ba683fed2c5ddb429776de849bc1fcdf.ppt

- Количество слайдов: 28

2012…A year in review 2013…A year to look forward to Bi-Weekly Safety Meeting January 10, 2013

2012…A year in review 2013…A year to look forward to Bi-Weekly Safety Meeting January 10, 2013

Safety Program Purpose Safety Data Report SMART Report 3 Keys to Success KPI and Promotions Safety Recognition 2013 Initiatives

Safety Program Purpose Safety Data Report SMART Report 3 Keys to Success KPI and Promotions Safety Recognition 2013 Initiatives

Provide employees with a safe work environment Comply with company mandated policies and procedures Comply with Federal and Cal OSHA requirements Injury and Illness Prevention Program General Duty Clause

Provide employees with a safe work environment Comply with company mandated policies and procedures Comply with Federal and Cal OSHA requirements Injury and Illness Prevention Program General Duty Clause

Pre-qualify for work on client sites Pass third party client audits Maintain an EMR (Experience Modification Rate) And an An ORIR (OSHA Recordable Incident Rate) Acceptable to our clients requirements which in the refinery and pipeline industry is 1. 0

Pre-qualify for work on client sites Pass third party client audits Maintain an EMR (Experience Modification Rate) And an An ORIR (OSHA Recordable Incident Rate) Acceptable to our clients requirements which in the refinery and pipeline industry is 1. 0

Save $$ on insurance premiums Market to our clients our low injury rate Currently at over 1 million hours since last injury (Mangan, Inc. ) Looking forward to breaking our previous record of 1. 7 million hours

Save $$ on insurance premiums Market to our clients our low injury rate Currently at over 1 million hours since last injury (Mangan, Inc. ) Looking forward to breaking our previous record of 1. 7 million hours

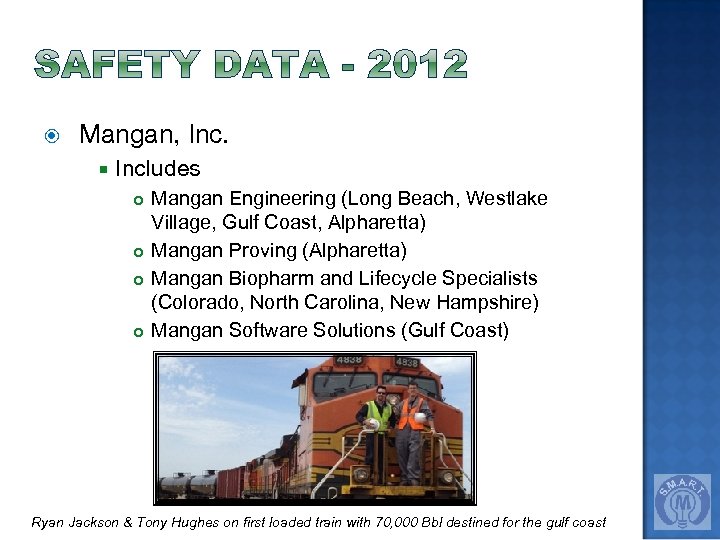

Mangan, Includes Mangan Engineering (Long Beach, Westlake Village, Gulf Coast, Alpharetta) Mangan Proving (Alpharetta) Mangan Biopharm and Lifecycle Specialists (Colorado, North Carolina, New Hampshire) Mangan Software Solutions (Gulf Coast) Ryan Jackson & Tony Hughes on first loaded train with 70, 000 Bbl destined for the gulf coast

Mangan, Includes Mangan Engineering (Long Beach, Westlake Village, Gulf Coast, Alpharetta) Mangan Proving (Alpharetta) Mangan Biopharm and Lifecycle Specialists (Colorado, North Carolina, New Hampshire) Mangan Software Solutions (Gulf Coast) Ryan Jackson & Tony Hughes on first loaded train with 70, 000 Bbl destined for the gulf coast

Mangan Renewables Providing multiple renewable energy solutions and located in Long Beach, CA Includes direct employees and leased labor employees per project site Work is performed in a heavy construction environment Renewables site activity

Mangan Renewables Providing multiple renewable energy solutions and located in Long Beach, CA Includes direct employees and leased labor employees per project site Work is performed in a heavy construction environment Renewables site activity

Power & Control Systems Inc. (PCS) Panel shop situated in Cypress, California. Joined the Mangan family in August 2012 Samples of PCS work

Power & Control Systems Inc. (PCS) Panel shop situated in Cypress, California. Joined the Mangan family in August 2012 Samples of PCS work

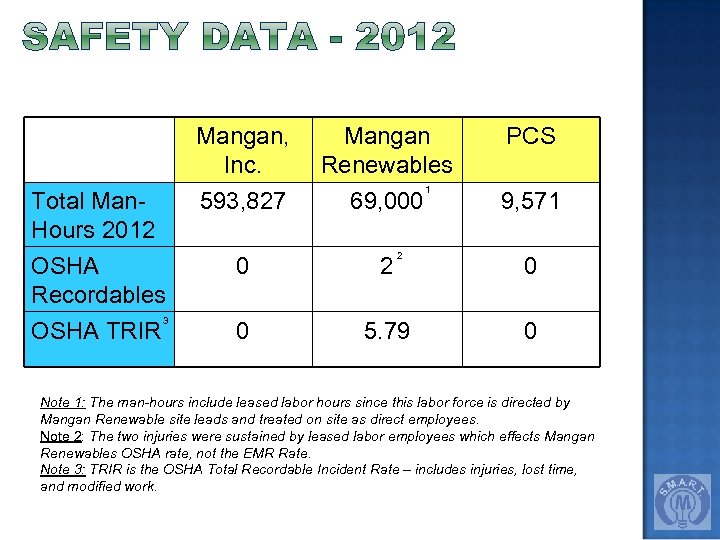

Mangan, Inc. 593, 827 Total Man. Hours 2012 Mangan Renewables 1 69, 000 2 OSHA Recordables 0 2 3 0 5. 79 OSHA TRIR PCS 9, 571 0 0 Note 1: The man-hours include leased labor hours since this labor force is directed by Mangan Renewable site leads and treated on site as direct employees. Note 2: The two injuries were sustained by leased labor employees which effects Mangan Renewables OSHA rate, not the EMR Rate. Note 3: TRIR is the OSHA Total Recordable Incident Rate – includes injuries, lost time, and modified work.

Mangan, Inc. 593, 827 Total Man. Hours 2012 Mangan Renewables 1 69, 000 2 OSHA Recordables 0 2 3 0 5. 79 OSHA TRIR PCS 9, 571 0 0 Note 1: The man-hours include leased labor hours since this labor force is directed by Mangan Renewable site leads and treated on site as direct employees. Note 2: The two injuries were sustained by leased labor employees which effects Mangan Renewables OSHA rate, not the EMR Rate. Note 3: TRIR is the OSHA Total Recordable Incident Rate – includes injuries, lost time, and modified work.

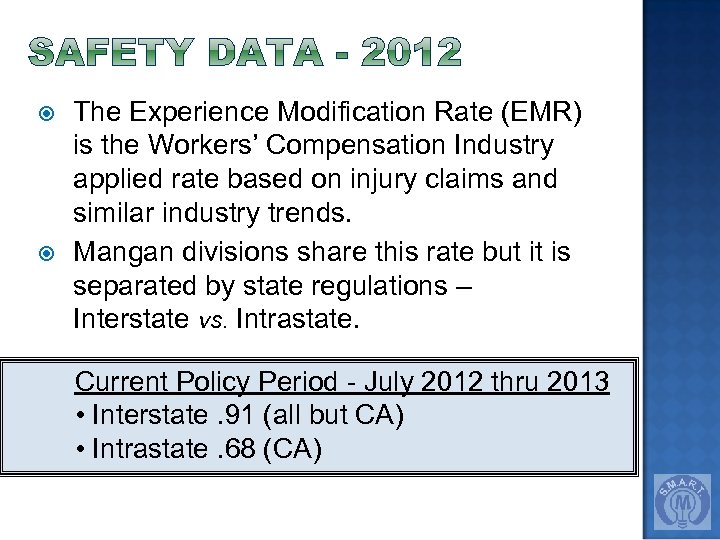

The Experience Modification Rate (EMR) is the Workers’ Compensation Industry applied rate based on injury claims and similar industry trends. Mangan divisions share this rate but it is separated by state regulations – Interstate vs. Intrastate. Current Policy Period - July 2012 thru 2013 • Interstate. 91 (all but CA) • Intrastate. 68 (CA)

The Experience Modification Rate (EMR) is the Workers’ Compensation Industry applied rate based on injury claims and similar industry trends. Mangan divisions share this rate but it is separated by state regulations – Interstate vs. Intrastate. Current Policy Period - July 2012 thru 2013 • Interstate. 91 (all but CA) • Intrastate. 68 (CA)

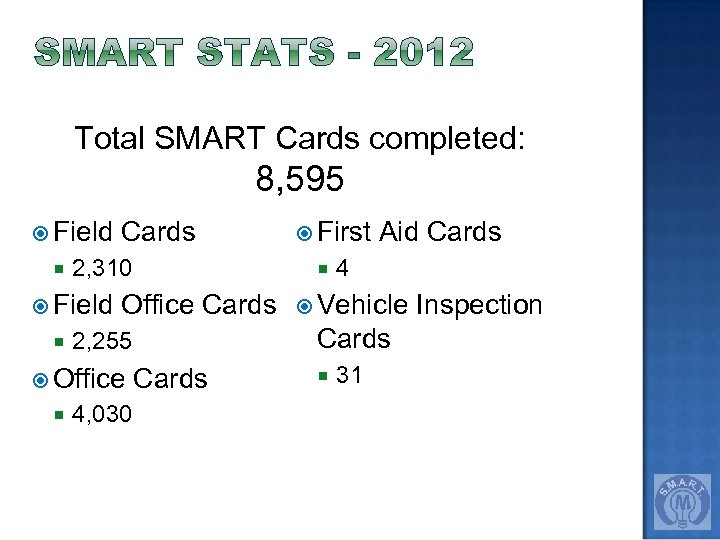

Total SMART Cards completed: 8, 595 Field Cards 2, 310 First Aid Cards 4 Field Office Cards Vehicle Inspection 2, 255 Office Cards 4, 030 Cards 31

Total SMART Cards completed: 8, 595 Field Cards 2, 310 First Aid Cards 4 Field Office Cards Vehicle Inspection 2, 255 Office Cards 4, 030 Cards 31

Journal Entries 1, 894 Action Items 178 entered 170 completed Bio. Pharma environments

Journal Entries 1, 894 Action Items 178 entered 170 completed Bio. Pharma environments

Manage safety as a process, not a program. Safety is an individual process, not a program. Each employee participates on their own safety creating a company wide safety culture. Tank survey: use gloves when climbing the stairway along side of the tank. Be careful coming down the (Steep) stairway and hold on to the railing. X-ray techs just setting up barricade tape & tools. Let them know when I set up to work and when I left their area. After working later than usual, I noticed that part of the path between my office and the remote parking lot I use is not illuminated by street lighting. I have notified client site services of this issue.

Manage safety as a process, not a program. Safety is an individual process, not a program. Each employee participates on their own safety creating a company wide safety culture. Tank survey: use gloves when climbing the stairway along side of the tank. Be careful coming down the (Steep) stairway and hold on to the railing. X-ray techs just setting up barricade tape & tools. Let them know when I set up to work and when I left their area. After working later than usual, I noticed that part of the path between my office and the remote parking lot I use is not illuminated by street lighting. I have notified client site services of this issue.

Manage the causes (exposure to risk factors), not the consequences (injuries). Employees are empowered to manage their immediate environment to mitigate observed exposures to avoid the potential for injury or incidents. Each employee can exercise their ‘Stop Work Authority’ with the complete support of upper management. Was drilling lugs to fit a bolt, used safety glasses to prevent metal shards from entering eye. There is construction going on at the site. Observed a loose nail in the hallway, reported it to a nearby construction worker and it was removed. Contractor standing on ladder in path of door without notifying others inside or taping off door. Asked contractor to tape off other side of door and he did so.

Manage the causes (exposure to risk factors), not the consequences (injuries). Employees are empowered to manage their immediate environment to mitigate observed exposures to avoid the potential for injury or incidents. Each employee can exercise their ‘Stop Work Authority’ with the complete support of upper management. Was drilling lugs to fit a bolt, used safety glasses to prevent metal shards from entering eye. There is construction going on at the site. Observed a loose nail in the hallway, reported it to a nearby construction worker and it was removed. Contractor standing on ladder in path of door without notifying others inside or taping off door. Asked contractor to tape off other side of door and he did so.

Always verify that changes implemented reduce exposure and achieve intended results. When a hazard is observed, employee follow through by reporting the hazards and implementing change completes the process of identifying a hazard and mitigating the exposures to an acceptable risk before proceeding. Welders did not have permit for hot work; requested workers to obtain permit prior to proceeding. After completing the ergonomics course online, I have modified my working area a little better. Recommend everyone review it every once in awhile to see if improvements can be made. A risk assessment checklist has been reviewed and signed off by Mangan and refinery management. Follow steps carefully to ensure process is not impacted.

Always verify that changes implemented reduce exposure and achieve intended results. When a hazard is observed, employee follow through by reporting the hazards and implementing change completes the process of identifying a hazard and mitigating the exposures to an acceptable risk before proceeding. Welders did not have permit for hot work; requested workers to obtain permit prior to proceeding. After completing the ergonomics course online, I have modified my working area a little better. Recommend everyone review it every once in awhile to see if improvements can be made. A risk assessment checklist has been reviewed and signed off by Mangan and refinery management. Follow steps carefully to ensure process is not impacted.

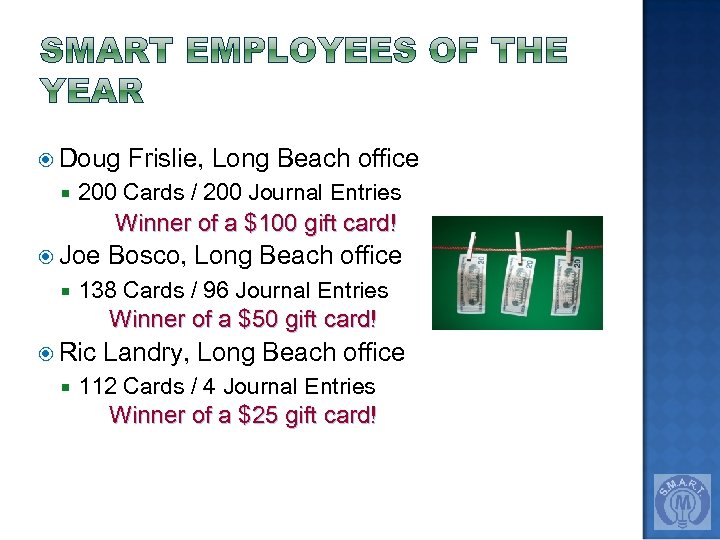

Doug Frislie, Long Beach office 200 Cards / 200 Journal Entries Winner of a $100 gift card! Joe Bosco, Long Beach office 138 Cards / 96 Journal Entries Winner of a $50 gift card! Ric Landry, Long Beach office 112 Cards / 4 Journal Entries Winner of a $25 gift card!

Doug Frislie, Long Beach office 200 Cards / 200 Journal Entries Winner of a $100 gift card! Joe Bosco, Long Beach office 138 Cards / 96 Journal Entries Winner of a $50 gift card! Ric Landry, Long Beach office 112 Cards / 4 Journal Entries Winner of a $25 gift card!

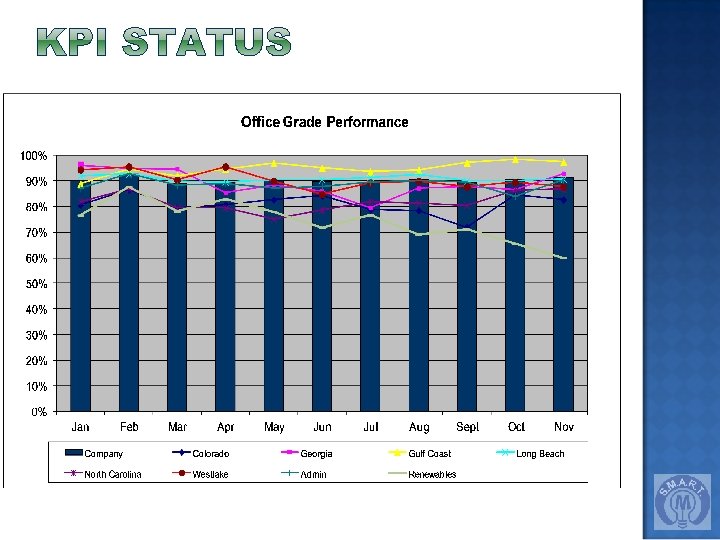

We track certain aspects of the safety program for compliance: Completed Annual Hearing Exams for field personnel Providing a current Driver’s License and Auto Liability Insurance Completion of at least 2 SMART cards monthly Completion of the biweekly safety meeting enrollments on Flex. Train How did your office do in 2012… We have results through November 2012

We track certain aspects of the safety program for compliance: Completed Annual Hearing Exams for field personnel Providing a current Driver’s License and Auto Liability Insurance Completion of at least 2 SMART cards monthly Completion of the biweekly safety meeting enrollments on Flex. Train How did your office do in 2012… We have results through November 2012

Most offices have a grade of ‘A’ or ‘B’ Keep track of your outstanding requirements through your individual Flex. Train site Renewals for hearing exams, Driver’s License and Insurance, as well as outstanding biweekly training will be posted Also look for client training expiration notices Expiration of your TWIC, OQ or other specific training tracked by safety

Most offices have a grade of ‘A’ or ‘B’ Keep track of your outstanding requirements through your individual Flex. Train site Renewals for hearing exams, Driver’s License and Insurance, as well as outstanding biweekly training will be posted Also look for client training expiration notices Expiration of your TWIC, OQ or other specific training tracked by safety

$ in Gifts 97 (over $8, 000) in Gift Cards 4 Nomex Jackets 8 Mangan Laptop Backpacks 5 i. Pads Redeem your points now if it has been two years… An email will go to employees whose points will expire in February and monthly going forward

$ in Gifts 97 (over $8, 000) in Gift Cards 4 Nomex Jackets 8 Mangan Laptop Backpacks 5 i. Pads Redeem your points now if it has been two years… An email will go to employees whose points will expire in February and monthly going forward

BP Carson Outstanding Safety Contractor Annual Recognition Award

BP Carson Outstanding Safety Contractor Annual Recognition Award

BP U. S. Pipeline & Logistics Contractor Safety Award Chevron El Segundo Gold Safety Award Client recongintion… When success happens, the Team needs to be recognized! The Butane Spheres (TK 86 -89) LOM SIS Project (02 MU 60 XX) completed its turnover last week Thursday late in the day. This project was the first of many SIS projects planned for the BP Refinery. Through two years of planning and execution, it was commissioned and signed off with only a few small punch list items remaining. This project finished with the following record: 1. NO Safety Incidents, NO Recordables 2. Under Budget 3. On schedule Thank you to a great team of people!

BP U. S. Pipeline & Logistics Contractor Safety Award Chevron El Segundo Gold Safety Award Client recongintion… When success happens, the Team needs to be recognized! The Butane Spheres (TK 86 -89) LOM SIS Project (02 MU 60 XX) completed its turnover last week Thursday late in the day. This project was the first of many SIS projects planned for the BP Refinery. Through two years of planning and execution, it was commissioned and signed off with only a few small punch list items remaining. This project finished with the following record: 1. NO Safety Incidents, NO Recordables 2. Under Budget 3. On schedule Thank you to a great team of people!

Field Safety Program Greater participation in the Job Safety Analysis Employee field audits Field inspections Web-based SMART Cards and Job Safety Analysis Customized by division

Field Safety Program Greater participation in the Job Safety Analysis Employee field audits Field inspections Web-based SMART Cards and Job Safety Analysis Customized by division

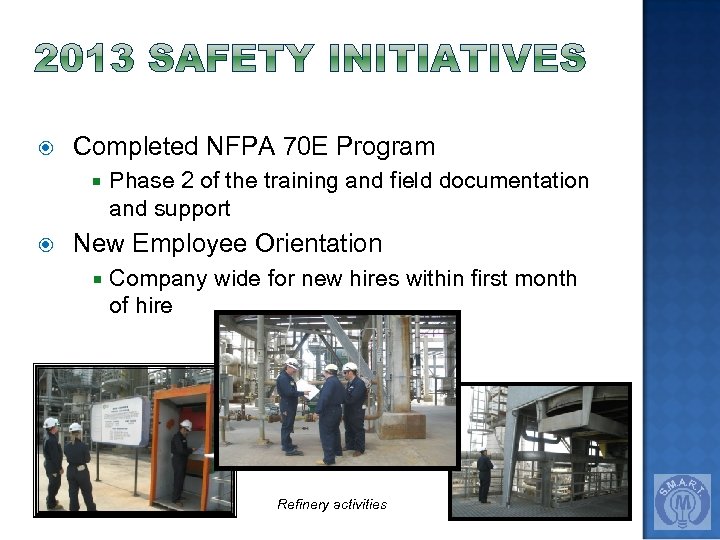

Completed NFPA 70 E Program Phase 2 of the training and field documentation and support New Employee Orientation Company wide for new hires within first month of hire Refinery activities

Completed NFPA 70 E Program Phase 2 of the training and field documentation and support New Employee Orientation Company wide for new hires within first month of hire Refinery activities

Google hosted safety sites Safety Resource Center Policies and Forms Safety Committee Meeting Notes Bid and Pre-Qualifier Data Emergency Action Plan Crisis Recovery and Emergency Response resources Vehicle Accident Documentation Insurance Certificate and Accident Documentation Kit

Google hosted safety sites Safety Resource Center Policies and Forms Safety Committee Meeting Notes Bid and Pre-Qualifier Data Emergency Action Plan Crisis Recovery and Emergency Response resources Vehicle Accident Documentation Insurance Certificate and Accident Documentation Kit

Google hosted safety sites Client Resource Center KPI Client forms and safety correspondence Safety performance tracking Points for Participation Opportunity to cash-in on your participation in the company’s safety programs

Google hosted safety sites Client Resource Center KPI Client forms and safety correspondence Safety performance tracking Points for Participation Opportunity to cash-in on your participation in the company’s safety programs

Let’s make 2013 a marked year for safety and continue to work towards an injury and incident free work place. Contribute to maintaining an ‘A’ on your office KPI score. Maintain the company safety culture through your participation.

Let’s make 2013 a marked year for safety and continue to work towards an injury and incident free work place. Contribute to maintaining an ‘A’ on your office KPI score. Maintain the company safety culture through your participation.

In our next biweekly safety meeting we’ll cover the 2012 Flash Reports and lessons learned. See you then, and stay safe!

In our next biweekly safety meeting we’ll cover the 2012 Flash Reports and lessons learned. See you then, and stay safe!