af52e05551bdb64d0634d8aa2c4155dd.ppt

- Количество слайдов: 19

201 MHz Cavity Status and Test Plans at MTA MICE Collaboration Meeting at RAL, UK October 22 ~ 24, 2005 Derun Li Center for Beam Physics Lawrence Berkeley National Laboratory

201 MHz Cavity Status and Test Plans at MTA MICE Collaboration Meeting at RAL, UK October 22 ~ 24, 2005 Derun Li Center for Beam Physics Lawrence Berkeley National Laboratory

Cavity Status @ Last Meeting MICE Collaboration meeting last June at Nu. Fact-2005 in Frascati u Cavity fabrication: in collaboration with J-Lab, University of Mississippi, Oxford University è Cavity parts fabrication at Mississippi; e-beam welding, EP and cleaning at J-Lab è Power couplers: assembly and high power tests at SNS è Vacuum assembly and tests at J-Lab, … , shipping è Curved Be windows: in collaboration with Oxford University u In MTA, FNAL è Preparation for accepting the cavity: installation, baking, vacuum, RF transmission lines, … è Cleaning room purchased and will allow us for in situ assembly of è Couplers è Window replacement è Inspection of cavity è Low power measurement: frequency and coupling MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 2

Cavity Status @ Last Meeting MICE Collaboration meeting last June at Nu. Fact-2005 in Frascati u Cavity fabrication: in collaboration with J-Lab, University of Mississippi, Oxford University è Cavity parts fabrication at Mississippi; e-beam welding, EP and cleaning at J-Lab è Power couplers: assembly and high power tests at SNS è Vacuum assembly and tests at J-Lab, … , shipping è Curved Be windows: in collaboration with Oxford University u In MTA, FNAL è Preparation for accepting the cavity: installation, baking, vacuum, RF transmission lines, … è Cleaning room purchased and will allow us for in situ assembly of è Couplers è Window replacement è Inspection of cavity è Low power measurement: frequency and coupling MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 2

• Cavity Progress Since Last MICE Meeting Cavity fabrication: in collaboration with J-Lab, University of Mississippi, Oxford University ü Cavity parts fabrication at Mississippi; e-beam welding, EPs and cleaning at J-Lab ü Power couplers: assembly and high power tests at SNS ü Vacuum assembly and tests at J-Lab, … , shipping ü Curved Be windows: in collaboration with Oxford University: three curved Be windows, one with Ti-N coating l Cavity shipped in early September, and now at MTA FNAL ü Strong supports and helps from FNAL: Preparation for accepting the cavity: installation, baking, vacuum, RF transmission lines, … ü Cleaning room was ready for in situ assembly of ü Couplers ü Window replacement ü Inspection of cavity ü Cavity installation ü Vacuum leak tight ü Low power measurement: frequency and coupling MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 3

• Cavity Progress Since Last MICE Meeting Cavity fabrication: in collaboration with J-Lab, University of Mississippi, Oxford University ü Cavity parts fabrication at Mississippi; e-beam welding, EPs and cleaning at J-Lab ü Power couplers: assembly and high power tests at SNS ü Vacuum assembly and tests at J-Lab, … , shipping ü Curved Be windows: in collaboration with Oxford University: three curved Be windows, one with Ti-N coating l Cavity shipped in early September, and now at MTA FNAL ü Strong supports and helps from FNAL: Preparation for accepting the cavity: installation, baking, vacuum, RF transmission lines, … ü Cleaning room was ready for in situ assembly of ü Couplers ü Window replacement ü Inspection of cavity ü Cavity installation ü Vacuum leak tight ü Low power measurement: frequency and coupling MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 3

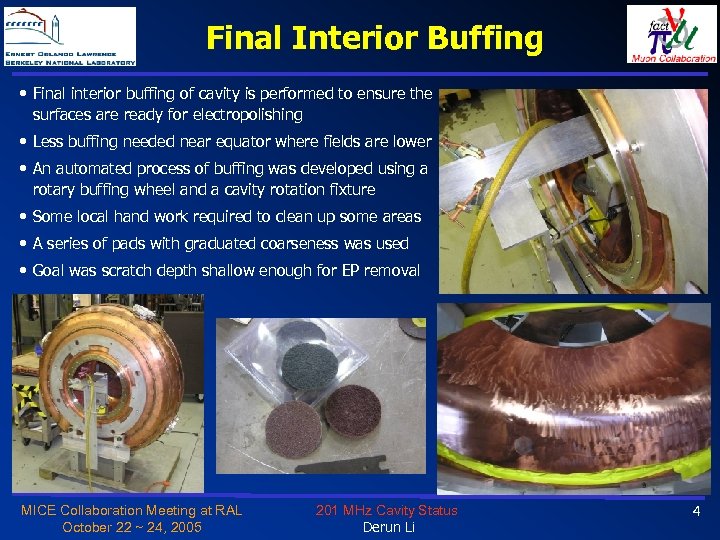

Final Interior Buffing • Final interior buffing of cavity is performed to ensure the surfaces are ready for electropolishing • Less buffing needed near equator where fields are lower • An automated process of buffing was developed using a rotary buffing wheel and a cavity rotation fixture • Some local hand work required to clean up some areas • A series of pads with graduated coarseness was used • Goal was scratch depth shallow enough for EP removal MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 4

Final Interior Buffing • Final interior buffing of cavity is performed to ensure the surfaces are ready for electropolishing • Less buffing needed near equator where fields are lower • An automated process of buffing was developed using a rotary buffing wheel and a cavity rotation fixture • Some local hand work required to clean up some areas • A series of pads with graduated coarseness was used • Goal was scratch depth shallow enough for EP removal MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 4

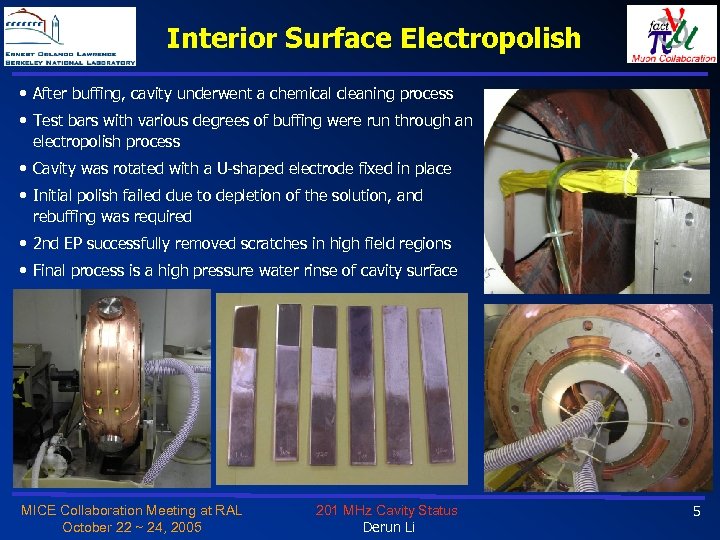

Interior Surface Electropolish • After buffing, cavity underwent a chemical cleaning process • Test bars with various degrees of buffing were run through an electropolish process • Cavity was rotated with a U-shaped electrode fixed in place • Initial polish failed due to depletion of the solution, and rebuffing was required • 2 nd EP successfully removed scratches in high field regions • Final process is a high pressure water rinse of cavity surface MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 5

Interior Surface Electropolish • After buffing, cavity underwent a chemical cleaning process • Test bars with various degrees of buffing were run through an electropolish process • Cavity was rotated with a U-shaped electrode fixed in place • Initial polish failed due to depletion of the solution, and rebuffing was required • 2 nd EP successfully removed scratches in high field regions • Final process is a high pressure water rinse of cavity surface MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 5

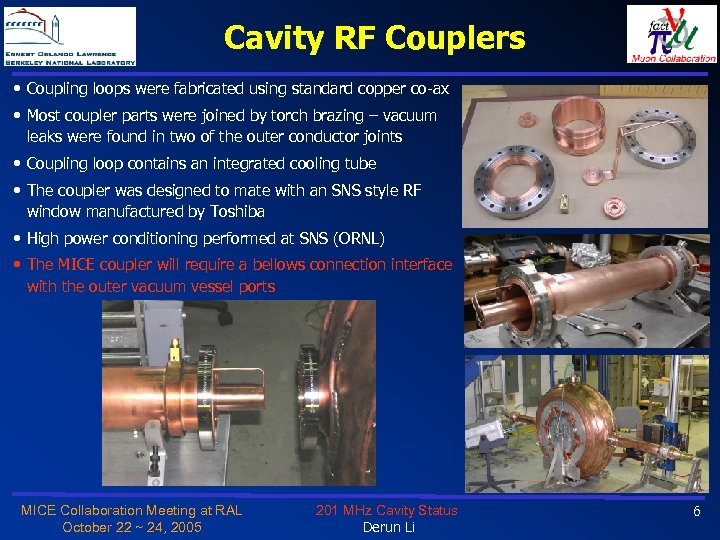

Cavity RF Couplers • Coupling loops were fabricated using standard copper co-ax • Most coupler parts were joined by torch brazing – vacuum leaks were found in two of the outer conductor joints • Coupling loop contains an integrated cooling tube • The coupler was designed to mate with an SNS style RF window manufactured by Toshiba • High power conditioning performed at SNS (ORNL) • The MICE coupler will require a bellows connection interface with the outer vacuum vessel ports MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 6

Cavity RF Couplers • Coupling loops were fabricated using standard copper co-ax • Most coupler parts were joined by torch brazing – vacuum leaks were found in two of the outer conductor joints • Coupling loop contains an integrated cooling tube • The coupler was designed to mate with an SNS style RF window manufactured by Toshiba • High power conditioning performed at SNS (ORNL) • The MICE coupler will require a bellows connection interface with the outer vacuum vessel ports MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 6

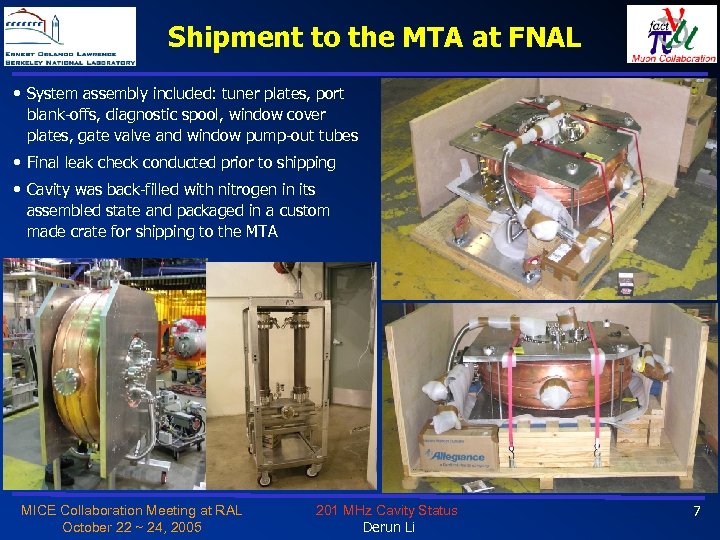

Shipment to the MTA at FNAL • System assembly included: tuner plates, port blank-offs, diagnostic spool, window cover plates, gate valve and window pump-out tubes • Final leak check conducted prior to shipping • Cavity was back-filled with nitrogen in its assembled state and packaged in a custom made crate for shipping to the MTA MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 7

Shipment to the MTA at FNAL • System assembly included: tuner plates, port blank-offs, diagnostic spool, window cover plates, gate valve and window pump-out tubes • Final leak check conducted prior to shipping • Cavity was back-filled with nitrogen in its assembled state and packaged in a custom made crate for shipping to the MTA MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 7

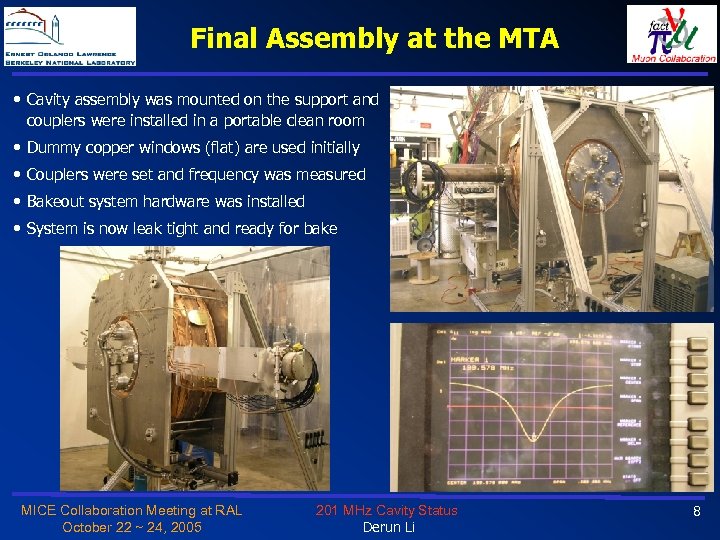

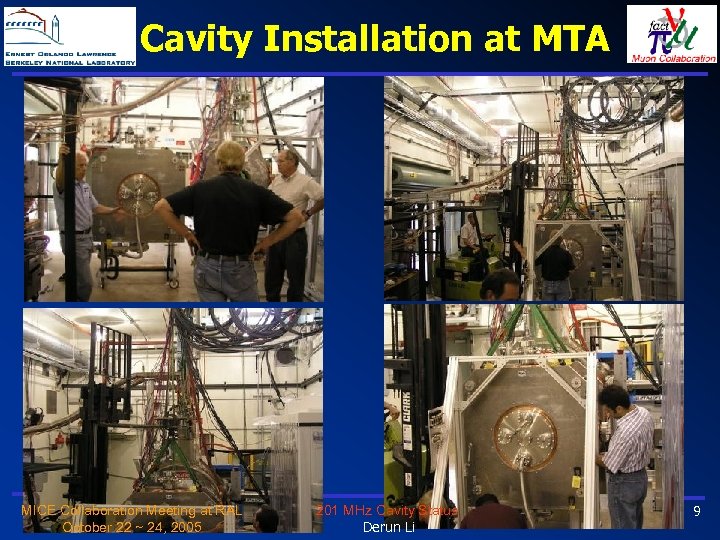

Final Assembly at the MTA • Cavity assembly was mounted on the support and couplers were installed in a portable clean room • Dummy copper windows (flat) are used initially • Couplers were set and frequency was measured • Bakeout system hardware was installed • System is now leak tight and ready for bake MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 8

Final Assembly at the MTA • Cavity assembly was mounted on the support and couplers were installed in a portable clean room • Dummy copper windows (flat) are used initially • Couplers were set and frequency was measured • Bakeout system hardware was installed • System is now leak tight and ready for bake MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 8

Cavity Installation at MTA MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 9

Cavity Installation at MTA MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 9

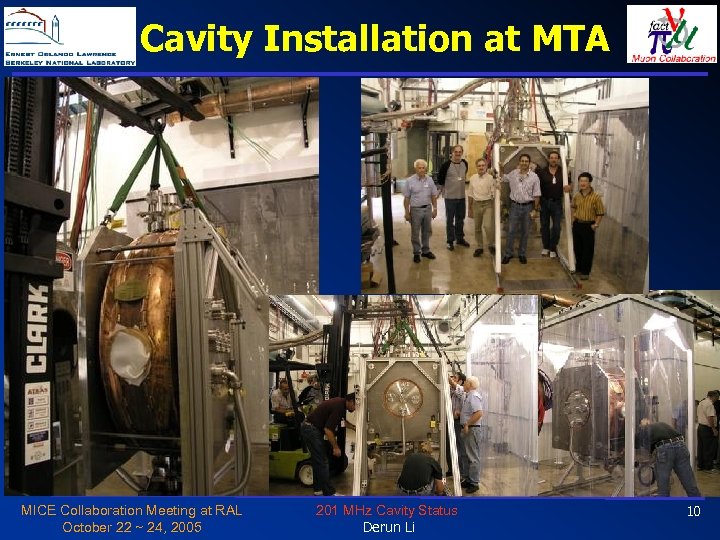

Cavity Installation at MTA MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 10

Cavity Installation at MTA MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 10

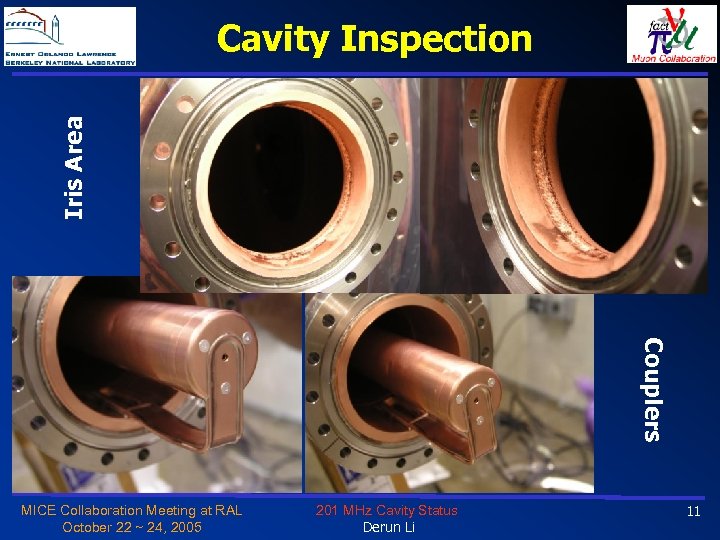

Iris Area Cavity Inspection Couplers MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 11

Iris Area Cavity Inspection Couplers MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 11

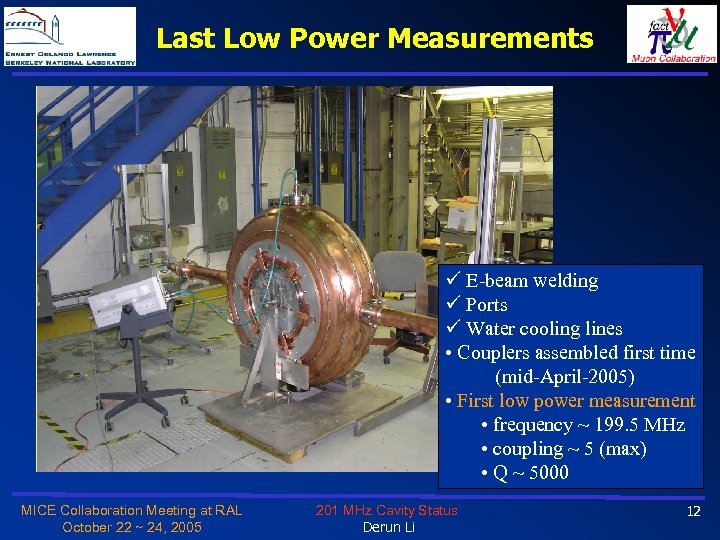

Last Low Power Measurements ü E-beam welding ü Ports ü Water cooling lines • Couplers assembled first time (mid-April-2005) • First low power measurement • frequency ~ 199. 5 MHz • coupling ~ 5 (max) • Q ~ 5000 MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 12

Last Low Power Measurements ü E-beam welding ü Ports ü Water cooling lines • Couplers assembled first time (mid-April-2005) • First low power measurement • frequency ~ 199. 5 MHz • coupling ~ 5 (max) • Q ~ 5000 MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 12

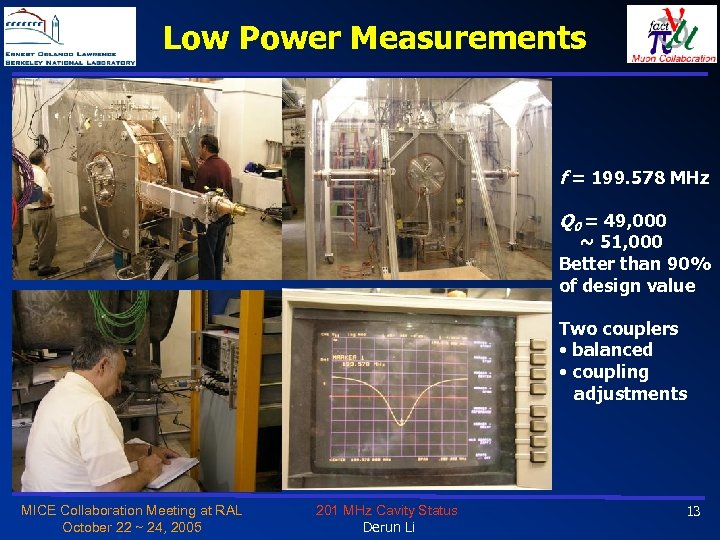

Low Power Measurements f = 199. 578 MHz Q 0 = 49, 000 ~ 51, 000 Better than 90% of design value Two couplers • balanced • coupling adjustments MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 13

Low Power Measurements f = 199. 578 MHz Q 0 = 49, 000 ~ 51, 000 Better than 90% of design value Two couplers • balanced • coupling adjustments MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 13

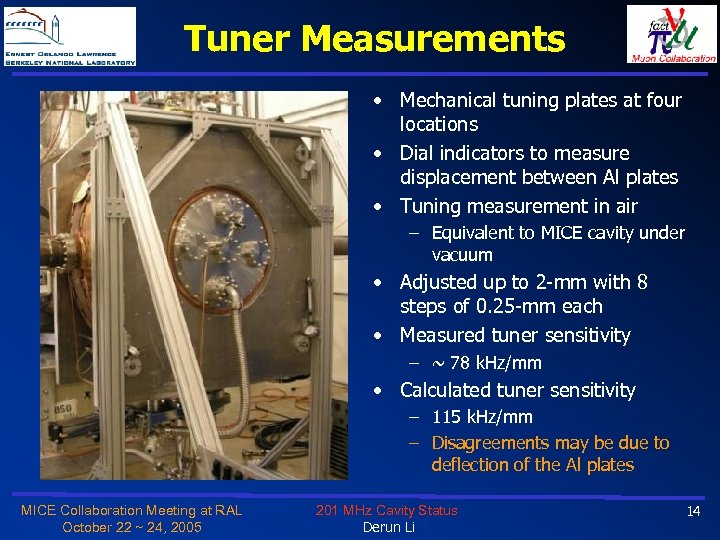

Tuner Measurements • Mechanical tuning plates at four locations • Dial indicators to measure displacement between Al plates • Tuning measurement in air – Equivalent to MICE cavity under vacuum • Adjusted up to 2 -mm with 8 steps of 0. 25 -mm each • Measured tuner sensitivity – ~ 78 k. Hz/mm • Calculated tuner sensitivity – 115 k. Hz/mm – Disagreements may be due to deflection of the Al plates MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 14

Tuner Measurements • Mechanical tuning plates at four locations • Dial indicators to measure displacement between Al plates • Tuning measurement in air – Equivalent to MICE cavity under vacuum • Adjusted up to 2 -mm with 8 steps of 0. 25 -mm each • Measured tuner sensitivity – ~ 78 k. Hz/mm • Calculated tuner sensitivity – 115 k. Hz/mm – Disagreements may be due to deflection of the Al plates MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 14

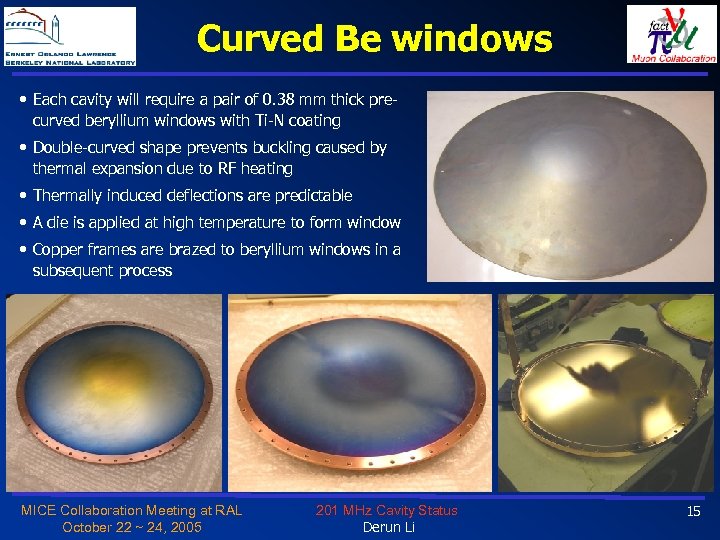

Curved Be windows • Each cavity will require a pair of 0. 38 mm thick precurved beryllium windows with Ti-N coating • Double-curved shape prevents buckling caused by thermal expansion due to RF heating • Thermally induced deflections are predictable • A die is applied at high temperature to form window • Copper frames are brazed to beryllium windows in a subsequent process MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 15

Curved Be windows • Each cavity will require a pair of 0. 38 mm thick precurved beryllium windows with Ti-N coating • Double-curved shape prevents buckling caused by thermal expansion due to RF heating • Thermally induced deflections are predictable • A die is applied at high temperature to form window • Copper frames are brazed to beryllium windows in a subsequent process MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 15

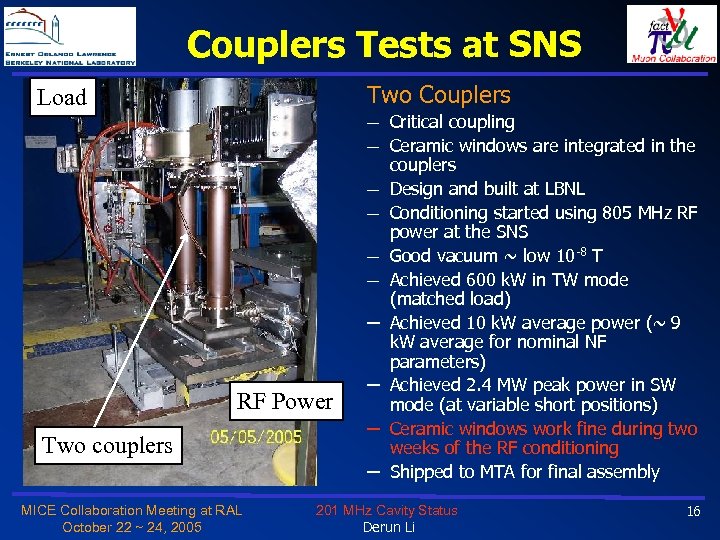

Couplers Tests at SNS Two Couplers Load ─ Critical coupling ─ Ceramic windows are integrated in the ─ ─ ─ RF Power Two couplers ─ ─ ─ MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 couplers Design and built at LBNL Conditioning started using 805 MHz RF power at the SNS Good vacuum ~ low 10 -8 T Achieved 600 k. W in TW mode (matched load) Achieved 10 k. W average power (~ 9 k. W average for nominal NF parameters) Achieved 2. 4 MW peak power in SW mode (at variable short positions) Ceramic windows work fine during two weeks of the RF conditioning Shipped to MTA for final assembly 201 MHz Cavity Status Derun Li 16

Couplers Tests at SNS Two Couplers Load ─ Critical coupling ─ Ceramic windows are integrated in the ─ ─ ─ RF Power Two couplers ─ ─ ─ MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 couplers Design and built at LBNL Conditioning started using 805 MHz RF power at the SNS Good vacuum ~ low 10 -8 T Achieved 600 k. W in TW mode (matched load) Achieved 10 k. W average power (~ 9 k. W average for nominal NF parameters) Achieved 2. 4 MW peak power in SW mode (at variable short positions) Ceramic windows work fine during two weeks of the RF conditioning Shipped to MTA for final assembly 201 MHz Cavity Status Derun Li 16

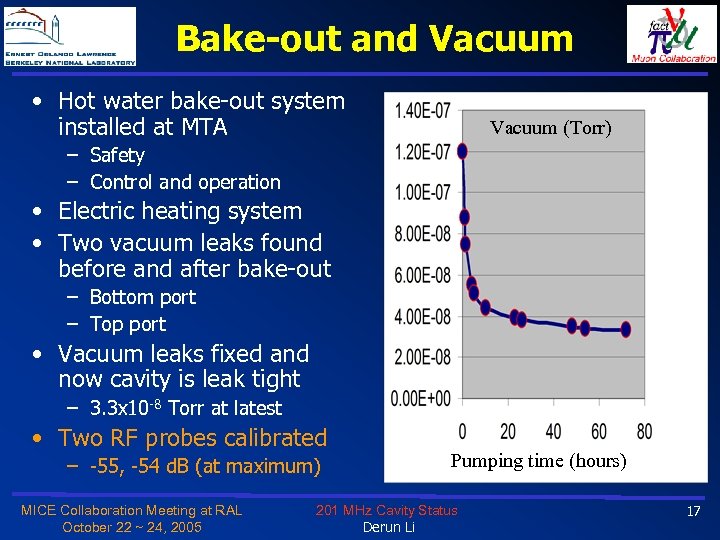

Bake-out and Vacuum • Hot water bake-out system installed at MTA Vacuum (Torr) – Safety – Control and operation • Electric heating system • Two vacuum leaks found before and after bake-out – Bottom port – Top port • Vacuum leaks fixed and now cavity is leak tight – 3. 3 x 10 -8 Torr at latest • Two RF probes calibrated – -55, -54 d. B (at maximum) MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 Pumping time (hours) 201 MHz Cavity Status Derun Li 17

Bake-out and Vacuum • Hot water bake-out system installed at MTA Vacuum (Torr) – Safety – Control and operation • Electric heating system • Two vacuum leaks found before and after bake-out – Bottom port – Top port • Vacuum leaks fixed and now cavity is leak tight – 3. 3 x 10 -8 Torr at latest • Two RF probes calibrated – -55, -54 d. B (at maximum) MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 Pumping time (hours) 201 MHz Cavity Status Derun Li 17

High Power Test at MTA Plans underway – Coordination among LBNL, FNAL, J-Lab and ANL > Weekly video meetings > MUCOOL Friday meetings – Diagnostics (RF probes, dark current, x-ray, vacuum, … ) – Near term plan > Purchase high power RF components – Power splitter (matched Tee) at 6” coaxial transmission line – Transitions to 4” coaxial lines with elbows to the couplers – Directional couplers – High power test plans being developed > Expect to have RF power (up to ~ 5 MW) in 6 ~ 8 weeks > Test with Ti-N coated flat copper windows (installed) first – Double check coupling balance and adjustment before high power – Double check calibration of RF probes > Conditioning without magnetic field first – Combinations of short pulse and high RF powers > Curved Be windows + magnetic fields later – Suggestions are always very welcome MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 18

High Power Test at MTA Plans underway – Coordination among LBNL, FNAL, J-Lab and ANL > Weekly video meetings > MUCOOL Friday meetings – Diagnostics (RF probes, dark current, x-ray, vacuum, … ) – Near term plan > Purchase high power RF components – Power splitter (matched Tee) at 6” coaxial transmission line – Transitions to 4” coaxial lines with elbows to the couplers – Directional couplers – High power test plans being developed > Expect to have RF power (up to ~ 5 MW) in 6 ~ 8 weeks > Test with Ti-N coated flat copper windows (installed) first – Double check coupling balance and adjustment before high power – Double check calibration of RF probes > Conditioning without magnetic field first – Combinations of short pulse and high RF powers > Curved Be windows + magnetic fields later – Suggestions are always very welcome MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 18

Summary • Cavity assembly at MTA, FNAL is complete – Cavity is vacuum leak tight, now at ~ 3. 3 x 10 -8 Torr – More RF components need to be ordered – Two couplers have been balanced and adjusted – Two RF probes calibrated • Curved Be windows with Ti-N coatings (one is ready now, two are underway) will be ready for high power tests • High power test plans being developed • Problems we had with cavity ports are not an issue for MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 19

Summary • Cavity assembly at MTA, FNAL is complete – Cavity is vacuum leak tight, now at ~ 3. 3 x 10 -8 Torr – More RF components need to be ordered – Two couplers have been balanced and adjusted – Two RF probes calibrated • Curved Be windows with Ti-N coatings (one is ready now, two are underway) will be ready for high power tests • High power test plans being developed • Problems we had with cavity ports are not an issue for MICE Collaboration Meeting at RAL October 22 ~ 24, 2005 201 MHz Cavity Status Derun Li 19