226b90a8de2e68c8eb3943aab65801bb.ppt

- Количество слайдов: 173

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER STAFF • Greg Carlsson, BSEE • Rich Dehnel, BSEE • Michael Host, BSEE • Dave Jasinski, BSEE • Kentucky Pommerening, BSEE • Jarrod Widmann, BSEE AND BSCS

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER STAFF • Greg Carlsson, BSEE • Rich Dehnel, BSEE • Michael Host, BSEE • Dave Jasinski, BSEE • Kentucky Pommerening, BSEE • Jarrod Widmann, BSEE AND BSCS

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Project Abstract • Precision AC motor control is currently an expensive option requiring a $200+ encoder and supporting circuitry. This project aims to design a cost effective alternative with a flexible interface which can be implemented in nearly any industrial AC motor application to provide closed-loop control. • Cost, reliability, accuracy, and safety are key aspects in the scope of this project. Page 2

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Project Abstract • Precision AC motor control is currently an expensive option requiring a $200+ encoder and supporting circuitry. This project aims to design a cost effective alternative with a flexible interface which can be implemented in nearly any industrial AC motor application to provide closed-loop control. • Cost, reliability, accuracy, and safety are key aspects in the scope of this project. Page 2

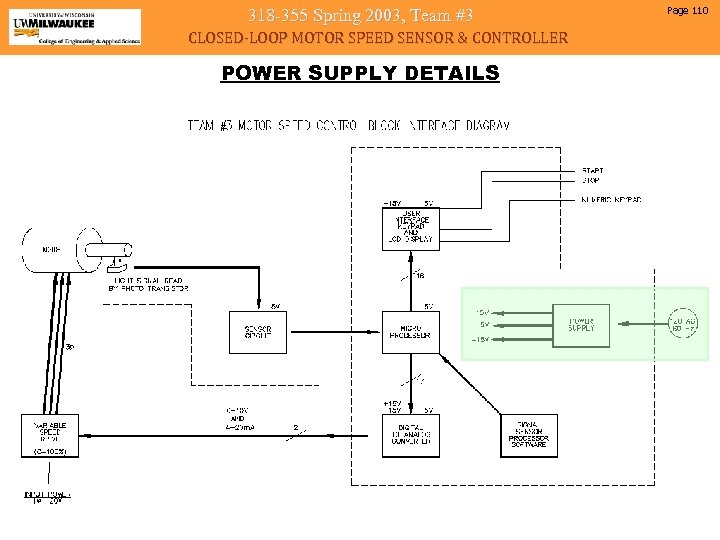

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Product Description • The input to the Closed Loop Motor Speed Sensor and Controller will be generated by an optical interrupting device which detects the shaft speed of a motor. • The input signal will be sent to a microprocessor which compares the input signal to a pre-programmed reference value. • This value will then be manipulated in the digital domain to provide an analog feedback signal to the motor controller. • A user interface is used to enter the reference value to the micro and display the actual motor shaft speed. • A power supply is used to supply the various circuits. Page 3

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Product Description • The input to the Closed Loop Motor Speed Sensor and Controller will be generated by an optical interrupting device which detects the shaft speed of a motor. • The input signal will be sent to a microprocessor which compares the input signal to a pre-programmed reference value. • This value will then be manipulated in the digital domain to provide an analog feedback signal to the motor controller. • A user interface is used to enter the reference value to the micro and display the actual motor shaft speed. • A power supply is used to supply the various circuits. Page 3

318 -355 Spring 2003, Team #3 Page 4 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Product Feature Set The desired features for our product included: • Accurate control of desired speed level • Analog output of 0 -10 VDC or 4 -20 m. A. This signal will be used as a control signal to an AC motor drive, or as a monitor signal to a chart recorder or data logger. • Instantaneous under/over speed indicator • Programmable scaling factor for display output • Constantly displayed set-point and actual speed values.

318 -355 Spring 2003, Team #3 Page 4 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Product Feature Set The desired features for our product included: • Accurate control of desired speed level • Analog output of 0 -10 VDC or 4 -20 m. A. This signal will be used as a control signal to an AC motor drive, or as a monitor signal to a chart recorder or data logger. • Instantaneous under/over speed indicator • Programmable scaling factor for display output • Constantly displayed set-point and actual speed values.

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Target Market • This product is being developed for use in industrial environments that require precision speed control of an AC induction motor. A variable frequency drive containing an analog input of 0 -10 VDC or 4 -20 m. A should be controlling the motor. • An alternative application of this device is for data logging an application containing a rotating machine. • The prototype design is geared toward the North American market (120 VAC, 60 Hz), but can easily be adapted to conform to other electrical power systems throughout the world. Page 5

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Target Market • This product is being developed for use in industrial environments that require precision speed control of an AC induction motor. A variable frequency drive containing an analog input of 0 -10 VDC or 4 -20 m. A should be controlling the motor. • An alternative application of this device is for data logging an application containing a rotating machine. • The prototype design is geared toward the North American market (120 VAC, 60 Hz), but can easily be adapted to conform to other electrical power systems throughout the world. Page 5

Page 6 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Team Page (1) • Greg Carlsson • Rich Dehnel • Michael Host Expertise: Audio Systems, hardware design, audio op-amp implementation Expertise: Control & integration, building electrical systems layout Expertise: HW, board layout, VHDL, digital design, product troubleshooting Experience: 3 years at Audio Video Specialties Experience: 12 years at Grande Cheese, 2 years at Lang Associates Experience: 1. 5 Years at Rockwell Automation, Quality Systems Engineering

Page 6 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Team Page (1) • Greg Carlsson • Rich Dehnel • Michael Host Expertise: Audio Systems, hardware design, audio op-amp implementation Expertise: Control & integration, building electrical systems layout Expertise: HW, board layout, VHDL, digital design, product troubleshooting Experience: 3 years at Audio Video Specialties Experience: 12 years at Grande Cheese, 2 years at Lang Associates Experience: 1. 5 Years at Rockwell Automation, Quality Systems Engineering

Page 7 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Team Page (2) • Dave Jasinski Expertise: Quality control, reliability, product safety & manufacturing processes Experience: 22+ years in electronics manufacturing, currently employed at • Kentucky Pommerening • Jarrod Widmann Expertise: Hardware design, board layout, compliance testing Expertise: Software, embedded systems & digital design Experience: 1 year internship at ABB – Research and Development Experience: Three co -op sessions at Hamilton Sundstrand Aerospace

Page 7 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Team Page (2) • Dave Jasinski Expertise: Quality control, reliability, product safety & manufacturing processes Experience: 22+ years in electronics manufacturing, currently employed at • Kentucky Pommerening • Jarrod Widmann Expertise: Hardware design, board layout, compliance testing Expertise: Software, embedded systems & digital design Experience: 1 year internship at ABB – Research and Development Experience: Three co -op sessions at Hamilton Sundstrand Aerospace

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Team Logistics • Due to the fact that two members are part-time students, the team met primarily on weekends, mostly Sunday afternoons. Action items were assigned, ideas exchanged, and questions were discussed and resolved. • Emails were constantly being exchanged between members to share information. • Each team member dedicated about 8 hours per week to this project. Responsibilities were assigned as follows: • Website Manager: Greg Carlsson • Project Archiver: Rich Dehnel • Presentation Manager: Dave Jasinski • Report Managers: Mike Host and Kentucky Pommenering • Financial Manager: Jarrod Widmann Page 8

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Team Logistics • Due to the fact that two members are part-time students, the team met primarily on weekends, mostly Sunday afternoons. Action items were assigned, ideas exchanged, and questions were discussed and resolved. • Emails were constantly being exchanged between members to share information. • Each team member dedicated about 8 hours per week to this project. Responsibilities were assigned as follows: • Website Manager: Greg Carlsson • Project Archiver: Rich Dehnel • Presentation Manager: Dave Jasinski • Report Managers: Mike Host and Kentucky Pommenering • Financial Manager: Jarrod Widmann Page 8

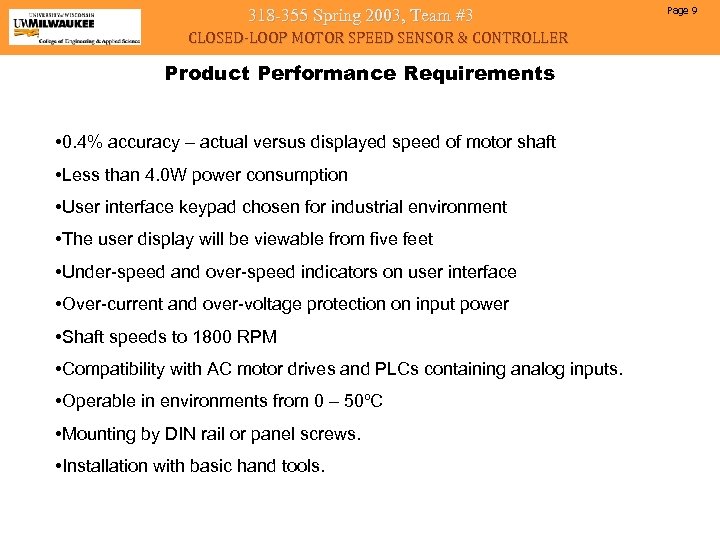

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Product Performance Requirements • 0. 4% accuracy – actual versus displayed speed of motor shaft • Less than 4. 0 W power consumption • User interface keypad chosen for industrial environment • The user display will be viewable from five feet • Under-speed and over-speed indicators on user interface • Over-current and over-voltage protection on input power • Shaft speeds to 1800 RPM • Compatibility with AC motor drives and PLCs containing analog inputs. • Operable in environments from 0 – 50ºC • Mounting by DIN rail or panel screws. • Installation with basic hand tools. Page 9

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Product Performance Requirements • 0. 4% accuracy – actual versus displayed speed of motor shaft • Less than 4. 0 W power consumption • User interface keypad chosen for industrial environment • The user display will be viewable from five feet • Under-speed and over-speed indicators on user interface • Over-current and over-voltage protection on input power • Shaft speeds to 1800 RPM • Compatibility with AC motor drives and PLCs containing analog inputs. • Operable in environments from 0 – 50ºC • Mounting by DIN rail or panel screws. • Installation with basic hand tools. Page 9

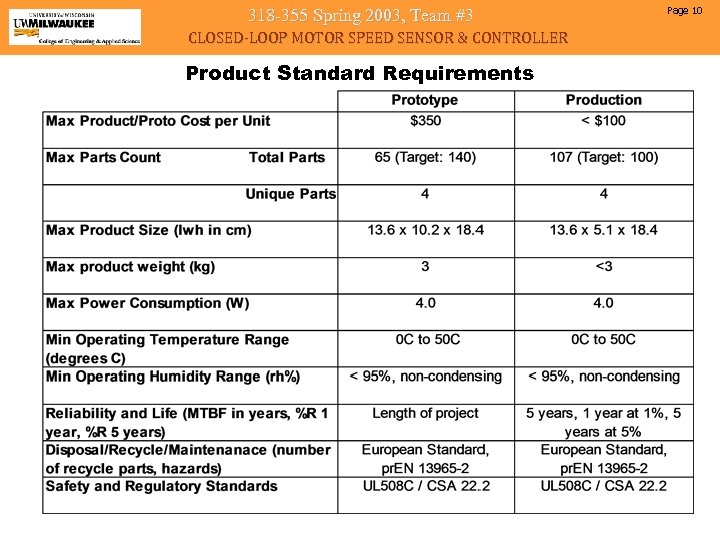

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Product Standard Requirements Page 10

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Product Standard Requirements Page 10

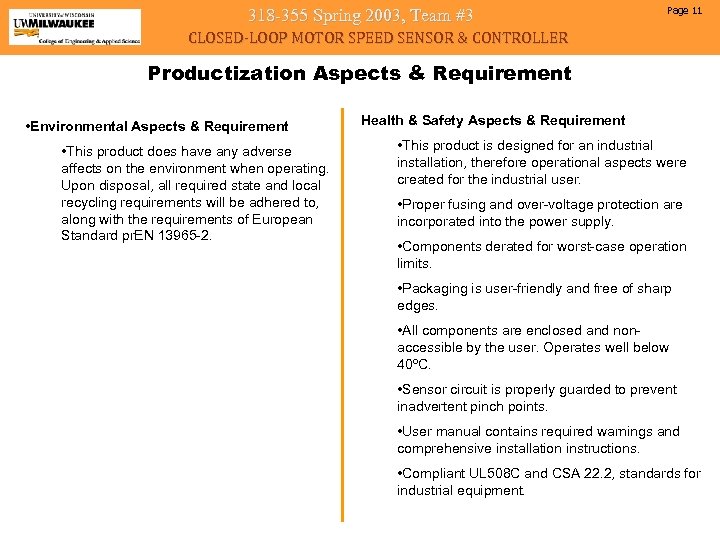

318 -355 Spring 2003, Team #3 Page 11 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Productization Aspects & Requirement • Environmental Aspects & Requirement • This product does have any adverse affects on the environment when operating. Upon disposal, all required state and local recycling requirements will be adhered to, along with the requirements of European Standard pr. EN 13965 -2. Health & Safety Aspects & Requirement • This product is designed for an industrial installation, therefore operational aspects were created for the industrial user. • Proper fusing and over-voltage protection are incorporated into the power supply. • Components derated for worst-case operation limits. • Packaging is user-friendly and free of sharp edges. • All components are enclosed and nonaccessible by the user. Operates well below 40ºC. • Sensor circuit is properly guarded to prevent inadvertent pinch points. • User manual contains required warnings and comprehensive installation instructions. • Compliant UL 508 C and CSA 22. 2, standards for industrial equipment.

318 -355 Spring 2003, Team #3 Page 11 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Productization Aspects & Requirement • Environmental Aspects & Requirement • This product does have any adverse affects on the environment when operating. Upon disposal, all required state and local recycling requirements will be adhered to, along with the requirements of European Standard pr. EN 13965 -2. Health & Safety Aspects & Requirement • This product is designed for an industrial installation, therefore operational aspects were created for the industrial user. • Proper fusing and over-voltage protection are incorporated into the power supply. • Components derated for worst-case operation limits. • Packaging is user-friendly and free of sharp edges. • All components are enclosed and nonaccessible by the user. Operates well below 40ºC. • Sensor circuit is properly guarded to prevent inadvertent pinch points. • User manual contains required warnings and comprehensive installation instructions. • Compliant UL 508 C and CSA 22. 2, standards for industrial equipment.

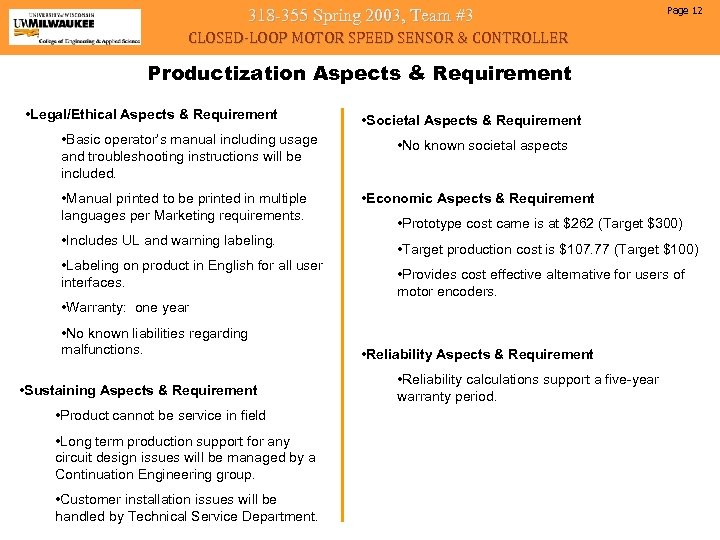

318 -355 Spring 2003, Team #3 Page 12 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Productization Aspects & Requirement • Legal/Ethical Aspects & Requirement • Basic operator’s manual including usage and troubleshooting instructions will be included. • Manual printed to be printed in multiple languages per Marketing requirements. • Includes UL and warning labeling. • Labeling on product in English for all user interfaces. • Societal Aspects & Requirement • No known societal aspects • Economic Aspects & Requirement • Prototype cost came is at $262 (Target $300) • Target production cost is $107. 77 (Target $100) • Provides cost effective alternative for users of motor encoders. • Warranty: one year • No known liabilities regarding malfunctions. • Sustaining Aspects & Requirement • Product cannot be service in field • Long term production support for any circuit design issues will be managed by a Continuation Engineering group. • Customer installation issues will be handled by Technical Service Department. • Reliability Aspects & Requirement • Reliability calculations support a five-year warranty period.

318 -355 Spring 2003, Team #3 Page 12 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Productization Aspects & Requirement • Legal/Ethical Aspects & Requirement • Basic operator’s manual including usage and troubleshooting instructions will be included. • Manual printed to be printed in multiple languages per Marketing requirements. • Includes UL and warning labeling. • Labeling on product in English for all user interfaces. • Societal Aspects & Requirement • No known societal aspects • Economic Aspects & Requirement • Prototype cost came is at $262 (Target $300) • Target production cost is $107. 77 (Target $100) • Provides cost effective alternative for users of motor encoders. • Warranty: one year • No known liabilities regarding malfunctions. • Sustaining Aspects & Requirement • Product cannot be service in field • Long term production support for any circuit design issues will be managed by a Continuation Engineering group. • Customer installation issues will be handled by Technical Service Department. • Reliability Aspects & Requirement • Reliability calculations support a five-year warranty period.

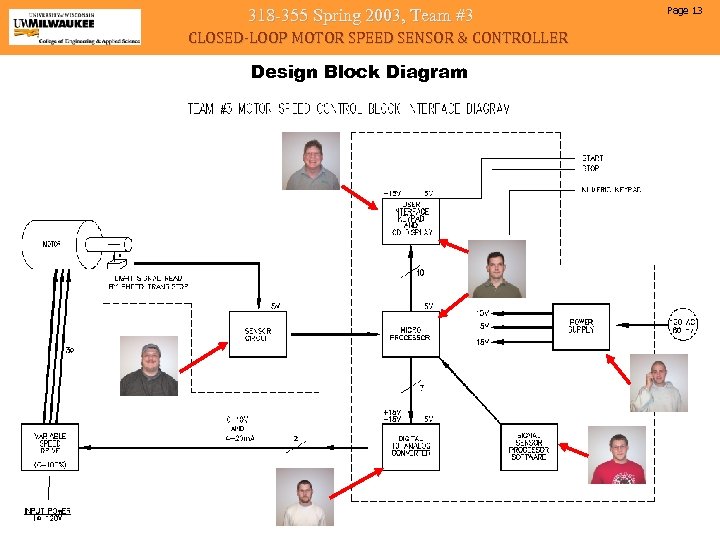

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Design Block Diagram Page 13

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Design Block Diagram Page 13

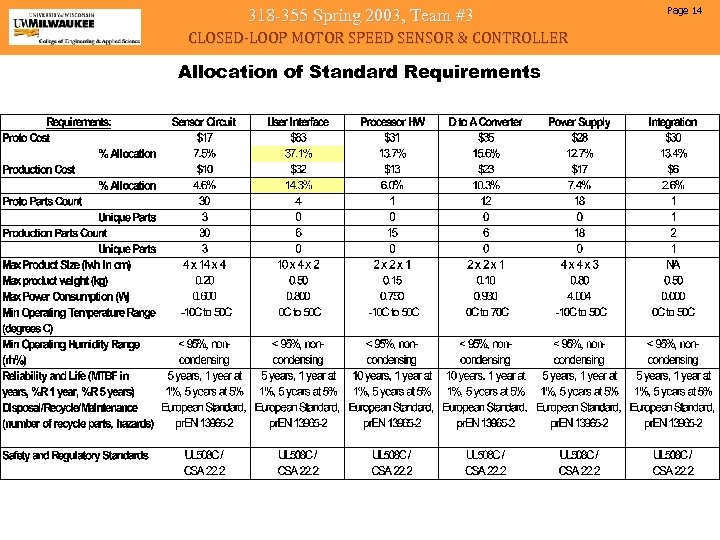

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Allocation of Standard Requirements Page 14

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Allocation of Standard Requirements Page 14

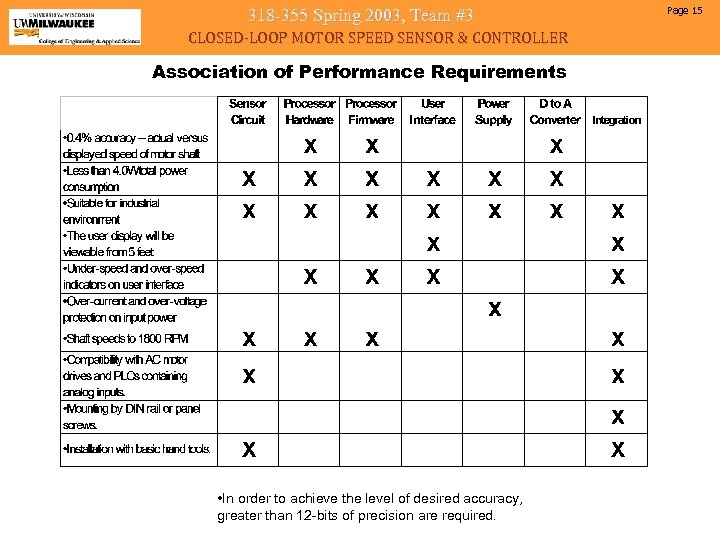

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Association of Performance Requirements • In order to achieve the level of desired accuracy, greater than 12 -bits of precision are required. Page 15

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Association of Performance Requirements • In order to achieve the level of desired accuracy, greater than 12 -bits of precision are required. Page 15

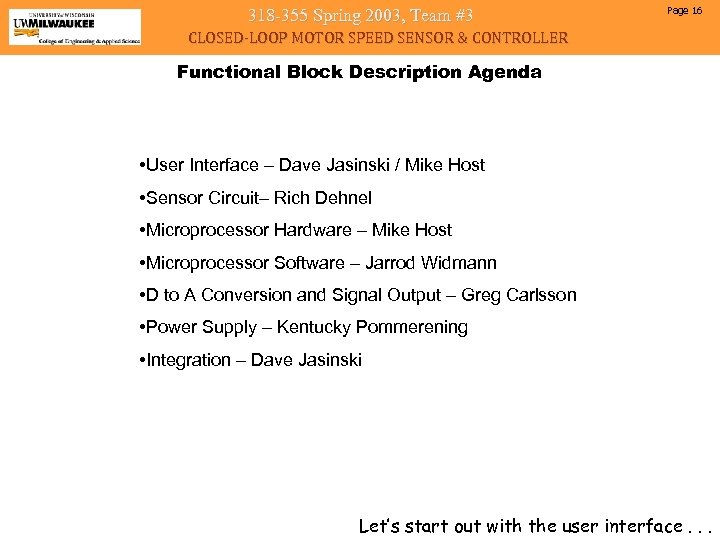

318 -355 Spring 2003, Team #3 Page 16 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Functional Block Description Agenda • User Interface – Dave Jasinski / Mike Host • Sensor Circuit– Rich Dehnel • Microprocessor Hardware – Mike Host • Microprocessor Software – Jarrod Widmann • D to A Conversion and Signal Output – Greg Carlsson • Power Supply – Kentucky Pommerening • Integration – Dave Jasinski Let’s start out with the user interface. . .

318 -355 Spring 2003, Team #3 Page 16 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Functional Block Description Agenda • User Interface – Dave Jasinski / Mike Host • Sensor Circuit– Rich Dehnel • Microprocessor Hardware – Mike Host • Microprocessor Software – Jarrod Widmann • D to A Conversion and Signal Output – Greg Carlsson • Power Supply – Kentucky Pommerening • Integration – Dave Jasinski Let’s start out with the user interface. . .

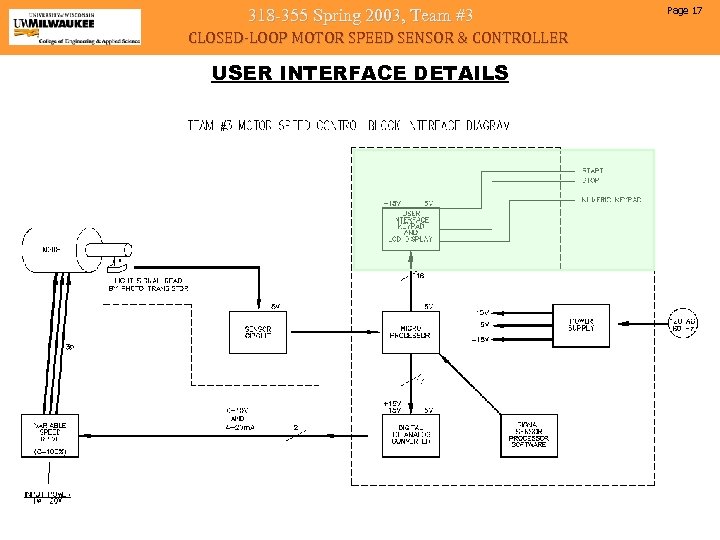

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER USER INTERFACE DETAILS Page 17

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER USER INTERFACE DETAILS Page 17

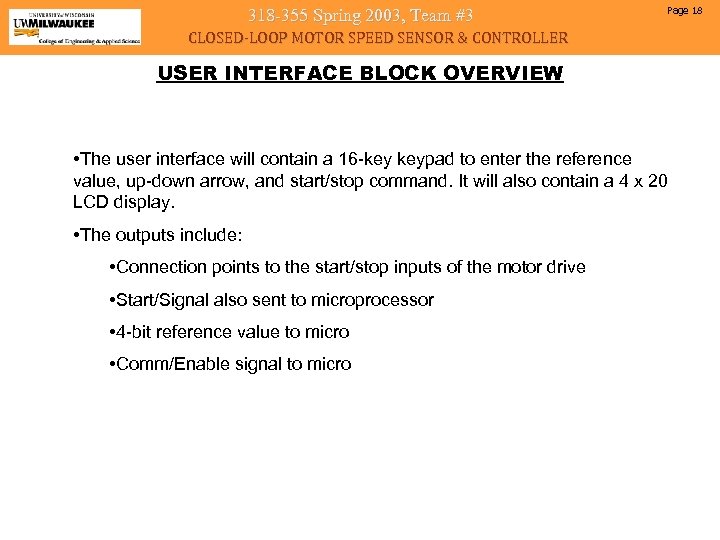

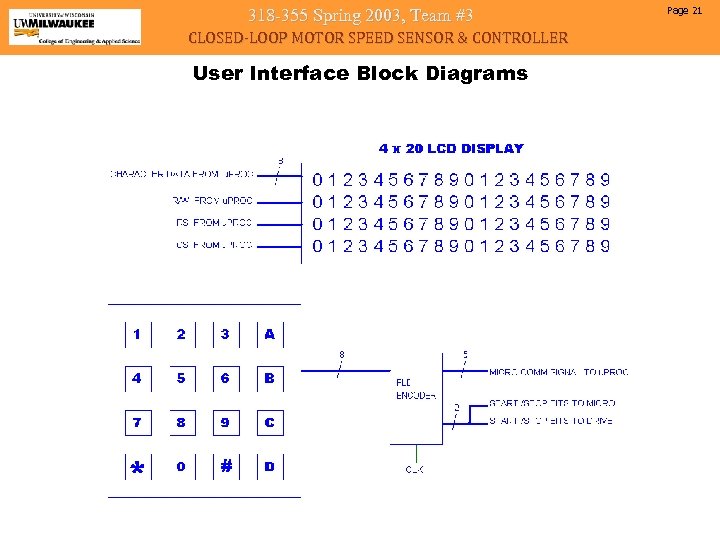

318 -355 Spring 2003, Team #3 Page 18 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER USER INTERFACE BLOCK OVERVIEW • The user interface will contain a 16 -key keypad to enter the reference value, up-down arrow, and start/stop command. It will also contain a 4 x 20 LCD display. • The outputs include: • Connection points to the start/stop inputs of the motor drive • Start/Signal also sent to microprocessor • 4 -bit reference value to micro • Comm/Enable signal to micro

318 -355 Spring 2003, Team #3 Page 18 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER USER INTERFACE BLOCK OVERVIEW • The user interface will contain a 16 -key keypad to enter the reference value, up-down arrow, and start/stop command. It will also contain a 4 x 20 LCD display. • The outputs include: • Connection points to the start/stop inputs of the motor drive • Start/Signal also sent to microprocessor • 4 -bit reference value to micro • Comm/Enable signal to micro

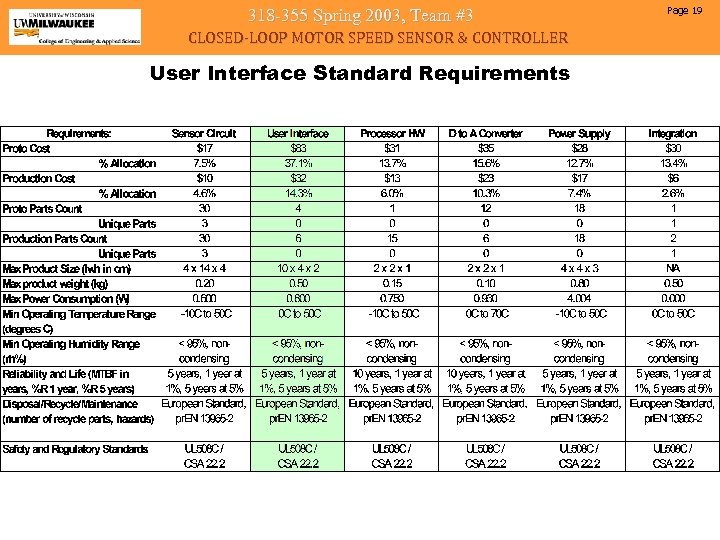

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Standard Requirements Page 19

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Standard Requirements Page 19

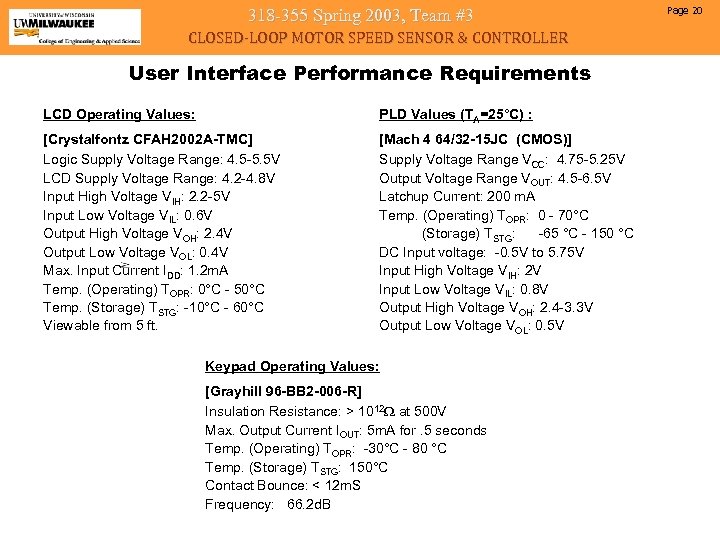

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Performance Requirements LCD Operating Values: PLD Values (TA=25°C) : [Crystalfontz CFAH 2002 A-TMC] Logic Supply Voltage Range: 4. 5 -5. 5 V LCD Supply Voltage Range: 4. 2 -4. 8 V Input High Voltage VIH: 2. 2 -5 V Input Low Voltage VIL: 0. 6 V Output High Voltage VOH: 2. 4 V Output Low Voltage VOL: 0. 4 V Max. Input Current IDD: 1. 2 m. A Temp. (Operating) TOPR: 0°C - 50°C Temp. (Storage) TSTG: -10°C - 60°C Viewable from 5 ft. [Mach 4 64/32 -15 JC (CMOS)] Supply Voltage Range VCC: 4. 75 -5. 25 V Output Voltage Range VOUT: 4. 5 -6. 5 V Latchup Current: 200 m. A Temp. (Operating) TOPR: 0 - 70°C (Storage) TSTG: -65 °C - 150 °C DC Input voltage: -0. 5 V to 5. 75 V Input High Voltage VIH: 2 V Input Low Voltage VIL: 0. 8 V Output High Voltage VOH: 2. 4 -3. 3 V Output Low Voltage VOL: 0. 5 V Keypad Operating Values: [Grayhill 96 -BB 2 -006 -R] Insulation Resistance: > 1012 at 500 V Max. Output Current IOUT: 5 m. A for. 5 seconds Temp. (Operating) TOPR: -30°C - 80 °C Temp. (Storage) TSTG: 150°C Contact Bounce: < 12 m. S Frequency: 66. 2 d. B Page 20

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Performance Requirements LCD Operating Values: PLD Values (TA=25°C) : [Crystalfontz CFAH 2002 A-TMC] Logic Supply Voltage Range: 4. 5 -5. 5 V LCD Supply Voltage Range: 4. 2 -4. 8 V Input High Voltage VIH: 2. 2 -5 V Input Low Voltage VIL: 0. 6 V Output High Voltage VOH: 2. 4 V Output Low Voltage VOL: 0. 4 V Max. Input Current IDD: 1. 2 m. A Temp. (Operating) TOPR: 0°C - 50°C Temp. (Storage) TSTG: -10°C - 60°C Viewable from 5 ft. [Mach 4 64/32 -15 JC (CMOS)] Supply Voltage Range VCC: 4. 75 -5. 25 V Output Voltage Range VOUT: 4. 5 -6. 5 V Latchup Current: 200 m. A Temp. (Operating) TOPR: 0 - 70°C (Storage) TSTG: -65 °C - 150 °C DC Input voltage: -0. 5 V to 5. 75 V Input High Voltage VIH: 2 V Input Low Voltage VIL: 0. 8 V Output High Voltage VOH: 2. 4 -3. 3 V Output Low Voltage VOL: 0. 5 V Keypad Operating Values: [Grayhill 96 -BB 2 -006 -R] Insulation Resistance: > 1012 at 500 V Max. Output Current IOUT: 5 m. A for. 5 seconds Temp. (Operating) TOPR: -30°C - 80 °C Temp. (Storage) TSTG: 150°C Contact Bounce: < 12 m. S Frequency: 66. 2 d. B Page 20

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Block Diagrams Page 21

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Block Diagrams Page 21

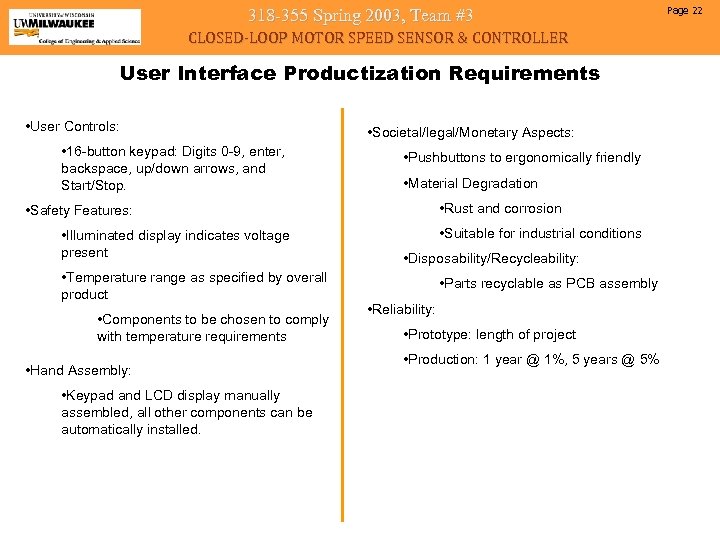

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Productization Requirements • User Controls: • 16 -button keypad: Digits 0 -9, enter, backspace, up/down arrows, and Start/Stop. • Safety Features: • Illuminated display indicates voltage present • Temperature range as specified by overall product • Components to be chosen to comply with temperature requirements • Hand Assembly: • Keypad and LCD display manually assembled, all other components can be automatically installed. • Societal/legal/Monetary Aspects: • Pushbuttons to ergonomically friendly • Material Degradation • Rust and corrosion • Suitable for industrial conditions • Disposability/Recycleability: • Parts recyclable as PCB assembly • Reliability: • Prototype: length of project • Production: 1 year @ 1%, 5 years @ 5% Page 22

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Productization Requirements • User Controls: • 16 -button keypad: Digits 0 -9, enter, backspace, up/down arrows, and Start/Stop. • Safety Features: • Illuminated display indicates voltage present • Temperature range as specified by overall product • Components to be chosen to comply with temperature requirements • Hand Assembly: • Keypad and LCD display manually assembled, all other components can be automatically installed. • Societal/legal/Monetary Aspects: • Pushbuttons to ergonomically friendly • Material Degradation • Rust and corrosion • Suitable for industrial conditions • Disposability/Recycleability: • Parts recyclable as PCB assembly • Reliability: • Prototype: length of project • Production: 1 year @ 1%, 5 years @ 5% Page 22

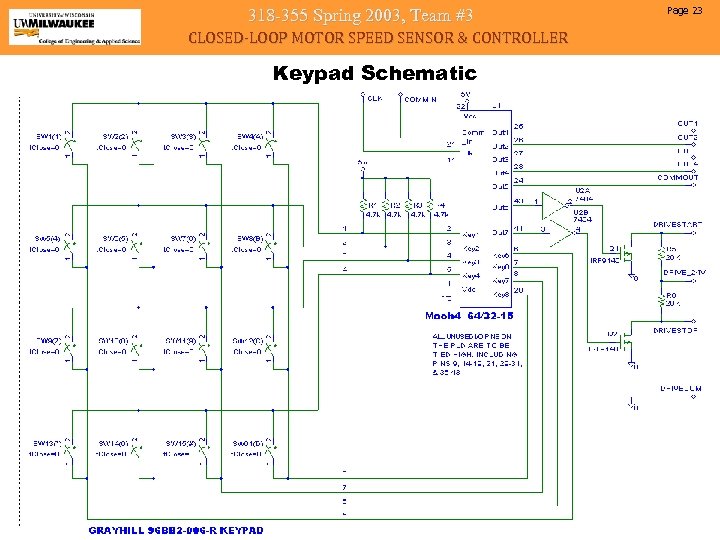

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Keypad Schematic Page 23

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Keypad Schematic Page 23

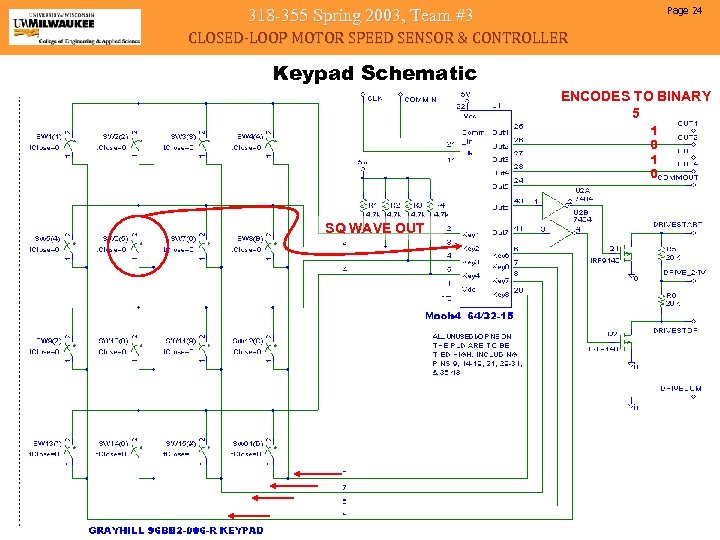

Page 24 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Keypad Schematic ENCODES TO BINARY 5 1 0 SQ WAVE OUT

Page 24 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Keypad Schematic ENCODES TO BINARY 5 1 0 SQ WAVE OUT

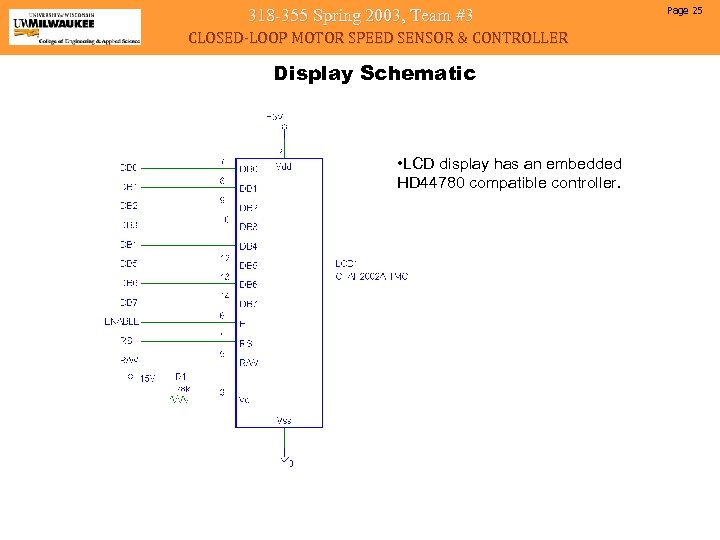

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Display Schematic • LCD display has an embedded HD 44780 compatible controller. Page 25

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Display Schematic • LCD display has an embedded HD 44780 compatible controller. Page 25

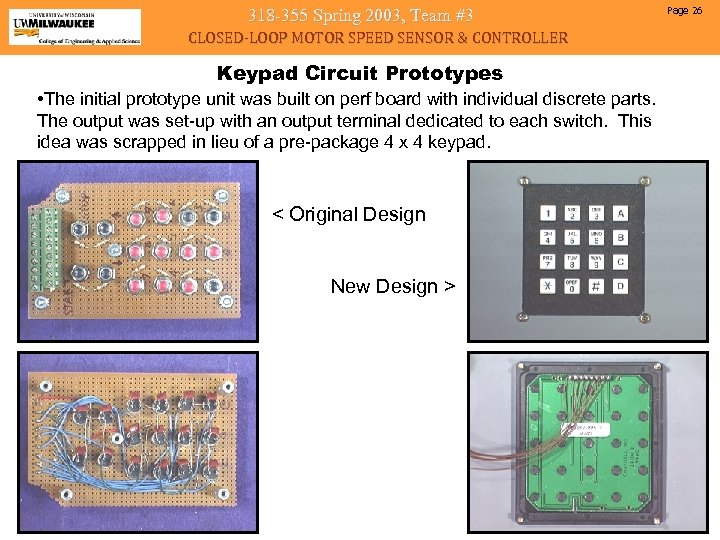

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Keypad Circuit Prototypes • The initial prototype unit was built on perf board with individual discrete parts. The output was set-up with an output terminal dedicated to each switch. This idea was scrapped in lieu of a pre-package 4 x 4 keypad. < Original Design _ ___ New Design > Page 26

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Keypad Circuit Prototypes • The initial prototype unit was built on perf board with individual discrete parts. The output was set-up with an output terminal dedicated to each switch. This idea was scrapped in lieu of a pre-package 4 x 4 keypad. < Original Design _ ___ New Design > Page 26

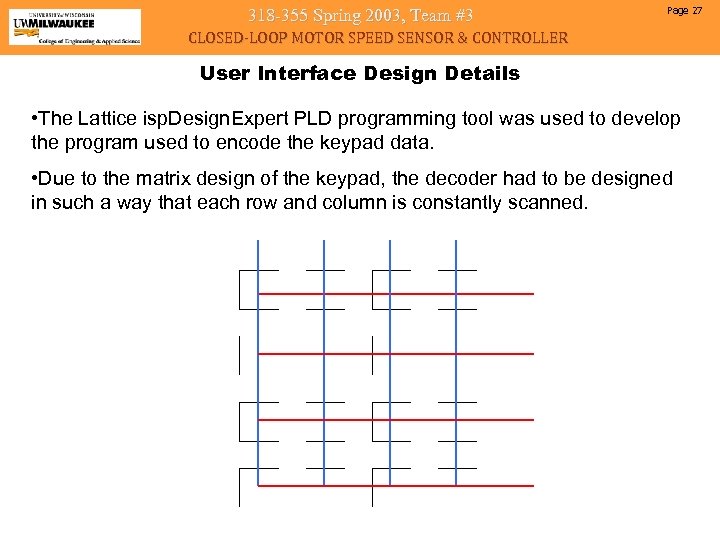

318 -355 Spring 2003, Team #3 Page 27 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Design Details • The Lattice isp. Design. Expert PLD programming tool was used to develop the program used to encode the keypad data. • Due to the matrix design of the keypad, the decoder had to be designed in such a way that each row and column is constantly scanned.

318 -355 Spring 2003, Team #3 Page 27 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Design Details • The Lattice isp. Design. Expert PLD programming tool was used to develop the program used to encode the keypad data. • Due to the matrix design of the keypad, the decoder had to be designed in such a way that each row and column is constantly scanned.

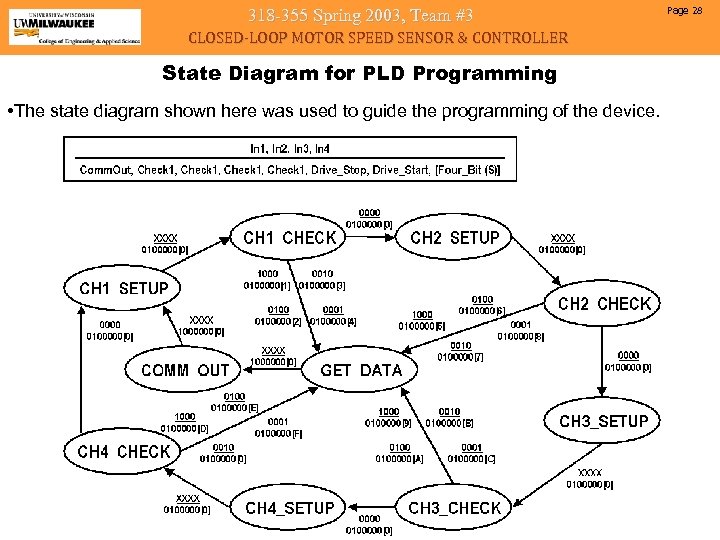

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER State Diagram for PLD Programming • The state diagram shown here was used to guide the programming of the device. Page 28

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER State Diagram for PLD Programming • The state diagram shown here was used to guide the programming of the device. Page 28

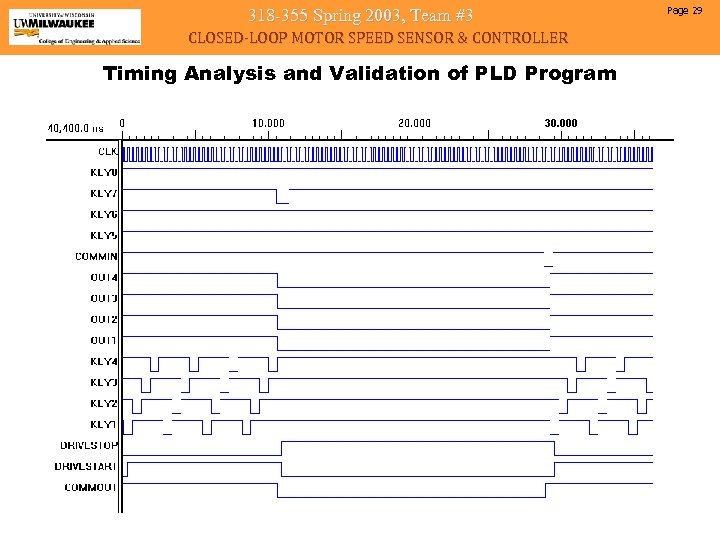

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Timing Analysis and Validation of PLD Program Page 29

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Timing Analysis and Validation of PLD Program Page 29

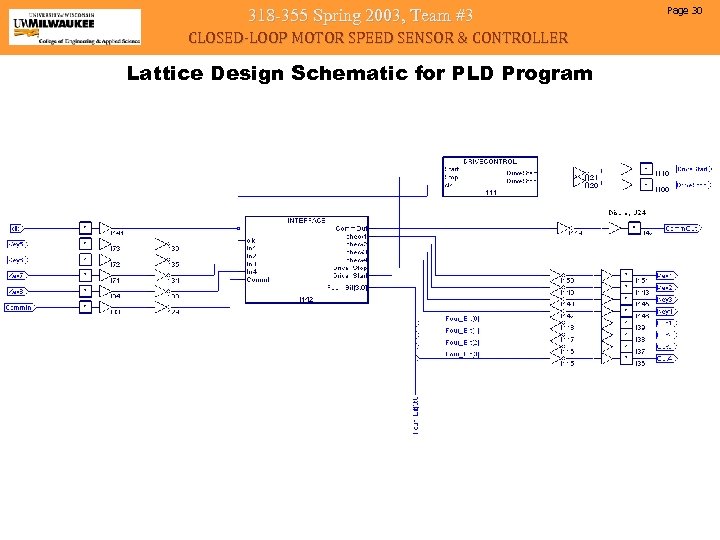

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Lattice Design Schematic for PLD Program Page 30

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Lattice Design Schematic for PLD Program Page 30

318 -355 Spring 2003, Team #3 Page 31 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Worst Case Analysis • Worst Case Analysis: Timing analysis for user interface and microprocessor circuit will be detailed in Microprocessor Hardware section. Mass Production Aspects • The user interface will consists of three assembly sections: • LCD Display: Manually installed on front of enclosure, interconnected with flat cable. • Keypad: Manually installed on front of enclosure, interconnected with flat cable. • Encoder Circuitry: Located on main PCB. Components to be SMT, automatically installed.

318 -355 Spring 2003, Team #3 Page 31 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Worst Case Analysis • Worst Case Analysis: Timing analysis for user interface and microprocessor circuit will be detailed in Microprocessor Hardware section. Mass Production Aspects • The user interface will consists of three assembly sections: • LCD Display: Manually installed on front of enclosure, interconnected with flat cable. • Keypad: Manually installed on front of enclosure, interconnected with flat cable. • Encoder Circuitry: Located on main PCB. Components to be SMT, automatically installed.

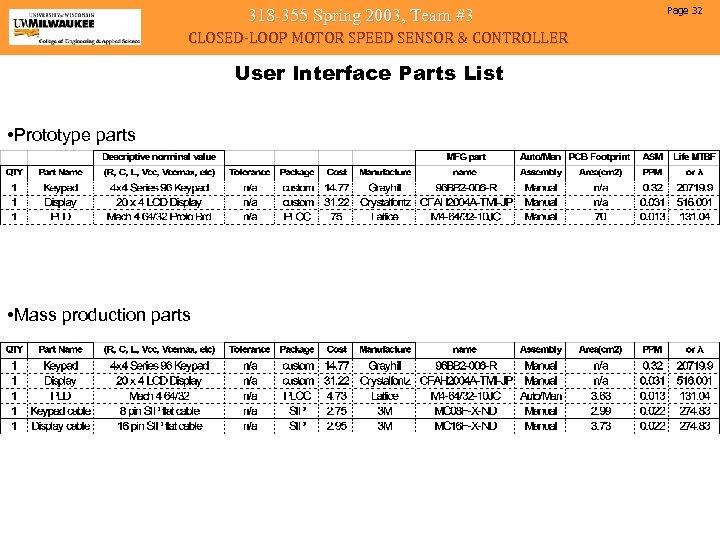

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Parts List • Prototype parts • Mass production parts Page 32

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Parts List • Prototype parts • Mass production parts Page 32

318 -355 Spring 2003, Team #3 Page 33 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Validation Plan and Results • Exercise keypad during the validation testing of the product software. • Keypad operating as expected during validation testing • Attempt to create a system anomaly when multiple keys are pressed simultaneously. • Unable to create this scenario • Verification that LCD displays proper characters and illuminates properly. • Due to programming difficulties, the LCD could not be verified. • Verify that maximum allowable debounce time is not exceeded. • Problems with the PLD code required entry of each digit individually to alleviate debounce problem. • Draws less than 750 m. W • Not verified • Suitable for industrial environments • By inspection and material selection

318 -355 Spring 2003, Team #3 Page 33 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Validation Plan and Results • Exercise keypad during the validation testing of the product software. • Keypad operating as expected during validation testing • Attempt to create a system anomaly when multiple keys are pressed simultaneously. • Unable to create this scenario • Verification that LCD displays proper characters and illuminates properly. • Due to programming difficulties, the LCD could not be verified. • Verify that maximum allowable debounce time is not exceeded. • Problems with the PLD code required entry of each digit individually to alleviate debounce problem. • Draws less than 750 m. W • Not verified • Suitable for industrial environments • By inspection and material selection

318 -355 Spring 2003, Team #3 Page 34 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Validation Results • Exercise keypad: operating as expected during validation testing • Two keys pressed: Unable to create this scenario • Due to programming difficulties, the LCD could not be verified. • Debounce time verification revealed problems with the PLD code, therefore entry of each digit was required. • Draws less than 750 m. W: not verified • Suitable for industrial environments: by inspection and material selection

318 -355 Spring 2003, Team #3 Page 34 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Validation Results • Exercise keypad: operating as expected during validation testing • Two keys pressed: Unable to create this scenario • Due to programming difficulties, the LCD could not be verified. • Debounce time verification revealed problems with the PLD code, therefore entry of each digit was required. • Draws less than 750 m. W: not verified • Suitable for industrial environments: by inspection and material selection

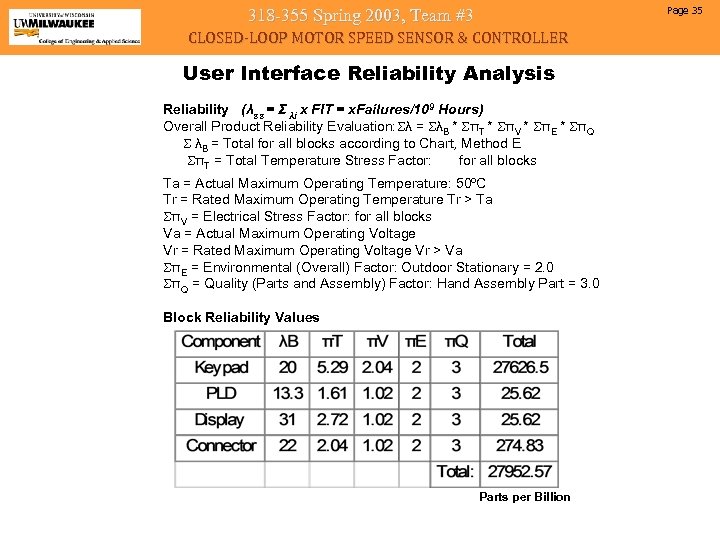

Page 35 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Reliability Analysis Reliability (λss = Σ λi x FIT = x. Failures/109 Hours) Overall Product Reliability Evaluation: λ = λB * πT * πV * πE * πQ λB = Total for all blocks according to Chart, Method E πT = Total Temperature Stress Factor: for all blocks Ta = Actual Maximum Operating Temperature: 50ºC Tr = Rated Maximum Operating Temperature Tr > Ta πV = Electrical Stress Factor: for all blocks Va = Actual Maximum Operating Voltage Vr = Rated Maximum Operating Voltage Vr > Va πE = Environmental (Overall) Factor: Outdoor Stationary = 2. 0 πQ = Quality (Parts and Assembly) Factor: Hand Assembly Part = 3. 0 Block Reliability Values Parts per Billion

Page 35 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER User Interface Reliability Analysis Reliability (λss = Σ λi x FIT = x. Failures/109 Hours) Overall Product Reliability Evaluation: λ = λB * πT * πV * πE * πQ λB = Total for all blocks according to Chart, Method E πT = Total Temperature Stress Factor: for all blocks Ta = Actual Maximum Operating Temperature: 50ºC Tr = Rated Maximum Operating Temperature Tr > Ta πV = Electrical Stress Factor: for all blocks Va = Actual Maximum Operating Voltage Vr = Rated Maximum Operating Voltage Vr > Va πE = Environmental (Overall) Factor: Outdoor Stationary = 2. 0 πQ = Quality (Parts and Assembly) Factor: Hand Assembly Part = 3. 0 Block Reliability Values Parts per Billion

318 -355 Spring 2003, Team #3 Page 36 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Let’s cover the Sensor Circuit next. .

318 -355 Spring 2003, Team #3 Page 36 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Let’s cover the Sensor Circuit next. .

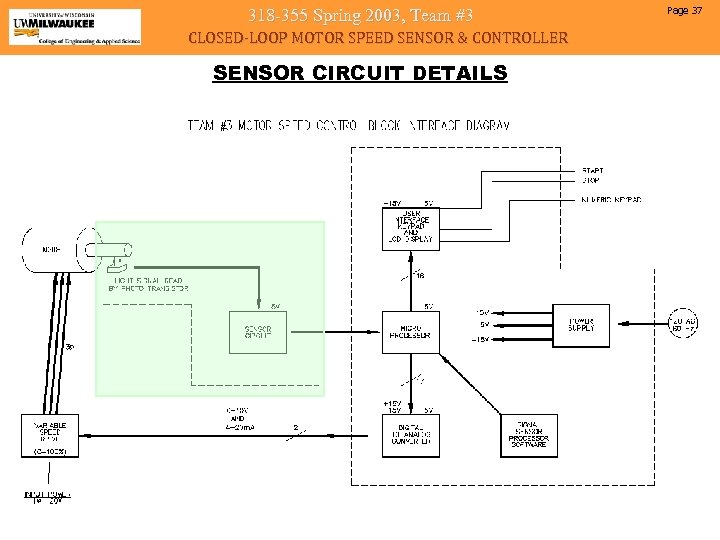

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER SENSOR CIRCUIT DETAILS Page 37

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER SENSOR CIRCUIT DETAILS Page 37

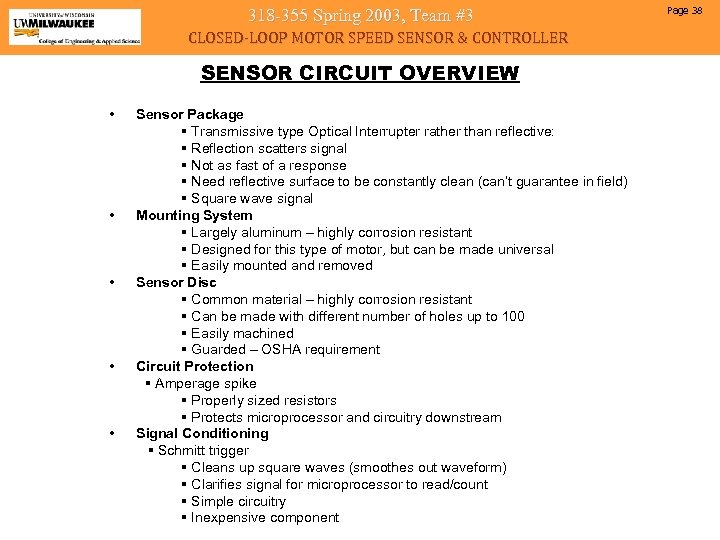

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER SENSOR CIRCUIT OVERVIEW • • • Sensor Package Transmissive type Optical Interrupter rather than reflective: Reflection scatters signal Not as fast of a response Need reflective surface to be constantly clean (can’t guarantee in field) Square wave signal Mounting System Largely aluminum – highly corrosion resistant Designed for this type of motor, but can be made universal Easily mounted and removed Sensor Disc Common material – highly corrosion resistant Can be made with different number of holes up to 100 Easily machined Guarded – OSHA requirement Circuit Protection Amperage spike Properly sized resistors Protects microprocessor and circuitry downstream Signal Conditioning Schmitt trigger Cleans up square waves (smoothes out waveform) Clarifies signal for microprocessor to read/count Simple circuitry Inexpensive component Page 38

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER SENSOR CIRCUIT OVERVIEW • • • Sensor Package Transmissive type Optical Interrupter rather than reflective: Reflection scatters signal Not as fast of a response Need reflective surface to be constantly clean (can’t guarantee in field) Square wave signal Mounting System Largely aluminum – highly corrosion resistant Designed for this type of motor, but can be made universal Easily mounted and removed Sensor Disc Common material – highly corrosion resistant Can be made with different number of holes up to 100 Easily machined Guarded – OSHA requirement Circuit Protection Amperage spike Properly sized resistors Protects microprocessor and circuitry downstream Signal Conditioning Schmitt trigger Cleans up square waves (smoothes out waveform) Clarifies signal for microprocessor to read/count Simple circuitry Inexpensive component Page 38

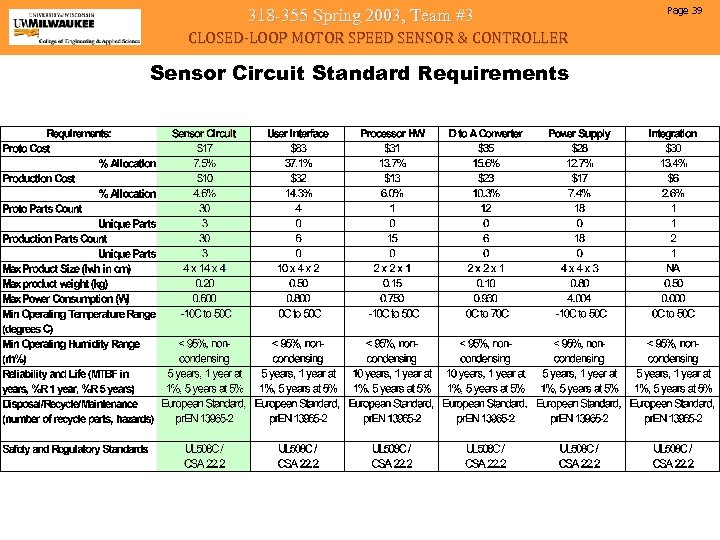

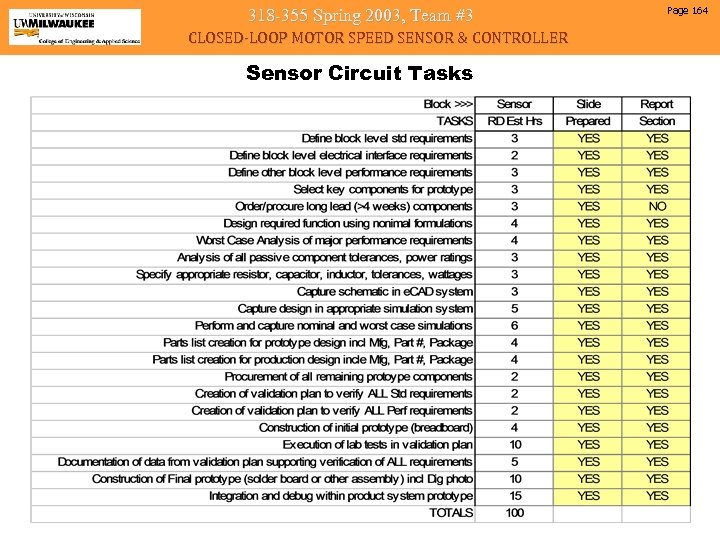

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Standard Requirements Page 39

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Standard Requirements Page 39

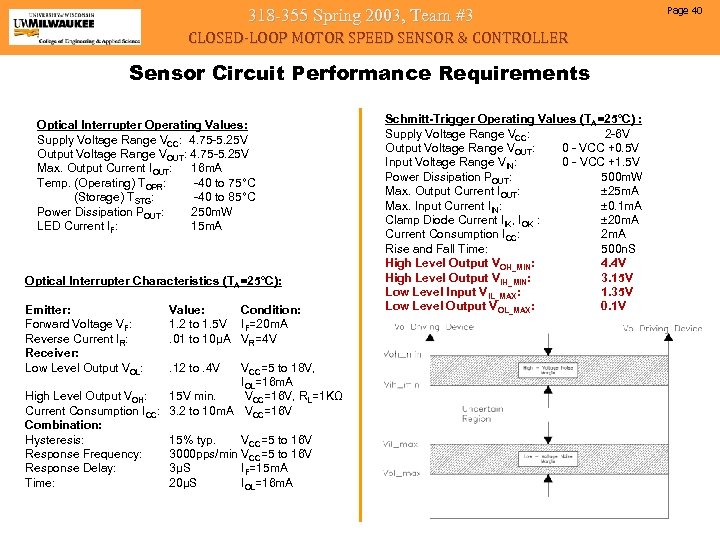

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Performance Requirements Optical Interrupter Operating Values: Supply Voltage Range VCC: 4. 75 -5. 25 V Output Voltage Range VOUT: 4. 75 -5. 25 V Max. Output Current IOUT: 16 m. A Temp. (Operating) TOPR: -40 to 75°C (Storage) T STG: -40 to 85°C Power Dissipation POUT: 250 m. W LED Current IF: 15 m. A Optical Interrupter Characteristics (TA=25°C): Emitter: Forward Voltage VF: Reverse Current IR: Receiver: Low Level Output VOL: Value: Condition: 1. 2 to 1. 5 V IF=20 m. A. 01 to 10μA VR=4 V. 12 to. 4 V VCC=5 to 18 V, IOL=16 m. A High Level Output VOH: 15 V min. VCC=16 V, RL=1 KΩ Current Consumption ICC: 3. 2 to 10 m. A VCC=16 V Combination: Hysteresis: 15% typ. VCC=5 to 16 V Response Frequency: 3000 pps/min VCC=5 to 16 V Response Delay: 3μS IF=15 m. A Time: 20μS IOL=16 m. A Schmitt-Trigger Operating Values (TA=25°C) : Supply Voltage Range VCC: 2 -6 V Output Voltage Range VOUT: 0 - VCC +0. 5 V Input Voltage Range VIN: 0 - VCC +1. 5 V Power Dissipation POUT: 500 m. W Max. Output Current IOUT: ± 25 m. A Max. Input Current IIN: ± 0. 1 m. A Clamp Diode Current IIK, IOK : ± 20 m. A Current Consumption ICC: 2 m. A Rise and Fall Time: 500 n. S High Level Output V OH_MIN: 4. 4 V High Level Output V IH_MIN: 3. 15 V Low Level Input V IL_MAX: 1. 35 V Low Level Output V OL_MAX: 0. 1 V Page 40

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Performance Requirements Optical Interrupter Operating Values: Supply Voltage Range VCC: 4. 75 -5. 25 V Output Voltage Range VOUT: 4. 75 -5. 25 V Max. Output Current IOUT: 16 m. A Temp. (Operating) TOPR: -40 to 75°C (Storage) T STG: -40 to 85°C Power Dissipation POUT: 250 m. W LED Current IF: 15 m. A Optical Interrupter Characteristics (TA=25°C): Emitter: Forward Voltage VF: Reverse Current IR: Receiver: Low Level Output VOL: Value: Condition: 1. 2 to 1. 5 V IF=20 m. A. 01 to 10μA VR=4 V. 12 to. 4 V VCC=5 to 18 V, IOL=16 m. A High Level Output VOH: 15 V min. VCC=16 V, RL=1 KΩ Current Consumption ICC: 3. 2 to 10 m. A VCC=16 V Combination: Hysteresis: 15% typ. VCC=5 to 16 V Response Frequency: 3000 pps/min VCC=5 to 16 V Response Delay: 3μS IF=15 m. A Time: 20μS IOL=16 m. A Schmitt-Trigger Operating Values (TA=25°C) : Supply Voltage Range VCC: 2 -6 V Output Voltage Range VOUT: 0 - VCC +0. 5 V Input Voltage Range VIN: 0 - VCC +1. 5 V Power Dissipation POUT: 500 m. W Max. Output Current IOUT: ± 25 m. A Max. Input Current IIN: ± 0. 1 m. A Clamp Diode Current IIK, IOK : ± 20 m. A Current Consumption ICC: 2 m. A Rise and Fall Time: 500 n. S High Level Output V OH_MIN: 4. 4 V High Level Output V IH_MIN: 3. 15 V Low Level Input V IL_MAX: 1. 35 V Low Level Output V OL_MAX: 0. 1 V Page 40

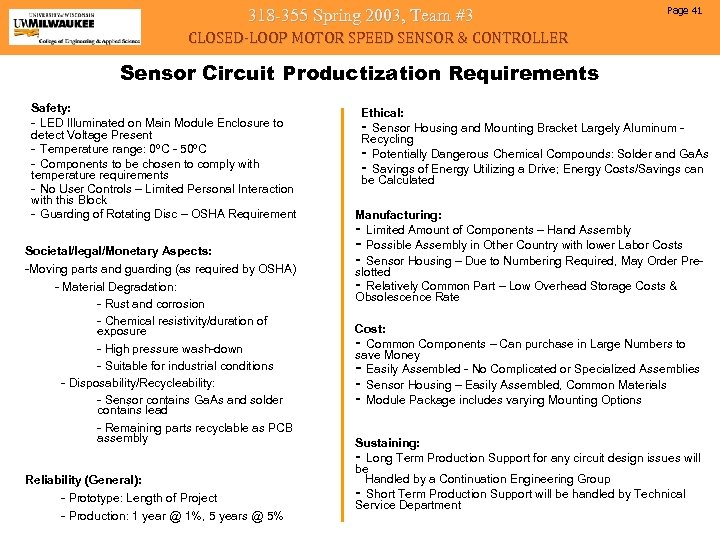

318 -355 Spring 2003, Team #3 Page 41 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Productization Requirements Safety: - LED Illuminated on Main Module Enclosure to detect Voltage Present - Temperature range: 0ºC - 50ºC - Components to be chosen to comply with temperature requirements - No User Controls – Limited Personal Interaction with this Block - Guarding of Rotating Disc – OSHA Requirement Societal/legal/Monetary Aspects: -Moving parts and guarding (as required by OSHA) - Material Degradation: - Rust and corrosion - Chemical resistivity/duration of exposure - High pressure wash-down - Suitable for industrial conditions - Disposability/Recycleability: - Sensor contains Ga. As and solder contains lead - Remaining parts recyclable as PCB assembly Reliability (General): - Prototype: Length of Project - Production: 1 year @ 1%, 5 years @ 5% Ethical: - Sensor Housing and Mounting Bracket Largely Aluminum - Recycling - Potentially Dangerous Chemical Compounds: Solder and Ga. As - Savings of Energy Utilizing a Drive; Energy Costs/Savings can be Calculated Manufacturing: - Limited Amount of Components – Hand Assembly - Possible Assembly in Other Country with lower Labor Costs - Sensor Housing – Due to Numbering Required, May Order Preslotted - Relatively Common Part – Low Overhead Storage Costs & Obsolescence Rate Cost: - Common Components – Can purchase in Large Numbers to save Money - Easily Assembled - No Complicated or Specialized Assemblies - Sensor Housing – Easily Assembled, Common Materials - Module Package includes varying Mounting Options Sustaining: - Long Term Production Support for any circuit design issues will be Handled by a Continuation Engineering Group - Short Term Production Support will be handled by Technical Service Department

318 -355 Spring 2003, Team #3 Page 41 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Productization Requirements Safety: - LED Illuminated on Main Module Enclosure to detect Voltage Present - Temperature range: 0ºC - 50ºC - Components to be chosen to comply with temperature requirements - No User Controls – Limited Personal Interaction with this Block - Guarding of Rotating Disc – OSHA Requirement Societal/legal/Monetary Aspects: -Moving parts and guarding (as required by OSHA) - Material Degradation: - Rust and corrosion - Chemical resistivity/duration of exposure - High pressure wash-down - Suitable for industrial conditions - Disposability/Recycleability: - Sensor contains Ga. As and solder contains lead - Remaining parts recyclable as PCB assembly Reliability (General): - Prototype: Length of Project - Production: 1 year @ 1%, 5 years @ 5% Ethical: - Sensor Housing and Mounting Bracket Largely Aluminum - Recycling - Potentially Dangerous Chemical Compounds: Solder and Ga. As - Savings of Energy Utilizing a Drive; Energy Costs/Savings can be Calculated Manufacturing: - Limited Amount of Components – Hand Assembly - Possible Assembly in Other Country with lower Labor Costs - Sensor Housing – Due to Numbering Required, May Order Preslotted - Relatively Common Part – Low Overhead Storage Costs & Obsolescence Rate Cost: - Common Components – Can purchase in Large Numbers to save Money - Easily Assembled - No Complicated or Specialized Assemblies - Sensor Housing – Easily Assembled, Common Materials - Module Package includes varying Mounting Options Sustaining: - Long Term Production Support for any circuit design issues will be Handled by a Continuation Engineering Group - Short Term Production Support will be handled by Technical Service Department

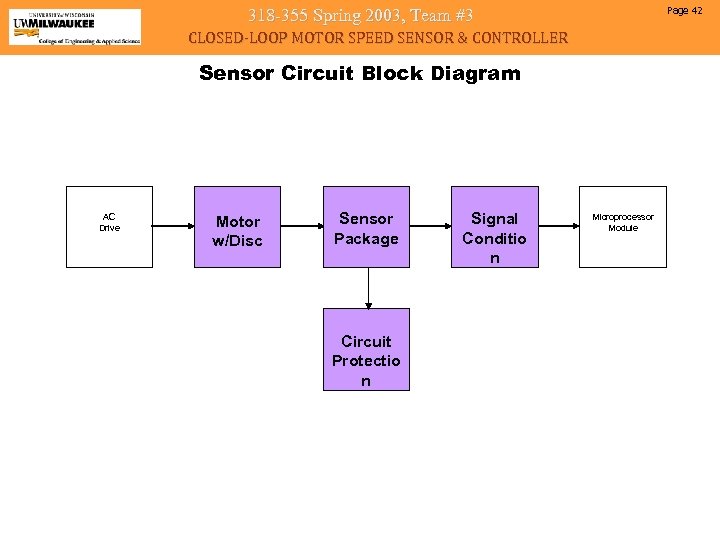

Page 42 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Block Diagram AC Drive Motor w/Disc Sensor Package Circuit Protectio n Signal Conditio n Microprocessor Module

Page 42 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Block Diagram AC Drive Motor w/Disc Sensor Package Circuit Protectio n Signal Conditio n Microprocessor Module

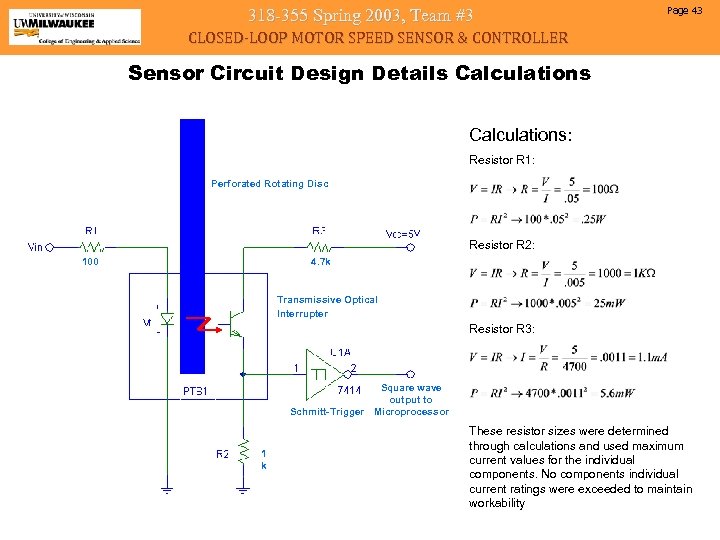

318 -355 Spring 2003, Team #3 Page 43 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Design Details Calculations: Resistor R 1: Perforated Rotating Disc Resistor R 2: 100 4. 7 k Transmissive Optical Interrupter Resistor R 3: Square wave output to Schmitt-Trigger Microprocessor 1 k These resistor sizes were determined through calculations and used maximum current values for the individual components. No components individual current ratings were exceeded to maintain workability

318 -355 Spring 2003, Team #3 Page 43 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Design Details Calculations: Resistor R 1: Perforated Rotating Disc Resistor R 2: 100 4. 7 k Transmissive Optical Interrupter Resistor R 3: Square wave output to Schmitt-Trigger Microprocessor 1 k These resistor sizes were determined through calculations and used maximum current values for the individual components. No components individual current ratings were exceeded to maintain workability

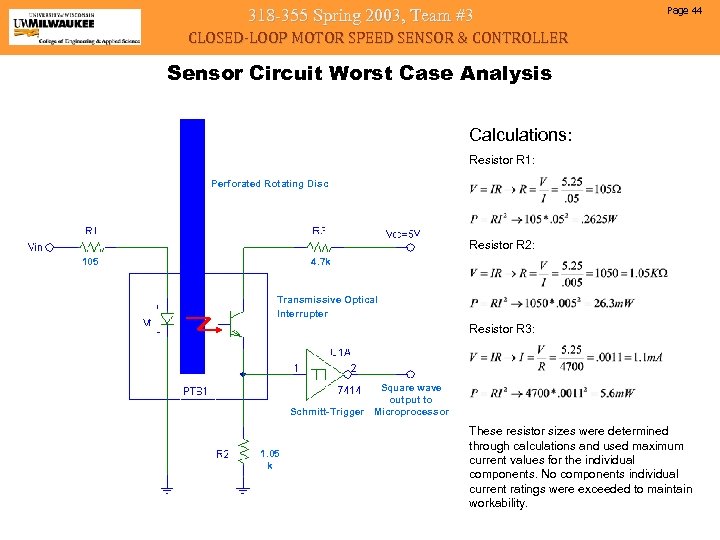

318 -355 Spring 2003, Team #3 Page 44 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Worst Case Analysis Calculations: Resistor R 1: Perforated Rotating Disc Resistor R 2: 105 4. 7 k Transmissive Optical Interrupter Resistor R 3: Square wave output to Schmitt-Trigger Microprocessor 1. 05 k These resistor sizes were determined through calculations and used maximum current values for the individual components. No components individual current ratings were exceeded to maintain workability.

318 -355 Spring 2003, Team #3 Page 44 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Worst Case Analysis Calculations: Resistor R 1: Perforated Rotating Disc Resistor R 2: 105 4. 7 k Transmissive Optical Interrupter Resistor R 3: Square wave output to Schmitt-Trigger Microprocessor 1. 05 k These resistor sizes were determined through calculations and used maximum current values for the individual components. No components individual current ratings were exceeded to maintain workability.

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Mass Production • Final assembly of the sensor circuit will be primarily hand assembly due to the mechanical nature of the design. • The discrete components will be mounted on a PC board using surface mount technology. • For mass production, the enclosure could be redesigned to eliminate any fasteners, and replace then with a snap-fit configuration. Page 45

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Mass Production • Final assembly of the sensor circuit will be primarily hand assembly due to the mechanical nature of the design. • The discrete components will be mounted on a PC board using surface mount technology. • For mass production, the enclosure could be redesigned to eliminate any fasteners, and replace then with a snap-fit configuration. Page 45

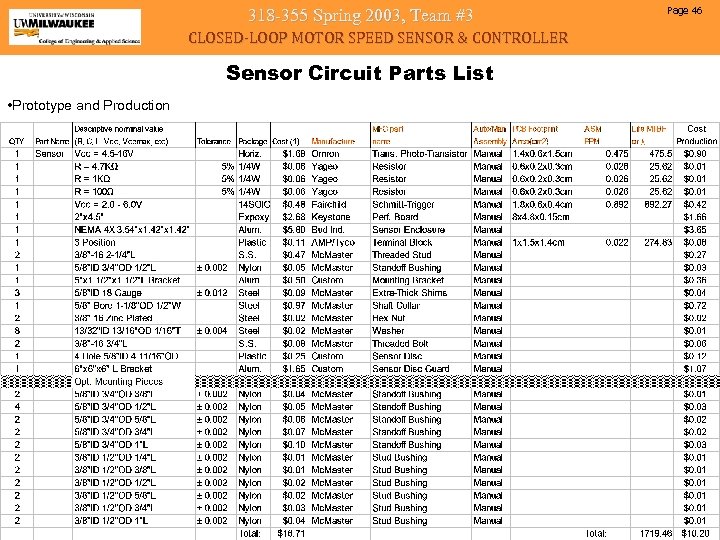

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Parts List • Prototype and Production Page 46

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Parts List • Prototype and Production Page 46

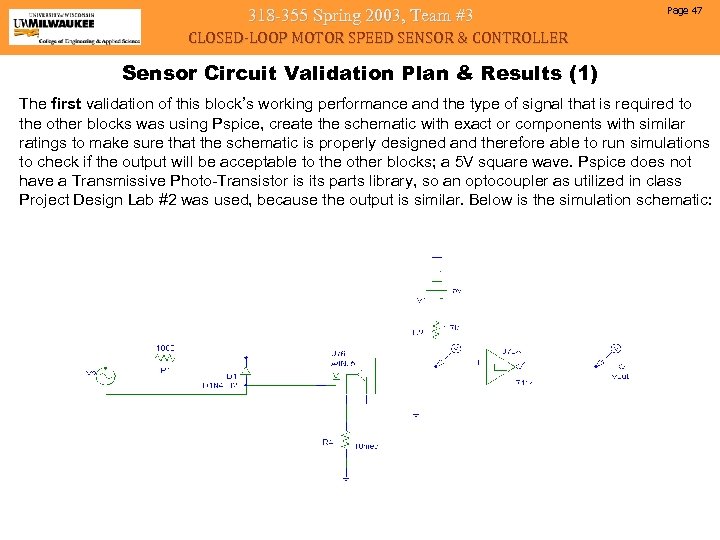

318 -355 Spring 2003, Team #3 Page 47 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (1) The first validation of this block’s working performance and the type of signal that is required to the other blocks was using Pspice, create the schematic with exact or components with similar ratings to make sure that the schematic is properly designed and therefore able to run simulations to check if the output will be acceptable to the other blocks; a 5 V square wave. Pspice does not have a Transmissive Photo-Transistor is its parts library, so an optocoupler as utilized in class Project Design Lab #2 was used, because the output is similar. Below is the simulation schematic:

318 -355 Spring 2003, Team #3 Page 47 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (1) The first validation of this block’s working performance and the type of signal that is required to the other blocks was using Pspice, create the schematic with exact or components with similar ratings to make sure that the schematic is properly designed and therefore able to run simulations to check if the output will be acceptable to the other blocks; a 5 V square wave. Pspice does not have a Transmissive Photo-Transistor is its parts library, so an optocoupler as utilized in class Project Design Lab #2 was used, because the output is similar. Below is the simulation schematic:

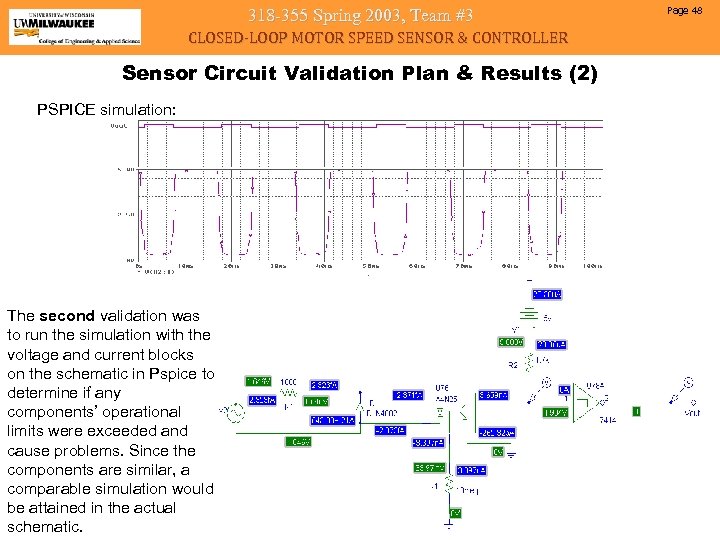

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (2) PSPICE simulation: The second validation was to run the simulation with the voltage and current blocks on the schematic in Pspice to determine if any components’ operational limits were exceeded and cause problems. Since the components are similar, a comparable simulation would be attained in the actual schematic. Page 48

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (2) PSPICE simulation: The second validation was to run the simulation with the voltage and current blocks on the schematic in Pspice to determine if any components’ operational limits were exceeded and cause problems. Since the components are similar, a comparable simulation would be attained in the actual schematic. Page 48

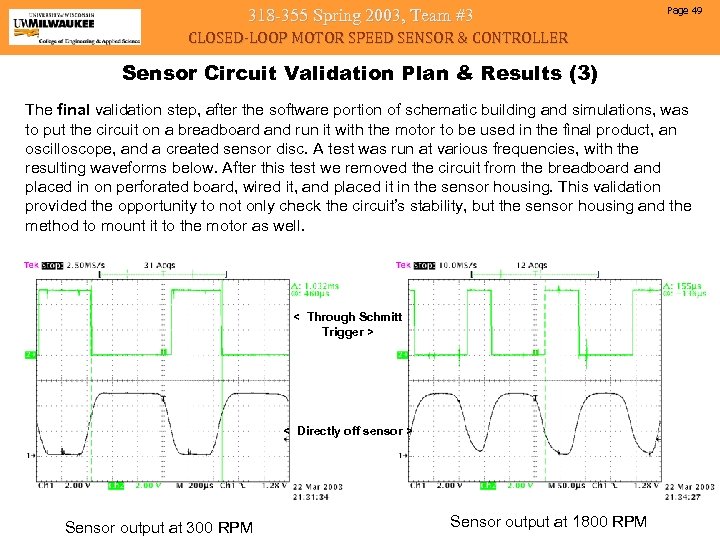

318 -355 Spring 2003, Team #3 Page 49 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (3) The final validation step, after the software portion of schematic building and simulations, was to put the circuit on a breadboard and run it with the motor to be used in the final product, an oscilloscope, and a created sensor disc. A test was run at various frequencies, with the resulting waveforms below. After this test we removed the circuit from the breadboard and placed in on perforated board, wired it, and placed it in the sensor housing. This validation provided the opportunity to not only check the circuit’s stability, but the sensor housing and the method to mount it to the motor as well. < Through Schmitt Trigger > < Directly off sensor > Sensor output at 300 RPM Sensor output at 1800 RPM

318 -355 Spring 2003, Team #3 Page 49 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (3) The final validation step, after the software portion of schematic building and simulations, was to put the circuit on a breadboard and run it with the motor to be used in the final product, an oscilloscope, and a created sensor disc. A test was run at various frequencies, with the resulting waveforms below. After this test we removed the circuit from the breadboard and placed in on perforated board, wired it, and placed it in the sensor housing. This validation provided the opportunity to not only check the circuit’s stability, but the sensor housing and the method to mount it to the motor as well. < Through Schmitt Trigger > < Directly off sensor > Sensor output at 300 RPM Sensor output at 1800 RPM

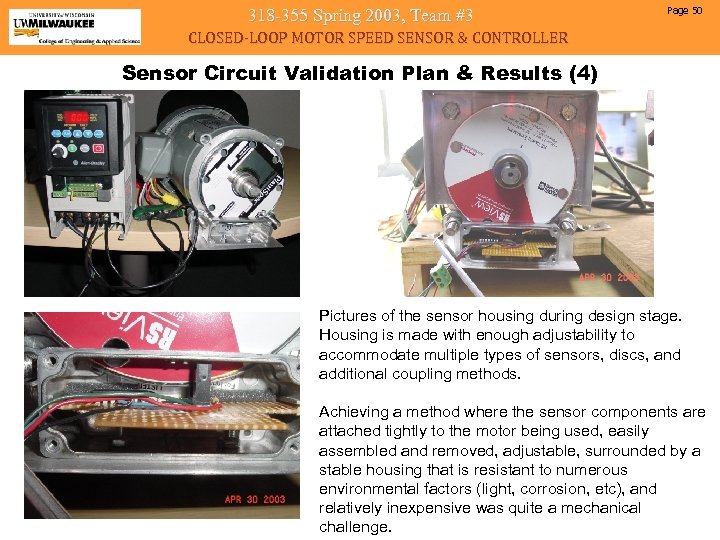

318 -355 Spring 2003, Team #3 Page 50 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (4) Pictures of the sensor housing during design stage. Housing is made with enough adjustability to accommodate multiple types of sensors, discs, and additional coupling methods. Achieving a method where the sensor components are attached tightly to the motor being used, easily assembled and removed, adjustable, surrounded by a stable housing that is resistant to numerous environmental factors (light, corrosion, etc), and relatively inexpensive was quite a mechanical challenge.

318 -355 Spring 2003, Team #3 Page 50 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (4) Pictures of the sensor housing during design stage. Housing is made with enough adjustability to accommodate multiple types of sensors, discs, and additional coupling methods. Achieving a method where the sensor components are attached tightly to the motor being used, easily assembled and removed, adjustable, surrounded by a stable housing that is resistant to numerous environmental factors (light, corrosion, etc), and relatively inexpensive was quite a mechanical challenge.

318 -355 Spring 2003, Team #3 Page 51 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (5) • Draws less than 600 m. W: not verified • Suitable for industrial environments: by inspection and material selection • Can be installed with basic hand tools • Only tested on one brand of drive, could not attain other drive products for testing.

318 -355 Spring 2003, Team #3 Page 51 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Validation Plan & Results (5) • Draws less than 600 m. W: not verified • Suitable for industrial environments: by inspection and material selection • Can be installed with basic hand tools • Only tested on one brand of drive, could not attain other drive products for testing.

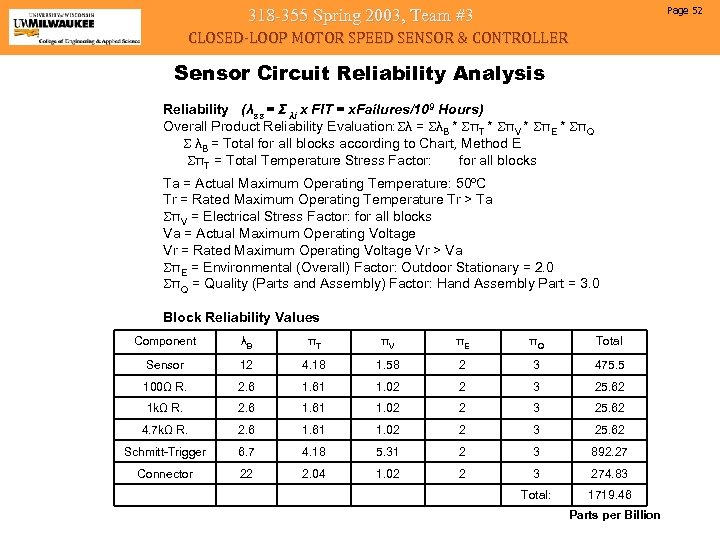

Page 52 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Reliability Analysis Reliability (λss = Σ λi x FIT = x. Failures/109 Hours) Overall Product Reliability Evaluation: λ = λB * πT * πV * πE * πQ λB = Total for all blocks according to Chart, Method E πT = Total Temperature Stress Factor: for all blocks Ta = Actual Maximum Operating Temperature: 50ºC Tr = Rated Maximum Operating Temperature Tr > Ta πV = Electrical Stress Factor: for all blocks Va = Actual Maximum Operating Voltage Vr = Rated Maximum Operating Voltage Vr > Va πE = Environmental (Overall) Factor: Outdoor Stationary = 2. 0 πQ = Quality (Parts and Assembly) Factor: Hand Assembly Part = 3. 0 Block Reliability Values Component λB πT πV πE πQ Total Sensor 12 4. 18 1. 58 2 3 475. 5 100Ω R. 2. 6 1. 61 1. 02 2 3 25. 62 1 kΩ R. 2. 6 1. 61 1. 02 2 3 25. 62 4. 7 kΩ R. 2. 6 1. 61 1. 02 2 3 25. 62 Schmitt-Trigger 6. 7 4. 18 5. 31 2 3 892. 27 Connector 22 2. 04 1. 02 2 3 274. 83 Total: 1719. 46 Parts per Billion

Page 52 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Sensor Circuit Reliability Analysis Reliability (λss = Σ λi x FIT = x. Failures/109 Hours) Overall Product Reliability Evaluation: λ = λB * πT * πV * πE * πQ λB = Total for all blocks according to Chart, Method E πT = Total Temperature Stress Factor: for all blocks Ta = Actual Maximum Operating Temperature: 50ºC Tr = Rated Maximum Operating Temperature Tr > Ta πV = Electrical Stress Factor: for all blocks Va = Actual Maximum Operating Voltage Vr = Rated Maximum Operating Voltage Vr > Va πE = Environmental (Overall) Factor: Outdoor Stationary = 2. 0 πQ = Quality (Parts and Assembly) Factor: Hand Assembly Part = 3. 0 Block Reliability Values Component λB πT πV πE πQ Total Sensor 12 4. 18 1. 58 2 3 475. 5 100Ω R. 2. 6 1. 61 1. 02 2 3 25. 62 1 kΩ R. 2. 6 1. 61 1. 02 2 3 25. 62 4. 7 kΩ R. 2. 6 1. 61 1. 02 2 3 25. 62 Schmitt-Trigger 6. 7 4. 18 5. 31 2 3 892. 27 Connector 22 2. 04 1. 02 2 3 274. 83 Total: 1719. 46 Parts per Billion

318 -355 Spring 2003, Team #3 Page 53 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Next is the Microprocessor Hardware Overview. . .

318 -355 Spring 2003, Team #3 Page 53 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Next is the Microprocessor Hardware Overview. . .

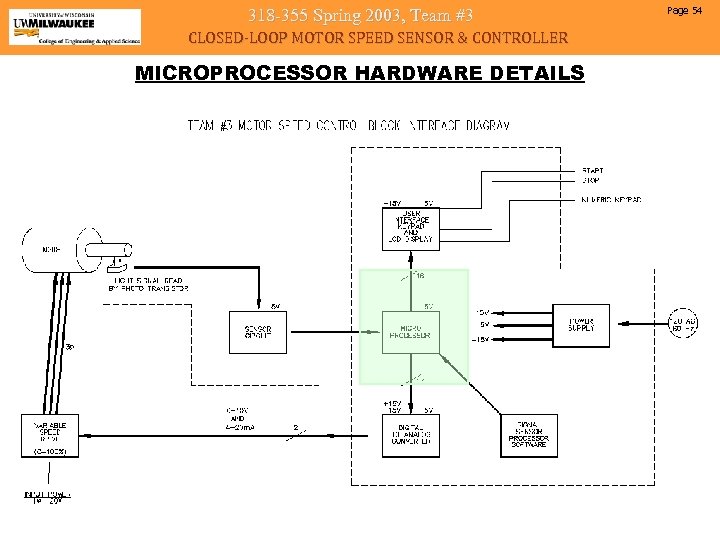

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER MICROPROCESSOR HARDWARE DETAILS Page 54

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER MICROPROCESSOR HARDWARE DETAILS Page 54

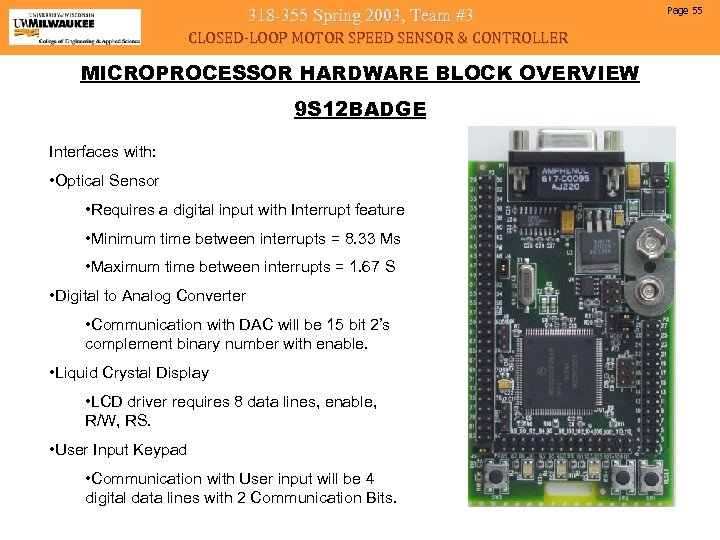

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER MICROPROCESSOR HARDWARE BLOCK OVERVIEW 9 S 12 BADGE Interfaces with: • Optical Sensor • Requires a digital input with Interrupt feature • Minimum time between interrupts = 8. 33 Ms • Maximum time between interrupts = 1. 67 S • Digital to Analog Converter • Communication with DAC will be 15 bit 2’s complement binary number with enable. • Liquid Crystal Display • LCD driver requires 8 data lines, enable, R/W, RS. • User Input Keypad • Communication with User input will be 4 digital data lines with 2 Communication Bits. Page 55

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER MICROPROCESSOR HARDWARE BLOCK OVERVIEW 9 S 12 BADGE Interfaces with: • Optical Sensor • Requires a digital input with Interrupt feature • Minimum time between interrupts = 8. 33 Ms • Maximum time between interrupts = 1. 67 S • Digital to Analog Converter • Communication with DAC will be 15 bit 2’s complement binary number with enable. • Liquid Crystal Display • LCD driver requires 8 data lines, enable, R/W, RS. • User Input Keypad • Communication with User input will be 4 digital data lines with 2 Communication Bits. Page 55

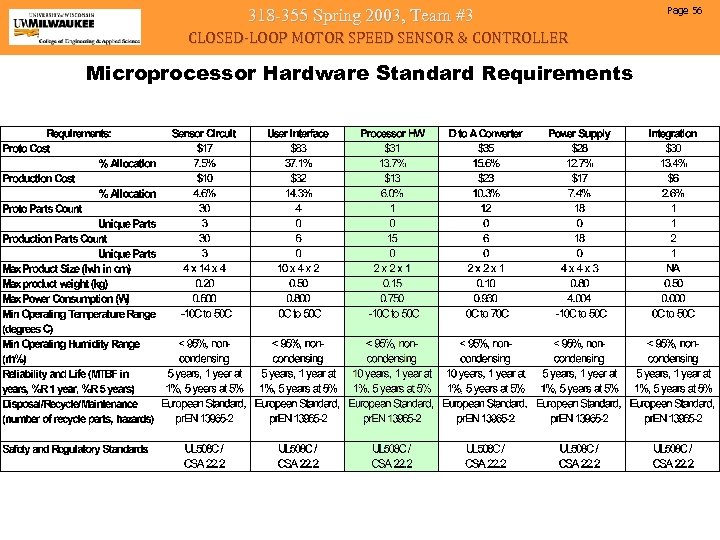

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Standard Requirements Page 56

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Standard Requirements Page 56

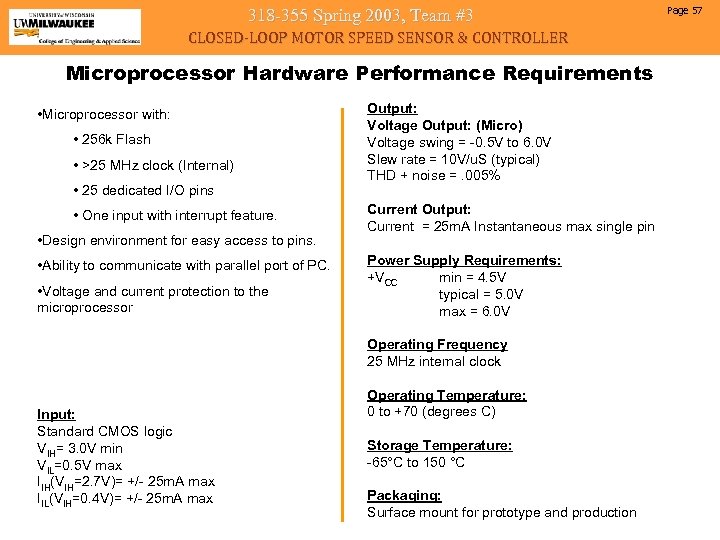

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Performance Requirements • Microprocessor with: • 256 k Flash • >25 MHz clock (Internal) • 25 dedicated I/O pins • One input with interrupt feature. • Design environment for easy access to pins. • Ability to communicate with parallel port of PC. • Voltage and current protection to the microprocessor Output: Voltage Output: (Micro) Voltage swing = -0. 5 V to 6. 0 V Slew rate = 10 V/u. S (typical) THD + noise =. 005% Current Output: Current = 25 m. A Instantaneous max single pin Power Supply Requirements: +VCC min = 4. 5 V typical = 5. 0 V max = 6. 0 V Operating Frequency 25 MHz internal clock Input: Standard CMOS logic VIH= 3. 0 V min VIL=0. 5 V max IIH(VIH=2. 7 V)= +/- 25 m. A max IIL(VIH=0. 4 V)= +/- 25 m. A max Operating Temperature: 0 to +70 (degrees C) Storage Temperature: -65°C to 150 °C Packaging: Surface mount for prototype and production Page 57

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Performance Requirements • Microprocessor with: • 256 k Flash • >25 MHz clock (Internal) • 25 dedicated I/O pins • One input with interrupt feature. • Design environment for easy access to pins. • Ability to communicate with parallel port of PC. • Voltage and current protection to the microprocessor Output: Voltage Output: (Micro) Voltage swing = -0. 5 V to 6. 0 V Slew rate = 10 V/u. S (typical) THD + noise =. 005% Current Output: Current = 25 m. A Instantaneous max single pin Power Supply Requirements: +VCC min = 4. 5 V typical = 5. 0 V max = 6. 0 V Operating Frequency 25 MHz internal clock Input: Standard CMOS logic VIH= 3. 0 V min VIL=0. 5 V max IIH(VIH=2. 7 V)= +/- 25 m. A max IIL(VIH=0. 4 V)= +/- 25 m. A max Operating Temperature: 0 to +70 (degrees C) Storage Temperature: -65°C to 150 °C Packaging: Surface mount for prototype and production Page 57

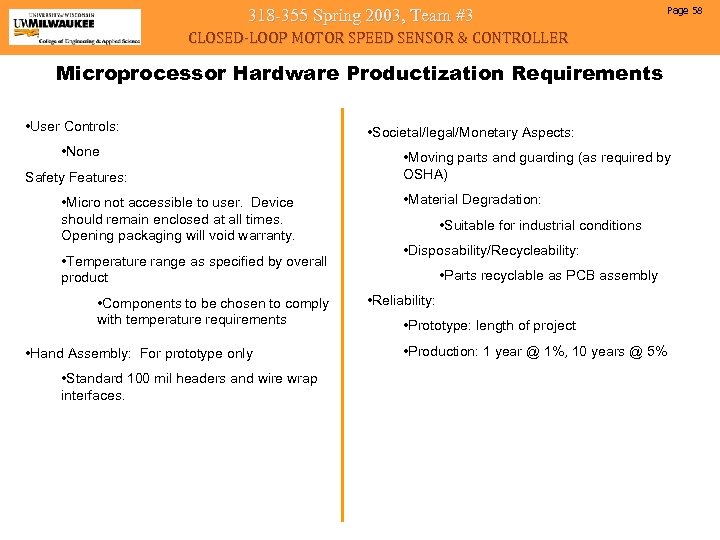

318 -355 Spring 2003, Team #3 Page 58 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Productization Requirements • User Controls: • None Safety Features: • Micro not accessible to user. Device should remain enclosed at all times. Opening packaging will void warranty. • Temperature range as specified by overall product • Components to be chosen to comply with temperature requirements • Hand Assembly: For prototype only • Standard 100 mil headers and wire wrap interfaces. • Societal/legal/Monetary Aspects: • Moving parts and guarding (as required by OSHA) • Material Degradation: • Suitable for industrial conditions • Disposability/Recycleability: • Parts recyclable as PCB assembly • Reliability: • Prototype: length of project • Production: 1 year @ 1%, 10 years @ 5%

318 -355 Spring 2003, Team #3 Page 58 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Productization Requirements • User Controls: • None Safety Features: • Micro not accessible to user. Device should remain enclosed at all times. Opening packaging will void warranty. • Temperature range as specified by overall product • Components to be chosen to comply with temperature requirements • Hand Assembly: For prototype only • Standard 100 mil headers and wire wrap interfaces. • Societal/legal/Monetary Aspects: • Moving parts and guarding (as required by OSHA) • Material Degradation: • Suitable for industrial conditions • Disposability/Recycleability: • Parts recyclable as PCB assembly • Reliability: • Prototype: length of project • Production: 1 year @ 1%, 10 years @ 5%

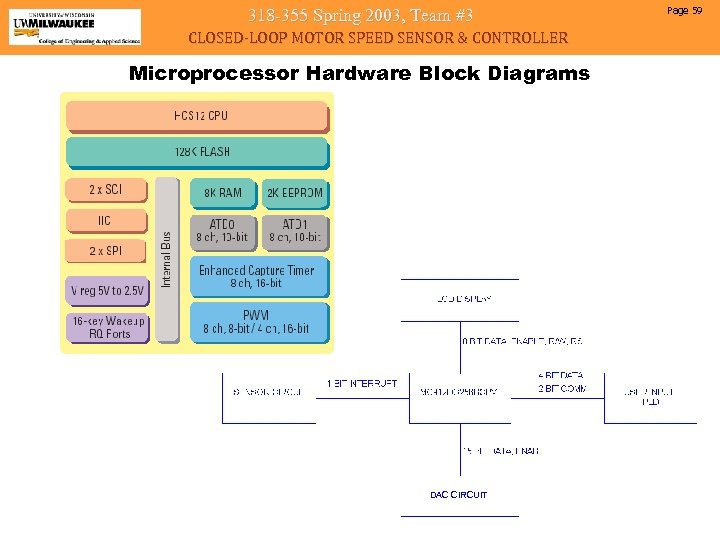

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Block Diagrams DAC CIRCUIT Page 59

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Block Diagrams DAC CIRCUIT Page 59

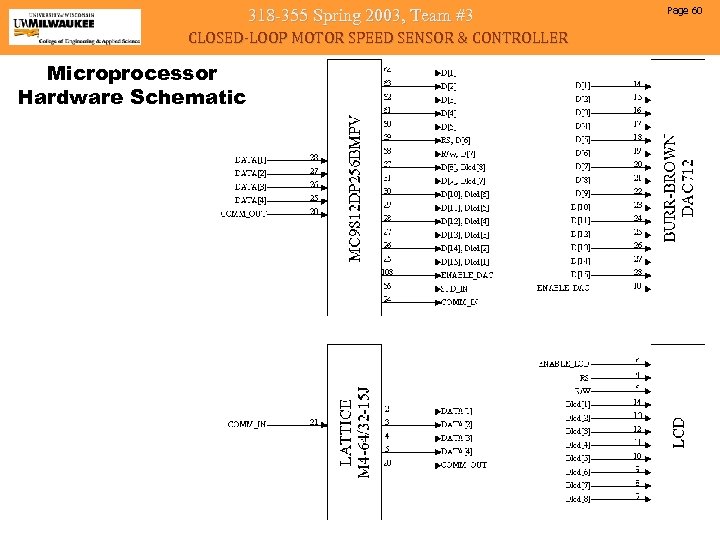

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Schematic Page 60

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Schematic Page 60

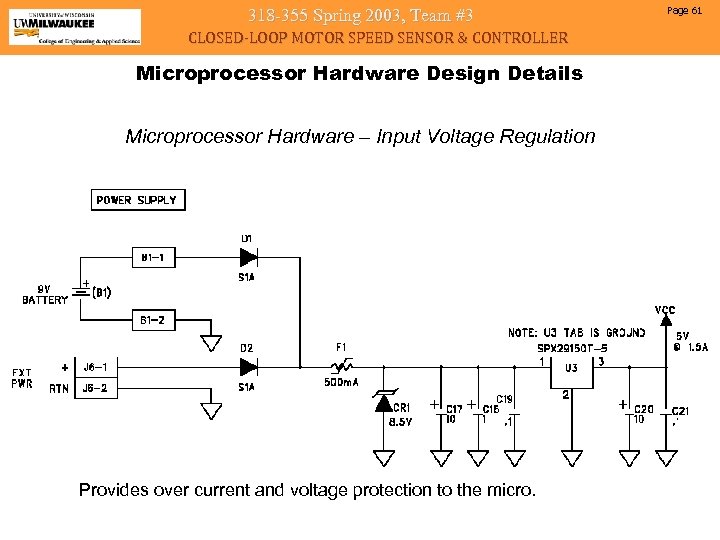

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Design Details Microprocessor Hardware – Input Voltage Regulation Provides over current and voltage protection to the micro. Page 61

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Design Details Microprocessor Hardware – Input Voltage Regulation Provides over current and voltage protection to the micro. Page 61

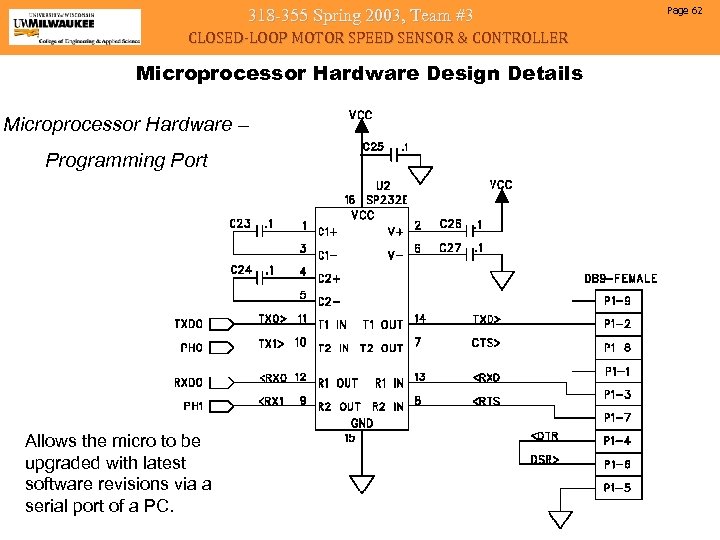

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Design Details Microprocessor Hardware – Programming Port Allows the micro to be upgraded with latest software revisions via a serial port of a PC. Page 62

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Design Details Microprocessor Hardware – Programming Port Allows the micro to be upgraded with latest software revisions via a serial port of a PC. Page 62

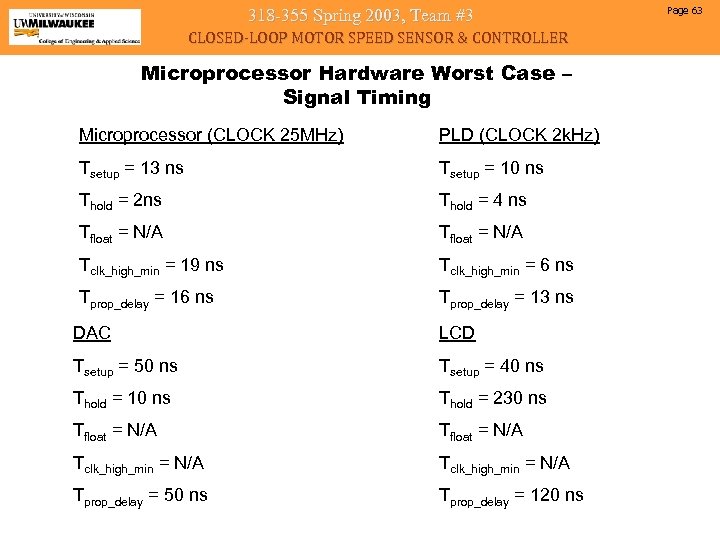

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case – Signal Timing Microprocessor (CLOCK 25 MHz) PLD (CLOCK 2 k. Hz) Tsetup = 13 ns Tsetup = 10 ns Thold = 2 ns Thold = 4 ns Tfloat = N/A Tclk_high_min = 19 ns Tclk_high_min = 6 ns Tprop_delay = 16 ns Tprop_delay = 13 ns DAC LCD Tsetup = 50 ns Tsetup = 40 ns Thold = 10 ns Thold = 230 ns Tfloat = N/A Tclk_high_min = N/A Tprop_delay = 50 ns Tprop_delay = 120 ns Page 63

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case – Signal Timing Microprocessor (CLOCK 25 MHz) PLD (CLOCK 2 k. Hz) Tsetup = 13 ns Tsetup = 10 ns Thold = 2 ns Thold = 4 ns Tfloat = N/A Tclk_high_min = 19 ns Tclk_high_min = 6 ns Tprop_delay = 16 ns Tprop_delay = 13 ns DAC LCD Tsetup = 50 ns Tsetup = 40 ns Thold = 10 ns Thold = 230 ns Tfloat = N/A Tclk_high_min = N/A Tprop_delay = 50 ns Tprop_delay = 120 ns Page 63

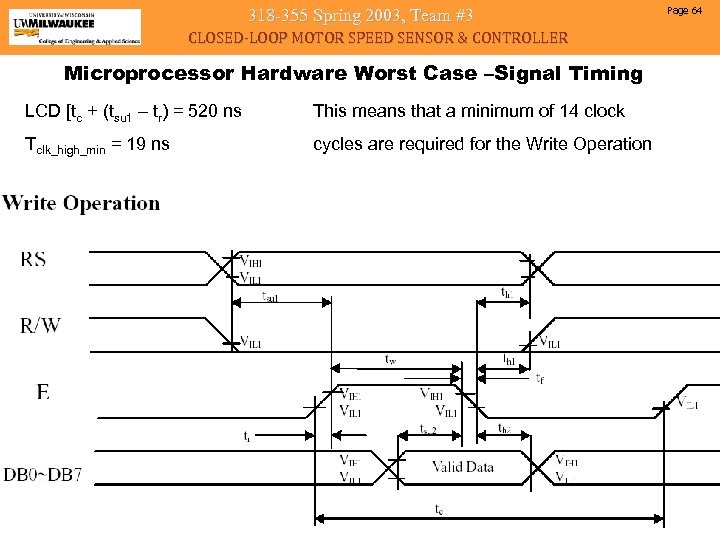

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case –Signal Timing LCD [tc + (tsu 1 – tr) = 520 ns This means that a minimum of 14 clock Tclk_high_min = 19 ns cycles are required for the Write Operation Page 64

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case –Signal Timing LCD [tc + (tsu 1 – tr) = 520 ns This means that a minimum of 14 clock Tclk_high_min = 19 ns cycles are required for the Write Operation Page 64

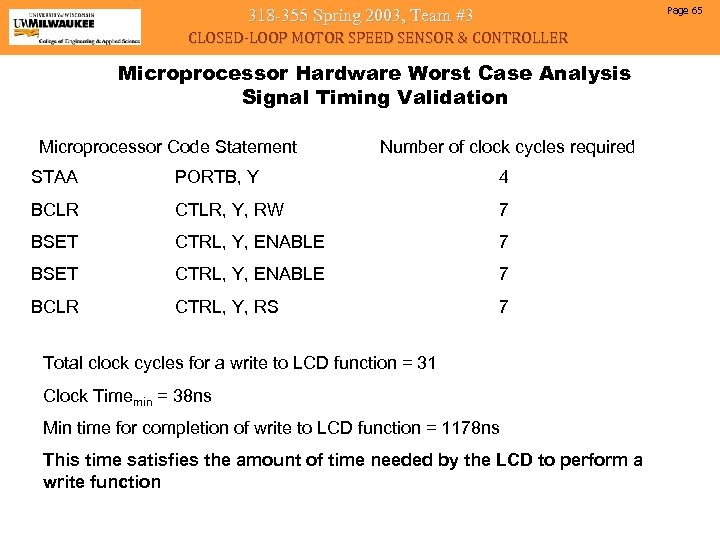

Page 65 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case Analysis Signal Timing Validation Microprocessor Code Statement Number of clock cycles required STAA PORTB, Y 4 BCLR CTLR, Y, RW 7 BSET CTRL, Y, ENABLE 7 BCLR CTRL, Y, RS 7 Total clock cycles for a write to LCD function = 31 Clock Timemin = 38 ns Min time for completion of write to LCD function = 1178 ns This time satisfies the amount of time needed by the LCD to perform a write function

Page 65 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case Analysis Signal Timing Validation Microprocessor Code Statement Number of clock cycles required STAA PORTB, Y 4 BCLR CTLR, Y, RW 7 BSET CTRL, Y, ENABLE 7 BCLR CTRL, Y, RS 7 Total clock cycles for a write to LCD function = 31 Clock Timemin = 38 ns Min time for completion of write to LCD function = 1178 ns This time satisfies the amount of time needed by the LCD to perform a write function

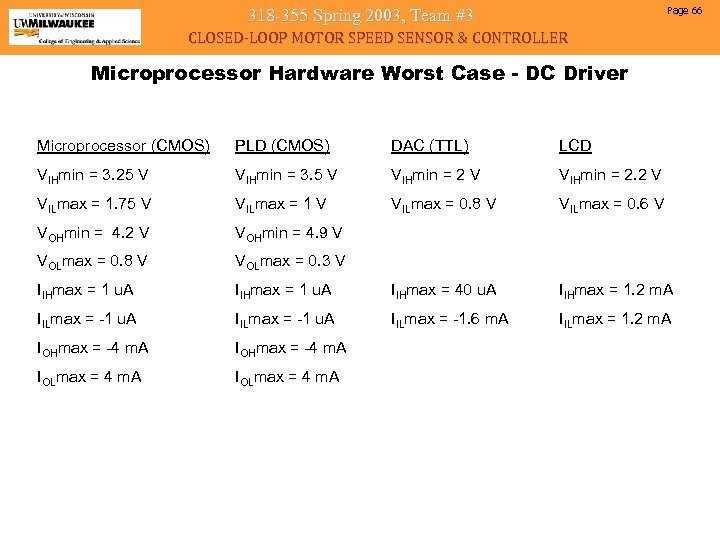

Page 66 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case - DC Driver Microprocessor (CMOS) PLD (CMOS) DAC (TTL) LCD VIHmin = 3. 25 V VIHmin = 3. 5 V VIHmin = 2. 2 V VILmax = 1. 75 V VILmax = 1 V VILmax = 0. 8 V VILmax = 0. 6 V VOHmin = 4. 2 V VOHmin = 4. 9 V VOLmax = 0. 8 V VOLmax = 0. 3 V IIHmax = 1 u. A IIHmax = 40 u. A IIHmax = 1. 2 m. A IILmax = -1 u. A IILmax = -1. 6 m. A IILmax = 1. 2 m. A IOHmax = -4 m. A IOLmax = 4 m. A

Page 66 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case - DC Driver Microprocessor (CMOS) PLD (CMOS) DAC (TTL) LCD VIHmin = 3. 25 V VIHmin = 3. 5 V VIHmin = 2. 2 V VILmax = 1. 75 V VILmax = 1 V VILmax = 0. 8 V VILmax = 0. 6 V VOHmin = 4. 2 V VOHmin = 4. 9 V VOLmax = 0. 8 V VOLmax = 0. 3 V IIHmax = 1 u. A IIHmax = 40 u. A IIHmax = 1. 2 m. A IILmax = -1 u. A IILmax = -1. 6 m. A IILmax = 1. 2 m. A IOHmax = -4 m. A IOLmax = 4 m. A

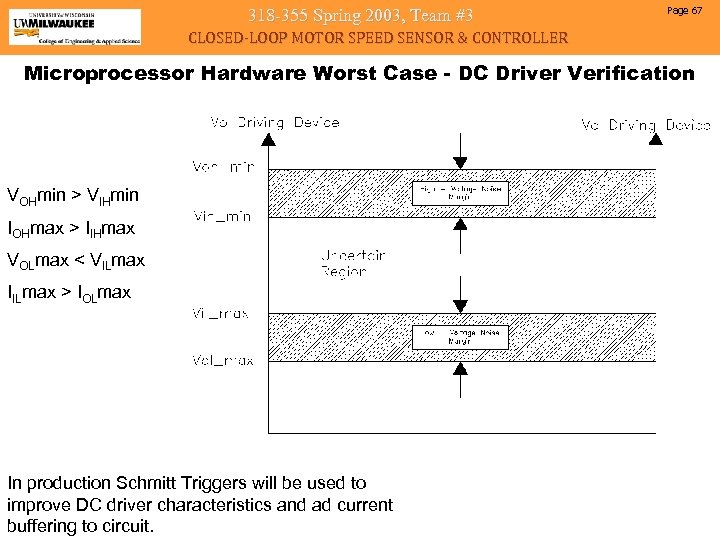

318 -355 Spring 2003, Team #3 Page 67 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case - DC Driver Verification VOHmin > VIHmin IOHmax > IIHmax VOLmax < VILmax IILmax > IOLmax In production Schmitt Triggers will be used to improve DC driver characteristics and ad current buffering to circuit.

318 -355 Spring 2003, Team #3 Page 67 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Worst Case - DC Driver Verification VOHmin > VIHmin IOHmax > IIHmax VOLmax < VILmax IILmax > IOLmax In production Schmitt Triggers will be used to improve DC driver characteristics and ad current buffering to circuit.

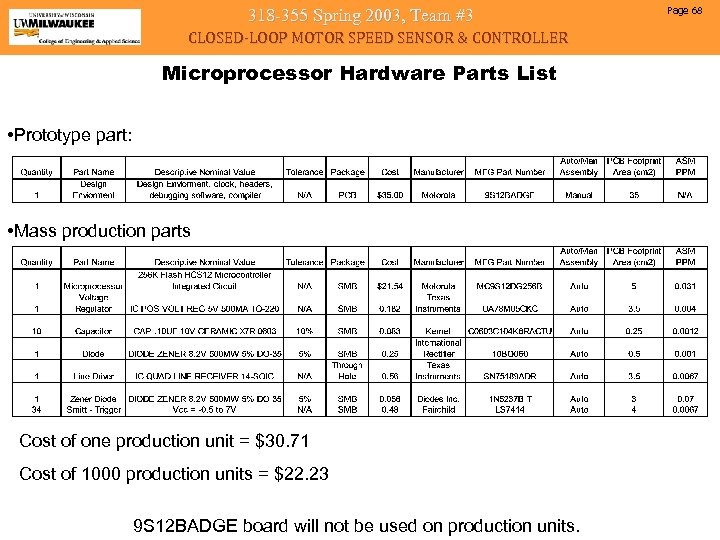

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Parts List • Prototype part: • Mass production parts Cost of one production unit = $30. 71 Cost of 1000 production units = $22. 23 9 S 12 BADGE board will not be used on production units. Page 68

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Parts List • Prototype part: • Mass production parts Cost of one production unit = $30. 71 Cost of 1000 production units = $22. 23 9 S 12 BADGE board will not be used on production units. Page 68

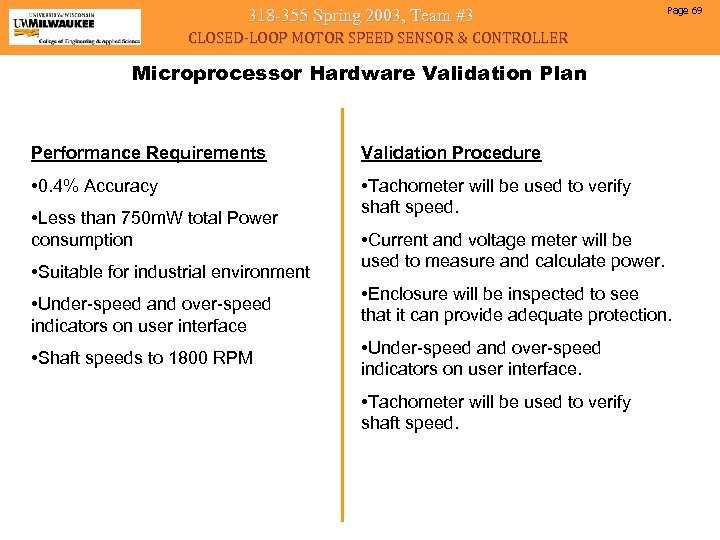

318 -355 Spring 2003, Team #3 Page 69 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Validation Plan Performance Requirements Validation Procedure • 0. 4% Accuracy • Tachometer will be used to verify shaft speed. • Less than 750 m. W total Power consumption • Suitable for industrial environment • Under-speed and over-speed indicators on user interface • Shaft speeds to 1800 RPM • Current and voltage meter will be used to measure and calculate power. • Enclosure will be inspected to see that it can provide adequate protection. • Under-speed and over-speed indicators on user interface. • Tachometer will be used to verify shaft speed.

318 -355 Spring 2003, Team #3 Page 69 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Validation Plan Performance Requirements Validation Procedure • 0. 4% Accuracy • Tachometer will be used to verify shaft speed. • Less than 750 m. W total Power consumption • Suitable for industrial environment • Under-speed and over-speed indicators on user interface • Shaft speeds to 1800 RPM • Current and voltage meter will be used to measure and calculate power. • Enclosure will be inspected to see that it can provide adequate protection. • Under-speed and over-speed indicators on user interface. • Tachometer will be used to verify shaft speed.

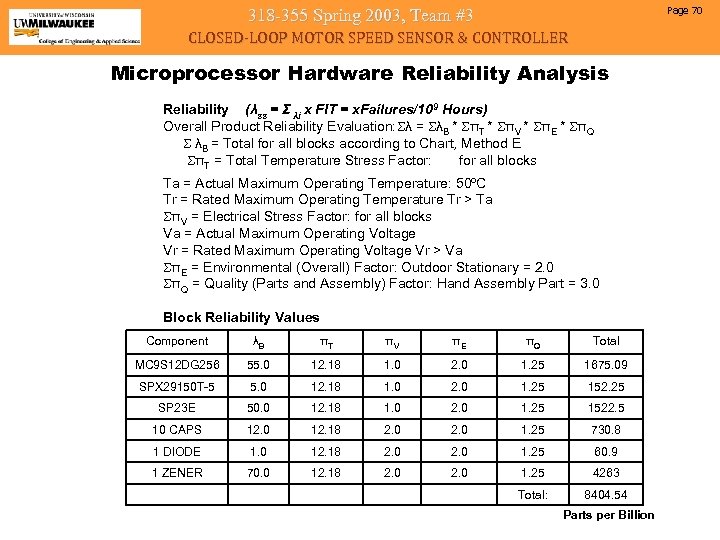

Page 70 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Reliability Analysis Reliability (λss = Σ λi x FIT = x. Failures/109 Hours) Overall Product Reliability Evaluation: λ = λB * πT * πV * πE * πQ λB = Total for all blocks according to Chart, Method E πT = Total Temperature Stress Factor: for all blocks Ta = Actual Maximum Operating Temperature: 50ºC Tr = Rated Maximum Operating Temperature Tr > Ta πV = Electrical Stress Factor: for all blocks Va = Actual Maximum Operating Voltage Vr = Rated Maximum Operating Voltage Vr > Va πE = Environmental (Overall) Factor: Outdoor Stationary = 2. 0 πQ = Quality (Parts and Assembly) Factor: Hand Assembly Part = 3. 0 Block Reliability Values Component λB πT πV πE πQ Total MC 9 S 12 DG 256 55. 0 12. 18 1. 0 2. 0 1. 25 1675. 09 SPX 29150 T-5 5. 0 12. 18 1. 0 2. 0 1. 25 152. 25 SP 23 E 50. 0 12. 18 1. 0 2. 0 1. 25 1522. 5 10 CAPS 12. 0 12. 18 2. 0 1. 25 730. 8 1 DIODE 1. 0 12. 18 2. 0 1. 25 60. 9 1 ZENER 70. 0 12. 18 2. 0 1. 25 4263 Total: 8404. 54 Parts per Billion

Page 70 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Hardware Reliability Analysis Reliability (λss = Σ λi x FIT = x. Failures/109 Hours) Overall Product Reliability Evaluation: λ = λB * πT * πV * πE * πQ λB = Total for all blocks according to Chart, Method E πT = Total Temperature Stress Factor: for all blocks Ta = Actual Maximum Operating Temperature: 50ºC Tr = Rated Maximum Operating Temperature Tr > Ta πV = Electrical Stress Factor: for all blocks Va = Actual Maximum Operating Voltage Vr = Rated Maximum Operating Voltage Vr > Va πE = Environmental (Overall) Factor: Outdoor Stationary = 2. 0 πQ = Quality (Parts and Assembly) Factor: Hand Assembly Part = 3. 0 Block Reliability Values Component λB πT πV πE πQ Total MC 9 S 12 DG 256 55. 0 12. 18 1. 0 2. 0 1. 25 1675. 09 SPX 29150 T-5 5. 0 12. 18 1. 0 2. 0 1. 25 152. 25 SP 23 E 50. 0 12. 18 1. 0 2. 0 1. 25 1522. 5 10 CAPS 12. 0 12. 18 2. 0 1. 25 730. 8 1 DIODE 1. 0 12. 18 2. 0 1. 25 60. 9 1 ZENER 70. 0 12. 18 2. 0 1. 25 4263 Total: 8404. 54 Parts per Billion

318 -355 Spring 2003, Team #3 Page 71 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Let’s cover the Microprocessor Software Details next. . .

318 -355 Spring 2003, Team #3 Page 71 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Let’s cover the Microprocessor Software Details next. . .

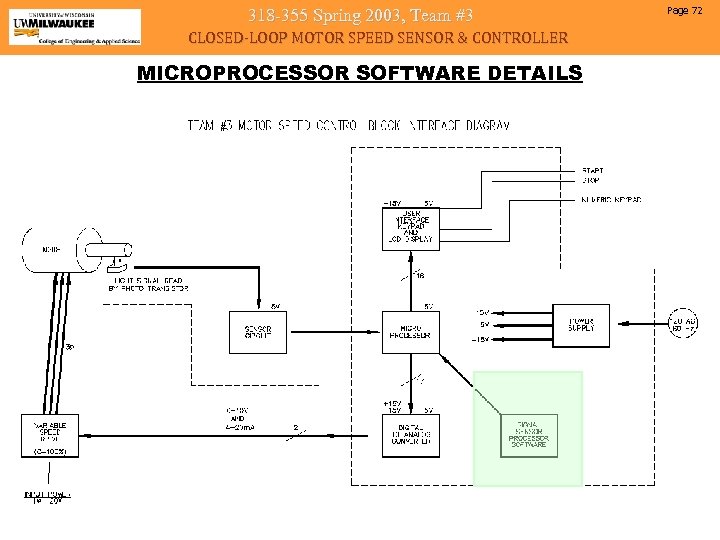

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER MICROPROCESSOR SOFTWARE DETAILS Page 72

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER MICROPROCESSOR SOFTWARE DETAILS Page 72

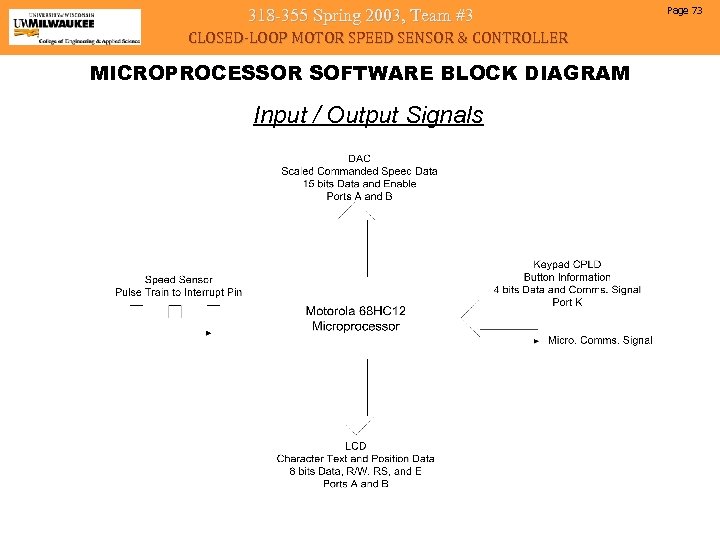

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER MICROPROCESSOR SOFTWARE BLOCK DIAGRAM Input / Output Signals Page 73

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER MICROPROCESSOR SOFTWARE BLOCK DIAGRAM Input / Output Signals Page 73

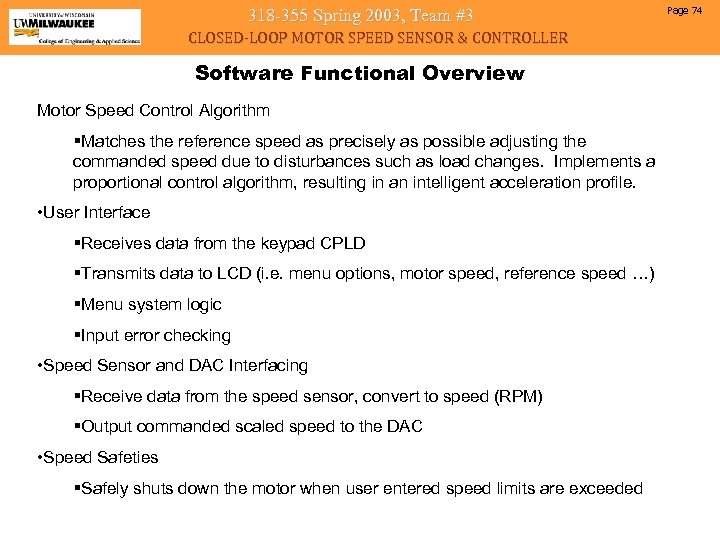

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software Functional Overview Motor Speed Control Algorithm Matches the reference speed as precisely as possible adjusting the commanded speed due to disturbances such as load changes. Implements a proportional control algorithm, resulting in an intelligent acceleration profile. • User Interface Receives data from the keypad CPLD Transmits data to LCD (i. e. menu options, motor speed, reference speed …) Menu system logic Input error checking • Speed Sensor and DAC Interfacing Receive data from the speed sensor, convert to speed (RPM) Output commanded scaled speed to the DAC • Speed Safeties Safely shuts down the motor when user entered speed limits are exceeded Page 74

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software Functional Overview Motor Speed Control Algorithm Matches the reference speed as precisely as possible adjusting the commanded speed due to disturbances such as load changes. Implements a proportional control algorithm, resulting in an intelligent acceleration profile. • User Interface Receives data from the keypad CPLD Transmits data to LCD (i. e. menu options, motor speed, reference speed …) Menu system logic Input error checking • Speed Sensor and DAC Interfacing Receive data from the speed sensor, convert to speed (RPM) Output commanded scaled speed to the DAC • Speed Safeties Safely shuts down the motor when user entered speed limits are exceeded Page 74

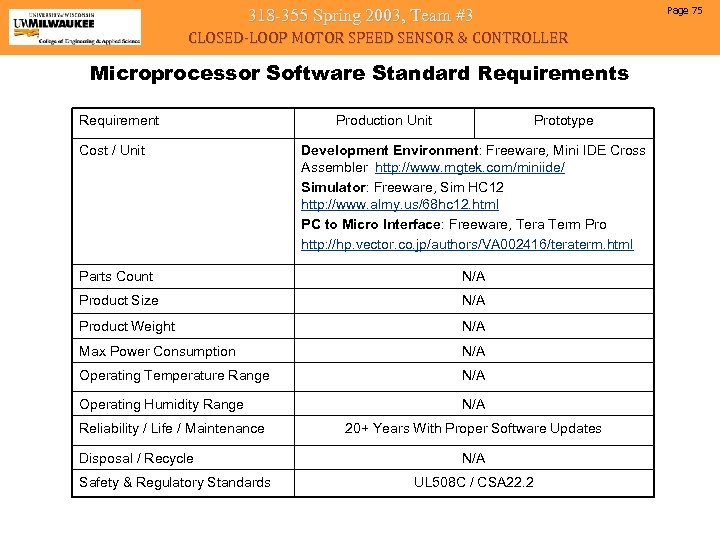

Page 75 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Software Standard Requirements Requirement Cost / Unit Production Unit Prototype Development Environment: Freeware, Mini IDE Cross Assembler http: //www. mgtek. com/miniide/ Simulator: Freeware, Sim HC 12 http: //www. almy. us/68 hc 12. html PC to Micro Interface: Freeware, Tera Term Pro http: //hp. vector. co. jp/authors/VA 002416/teraterm. html Parts Count N/A Product Size N/A Product Weight N/A Max Power Consumption N/A Operating Temperature Range N/A Operating Humidity Range N/A Reliability / Life / Maintenance Disposal / Recycle Safety & Regulatory Standards 20+ Years With Proper Software Updates N/A UL 508 C / CSA 22. 2

Page 75 318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Microprocessor Software Standard Requirements Requirement Cost / Unit Production Unit Prototype Development Environment: Freeware, Mini IDE Cross Assembler http: //www. mgtek. com/miniide/ Simulator: Freeware, Sim HC 12 http: //www. almy. us/68 hc 12. html PC to Micro Interface: Freeware, Tera Term Pro http: //hp. vector. co. jp/authors/VA 002416/teraterm. html Parts Count N/A Product Size N/A Product Weight N/A Max Power Consumption N/A Operating Temperature Range N/A Operating Humidity Range N/A Reliability / Life / Maintenance Disposal / Recycle Safety & Regulatory Standards 20+ Years With Proper Software Updates N/A UL 508 C / CSA 22. 2

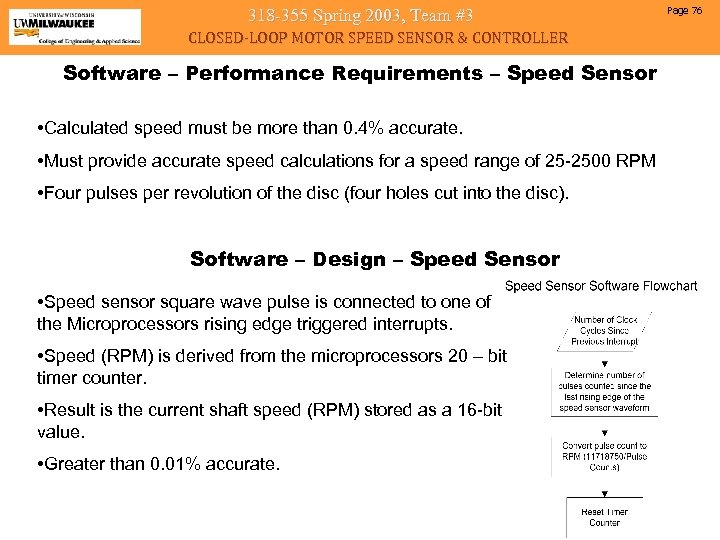

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – Speed Sensor • Calculated speed must be more than 0. 4% accurate. • Must provide accurate speed calculations for a speed range of 25 -2500 RPM • Four pulses per revolution of the disc (four holes cut into the disc). Software – Design – Speed Sensor • Speed sensor square wave pulse is connected to one of the Microprocessors rising edge triggered interrupts. • Speed (RPM) is derived from the microprocessors 20 – bit timer counter. • Result is the current shaft speed (RPM) stored as a 16 -bit value. • Greater than 0. 01% accurate. Page 76

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – Speed Sensor • Calculated speed must be more than 0. 4% accurate. • Must provide accurate speed calculations for a speed range of 25 -2500 RPM • Four pulses per revolution of the disc (four holes cut into the disc). Software – Design – Speed Sensor • Speed sensor square wave pulse is connected to one of the Microprocessors rising edge triggered interrupts. • Speed (RPM) is derived from the microprocessors 20 – bit timer counter. • Result is the current shaft speed (RPM) stored as a 16 -bit value. • Greater than 0. 01% accurate. Page 76

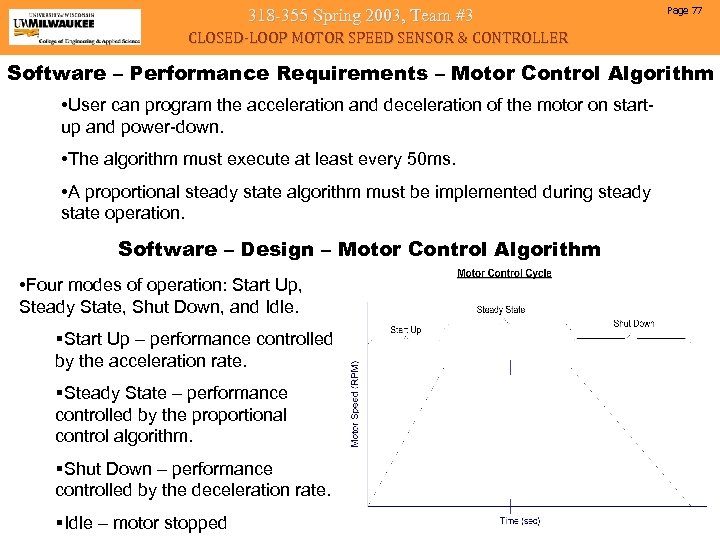

318 -355 Spring 2003, Team #3 Page 77 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – Motor Control Algorithm • User can program the acceleration and deceleration of the motor on startup and power-down. • The algorithm must execute at least every 50 ms. • A proportional steady state algorithm must be implemented during steady state operation. Software – Design – Motor Control Algorithm • Four modes of operation: Start Up, Steady State, Shut Down, and Idle. Start Up – performance controlled by the acceleration rate. Steady State – performance controlled by the proportional control algorithm. Shut Down – performance controlled by the deceleration rate. Idle – motor stopped

318 -355 Spring 2003, Team #3 Page 77 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – Motor Control Algorithm • User can program the acceleration and deceleration of the motor on startup and power-down. • The algorithm must execute at least every 50 ms. • A proportional steady state algorithm must be implemented during steady state operation. Software – Design – Motor Control Algorithm • Four modes of operation: Start Up, Steady State, Shut Down, and Idle. Start Up – performance controlled by the acceleration rate. Steady State – performance controlled by the proportional control algorithm. Shut Down – performance controlled by the deceleration rate. Idle – motor stopped

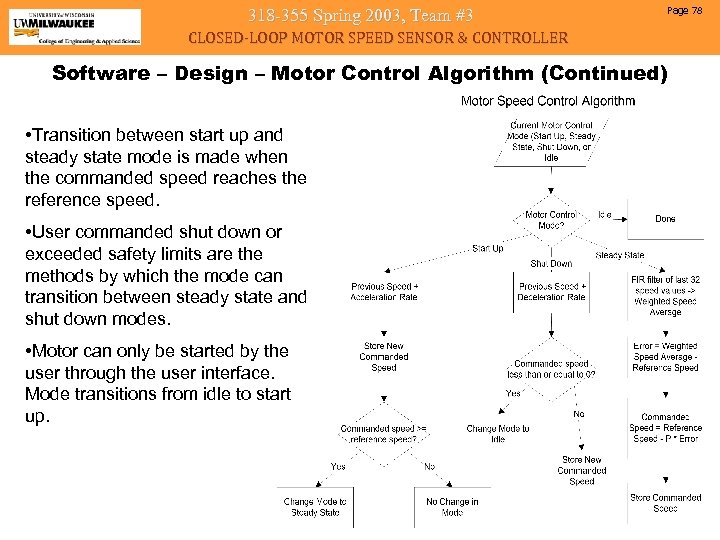

318 -355 Spring 2003, Team #3 Page 78 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Design – Motor Control Algorithm (Continued) • Transition between start up and steady state mode is made when the commanded speed reaches the reference speed. • User commanded shut down or exceeded safety limits are the methods by which the mode can transition between steady state and shut down modes. • Motor can only be started by the user through the user interface. Mode transitions from idle to start up.

318 -355 Spring 2003, Team #3 Page 78 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Design – Motor Control Algorithm (Continued) • Transition between start up and steady state mode is made when the commanded speed reaches the reference speed. • User commanded shut down or exceeded safety limits are the methods by which the mode can transition between steady state and shut down modes. • Motor can only be started by the user through the user interface. Mode transitions from idle to start up.

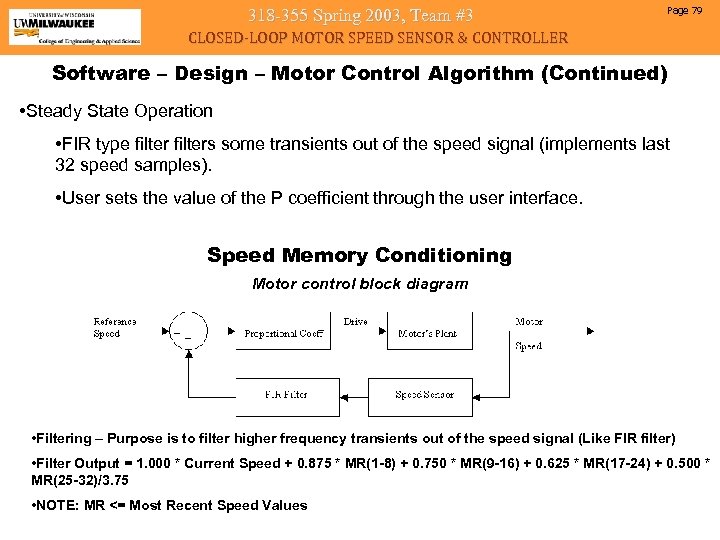

318 -355 Spring 2003, Team #3 Page 79 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Design – Motor Control Algorithm (Continued) • Steady State Operation • FIR type filters some transients out of the speed signal (implements last 32 speed samples). • User sets the value of the P coefficient through the user interface. Speed Memory Conditioning Motor control block diagram • Filtering – Purpose is to filter higher frequency transients out of the speed signal (Like FIR filter) • Filter Output = 1. 000 * Current Speed + 0. 875 * MR(1 -8) + 0. 750 * MR(9 -16) + 0. 625 * MR(17 -24) + 0. 500 * MR(25 -32)/3. 75 • NOTE: MR <= Most Recent Speed Values

318 -355 Spring 2003, Team #3 Page 79 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Design – Motor Control Algorithm (Continued) • Steady State Operation • FIR type filters some transients out of the speed signal (implements last 32 speed samples). • User sets the value of the P coefficient through the user interface. Speed Memory Conditioning Motor control block diagram • Filtering – Purpose is to filter higher frequency transients out of the speed signal (Like FIR filter) • Filter Output = 1. 000 * Current Speed + 0. 875 * MR(1 -8) + 0. 750 * MR(9 -16) + 0. 625 * MR(17 -24) + 0. 500 * MR(25 -32)/3. 75 • NOTE: MR <= Most Recent Speed Values

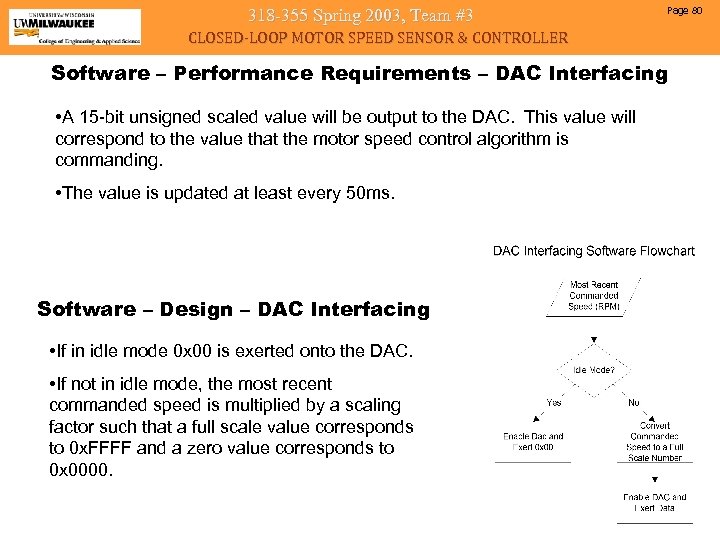

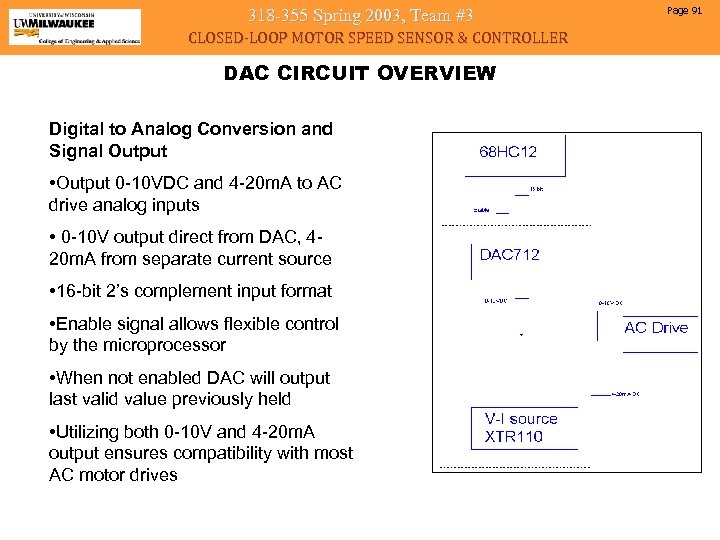

318 -355 Spring 2003, Team #3 Page 80 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – DAC Interfacing • A 15 -bit unsigned scaled value will be output to the DAC. This value will correspond to the value that the motor speed control algorithm is commanding. • The value is updated at least every 50 ms. Software – Design – DAC Interfacing • If in idle mode 0 x 00 is exerted onto the DAC. • If not in idle mode, the most recent commanded speed is multiplied by a scaling factor such that a full scale value corresponds to 0 x. FFFF and a zero value corresponds to 0 x 0000.

318 -355 Spring 2003, Team #3 Page 80 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – DAC Interfacing • A 15 -bit unsigned scaled value will be output to the DAC. This value will correspond to the value that the motor speed control algorithm is commanding. • The value is updated at least every 50 ms. Software – Design – DAC Interfacing • If in idle mode 0 x 00 is exerted onto the DAC. • If not in idle mode, the most recent commanded speed is multiplied by a scaling factor such that a full scale value corresponds to 0 x. FFFF and a zero value corresponds to 0 x 0000.

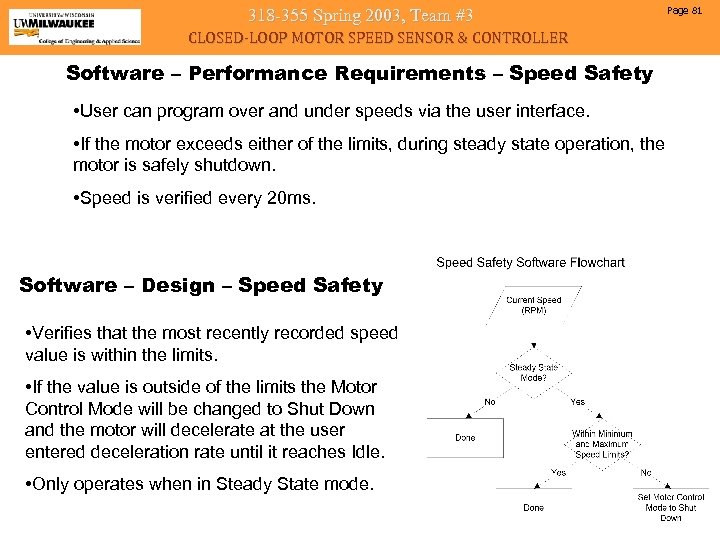

318 -355 Spring 2003, Team #3 Page 81 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – Speed Safety • User can program over and under speeds via the user interface. • If the motor exceeds either of the limits, during steady state operation, the motor is safely shutdown. • Speed is verified every 20 ms. Software – Design – Speed Safety • Verifies that the most recently recorded speed value is within the limits. • If the value is outside of the limits the Motor Control Mode will be changed to Shut Down and the motor will decelerate at the user entered deceleration rate until it reaches Idle. • Only operates when in Steady State mode.

318 -355 Spring 2003, Team #3 Page 81 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – Speed Safety • User can program over and under speeds via the user interface. • If the motor exceeds either of the limits, during steady state operation, the motor is safely shutdown. • Speed is verified every 20 ms. Software – Design – Speed Safety • Verifies that the most recently recorded speed value is within the limits. • If the value is outside of the limits the Motor Control Mode will be changed to Shut Down and the motor will decelerate at the user entered deceleration rate until it reaches Idle. • Only operates when in Steady State mode.

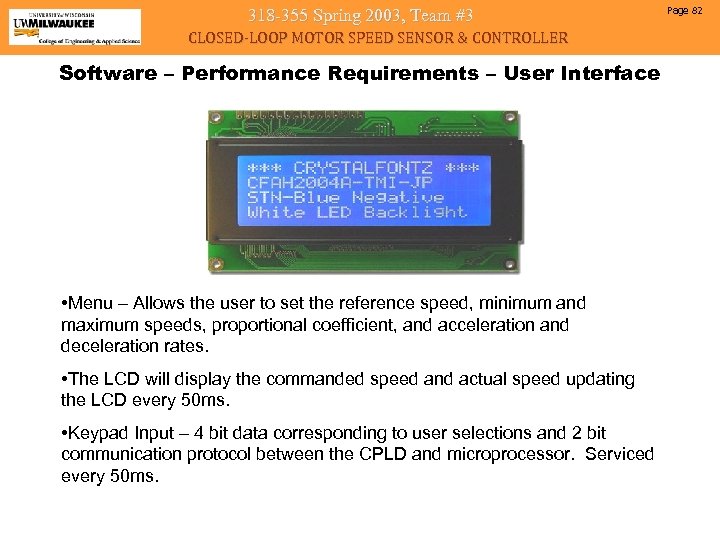

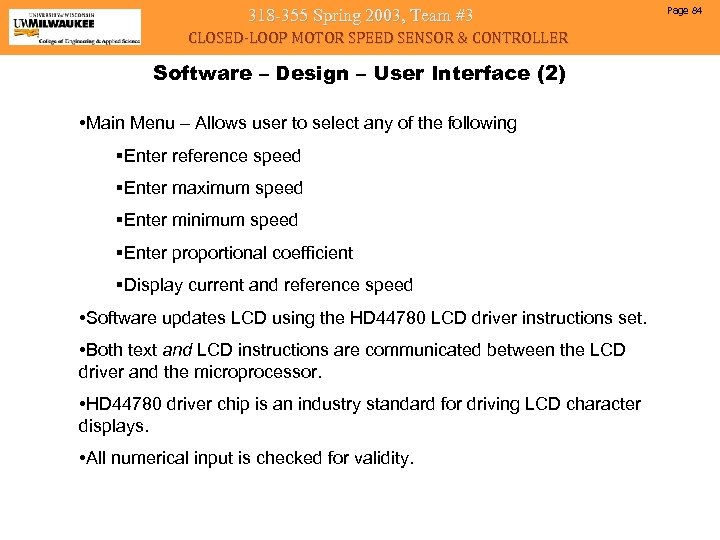

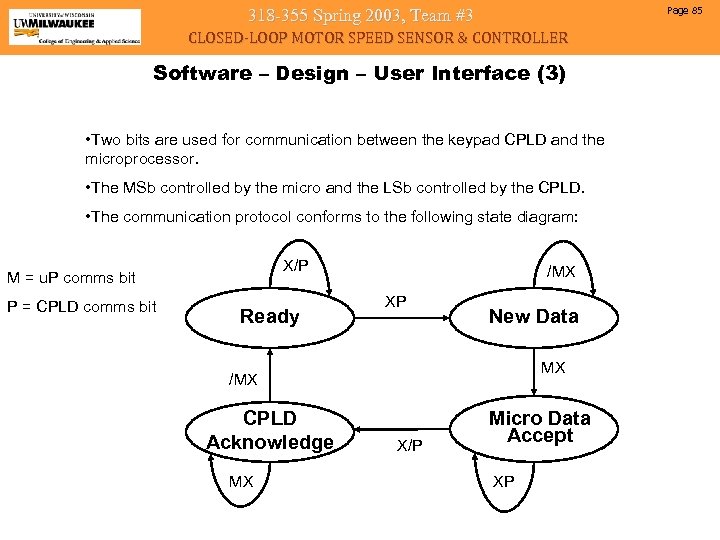

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – User Interface • Menu – Allows the user to set the reference speed, minimum and maximum speeds, proportional coefficient, and acceleration and deceleration rates. • The LCD will display the commanded speed and actual speed updating the LCD every 50 ms. • Keypad Input – 4 bit data corresponding to user selections and 2 bit communication protocol between the CPLD and microprocessor. Serviced every 50 ms. Page 82

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Performance Requirements – User Interface • Menu – Allows the user to set the reference speed, minimum and maximum speeds, proportional coefficient, and acceleration and deceleration rates. • The LCD will display the commanded speed and actual speed updating the LCD every 50 ms. • Keypad Input – 4 bit data corresponding to user selections and 2 bit communication protocol between the CPLD and microprocessor. Serviced every 50 ms. Page 82

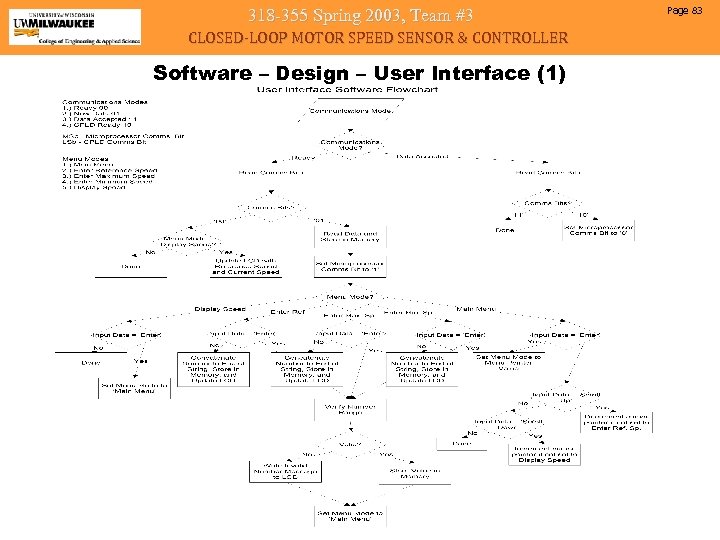

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Design – User Interface (1) Page 83

318 -355 Spring 2003, Team #3 CLOSED-LOOP MOTOR SPEED SENSOR & CONTROLLER Software – Design – User Interface (1) Page 83