61cd31ce8fd4a355fd4e921465a3ff66.ppt

- Количество слайдов: 34

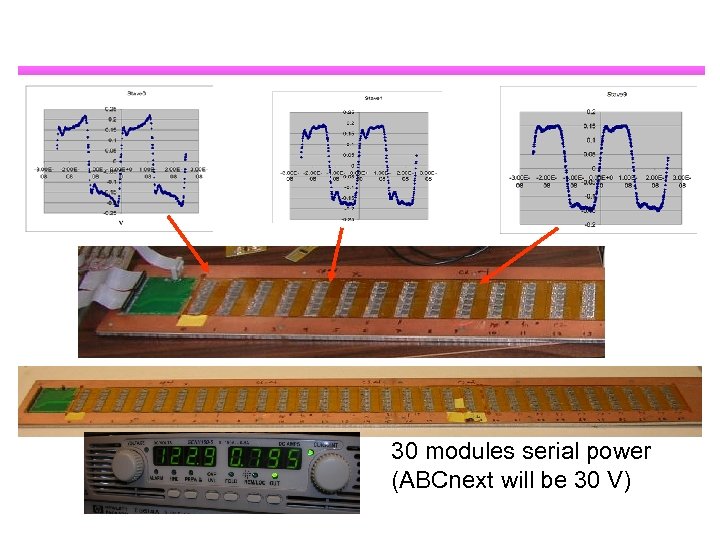

30 modules serial power (ABCnext will be 30 V)

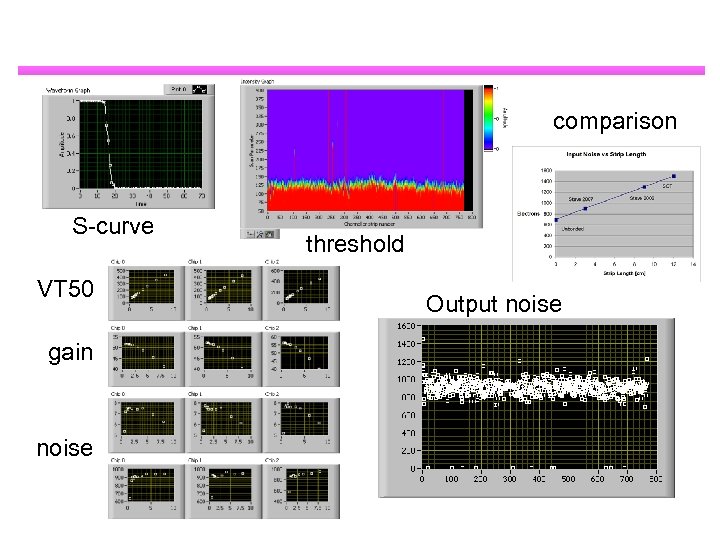

comparison S-curve VT 50 gain noise threshold Output noise

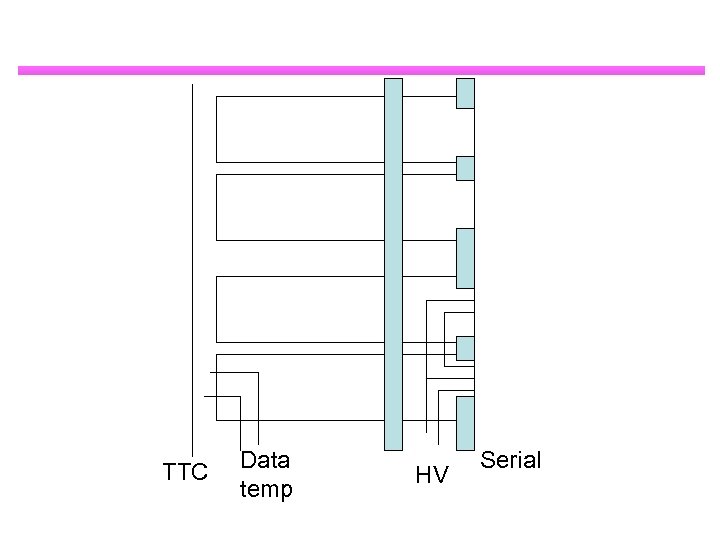

TTC Data temp HV Serial

A 1) Implications of glue on strip-side surface. A 2) Possibility of making front-side bias connection. A 3) Risks associated with backplane connection and conducting epoxy (ie can a bondwire be used? ). A 4) Rework implications for preserving sensor performance Comments: A 1 and A 2 could be studied first with miniatures while A 3 and A 4 would require studies with full size detectors. A 1 needs miniatures with kapton glued to surface to be irradiated with gammas, protons and neutrons. Interstrip isolation to be studies with cooled chuck and connection to LHC speed electronics. A 1 also needs study with full size detector cycled in temperature with large area representative kapton glued to surface to see implication of stressing silicon crystal on leakage current. For greater confidence, proton irradiation of several full-sized sensors glued with representative kapton circuit should be undertaken and evaluated at varying temperatures at least for IV characteristics. A 2 could use existing irradiated miniatures. A 3 and A 4 would require destructive studies using first modules. If required to use conductive epoxy contact (A 3) need long term programme to qualify

C 13) Assembly of single-sided objects and attachment to electrical bus and progressively test C 14) Irradiate single-sided objects on short stave sections C 15) Define and prototype corresponding petal/forward stave (with all the additional procurement of varying components that this implies) C 15) Studies of electrical cross-talk and HV multiplexing (both petal and stave) C 16) Initiate studies on robotic assembly to ensure uniform tolerances and efficiency (Edge alignment; robotics and survey should all be used -not alternatives) Comments: The items are in some sort of possible chronological order but this is not a project plan as it stands. One of the key issues that relates to all aspects is risk analysis. The rework requirements depend on what is the most likely or most harmful failure mechanism. The QA is vital. Repair scenarios for damage to hybrids, the bus or other items should be defined and the number of items sacrificed to make a repair evaluated as part of the risk estimation. An important issue is to irradiated and test "modules" (C 14) and to integrate this into a more cohesive irradiation programme with chips and sensors. C 15 represented a huge programme for which there is insufficient effort. Hopefully the outer barrels do not need any special effort but there may be optimisations there to take advantage of the lower power density and lower cooling required for the sensors.

61cd31ce8fd4a355fd4e921465a3ff66.ppt