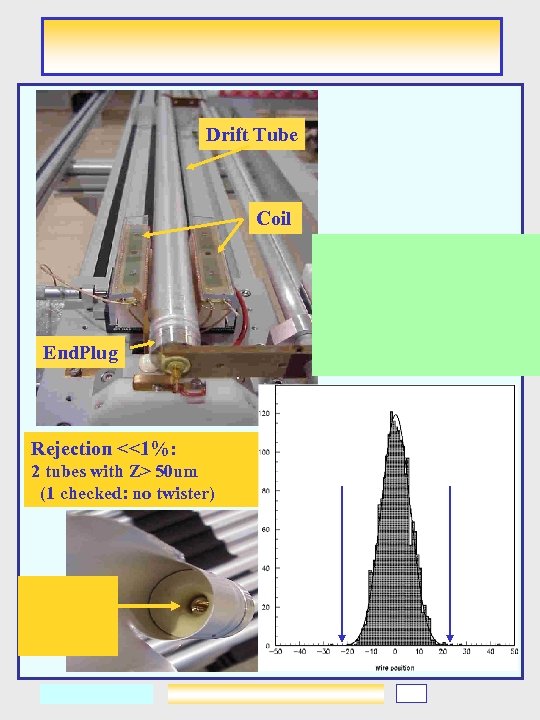

Drift Tube Coil End. Plug Rejection <<1%: 2 tubes with Z> 50 um (1 checked: no twister)

Drift Tube Coil End. Plug Rejection <<1%: 2 tubes with Z> 50 um (1 checked: no twister)

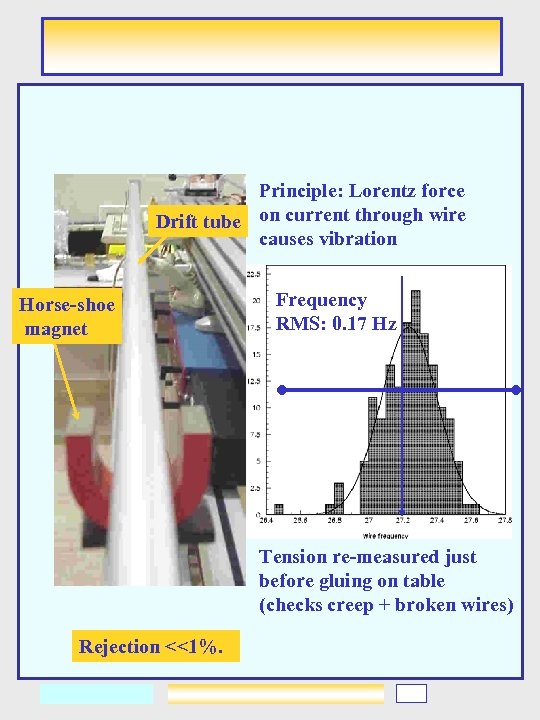

Principle: Lorentz force Drift tube on current through wire causes vibration Horse-shoe magnet Frequency RMS: 0. 17 Hz Tension re-measured just before gluing on table (checks creep + broken wires) Rejection <<1%.

Principle: Lorentz force Drift tube on current through wire causes vibration Horse-shoe magnet Frequency RMS: 0. 17 Hz Tension re-measured just before gluing on table (checks creep + broken wires) Rejection <<1%.

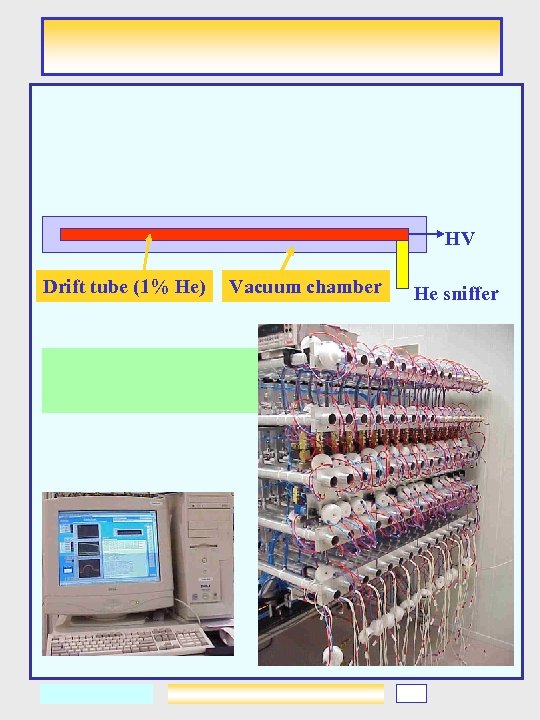

HV Drift tube (1% He) Vacuum chamber He sniffer

HV Drift tube (1% He) Vacuum chamber He sniffer

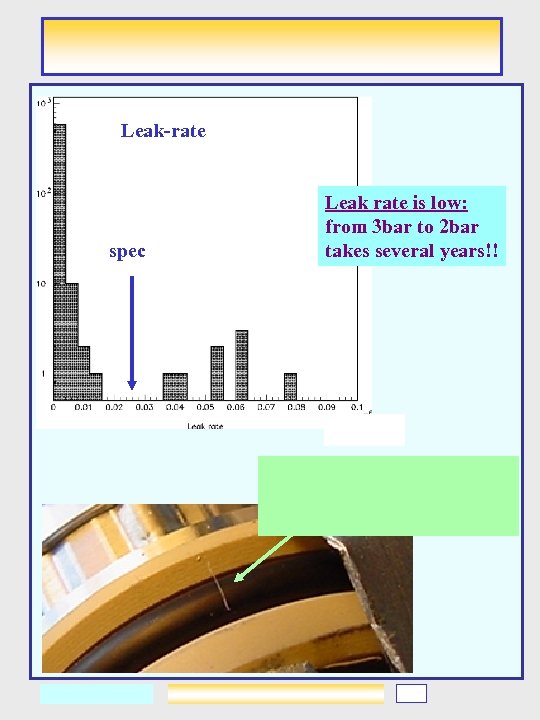

Leak-rate spec Leak rate is low: from 3 bar to 2 bar takes several years!!

Leak-rate spec Leak rate is low: from 3 bar to 2 bar takes several years!!

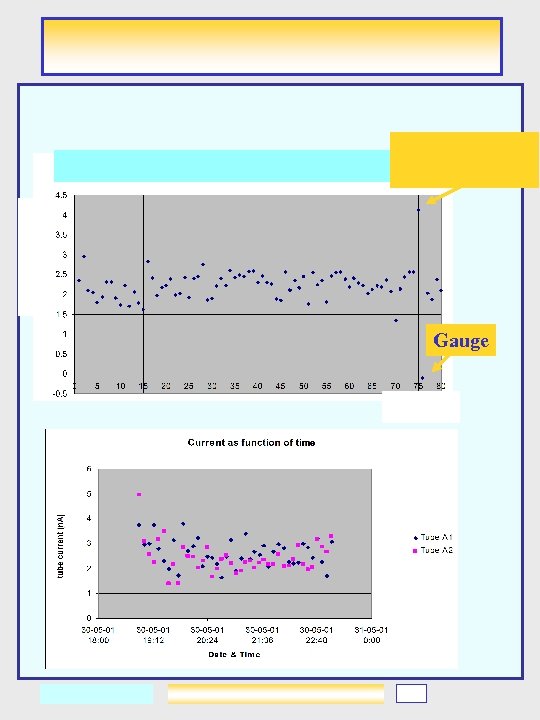

Gauge

Gauge

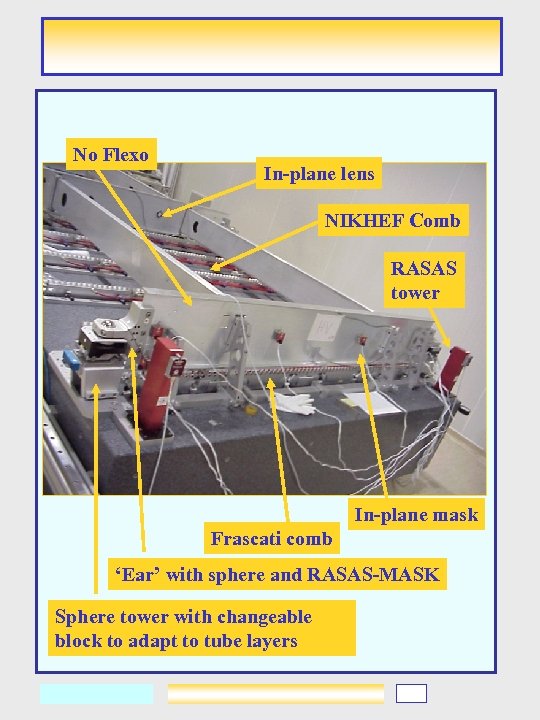

No Flexo In-plane lens NIKHEF Comb RASAS tower In-plane mask Frascati comb ‘Ear’ with sphere and RASAS-MASK Sphere tower with changeable block to adapt to tube layers

No Flexo In-plane lens NIKHEF Comb RASAS tower In-plane mask Frascati comb ‘Ear’ with sphere and RASAS-MASK Sphere tower with changeable block to adapt to tube layers

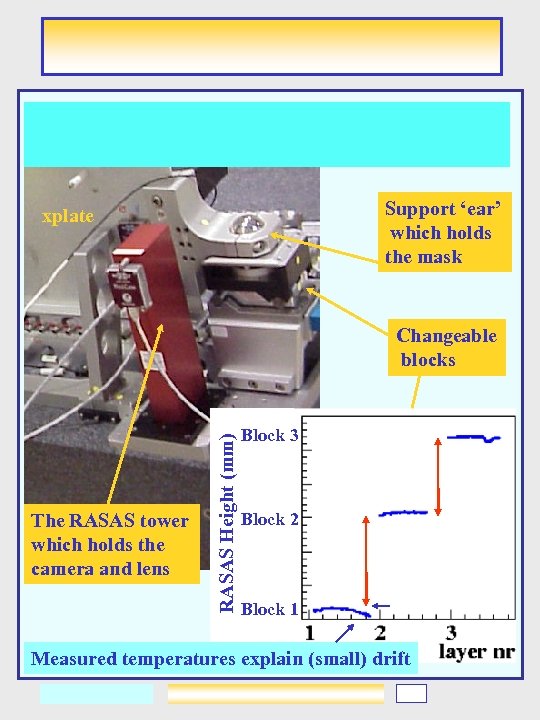

Support ‘ear’ which holds the mask xplate The RASAS tower which holds the camera and lens RASAS Height (mm) Changeable blocks Block 3 Block 2 Block 1 Measured temperatures explain (small) drift

Support ‘ear’ which holds the mask xplate The RASAS tower which holds the camera and lens RASAS Height (mm) Changeable blocks Block 3 Block 2 Block 1 Measured temperatures explain (small) drift

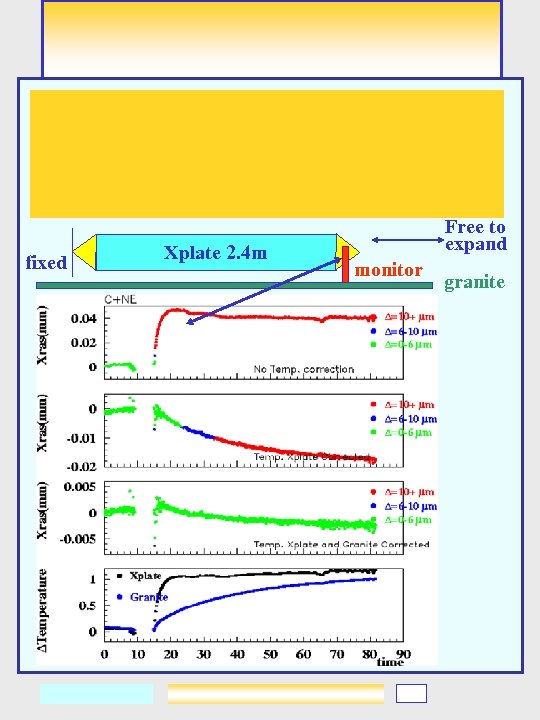

fixed Xplate 2. 4 m Free to expand monitor granite

fixed Xplate 2. 4 m Free to expand monitor granite

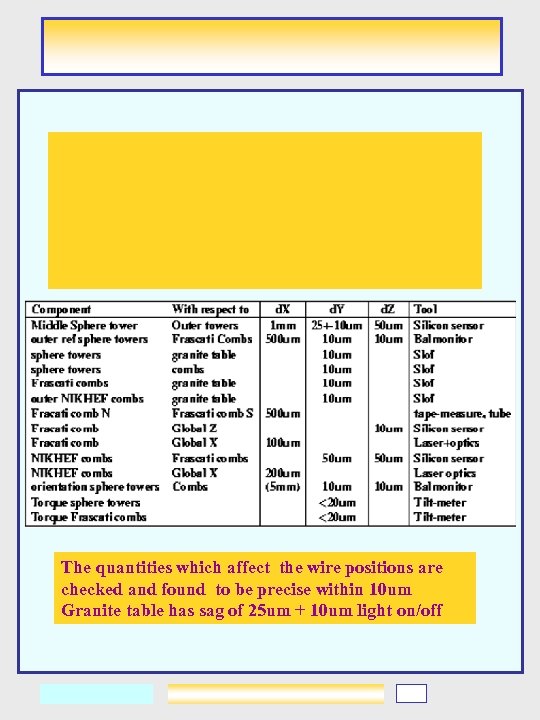

The quantities which affect the wire positions are checked and found to be precise within 10 um Granite table has sag of 25 um + 10 um light on/off

The quantities which affect the wire positions are checked and found to be precise within 10 um Granite table has sag of 25 um + 10 um light on/off

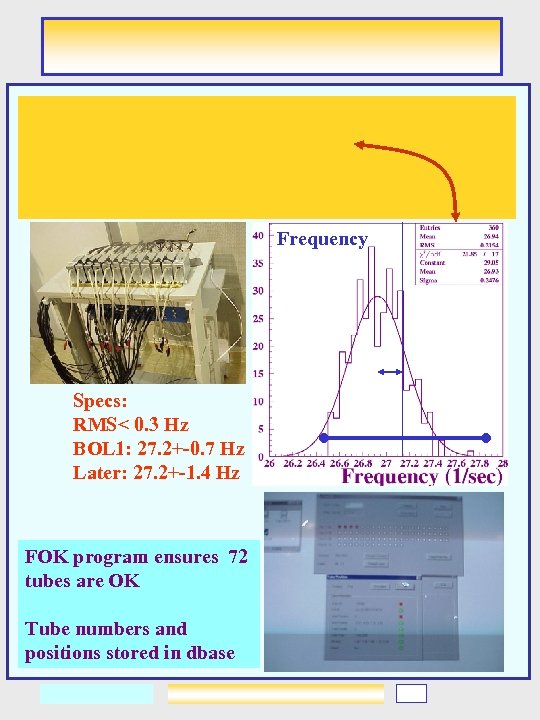

Frequency Specs: RMS< 0. 3 Hz BOL 1: 27. 2+-0. 7 Hz Later: 27. 2+-1. 4 Hz FOK program ensures 72 tubes are OK Tube numbers and positions stored in dbase

Frequency Specs: RMS< 0. 3 Hz BOL 1: 27. 2+-0. 7 Hz Later: 27. 2+-1. 4 Hz FOK program ensures 72 tubes are OK Tube numbers and positions stored in dbase

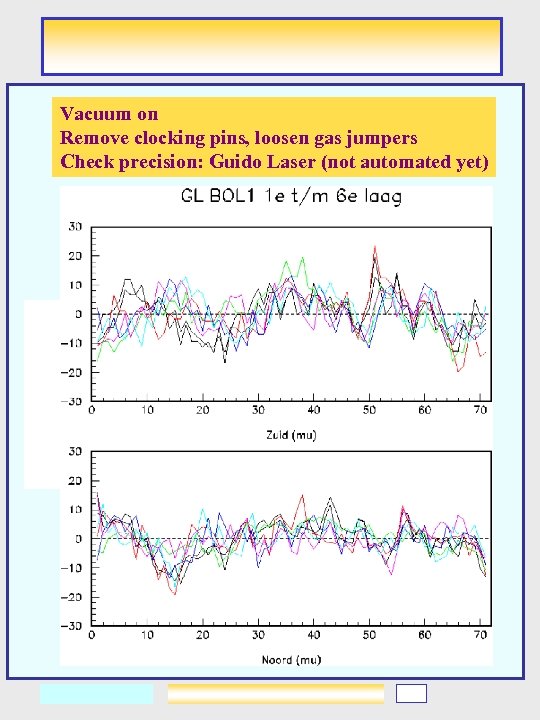

Vacuum on Remove clocking pins, loosen gas jumpers Check precision: Guido Laser (not automated yet)

Vacuum on Remove clocking pins, loosen gas jumpers Check precision: Guido Laser (not automated yet)

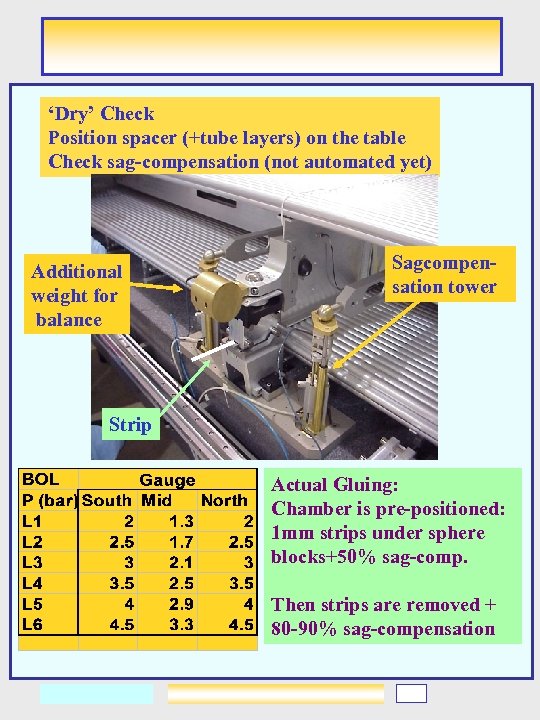

‘Dry’ Check Position spacer (+tube layers) on the table Check sag-compensation (not automated yet) Additional weight for balance Sagcompensation tower Strip Actual Gluing: Chamber is pre-positioned: 1 mm strips under sphere blocks+50% sag-comp. Then strips are removed + 80 -90% sag-compensation

‘Dry’ Check Position spacer (+tube layers) on the table Check sag-compensation (not automated yet) Additional weight for balance Sagcompensation tower Strip Actual Gluing: Chamber is pre-positioned: 1 mm strips under sphere blocks+50% sag-comp. Then strips are removed + 80 -90% sag-compensation

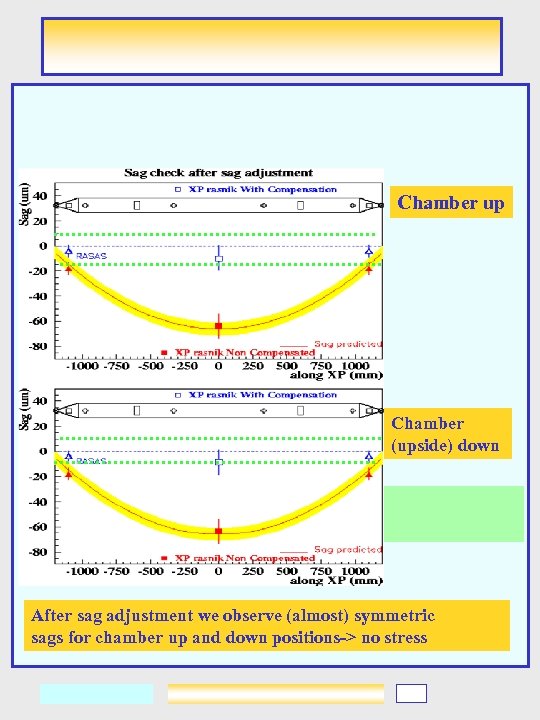

Chamber up Chamber (upside) down After sag adjustment we observe (almost) symmetric sags for chamber up and down positions-> no stress

Chamber up Chamber (upside) down After sag adjustment we observe (almost) symmetric sags for chamber up and down positions-> no stress

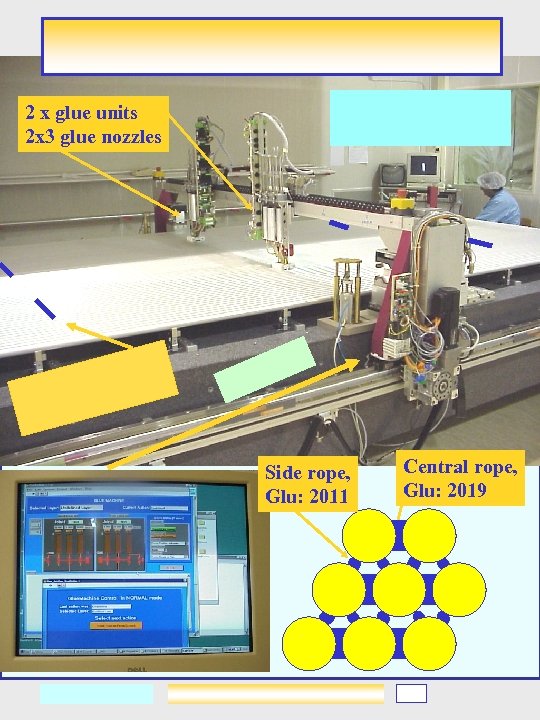

2 x glue units 2 x 3 glue nozzles Side rope, Glu: 2011 Central rope, Glu: 2019

2 x glue units 2 x 3 glue nozzles Side rope, Glu: 2011 Central rope, Glu: 2019

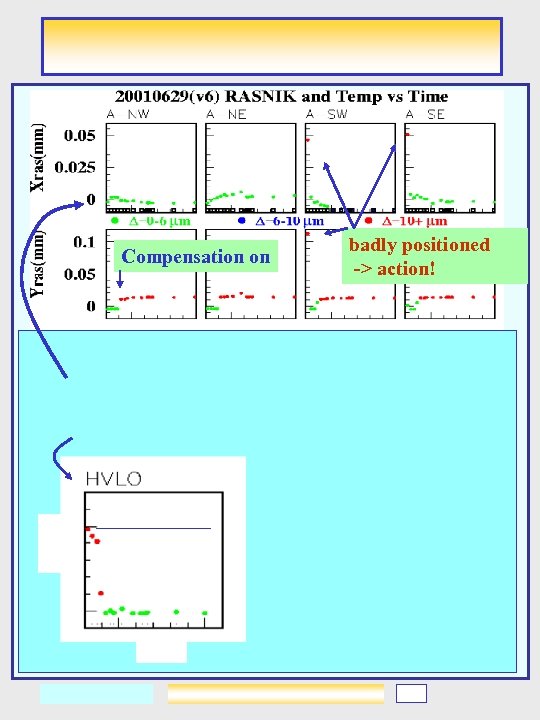

Compensation on badly positioned -> action!

Compensation on badly positioned -> action!

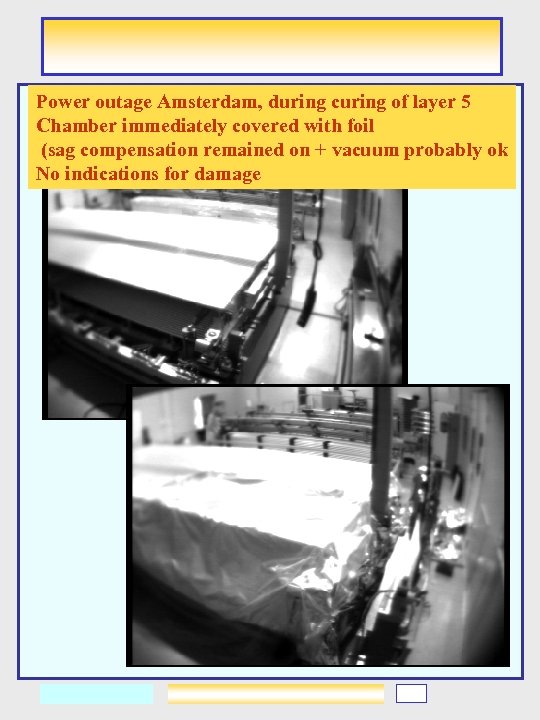

Power outage Amsterdam, during curing of layer 5 Chamber immediately covered with foil (sag compensation remained on + vacuum probably ok No indications for damage

Power outage Amsterdam, during curing of layer 5 Chamber immediately covered with foil (sag compensation remained on + vacuum probably ok No indications for damage

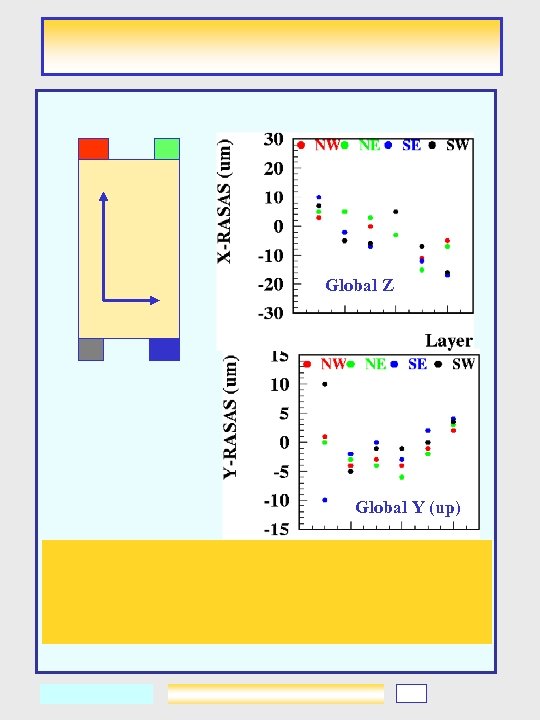

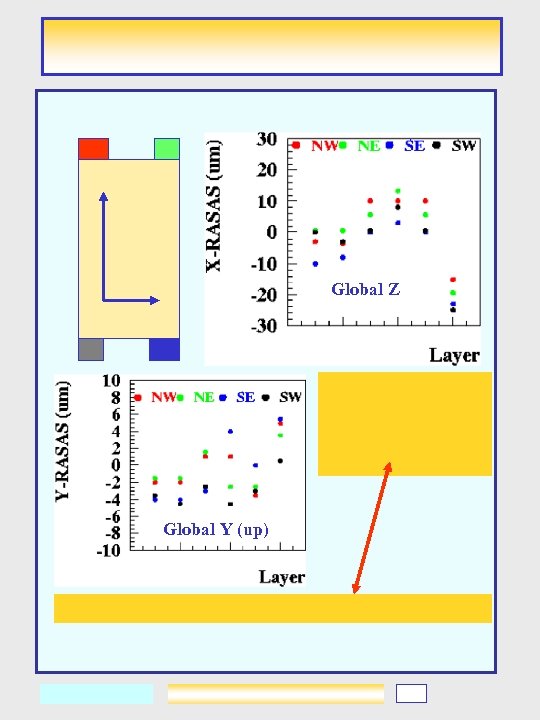

Global Z Global Y (up)

Global Z Global Y (up)

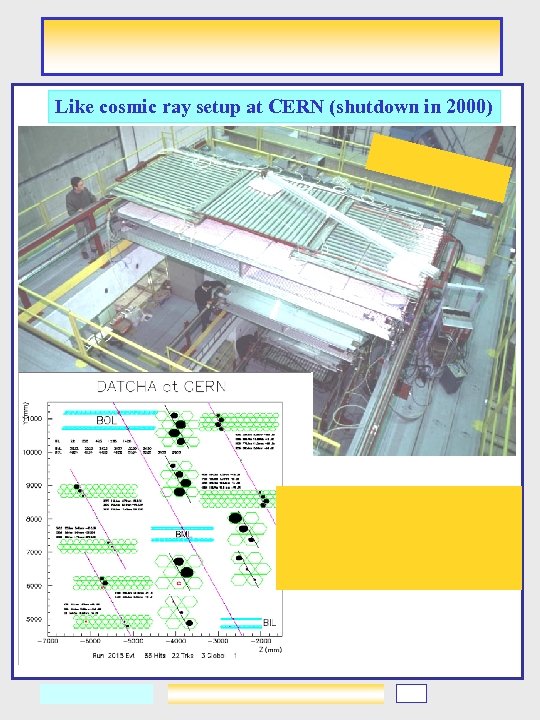

Like cosmic ray setup at CERN (shutdown in 2000)

Like cosmic ray setup at CERN (shutdown in 2000)

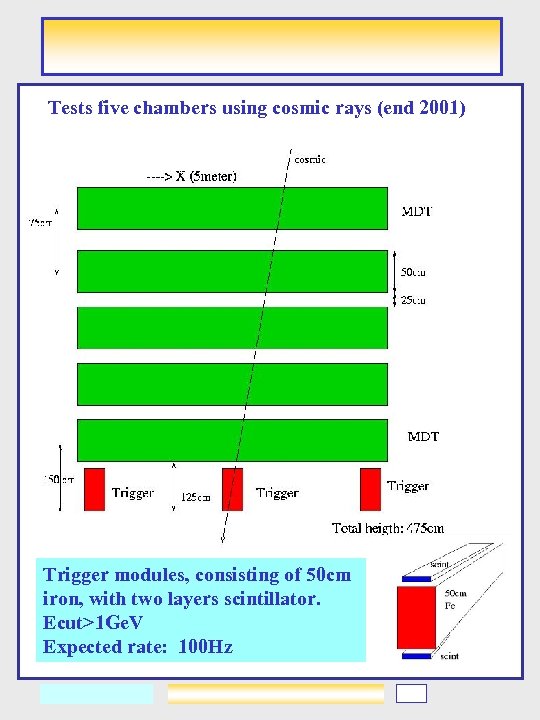

Tests five chambers using cosmic rays (end 2001) Trigger modules, consisting of 50 cm iron, with two layers scintillator. Ecut>1 Ge. V Expected rate: 100 Hz

Tests five chambers using cosmic rays (end 2001) Trigger modules, consisting of 50 cm iron, with two layers scintillator. Ecut>1 Ge. V Expected rate: 100 Hz

Global Z Global Y (up)

Global Z Global Y (up)