9fe9d5ea57edc24fc0632a1687d63b70.ppt

- Количество слайдов: 14

3 D Imaging Software Brad Boldizar, Aubrey Mc. Kelvey, and Mackenzie Thomas Advised by: Dr. Paul King Matt Moore

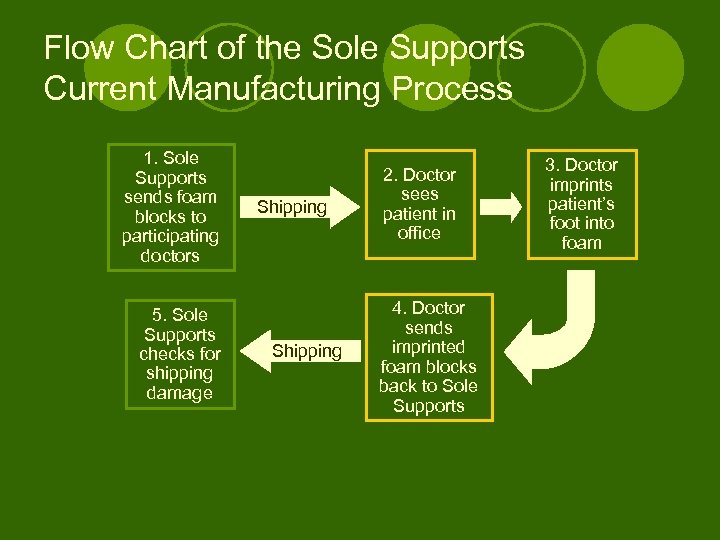

Flow Chart of the Sole Supports Current Manufacturing Process 1. Sole Supports sends foam blocks to participating doctors 5. Sole Supports checks for shipping damage Shipping 2. Doctor sees patient in office 4. Doctor sends imprinted foam blocks back to Sole Supports 3. Doctor imprints patient’s foot into foam

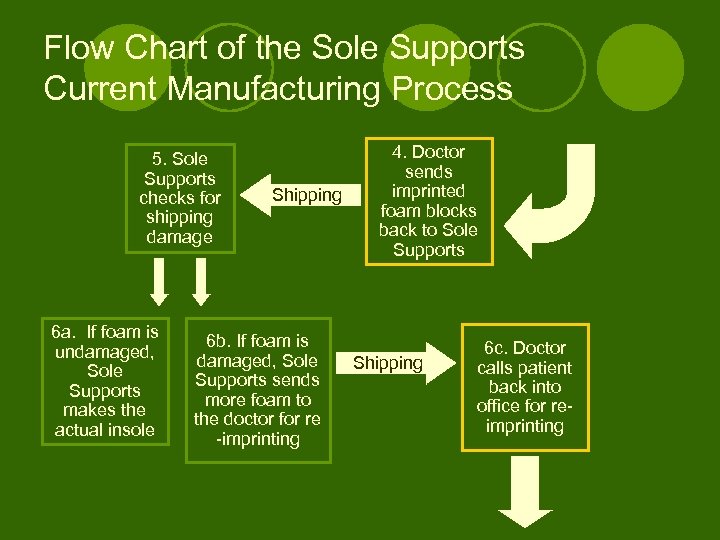

Flow Chart of the Sole Supports Current Manufacturing Process 5. Sole Supports checks for shipping damage 6 a. If foam is undamaged, Sole Supports makes the actual insole Shipping 6 b. If foam is damaged, Sole Supports sends more foam to the doctor for re -imprinting 4. Doctor sends imprinted foam blocks back to Sole Supports Shipping 6 c. Doctor calls patient back into office for reimprinting

Flow Chart of the Sole Supports Current Manufacturing Process 6 a. If foam is undamaged, Sole Supports makes the actual insole 6 b. If foam is damaged, Sole Supports sends more foam to the doctor for re -imprinting Shipping 6 c. Doctor calls patient back into office for reimprinting 6 d. Doctor sends imprinted foam blocks back to Sole Supports

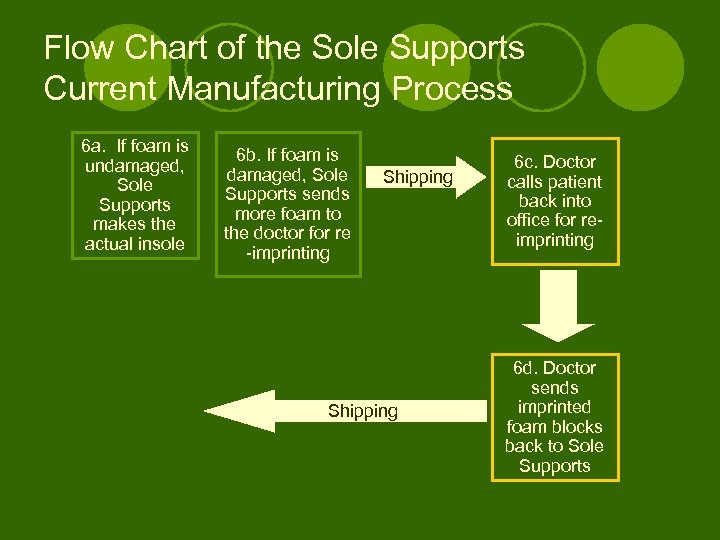

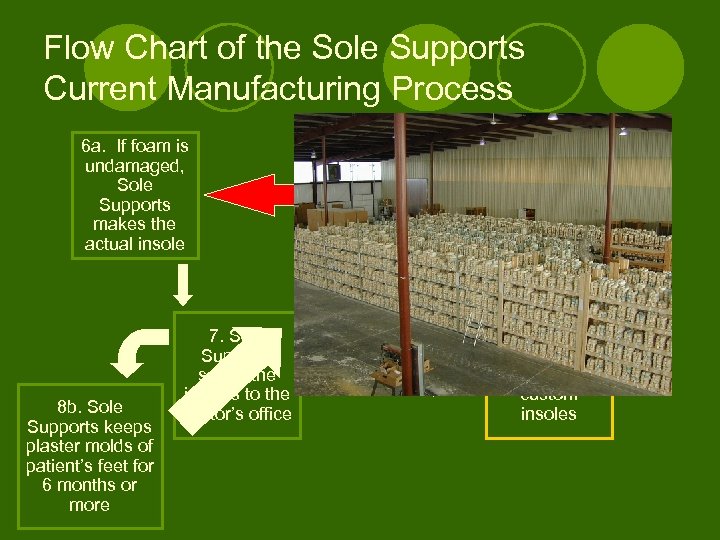

Flow Chart of the Sole Supports Current Manufacturing Process 6 a. If foam is undamaged, Sole Supports makes the actual insole 8 b. Sole Supports keeps plaster molds of patient’s feet for 6 months or more 7. Sole Supports sends the insoles to the doctor’s office Shipping 6 d. Doctor sends imprinted foam blocks back to Sole Supports 8 a. Doctors fit the patient with the new custom insoles

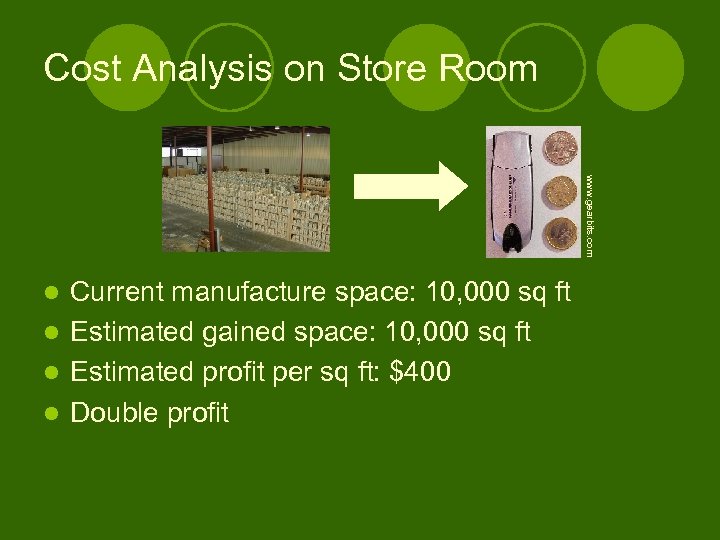

Cost Analysis on Store Room www. gearbits. com Current manufacture space: 10, 000 sq ft l Estimated gained space: 10, 000 sq ft l Estimated profit per sq ft: $400 l Double profit l

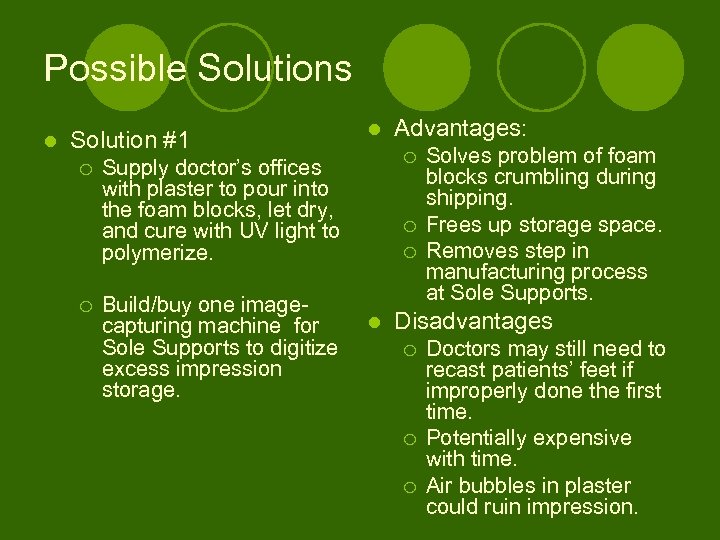

Possible Solutions l Solution #1 ¡ ¡ l ¡ Supply doctor’s offices with plaster to pour into the foam blocks, let dry, and cure with UV light to polymerize. Build/buy one imagecapturing machine for Sole Supports to digitize excess impression storage. Advantages: ¡ ¡ l Solves problem of foam blocks crumbling during shipping. Frees up storage space. Removes step in manufacturing process at Sole Supports. Disadvantages ¡ ¡ ¡ Doctors may still need to recast patients’ feet if improperly done the first time. Potentially expensive with time. Air bubbles in plaster could ruin impression.

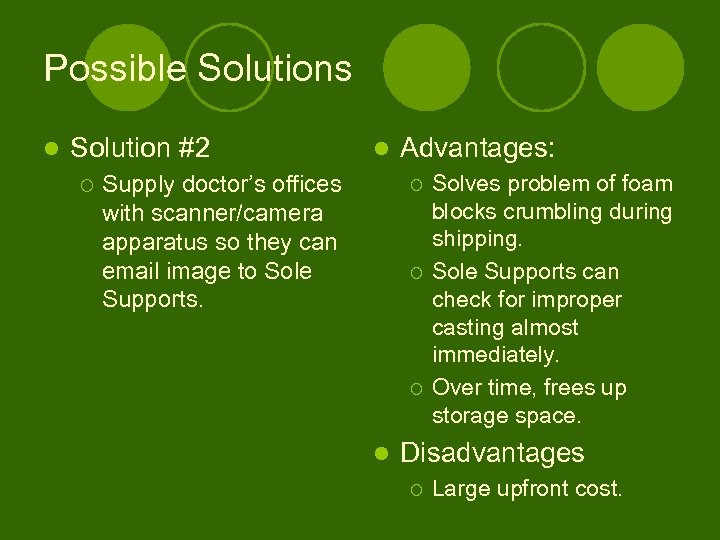

Possible Solutions l Solution #2 ¡ l Supply doctor’s offices with scanner/camera apparatus so they can email image to Sole Supports. Advantages: ¡ ¡ ¡ l Solves problem of foam blocks crumbling during shipping. Sole Supports can check for improper casting almost immediately. Over time, frees up storage space. Disadvantages ¡ Large upfront cost.

scanner Our project flowchart two-camera or scanned or photographed foot impression (. bmp) x Lab. View VI y z . txt file x y z … RHINO program (Sole Supports) 3 D Milling Machine (Sole Supports)

Accuracy Needed l l l According to preliminary testing of RHINO software with the 3 D milling machine at Sole Supports, it has been determined that the system works well with an error of 2 mm or less. With this in mind, we considered the scanner method’s potential accuracy. Assuming an arch depth of no more than 3 in, 3 in * 2. 54 cm/in = max error or 0. 2 cm error # of pixels According to this, we need at least 40 different pixel intensities, each one corresponding to 0. 2 cm depths. Since grayscale ranges from 0 255 and our preliminary tests showed many values within this range, it won’t be the 40 different pixel intensities that might give us trouble, but rather the 2 mm resolution in the z direction.

Past Work Created foam ramp to scan into computer. Imported into Lab. View VI to set up testing of scanner method. (Will test very soon. ) l Discussed two-camera method vs. scanner method with Dr. King. l Began research on the two-camera method. l

Current Work l Test foam ramp image with Lab. View VI to determine if pixel gradient is accurate enough (within 2 mm error). l Meet with Matt Moore, Sole Supports advisor. l Continue researching two-camera method, brainstorming what we would need to do to make this method work.

Future Work l Decide on image-capturing device ¡ Scanner l Create or two cameras? image-capturing apparatus. l Implement our program in conjunction with RHINO to make real foot molds (test it)

Timeline l l l This week: Continue researching two-camera method and finish testing scanner method, definitely decide on which solution best suits our needs. Visit Sole Supports to discuss/test progress with our advisor. February 17: Begin necessary calculations/plans/construction of image-capturing apparatus. February 17 -March 5: Continue to work out kinks in Lab. View program/de-bug. Continue apparatus construction. March 5: Begin testing all components of process together. April 5: Begin work on final paper and presentation.

9fe9d5ea57edc24fc0632a1687d63b70.ppt