4959d67541a8b82dfe2c57b307daae67.ppt

- Количество слайдов: 29

3 D PLUS COMPANY PRESENTATION THEMIS Project Review 7 th April 2004 www. 3 d-plus. com 641, Rue Hélène Boucher 78532 BUC - FRANCE

3 D PLUS COMPANY PRESENTATION THEMIS Project Review 7 th April 2004 www. 3 d-plus. com 641, Rue Hélène Boucher 78532 BUC - FRANCE

Agenda – THEMIS Review • 15. 30 Welcome • 15. 45 – 16. 45 3 D PLUS Presentation • 16. 45 – 17. 30 Company Tour (2 groups) - Hi-Rel Facility - Industrial Facility

Agenda – THEMIS Review • 15. 30 Welcome • 15. 45 – 16. 45 3 D PLUS Presentation • 16. 45 – 17. 30 Company Tour (2 groups) - Hi-Rel Facility - Industrial Facility

Company overview • 3 Dplus mission : Design, manufacture and sell 3 D modules for Active, Passive, Opto-electronics and MEMS components packaging in Hi-Rel and harsh environment electronic applications • 3 Dplus Offer : Standard Products as well as Custom or Semi Custom Solutions. • Established on 1995, Independent • Technology and process are based on 3 D PLUS's patents portofolio • 3 Dplus is the only one in Europe to specialise in this technology. • Worldwide Rep network • Existing production capability: 20 000 High Rel. modules per year • Extension to 200 000 modules per year since Mid 2003 for Non Space Markets

Company overview • 3 Dplus mission : Design, manufacture and sell 3 D modules for Active, Passive, Opto-electronics and MEMS components packaging in Hi-Rel and harsh environment electronic applications • 3 Dplus Offer : Standard Products as well as Custom or Semi Custom Solutions. • Established on 1995, Independent • Technology and process are based on 3 D PLUS's patents portofolio • 3 Dplus is the only one in Europe to specialise in this technology. • Worldwide Rep network • Existing production capability: 20 000 High Rel. modules per year • Extension to 200 000 modules per year since Mid 2003 for Non Space Markets

Company – History • • Created in 1995 by C. VAL who was previously member of scientist and technical council of Thomson Group In 2001, 3 Dplus set up a subsidiary in Mc Kinney, Texas, USA. The head-quarter’s production Line was successfully evaluated/qualified by CNES, ESA and NASA. In 2002, 3 Dplus released a increase of capital and built a new manufacturing plant in BUC, France for medium series manufacturing. Quality: – ESA, CNES and NASA approval – Customers agreement – • ISO 9001 -(2000) certified in April 2003 3 Dplus will continue to strengthen its position in the following fields : – Space – Military / Aero – Niche Automotive and Industry – Medical – High Performance Computers, embedded Computers, Servers and Workstations, DIMM on Module Memory boards. • 3 Dplus will continue to set up partnerships with application specialists like Astrium, Alcatel, Hewlett Packard, Nortel, PNY, … to develop and offer stateof-the-art standard products.

Company – History • • Created in 1995 by C. VAL who was previously member of scientist and technical council of Thomson Group In 2001, 3 Dplus set up a subsidiary in Mc Kinney, Texas, USA. The head-quarter’s production Line was successfully evaluated/qualified by CNES, ESA and NASA. In 2002, 3 Dplus released a increase of capital and built a new manufacturing plant in BUC, France for medium series manufacturing. Quality: – ESA, CNES and NASA approval – Customers agreement – • ISO 9001 -(2000) certified in April 2003 3 Dplus will continue to strengthen its position in the following fields : – Space – Military / Aero – Niche Automotive and Industry – Medical – High Performance Computers, embedded Computers, Servers and Workstations, DIMM on Module Memory boards. • 3 Dplus will continue to set up partnerships with application specialists like Astrium, Alcatel, Hewlett Packard, Nortel, PNY, … to develop and offer stateof-the-art standard products.

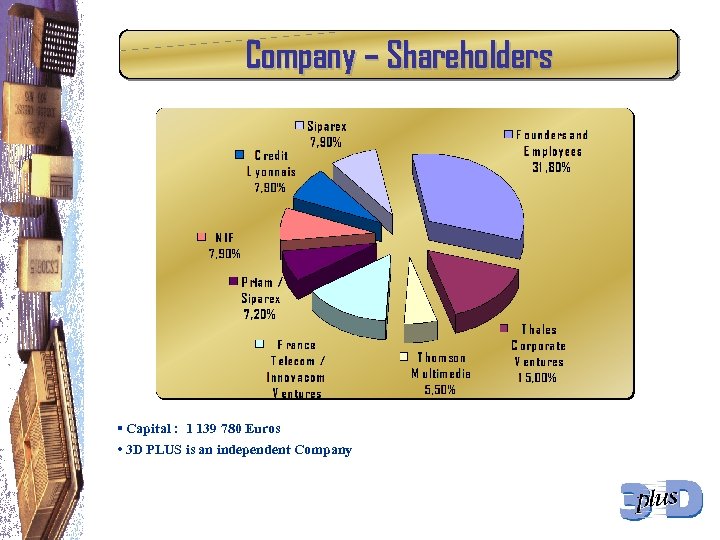

Company – Shareholders • Capital : 1 139 780 Euros • 3 D PLUS is an independent Company

Company – Shareholders • Capital : 1 139 780 Euros • 3 D PLUS is an independent Company

Company – Locations 3 Dplus Head-Office, Design and Technology Center, High Rel. Manufacturing line qualified for Space Applications : 641, rue Helene-Boucher 78532 Buc, France 3 Dplus Medium Series Manufacturing Line : 423, rue Audemars 78532 Buc, France 3 Dplus USA : Marketing and Sales Office for North America 2570 Eldorado Parkway, Suite 150 Mc. Kinney, TX 75070, USA

Company – Locations 3 Dplus Head-Office, Design and Technology Center, High Rel. Manufacturing line qualified for Space Applications : 641, rue Helene-Boucher 78532 Buc, France 3 Dplus Medium Series Manufacturing Line : 423, rue Audemars 78532 Buc, France 3 Dplus USA : Marketing and Sales Office for North America 2570 Eldorado Parkway, Suite 150 Mc. Kinney, TX 75070, USA

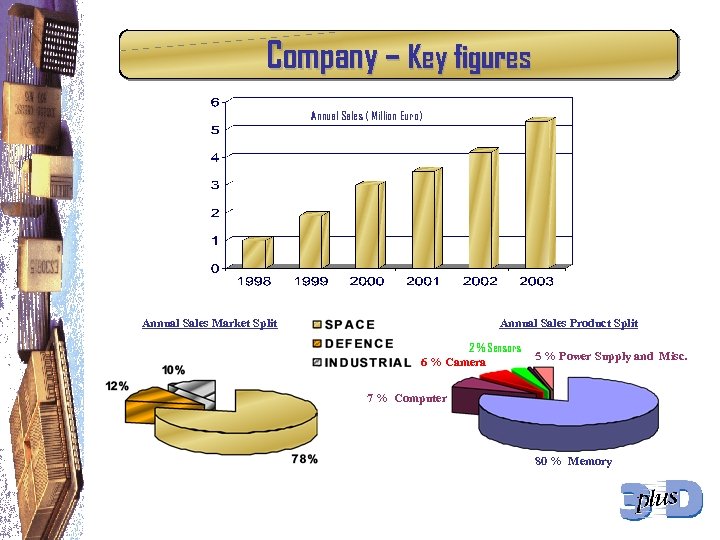

Company – Key figures Annual Sales ( Million Euro) Annual Sales Market Split Annual Sales Product Split 2 % Sensors 6 % Camera 5 % Power Supply and Misc. 7 % Computer 80 % Memory

Company – Key figures Annual Sales ( Million Euro) Annual Sales Market Split Annual Sales Product Split 2 % Sensors 6 % Camera 5 % Power Supply and Misc. 7 % Computer 80 % Memory

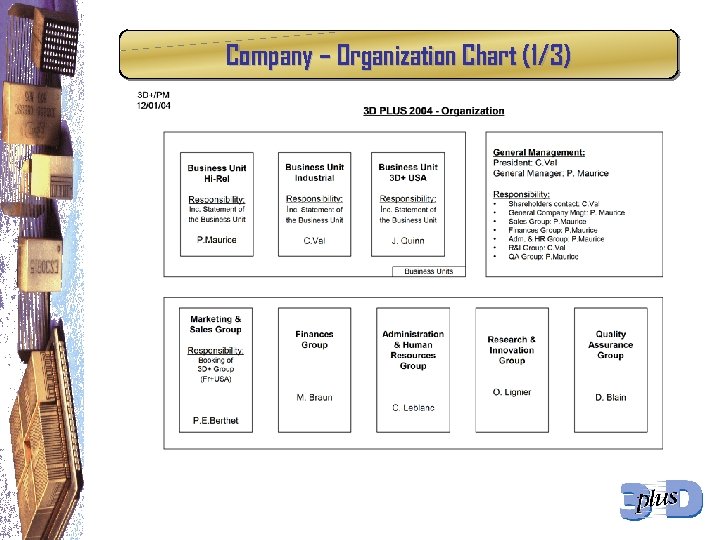

Company – Organization Chart (1/3)

Company – Organization Chart (1/3)

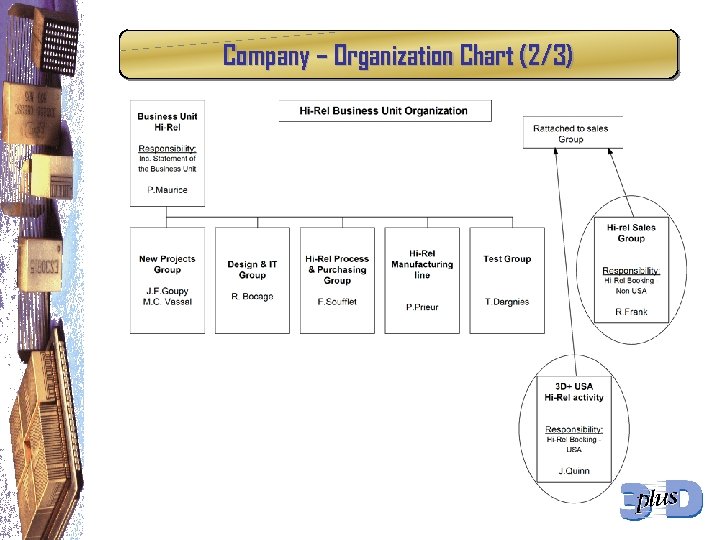

Company – Organization Chart (2/3)

Company – Organization Chart (2/3)

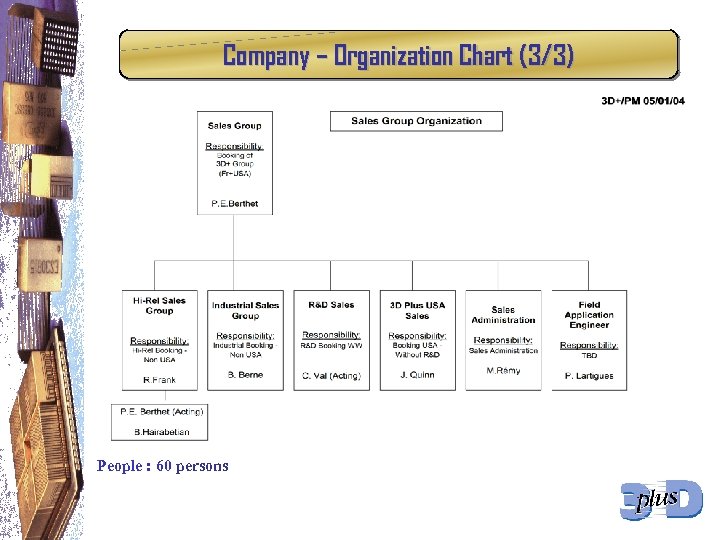

Company – Organization Chart (3/3) People : 60 persons

Company – Organization Chart (3/3) People : 60 persons

Company – Our Rep Network Canada Russia Scandinavia Netherlands Great Britain Germany USA China France Japan Spain Korea Italy Israël Brazil India Argentina South Africa

Company – Our Rep Network Canada Russia Scandinavia Netherlands Great Britain Germany USA China France Japan Spain Korea Italy Israël Brazil India Argentina South Africa

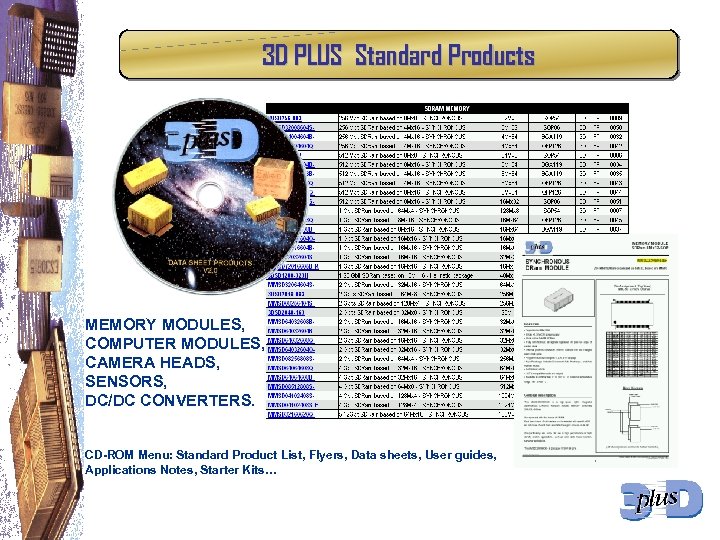

3 D PLUS Standard Products MEMORY MODULES, COMPUTER MODULES, CAMERA HEADS, SENSORS, DC/DC CONVERTERS. CD-ROM Menu: Standard Product List, Flyers, Data sheets, User guides, Applications Notes, Starter Kits…

3 D PLUS Standard Products MEMORY MODULES, COMPUTER MODULES, CAMERA HEADS, SENSORS, DC/DC CONVERTERS. CD-ROM Menu: Standard Product List, Flyers, Data sheets, User guides, Applications Notes, Starter Kits…

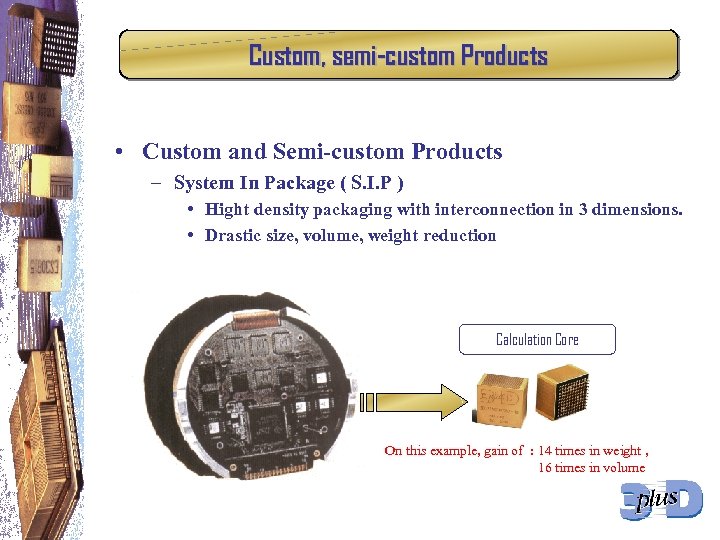

Custom, semi-custom Products • Custom and Semi-custom Products – System In Package ( S. I. P ) • Hight density packaging with interconnection in 3 dimensions. • Drastic size, volume, weight reduction Calculation Core On this example, gain of : 14 times in weight , 16 times in volume

Custom, semi-custom Products • Custom and Semi-custom Products – System In Package ( S. I. P ) • Hight density packaging with interconnection in 3 dimensions. • Drastic size, volume, weight reduction Calculation Core On this example, gain of : 14 times in weight , 16 times in volume

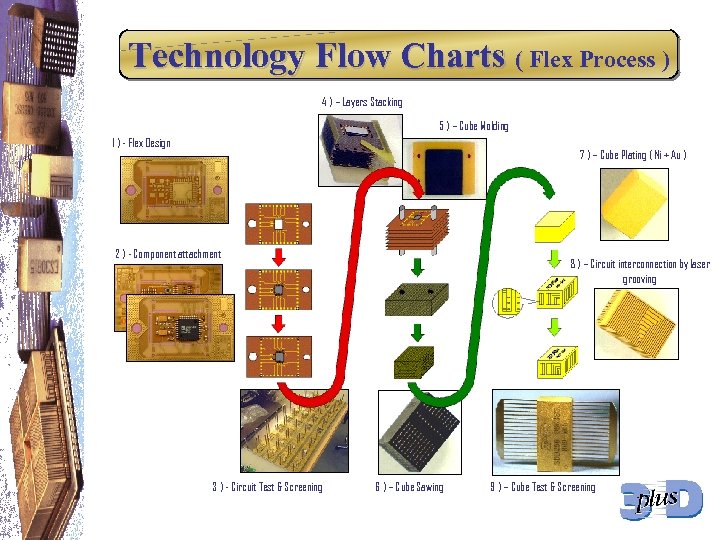

Technology Flow Charts ( Flex Process ) ( 4 ) – Layers Stacking 5 ) – Cube Molding 1 ) - Flex Design 7 ) – Cube Plating ( Ni + Au ) 2 ) - Component attachment 3 ) - Circuit Test & Screening 8 ) – Circuit interconnection by laser grooving 6 ) – Cube Sawing 9 ) – Cube Test & Screening

Technology Flow Charts ( Flex Process ) ( 4 ) – Layers Stacking 5 ) – Cube Molding 1 ) - Flex Design 7 ) – Cube Plating ( Ni + Au ) 2 ) - Component attachment 3 ) - Circuit Test & Screening 8 ) – Circuit interconnection by laser grooving 6 ) – Cube Sawing 9 ) – Cube Test & Screening

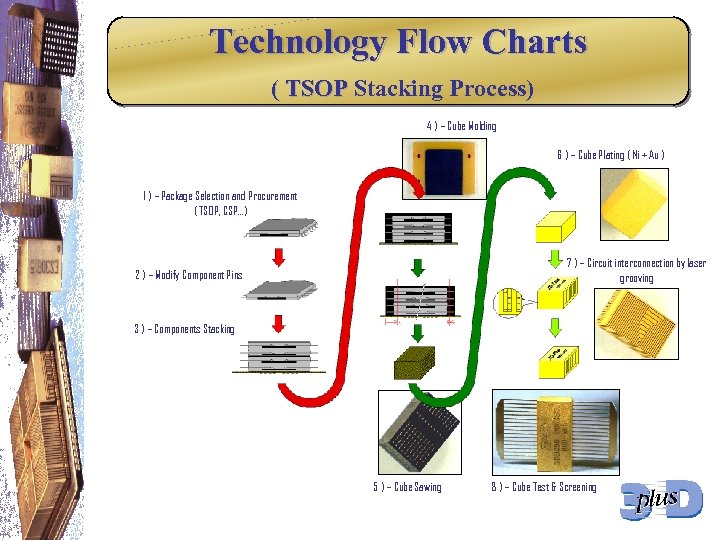

Technology Flow Charts ( TSOP Stacking Process) ( TSOP 4 ) – Cube Molding 6 ) – Cube Plating ( Ni + Au ) 1 ) – Package Selection and Procurement ( TSOP, CSP…) 7 ) – Circuit interconnection by laser grooving 2 ) – Modify Component Pins 3 ) – Components Stacking 5 ) – Cube Sawing 8 ) – Cube Test & Screening

Technology Flow Charts ( TSOP Stacking Process) ( TSOP 4 ) – Cube Molding 6 ) – Cube Plating ( Ni + Au ) 1 ) – Package Selection and Procurement ( TSOP, CSP…) 7 ) – Circuit interconnection by laser grooving 2 ) – Modify Component Pins 3 ) – Components Stacking 5 ) – Cube Sawing 8 ) – Cube Test & Screening

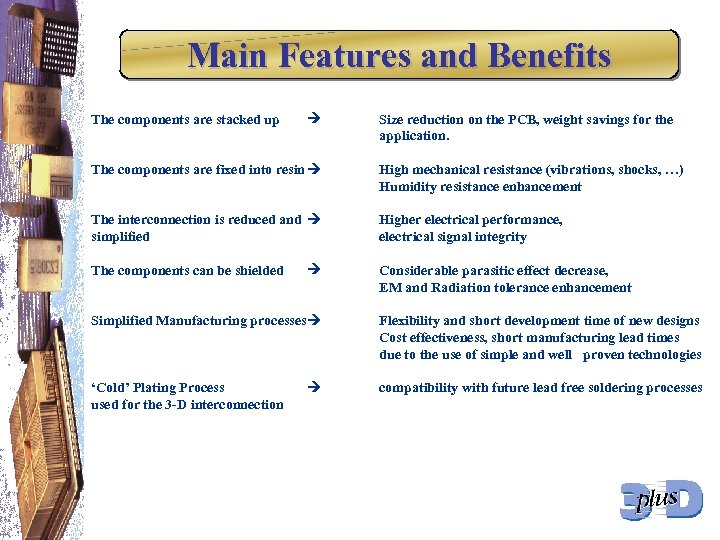

Main Features and Benefits The components are stacked up Size reduction on the PCB, weight savings for the application. The components are fixed into resin High mechanical resistance (vibrations, shocks, …) Humidity resistance enhancement The interconnection is reduced and simplified Higher electrical performance, electrical signal integrity The components can be shielded Simplified Manufacturing processes ‘Cold’ Plating Process used for the 3 -D interconnection Considerable parasitic effect decrease, EM and Radiation tolerance enhancement Flexibility and short development time of new designs Cost effectiveness, short manufacturing lead times due to the use of simple and well proven technologies compatibility with future lead free soldering processes

Main Features and Benefits The components are stacked up Size reduction on the PCB, weight savings for the application. The components are fixed into resin High mechanical resistance (vibrations, shocks, …) Humidity resistance enhancement The interconnection is reduced and simplified Higher electrical performance, electrical signal integrity The components can be shielded Simplified Manufacturing processes ‘Cold’ Plating Process used for the 3 -D interconnection Considerable parasitic effect decrease, EM and Radiation tolerance enhancement Flexibility and short development time of new designs Cost effectiveness, short manufacturing lead times due to the use of simple and well proven technologies compatibility with future lead free soldering processes

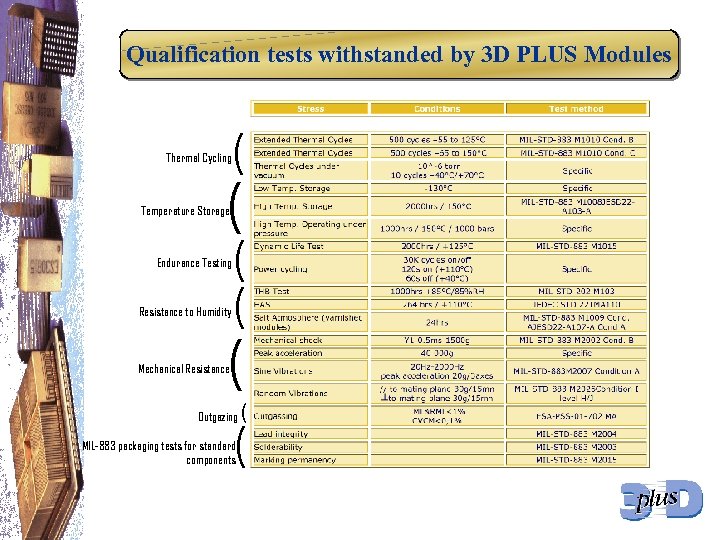

Qualification tests withstanded by 3 D PLUS Modules Thermal Cycling ( ( Temperature Storage Endurance Testing Resistance to Humidity ( ( ( Mechanical Resistance Outgazing ( ( MIL-883 packaging tests for standard components

Qualification tests withstanded by 3 D PLUS Modules Thermal Cycling ( ( Temperature Storage Endurance Testing Resistance to Humidity ( ( ( Mechanical Resistance Outgazing ( ( MIL-883 packaging tests for standard components

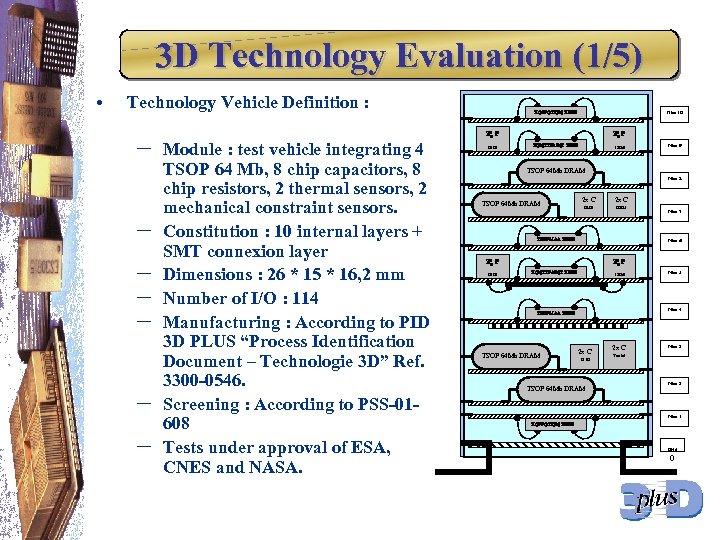

3 D Technology Evaluation (1/5) • Technology Vehicle Definition : – – – – CORROSION CHIP Film 10 2 x R Module : test vehicle integrating 4 TSOP 64 Mb, 8 chip capacitors, 8 chip resistors, 2 thermal sensors, 2 mechanical constraint sensors. Constitution : 10 internal layers + SMT connexion layer Dimensions : 26 * 15 * 16, 2 mm Number of I/O : 114 Manufacturing : According to PID 3 D PLUS “Process Identification Document – Technologie 3 D” Ref. 3300 -0546. Screening : According to PSS-01608 Tests under approval of ESA, CNES and NASA. 0505 2 x R CONSTRAINT CHIP 1206 Film 9 TSOP 64 Mb DRAM Film 8 TSOP 64 Mb DRAM 2 x C 0805 THERMAL CHIP Film 6 2 x R 0505 Film 7 2 x R CONSTRAINT CHIP 1206 Film 4 THERMAL CHIP TSOP 64 Mb DRAM Film 5 2 x C 1210 TSOP 64 Mb DRAM 2 x C Film 3 Tantal Film 2 Film 1 CORROSION CHIP Grid 0

3 D Technology Evaluation (1/5) • Technology Vehicle Definition : – – – – CORROSION CHIP Film 10 2 x R Module : test vehicle integrating 4 TSOP 64 Mb, 8 chip capacitors, 8 chip resistors, 2 thermal sensors, 2 mechanical constraint sensors. Constitution : 10 internal layers + SMT connexion layer Dimensions : 26 * 15 * 16, 2 mm Number of I/O : 114 Manufacturing : According to PID 3 D PLUS “Process Identification Document – Technologie 3 D” Ref. 3300 -0546. Screening : According to PSS-01608 Tests under approval of ESA, CNES and NASA. 0505 2 x R CONSTRAINT CHIP 1206 Film 9 TSOP 64 Mb DRAM Film 8 TSOP 64 Mb DRAM 2 x C 0805 THERMAL CHIP Film 6 2 x R 0505 Film 7 2 x R CONSTRAINT CHIP 1206 Film 4 THERMAL CHIP TSOP 64 Mb DRAM Film 5 2 x C 1210 TSOP 64 Mb DRAM 2 x C Film 3 Tantal Film 2 Film 1 CORROSION CHIP Grid 0

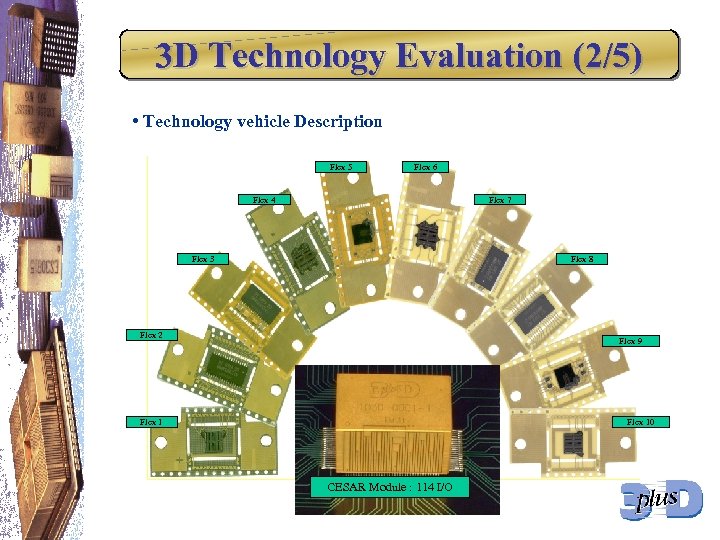

3 D Technology Evaluation (2/5) • Technology vehicle Description Flex 5 Flex 6 Flex 4 Flex 7 Flex 3 Flex 8 Flex 2 Flex 9 Flex 10 CESAR Module : 114 I/O

3 D Technology Evaluation (2/5) • Technology vehicle Description Flex 5 Flex 6 Flex 4 Flex 7 Flex 3 Flex 8 Flex 2 Flex 9 Flex 10 CESAR Module : 114 I/O

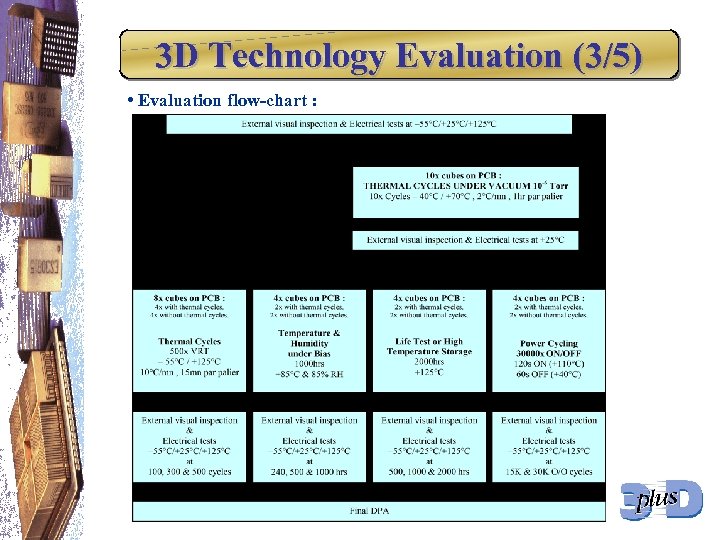

3 D Technology Evaluation (3/5) • Evaluation flow-chart :

3 D Technology Evaluation (3/5) • Evaluation flow-chart :

3 D Technology Evaluation (4/5) • TEST RESULTS – All test results are satisfactory – Evaluation successful and huge margins defined versus space qualification level requirements. Remark : Evaluation report written by ESA, CNES and NASA are available. • • • Evaluation approval successfully pronounced by ESA, CNES and NASA 3 D PLUS was introduced in NASA QPL Kick-Off formal generic qualification

3 D Technology Evaluation (4/5) • TEST RESULTS – All test results are satisfactory – Evaluation successful and huge margins defined versus space qualification level requirements. Remark : Evaluation report written by ESA, CNES and NASA are available. • • • Evaluation approval successfully pronounced by ESA, CNES and NASA 3 D PLUS was introduced in NASA QPL Kick-Off formal generic qualification

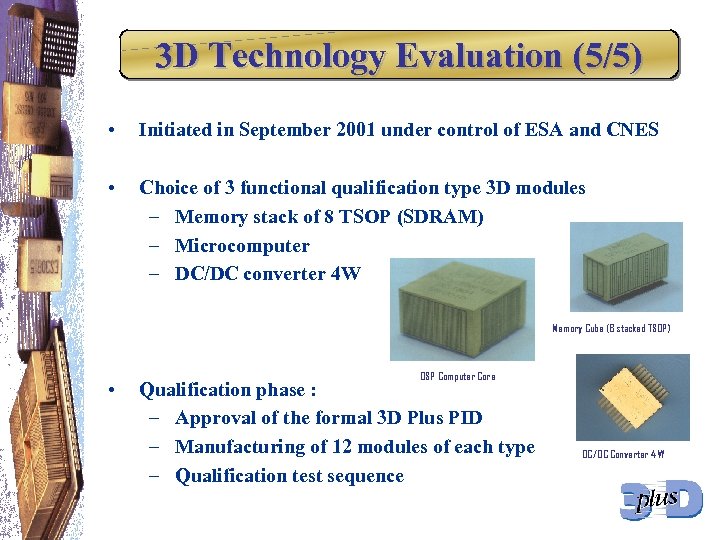

3 D Technology Evaluation (5/5) • Initiated in September 2001 under control of ESA and CNES • Choice of 3 functional qualification type 3 D modules – Memory stack of 8 TSOP (SDRAM) – Microcomputer – DC/DC converter 4 W Memory Cube (8 stacked TSOP) • DSP Computer Core Qualification phase : – Approval of the formal 3 D Plus PID – Manufacturing of 12 modules of each type – Qualification test sequence DC/DC Converter 4 W

3 D Technology Evaluation (5/5) • Initiated in September 2001 under control of ESA and CNES • Choice of 3 functional qualification type 3 D modules – Memory stack of 8 TSOP (SDRAM) – Microcomputer – DC/DC converter 4 W Memory Cube (8 stacked TSOP) • DSP Computer Core Qualification phase : – Approval of the formal 3 D Plus PID – Manufacturing of 12 modules of each type – Qualification test sequence DC/DC Converter 4 W

3 D PLUS Technology Qualification • Several Project/Product Qualification successfully passed since the beginning of 3 D PLUS for COROT, CLUSTER II, PROBA, SMART 1, ROSETTA, MARS EXPRESS, ENVISAT… • Successful Generic Evaluation by CNES/ESA/NASA on December 2001 • See CNES/ESA Evaluation report (ESCCON 2002 – France) • See NASA Evaluation report (ESCCON 2002 – France) • Generic Qualification by CNES/ESA on 4 Q 2003 • Final Presentation of the 3 D qualification (Document ref. 3300 -05633) will take place at ESTEC on 28 th April 2004. • Several Customer’s Internal Agreements in the Space Industry • Successful ISO 9001 -2000 Certification on April 2003 ð 3 D PLUS Technology, Processes and Products benefit from a large experience and a high quality referential

3 D PLUS Technology Qualification • Several Project/Product Qualification successfully passed since the beginning of 3 D PLUS for COROT, CLUSTER II, PROBA, SMART 1, ROSETTA, MARS EXPRESS, ENVISAT… • Successful Generic Evaluation by CNES/ESA/NASA on December 2001 • See CNES/ESA Evaluation report (ESCCON 2002 – France) • See NASA Evaluation report (ESCCON 2002 – France) • Generic Qualification by CNES/ESA on 4 Q 2003 • Final Presentation of the 3 D qualification (Document ref. 3300 -05633) will take place at ESTEC on 28 th April 2004. • Several Customer’s Internal Agreements in the Space Industry • Successful ISO 9001 -2000 Certification on April 2003 ð 3 D PLUS Technology, Processes and Products benefit from a large experience and a high quality referential

Manufacturing and quality assurance of stack production Quality Assurance Documents 3 D PLUS Quality Manual Þ Generic quality process at 3 D PLUS. Process Identification Document Þ Freeze the qualified technological capability domain of 3 D PLUS (i. e Process list, inspection criteria, material list, parts procurement rules, screening test, …) Product Configuration Management : CADM Þ Module procurement specification Þ Product definition Þ Manufacturing travelers Þ Test specification Þ Product Assurance Plan End Item Data Package : Þ Include all the traceability information (material, parts, operations, LAT, …) of the manufactured lot Þ As built/As design configuration list for the manufactured modules

Manufacturing and quality assurance of stack production Quality Assurance Documents 3 D PLUS Quality Manual Þ Generic quality process at 3 D PLUS. Process Identification Document Þ Freeze the qualified technological capability domain of 3 D PLUS (i. e Process list, inspection criteria, material list, parts procurement rules, screening test, …) Product Configuration Management : CADM Þ Module procurement specification Þ Product definition Þ Manufacturing travelers Þ Test specification Þ Product Assurance Plan End Item Data Package : Þ Include all the traceability information (material, parts, operations, LAT, …) of the manufactured lot Þ As built/As design configuration list for the manufactured modules

Quality levels and screening flow chart • Product Identification Document (PID) ref. 3300 -0546 -2 for : – Parts procurement, – Modules manufacturing, – Modules screening, – Lot Acceptance Test. The PID is compliant to ESA quality standard for Space applications. • Quality levels for Space applications : 3 quality levels are defined in 3 D PLUS PID and described in the document ref. 3 DPA 0350 : – Commercial – Industrial => Engineering Models for Space applications – Space => Flight Models for Space applications

Quality levels and screening flow chart • Product Identification Document (PID) ref. 3300 -0546 -2 for : – Parts procurement, – Modules manufacturing, – Modules screening, – Lot Acceptance Test. The PID is compliant to ESA quality standard for Space applications. • Quality levels for Space applications : 3 quality levels are defined in 3 D PLUS PID and described in the document ref. 3 DPA 0350 : – Commercial – Industrial => Engineering Models for Space applications – Space => Flight Models for Space applications

3 D PLUS Standard Services For Space Application • Basic Parts Procurement and Selection (Lot Acceptance Tests) • Radiation Tolerance Verification Tests (Radiation Hardness Assurance activity of 3 D PLUS includes Total Dose and SEU/SEL tests) • 3 D Modules Manufacturing • 3 D Modules Lot Acceptance Tests and DPA • End-Item-Data Package (full trace for manufacturig, screening, tests results, parts and material …) ð 3 D PLUS is the One-Stop Shop for Space Qualified Parts procurement

3 D PLUS Standard Services For Space Application • Basic Parts Procurement and Selection (Lot Acceptance Tests) • Radiation Tolerance Verification Tests (Radiation Hardness Assurance activity of 3 D PLUS includes Total Dose and SEU/SEL tests) • 3 D Modules Manufacturing • 3 D Modules Lot Acceptance Tests and DPA • End-Item-Data Package (full trace for manufacturig, screening, tests results, parts and material …) ð 3 D PLUS is the One-Stop Shop for Space Qualified Parts procurement

3 D PLUS Heritage for Space Applications (1/2) • • • 1997: First order of Memory Modules (Flex process) for Space Applications – Cluster 2 - ASTRIUM Gmb. H – Cooperation with IBM Product : Stacks of 10 Die 16 Mb DRAM FPM from IBM (4 stacks mounted in an hermetic package) with a total capacity of 640 Mb (40 Mx 16) ~1000 Flight Models manufactured for Cluster-2 / Envisat / Metop projects for ASTRIUM 1998: First order of Memory Modules (TSOP process) for Space Applications –Microsat Project - CNES Product : Stacks of 4 TSOPs 64 Mb DRAM EDO from Samsung Capacity: 256 Mb (32 Mx 8) 2000: 512 Mb SDRAM Development for Space applications Product : Stacks of 8 TSOPs 64 Mb SDRAM From Samsung ~5000 Flight Models manufactured For Radarsat (Canada), Cosmo/Skymed (Italy) • 2001: Development of a Micro Computer module based on the TSC 21020 DSP and replacing a double Euro Computer board ~50 Flight Models manufactured for Rosetta, Mars Express, Smart-1, Net-Lander (ESA) • 2001 : Development of a micro camera for space applications ~50 Flight Models manufactured for Rosetta and Smart-1

3 D PLUS Heritage for Space Applications (1/2) • • • 1997: First order of Memory Modules (Flex process) for Space Applications – Cluster 2 - ASTRIUM Gmb. H – Cooperation with IBM Product : Stacks of 10 Die 16 Mb DRAM FPM from IBM (4 stacks mounted in an hermetic package) with a total capacity of 640 Mb (40 Mx 16) ~1000 Flight Models manufactured for Cluster-2 / Envisat / Metop projects for ASTRIUM 1998: First order of Memory Modules (TSOP process) for Space Applications –Microsat Project - CNES Product : Stacks of 4 TSOPs 64 Mb DRAM EDO from Samsung Capacity: 256 Mb (32 Mx 8) 2000: 512 Mb SDRAM Development for Space applications Product : Stacks of 8 TSOPs 64 Mb SDRAM From Samsung ~5000 Flight Models manufactured For Radarsat (Canada), Cosmo/Skymed (Italy) • 2001: Development of a Micro Computer module based on the TSC 21020 DSP and replacing a double Euro Computer board ~50 Flight Models manufactured for Rosetta, Mars Express, Smart-1, Net-Lander (ESA) • 2001 : Development of a micro camera for space applications ~50 Flight Models manufactured for Rosetta and Smart-1

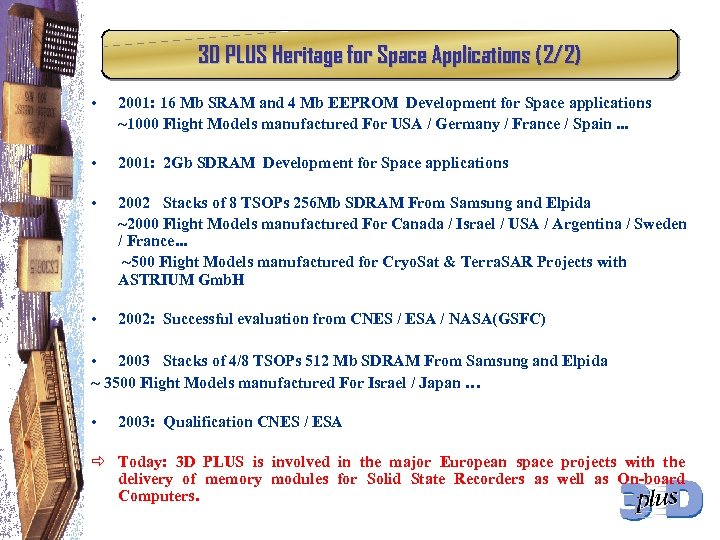

3 D PLUS Heritage for Space Applications (2/2) • 2001: 16 Mb SRAM and 4 Mb EEPROM Development for Space applications ~1000 Flight Models manufactured For USA / Germany / France / Spain. . . • 2001: 2 Gb SDRAM Development for Space applications • 2002 Stacks of 8 TSOPs 256 Mb SDRAM From Samsung and Elpida ~2000 Flight Models manufactured For Canada / Israel / USA / Argentina / Sweden / France. . . ~500 Flight Models manufactured for Cryo. Sat & Terra. SAR Projects with ASTRIUM Gmb. H • 2002: Successful evaluation from CNES / ESA / NASA(GSFC) • 2003 Stacks of 4/8 TSOPs 512 Mb SDRAM From Samsung and Elpida ~ 3500 Flight Models manufactured For Israel / Japan … • 2003: Qualification CNES / ESA ð Today: 3 D PLUS is involved in the major European space projects with the delivery of memory modules for Solid State Recorders as well as On-board Computers.

3 D PLUS Heritage for Space Applications (2/2) • 2001: 16 Mb SRAM and 4 Mb EEPROM Development for Space applications ~1000 Flight Models manufactured For USA / Germany / France / Spain. . . • 2001: 2 Gb SDRAM Development for Space applications • 2002 Stacks of 8 TSOPs 256 Mb SDRAM From Samsung and Elpida ~2000 Flight Models manufactured For Canada / Israel / USA / Argentina / Sweden / France. . . ~500 Flight Models manufactured for Cryo. Sat & Terra. SAR Projects with ASTRIUM Gmb. H • 2002: Successful evaluation from CNES / ESA / NASA(GSFC) • 2003 Stacks of 4/8 TSOPs 512 Mb SDRAM From Samsung and Elpida ~ 3500 Flight Models manufactured For Israel / Japan … • 2003: Qualification CNES / ESA ð Today: 3 D PLUS is involved in the major European space projects with the delivery of memory modules for Solid State Recorders as well as On-board Computers.

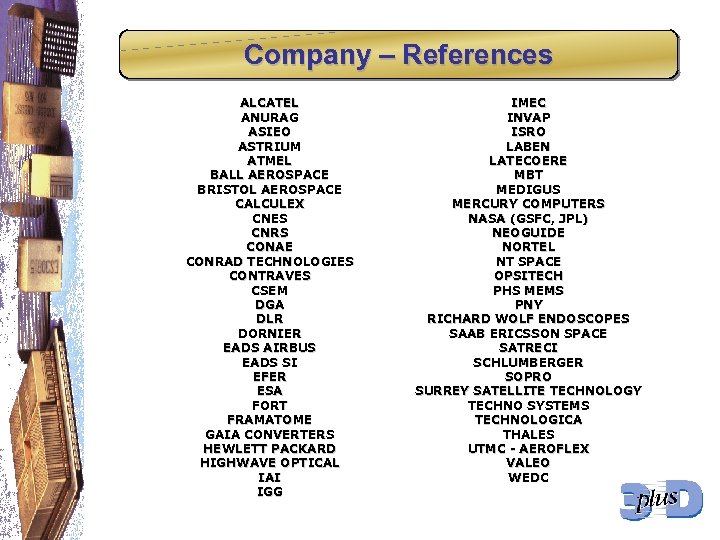

Company – References ALCATEL ANURAG ASIEO ASTRIUM ATMEL BALL AEROSPACE BRISTOL AEROSPACE CALCULEX CNES CNRS CONAE CONRAD TECHNOLOGIES CONTRAVES CSEM DGA DLR DORNIER EADS AIRBUS EADS SI EFER ESA FORT FRAMATOME GAIA CONVERTERS HEWLETT PACKARD HIGHWAVE OPTICAL IAI IGG IMEC INVAP ISRO LABEN LATECOERE MBT MEDIGUS MERCURY COMPUTERS NASA (GSFC, JPL) NEOGUIDE NORTEL NT SPACE OPSITECH PHS MEMS PNY RICHARD WOLF ENDOSCOPES SAAB ERICSSON SPACE SATRECI SCHLUMBERGER SOPRO SURREY SATELLITE TECHNOLOGY TECHNO SYSTEMS TECHNOLOGICA THALES UTMC - AEROFLEX VALEO WEDC

Company – References ALCATEL ANURAG ASIEO ASTRIUM ATMEL BALL AEROSPACE BRISTOL AEROSPACE CALCULEX CNES CNRS CONAE CONRAD TECHNOLOGIES CONTRAVES CSEM DGA DLR DORNIER EADS AIRBUS EADS SI EFER ESA FORT FRAMATOME GAIA CONVERTERS HEWLETT PACKARD HIGHWAVE OPTICAL IAI IGG IMEC INVAP ISRO LABEN LATECOERE MBT MEDIGUS MERCURY COMPUTERS NASA (GSFC, JPL) NEOGUIDE NORTEL NT SPACE OPSITECH PHS MEMS PNY RICHARD WOLF ENDOSCOPES SAAB ERICSSON SPACE SATRECI SCHLUMBERGER SOPRO SURREY SATELLITE TECHNOLOGY TECHNO SYSTEMS TECHNOLOGICA THALES UTMC - AEROFLEX VALEO WEDC