974d8e5913499bebd51567052327ebdb.ppt

- Количество слайдов: 84

© 2011 Jones and Bartlett Publishers, LLC

Donald E. Lighter, MD, MBA, FAAP, FACHE Professor, University of Tennessee, Knoxville Lean Processing and Standardization in Healthcare Quality © 2011 Jones and Bartlett Publishers, LLC

Lean Manufacturing • Toyota – 1950 s (Taiichi Ohno) – International competition – Quality issues – Worker dissatisfaction and insecurity – Pending layoffs • Agreement with employees – Lifetime security – Workforce reductions – Cooperation with improvement efforts © 2011 Jones and Bartlett Publishers, LLC

Systems Concepts • System – integrated series of parts with a clearly defined function or goal – Examples? • Characteristics – Each part has defined purpose – Parts are interdependent – Understand part’s function in system – System is understood by interaction of parts © 2011 Jones and Bartlett Publishers, LLC

Systems Thinking • Ability to understand structure and function of system • Ability to understand interaction of parts and synergism • Resulting in – Ability to lead system – Ability to change system without deleterious effects – Ability to reduce detrimental effects of system © 2011 Jones and Bartlett Publishers, LLC

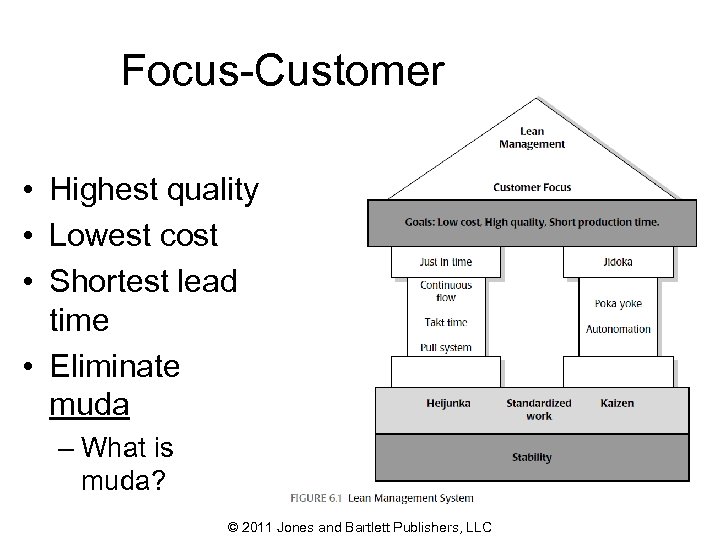

Focus-Customer • Highest quality • Lowest cost • Shortest lead time • Eliminate muda – What is muda? © 2011 Jones and Bartlett Publishers, LLC

Costumer-Focus • • • Productivity Quality Cost Delivery time Safety and environment Morale © 2011 Jones and Bartlett Publishers, LLC

Muda-Japenese concept of Waste • Human effort divided into: – Actual work – valued by customer – Auxiliary work – supports actual work – Muda – creates no value • Examples? © 2011 Jones and Bartlett Publishers, LLC

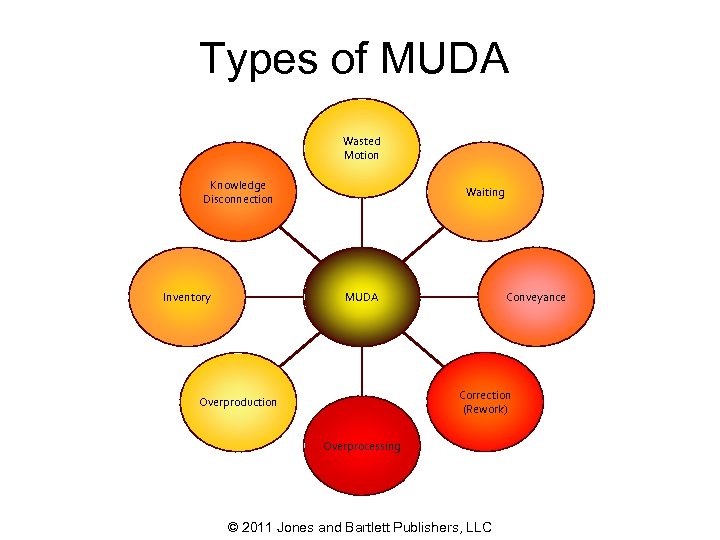

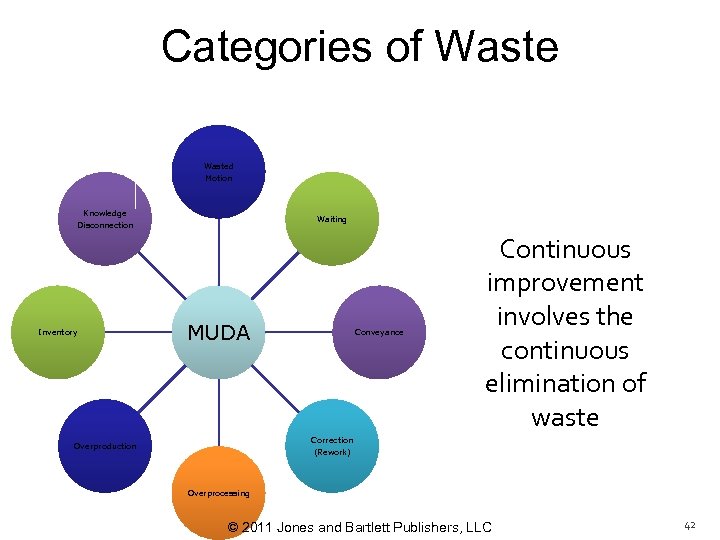

Types of MUDA Wasted Motion Knowledge Disconnection Inventory Waiting Conveyance MUDA Correction (Rework) Overproduction Overprocessing © 2011 Jones and Bartlett Publishers, LLC

Let’s examine MUDA • How do these concepts fit health care? – Overprocessing – doing more than the customer requires – Overproduction – making things that don’t sell – Correction (rework) – fix defective services or products – Conveyance – problems with getting production materials to site of production – Inventory – unnecessary materials or products © 2011 Jones and Bartlett Publishers, LLC

Other major concepts • Mura – uneven processes (bumps in the road) – What situations in health care? • Muri – “hard to do” – Most often due to process design – Variation – Ergonomics – Wrong tools – Inadequate specifications © 2011 Jones and Bartlett Publishers, LLC

Stability • Four “Ms” – Man(woman) – Machine – Material – Methods • Need for standards – Clear image of desired condition – Make abnormalities obvious – Clear, simple, visual © 2011 Jones and Bartlett Publishers, LLC

Visual Management • Point of care graphic detail • Simple, easy to follow (examples? ) • Visual management triangle See As A Group Know As A Group © 2011 Jones and Bartlett Publishers, LLC Act As A Group

Organization – The 5 (6) Ss • Sort • Set in order • Shine • Standardize • Sustain • (Safety) © 2011 Jones and Bartlett Publishers, LLC

Organize the Workplace – The 5 Ss • Sort – Keep what you need, get rid of the rest – Red-tag what’s not needed for disposition • Red-tag removal process • Red-tag “pause” • Red-tag recycling and capital asset disposal procedure • Measure volume of red-tagged items • Team decisions for disposal – “Just in case” management – the pack rat • • Set in order Shine Standardize Sustain © 2011 Jones and Bartlett Publishers, LLC

Organize the Workplace – The 5 Ss • Sort • Set in order – Process planning to reduce waste – Map processes using flowcharts, other tools (remember the workflow chart? ) – Use visual systems to manage flow • Shine • Standardize • Sustain © 2011 Jones and Bartlett Publishers, LLC

Organize the Workplace – The 5 Ss • Sort • Set in order • Shine – Creation of a clean workplace – Connotes a pristine work environment (e. g. work habits, relationships) – Use color to code process steps and relationships • Standardize • Sustain © 2011 Jones and Bartlett Publishers, LLC

Organize the Workplace – The 5 Ss • • Sort Set in order Shine Standardize – Things tend to fall apart – Make workflow methodical as much as possible (examples? ) • Sustain © 2011 Jones and Bartlett Publishers, LLC

Organize the Workplace – The 5 Ss • • • Sort Set in order Shine Standardize Sustain – Promotion – Communication – Training © 2011 Jones and Bartlett Publishers, LLC

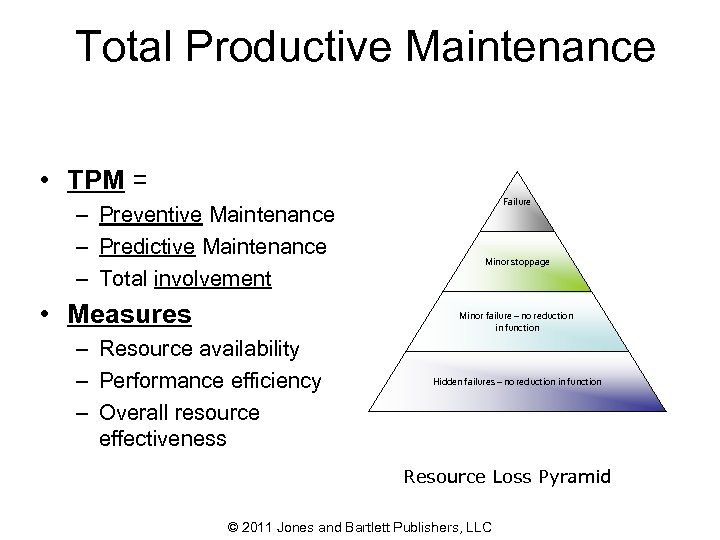

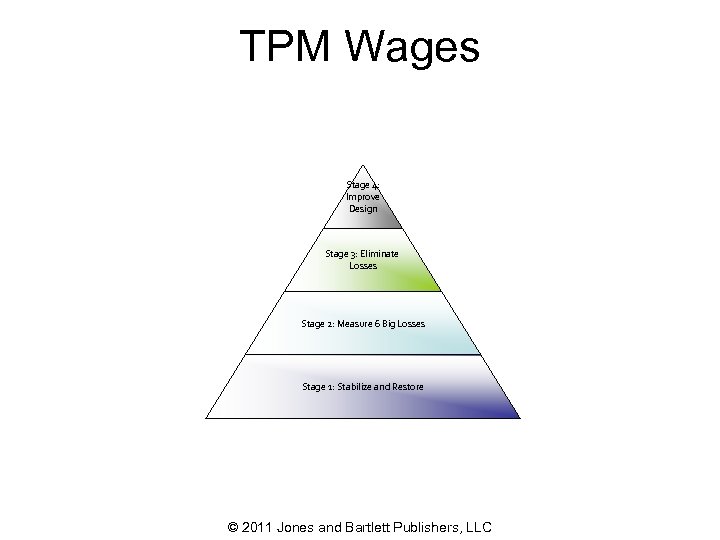

Total Productive Maintenance • TPM = – Preventive Maintenance – Predictive Maintenance – Total involvement • Measures Failure Minor stoppage Minor failure – no reduction in function – Resource availability – Performance efficiency – Overall resource effectiveness Hidden failures – no reduction in function Resource Loss Pyramid © 2011 Jones and Bartlett Publishers, LLC

Productivity Hits • Six big losses – Breakdowns – Adjustment and set up delays – Idling and minor stoppages – Speed below specifications – Process defects – Reduced yield • Cause: – Downtime – Reduced throughput – Defects – Accidents © 2011 Jones and Bartlett Publishers, LLC

TPM Wages Stage 4: Improve Design Stage 3: Eliminate Losses Stage 2: Measure 6 Big Losses Stage 1: Stabilize and Restore © 2011 Jones and Bartlett Publishers, LLC

Standardized Work • Basic principles – No single best way to do work – Workers should design work – Purpose of standardized work is to provide a basis for improvement • Optimize PQCDSM – Productivity – Quality – Cost – Delivery time – Safety and environment – Morale © 2011 Jones and Bartlett Publishers, LLC

Maximize Human Resources • People are usually the constraining factor • Machines can produce muda (waste) if allowed to produce constantly • Small, simple machines preferable to large complex machines (think microsystems) – More human input for moving work in progress from one machine to another – Cheaper to purchase and run – Simpler to repair – Adjust to demand changes more quickly © 2011 Jones and Bartlett Publishers, LLC

Labor Destiny Work Motion (determined by customer demand) (managers optimize motion) © 2011 Jones and Bartlett Publishers, LLC

Advantages to Standardization • • Process stability and reproducibility Clear start and stop for each process Organizational learning (CPGs) Audit and problem solving (measurement is key) • Employee involvement and poka yoke • Kaizen • Training © 2011 Jones and Bartlett Publishers, LLC

Prerequisites for Standardization • Quality inputs • Functioning process components (human, machine) • Input adequacy (no shortages) • No wait time for work in progress • Optimum safety © 2011 Jones and Bartlett Publishers, LLC

Elements of Standardized Work • Takt time must be understood – Daily operating time/required daily output – Not the same as cycle time (actual time per unit) – Provides a target for production (e. g. number of bills that should be produced in a given time), from which cycle time requirements (throughput) can be defined • Work sequence must be defined – Process steps in work flow (flowchart) – Provides targets for improvement • Inventory (in process stock) must be optimized © 2011 Jones and Bartlett Publishers, LLC

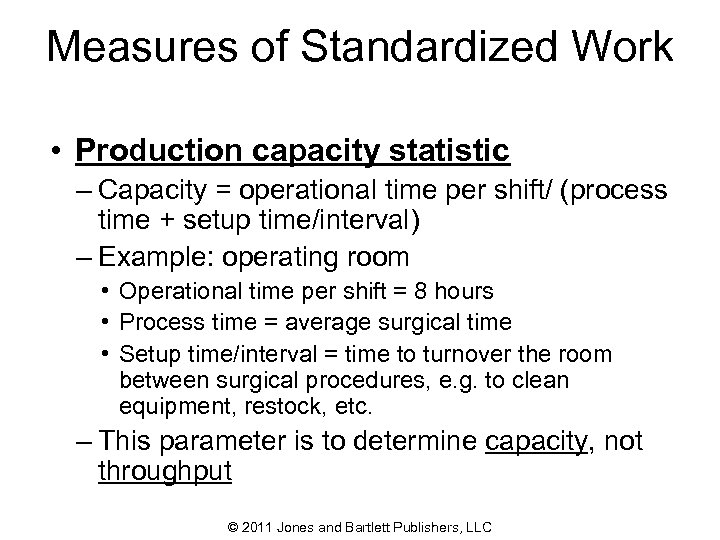

Measures of Standardized Work • Production capacity statistic – Capacity = operational time per shift/ (process time + setup time/interval) – Example: operating room • Operational time per shift = 8 hours • Process time = average surgical time • Setup time/interval = time to turnover the room between surgical procedures, e. g. to clean equipment, restock, etc. – This parameter is to determine capacity, not throughput © 2011 Jones and Bartlett Publishers, LLC

Improving safety with lean process management Implications of lean – poka yoke © 2011 Jones and Bartlett Publishers, LLC

Concepts We’ll Discuss • • • Cost of poor quality Waste reduction Zero Defect Quality ( ZDQ) Understanding process errors Poka-Yoke © 2011 Jones and Bartlett Publishers, LLC 31

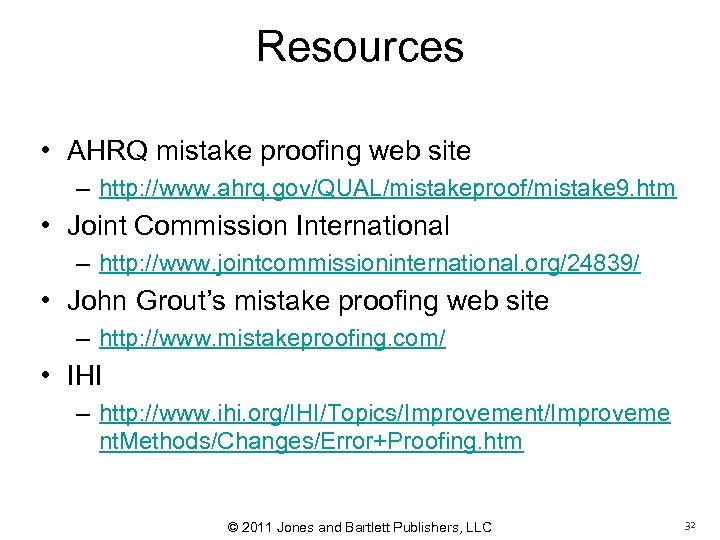

Resources • AHRQ mistake proofing web site – http: //www. ahrq. gov/QUAL/mistakeproof/mistake 9. htm • Joint Commission International – http: //www. jointcommissioninternational. org/24839/ • John Grout’s mistake proofing web site – http: //www. mistakeproofing. com/ • IHI – http: //www. ihi. org/IHI/Topics/Improvement/Improveme nt. Methods/Changes/Error+Proofing. htm © 2011 Jones and Bartlett Publishers, LLC 32

Cost of Poor Quality © 2011 Jones and Bartlett Publishers, LLC 33

Cost of Poor Quality • IOM report 1999 – 98 K deaths per year • Medication errors – pediatrics – 4/10/08 – Joint Commission Alert: Prevent Pediatric Medication Errors Children Are Three Times More at Risk than Adults • Patient safety from falls – Rate – 4. 3 per 1000 patient days © 2011 Jones and Bartlett Publishers, LLC 34

Patient errors 2004 -2006 • Patient safety incidents – Medicare data Ø 1. 12 million total patient safety incidents/41 million hospitalizations (~3%) Ø $8. 8 billion of excess cost • Post-op indicators worsened -> accounted for ~72 percent of all the potentially preventable deaths Ø post-operative respiratory failure Ø post-operative pulmonary embolism or deep vein thrombosis Ø post-operative sepsis Ø post-operative abdominal wound dehiscence • AHRQ Patient Safety Indicators with the highest incidence rates (~63. 4% of total) Ø Decubitus ulcer Ø Failure to rescue Ø Post-operative respiratory failure The fifth annual Health. Grades patient safety in American hospitals study, Available at: www. healthgrades. com, April, 2008. 35 © 2011 Jones and Bartlett Publishers, LLC

Patient Errors (cont. ) • 270, 491 actual in-hospital deaths among patients who developed one or more of the 16 patient safety incidents, – 238, 337 deaths were attributable to patient safety incidents and potentially preventable – Medicare patients who experienced a patient safety incident had a one-in-five chance of dying as a result of the incident • Medicare patients in the Health. Grades Distinguished Hospitals for Patient Safety™ had a 43 -percent lower risk of one or more PSIs compared to patients at the bottom ranked hospitals across all 13 PSIs studied. © 2011 Jones and Bartlett Publishers, LLC 36

What if all of us performed well? • If all hospitals performed at the higher level: – 220, 106 fewer patient safety incidents – 37, 214 Medicare deaths avoided – $2. 0 billion savings during 2004 to 2006. © 2011 Jones and Bartlett Publishers, LLC 37

Cost of defects • Does it cost more to make processes better? – In most cases, NO! • How does quality improve cost? – Reduced waste – Reduced re-work – Reduced inspection costs – Reduced liability of malpractice © 2011 Jones and Bartlett Publishers, LLC 38

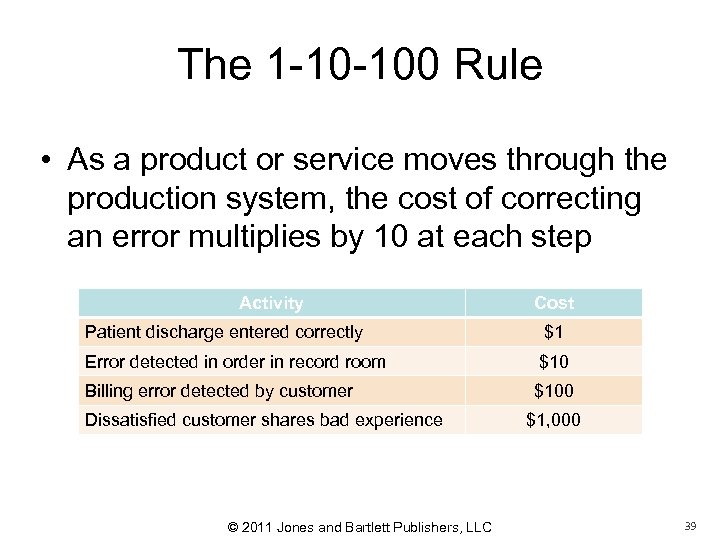

The 1 -10 -100 Rule • As a product or service moves through the production system, the cost of correcting an error multiplies by 10 at each step Activity Cost Patient discharge entered correctly $1 Error detected in order in record room $10 Billing error detected by customer $100 Dissatisfied customer shares bad experience © 2011 Jones and Bartlett Publishers, LLC $1, 000 39

Waste Reduction © 2011 Jones and Bartlett Publishers, LLC 40

Waste? We now what this… • Anything done during a work process that adds cost, but does not add value for the customer • Objective – eliminate non-value added work © 2011 Jones and Bartlett Publishers, LLC 41

Categories of Wasted Motion Knowledge Waiting Disconnection Inventory MUDA Conveyance Continuous improvement involves the continuous elimination of waste Correction Overproduction (Rework) Overprocessing © 2011 Jones and Bartlett Publishers, LLC 42

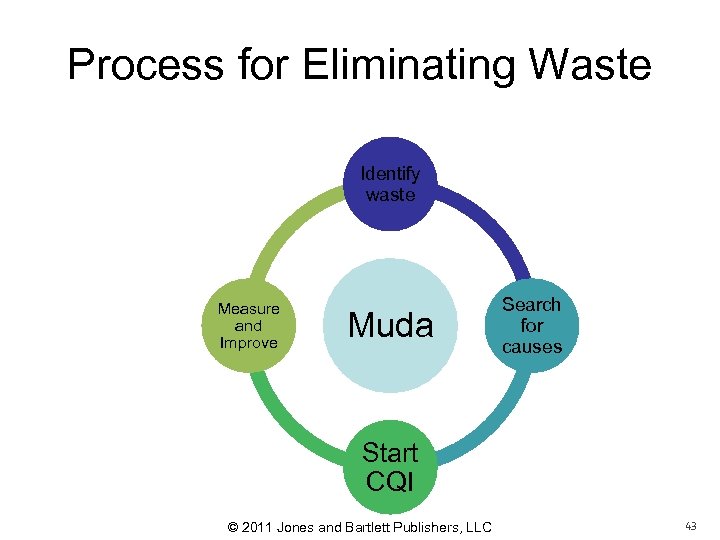

Process for Eliminating Waste Identify waste Measure and Improve Muda Search for causes Start CQI © 2011 Jones and Bartlett Publishers, LLC 43

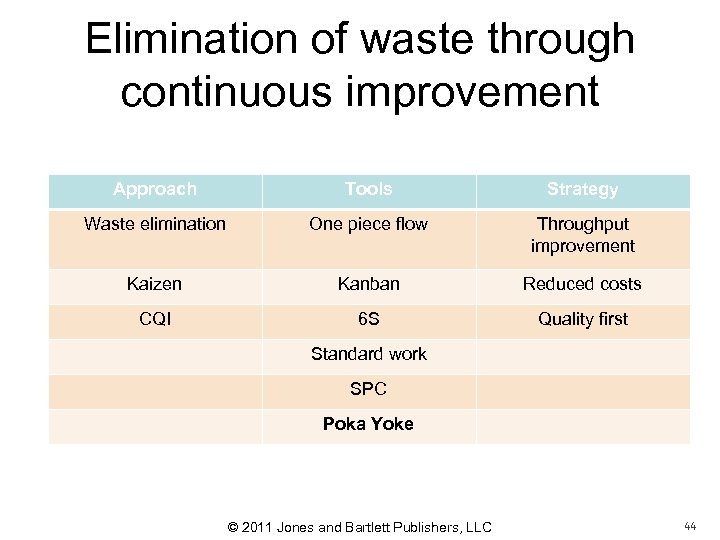

Elimination of waste through continuous improvement Approach Tools Strategy Waste elimination One piece flow Throughput improvement Kaizen Kanban Reduced costs CQI 6 S Quality first Standard work SPC Poka Yoke © 2011 Jones and Bartlett Publishers, LLC 44

Zero Defect Quality © 2011 Jones and Bartlett Publishers, LLC 45

Zero Defect Quality (ZDQ) • Primary goal of improvement efforts • Targets: – Defects – Inventory excesses – Wasted motion – Unnecessary delays – Misused resources – Unused resources – Ineffective processes © 2011 Jones and Bartlett Publishers, LLC 46

One Advantage of ZDQ • Maintain customer satisfaction and loyalty – Increase volume – Increase revenues – Reduce liability – Improve collection rates © 2011 Jones and Bartlett Publishers, LLC 47

ZDQ: What Is It? • Conformance to quality requirements • Defect prevention preferred to inspection and correction • No defects becomes the quality standard • Quality is measured in appropriate metrics and financial terms (concept of value) © 2011 Jones and Bartlett Publishers, LLC 48

Phillip Crosby’s Steps to Zero Defects 1. 2. 3. 4. 5. 6. 7. 8. 9. Make it clear that the management is committed to quality Form quality improvement teams with representatives from all departments Assess and evaluate the quality awareness/concern of employees Raise the quality awareness/concern of employees Take actions to correct problems Establish a committee for a zero defects program Train supervisors Hold a "zero defect day“ Encourage people to establish improvement goals for themselves and their teams 10. Encourage employees to communicate to management the obstacles to attaining improvement goals 11. Recognize those who participate 12. Establish Quality Councils 13. Do it all over again - the quality improvement program never ends © 2011 Jones and Bartlett Publishers, LLC 49

Important Attribute of ZDQ System • CULTURE! – Systems are at the root of errors – not usually people – Systems should be designed to eliminate human errors – MISTAKE PROOFING – Managers must direct work to mistake-proof systems – Punitive culture not a productive culture © 2011 Jones and Bartlett Publishers, LLC 50

Four Components of ZDQ • Point of Origin Inspection • 100 % Audit Checks • Immediate Feedback • Poka-Yoke © 2011 Jones and Bartlett Publishers, LLC 51

Inspection • Three basic approaches – Judgment/standards inspection – Informative inspection – Point of origin inspection • Only Point of Origin Inspection has the potential of eliminating defects © 2011 Jones and Bartlett Publishers, LLC 52

Point of Origin Inspection • Focus on prevention, as well as detection • Each individual member of the team involved in evaluating each element of work continually • No part passes to the next step if defective • Each step becomes an inspection point, each can halt the process to correct defect Detect Error Feedback/Corrective Action • End result -> zero defects in finished product or service © 2011 Jones and Bartlett Publishers, LLC 53

Point of Origin Inspection is different • “Inspection” done continuously • Corrections can be made immediately • Process output will have zero defects • Staff members feel empowered, not inspected • Reduces need for specific inspection steps in a process – all steps include inspection © 2011 Jones and Bartlett Publishers, LLC

Point of Origin Inspection in health care • Stop point in pre-op • Crew resource management – Every member of the crew empowered to halt process – Every member esteemed for specific process knowledge – No team member assumed to have all encompassing knowledge © 2011 Jones and Bartlett Publishers, LLC

Everyday Examples of Mistake Proofing 3. 5 inch diskettes cannot be inserted unless diskette is oriented correctly. This is as far as a disk can be inserted upsidedown. The beveled corner of the diskette along with the fact that the diskette is not square, prohibit incorrect orientation. © 2011 Jones and Bartlett Publishers, LLC

Examples of Mistake Proofing New lawn mowers are required to have a safety bar on the handle that must be pulled back in order to start the engine. If you let go of the safety bar, the mower blade stops in 3 seconds or less. © 2011 Jones and Bartlett Publishers, LLC

We Learn From Other Industries Drive Bar on Portable X-ray: The drive bar is the steering mechanism of the portable xray unit. This bar must be depressed in order for the unit to move. If the technologist takes their hands off of this bar the portable immediately stops. © 2011 Jones and Bartlett Publishers, LLC 58

Traditional Approach – Fix the Human “The old way of dealing with human error was to scold people, retrain them, and tell them to be more careful … My view is that you can’t do much to change human nature, and people are going to make mistakes. If you can’t tolerate them. . . you should remove the opportunities for error. ” “Training and motivation work best when the physical part of the system is welldesigned. If you train people to use poorly designed systems, they’ll be OK for awhile. Eventually, they’ll go back to what they’re used to or what’s easy, instead of what’s safe. ” “You’re not going to become world class through just training, you have to improve the system so that the easy way to do a job is also the safe, right way. The potential for human error can be dramatically reduced. ” Chappell, L. 1996. The Pokayoke Solution. Automotive News Insights, (August 5): 24 i. La. Bar, G. 1996. Can Ergonomics Cure ‘Human Error’? Occupational Hazards 58(4): 48 -51. © 2011 Jones and Bartlett Publishers, LLC 59

10 Types of Human Mistakes Ø Forgetfulness Ø Inadvertent or sloppiness Ø Misunderstanding Ø Slow responses Ø Wrong identification Ø Lack of standardization Ø Lack of experience Ø Willful (ignoring rules or procedure) Ø Surprise (unexpected machine operation, etc. ) Ø Intentional (sabotage) © 2011 Jones and Bartlett Publishers, LLC 60

A Better Approach: Refine the process to avoid human errors… © 2011 Jones and Bartlett Publishers, LLC 61

Process Mistake Proofing © 2011 Jones and Bartlett Publishers, LLC 62

Basic Principles • Business activities consist of processes • Information flow • Financial resource flows • Purchasing • Care delivery • All processes have the potential for producing errors or defects • All processes offer opportunities for the elimination of errors and defects to improve quality © 2011 Jones and Bartlett Publishers, LLC 63

Goal for Process Improvement • Eliminate waste • Systems thinking - understand each process and its relationship to other processes • Systems analysis – Identify the inputs and outputs of each process – Know suppliers and customers of the process – In 6 s terms – SIPOC © 2011 Jones and Bartlett Publishers, LLC 64

Sources of Improvement Opportunities • Variation! • Process variation caused by: – Lack of standardization – Incorrect procedures – Defective machines or equipment – Non-conforming supplies or materials – Human factors © 2011 Jones and Bartlett Publishers, LLC 65

Tool for Mistake Proofing • Process standardization • Kanban – visual processes • Continuous process management – equipment management • Ergonomics and human factor engineering Poka Yoke! © 2011 Jones and Bartlett Publishers, LLC 66

Poka Yoke – Steps to Error Proofing © 2011 Jones and Bartlett Publishers, LLC 67

Poka-Yoke POKA-YOKE to avoid (yokeru) inadvertent errors (poka) © 2011 Jones and Bartlett Publishers, LLC

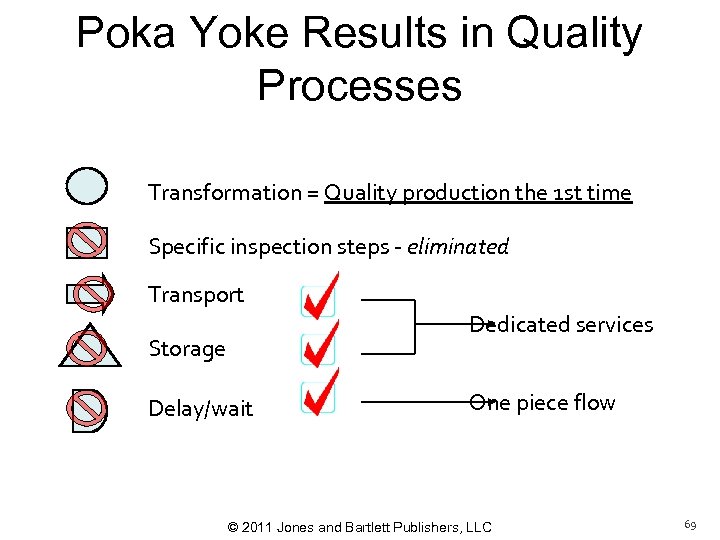

Poka Yoke Results in Quality Processes Transformation = Quality production the 1 st time Specific inspection steps - eliminated Transport Dedicated services Storage Delay/wait One piece flow © 2011 Jones and Bartlett Publishers, LLC 69

Rapid Feedback • Differs from traditional inspection systems – Correction as soon as error is detected – Address problems to avoid perpetuation of error – Inspection steps become unnecessary • Goal is to prevent defective processes from continuing and leading to defective output © 2011 Jones and Bartlett Publishers, LLC 70

7 Steps to Poka Yoke 1. Quality Processes - Design robust quality processes to achieve zero defects. 2. Utilize a Team Environment- leverage the team’s knowledge, experience to enhance improvement efforts. 3. Elimination of Errors -Utilize robust problem solving methods to drive defects towards zero. 4. Eliminate the “Root Cause” of The Errors - Use the 5 Why’s and 2 H’s approach © 2011 Jones and Bartlett Publishers, LLC 71

Poka Yoke Steps 5. Do It Right The First Time - Utilizing resources to perform functions correctly the “first” time. 6. Eliminate Non-Value Added Decisions – Find waste and cut those steps 7. Implement an Incremental Continual Improvement Approach – BEEP! – Implement improvement actions immediately – Focus on incremental improvements – Target is 100% © 2011 Jones and Bartlett Publishers, LLC 72

Poka Yoke in Health Care • A Poka Yoke device or procedure is one that easily identifies a flaw or error to prevent incorrect parts of a process from being propagated – Any method that can help caregivers or operators avoid mistakes – The Lean Healthcare concept recognizes that the optimal location to prevent or correct mistakes is at the point of creation of the problem – Late recognition of a mistake or defect is never as efficient and typically has a cumulative effect © 2011 Jones and Bartlett Publishers, LLC 73

Approaches to Poka Yoke • Error proofing (poka yoke) is a technique of preventing errors – By designing the process, equipment, and tools so that a procedure literally cannot be performed incorrectly – Example: Use of visual or other signals to indicate a risk of error, e. g. end tidal CO 2 detector to indicate a rising CO 2 level in an intubated patient © 2011 Jones and Bartlett Publishers, LLC 74

Poka Yoke and Point of Origin Inspections • Proactive Approach – A fully implemented ZDQ system involves poka-yoke at each step during the process – Errors that are detected are immediately eliminated or the process may be stopped – Example: incompatible name and wristband ID detected at pre-op stopping point – Example: bar coding medications © 2011 Jones and Bartlett Publishers, LLC 75

Poka Yoke and Informative Inspections • Reactive approach • Check occurs at the end of the process • Can be an operator check at the end of the process or a successive check at the beginning of the next process • Not 100% effective, will not eliminate all defects • Effective in preventing defects from being passed to next process • Creates waste © 2011 Jones and Bartlett Publishers, LLC 76

Two Types of Error Proofed Systems… • Control system – Humans not required to shut down the process – High capability of zero defects • Warning system – Useful if automatic shut off system is not an option – Warning or alarm system used to get user’s attention • Dials • Lights • Sounds • Color coding © 2011 Jones and Bartlett Publishers, LLC 77

Poka Yoke Responses • Control approach – Shuts down the process when an error occurs – Keeps the suspected problem issue or part in place rather than passing it on • Warning approach – Signals the operator to slow or stop the process and correct the problem or move the defect offline © 2011 Jones and Bartlett Publishers, LLC 78

Poka Yoke Methods • Three approaches – Contact method – Counting method – Motion-sequence method • Each method can be used in either control or warning system © 2011 Jones and Bartlett Publishers, LLC 79

Contact Method • Detects contact between some sensing unit and a part of the process – Example: end tidal CO 2 detector inline with respiratory apparatus for intubated patient – May have capacity to stop the process (control) or warn of potential error in process (warning) © 2011 Jones and Bartlett Publishers, LLC 80

Counting Method • Used when a specific number of operations, pieces, or volumes are required within a process – Example: IV pumps that shut off and alarm when a drug solution is infused – Control – machine shuts off or process stops – Warning – indicator notifies operator of condition © 2011 Jones and Bartlett Publishers, LLC 81

Another Approach to counts… • Detecting incorrect counts after a procedure ends – Example: sponge count after surgical procedure – Variance from expected triggers corrective action to ameliorate error © 2011 Jones and Bartlett Publishers, LLC 82

Motion Sequence Method • Sensors determine if a specific condition or step in the process has occurred or has occurred out of sequence – Warning or control approaches may be used – Example: color coding system or checklist in office to ensure that each step of patient visit has been completed, e. g. to ensure that nurse has checked for lab results before MD sees patient © 2011 Jones and Bartlett Publishers, LLC 83

Poka Yoke Means Error Free • Applications in health care broad • Requires staff empowerment • Capability of stopping process or taking error offline for correction • Crew resource management ensures staff empowerment and vigilance • No more excuses! © 2011 Jones and Bartlett Publishers, LLC

974d8e5913499bebd51567052327ebdb.ppt