6fbf85651cd79c76633ce4b32624bee0.ppt

- Количество слайдов: 54

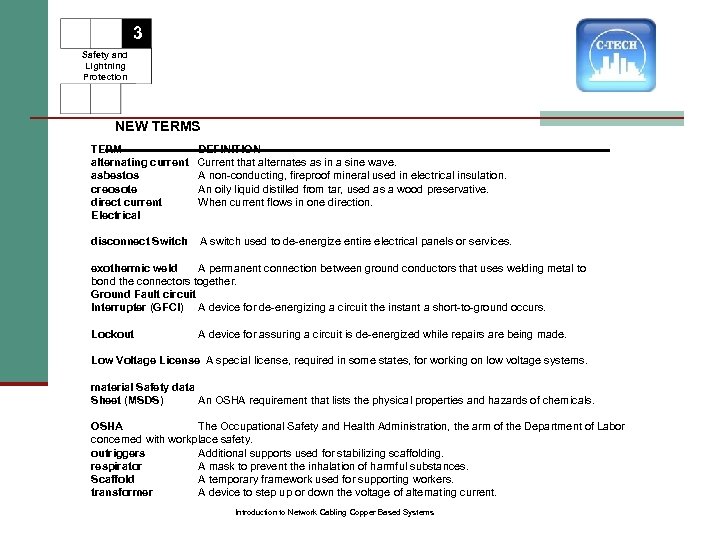

3 Safety and Lightning Protection INTRODUCTION TO NETWORK CABLING MODULE 3 Safety and Lightning Protection Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection INTRODUCTION TO NETWORK CABLING MODULE 3 Safety and Lightning Protection Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection 1 Goal 3 At the completion of this module, students will be able to identify and explain the safety precautions in terms of personal protection, workplace safety, and other hazards found on the job site. Students will also be familiarized with Fire Stopping and Grounding and Bonding processes and practices. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection 1 Goal 3 At the completion of this module, students will be able to identify and explain the safety precautions in terms of personal protection, workplace safety, and other hazards found on the job site. Students will also be familiarized with Fire Stopping and Grounding and Bonding processes and practices. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Objectives: • • • Define Safety as it applies to the Network Cabling Specialist Define OSHA and its role in workplace safety Identify and explain the safety procedures to be followed for personal protection to protect: • Head and Scalp, 3. 3. 2 Eyes and Ears, 3. 3. 3 Hands and Feet, 3. 3. 4 Respiratory, • Skin, 3. 3. 6 Back Identify and explain the safety procedures to be followed at the work site to include: • Special Instructions, 3. 4. 2 Special Training, 3. 4. 3 Restrictions, 3. 4. 4 Permits, 3. 4. 5 Work Permits • Lock-Out procedures, 3. 4. 7 Access Routes, 3. 4. 8 Locations of Safety Equipment Identify and explain the safety procedures to be followed to prevent electrical hazards to include: • Function and use of Ground Fault Circuit Interrupter (G. F. C. I. ), 3. 5. 2 Extension Cords, • Proximity and Hot Work, 3. 5. 4 Insulated Tools Define the importance of Bonding and Grounding electrical circuits and telecommunications devices Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Objectives: • • • Define Safety as it applies to the Network Cabling Specialist Define OSHA and its role in workplace safety Identify and explain the safety procedures to be followed for personal protection to protect: • Head and Scalp, 3. 3. 2 Eyes and Ears, 3. 3. 3 Hands and Feet, 3. 3. 4 Respiratory, • Skin, 3. 3. 6 Back Identify and explain the safety procedures to be followed at the work site to include: • Special Instructions, 3. 4. 2 Special Training, 3. 4. 3 Restrictions, 3. 4. 4 Permits, 3. 4. 5 Work Permits • Lock-Out procedures, 3. 4. 7 Access Routes, 3. 4. 8 Locations of Safety Equipment Identify and explain the safety procedures to be followed to prevent electrical hazards to include: • Function and use of Ground Fault Circuit Interrupter (G. F. C. I. ), 3. 5. 2 Extension Cords, • Proximity and Hot Work, 3. 5. 4 Insulated Tools Define the importance of Bonding and Grounding electrical circuits and telecommunications devices Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Objectives (continued): • • • Distinguish between Alternating Current and Direct Current Define the purpose of Material Safety Data Sheets when working with hazardous materials. Identify and explain the safety procedures to be followed when working with tools to include: • Hand Tools, 3. 9. 2 Power Tools Define workspace safety with regards to: • Stability Control, 3. 10. 2 Fall Prevention and Protection, 3. 10. 3 Ladder Safety, 3. 10. 4 Scaffolding, 3. 10. 5 Scissor Lifts, 3. 10. 6 Barricades, 3. 10. 7 Crawl Spaces Identify and explain the safety procedures and precautions that should be followed for fire prevention and safety to include: • Location and Access to Fire Alarms, 3. 11. 2 Emergency Exits, 3. 11. 3 Classes of Fire Extinguishers---and Types of Fires • Identify common safety practices while working in hallways, public spaces, manholes, under ground, crawl spaces and the importance of barricades. • State the OSHA requirements that tell when a ladder cannot be used Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Objectives (continued): • • • Distinguish between Alternating Current and Direct Current Define the purpose of Material Safety Data Sheets when working with hazardous materials. Identify and explain the safety procedures to be followed when working with tools to include: • Hand Tools, 3. 9. 2 Power Tools Define workspace safety with regards to: • Stability Control, 3. 10. 2 Fall Prevention and Protection, 3. 10. 3 Ladder Safety, 3. 10. 4 Scaffolding, 3. 10. 5 Scissor Lifts, 3. 10. 6 Barricades, 3. 10. 7 Crawl Spaces Identify and explain the safety procedures and precautions that should be followed for fire prevention and safety to include: • Location and Access to Fire Alarms, 3. 11. 2 Emergency Exits, 3. 11. 3 Classes of Fire Extinguishers---and Types of Fires • Identify common safety practices while working in hallways, public spaces, manholes, under ground, crawl spaces and the importance of barricades. • State the OSHA requirements that tell when a ladder cannot be used Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Safety Precautions • is performing your daily tasks in a safe manner. • is protecting people, equipment, and the environment. • is required on the job! Before beginning any job, it is important to understand how to do it safely. Safety is your responsibility. If you don’t understand how to do the job safely, stop what you are doing. Ask your supervisor to explain or demonstrate the safety precautions fully. OSHA The Occupational Safety and Health Administration (OSHA) is the arm of the Department of Labor concerned with workplace safety. OSHA establishes protective standards, enforces those standards, and reaches out to employers and employees through technical assistance and consultation programs. OSHA regulations have the force of law. Nearly every working man and woman in the nation comes under OSHA's jurisdiction. Many publications and other sources of safety information are available at the agency’s website: http: //www. osha. gov. Safety in network cabling involves many areas of the work site, such as the following. First Aid Kit and Eye Wash A first aid kit and eye wash kit are essential safety equipment for every job. They should be inspected and restocked periodically. Emergency telephone numbers should also be kept in these kits. As a Network Cabling Professional, you should keep these items in your truck. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Safety Precautions • is performing your daily tasks in a safe manner. • is protecting people, equipment, and the environment. • is required on the job! Before beginning any job, it is important to understand how to do it safely. Safety is your responsibility. If you don’t understand how to do the job safely, stop what you are doing. Ask your supervisor to explain or demonstrate the safety precautions fully. OSHA The Occupational Safety and Health Administration (OSHA) is the arm of the Department of Labor concerned with workplace safety. OSHA establishes protective standards, enforces those standards, and reaches out to employers and employees through technical assistance and consultation programs. OSHA regulations have the force of law. Nearly every working man and woman in the nation comes under OSHA's jurisdiction. Many publications and other sources of safety information are available at the agency’s website: http: //www. osha. gov. Safety in network cabling involves many areas of the work site, such as the following. First Aid Kit and Eye Wash A first aid kit and eye wash kit are essential safety equipment for every job. They should be inspected and restocked periodically. Emergency telephone numbers should also be kept in these kits. As a Network Cabling Professional, you should keep these items in your truck. Introduction to Network Cabling Copper Based Systems

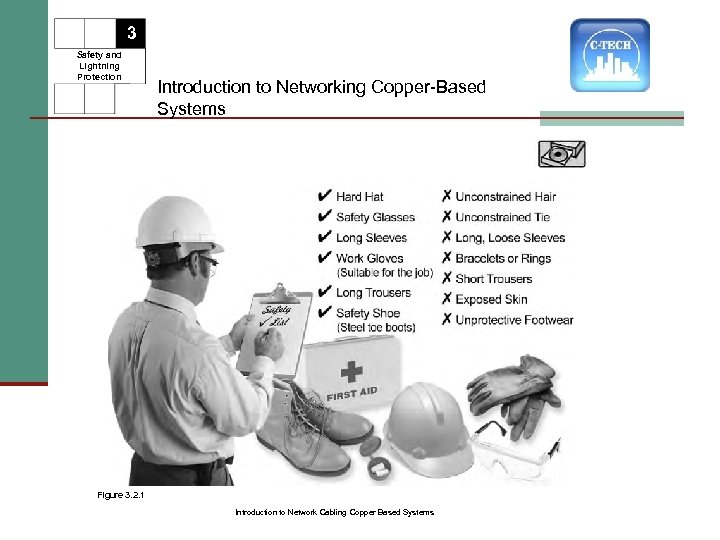

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Personal Protection - Clothing Shirts covering the shoulders and trousers covering the full leg and ankle should be worn all the time. Rings and bracelets should not be worn. Long neckties should be tucked in. Long hair and loose sleeves that might become caught in machinery should be tied back, tucked in or secured while working on or near moving machinery. NEW TERM OSHA - The Occupational Safety and Health Administration, the arm of the Department of Labor concerned with workplace safety. Head and Scalp Hard hats, worn properly and in good condition, should be worn: In any area posted as a hard hat area. Beneath overhead work. During work in manholes and on telephone poles. In other areas where a head bumping hazard is present. Eyes and Ears Safety glasses should be worn by everyone who is doing mechanical/electrical work, working with chemicals, or working with exposed copper wiring or optical fiber. These glasses should be stored in your pocket, not the tool belt, to avoid scratches. Hearing protection should be worn where required. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Personal Protection - Clothing Shirts covering the shoulders and trousers covering the full leg and ankle should be worn all the time. Rings and bracelets should not be worn. Long neckties should be tucked in. Long hair and loose sleeves that might become caught in machinery should be tied back, tucked in or secured while working on or near moving machinery. NEW TERM OSHA - The Occupational Safety and Health Administration, the arm of the Department of Labor concerned with workplace safety. Head and Scalp Hard hats, worn properly and in good condition, should be worn: In any area posted as a hard hat area. Beneath overhead work. During work in manholes and on telephone poles. In other areas where a head bumping hazard is present. Eyes and Ears Safety glasses should be worn by everyone who is doing mechanical/electrical work, working with chemicals, or working with exposed copper wiring or optical fiber. These glasses should be stored in your pocket, not the tool belt, to avoid scratches. Hearing protection should be worn where required. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Safety Precautions Safety… is performing your daily tasks in a safe manner. is protecting people, equipment, and the environment. is required on the job! Head and Scalp Hard hats, worn properly and in good condition, should be worn: In any area posted as a hard hat area. Beneath overhead work. During work in manholes and on telephone poles. In other areas where a head bumping hazard is present. Eyes and Ears Safety glasses should be worn by everyone who is doing mechanical/electrical work, working with chemicals, or working with exposed copper wiring or optical fiber. These glasses should be stored in your pocket, not the tool belt, to avoid scratches. Hearing protection should be worn where required. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Safety Precautions Safety… is performing your daily tasks in a safe manner. is protecting people, equipment, and the environment. is required on the job! Head and Scalp Hard hats, worn properly and in good condition, should be worn: In any area posted as a hard hat area. Beneath overhead work. During work in manholes and on telephone poles. In other areas where a head bumping hazard is present. Eyes and Ears Safety glasses should be worn by everyone who is doing mechanical/electrical work, working with chemicals, or working with exposed copper wiring or optical fiber. These glasses should be stored in your pocket, not the tool belt, to avoid scratches. Hearing protection should be worn where required. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Do’s and Don’ts - Read Carefully! (continued) Hands and Feet Gloves suitable for the job being performed should be worn unless the job cannot be done with gloves, or unless wearing gloves increases the hazard. Safety shoes or toe protection should be worn at all times by persons doing mechanical/electrical construction work. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Do’s and Don’ts - Read Carefully! (continued) Hands and Feet Gloves suitable for the job being performed should be worn unless the job cannot be done with gloves, or unless wearing gloves increases the hazard. Safety shoes or toe protection should be worn at all times by persons doing mechanical/electrical construction work. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Figure 3. 2. 1 Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Introduction to Networking Copper-Based Systems Figure 3. 2. 1 Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Objectives (continued): • • • Identify and explain the safety procedures and precautions that should be followed for fire prevention and safety to include: • Location and access to fire alarms • Emergency exits • Class of fire extinguishers and types of fire Define the importance of Bonding and Grounding in regards to lightning protection Identify the parts of a lightning protection system as: • Air Terminals • Conductors • Ground Terminations • Surge Arrestors and Suppressors • Identify what gets grounded in both residential and commercial applications Identify ground resistance minimums for both the NEC and TIA/EIA standards Define the importance of Bonding and Grounding electrical circuits and telecommunications devices Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Objectives (continued): • • • Identify and explain the safety procedures and precautions that should be followed for fire prevention and safety to include: • Location and access to fire alarms • Emergency exits • Class of fire extinguishers and types of fire Define the importance of Bonding and Grounding in regards to lightning protection Identify the parts of a lightning protection system as: • Air Terminals • Conductors • Ground Terminations • Surge Arrestors and Suppressors • Identify what gets grounded in both residential and commercial applications Identify ground resistance minimums for both the NEC and TIA/EIA standards Define the importance of Bonding and Grounding electrical circuits and telecommunications devices Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Objectives (continued): • • Identify grounding systems to include telecommunications room bonding backbone (TBB), telecom main grounding busbar (TMGB) and how they are connected for maximum surge protection Identify bonding techniques as Bolting, Crimping and Exothermic Welding Identify the characteristics of both AC and DC electrical systems Using Ohm's law solve for Voltage, Resistance and Current Define power as Voltage times Current Identify static electricity, its effects and how it can be prevented State general requirements to obtain a low voltage license Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Objectives (continued): • • Identify grounding systems to include telecommunications room bonding backbone (TBB), telecom main grounding busbar (TMGB) and how they are connected for maximum surge protection Identify bonding techniques as Bolting, Crimping and Exothermic Welding Identify the characteristics of both AC and DC electrical systems Using Ohm's law solve for Voltage, Resistance and Current Define power as Voltage times Current Identify static electricity, its effects and how it can be prevented State general requirements to obtain a low voltage license Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Skin If the possibility exists of exposure to creosote or other irritants (like fiberglass), proper personal protective equipment, as specified on the Material Safety Data Sheet (MSDS—see page 3 -9), should be worn. These may include safety glasses, rubber gloves, and similar protective clothing. Poisonous Plants A common hazard when running cable out of doors is poisonous plants. The most common poisonous plants in North America are poison ivy, poison oak and poison sumac. These plants are all related, and they all produce a resin on their leaves and other plant parts that can cause a severe skin rash. About 2/3 of the population is allergic to these plants. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Skin If the possibility exists of exposure to creosote or other irritants (like fiberglass), proper personal protective equipment, as specified on the Material Safety Data Sheet (MSDS—see page 3 -9), should be worn. These may include safety glasses, rubber gloves, and similar protective clothing. Poisonous Plants A common hazard when running cable out of doors is poisonous plants. The most common poisonous plants in North America are poison ivy, poison oak and poison sumac. These plants are all related, and they all produce a resin on their leaves and other plant parts that can cause a severe skin rash. About 2/3 of the population is allergic to these plants. Introduction to Network Cabling Copper Based Systems

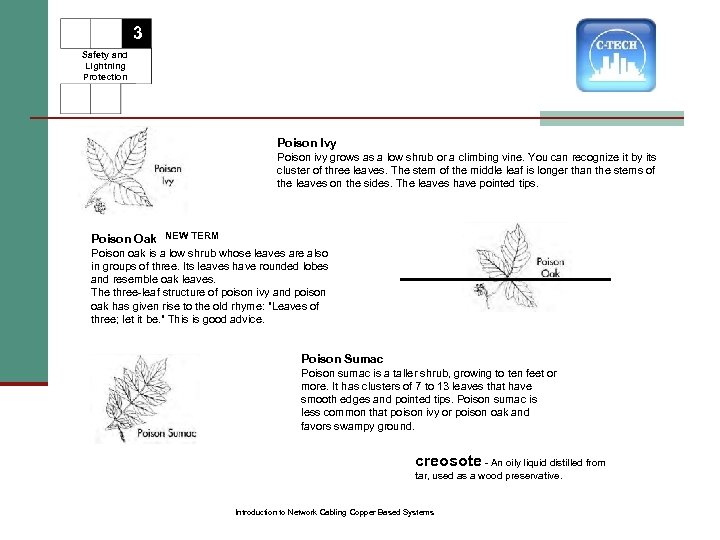

3 Safety and Lightning Protection Poison Ivy Poison ivy grows as a low shrub or a climbing vine. You can recognize it by its cluster of three leaves. The stem of the middle leaf is longer than the stems of the leaves on the sides. The leaves have pointed tips. Poison Oak NEW TERM Poison oak is a low shrub whose leaves are also in groups of three. Its leaves have rounded lobes and resemble oak leaves. The three-leaf structure of poison ivy and poison oak has given rise to the old rhyme: "Leaves of three; let it be. " This is good advice. Poison Sumac Poison sumac is a taller shrub, growing to ten feet or more. It has clusters of 7 to 13 leaves that have smooth edges and pointed tips. Poison sumac is less common that poison ivy or poison oak and favors swampy ground. creosote - An oily liquid distilled from tar, used as a wood preservative. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Poison Ivy Poison ivy grows as a low shrub or a climbing vine. You can recognize it by its cluster of three leaves. The stem of the middle leaf is longer than the stems of the leaves on the sides. The leaves have pointed tips. Poison Oak NEW TERM Poison oak is a low shrub whose leaves are also in groups of three. Its leaves have rounded lobes and resemble oak leaves. The three-leaf structure of poison ivy and poison oak has given rise to the old rhyme: "Leaves of three; let it be. " This is good advice. Poison Sumac Poison sumac is a taller shrub, growing to ten feet or more. It has clusters of 7 to 13 leaves that have smooth edges and pointed tips. Poison sumac is less common that poison ivy or poison oak and favors swampy ground. creosote - An oily liquid distilled from tar, used as a wood preservative. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Back Never try to lift more than you can handle safely. Consider the size, shape, and weight of the load. Don’t bend over the object to be lifted. Instead, squat down next to it with the knees bent and lift with your legs. Certain behaviors increase the risk of back injury, such as twisting the upper body, especially when lifting; extended reaching; working over shoulder level, or maintaining any other awkward posture for more than one minute. Respiratory respirators must be approved by the National Institute for Occupational Safety and Health and the Mine Safety and Health Administration (NIOSH/MSHA). Facial hair in the area of the respirator-sealing surface is prohibited. Figure 3. 4. 1 respirator - A mask to prevent the inhalation of harmful substances. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Back Never try to lift more than you can handle safely. Consider the size, shape, and weight of the load. Don’t bend over the object to be lifted. Instead, squat down next to it with the knees bent and lift with your legs. Certain behaviors increase the risk of back injury, such as twisting the upper body, especially when lifting; extended reaching; working over shoulder level, or maintaining any other awkward posture for more than one minute. Respiratory respirators must be approved by the National Institute for Occupational Safety and Health and the Mine Safety and Health Administration (NIOSH/MSHA). Facial hair in the area of the respirator-sealing surface is prohibited. Figure 3. 4. 1 respirator - A mask to prevent the inhalation of harmful substances. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Job Requirements Working in Site Areas When arriving at a work area for the first time, contact the person in charge for special instructions, restrictions, permits, the location of exits, lockouts (equipment that must not be used), and cover special training that is required to do the job safely. You should locate any emergency alarms or emergency equipment necessary to do your job safely. Find out where first aid kits and eyewash stations are located. Pay attention to any changes to your work environment, such as unexpected liquids or vapors, and report them to the person in charge. Permits Written, properly authorized, current permits may be required before you begin work. Permits must be posted in the work area. A work permit is required for work of any type, but additional permits, such as an Electrically Hazardous Task Plan, may be required to perform work on or near exposed energized electrical conductors. The National Electric Code The National Fire Protection Association publishes the National Electrical Code (NEC) every three years. The NEC covers installations of electric conductors and equipment within or on public and private buildings. NEC standards are voluntary, but many jurisdictions include them in their building codes. All premises wiring should comply with the NEC and local ordinances. All cables and apparatus must be "approved for the purpose. " Generally, this means that the product must be UL (Underwriter’s Laboratory) listed for a particular purpose or type of installation environment. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Job Requirements Working in Site Areas When arriving at a work area for the first time, contact the person in charge for special instructions, restrictions, permits, the location of exits, lockouts (equipment that must not be used), and cover special training that is required to do the job safely. You should locate any emergency alarms or emergency equipment necessary to do your job safely. Find out where first aid kits and eyewash stations are located. Pay attention to any changes to your work environment, such as unexpected liquids or vapors, and report them to the person in charge. Permits Written, properly authorized, current permits may be required before you begin work. Permits must be posted in the work area. A work permit is required for work of any type, but additional permits, such as an Electrically Hazardous Task Plan, may be required to perform work on or near exposed energized electrical conductors. The National Electric Code The National Fire Protection Association publishes the National Electrical Code (NEC) every three years. The NEC covers installations of electric conductors and equipment within or on public and private buildings. NEC standards are voluntary, but many jurisdictions include them in their building codes. All premises wiring should comply with the NEC and local ordinances. All cables and apparatus must be "approved for the purpose. " Generally, this means that the product must be UL (Underwriter’s Laboratory) listed for a particular purpose or type of installation environment. Introduction to Network Cabling Copper Based Systems

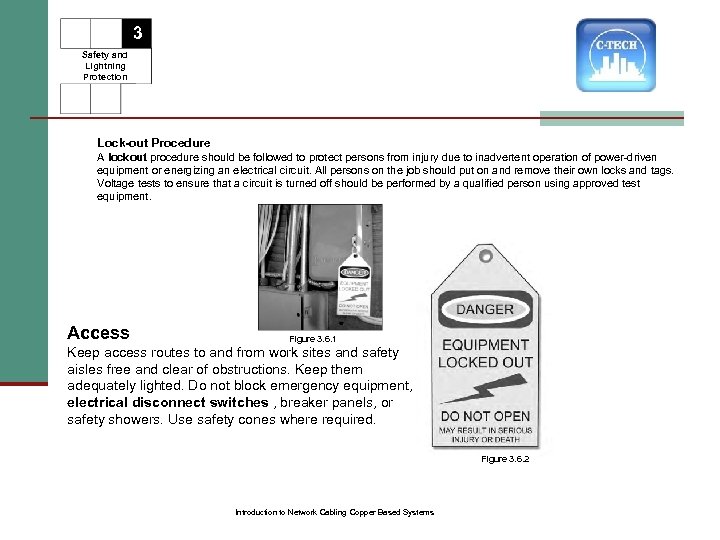

3 Safety and Lightning Protection Lock-out Procedure A lockout procedure should be followed to protect persons from injury due to inadvertent operation of power-driven equipment or energizing an electrical circuit. All persons on the job should put on and remove their own locks and tags. Voltage tests to ensure that a circuit is turned off should be performed by a qualified person using approved test equipment. Access Figure 3. 6. 1 Keep access routes to and from work sites and safety aisles free and clear of obstructions. Keep them adequately lighted. Do not block emergency equipment, electrical disconnect switches , breaker panels, or safety showers. Use safety cones where required. Figure 3. 6. 2 Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Lock-out Procedure A lockout procedure should be followed to protect persons from injury due to inadvertent operation of power-driven equipment or energizing an electrical circuit. All persons on the job should put on and remove their own locks and tags. Voltage tests to ensure that a circuit is turned off should be performed by a qualified person using approved test equipment. Access Figure 3. 6. 1 Keep access routes to and from work sites and safety aisles free and clear of obstructions. Keep them adequately lighted. Do not block emergency equipment, electrical disconnect switches , breaker panels, or safety showers. Use safety cones where required. Figure 3. 6. 2 Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Electrical Tools and Temporary or Portable Equipment Ground Fault circuit Interrupters (GFCIS) should be used on all extension cords and portable tools. These are portable circuit breakers. You plug them in between your tool and the power source. If there is a short in the tool, the circuit breaker “pops”, and you are protected from electric shock. The tool should not be used until this problem is corrected. All 120 volt receptacle outlets should have third wire grounding. Twowire, double insulated portable tools are acceptable for use, if the tool and power cord are approved by a recognized testing laboratory, such as Underwriter’s Laboratories (UL). Figure 3. 7. 1 Hot Work Hot work is defined as any work that involves intentional physical contact using hands or tools (except for approved test equipment) with exposed energized equipment. Hot work is usually not allowed for Network Cabling Professionals without prior supervisory approval. Proximity Work Proximity work is defined as any work performed near exposed and unguarded energized electrical systems where tools, equipment, hands, etc. , could come in contact with live circuits. Proximity work should be avoided. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Electrical Tools and Temporary or Portable Equipment Ground Fault circuit Interrupters (GFCIS) should be used on all extension cords and portable tools. These are portable circuit breakers. You plug them in between your tool and the power source. If there is a short in the tool, the circuit breaker “pops”, and you are protected from electric shock. The tool should not be used until this problem is corrected. All 120 volt receptacle outlets should have third wire grounding. Twowire, double insulated portable tools are acceptable for use, if the tool and power cord are approved by a recognized testing laboratory, such as Underwriter’s Laboratories (UL). Figure 3. 7. 1 Hot Work Hot work is defined as any work that involves intentional physical contact using hands or tools (except for approved test equipment) with exposed energized equipment. Hot work is usually not allowed for Network Cabling Professionals without prior supervisory approval. Proximity Work Proximity work is defined as any work performed near exposed and unguarded energized electrical systems where tools, equipment, hands, etc. , could come in contact with live circuits. Proximity work should be avoided. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Tools Hand Tools Use tools to do the job for which they were designed. Keep hand tools in good operating condition: sharp, clean, oiled, dressed, etc. Always wear safety glasses when using hand tools. Keep tools that are subject to impact (chisels, star drills, etc. ), which tend to "flare", dressed (sharpened and filed smooth). This will help avoid pieces breaking off when the tool is struck and flying dangerously through the air. And remember to wear safety glasses when using any kind of tool. • Do not force tools beyond their capacity. • Keep tools clean and free of grease to prevent slippage. • Do not carry pointed tools in your pockets. Figure 3. 10. 1 Figure 3. 10. 2 Power Tools Always wear safety glasses. Loose clothing, long hair that is not secured, rings, and other jewelry should not be worn around rotating equipment. Sleeves should be kept buttoned or rolled up. Power tools should not be operated without proper training and instructions. Each power tool should be examined before use and defective tools should be tagged and taken out of service. Portable electrical equipment and tools should be grounded unless they are double-insulated. Ground Fault Circuit Interrupters (GFCI) should be used on all extension cords and portable electrical tools. Before making adjustments, servicing, or repairing electric or pneumatic tools, electric cords should be unplugged and the air lines should be deactivated and bled of their remaining air. Lower all hydraulic lifts. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Tools Hand Tools Use tools to do the job for which they were designed. Keep hand tools in good operating condition: sharp, clean, oiled, dressed, etc. Always wear safety glasses when using hand tools. Keep tools that are subject to impact (chisels, star drills, etc. ), which tend to "flare", dressed (sharpened and filed smooth). This will help avoid pieces breaking off when the tool is struck and flying dangerously through the air. And remember to wear safety glasses when using any kind of tool. • Do not force tools beyond their capacity. • Keep tools clean and free of grease to prevent slippage. • Do not carry pointed tools in your pockets. Figure 3. 10. 1 Figure 3. 10. 2 Power Tools Always wear safety glasses. Loose clothing, long hair that is not secured, rings, and other jewelry should not be worn around rotating equipment. Sleeves should be kept buttoned or rolled up. Power tools should not be operated without proper training and instructions. Each power tool should be examined before use and defective tools should be tagged and taken out of service. Portable electrical equipment and tools should be grounded unless they are double-insulated. Ground Fault Circuit Interrupters (GFCI) should be used on all extension cords and portable electrical tools. Before making adjustments, servicing, or repairing electric or pneumatic tools, electric cords should be unplugged and the air lines should be deactivated and bled of their remaining air. Lower all hydraulic lifts. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Crawl Space Hazards A crawl space is any confined space through which cabling runs where an installer can enter, but not stand upright. These include the areas beneath raised floors and above dropped ceilings. You should always wear head protection in these confined areas to guard against any hard surfaces or sharp edges that may be present. You may need a filter mask or breathing apparatus if dust or insulation or other breathing hazards are present. Make sure there is enough light to work by. Bring a flashlight or worklight if there is not enough light. Identify any other systems that might be using the space: HVAC, electrical power, etc. These may present hazards to you, and you may present a hazard to them. Walk or crawl only on those surfaces meant to support your weight. Always test an area before you put your weight on it. Do not drop or throw anything from the area above a suspended ceiling. Rope off or otherwise barricade the area beneath where you are working. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Crawl Space Hazards A crawl space is any confined space through which cabling runs where an installer can enter, but not stand upright. These include the areas beneath raised floors and above dropped ceilings. You should always wear head protection in these confined areas to guard against any hard surfaces or sharp edges that may be present. You may need a filter mask or breathing apparatus if dust or insulation or other breathing hazards are present. Make sure there is enough light to work by. Bring a flashlight or worklight if there is not enough light. Identify any other systems that might be using the space: HVAC, electrical power, etc. These may present hazards to you, and you may present a hazard to them. Walk or crawl only on those surfaces meant to support your weight. Always test an area before you put your weight on it. Do not drop or throw anything from the area above a suspended ceiling. Rope off or otherwise barricade the area beneath where you are working. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Stability Control It is the responsibility of all workers to ensure that personnel, material, and equipment are safe from unexpected movement. Falling, slipping, rolling, tripping, or any other uncontrolled motions (including that caused by high winds) should be avoided. When working off the ground use caution and secure tools and equipment against falling. Do not store materials or tools on ducts, lighting fixtures, beams, suspended ceilings, ladders, or similar elevated locations. When working above others, protect the area below you. Wipe all spills to avoid slipping hazards. Block all materials and equipment, like cable reels and conduit, to prevent rolling. Fall Prevention and Protection Fall prevention eliminates a hazardous situation and removes the chance of falling. Fall protection follows recognition that a hazardous condition can not be fully or adequately eliminated, and therefore fall prevention equipment and procedures are needed. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Stability Control It is the responsibility of all workers to ensure that personnel, material, and equipment are safe from unexpected movement. Falling, slipping, rolling, tripping, or any other uncontrolled motions (including that caused by high winds) should be avoided. When working off the ground use caution and secure tools and equipment against falling. Do not store materials or tools on ducts, lighting fixtures, beams, suspended ceilings, ladders, or similar elevated locations. When working above others, protect the area below you. Wipe all spills to avoid slipping hazards. Block all materials and equipment, like cable reels and conduit, to prevent rolling. Fall Prevention and Protection Fall prevention eliminates a hazardous situation and removes the chance of falling. Fall protection follows recognition that a hazardous condition can not be fully or adequately eliminated, and therefore fall prevention equipment and procedures are needed. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Activity 3. 1: Safety Precautions 1. The Occupational Safety and Health Administration (OSHA) covers safety matters related to the workplace a. True b. False 2. An example of how NOT to show up at a work site would be a. Wearing cutoff shorts b. Wearing safety shoes c. Having Safety Glasses d. Wearing your shirt tucked in 3. It is permissible to have a beard while wearing a respirator a. True b. False 4. Poison Ivy and Poison Oak can be identified by a. 2 leaves b. 3 leaves c. 4 leaves d. 5 leaves Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Activity 3. 1: Safety Precautions 1. The Occupational Safety and Health Administration (OSHA) covers safety matters related to the workplace a. True b. False 2. An example of how NOT to show up at a work site would be a. Wearing cutoff shorts b. Wearing safety shoes c. Having Safety Glasses d. Wearing your shirt tucked in 3. It is permissible to have a beard while wearing a respirator a. True b. False 4. Poison Ivy and Poison Oak can be identified by a. 2 leaves b. 3 leaves c. 4 leaves d. 5 leaves Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Activity 3. 1: Safety Precautions (continued) 1. When arriving at a job site for the first time, insure that you know the locations of all safety equipment and are briefed on all safety requirements. a. True b. False 2. If a piece of equipment has a lockout tag, you should inspect it carefully before turning it on. a. True b. False 3. Work that involves working on energized equipment is: a. Proximity Work 1. Cold Work a. Hot Work b. Cabling Work 4. When lifting an object a. Extend your body as far as possible b. Use a quick jerking motion 1. Maintain an awkward position a. Lift close to your body 5. Ground Fault Circuit Interrupters (GFCIs) protect against electrical shock hazards. a. True b. False Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Activity 3. 1: Safety Precautions (continued) 1. When arriving at a job site for the first time, insure that you know the locations of all safety equipment and are briefed on all safety requirements. a. True b. False 2. If a piece of equipment has a lockout tag, you should inspect it carefully before turning it on. a. True b. False 3. Work that involves working on energized equipment is: a. Proximity Work 1. Cold Work a. Hot Work b. Cabling Work 4. When lifting an object a. Extend your body as far as possible b. Use a quick jerking motion 1. Maintain an awkward position a. Lift close to your body 5. Ground Fault Circuit Interrupters (GFCIs) protect against electrical shock hazards. a. True b. False Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Hazardous Materials Asbestos Materials The composition of any materials to be removed or otherwise disturbed should be verified by the person in charge before any work starts. Materials containing asbestos can include: Insulating materials Floor tiles and Roofing material Fireproofing material asbestos material should not be used for new installations or repair work. All applicable federal, state, and site regulations for removal, handling, and disposal of asbestos-containing materials should be followed. Material Safety Data Sheets (MSDS) One OSHA requirement is the use of material Safety data Sheets (MSDS) for hazardous substances that are used in the workplace. These documents describe the physical hazards (whether the substance can catch fire or explode) as well as health hazards (irritation, lung damage, cancer). Regulations require manufacturers of these substances to supply this safety information to employers. The employers in turn are required to make their employees aware of the hazards. Material Safety Data Sheets should be on file and immediately available. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Hazardous Materials Asbestos Materials The composition of any materials to be removed or otherwise disturbed should be verified by the person in charge before any work starts. Materials containing asbestos can include: Insulating materials Floor tiles and Roofing material Fireproofing material asbestos material should not be used for new installations or repair work. All applicable federal, state, and site regulations for removal, handling, and disposal of asbestos-containing materials should be followed. Material Safety Data Sheets (MSDS) One OSHA requirement is the use of material Safety data Sheets (MSDS) for hazardous substances that are used in the workplace. These documents describe the physical hazards (whether the substance can catch fire or explode) as well as health hazards (irritation, lung damage, cancer). Regulations require manufacturers of these substances to supply this safety information to employers. The employers in turn are required to make their employees aware of the hazards. Material Safety Data Sheets should be on file and immediately available. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Tools Hand Tools Use tools to do the job for which they were designed. Keep hand tools in good operating condition: sharp, clean, oiled, dressed, etc. Always wear safety glasses when using hand tools. Keep tools that are subject to impact (chisels, star drills, etc. ), which tend to "flare", dressed (sharpened and filed smooth). This will help avoid pieces breaking off when the tool is struck and flying dangerously through the air. And remember to wear safety glasses when using any kind of tool. • Do not force tools beyond their capacity. • Keep tools clean and free of grease to prevent slippage. • Do not carry pointed tools in your pockets. Power Tools Always wear safety glasses. Loose clothing, long hair that is not secured, rings, and other jewelry should not be worn around rotating equipment. Sleeves should be kept buttoned or rolled up. Power tools should not be operated without proper training and instructions. Each power tool should be examined before use and defective tools should be tagged and taken out of service. Portable electrical equipment and tools should be grounded unless they are double-insulated. Ground Fault Circuit Interrupters (GFCI) should be used on all extension cords and portable electrical tools. Before making adjustments, servicing, or repairing electric or pneumatic tools, electric cords should be unplugged and the air lines should be deactivated and bled of their remaining air. Lower all hydraulic lifts. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Tools Hand Tools Use tools to do the job for which they were designed. Keep hand tools in good operating condition: sharp, clean, oiled, dressed, etc. Always wear safety glasses when using hand tools. Keep tools that are subject to impact (chisels, star drills, etc. ), which tend to "flare", dressed (sharpened and filed smooth). This will help avoid pieces breaking off when the tool is struck and flying dangerously through the air. And remember to wear safety glasses when using any kind of tool. • Do not force tools beyond their capacity. • Keep tools clean and free of grease to prevent slippage. • Do not carry pointed tools in your pockets. Power Tools Always wear safety glasses. Loose clothing, long hair that is not secured, rings, and other jewelry should not be worn around rotating equipment. Sleeves should be kept buttoned or rolled up. Power tools should not be operated without proper training and instructions. Each power tool should be examined before use and defective tools should be tagged and taken out of service. Portable electrical equipment and tools should be grounded unless they are double-insulated. Ground Fault Circuit Interrupters (GFCI) should be used on all extension cords and portable electrical tools. Before making adjustments, servicing, or repairing electric or pneumatic tools, electric cords should be unplugged and the air lines should be deactivated and bled of their remaining air. Lower all hydraulic lifts. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Crawl Space Hazards A crawl space is any confined space through which cabling runs where an installer can enter, but not stand upright. These include the areas beneath raised floors and above dropped ceilings. You should always wear head protection in these confined areas to guard against any hard surfaces or sharp edges that may be present. Make sure there is enough light to work by. Bring a flashlight or worklight if there is not enough light. Identify any other systems that might be using the space: HVAC, electrical power, etc. These may present hazards to you, and you may present a hazard to them. You may need a filter mask or breathing apparatus if dust or insulation or other breathing hazards are present. Walk or crawl only on those surfaces meant to support your weight. Always test an area before you put your weight on it. Do not drop or throw anything from the area above a suspended ceiling. Rope off or otherwise barricade the area beneath where you are working. Stability Control It is the responsibility of all workers to ensure that personnel, material, and equipment are safe from unexpected movement. Falling, slipping, rolling, tripping, or any other uncontrolled motions (including that caused by high winds) should be avoided. When working off the ground use caution and secure tools and equipment against falling. Do not store materials or tools on ducts, lighting fixtures, beams, suspended ceilings, ladders, or similar elevated locations. When working above others, protect the area below you. Wipe all spills to avoid slipping hazards. Block all materials and equipment, like cable reels and conduit, to prevent rolling. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Crawl Space Hazards A crawl space is any confined space through which cabling runs where an installer can enter, but not stand upright. These include the areas beneath raised floors and above dropped ceilings. You should always wear head protection in these confined areas to guard against any hard surfaces or sharp edges that may be present. Make sure there is enough light to work by. Bring a flashlight or worklight if there is not enough light. Identify any other systems that might be using the space: HVAC, electrical power, etc. These may present hazards to you, and you may present a hazard to them. You may need a filter mask or breathing apparatus if dust or insulation or other breathing hazards are present. Walk or crawl only on those surfaces meant to support your weight. Always test an area before you put your weight on it. Do not drop or throw anything from the area above a suspended ceiling. Rope off or otherwise barricade the area beneath where you are working. Stability Control It is the responsibility of all workers to ensure that personnel, material, and equipment are safe from unexpected movement. Falling, slipping, rolling, tripping, or any other uncontrolled motions (including that caused by high winds) should be avoided. When working off the ground use caution and secure tools and equipment against falling. Do not store materials or tools on ducts, lighting fixtures, beams, suspended ceilings, ladders, or similar elevated locations. When working above others, protect the area below you. Wipe all spills to avoid slipping hazards. Block all materials and equipment, like cable reels and conduit, to prevent rolling. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Fall Prevention and Protection Fall prevention eliminates a hazardous situation and removes the chance of falling. Fall protection follows recognition that a hazardous condition can not be fully or adequately eliminated, and therefore fall prevention equipment and procedures are needed. Ladders • • • • You should inspect every ladder before using it. Remove any ladder from service that is found to be defective. Painted ladders are not permitted; the paint might conceal cracks or structural flaws. If it is necessary to place a ladder in or behind a doorway, barricade the work area and post warning signs on both sides of the door. While going up and coming down a ladder, use both hands. Use a hand line or rope to raise or lower materials. Keep both feet on the ladder rungs; do not reach out too far. Do not place one foot on a line or piece of equipment and the other on a ladder rung. Change the position of the ladder as often as necessary to keep within reach of the work. Here’s a rule of thumb: always keep your belt buckle between the rungs. Face the ladder when working from it. Do not allow more than one person on a ladder unless the ladder is designed for more than one person. Do not use metal ladders when electric welding or near hot electric lines or services. Under no circumstances use chairs or other furniture as ladders. Use type 1 A ladders (300 -lb. rating) as a minimum. When using a stepladder, keep it level on all four feet with spreaders locked in place. Do not use a stepladder as a straight ladder. When using a straight ladder, observe the 1: 4 ratio. To do this, place the ladder so its base is one foot away from what it leans against for every four feet in height to the point where the ladder rests. Do not climb higher than the third rung from the top on straight or extension ladders, or the second tread from the top of stepladders. Introduction to Network Cabling Copper Based Systems Figure 3. 12. 1

3 Safety and Lightning Protection Fall Prevention and Protection Fall prevention eliminates a hazardous situation and removes the chance of falling. Fall protection follows recognition that a hazardous condition can not be fully or adequately eliminated, and therefore fall prevention equipment and procedures are needed. Ladders • • • • You should inspect every ladder before using it. Remove any ladder from service that is found to be defective. Painted ladders are not permitted; the paint might conceal cracks or structural flaws. If it is necessary to place a ladder in or behind a doorway, barricade the work area and post warning signs on both sides of the door. While going up and coming down a ladder, use both hands. Use a hand line or rope to raise or lower materials. Keep both feet on the ladder rungs; do not reach out too far. Do not place one foot on a line or piece of equipment and the other on a ladder rung. Change the position of the ladder as often as necessary to keep within reach of the work. Here’s a rule of thumb: always keep your belt buckle between the rungs. Face the ladder when working from it. Do not allow more than one person on a ladder unless the ladder is designed for more than one person. Do not use metal ladders when electric welding or near hot electric lines or services. Under no circumstances use chairs or other furniture as ladders. Use type 1 A ladders (300 -lb. rating) as a minimum. When using a stepladder, keep it level on all four feet with spreaders locked in place. Do not use a stepladder as a straight ladder. When using a straight ladder, observe the 1: 4 ratio. To do this, place the ladder so its base is one foot away from what it leans against for every four feet in height to the point where the ladder rests. Do not climb higher than the third rung from the top on straight or extension ladders, or the second tread from the top of stepladders. Introduction to Network Cabling Copper Based Systems Figure 3. 12. 1

3 Safety and Lightning Protection Ladders (continued) • • • Remove tools and equipment from the ladder before moving it. Tie off a stepladder when using it close to the edge of an elevated platform, roof, or floor opening and utilize fall protection. Stepladders 8 feet tall and taller should be tied off or attended when in use. Secure ladders when carrying them on a truck. When carrying a ladder, watch out for overhead power lines. Scaffolding • • Always use a ladder to climb on to a scaffold; don’t climb on the scaffold itself. All scaffolds should be erected level and plumb on a firm base. Be mindful of electric wires when erecting or walking on a scaffold. A scaffold should be tied off or stabilized with outriggers when its height is more than three (3) times its width, and should also be tied off horizontally every 30 feet. The safe working loads on all scaffolds should not be exceeded. Do not alter any scaffold member by welding, burning, cutting, drilling, or bending. Scaffolds under which personnel are to pass should be provided with ½ inch mesh, No. 18 gauge wire screen or equivalent between the toe board and handrail. Introduction to Network Cabling Copper Based Systems Figure 3. 1 A scaffolding erected on a residence. Do you think there should be a barricade underneath?

3 Safety and Lightning Protection Ladders (continued) • • • Remove tools and equipment from the ladder before moving it. Tie off a stepladder when using it close to the edge of an elevated platform, roof, or floor opening and utilize fall protection. Stepladders 8 feet tall and taller should be tied off or attended when in use. Secure ladders when carrying them on a truck. When carrying a ladder, watch out for overhead power lines. Scaffolding • • Always use a ladder to climb on to a scaffold; don’t climb on the scaffold itself. All scaffolds should be erected level and plumb on a firm base. Be mindful of electric wires when erecting or walking on a scaffold. A scaffold should be tied off or stabilized with outriggers when its height is more than three (3) times its width, and should also be tied off horizontally every 30 feet. The safe working loads on all scaffolds should not be exceeded. Do not alter any scaffold member by welding, burning, cutting, drilling, or bending. Scaffolds under which personnel are to pass should be provided with ½ inch mesh, No. 18 gauge wire screen or equivalent between the toe board and handrail. Introduction to Network Cabling Copper Based Systems Figure 3. 1 A scaffolding erected on a residence. Do you think there should be a barricade underneath?

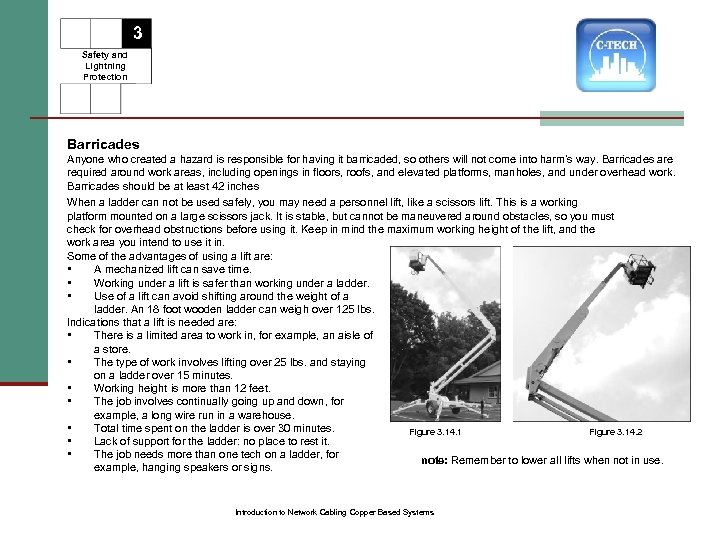

3 Safety and Lightning Protection Barricades Anyone who created a hazard is responsible for having it barricaded, so others will not come into harm’s way. Barricades are required around work areas, including openings in floors, roofs, and elevated platforms, manholes, and under overhead work. Barricades should be at least 42 inches When a ladder can not be used safely, you may need a personnel lift, like a scissors lift. This is a working platform mounted on a large scissors jack. It is stable, but cannot be maneuvered around obstacles, so you must check for overhead obstructions before using it. Keep in mind the maximum working height of the lift, and the work area you intend to use it in. Some of the advantages of using a lift are: • A mechanized lift can save time. • Working under a lift is safer than working under a ladder. • Use of a lift can avoid shifting around the weight of a ladder. An 18 foot wooden ladder can weigh over 125 lbs. Indications that a lift is needed are: • There is a limited area to work in, for example, an aisle of a store. • The type of work involves lifting over 25 lbs. and staying on a ladder over 15 minutes. • Working height is more than 12 feet. • The job involves continually going up and down, for example, a long wire run in a warehouse. • Total time spent on the ladder is over 30 minutes. Figure 3. 14. 1 Figure 3. 14. 2 • Lack of support for the ladder: no place to rest it. • The job needs more than one tech on a ladder, for note: Remember to lower all lifts when not in use. example, hanging speakers or signs. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Barricades Anyone who created a hazard is responsible for having it barricaded, so others will not come into harm’s way. Barricades are required around work areas, including openings in floors, roofs, and elevated platforms, manholes, and under overhead work. Barricades should be at least 42 inches When a ladder can not be used safely, you may need a personnel lift, like a scissors lift. This is a working platform mounted on a large scissors jack. It is stable, but cannot be maneuvered around obstacles, so you must check for overhead obstructions before using it. Keep in mind the maximum working height of the lift, and the work area you intend to use it in. Some of the advantages of using a lift are: • A mechanized lift can save time. • Working under a lift is safer than working under a ladder. • Use of a lift can avoid shifting around the weight of a ladder. An 18 foot wooden ladder can weigh over 125 lbs. Indications that a lift is needed are: • There is a limited area to work in, for example, an aisle of a store. • The type of work involves lifting over 25 lbs. and staying on a ladder over 15 minutes. • Working height is more than 12 feet. • The job involves continually going up and down, for example, a long wire run in a warehouse. • Total time spent on the ladder is over 30 minutes. Figure 3. 14. 1 Figure 3. 14. 2 • Lack of support for the ladder: no place to rest it. • The job needs more than one tech on a ladder, for note: Remember to lower all lifts when not in use. example, hanging speakers or signs. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Fire Protection Alarms You should know: • • Where the nearest fire alarm box is located. How to turn on an alarm. The site emergency phone numbers. The proper exit route and place to meet. There are three major types of fires: • class a - Wood, paper, cloth, trash • class b - Flammable liquids, oil, gas, grease • class c - Electrical, energized electrical equipment Extinguishers You should know: • Where the nearest fire extinguisher is located. • How to operate it. • The type of fire on which it should be used. Fire extinguishers emit different fire-suppressant materials, based on the type of fire they are intended for: Water, Carbon Dioxide, or Multi-Purpose Dry Chemical. An extinguisher will be rated with symbols like those to the right, showing what kind of fire they are intended to put out. An extinguisher rated ABC can be used for almost any type of fire. Combustibles Combustible material should be kept away from steam lines, radiators, heaters, and hot process and service lines. Use nonflammable or flame retardant materials whenever possible. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Fire Protection Alarms You should know: • • Where the nearest fire alarm box is located. How to turn on an alarm. The site emergency phone numbers. The proper exit route and place to meet. There are three major types of fires: • class a - Wood, paper, cloth, trash • class b - Flammable liquids, oil, gas, grease • class c - Electrical, energized electrical equipment Extinguishers You should know: • Where the nearest fire extinguisher is located. • How to operate it. • The type of fire on which it should be used. Fire extinguishers emit different fire-suppressant materials, based on the type of fire they are intended for: Water, Carbon Dioxide, or Multi-Purpose Dry Chemical. An extinguisher will be rated with symbols like those to the right, showing what kind of fire they are intended to put out. An extinguisher rated ABC can be used for almost any type of fire. Combustibles Combustible material should be kept away from steam lines, radiators, heaters, and hot process and service lines. Use nonflammable or flame retardant materials whenever possible. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection ACTIVITY 3. 2 Safety • • • OSHA regulations and standards are voluntary. a. True b. False Safety glasses should be worn by everyone who is doing mechanical/electrical work, working with chemicals, or working with exposed wire or optical fiber. a. True b. False It is OK to begin work without the required work permit as long as you intend to get one within 24 hours. a. True b. False If you need a straight ladder, and one is not available, you may use a step ladder in its place. a. True b. False When working above others, barricade or otherwise protect the area beneath you. a. True b. False The 1: 4 ratio is a safety rule for the placement of ladders. a. True b. False Because it is enclosed, you don’t need to wear head protection in a crawl space. a. True b. False Material Safety Data Sheets contain private information of the manufacturer and should not be shown to anyone. a. True b. False Any type of fire extinguisher may be used on any type of fire. a. True b. False Always use a ladder to climb on to a scaffold. a. True b. False Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection ACTIVITY 3. 2 Safety • • • OSHA regulations and standards are voluntary. a. True b. False Safety glasses should be worn by everyone who is doing mechanical/electrical work, working with chemicals, or working with exposed wire or optical fiber. a. True b. False It is OK to begin work without the required work permit as long as you intend to get one within 24 hours. a. True b. False If you need a straight ladder, and one is not available, you may use a step ladder in its place. a. True b. False When working above others, barricade or otherwise protect the area beneath you. a. True b. False The 1: 4 ratio is a safety rule for the placement of ladders. a. True b. False Because it is enclosed, you don’t need to wear head protection in a crawl space. a. True b. False Material Safety Data Sheets contain private information of the manufacturer and should not be shown to anyone. a. True b. False Any type of fire extinguisher may be used on any type of fire. a. True b. False Always use a ladder to climb on to a scaffold. a. True b. False Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection and Grounding • • 1. 2. 3. 4. Lightning is one of the most dangerous and destructive weather phenomena. Care must be taken to protect electrical installations in buildings from the harmful effects of lightning strikes. Lightning protection consists of capturing a lightning strike and conducting it to ground safely, where its energy can be dissipated harmlessly into the earth. A lightning protection system is made up of: air terminals (lightning rods): Metal rods installed on the roof at regular intervals as defined by industry standards. conductors: Aluminum or copper cables that connect the air terminals and the other system components. Ground terminations: Metal rods driven into the earth to guide the lightning current harmlessly to ground. Surge arrestors and Suppressors: Devices installed along with a lightning protection system to protect electrical wiring and electronic systems and equipment. Lightning happens when a cloud builds up an electric charge of enough power to create a strong electric field around it. The electric field around the cloud ionizes the surrounding air—strips electrons from the air molecules— leaving the air positively charged. These "loose" electrons provide a pathway for an electric current to pass from the bottom of the cloud, which is negatively charged, to the ground, which is positively charged. Figure 3. 17. 2 Figure 3. 17. 1 Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection and Grounding • • 1. 2. 3. 4. Lightning is one of the most dangerous and destructive weather phenomena. Care must be taken to protect electrical installations in buildings from the harmful effects of lightning strikes. Lightning protection consists of capturing a lightning strike and conducting it to ground safely, where its energy can be dissipated harmlessly into the earth. A lightning protection system is made up of: air terminals (lightning rods): Metal rods installed on the roof at regular intervals as defined by industry standards. conductors: Aluminum or copper cables that connect the air terminals and the other system components. Ground terminations: Metal rods driven into the earth to guide the lightning current harmlessly to ground. Surge arrestors and Suppressors: Devices installed along with a lightning protection system to protect electrical wiring and electronic systems and equipment. Lightning happens when a cloud builds up an electric charge of enough power to create a strong electric field around it. The electric field around the cloud ionizes the surrounding air—strips electrons from the air molecules— leaving the air positively charged. These "loose" electrons provide a pathway for an electric current to pass from the bottom of the cloud, which is negatively charged, to the ground, which is positively charged. Figure 3. 17. 2 Figure 3. 17. 1 Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Lightning Facts A bolt of lightning contains over a megawatt of power. That’s more than a million watts, enough power to light over 10, 000 100 -watt light bulbs. A bolt of lightning is five times hotter than the surface of the sun. To find out how many miles away a lightning strike is, count the seconds between the flash and the thunder and divide by five. An average year sees about 25 million lightning strikes in the United States alone. Thunder is the shockwave produced when the superheated air around the lightning bolt explodes. Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Lightning Facts A bolt of lightning contains over a megawatt of power. That’s more than a million watts, enough power to light over 10, 000 100 -watt light bulbs. A bolt of lightning is five times hotter than the surface of the sun. To find out how many miles away a lightning strike is, count the seconds between the flash and the thunder and divide by five. An average year sees about 25 million lightning strikes in the United States alone. Thunder is the shockwave produced when the superheated air around the lightning bolt explodes. Introduction to Network Cabling Copper Based Systems

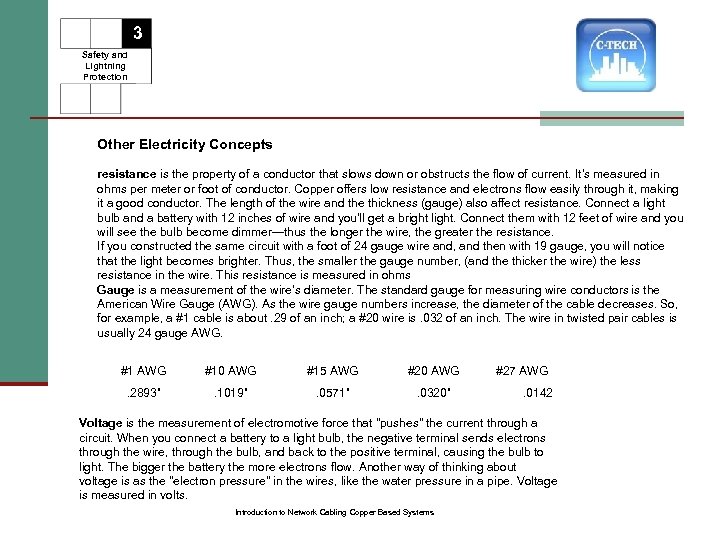

3 Safety and Lightning Protection Grounding Electrical grounding is the responsibility of the contractor who installed the site’s electrical system. However, you should verify the ground before you work with it. The National Electric Code requires that a ground electrode should be 25 ohms or less. If it isn't, you must augment it by driving a ground rod no closer than 6' from the primary electrode. The ground electrode is a metal stake driven into the ground to which the ground wire is attached. A telecom ground is held to much tighter tolerances, 5 ohms or less. Test the ground you have, and if it is not 5 ohms or less, you must alter the resistance of the ground or install another one. What Gets Grounded In your Home At your business • • • • • The TV antenna or ham radio antenna Cable TV entering your home Electrical panels Electrical outlets Outdoor lights Security systems and alarms Telephone lines and equipment Lightning rods Elevators Escalators Steel structures Cellular towers Antennas of any kind Outdoor lights Power poles Auxiliary buildings (storage, barns, etc) Emergency lights Bus ways, ducts Electrical and telephone communications rooms Metal conduits Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Grounding Electrical grounding is the responsibility of the contractor who installed the site’s electrical system. However, you should verify the ground before you work with it. The National Electric Code requires that a ground electrode should be 25 ohms or less. If it isn't, you must augment it by driving a ground rod no closer than 6' from the primary electrode. The ground electrode is a metal stake driven into the ground to which the ground wire is attached. A telecom ground is held to much tighter tolerances, 5 ohms or less. Test the ground you have, and if it is not 5 ohms or less, you must alter the resistance of the ground or install another one. What Gets Grounded In your Home At your business • • • • • The TV antenna or ham radio antenna Cable TV entering your home Electrical panels Electrical outlets Outdoor lights Security systems and alarms Telephone lines and equipment Lightning rods Elevators Escalators Steel structures Cellular towers Antennas of any kind Outdoor lights Power poles Auxiliary buildings (storage, barns, etc) Emergency lights Bus ways, ducts Electrical and telephone communications rooms Metal conduits Introduction to Network Cabling Copper Based Systems

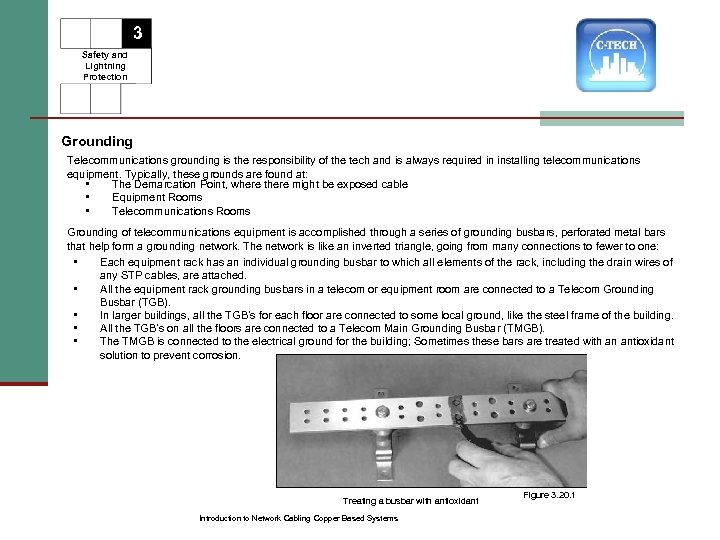

3 Safety and Lightning Protection Grounding Telecommunications grounding is the responsibility of the tech and is always required in installing telecommunications equipment. Typically, these grounds are found at: • The Demarcation Point, where there might be exposed cable • Equipment Rooms • Telecommunications Rooms Grounding of telecommunications equipment is accomplished through a series of grounding busbars, perforated metal bars that help form a grounding network. The network is like an inverted triangle, going from many connections to fewer to one: • • • Each equipment rack has an individual grounding busbar to which all elements of the rack, including the drain wires of any STP cables, are attached. All the equipment rack grounding busbars in a telecom or equipment room are connected to a Telecom Grounding Busbar (TGB). In larger buildings, all the TGB’s for each floor are connected to some local ground, like the steel frame of the building. All the TGB’s on all the floors are connected to a Telecom Main Grounding Busbar (TMGB). The TMGB is connected to the electrical ground for the building; Sometimes these bars are treated with an antioxidant solution to prevent corrosion. Treating a busbar with antioxidant Introduction to Network Cabling Copper Based Systems Figure 3. 20. 1

3 Safety and Lightning Protection Grounding Telecommunications grounding is the responsibility of the tech and is always required in installing telecommunications equipment. Typically, these grounds are found at: • The Demarcation Point, where there might be exposed cable • Equipment Rooms • Telecommunications Rooms Grounding of telecommunications equipment is accomplished through a series of grounding busbars, perforated metal bars that help form a grounding network. The network is like an inverted triangle, going from many connections to fewer to one: • • • Each equipment rack has an individual grounding busbar to which all elements of the rack, including the drain wires of any STP cables, are attached. All the equipment rack grounding busbars in a telecom or equipment room are connected to a Telecom Grounding Busbar (TGB). In larger buildings, all the TGB’s for each floor are connected to some local ground, like the steel frame of the building. All the TGB’s on all the floors are connected to a Telecom Main Grounding Busbar (TMGB). The TMGB is connected to the electrical ground for the building; Sometimes these bars are treated with an antioxidant solution to prevent corrosion. Treating a busbar with antioxidant Introduction to Network Cabling Copper Based Systems Figure 3. 20. 1

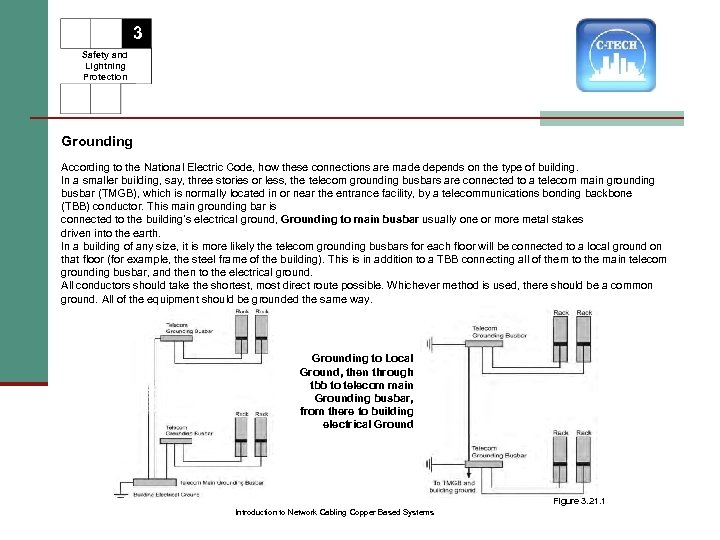

3 Safety and Lightning Protection Grounding According to the National Electric Code, how these connections are made depends on the type of building. In a smaller building, say, three stories or less, the telecom grounding busbars are connected to a telecom main grounding busbar (TMGB), which is normally located in or near the entrance facility, by a telecommunications bonding backbone (TBB) conductor. This main grounding bar is connected to the building’s electrical ground, Grounding to main busbar usually one or more metal stakes driven into the earth. In a building of any size, it is more likely the telecom grounding busbars for each floor will be connected to a local ground on that floor (for example, the steel frame of the building). This is in addition to a TBB connecting all of them to the main telecom grounding busbar, and then to the electrical ground. All conductors should take the shortest, most direct route possible. Whichever method is used, there should be a common ground. All of the equipment should be grounded the same way. Grounding to Local Ground, then through tbb to telecom main Grounding busbar, from there to building electrical Ground Figure 3. 21. 1 Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Grounding According to the National Electric Code, how these connections are made depends on the type of building. In a smaller building, say, three stories or less, the telecom grounding busbars are connected to a telecom main grounding busbar (TMGB), which is normally located in or near the entrance facility, by a telecommunications bonding backbone (TBB) conductor. This main grounding bar is connected to the building’s electrical ground, Grounding to main busbar usually one or more metal stakes driven into the earth. In a building of any size, it is more likely the telecom grounding busbars for each floor will be connected to a local ground on that floor (for example, the steel frame of the building). This is in addition to a TBB connecting all of them to the main telecom grounding busbar, and then to the electrical ground. All conductors should take the shortest, most direct route possible. Whichever method is used, there should be a common ground. All of the equipment should be grounded the same way. Grounding to Local Ground, then through tbb to telecom main Grounding busbar, from there to building electrical Ground Figure 3. 21. 1 Introduction to Network Cabling Copper Based Systems

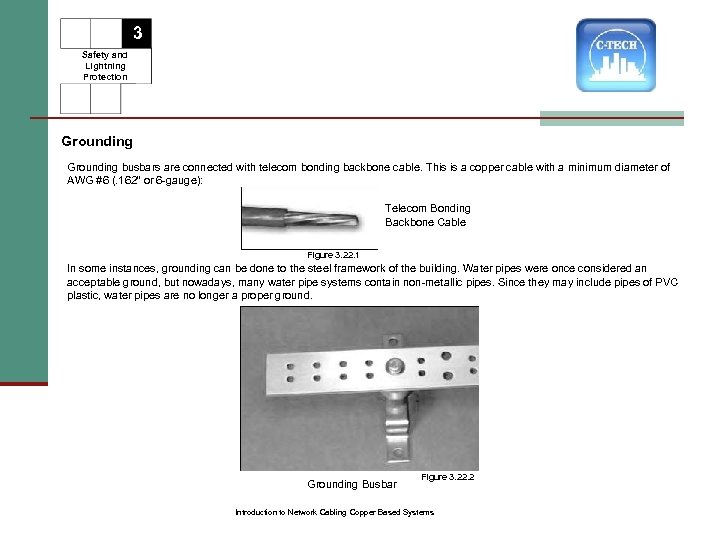

3 Safety and Lightning Protection Grounding busbars are connected with telecom bonding backbone cable. This is a copper cable with a minimum diameter of AWG #6 (. 162” or 6 -gauge): Telecom Bonding Backbone Cable Figure 3. 22. 1 In some instances, grounding can be done to the steel framework of the building. Water pipes were once considered an acceptable ground, but nowadays, many water pipe systems contain non-metallic pipes. Since they may include pipes of PVC plastic, water pipes are no longer a proper ground. Grounding Busbar Figure 3. 22. 2 Introduction to Network Cabling Copper Based Systems

3 Safety and Lightning Protection Grounding busbars are connected with telecom bonding backbone cable. This is a copper cable with a minimum diameter of AWG #6 (. 162” or 6 -gauge): Telecom Bonding Backbone Cable Figure 3. 22. 1 In some instances, grounding can be done to the steel framework of the building. Water pipes were once considered an acceptable ground, but nowadays, many water pipe systems contain non-metallic pipes. Since they may include pipes of PVC plastic, water pipes are no longer a proper ground. Grounding Busbar Figure 3. 22. 2 Introduction to Network Cabling Copper Based Systems

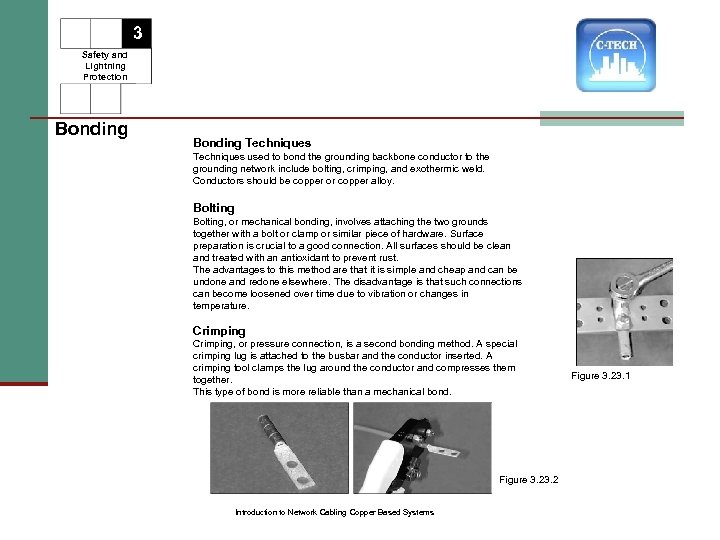

3 Safety and Lightning Protection Bonding Techniques used to bond the grounding backbone conductor to the grounding network include bolting, crimping, and exothermic weld. Conductors should be copper or copper alloy. Bolting, or mechanical bonding, involves attaching the two grounds together with a bolt or clamp or similar piece of hardware. Surface preparation is crucial to a good connection. All surfaces should be clean and treated with an antioxidant to prevent rust. The advantages to this method are that it is simple and cheap and can be undone and redone elsewhere. The disadvantage is that such connections can become loosened over time due to vibration or changes in temperature. Crimping, or pressure connection, is a second bonding method. A special crimping lug is attached to the busbar and the conductor inserted. A crimping tool clamps the lug around the conductor and compresses them together. This type of bond is more reliable than a mechanical bond. Figure 3. 2 Introduction to Network Cabling Copper Based Systems Figure 3. 23. 1

3 Safety and Lightning Protection Bonding Techniques used to bond the grounding backbone conductor to the grounding network include bolting, crimping, and exothermic weld. Conductors should be copper or copper alloy. Bolting, or mechanical bonding, involves attaching the two grounds together with a bolt or clamp or similar piece of hardware. Surface preparation is crucial to a good connection. All surfaces should be clean and treated with an antioxidant to prevent rust. The advantages to this method are that it is simple and cheap and can be undone and redone elsewhere. The disadvantage is that such connections can become loosened over time due to vibration or changes in temperature. Crimping, or pressure connection, is a second bonding method. A special crimping lug is attached to the busbar and the conductor inserted. A crimping tool clamps the lug around the conductor and compresses them together. This type of bond is more reliable than a mechanical bond. Figure 3. 2 Introduction to Network Cabling Copper Based Systems Figure 3. 23. 1

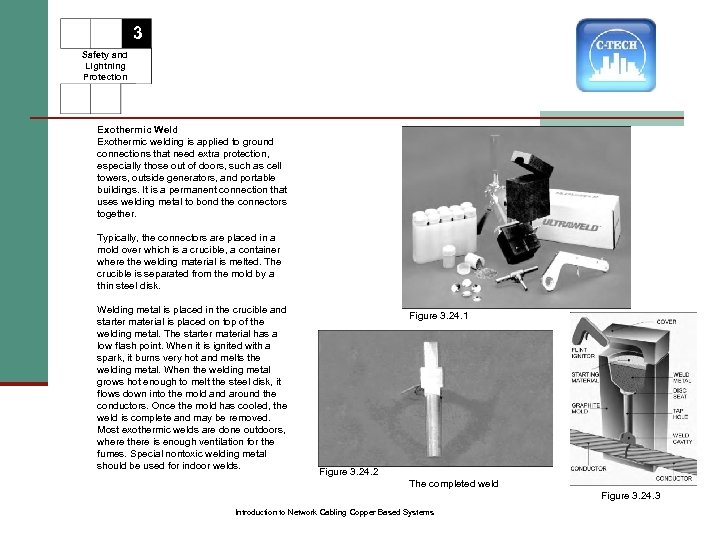

3 Safety and Lightning Protection Exothermic Weld Exothermic welding is applied to ground connections that need extra protection, especially those out of doors, such as cell towers, outside generators, and portable buildings. It is a permanent connection that uses welding metal to bond the connectors together. Typically, the connectors are placed in a mold over which is a crucible, a container where the welding material is melted. The crucible is separated from the mold by a thin steel disk. Welding metal is placed in the crucible and starter material is placed on top of the welding metal. The starter material has a low flash point. When it is ignited with a spark, it burns very hot and melts the welding metal. When the welding metal grows hot enough to melt the steel disk, it flows down into the mold and around the conductors. Once the mold has cooled, the weld is complete and may be removed. Most exothermic welds are done outdoors, where there is enough ventilation for the fumes. Special nontoxic welding metal should be used for indoor welds. Figure 3. 24. 1 Figure 3. 24. 2 The completed weld Figure 3. 24. 3 Introduction to Network Cabling Copper Based Systems