76d3bebcb338db6893f14b9eec0f941c.ppt

- Количество слайдов: 28

2010 DOE Hydrogen Program Review Advanced PEM Based Hydrogen Home Refueling Appliance (SBIR Phase I) Michael Pien, Ph. D. Principal Investigator Electro. Chem, Inc. Woburn, MA 01801 June 7, 2010 Project ID# PD 064 This presentation does not contain any proprietary, confidential, or otherwise restricted information 1 Electro. Chem Inc.

Over. View Barriers Timeline • Barriers addressed • Start July 2009 • End January 2010 • 100% Complete Electrolyzer Based Home Refueling System for Passenger Vehicles: – Feasibility Analysis – Safety Analysis and Codes – Projected Costs of system and product hydrogen Budget • Total project funding – DOE share = $100, 000 – Contractor share = none Partners • Project lead • Funding received in FY 09 = 100% Electro. Chem, Inc. 2 Electro. Chem Inc.

Objectives - Relevance • Develop Simplified PEM electrolyzer appliance design that supports high efficiency and safe operation at a scale suitable for home refueling of passenger fuel cell vehicles. • Determine technical feasibility, physical operating parameters, expected reliability and suitability for home use. • Determine safety requirements and applicable codes. • Analyze unit manufactured cost, reliability, operating and maintenance cost and total costs. • Examine market impact and acceptability. 3 Electro. Chem Inc.

Hydrogen Refueling @ Home - Relevance • Fuels Hydrogen Vehicle Market “One-Car-At-A-Time” • Use “Off Peak” Electricity for low cost H 2 fuel @Home • Safe storage of H 2 directly in vehicle tank • Convenient to Install and Use • Solves the “Infrastructure Challenge” • Most Rapid Market Expansion • Lowest Investment Risk HHR Unit • No Operating Manpower Cost • No Real Estate Cost • Low Excess Capacity Provides simplest, cleanest and most reliable H 2 production means. 4 Electro. Chem Inc.

Plan & Approach • Feasibility – Define operating requirements based on necessary performance and customer requirements. (capacity, location, noise, safety, maintenance. ) • Prelim Design – Specify acceptable designs and detailed performance specifications. (Power, size, operating schedule, life, efficiency, feed requirements) • Design Analysis – Perform bottoms-up and top-down cost analyses for the production of up to 500, 000 units/yr. Identify applicable safety codes and primary safety factors. Define required maintenance. • Process Analysis – In a bottoms-up approach, determine complete hydrogen cost analysis using H 2 A. • Technology Development Plan – Identify key technical factors requiring further development. 5 Electro. Chem Inc.

Strategic Approach • Eliminate factors (storage, manpower, real estate) driving high costs of forecourt H 2 fueling systems. • Design system around typical driver needs. • Implement the system simplifications allowed by the IFF design. • Determine all the necessary components in 3 complete versions of a home refueling electrolyzer system that assume differing technical advancements over current technology. • Determine safety factors by comparison with similar solutions already “codified”. • Determine bottoms-up cost , and leverage prior analyses targeting fuel cell volume manufacturing for vehicle production. • Compare with competitive electrolyzer system costs via power-rule scaling. 6 Electro. Chem Inc.

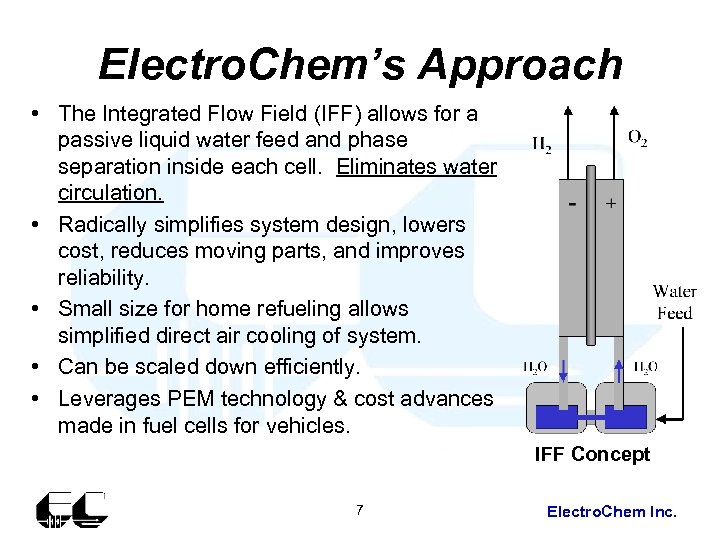

Electro. Chem’s Approach • The Integrated Flow Field (IFF) allows for a passive liquid water feed and phase separation inside each cell. Eliminates water circulation. • Radically simplifies system design, lowers cost, reduces moving parts, and improves reliability. • Small size for home refueling allows simplified direct air cooling of system. • Can be scaled down efficiently. • Leverages PEM technology & cost advances made in fuel cells for vehicles. IFF Concept 7 Electro. Chem Inc.

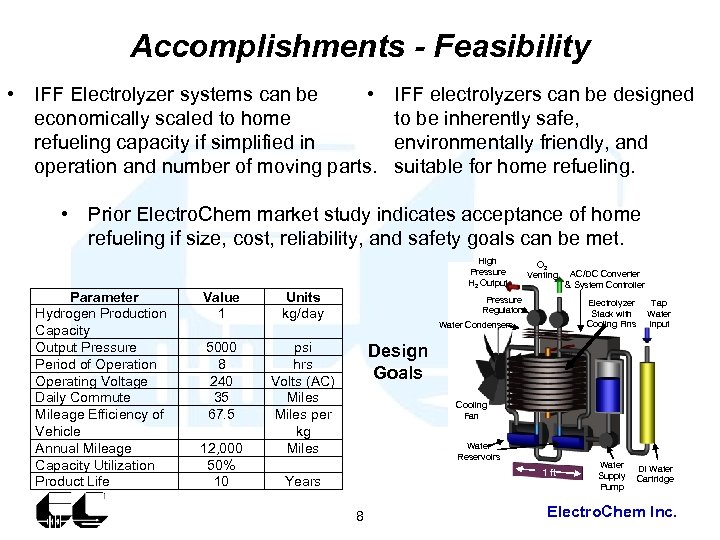

Accomplishments - Feasibility • IFF Electrolyzer systems can be • economically scaled to home refueling capacity if simplified in operation and number of moving parts. IFF electrolyzers can be designed to be inherently safe, environmentally friendly, and suitable for home refueling. • Prior Electro. Chem market study indicates acceptance of home refueling if size, cost, reliability, and safety goals can be met. Parameter Hydrogen Production Capacity Output Pressure Period of Operation Operating Voltage Daily Commute Mileage Efficiency of Vehicle Annual Mileage Capacity Utilization Product Life Value 1 Units kg/day 5000 8 240 35 67. 5 High Pressure H 2 Output psi hrs Volts (AC) Miles per kg Miles 12, 000 50% 10 O 2 Venting Pressure Regulators AC/DC Converter & System Controller Electrolyzer Stack with Cooling Fins Water Condensers Tap Water Input Design Goals Cooling Fan Water Reservoirs 1 ft Years 8 Water Supply Pump DI Water Cartridge Electro. Chem Inc.

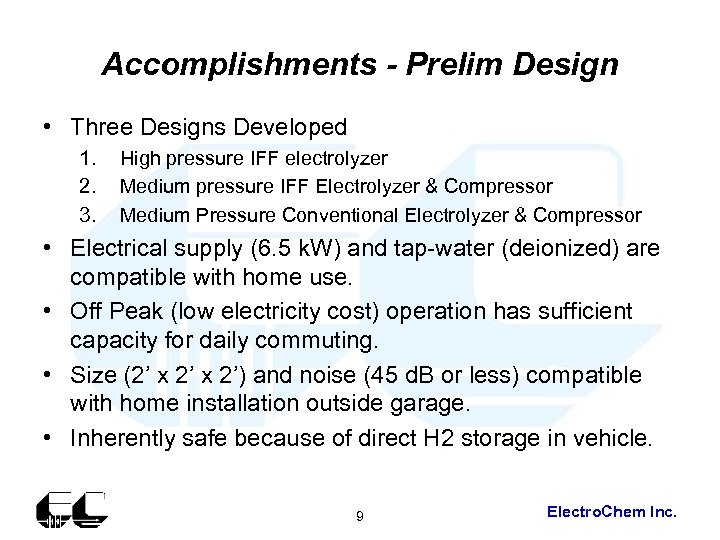

Accomplishments - Prelim Design • Three Designs Developed 1. 2. 3. High pressure IFF electrolyzer Medium pressure IFF Electrolyzer & Compressor Medium Pressure Conventional Electrolyzer & Compressor • Electrical supply (6. 5 k. W) and tap-water (deionized) are compatible with home use. • Off Peak (low electricity cost) operation has sufficient capacity for daily commuting. • Size (2’ x 2’) and noise (45 d. B or less) compatible with home installation outside garage. • Inherently safe because of direct H 2 storage in vehicle. 9 Electro. Chem Inc.

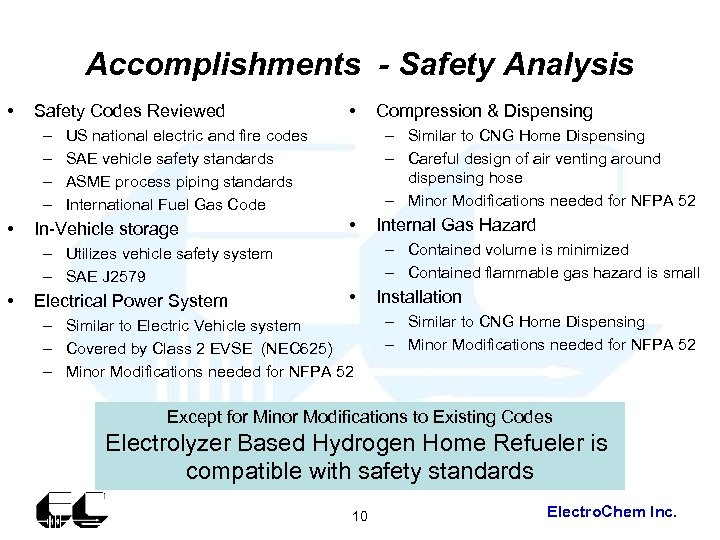

Accomplishments - Safety Analysis • Safety Codes Reviewed – – • • – Similar to CNG Home Dispensing – Careful design of air venting around dispensing hose – Minor Modifications needed for NFPA 52 US national electric and fire codes SAE vehicle safety standards ASME process piping standards International Fuel Gas Code In-Vehicle storage • Electrical Power System Internal Gas Hazard – Contained volume is minimized – Contained flammable gas hazard is small – Utilizes vehicle safety system – SAE J 2579 • Compression & Dispensing • – Similar to Electric Vehicle system – Covered by Class 2 EVSE (NEC 625) – Minor Modifications needed for NFPA 52 Installation – Similar to CNG Home Dispensing – Minor Modifications needed for NFPA 52 Except for Minor Modifications to Existing Codes Electrolyzer Based Hydrogen Home Refueler is compatible with safety standards 10 Electro. Chem Inc.

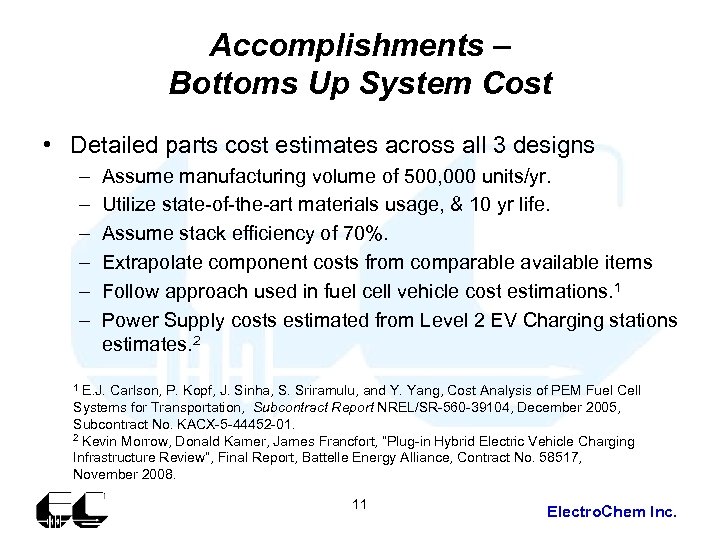

Accomplishments – Bottoms Up System Cost • Detailed parts cost estimates across all 3 designs – – – Assume manufacturing volume of 500, 000 units/yr. Utilize state-of-the-art materials usage, & 10 yr life. Assume stack efficiency of 70%. Extrapolate component costs from comparable available items Follow approach used in fuel cell vehicle cost estimations. 1 Power Supply costs estimated from Level 2 EV Charging stations estimates. 2 1 E. J. Carlson, P. Kopf, J. Sinha, S. Sriramulu, and Y. Yang, Cost Analysis of PEM Fuel Cell Systems for Transportation, Subcontract Report NREL/SR-560 -39104, December 2005, Subcontract No. KACX-5 -44452 -01. 2 Kevin Morrow, Donald Karner, James Francfort, “Plug-in Hybrid Electric Vehicle Charging Infrastructure Review”, Final Report, Battelle Energy Alliance, Contract No. 58517, November 2008. 11 Electro. Chem Inc.

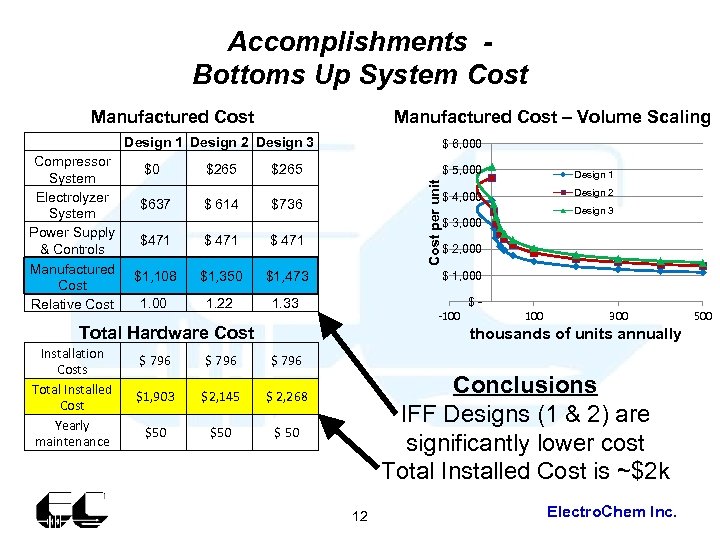

Accomplishments Bottoms Up System Cost Manufactured Cost – Volume Scaling Design 1 Design 2 Design 3 Compressor $0 $265 System Electrolyzer $637 $ 614 $736 System Power Supply $471 $ 471 & Controls Manufactured $1, 108 $1, 350 $1, 473 Cost 1. 00 1. 22 1. 33 Relative Cost $ 6, 000 Cost per unit $ 5, 000 $ 4, 000 Design 2 Design 3 $ 3, 000 $ 2, 000 $ 1, 000 $ - -100 Total Hardware Cost Installation Costs Total Installed Cost Yearly maintenance Design 1 100 300 thousands of units annually $ 796 $1, 903 $2, 145 $ 2, 268 $50 $ 50 Conclusions IFF Designs (1 & 2) are significantly lower cost Total Installed Cost is ~$2 k 12 Electro. Chem Inc. 500

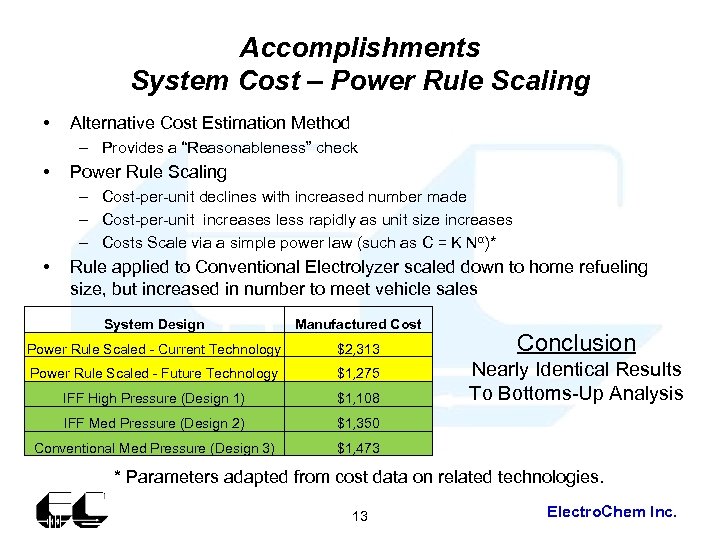

Accomplishments System Cost – Power Rule Scaling • Alternative Cost Estimation Method – Provides a “Reasonableness” check • Power Rule Scaling – Cost-per-unit declines with increased number made – Cost-per-unit increases less rapidly as unit size increases – Costs Scale via a simple power law (such as C = K Nα)* • Rule applied to Conventional Electrolyzer scaled down to home refueling size, but increased in number to meet vehicle sales System Design Manufactured Cost Power Rule Scaled - Current Technology $2, 313 Power Rule Scaled - Future Technology $1, 275 IFF High Pressure (Design 1) $1, 108 IFF Med Pressure (Design 2) $1, 350 Conventional Med Pressure (Design 3) $1, 473 Conclusion Nearly Identical Results To Bottoms-Up Analysis * Parameters adapted from cost data on related technologies. 13 Electro. Chem Inc.

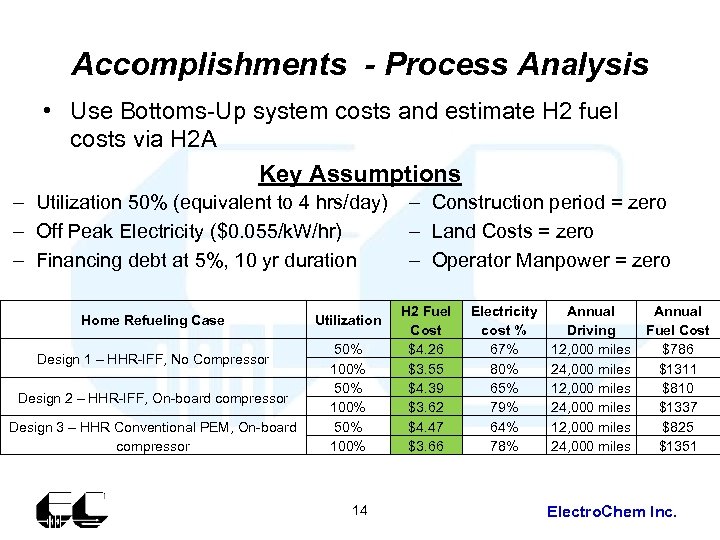

Accomplishments - Process Analysis • Use Bottoms-Up system costs and estimate H 2 fuel costs via H 2 A Key Assumptions – Utilization 50% (equivalent to 4 hrs/day) – Off Peak Electricity ($0. 055/k. W/hr) – Financing debt at 5%, 10 yr duration Home Refueling Case Design 1 – HHR-IFF, No Compressor Design 2 – HHR-IFF, On-board compressor Design 3 – HHR Conventional PEM, On-board compressor Utilization 50% 100% 14 – Construction period = zero – Land Costs = zero – Operator Manpower = zero H 2 Fuel Cost $4. 26 $3. 55 $4. 39 $3. 62 $4. 47 $3. 66 Electricity cost % 67% 80% 65% 79% 64% 78% Annual Driving 12, 000 miles 24, 000 miles Annual Fuel Cost $786 $1311 $810 $1337 $825 $1351 Electro. Chem Inc.

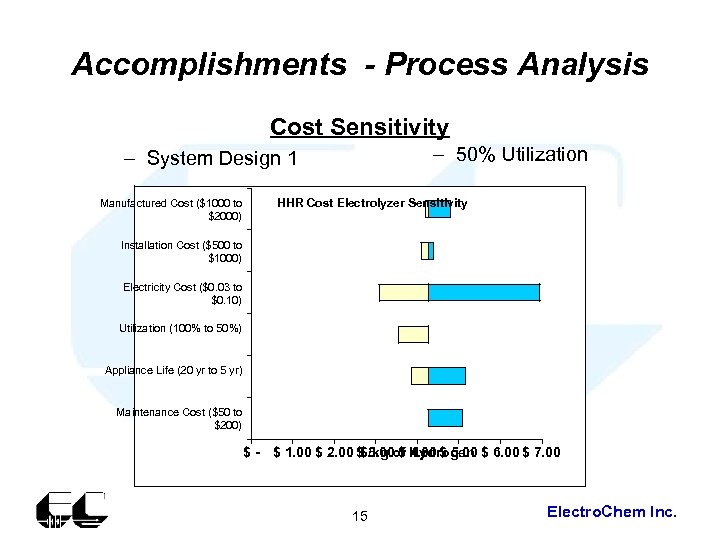

Accomplishments - Process Analysis Cost Sensitivity – 50% Utilization – System Design 1 Manufactured Cost ($1000 to $2000) HHR Cost Electrolyzer Sensitivity Installation Cost ($500 to $1000) Electricity Cost ($0. 03 to $0. 10) Utilization (100% to 50%) Appliance Life (20 yr to 5 yr) Maintenance Cost ($50 to $200) $ - $ 1. 00 $ 2. 00 $ 3. 00 of Hydrogen $ 6. 00 $ 7. 00 $/kg $ 4. 00 $ 5. 00 15 Electro. Chem Inc.

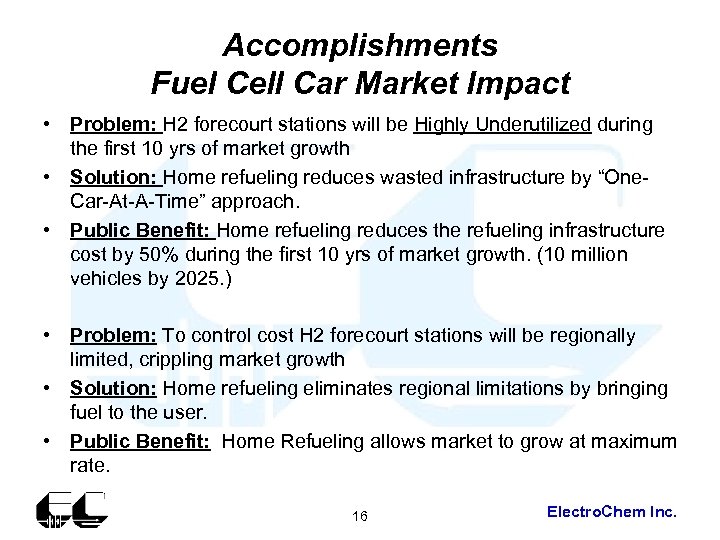

Accomplishments Fuel Cell Car Market Impact • Problem: H 2 forecourt stations will be Highly Underutilized during the first 10 yrs of market growth • Solution: Home refueling reduces wasted infrastructure by “One. Car-At-A-Time” approach. • Public Benefit: Home refueling reduces the refueling infrastructure cost by 50% during the first 10 yrs of market growth. (10 million vehicles by 2025. ) • Problem: To control cost H 2 forecourt stations will be regionally limited, crippling market growth • Solution: Home refueling eliminates regional limitations by bringing fuel to the user. • Public Benefit: Home Refueling allows market to grow at maximum rate. 16 Electro. Chem Inc.

Collaborations • EPRI supported effort demonstrated fundamental feasibility of IFF design • EPRI consultation on current program (Dan Rastler) 17 Electro. Chem Inc.

Proposed Future Work • Demonstrate complete system operation of IFF based PEM electrolyzer • Develop membranes for high pressure PEM electrolysis • Develop small sized H 2 compressors • Encourage modifications for safety codes for hydrogen home refueling systems. 18 Electro. Chem Inc.

Summary • Home refueling advances hydrogen vehicle market by solving “Infrastructure Challenge” • Technologically Integrated Flow Field (IFF) provides the lowest possible system cost, simplest design, and highest reliability • Mass production of low cost system and operation with offpeak electricity provides cost-competitive H 2 fuel. • Electrolyzer appliances are compatible with safe installation and operation at the home. • Modest sized units can provide refueling for passenger vehicles at 5000 psi and higher. 19 Electro. Chem Inc.

For More Information Please Contact: Michael Pien, Ph. D. Vice President of R&D Electrochem, Inc. 400 West Cummings Park Woburn, Massachusetts 01801 Phone: 1. 781. 938. 5300 Fax: 1. 781. 935. 6966 Email: mpien@fuelcell. com 20 Electro. Chem Inc.

Supplemental Slides. 21 Electro. Chem Inc.

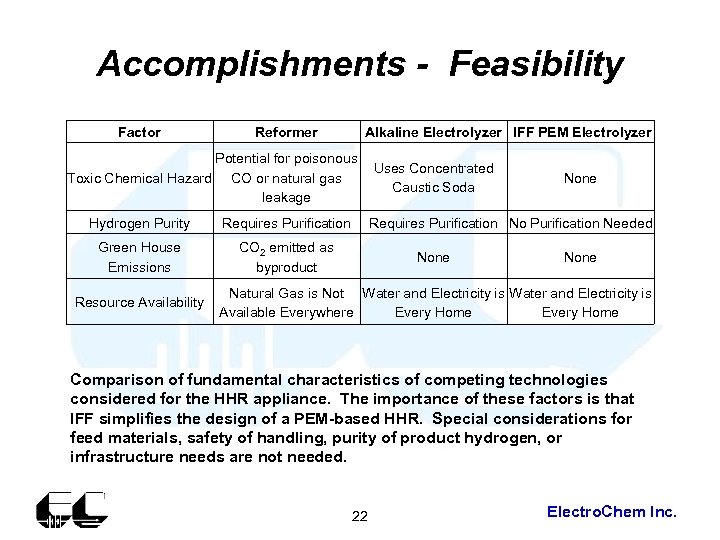

Accomplishments - Feasibility Factor Reformer Alkaline Electrolyzer IFF PEM Electrolyzer Potential for poisonous Uses Concentrated Toxic Chemical Hazard CO or natural gas Caustic Soda leakage Hydrogen Purity Requires Purification Green House Emissions CO 2 emitted as byproduct Resource Availability None Requires Purification No Purification Needed None Natural Gas is Not Water and Electricity is Available Everywhere Every Home Comparison of fundamental characteristics of competing technologies considered for the HHR appliance. The importance of these factors is that IFF simplifies the design of a PEM-based HHR. Special considerations for feed materials, safety of handling, purity of product hydrogen, or infrastructure needs are not needed. 22 Electro. Chem Inc.

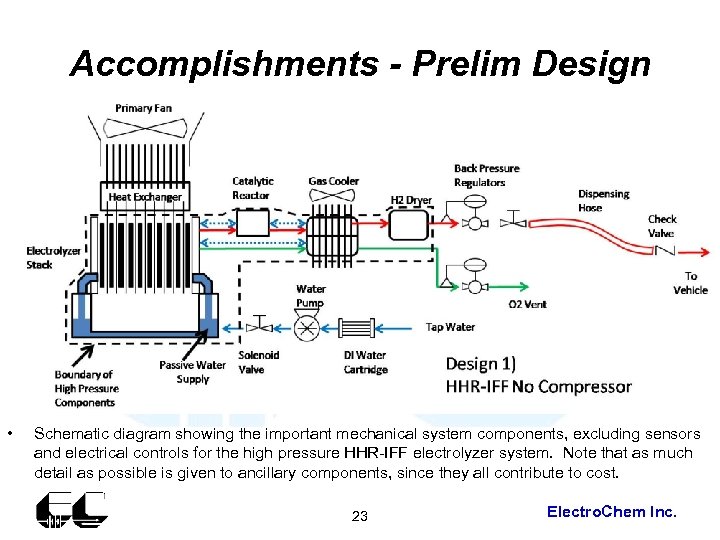

Accomplishments - Prelim Design • Schematic diagram showing the important mechanical system components, excluding sensors and electrical controls for the high pressure HHR-IFF electrolyzer system. Note that as much detail as possible is given to ancillary components, since they all contribute to cost. 23 Electro. Chem Inc.

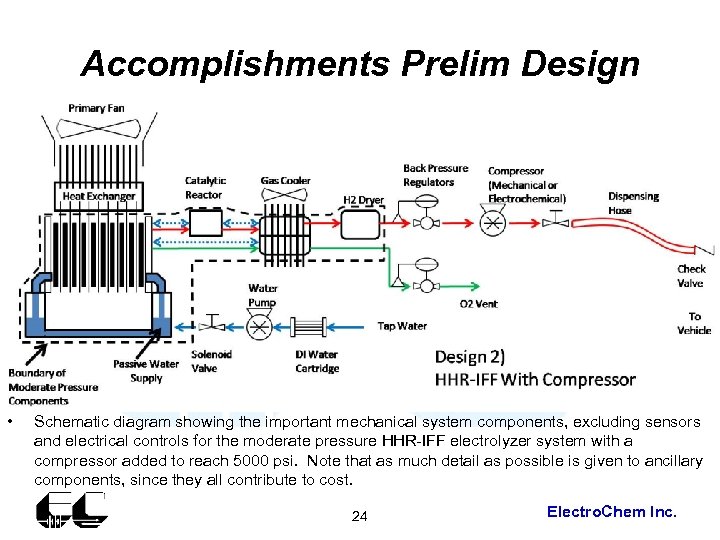

Accomplishments Prelim Design • Schematic diagram showing the important mechanical system components, excluding sensors and electrical controls for the moderate pressure HHR-IFF electrolyzer system with a compressor added to reach 5000 psi. Note that as much detail as possible is given to ancillary components, since they all contribute to cost. 24 Electro. Chem Inc.

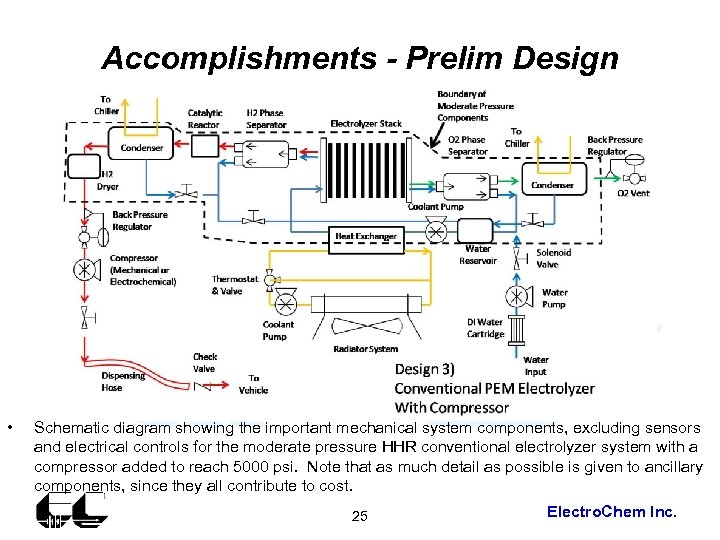

Accomplishments - Prelim Design • Schematic diagram showing the important mechanical system components, excluding sensors and electrical controls for the moderate pressure HHR conventional electrolyzer system with a compressor added to reach 5000 psi. Note that as much detail as possible is given to ancillary components, since they all contribute to cost. 25 Electro. Chem Inc.

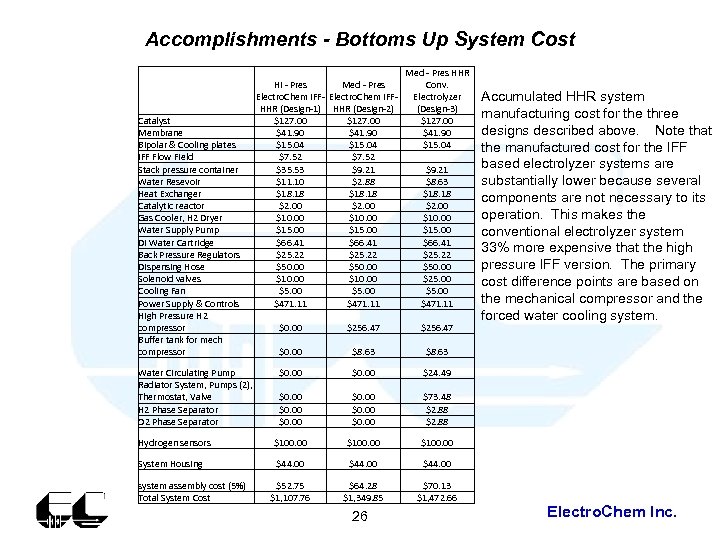

Accomplishments - Bottoms Up System Cost Catalyst Membrane Bipolar & Cooling plates IFF Flow Field Stack pressure container Water Resevoir Heat Exchanger Catalytic reactor Gas Cooler, H 2 Dryer Water Supply Pump DI Water Cartridge Back Pressure Regulators Dispensing Hose Solenoid valves Cooling Fan Power Supply & Controls High Pressure H 2 compressor Buffer tank for mech compressor Hi - Pres Med - Pres Electro. Chem IFF- Electro. Chem IFFHHR (Design-1) HHR (Design-2) $127. 00 $41. 90 $15. 04 $7. 52 $35. 53 $9. 21 $11. 10 $2. 88 $18. 18 $2. 00 $10. 00 $15. 00 $66. 41 $25. 22 $50. 00 $10. 00 $5. 00 $471. 11 Med - Pres HHR Conv. Electrolyzer (Design-3) $127. 00 $41. 90 $15. 04 $9. 21 $8. 63 $18. 18 $2. 00 $10. 00 $15. 00 $66. 41 $25. 22 $50. 00 $25. 00 $471. 11 $0. 00 $256. 47 $0. 00 $8. 63 $0. 00 $24. 49 $0. 00 $73. 48 $2. 88 Hydrogen sensors $100. 00 System Housing $44. 00 $52. 75 $1, 107. 76 $64. 28 $1, 349. 85 $70. 13 $1, 472. 66 Accumulated HHR system manufacturing cost for the three designs described above. Note that the manufactured cost for the IFF based electrolyzer systems are substantially lower because several components are not necessary to its operation. This makes the conventional electrolyzer system 33% more expensive that the high pressure IFF version. The primary cost difference points are based on the mechanical compressor and the forced water cooling system. Water Circulating Pump Radiator System, Pumps (2), Thermostat, Valve H 2 Phase Separator O 2 Phase Separator system assembly cost (5%) Total System Cost 26 Electro. Chem Inc.

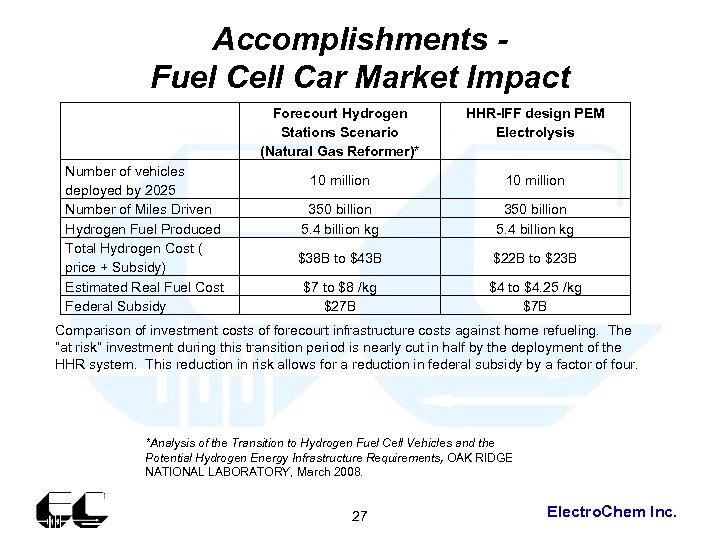

Accomplishments Fuel Cell Car Market Impact Forecourt Hydrogen Stations Scenario (Natural Gas Reformer)* Number of vehicles deployed by 2025 Number of Miles Driven Hydrogen Fuel Produced Total Hydrogen Cost ( price + Subsidy) Estimated Real Fuel Cost Federal Subsidy HHR-IFF design PEM Electrolysis 10 million 350 billion 5. 4 billion kg $38 B to $43 B $22 B to $23 B $7 to $8 /kg $27 B $4 to $4. 25 /kg $7 B Comparison of investment costs of forecourt infrastructure costs against home refueling. The “at risk” investment during this transition period is nearly cut in half by the deployment of the HHR system. This reduction in risk allows for a reduction in federal subsidy by a factor of four. *Analysis of the Transition to Hydrogen Fuel Cell Vehicles and the Potential Hydrogen Energy Infrastructure Requirements, OAK RIDGE NATIONAL LABORATORY, March 2008. 27 Electro. Chem Inc.

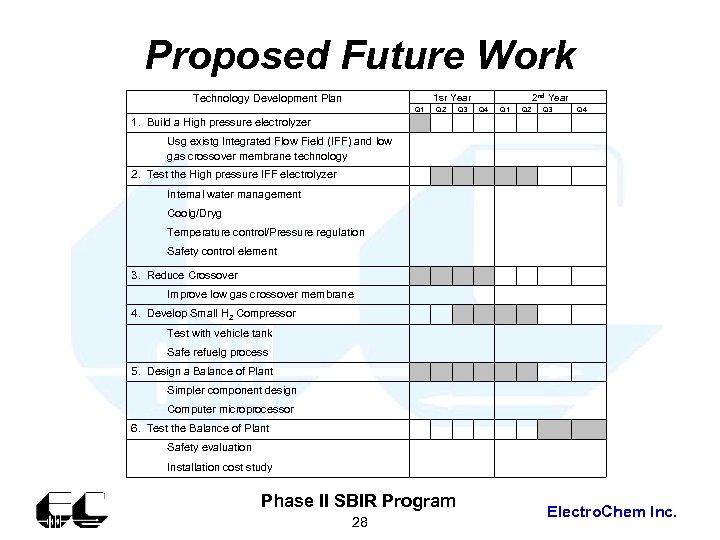

Proposed Future Work 1 sr Year Technology Development Plan Q 1 Q 2 Q 3 2 nd Year Q 4 Q 1 Q 2 Q 3 Q 4 1. Build a High pressure electrolyzer Usg existg Integrated Flow Field (IFF) and low gas crossover membrane technology 2. Test the High pressure IFF electrolyzer Internal water management Coolg/Dryg Temperature control/Pressure regulation Safety control element 3. Reduce Crossover Improve low gas crossover membrane 4. Develop Small H 2 Compressor Test with vehicle tank Safe refuelg process 5. Design a Balance of Plant Simpler component design Computer microprocessor 6. Test the Balance of Plant Safety evaluation Installation cost study Phase II SBIR Program 28 Electro. Chem Inc.

76d3bebcb338db6893f14b9eec0f941c.ppt