3 D Printing: And its use in RC Modeling Dan Frey 17 NOV 2015

3 D Printing: And its use in RC Modeling Dan Frey 17 NOV 2015

3 D Printing • Makes part from CAD files (STL format) • Builds layer by layer ~ 0. 010” thick (or thinner) • Thermoplastic materials (ABS, PLA, Nylon) mostly • Machines now as low as $175, many ~$500, can be >$30 K • Or outsource your parts

3 D Printing • Makes part from CAD files (STL format) • Builds layer by layer ~ 0. 010” thick (or thinner) • Thermoplastic materials (ABS, PLA, Nylon) mostly • Machines now as low as $175, many ~$500, can be >$30 K • Or outsource your parts

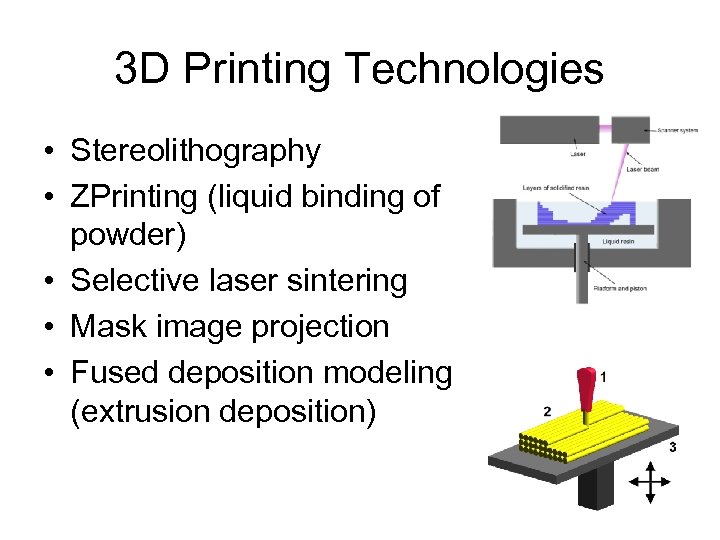

3 D Printing Technologies • Stereolithography • ZPrinting (liquid binding of powder) • Selective laser sintering • Mask image projection • Fused deposition modeling (extrusion deposition)

3 D Printing Technologies • Stereolithography • ZPrinting (liquid binding of powder) • Selective laser sintering • Mask image projection • Fused deposition modeling (extrusion deposition)

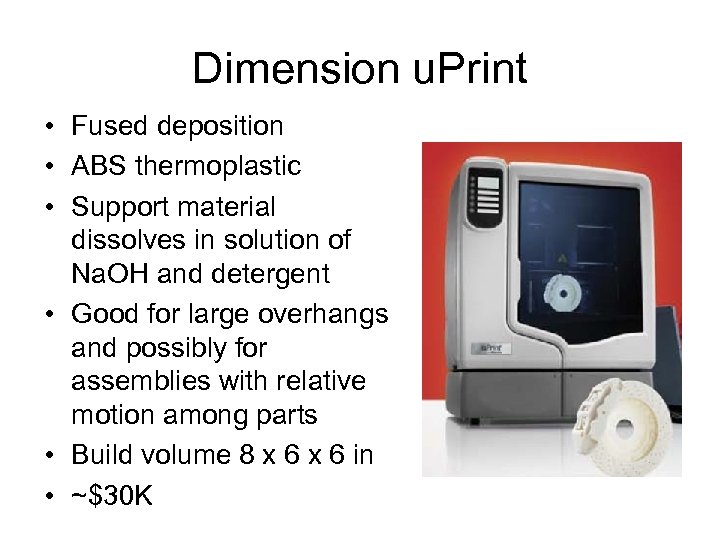

Dimension u. Print • Fused deposition • ABS thermoplastic • Support material dissolves in solution of Na. OH and detergent • Good for large overhangs and possibly for assemblies with relative motion among parts • Build volume 8 x 6 in • ~$30 K

Dimension u. Print • Fused deposition • ABS thermoplastic • Support material dissolves in solution of Na. OH and detergent • Good for large overhangs and possibly for assemblies with relative motion among parts • Build volume 8 x 6 in • ~$30 K

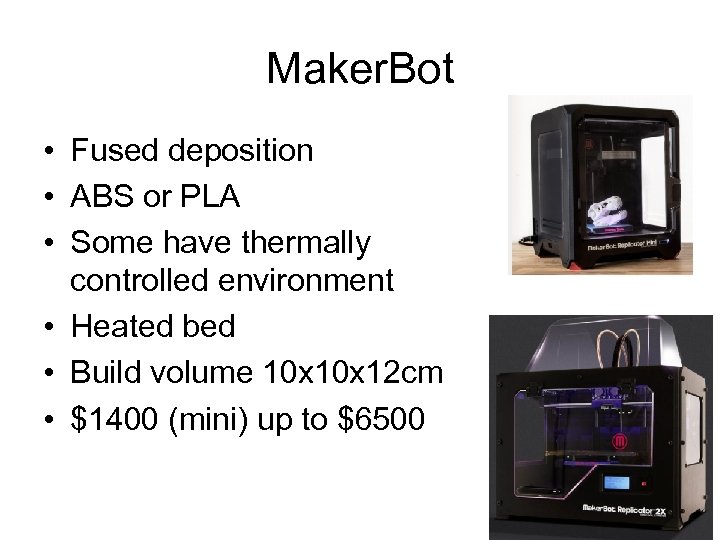

Maker. Bot • Fused deposition • ABS or PLA • Some have thermally controlled environment • Heated bed • Build volume 10 x 12 cm • $1400 (mini) up to $6500

Maker. Bot • Fused deposition • ABS or PLA • Some have thermally controlled environment • Heated bed • Build volume 10 x 12 cm • $1400 (mini) up to $6500

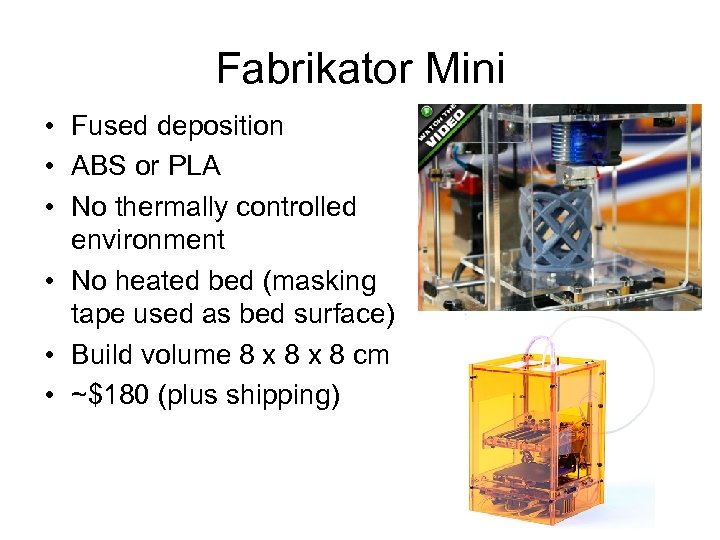

Fabrikator Mini • Fused deposition • ABS or PLA • No thermally controlled environment • No heated bed (masking tape used as bed surface) • Build volume 8 x 8 cm • ~$180 (plus shipping)

Fabrikator Mini • Fused deposition • ABS or PLA • No thermally controlled environment • No heated bed (masking tape used as bed surface) • Build volume 8 x 8 cm • ~$180 (plus shipping)

PLA Plastic ~$30/kg

PLA Plastic ~$30/kg

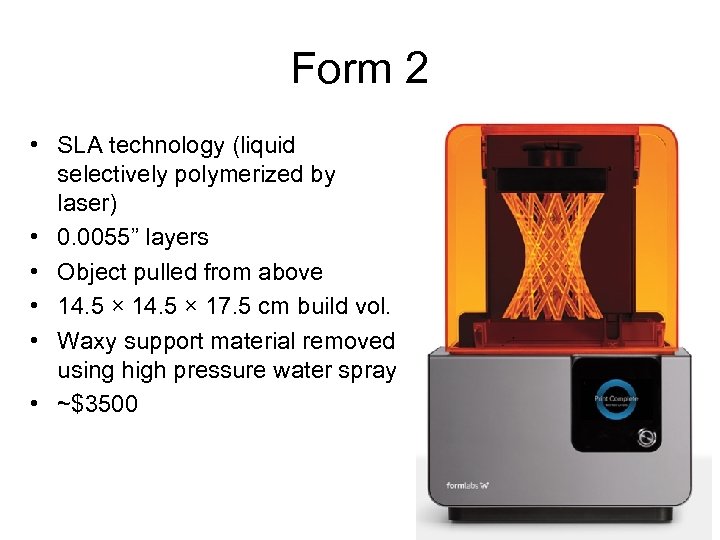

Form 2 • SLA technology (liquid selectively polymerized by laser) • 0. 0055” layers • Object pulled from above • 14. 5 × 17. 5 cm build vol. • Waxy support material removed using high pressure water spray • ~$3500

Form 2 • SLA technology (liquid selectively polymerized by laser) • 0. 0055” layers • Object pulled from above • 14. 5 × 17. 5 cm build vol. • Waxy support material removed using high pressure water spray • ~$3500

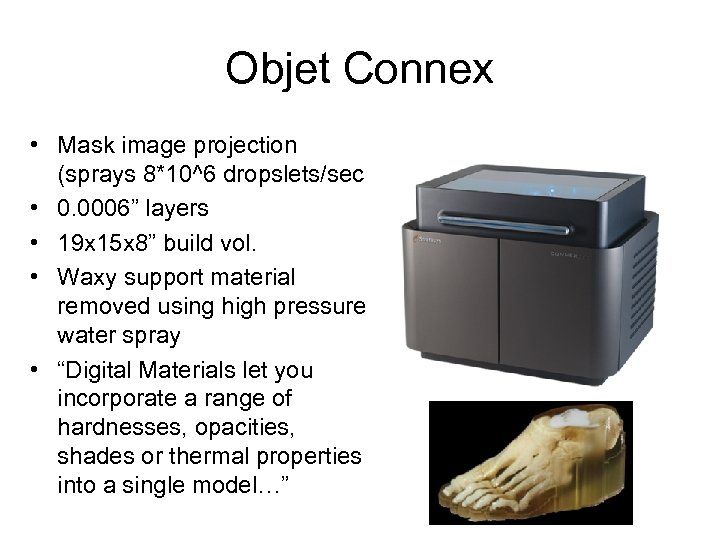

Objet Connex • Mask image projection (sprays 8*10^6 dropslets/sec) • 0. 0006” layers • 19 x 15 x 8” build vol. • Waxy support material removed using high pressure water spray • “Digital Materials let you incorporate a range of hardnesses, opacities, shades or thermal properties into a single model…”

Objet Connex • Mask image projection (sprays 8*10^6 dropslets/sec) • 0. 0006” layers • 19 x 15 x 8” build vol. • Waxy support material removed using high pressure water spray • “Digital Materials let you incorporate a range of hardnesses, opacities, shades or thermal properties into a single model…”

eos Formiga • Selective Laser Sintering (SLS) • 0. 06 mm layers • No support material needed (unbound powder inherently supports the part) • Machine ~$1 M

eos Formiga • Selective Laser Sintering (SLS) • 0. 06 mm layers • No support material needed (unbound powder inherently supports the part) • Machine ~$1 M

Outsourcing (rather than owning a 3 D printer) • e. g. shapeways. com • Has SLS nylon parts (“strong and flexible plastic”)

Outsourcing (rather than owning a 3 D printer) • e. g. shapeways. com • Has SLS nylon parts (“strong and flexible plastic”)

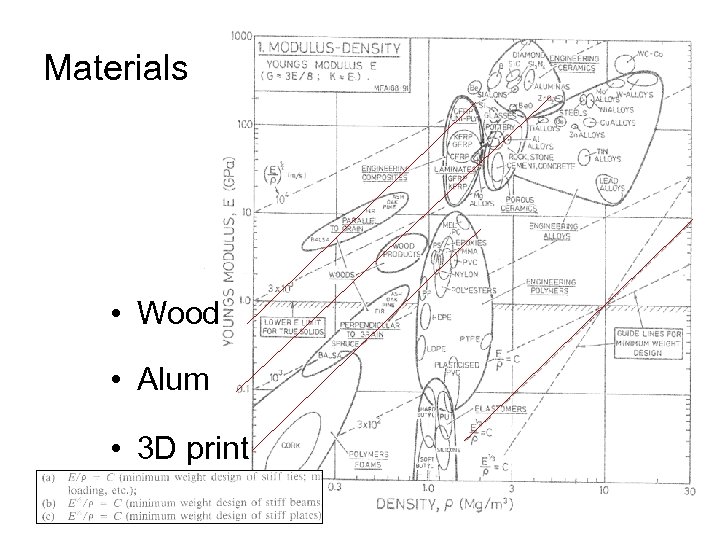

Materials • Wood • Alum • 3 D print

Materials • Wood • Alum • 3 D print

Mark One Composite 3 D Printer • Fused deposition • Carbon fiber, fiberglass, nylon • Machine ~$5. 5 K

Mark One Composite 3 D Printer • Fused deposition • Carbon fiber, fiberglass, nylon • Machine ~$5. 5 K