2b5697e5ee941f83913c4093c1c634ab.ppt

- Количество слайдов: 77

4 m. Blanco TCS Upgrade: Electronic Control and Drivers Eduardo Mondaca

Where we started? : Brief Review

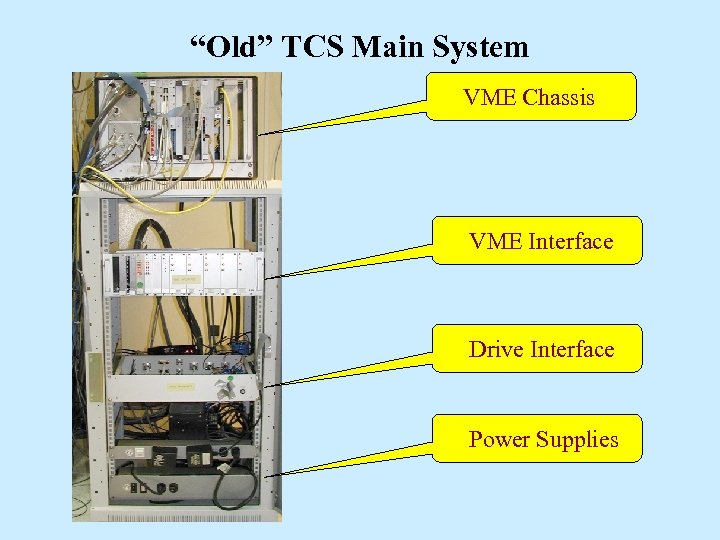

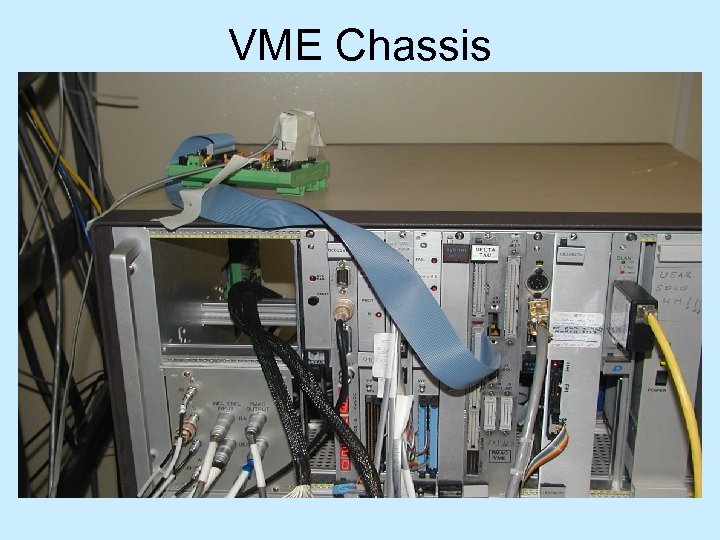

“Old” TCS Main System VME Chassis VME Interface Drive Interface Power Supplies

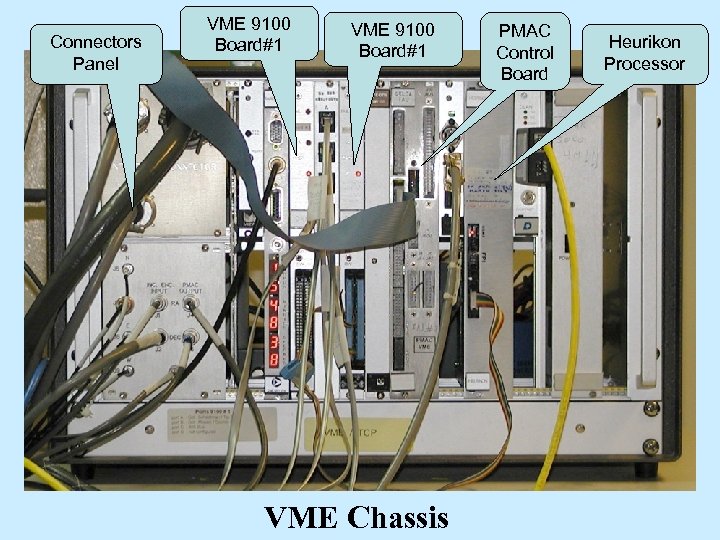

Connectors Panel VME 9100 Board#1 VME Chassis PMAC Control Board Heurikon Processor

VME Chassis

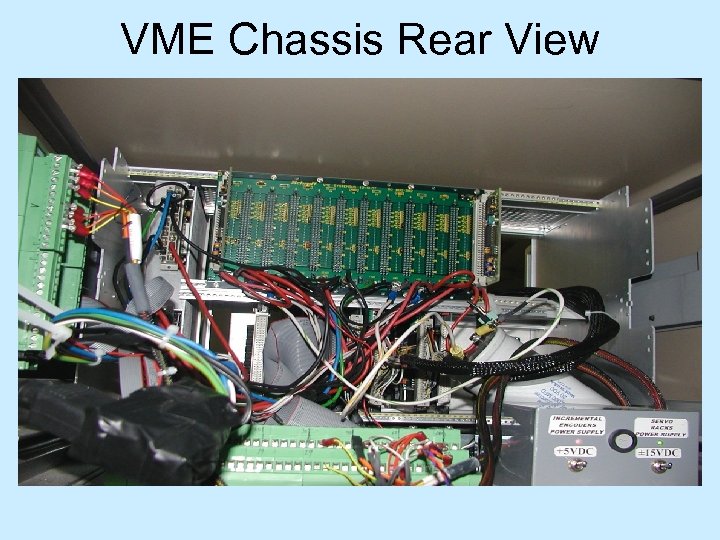

VME Chassis Rear View

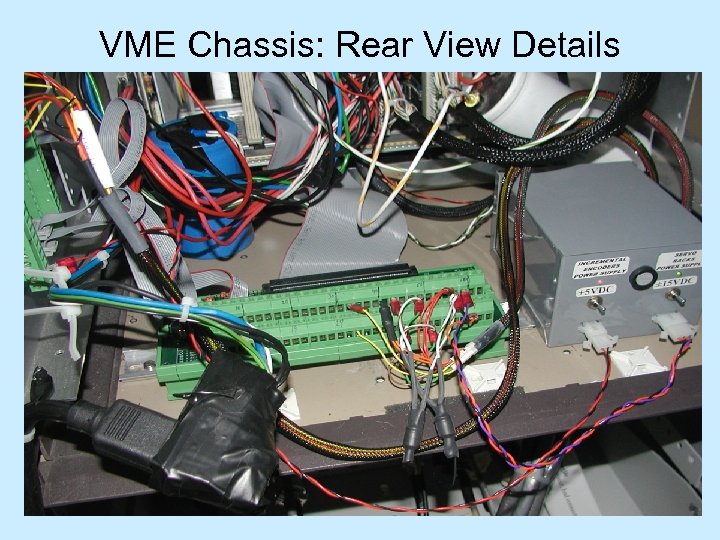

VME Chassis: Rear View Details

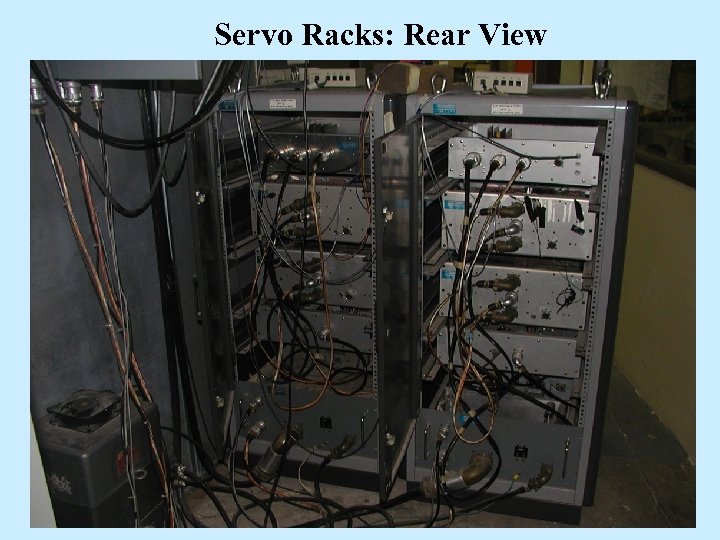

Servo Racks DEC Servo Rack RA Servo Rack

Servo Racks: Rear View

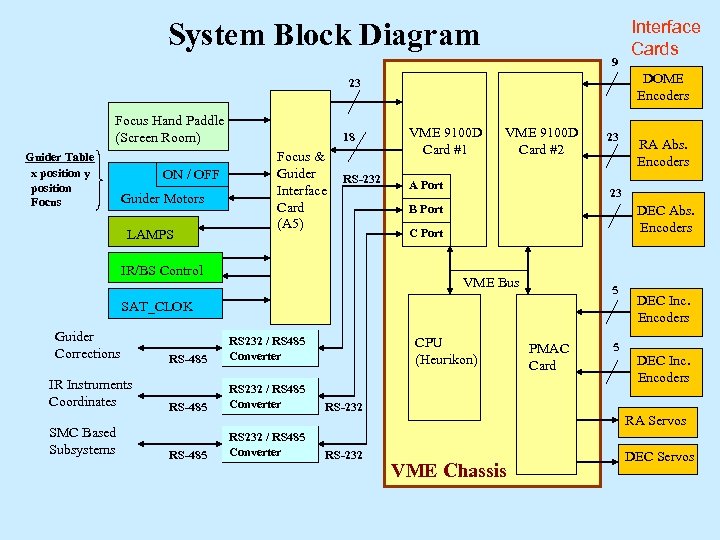

System Block Diagram 9 DOME Encoders 23 Focus Hand Paddle (Screen Room) Guider Table x position y position Focus ON / OFF Guider Motors LAMPS 18 Focus & Guider Interface Card (A 5) VME 9100 D Card #1 RS-232 A Port IR/BS Control VME 9100 D Card #2 23 B Port DEC Abs. Encoders C Port VME Bus IR Instruments Coordinates SMC Based Subsystems RS-485 RS 232 / RS 485 Converter CPU (Heurikon) RS-232 RA Abs. Encoders 23 5 SAT_CLOK Guider Corrections Interface Cards PMAC Card 5 DEC Inc. Encoders RA Servos VME Chassis DEC Servos

What we wanted?

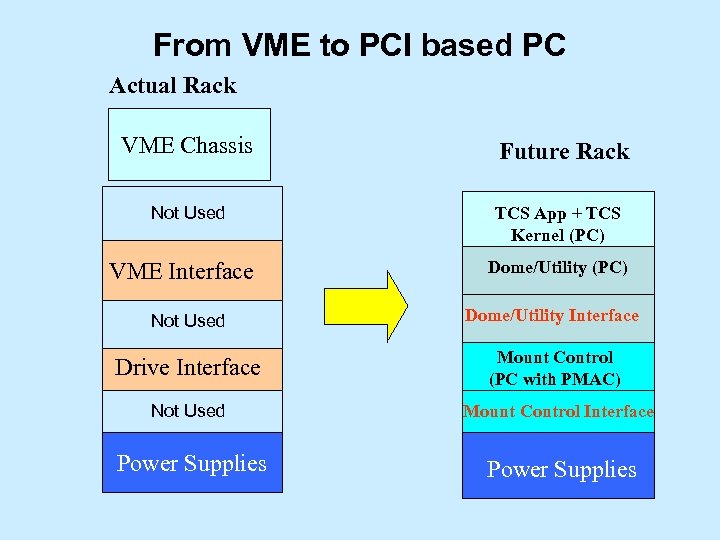

From VME to PCI based PC Actual Rack VME Chassis Not Used VME Interface Future Rack TCS App + TCS Kernel (PC) Dome/Utility (PC) Not Used Dome/Utility Interface Drive Interface Mount Control (PC with PMAC) Not Used Mount Control Interface Power Supplies

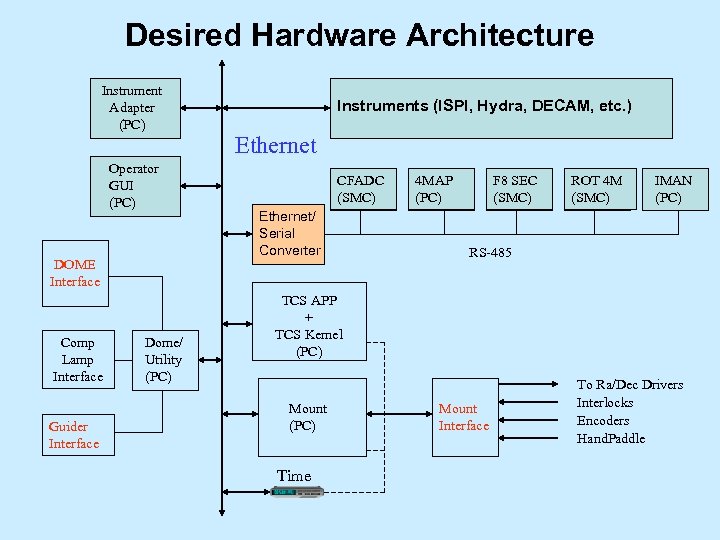

Desired Hardware Architecture Instrument Adapter (PC) Operator GUI (PC) DOME Interface Comp Lamp Interface Guider Interface Dome/ Utility (PC) Instruments (ISPI, Hydra, DECAM, etc. ) Ethernet CFADC (SMC) Ethernet/ Serial Converter 4 MAP (PC) F 8 SEC (SMC) ROT 4 M (SMC) IMAN (PC) RS-485 TCS APP + TCS Kernel (PC) Mount (PC) Time Mount Interface To Ra/Dec Drivers Interlocks Encoders Hand. Paddle

Constrains • Changes should be done in steps that permit to return quickly to the last state if something fails. • Minimize the impact on the normal telescope operation (e. g. Calibrations during daytime).

The First Steps: Intercepting the Signals

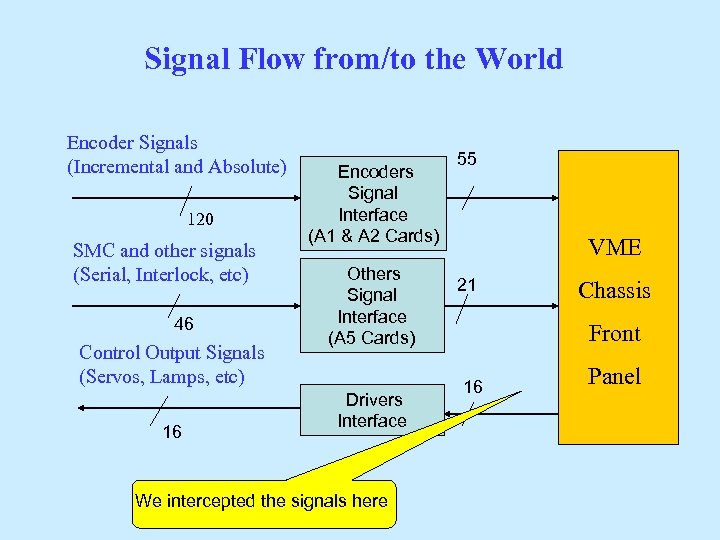

Signal Flow from/to the World Encoder Signals (Incremental and Absolute) 120 SMC and other signals (Serial, Interlock, etc) 46 Control Output Signals (Servos, Lamps, etc) 16 Encoders Signal Interface (A 1 & A 2 Cards) Others Signal Interface (A 5 Cards) Drivers Interface We intercepted the signals here 55 VME 21 Chassis Front 16 Panel

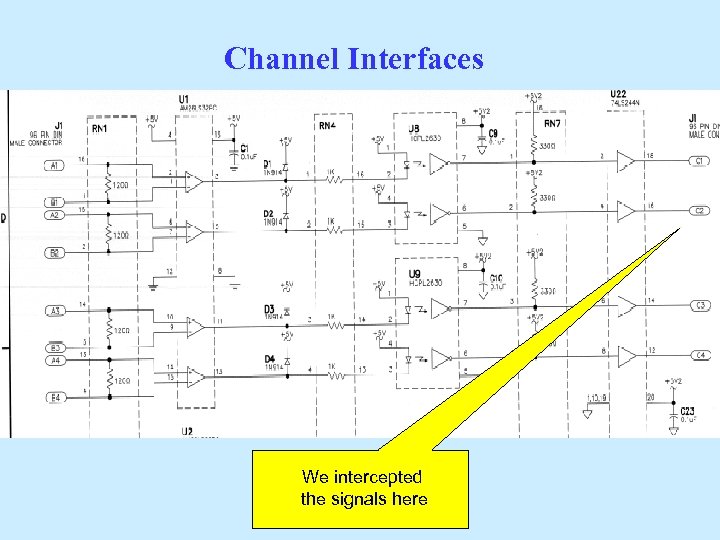

Channel Interfaces We intercepted the signals here

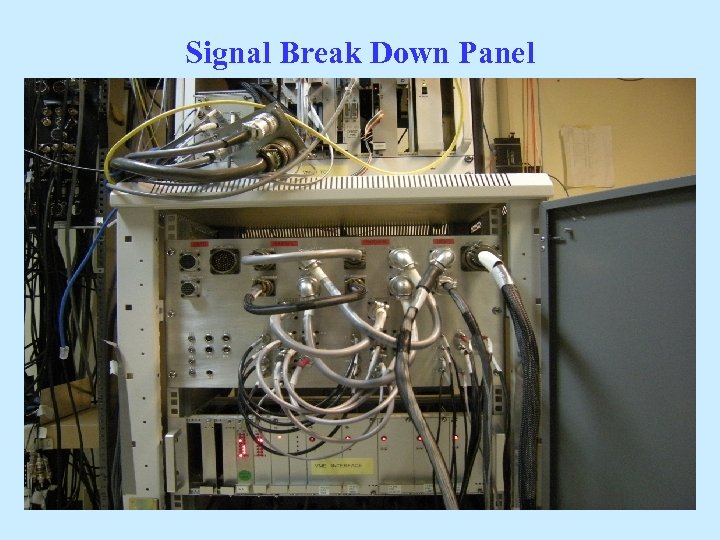

Signal Break Down Panel

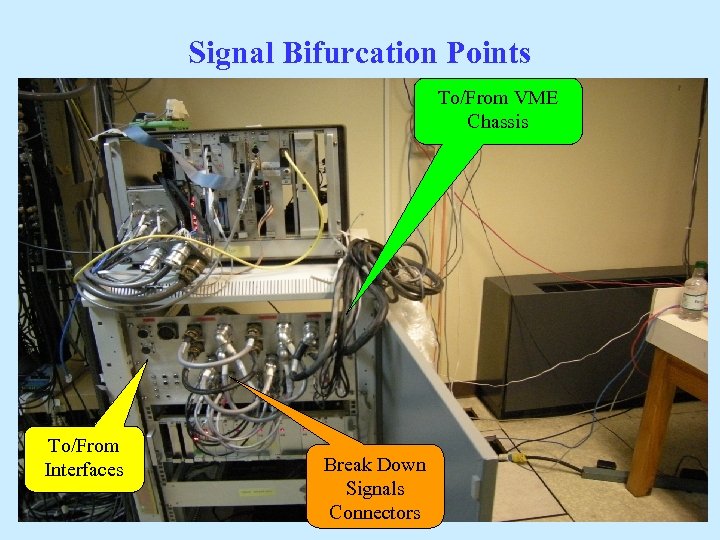

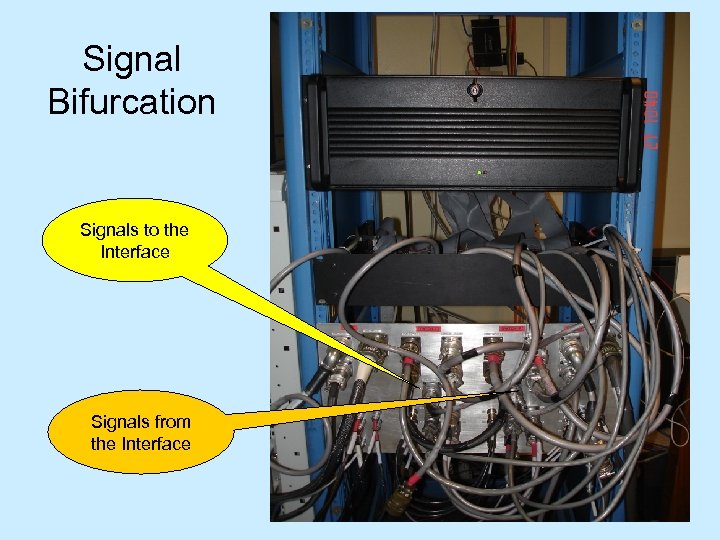

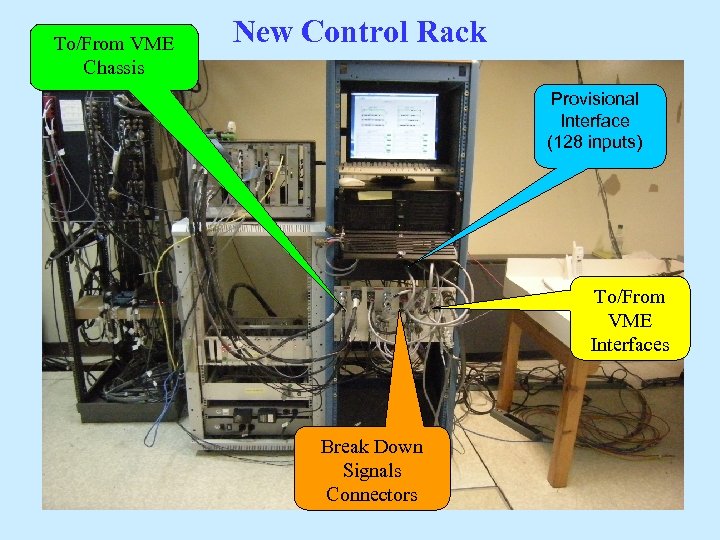

Signal Bifurcation Points To/From VME Chassis To/From Interfaces Break Down Signals Connectors

Second Step: Signal Acquisition

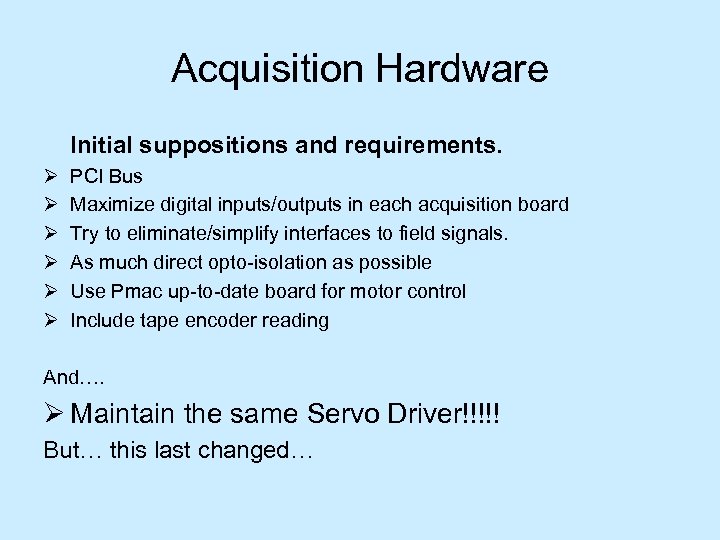

Acquisition Hardware Initial suppositions and requirements. Ø Ø Ø PCI Bus Maximize digital inputs/outputs in each acquisition board Try to eliminate/simplify interfaces to field signals. As much direct opto-isolation as possible Use Pmac up-to-date board for motor control Include tape encoder reading And…. Ø Maintain the same Servo Driver!!!!! But… this last changed…

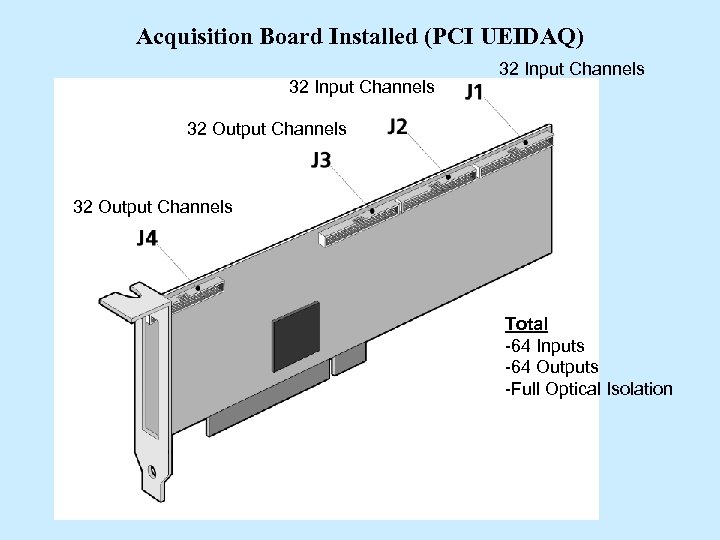

Acquisition Board Installed (PCI UEIDAQ) 32 Input Channels 32 Output Channels Total -64 Inputs -64 Outputs -Full Optical Isolation

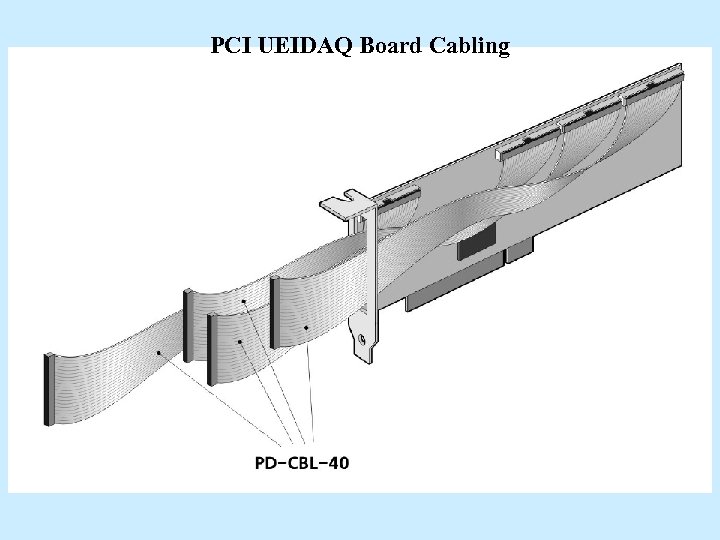

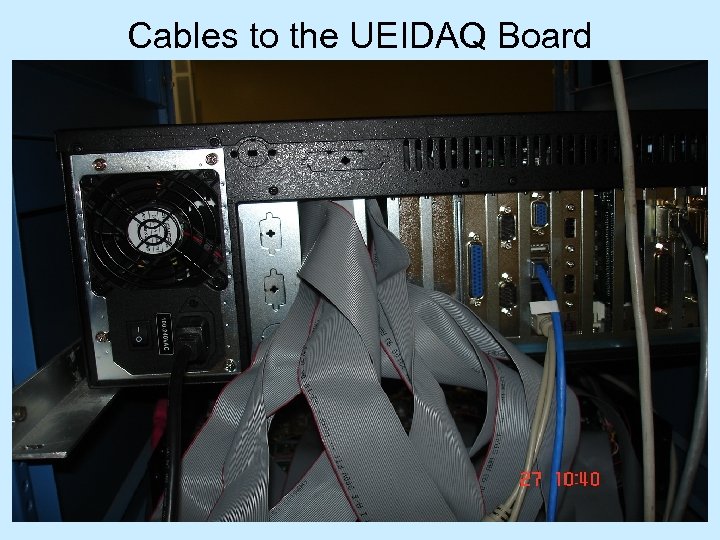

PCI UEIDAQ Board Cabling

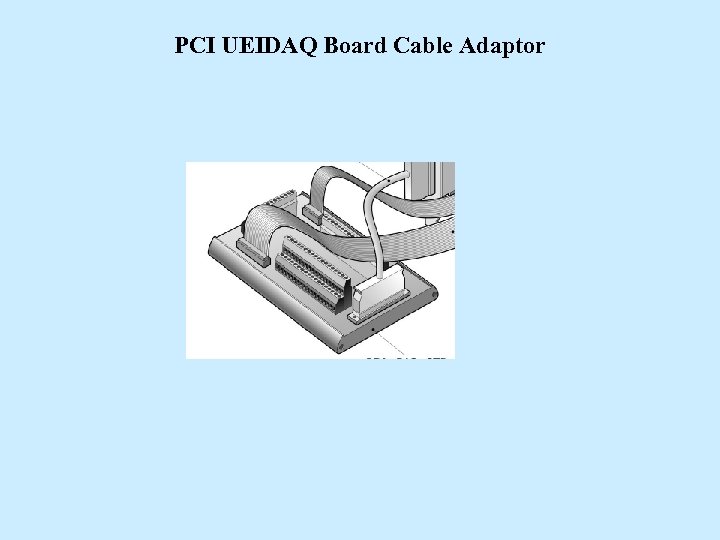

PCI UEIDAQ Board Cable Adaptor

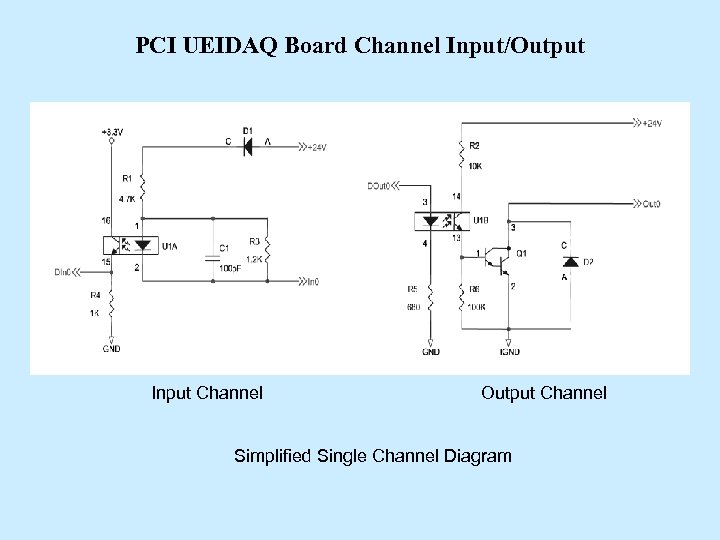

PCI UEIDAQ Board Channel Input/Output Input Channel Output Channel Simplified Single Channel Diagram

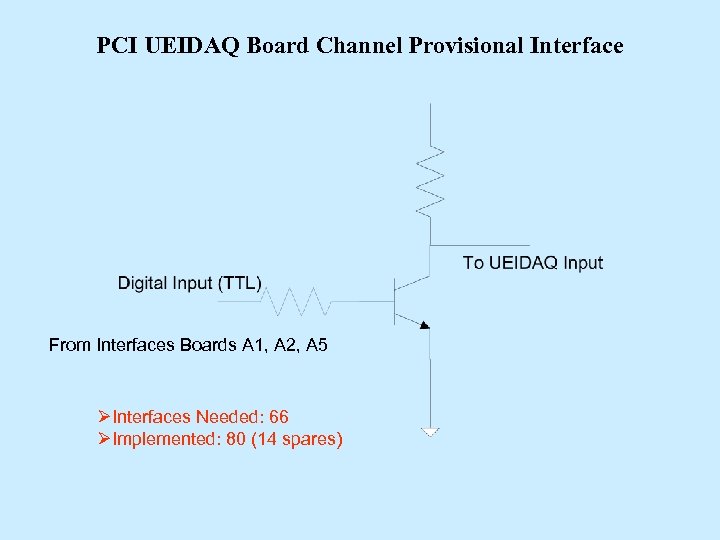

PCI UEIDAQ Board Channel Provisional Interface From Interfaces Boards A 1, A 2, A 5 ØInterfaces Needed: 66 ØImplemented: 80 (14 spares)

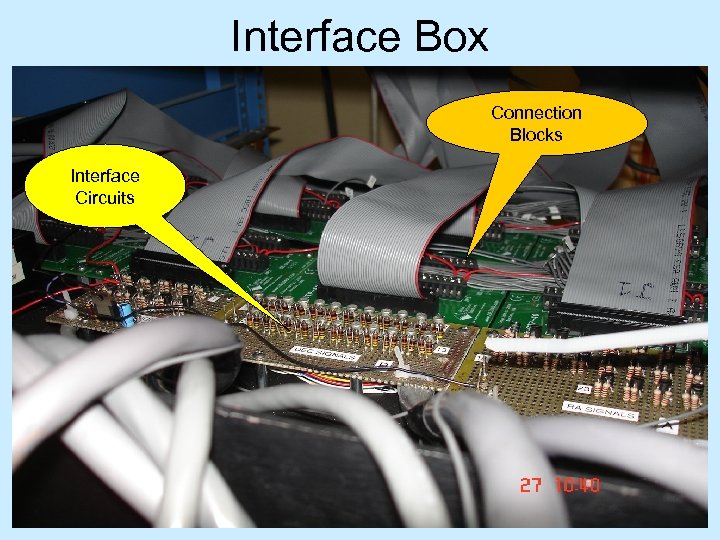

Interface Box Connection Blocks Interface Circuits

Signal Bifurcation Signals to the Interface Signals from the Interface

Cables to the UEIDAQ Board

To/From VME Chassis New Control Rack Provisional Interface (128 inputs) To/From VME Interfaces Break Down Signals Connectors

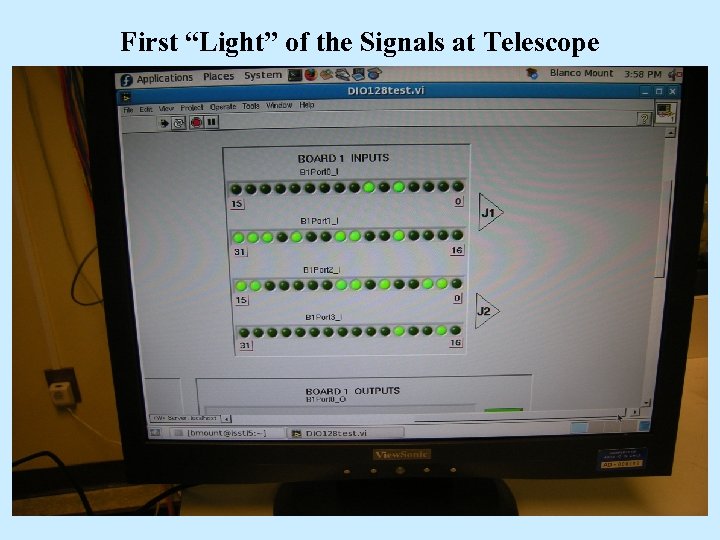

First “Light” of the Signals at Telescope

The Control Side: First Approach

Initial Goals • • • Re-use as much as possible the low level software Delta-Tau Turbo PMAC based control Use Delta-Tau Interpolator to read tape encoder PCI bus based system Real Time Linux Environment Maintain Servo Drivers!!!

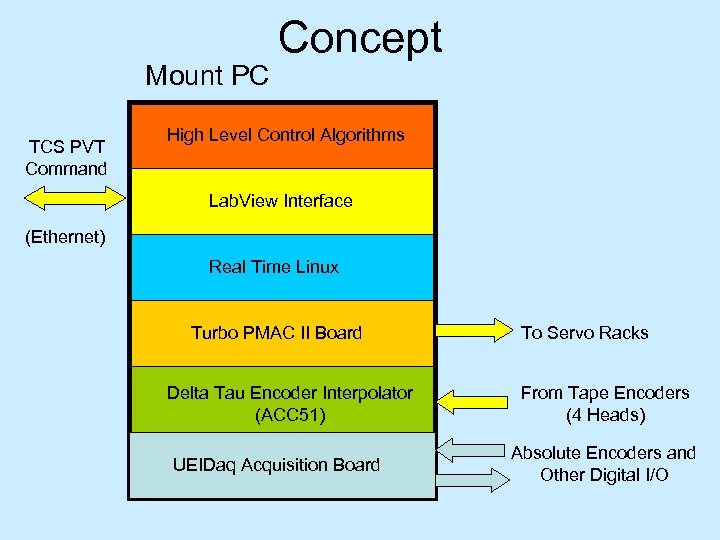

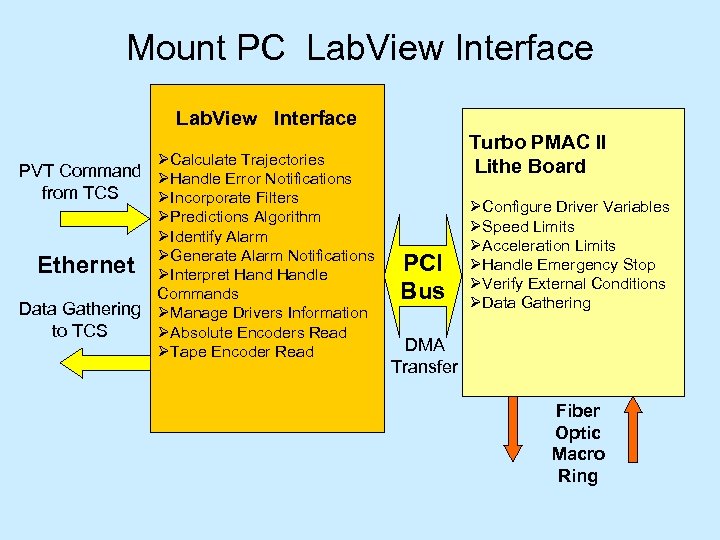

Mount PC TCS PVT Command Concept High Level Control Algorithms Lab. View Interface (Ethernet) Real Time Linux Turbo PMAC II Board Delta Tau Encoder Interpolator (ACC 51) UEIDaq Acquisition Board To Servo Racks From Tape Encoders (4 Heads) Absolute Encoders and Other Digital I/O

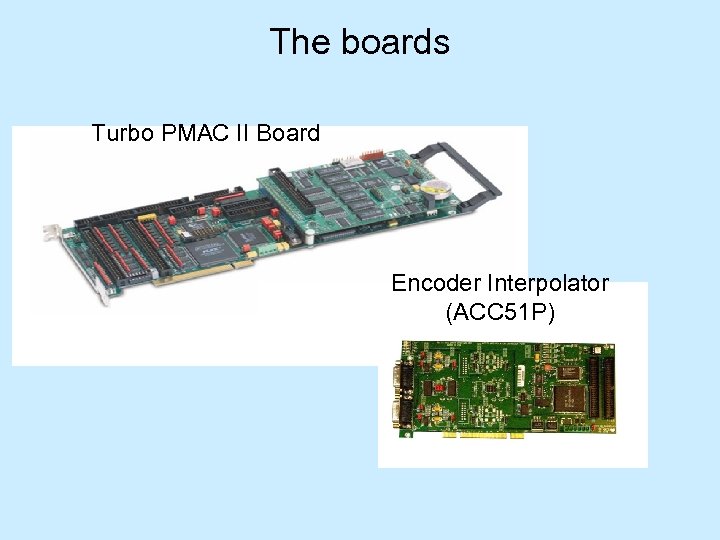

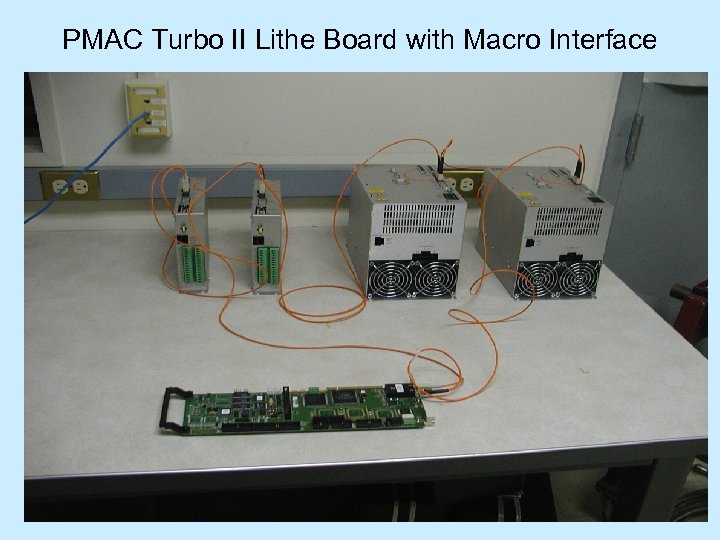

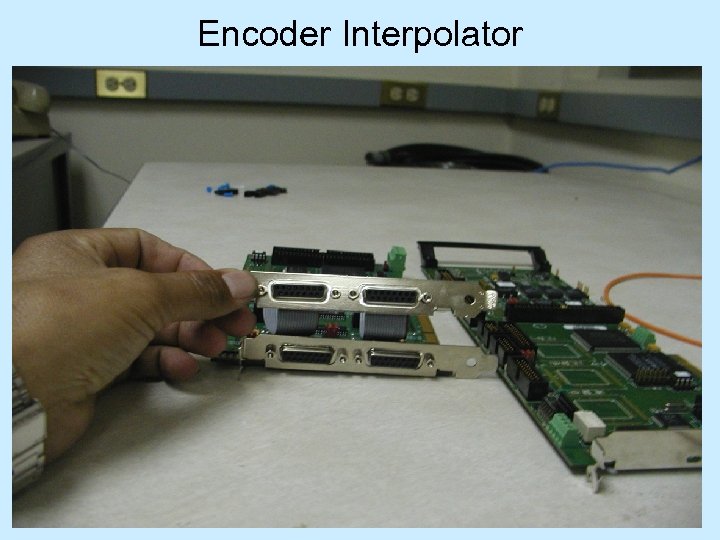

The boards Turbo PMAC II Board Encoder Interpolator (ACC 51 P)

New Goals: Change the Drivers Too

Servo Racks DEC Servo Rack RA Servo Rack

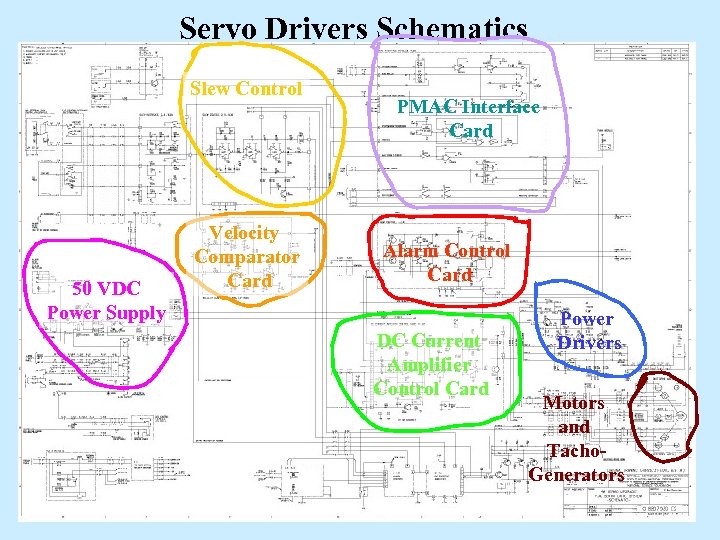

Servo Drivers Schematics Slew Control 50 VDC Power Supply Velocity Comparator Card PMAC Interface Card Alarm Control Card DC Current Amplifier Control Card Power Drivers Motors and Tacho. Generators

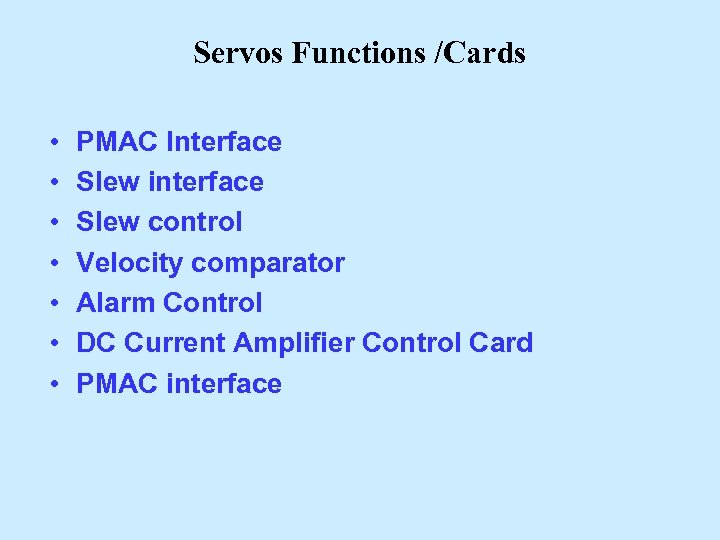

Servos Functions /Cards • • PMAC Interface Slew interface Slew control Velocity comparator Alarm Control DC Current Amplifier Control Card PMAC interface

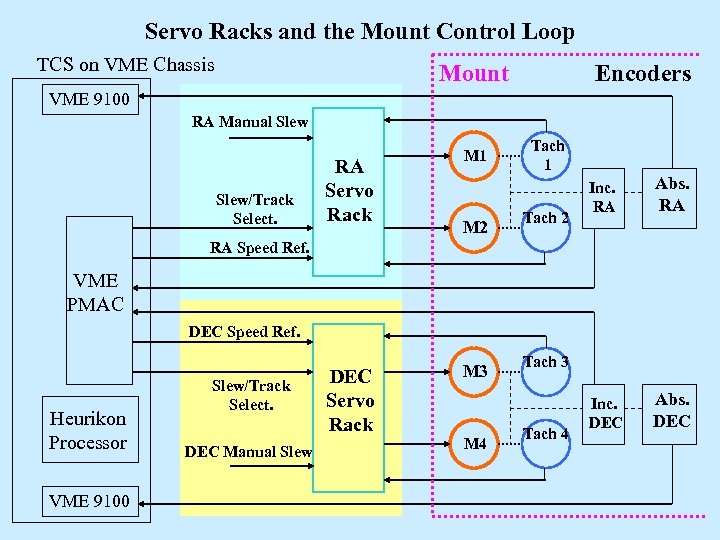

Servo Racks and the Mount Control Loop TCS on VME Chassis Mount Encoders VME 9100 RA Manual Slew/Track Select. RA Servo Rack M 1 M 2 Tach 1 Tach 2 Inc. RA Abs. RA Inc. DEC Abs. DEC RA Speed Ref. VME PMAC DEC Speed Ref. Heurikon Processor VME 9100 Slew/Track Select. DEC Manual Slew DEC Servo Rack M 3 M 4 Tach 3 Tach 4

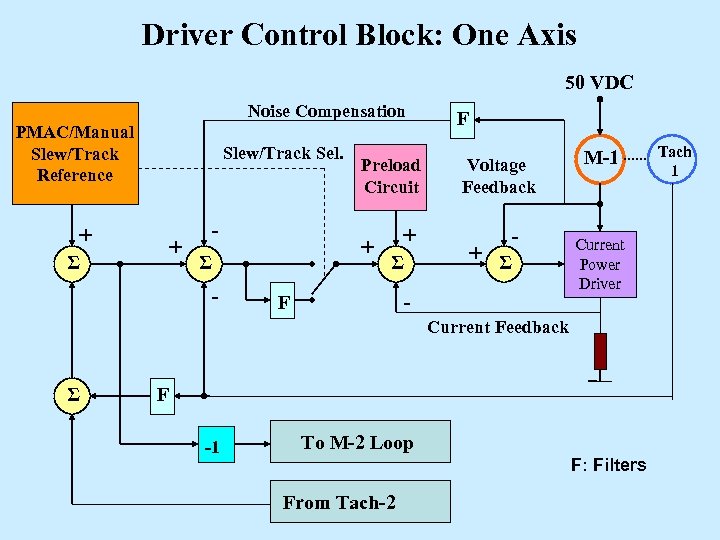

Driver Control Block: One Axis 50 VDC Noise Compensation PMAC/Manual Slew/Track Reference + Σ Slew/Track Sel. + - + Σ - Preload Circuit + Σ F F Voltage Feedback - + Σ - M-1 Current Power Driver Current Feedback Σ F -1 From M-2 Loop To Tach 2 F: Filters From Tach 2 From Tach-2 Tach 1

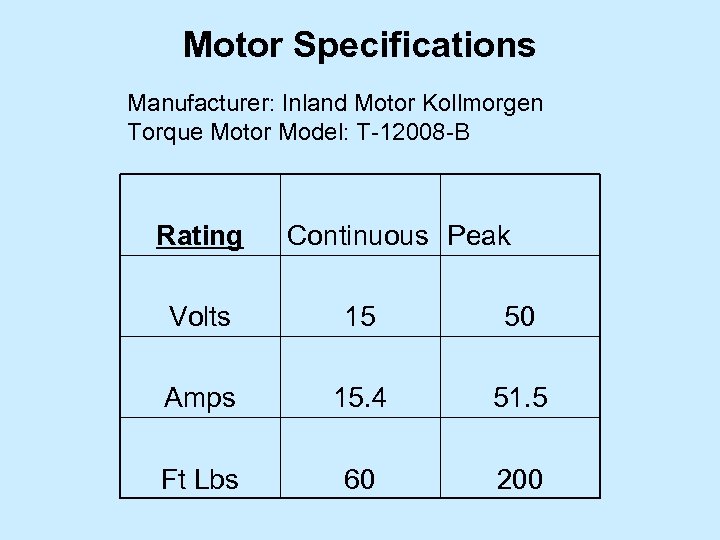

Motor Specifications Manufacturer: Inland Motor Kollmorgen Torque Motor Model: T-12008 -B Rating Continuous Peak Volts 15 50 Amps 15. 4 51. 5 Ft Lbs 60 200

Searching New Drivers

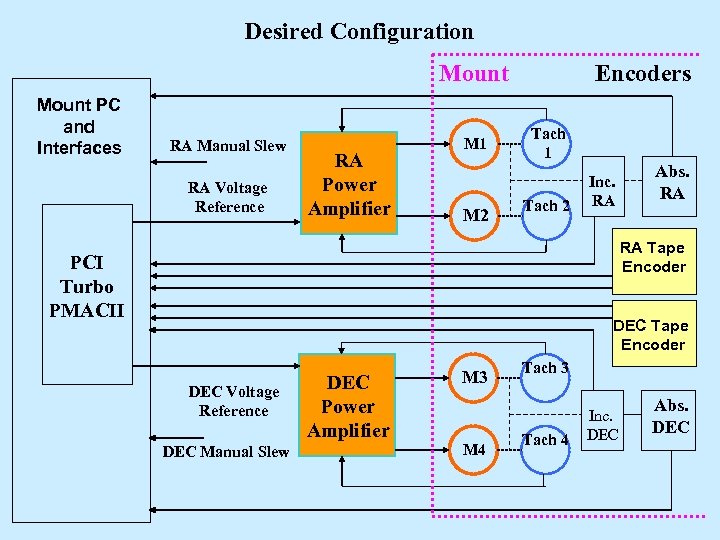

Desired Configuration Mount PC and Interfaces RA Manual Slew RA Voltage Reference RA Power Amplifier M 1 M 2 Encoders Tach 1 Tach 2 Inc. RA Abs. RA RA Tape Encoder PCI Turbo PMACII DEC Tape Encoder DEC Voltage Reference DEC Manual Slew DEC Power Amplifier M 3 M 4 Tach 3 Tach 4 Inc. DEC Abs. DEC

Devices Reviewed • • • ABB Allen Bradley (Rock. Well) Siemens Danfoss Yaskawa Others

The problems Ø Specific for industrial use Ø Mostly analog reference input Ø Mostly RS-486 interface Ø Some have Field. Bus, Can. Bus, and Device. Net buses Ø Lot of parameters to get an adequate configuration Ø Needed training for adequate maintenance and operation

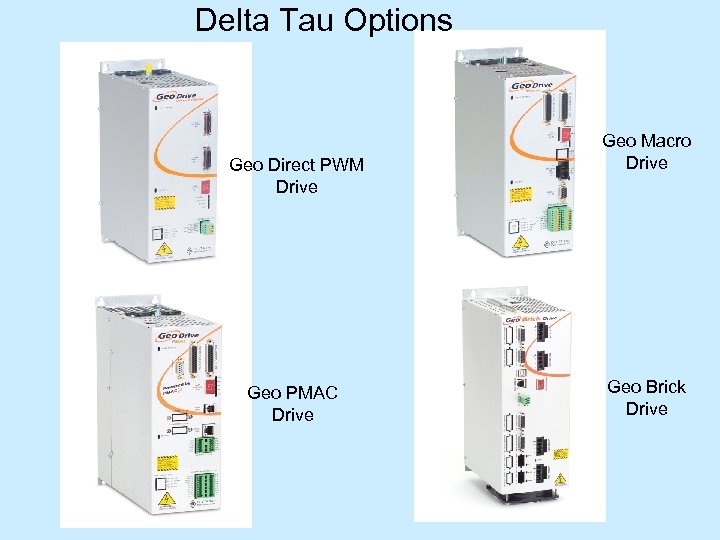

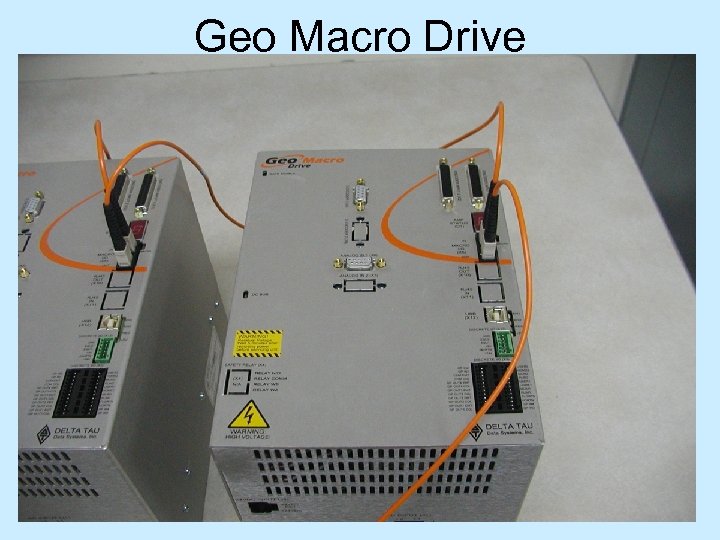

Delta Tau Options Geo Direct PWM Drive Geo PMAC Drive Geo Macro Drive Geo Brick Drive

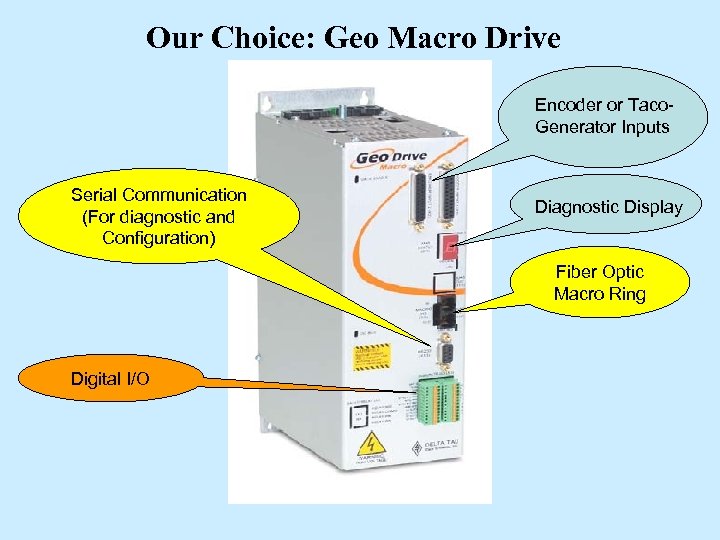

Our Choice: Geo Macro Drive Encoder or Taco. Generator Inputs Serial Communication (For diagnostic and Configuration) Diagnostic Display Fiber Optic Macro Ring Digital I/O

Advantage • • • Same variables as PMAC board Same commands and language Partially distributed control Fiber Optic Ring Communication Accessories that permit field signals connection to the Optic Macro Ring • Fully compatible with the controller board

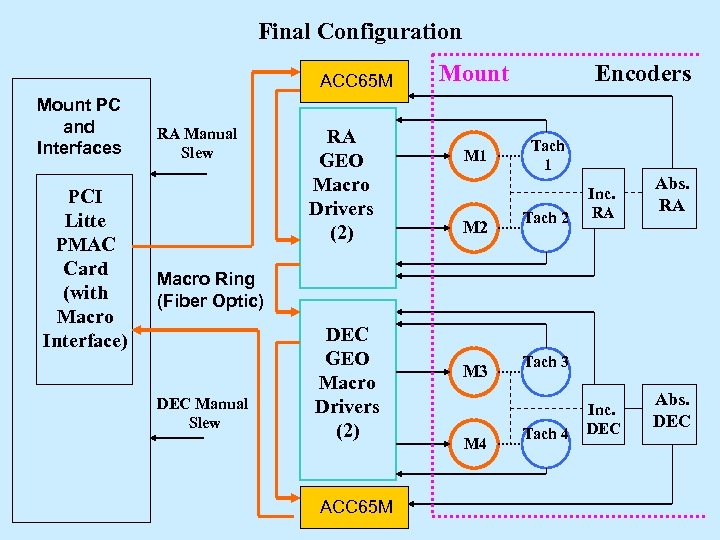

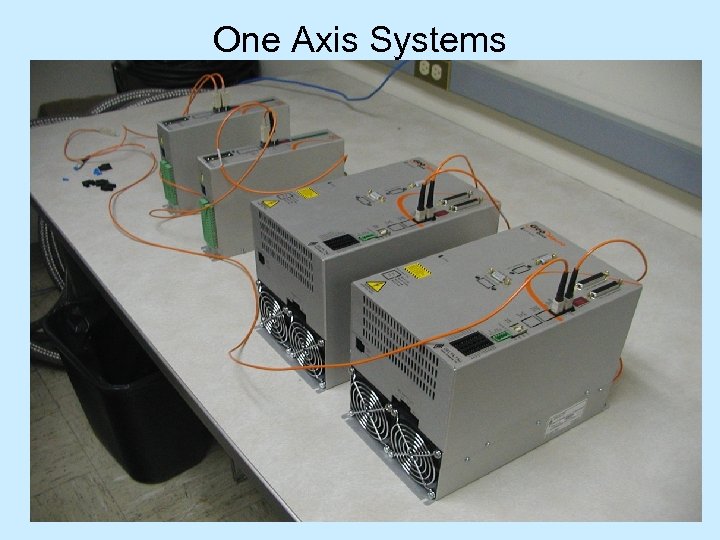

Final Configuration ACC 65 M Mount PC and Interfaces PCI Litte PMAC Card (with Macro Interface) RA Manual Slew RA GEO Macro Drivers (2) Mount M 1 M 2 Encoders Tach 1 Tach 2 Inc. RA Abs. RA Inc. DEC Abs. DEC Macro Ring (Fiber Optic) DEC Manual Slew DEC GEO Macro Drivers (2) ACC 65 M M 3 M 4 Tach 3 Tach 4

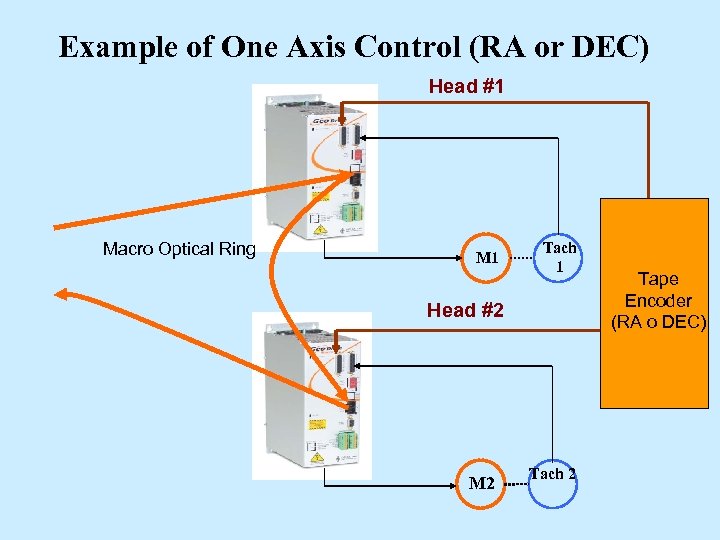

Example of One Axis Control (RA or DEC) Head #1 Macro Optical Ring M 1 Tach 1 Head #2 M 2 Tach 2 Tape Encoder (RA o DEC)

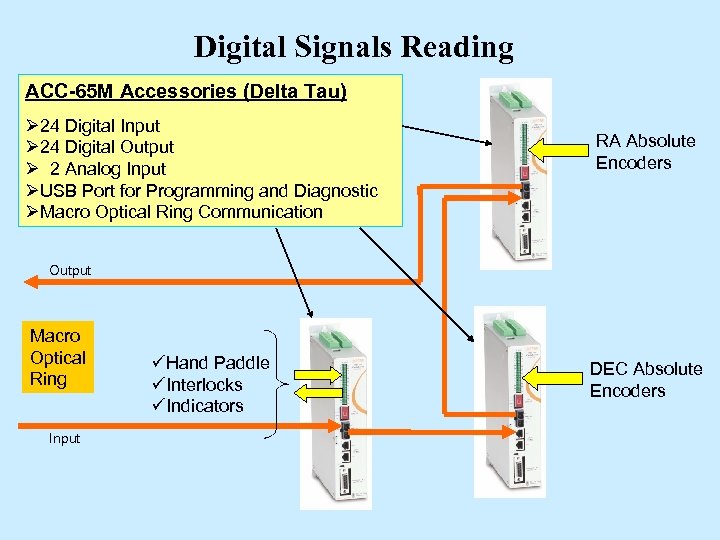

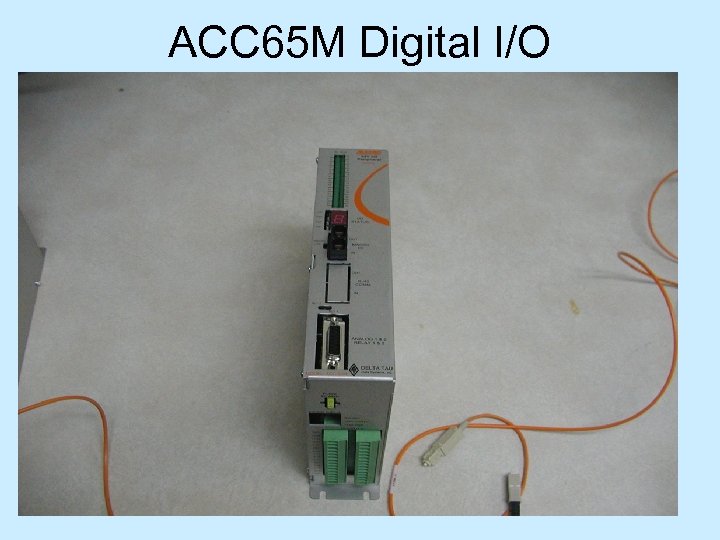

Digital Signals Reading ACC-65 M Accessories (Delta Tau) Ø 24 Digital Input Ø 24 Digital Output Ø 2 Analog Input ØUSB Port for Programming and Diagnostic ØMacro Optical Ring Communication RA Absolute Encoders Output Macro Optical Ring Input üHand Paddle üInterlocks üIndicators DEC Absolute Encoders

Macro Ring Optical Communication • • Data raw transmission at 125 Mbps. 2 of 10 redundancy transmission True data transmission speed of 100 Mbps Minimum loop update frequency of 2. 5 KHz Typically loop update frequency of 20 KHz Ring fully self synchronized All the enabled nodes have an unique address

Implementing

Geo Macro Drive

ACC 65 M Digital I/O

One Axis Systems

PMAC Turbo II Lithe Board with Macro Interface

Encoder Interpolator

Mount PC Lab. View Interface Turbo PMAC II Lithe Board ØCalculate Trajectories PVT Command ØHandle Error Notifications from TCS ØIncorporate Filters ØPredictions Algorithm ØIdentify Alarm ØGenerate Alarm Notifications Ethernet ØInterpret Handle Commands Data Gathering ØManage Drivers Information to TCS ØAbsolute Encoders Read ØTape Encoder Read PCI Bus ØConfigure Driver Variables ØSpeed Limits ØAcceleration Limits ØHandle Emergency Stop ØVerify External Conditions ØData Gathering DMA Transfer Fiber Optic Macro Ring

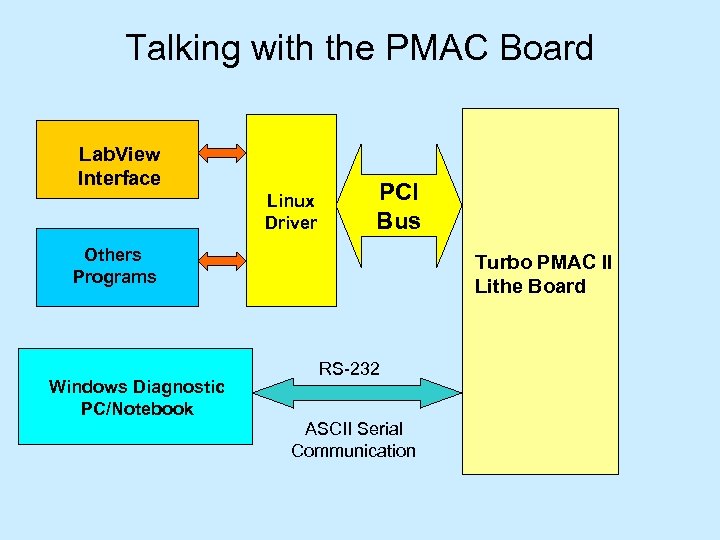

Talking with the PMAC Board Lab. View Interface Linux Driver PCI Bus Others Programs Windows Diagnostic PC/Notebook Turbo PMAC II Lithe Board RS-232 ASCII Serial Communication

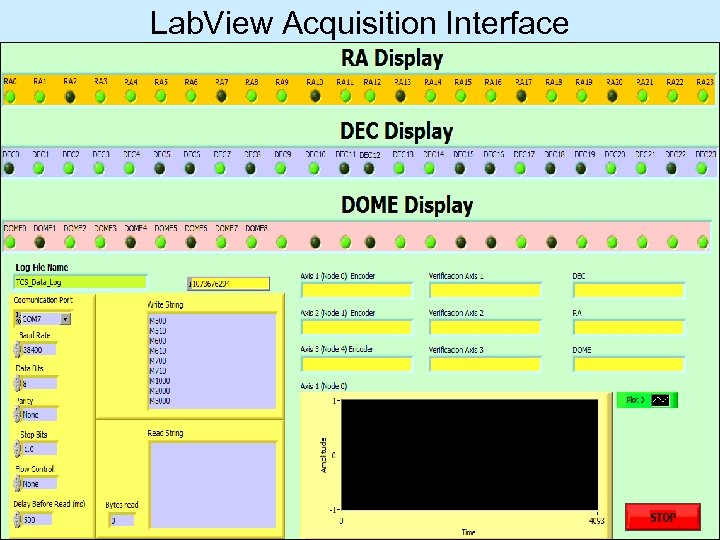

Lab. View Acquisition Interface

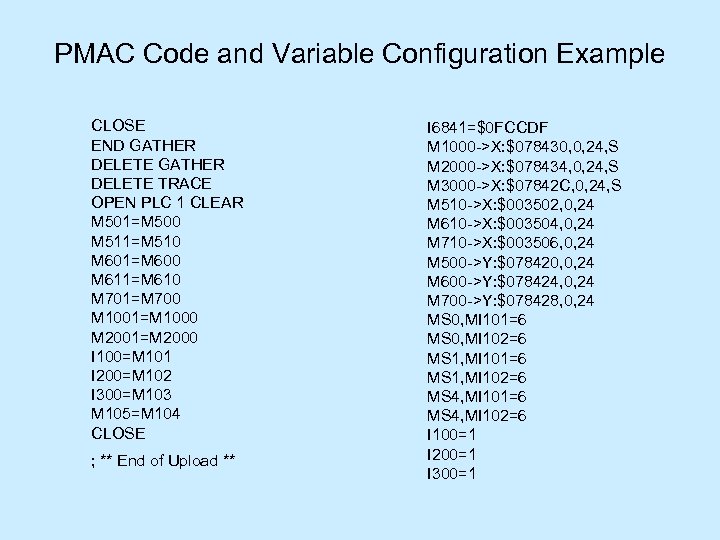

PMAC Code and Variable Configuration Example CLOSE END GATHER DELETE TRACE OPEN PLC 1 CLEAR M 501=M 500 M 511=M 510 M 601=M 600 M 611=M 610 M 701=M 700 M 1001=M 1000 M 2001=M 2000 I 100=M 101 I 200=M 102 I 300=M 103 M 105=M 104 CLOSE ; ** End of Upload ** I 6841=$0 FCCDF M 1000 ->X: $078430, 0, 24, S M 2000 ->X: $078434, 0, 24, S M 3000 ->X: $07842 C, 0, 24, S M 510 ->X: $003502, 0, 24 M 610 ->X: $003504, 0, 24 M 710 ->X: $003506, 0, 24 M 500 ->Y: $078420, 0, 24 M 600 ->Y: $078424, 0, 24 M 700 ->Y: $078428, 0, 24 MS 0, MI 101=6 MS 0, MI 102=6 MS 1, MI 101=6 MS 1, MI 102=6 MS 4, MI 101=6 MS 4, MI 102=6 I 100=1 I 200=1 I 300=1

Preparing the final Implementation

![Electrical Rack 1. 5 [m] Deep = 0. 4 [m] 0. 9 [m] Electrical Rack 1. 5 [m] Deep = 0. 4 [m] 0. 9 [m]](https://present5.com/presentation/2b5697e5ee941f83913c4093c1c634ab/image-65.jpg)

Electrical Rack 1. 5 [m] Deep = 0. 4 [m] 0. 9 [m]

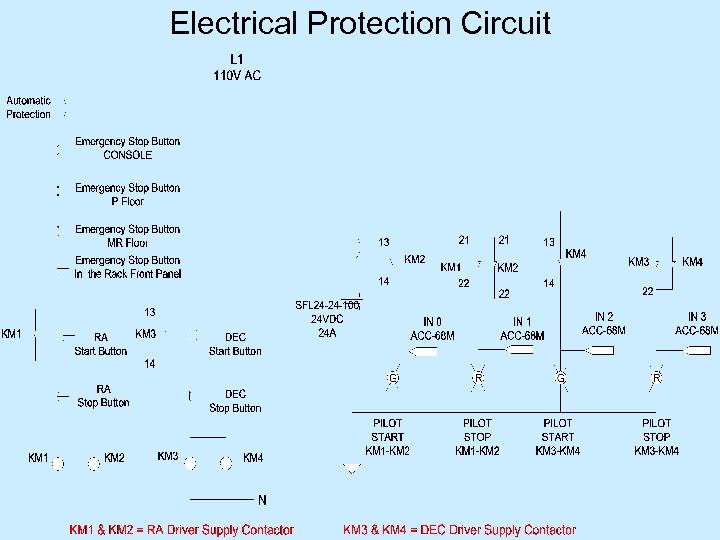

Electrical Protection Circuit

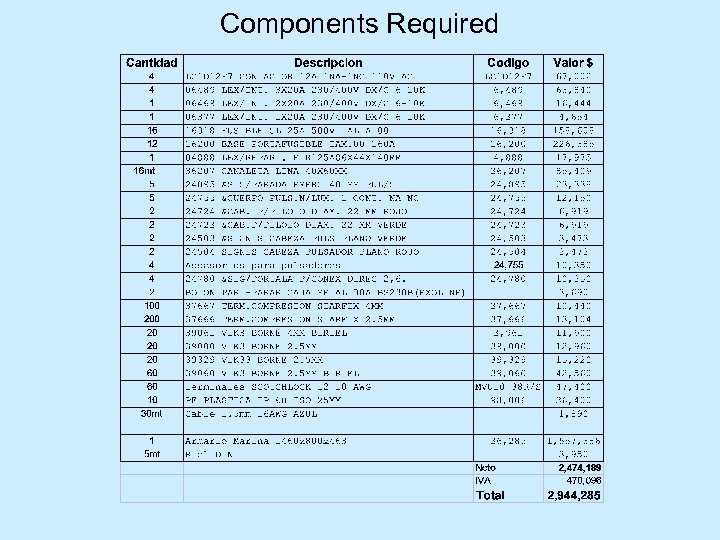

Components Required

Next Milestones

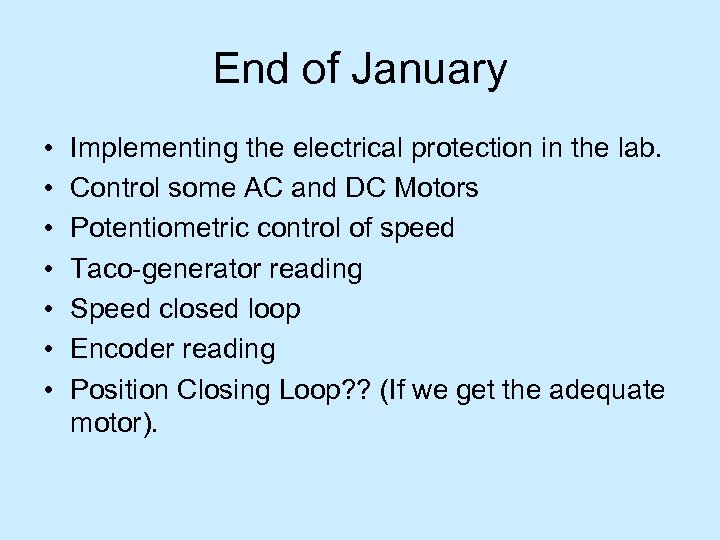

End of January • • Implementing the electrical protection in the lab. Control some AC and DC Motors Potentiometric control of speed Taco-generator reading Speed closed loop Encoder reading Position Closing Loop? ? (If we get the adequate motor).

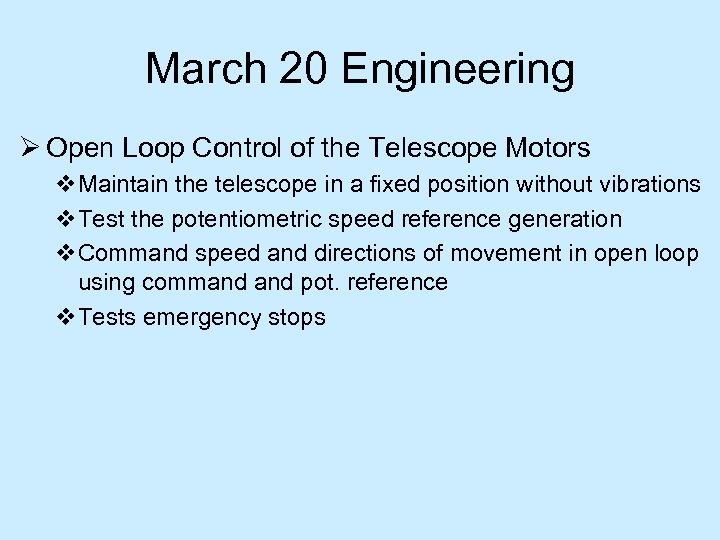

March 20 Engineering Ø Open Loop Control of the Telescope Motors v. Maintain the telescope in a fixed position without vibrations v. Test the potentiometric speed reference generation v. Command speed and directions of movement in open loop using command pot. reference v. Tests emergency stops

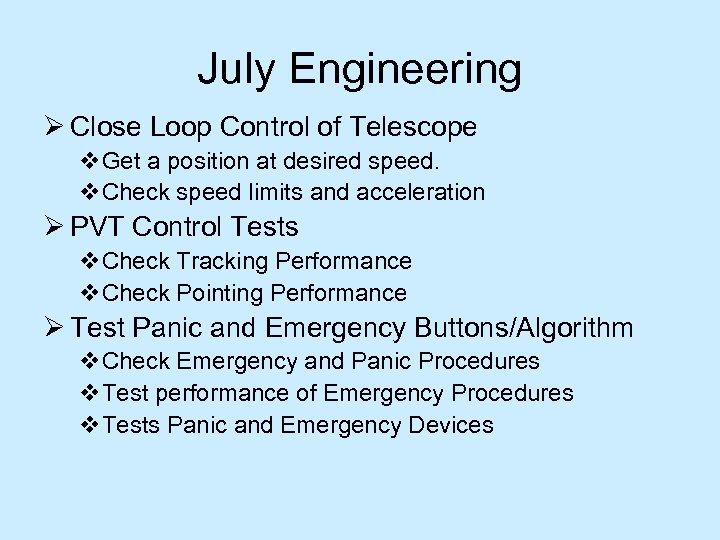

July Engineering Ø Close Loop Control of Telescope v. Get a position at desired speed. v. Check speed limits and acceleration Ø PVT Control Tests v. Check Tracking Performance v. Check Pointing Performance Ø Test Panic and Emergency Buttons/Algorithm v. Check Emergency and Panic Procedures v. Test performance of Emergency Procedures v. Tests Panic and Emergency Devices

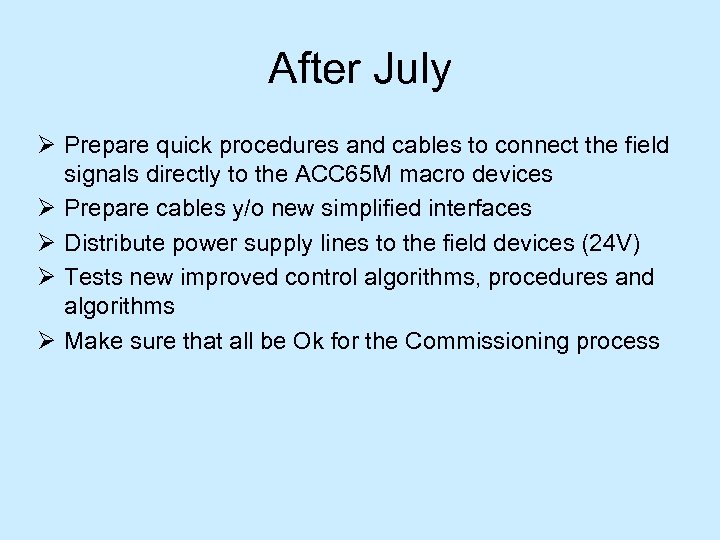

After July Ø Prepare quick procedures and cables to connect the field signals directly to the ACC 65 M macro devices Ø Prepare cables y/o new simplified interfaces Ø Distribute power supply lines to the field devices (24 V) Ø Tests new improved control algorithms, procedures and algorithms Ø Make sure that all be Ok for the Commissioning process

Resources

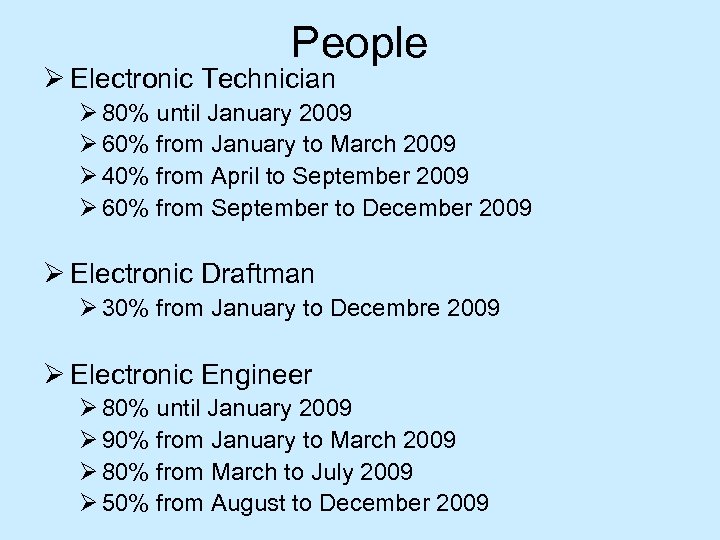

People Ø Electronic Technician Ø 80% until January 2009 Ø 60% from January to March 2009 Ø 40% from April to September 2009 Ø 60% from September to December 2009 Ø Electronic Draftman Ø 30% from January to Decembre 2009 Ø Electronic Engineer Ø 80% until January 2009 Ø 90% from January to March 2009 Ø 80% from March to July 2009 Ø 50% from August to December 2009

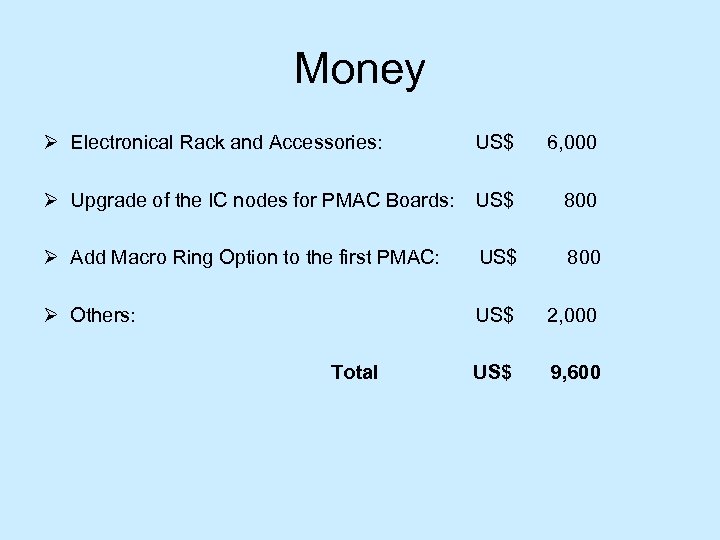

Money Ø Electronical Rack and Accessories: US$ 6, 000 Ø Upgrade of the IC nodes for PMAC Boards: US$ 800 Ø Add Macro Ring Option to the first PMAC: US$ 800 Ø Others: US$ 2, 000 US$ 9, 600 Total

Time Line

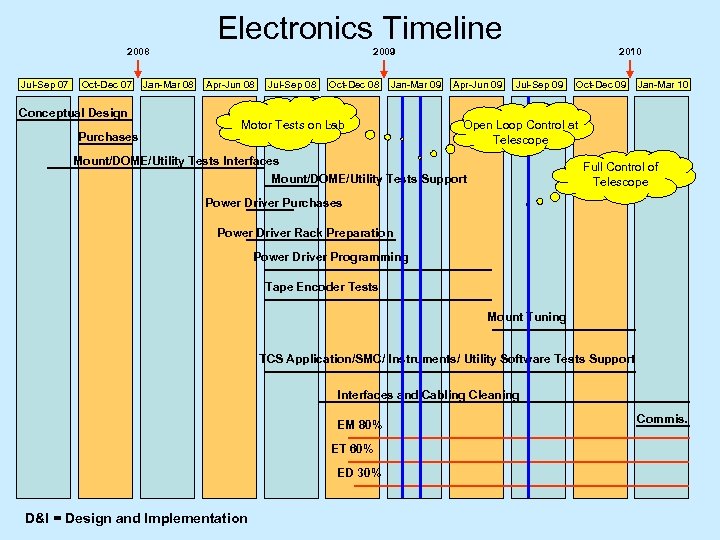

Electronics Timeline 2008 Jul-Sep 07 Oct-Dec 07 Conceptual Design Purchases Jan-Mar 08 2009 Apr-Jun 08 Jul-Sep 08 Oct-Dec 08 Jan-Mar 09 Motor Tests on Lab 2010 Apr-Jun 09 Jul-Sep 09 Oct-Dec 09 Jan-Mar 10 Open Loop Control at Telescope Mount/DOME/Utility Tests Interfaces Mount/DOME/Utility Tests Support Full Control of Telescope Power Driver Purchases Power Driver Rack Preparation Power Driver Programming Tape Encoder Tests Mount Tuning TCS Application/SMC/ Instruments/ Utility Software Tests Support Interfaces and Cabling Cleaning EM 80% ET 60% ED 30% D&I = Design and Implementation Commis.

2b5697e5ee941f83913c4093c1c634ab.ppt