407f3d7b97b05ded395d36ac8e180154.ppt

- Количество слайдов: 94

© 2008 BPM Microsystems Confidential and Proprietary

BPM Overview March 2010

Mission To Make It Easy For Our Customers Globally To Program Semiconductors With The Highest Quality At A Competitive Cost Per Device. © 2008 BPM Microsystems Confidential and Proprietary

What Is Device Programming? A device programmer is electronic equipment that gives the user the ability to program a custom data pattern into a programmable semiconductor device. This data, tells the otherwise standard chip, how to react with output signals when certain input signals occur. Data is transferred from a device programmer to the chip through the generation of an electronic signal. The timing and duration of this signal is dictated by the manufacturer of the semiconductor device and matches the characteristics of that particular device. © 2008 BPM Microsystems Confidential and Proprietary

What is a Device Programmer? Ø Device Programmer —A tool that gives the user the ability to program a set of data into a programmable memory device v. Programmer v. Socket module interface v. Algorithm (software program by BPM) v. Data pattern (supplied by customer) © 2008 BPM Microsystems Confidential and Proprietary

BPM Microsystems Overview Ø Founded in 1985 Ø The Leader in Device Programming Solutions Ø Largest Installed base of off-line vision-based automated programming systems Ø Headquarters - Houston, Texas USA Ø Global support with sales and service in 42 countries Ø 100% Dedicated to Device Programming Ø Intellectual Property Consists of both Hardware and Software Ø “Universal” Support for over 28, 000 devices Ø Support for over 148 semiconductor manufacturers © 2008 BPM Microsystems Confidential and Proprietary

BPM Microsystems Overview Ø Known for providing high quality, feature-rich programming solutions Ø Proven track record of product longevity Ø Historically embraced core technology upgrade path Ø Support for critical programming applications, military, aerospace, automotive, consumer, and commercial Ø Bad Block Management Expertise Ø Process Driven Organization Ø All development activities in USA Ø Do not compete in the low end market © 2008 BPM Microsystems Confidential and Proprietary

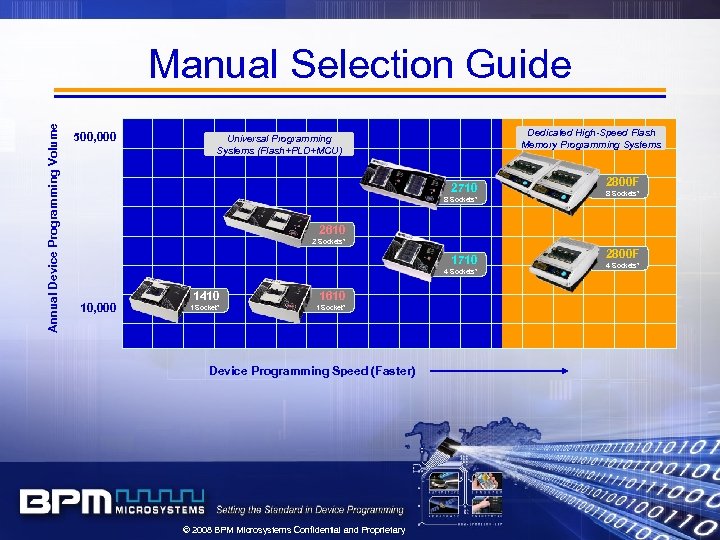

Annual Device Programming Volume Manual Selection Guide 500, 000 Dedicated High-Speed Flash Memory Programming Systems Universal Programming Systems (Flash+PLD+MCU) 2710 8 Sockets* 2800 F 8 Sockets* 2610 2 Sockets* 1710 4 Sockets* 10, 000 1410 1610 1 Socket* Device Programming Speed (Faster) © 2008 BPM Microsystems Confidential and Proprietary 2800 F 4 Sockets*

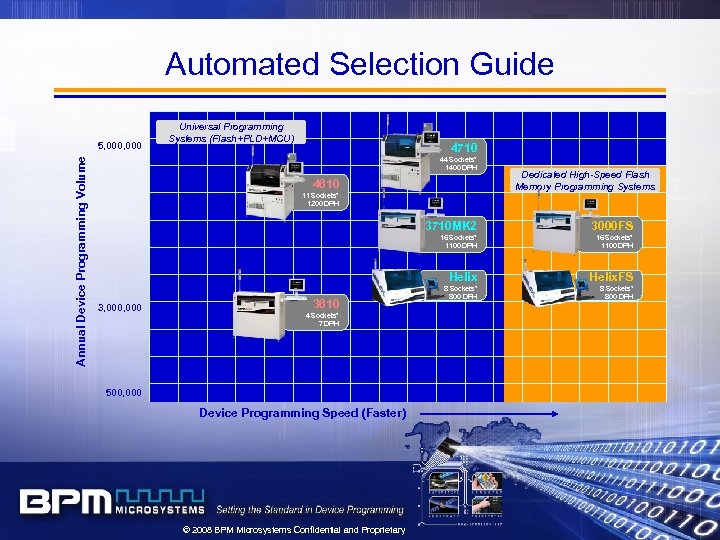

Automated Selection Guide Annual Device Programming Volume 5, 000 Universal Programming Systems (Flash+PLD+MCU) 4710 44 Sockets* 1400 DPH 4610 11 Sockets* 1200 DPH Dedicated High-Speed Flash Memory Programming Systems 3710 MK 2 3610 4 Sockets* 7 DPH 500, 000 Device Programming Speed (Faster) © 2008 BPM Microsystems Confidential and Proprietary 16 Sockets* 1100 DPH Helix 3, 000 3000 FS 16 Sockets* 1100 DPH Helix. FS 8 Sockets* 800 DPH

Recent Industry Awards (1) Ø Global Technology Award – Global SMT & Packaging Magazine v 2007 – Flashstream Technology v 2006 – Helix Automated Programming System v 2005 – Enhanced 7 th Generation Technology Ø SMT Vision Award – SMT Magazine v 2008 – Flashstream Technology v 2006 – Helix Automated Programming System © 2008 BPM Microsystems Confidential and Proprietary

Recent Industry Awards (2) Ø Customer Service Excellence Award – Circuits Assembly Magazine v 2008 – Best customer service v 2007 – Best customer service Ø Innovation Award – Electronics Manufacturing Asia v 2008 – Flashstream Technology v 2007 – Helix Automated Programming System v 2006 - Enhanced 7 th Generation Technology © 2008 BPM Microsystems Confidential and Proprietary

Keywords Ø Bits & Bytes Ø Type of programmable devices v. Memories (PROM, EEPROM, Flash EPROM) v. PLD’s (Programmable Logic Devices) (simple and complex) PAL’s, GAL’s, FPGA’s v. Microcontrollers © 2008 BPM Microsystems Confidential and Proprietary

Device Architectures Ø Programmable Logic Device (PLD) v. Includes such types as PAL, GAL, CPLD, FPGA, anti-fuse Ø Memory Devices (non-volatile memory) v. PROM, EEPROM, NAND flash, NOR flash, serial flash Ø Microcontrollers (MCU) v. A low cost computer on a chip © 2008 BPM Microsystems Confidential and Proprietary

Algorithms • Algorithms certified by semihouses • Algorithms released approximately every 6 weeks • Interim releases on website (www. bpmicro. com) • All algorithms written in proprietary Device Programming Language (DPL) • Because all of our programmers use DPL we are able to instantly support existing algorithms on new products (unlike other 3 rd party programmers who must start over writing new algorithms whenever they introduce new products) © 2008 BPM Microsystems Confidential and Proprietary

Global Company Global Sales and Service © 2008 BPM Microsystems Confidential and Proprietary

Who Are Potential Customers? Ø OEM, ODM Companies Ø Contract Manufacturers Ø Component Distributors Ø Programming Centers Ø PCB Rework Suppliers © 2008 BPM Microsystems Confidential and Proprietary

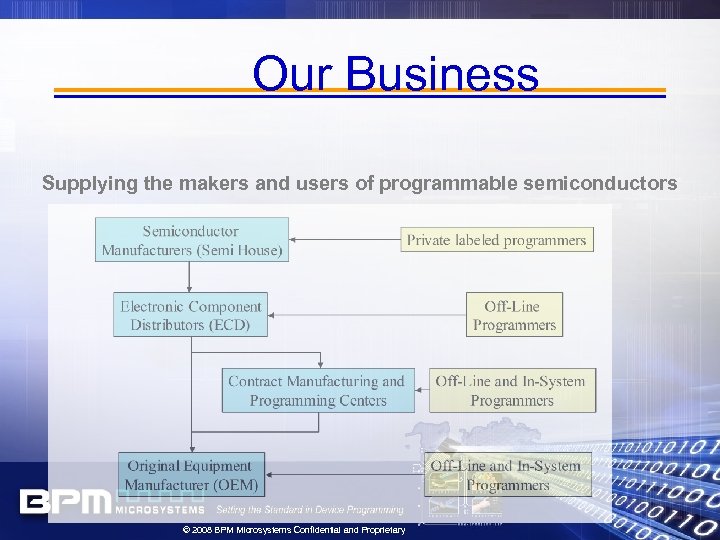

Our Business Supplying the makers and users of programmable semiconductors © 2008 BPM Microsystems Confidential and Proprietary

Customers Worldwide v Continental (formerly Motorola) v Scientific Atlanta v Philips v Siemens v Sang. Fei v Avnet v Action Circuits v Panasonic v Sanmina-SCI v Source Electronics v Ericsson v EDC AB Sweden v Alcatel v Bosch v Teklution v Systemation v UEC v APS v Nokia v Whelen Engineering v Actel A&J Programming v Nvidia v General Electric v Textron Defense Systems v ISI v v Solectron v Jabil v Macnica v Pantech v Flextronics v Maxon © 2008 BPM Microsystems Confidential and Proprietary v Arrow Electronics v E-Pro v Delphi Delco v Rood Technology v LG Electronics v Elcoteq v Elmitec v All American v Pan. Tech v Finmek v ADS v Alltemated v TRW v Integrated Systems v. Chamberlain Group v Telford v Epic Technologies v Textron Defense v Proex v Premier Semiconductor

Market Trends © 2008 BPM Microsystems Confidential and Proprietary

Trends in Electronics Industry Ø Increasing amounts of programmable chips on each PCB Ø Increasing attention on cost cutting Ø More lead-free components being used. Ø More Flash Memory being used in all applications Ø More MCU’s and Flash Memory being used in Automotive electronics (over 50 programmable devices on average per automobile) © 2008 BPM Microsystems Confidential and Proprietary

Trends in Device Programming Ø Lead free devices have caused socket life issues Ø Moore’s Law = device density and complexity doubles every 18 months Ø End products are becoming smarter requiring more chips per product Ø JTAG is falling out of favor due to total cost of implementation Ø Package proliferation – manufacturers using unique packages to deter “drop-in” replacement by competition. Ø Securing chip data patterns is increased concern due to intellectual property theft. © 2008 BPM Microsystems Confidential and Proprietary

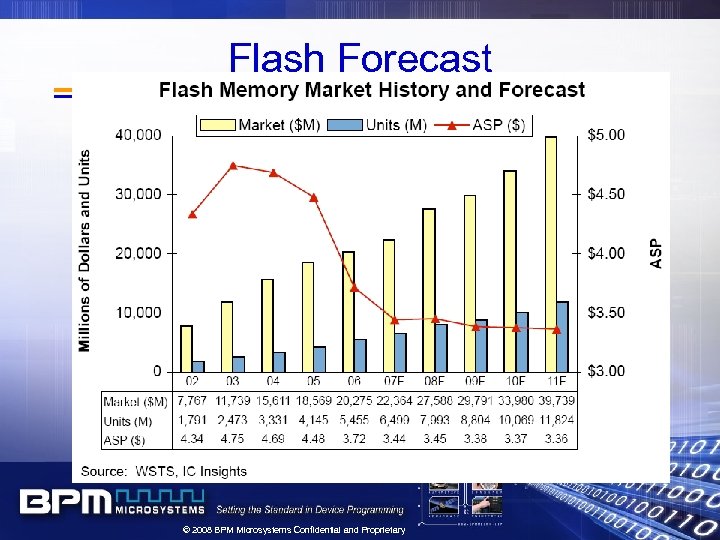

Flash Forecast © 2008 BPM Microsystems Confidential and Proprietary

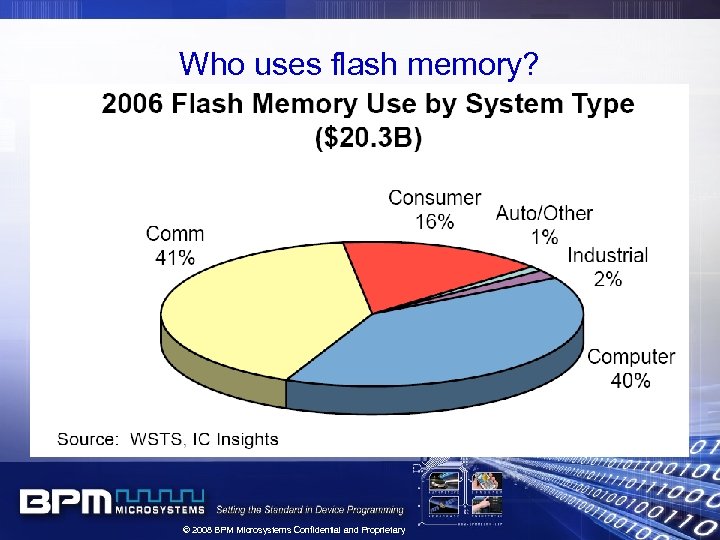

Who uses flash memory? © 2008 BPM Microsystems Confidential and Proprietary

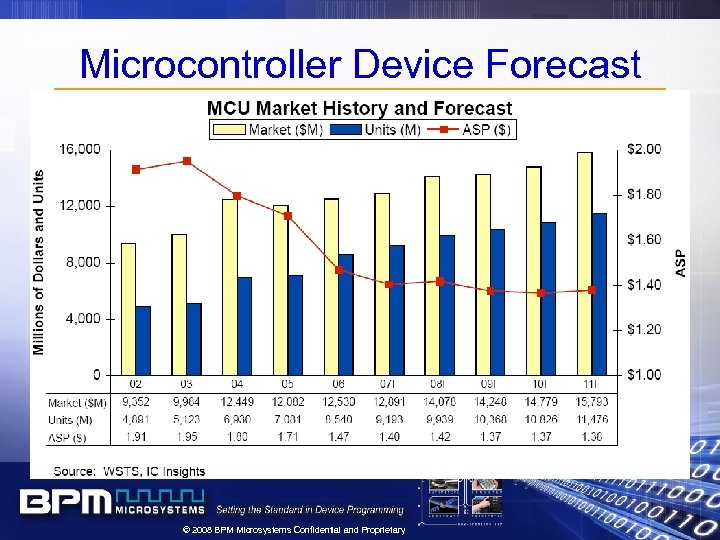

Microcontroller Device Forecast © 2008 BPM Microsystems Confidential and Proprietary

Product Offering Engineering Programmers Concurrent Programmers © 2008 BPM Microsystems Confidential and Proprietary Automated Programmers

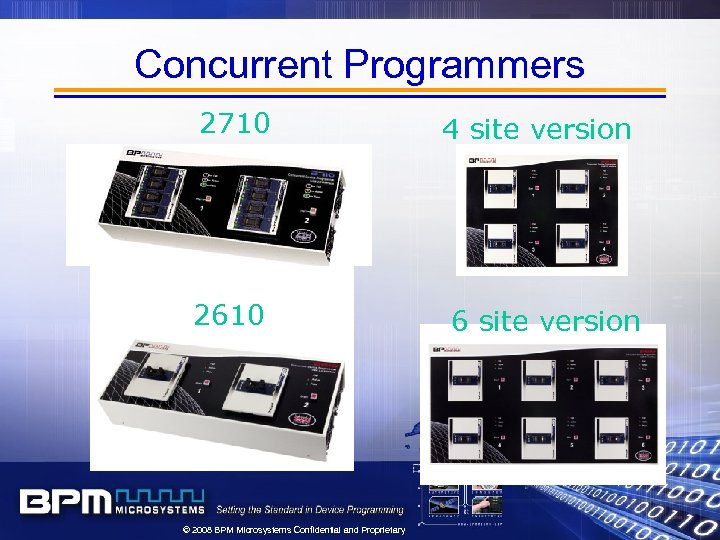

Concurrent Programmers 2710 2610 © 2008 BPM Microsystems Confidential and Proprietary 4 site version 6 site version

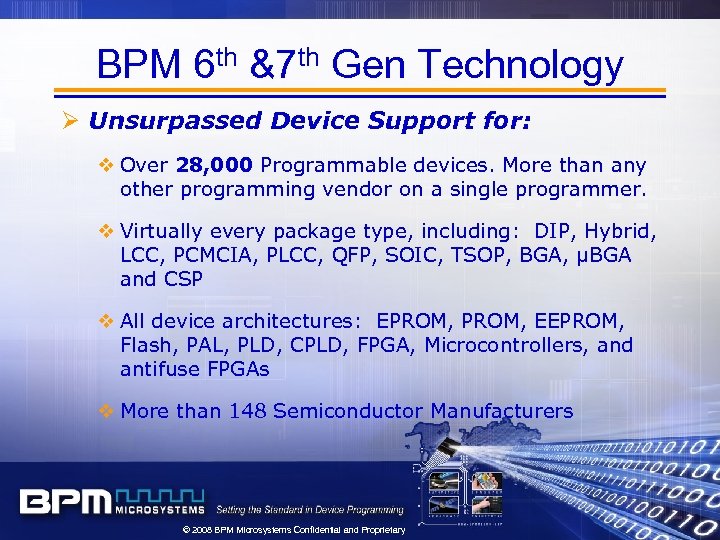

BPM 6 th &7 th Gen Technology Ø Unsurpassed Device Support for: v Over 28, 000 Programmable devices. More than any other programming vendor on a single programmer. v Virtually every package type, including: DIP, Hybrid, LCC, PCMCIA, PLCC, QFP, SOIC, TSOP, BGA, µBGA and CSP v All device architectures: EPROM, EEPROM, Flash, PAL, PLD, CPLD, FPGA, Microcontrollers, and antifuse FPGAs v More than 148 Semiconductor Manufacturers © 2008 BPM Microsystems Confidential and Proprietary

Flashstream Ø Fastest flash programmer on the planet Ø Fastest payback in the industry Ø Fastest way to capture your competitors’ market share! © 2008 BPM Microsystems Confidential and Proprietary

Vector Engine Technology Ø Tester derived technology platform Ø Faster speeds achieved through synchronous operation Ø In most cases, programs at theoretical limits of the silicon design, the faster the device is programmed Ø Provides the lowest possible programming overhead compared to theoretical minimum © 2008 BPM Microsystems Confidential and Proprietary

Vector Engine Technology Ø Utilizes proprietary co-processor design to hardware accelerate flash memory waveforms Ø Programs up to 64 Mbits per second NAND Ø Enables peak verify bandwidth at 800 Mb/s (20 ns cycle) on 4 devices simultaneously Ø Flexible to support future devices © 2008 BPM Microsystems Confidential and Proprietary

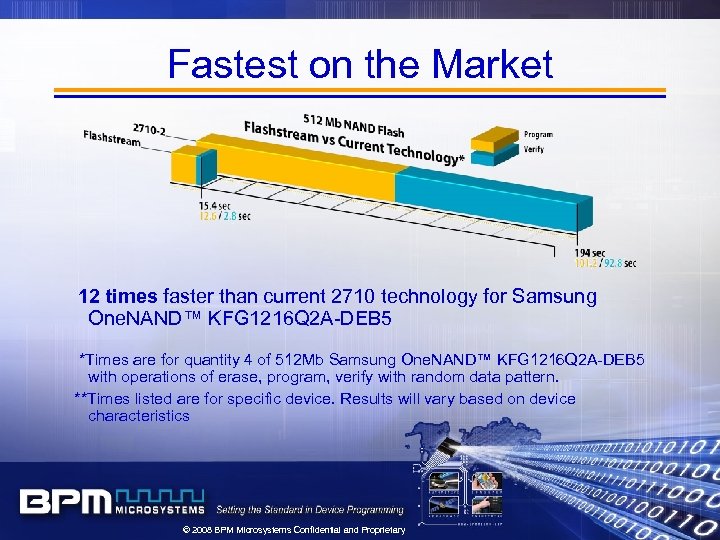

Fastest on the Market 12 times faster than current 2710 technology for Samsung One. NAND™ KFG 1216 Q 2 A-DEB 5 *Times are for quantity 4 of 512 Mb Samsung One. NAND™ KFG 1216 Q 2 A-DEB 5 with operations of erase, program, verify with random data pattern. **Times listed are for specific device. Results will vary based on device characteristics © 2008 BPM Microsystems Confidential and Proprietary

Flashstream vs the Competition Ø Average programming time on Flashstream compared directly to nearest competitor: v. NAND flash memory - over 5 times faster v. Serial flash memory - over 9 times faster v. NOR flash memory - over 1. 6 times faster © 2008 BPM Microsystems Confidential and Proprietary

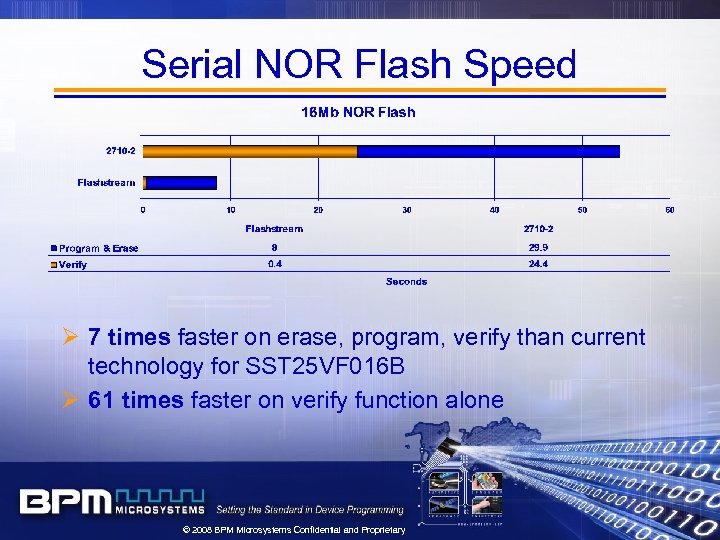

Serial NOR Flash Speed Ø 7 times faster on erase, program, verify than current technology for SST 25 VF 016 B Ø 61 times faster on verify function alone © 2008 BPM Microsystems Confidential and Proprietary

NAND Fastest Times Ø 2 Gb in 31. 1 seconds Ø 1 Gb in 19. 8 seconds Ø 512 Mb in 11. 1 seconds ØTimes include 100% of chip programmed on 4 sockets © 2008 BPM Microsystems Confidential and Proprietary

Flashstream Technology Ø NOR, Serial Flash and NAND Ø Managed NAND: movi. NAND, e-MMC, i. NAND, e. SD, e. MMC Ø Architecture and Software common to Manual and Automated systems Ø Scalable, Fault Tolerant Design independent memory, power, processor per site Ø Bad Block Management Scheme Ø Standard support up to 32 Gb + expandable in the future Ø Low voltage support Ø USB 2. 0 for Fast Download times and first part pass Ø Share. BP files worldwide with BPWin © 2008 BPM Microsystems Confidential and Proprietary

BPM Automated Programming Solutions Ø Chosen Worldwide by Leading ü ü OEMs Distributors Semiconductor Manufacturers EMS Providers © 2008 BPM Microsystems Confidential and Proprietary

APS Customers Worldwide • Continental • Actel • Philips • Siemens • AOC • Avnet • Action Circuits • Panasonic • Sanmina-SCI • Source Electronics • Ericsson • EDC AB Sweden • Alcatel • Bosch • Teklution • Systemation • UEC • APS • Nokia • Whelen Engineering • Scientific Atlanta A&J • Nvidia • General Electric • Textron Defense Systems • ISI • • Solectron • Jabil • Macnica • Pantech • Flextronics • Maxon © 2008 BPM Microsystems Confidential and Proprietary • Arrow Electronics • E-Pro • Delphi Delco • Rood Technology • LG Electronics • Elcoteq • Elmitec • All American • Pan. Tech • Finmek • ADS • Alltemated • TRW • Integrated Systems • Chamberlain Group • Telford • Epic Technologies • Textron Defense • Proex • Premier Semiconductor

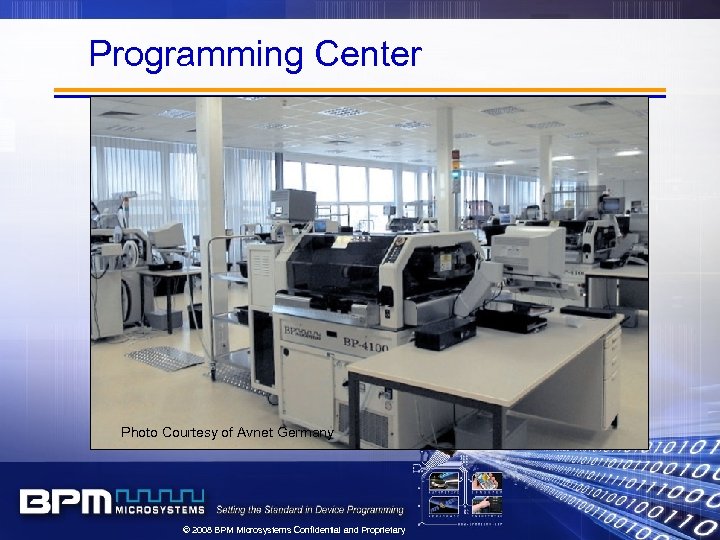

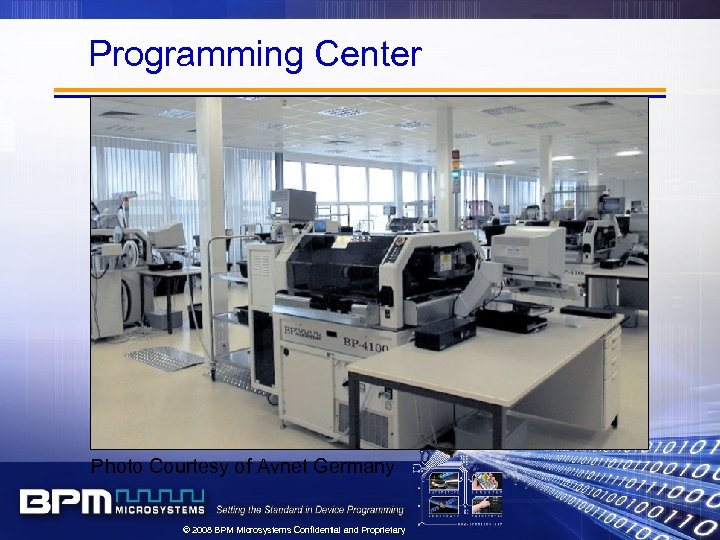

Programming Center Photo Courtesy of Avnet Germany © 2008 BPM Microsystems Confidential and Proprietary

Advantages of Off-Line Programming Ø Off-Line vs In-Line v Single high-speed off-line machine can support multiple production lines, reducing programming cost per device v Off-line programming reduces the chance of defective devices getting into the SMT process. v Programming time isolated from SMT production rate unlike in-line programming v Off-line programming will not dictate line beat rate if capacity and utilization are balanced v Rapid changeover and tightly managed version control v Ideal for multiple devices packages or types v Fault tolerant design for greatest uptime v “Instant” Capacity via Outsource or Manufacturing partners © 2008 BPM Microsystems Confidential and Proprietary

Advantages of Off-Line Programming (2) Ø Ø Reduces component inventory compared to outsourcing Minimizes rework compared to outsourcing Eliminate transit time compared to outsourcing External experts are responsible for algorithm development, maintenance and changes to meet current semiconductor spec changes Ø Full control of quality process Ø Most flexible solution of all programming methods © 2008 BPM Microsystems Confidential and Proprietary

Off-Line Programming Requirements Ø ROI must justify Capital investment and tooling cost Ø Production Planning Ø Dedicated floor space Ø New process qualification © 2008 BPM Microsystems Confidential and Proprietary

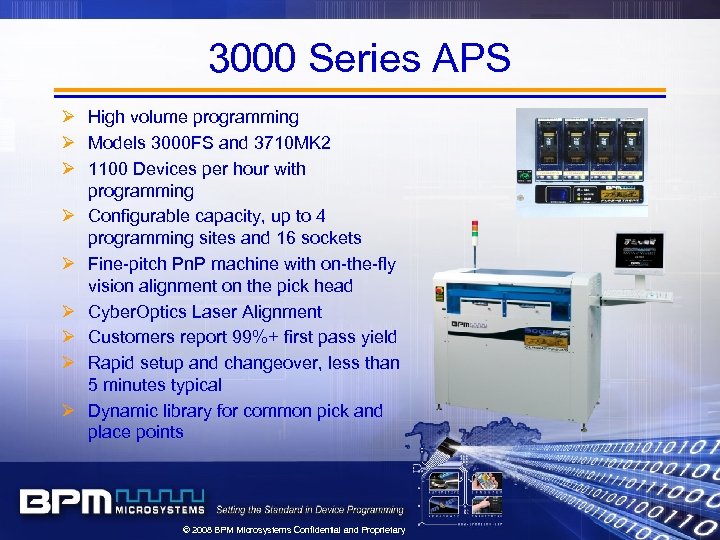

3000 Series APS Ø High volume programming Ø Models 3000 FS and 3710 MK 2 Ø 1100 Devices per hour with programming Ø Configurable capacity, up to 4 programming sites and 16 sockets Ø Fine-pitch Pn. P machine with on-the-fly vision alignment on the pick head Ø Cyber. Optics Laser Alignment Ø Customers report 99%+ first pass yield Ø Rapid setup and changeover, less than 5 minutes typical Ø Dynamic library for common pick and place points © 2008 BPM Microsystems Confidential and Proprietary

3000 FS and 3710 MK 2 APS Ø Fault tolerant programmer site independent processor, memory, and power supply per programming site Ø Site and System Diagnostics Ø Black Box File System Logging Ø Job. Master for consistent job control Ø Operator Mode, Supervisor Mode and Job Protection Mode Ø Individual socket cards for maximum service life and low first article cost Ø Common algorithms and socket cards with APS and manual programmers Ø Job. Master Jobs can be created and shared with APS Job © 2008 BPM Microsystems Confidential and Proprietary

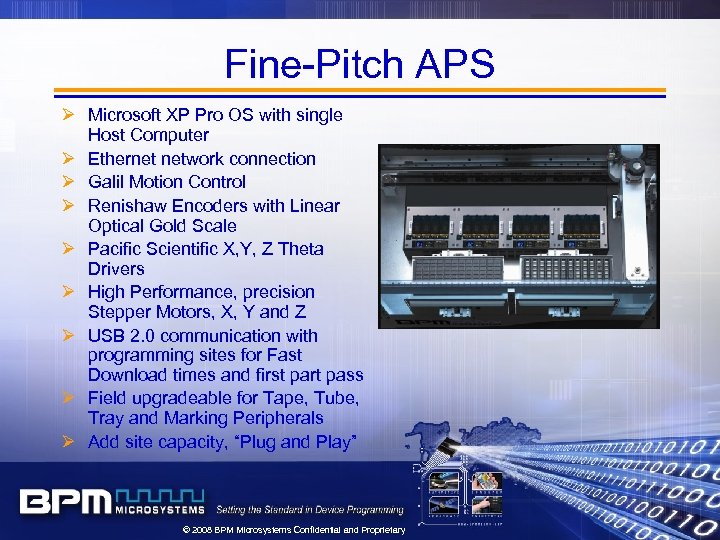

Fine-Pitch APS Ø Microsoft XP Pro OS with single Host Computer Ø Ethernet network connection Ø Galil Motion Control Ø Renishaw Encoders with Linear Optical Gold Scale Ø Pacific Scientific X, Y, Z Theta Drivers Ø High Performance, precision Stepper Motors, X, Y and Z Ø USB 2. 0 communication with programming sites for Fast Download times and first part pass Ø Field upgradeable for Tape, Tube, Tray and Marking Peripherals Ø Add site capacity, “Plug and Play” © 2008 BPM Microsystems Confidential and Proprietary

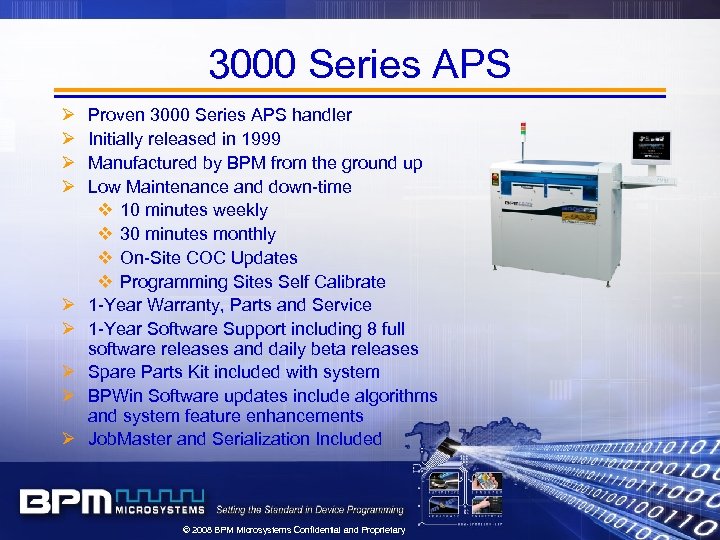

3000 Series APS Ø Ø Ø Ø Ø Proven 3000 Series APS handler Initially released in 1999 Manufactured by BPM from the ground up Low Maintenance and down-time v 10 minutes weekly v 30 minutes monthly v On-Site COC Updates v Programming Sites Self Calibrate 1 -Year Warranty, Parts and Service 1 -Year Software Support including 8 full software releases and daily beta releases Spare Parts Kit included with system BPWin Software updates include algorithms and system feature enhancements Job. Master and Serialization Included © 2008 BPM Microsystems Confidential and Proprietary

Requirements Ø Ø Standard Installation Requirements Voltage: 220 -260 VAC, 50/60 Hz Power Consumption 1 KVA Air Requirements: v 80 psi, 5. 56 bars v 2. 0 SCFM, 50. 1 L/Min Ø Environment: v Range of 13 - 32 Deg C v Relative Humidity 30 -80% v Clean manufacturing environment but “Clean Room” not required. Ø Floor Space Approximately 2 m x 1. 5 m Ø CE Mark Compliant © 2008 BPM Microsystems Confidential and Proprietary

Installation & Training Ø Installation and training completed in 5 business days or less v Day 1, Uncrating and Setup v Day 2, Power up and Testing v Day 3, Testing and Operator Training v Day 4, Operator and Maintenance Training v Day 5, Qualification Testing and Final Acceptance © 2008 BPM Microsystems Confidential and Proprietary

Tray Stacker TS 1500 Ø Exchanges trays providing continuous feeding of parts Ø Hours of unattended operation Ø Holds up to 15 standard JEDEC trays Ø I/O using one TS 1500 Ø Install two TS 1500’s to reduce tray exchange time to zero Ø Compatible with 3000 and 4000 series handlers © 2008 BPM Microsystems Confidential and Proprietary

BPM 4710 APS BPM Model 4710 with 4000 Series CO 2 Series Laser Marker © 2008 BPM Microsystems Confidential and Proprietary Model Programming Site Platform with 11 Universal sites and FX 4 socket modules

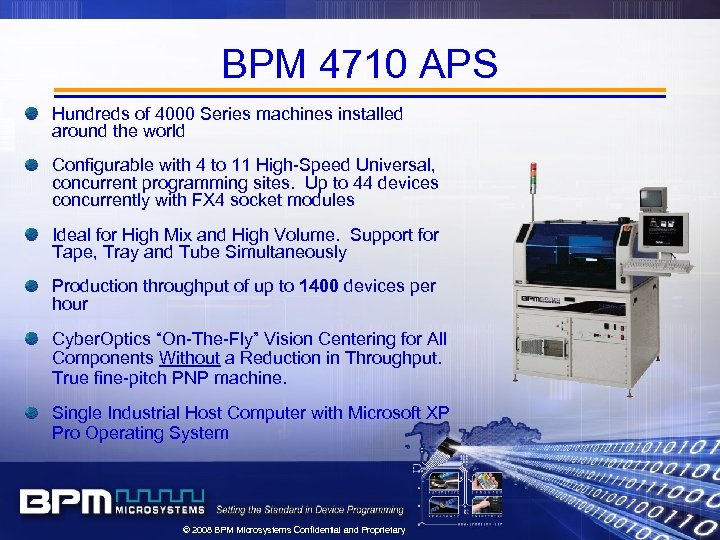

BPM 4710 APS Hundreds of 4000 Series machines installed around the world Configurable with 4 to 11 High-Speed Universal, concurrent programming sites. Up to 44 devices concurrently with FX 4 socket modules Ideal for High Mix and High Volume. Support for Tape, Tray and Tube Simultaneously Production throughput of up to 1400 devices per hour Cyber. Optics “On-The-Fly” Vision Centering for All Components Without a Reduction in Throughput. True fine-pitch PNP machine. Single Industrial Host Computer with Microsoft XP Pro Operating System © 2008 BPM Microsystems Confidential and Proprietary

BPM 4710 APS Universal 7 th Generation programming technology offer virtually the same broad device support as BPM manual programmers, over 25, 000 devices Supports all device technologies: EPROM, EEPROM Flash, PAL, PLD, CPLD, FPGA, Microcontrollers and Antifuse Hundreds of existing automated socket modules available to support most package types including: DIP, SOIC, TSOP, QFP, µBGA, and more New device support and socket modules added continuously Same software used as BPM manual programmers to assure easy transition from prototype to production. Job. Master files shared between manual and automated programmer. Share Automated Socket Modules with manual programming equipment © 2008 BPM Microsystems Confidential and Proprietary

BPM 4710 APS Modular design ensures many years of useful life Unsurpassed Reliability – Many 4000 Series machines operating 10 + years Fast Job setup and changeover time – Less than 5 minutes for existing jobs Configurable design assures unmatched versatility and productivity and therefore the lowest possible Cost Per Device Share Job. Master files with programming centers to instantly increase programming capacity Program and Laser Mark and Tape in a Single Operation – “devices ready for the SMT line” This “industry workhorse” is the ultimate automated fine-pitch programmer © 2008 BPM Microsystems Confidential and Proprietary

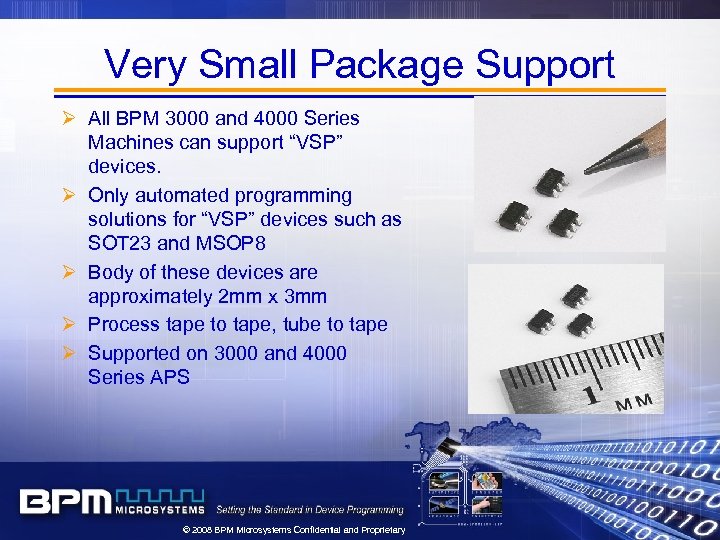

Very Small Package Support Ø All BPM 3000 and 4000 Series Machines can support “VSP” devices. Ø Only automated programming solutions for “VSP” devices such as SOT 23 and MSOP 8 Ø Body of these devices are approximately 2 mm x 3 mm Ø Process tape to tape, tube to tape Ø Supported on 3000 and 4000 Series APS © 2008 BPM Microsystems Confidential and Proprietary

APS Options BPM APS © 2008 BPM Microsystems Confidential and Proprietary

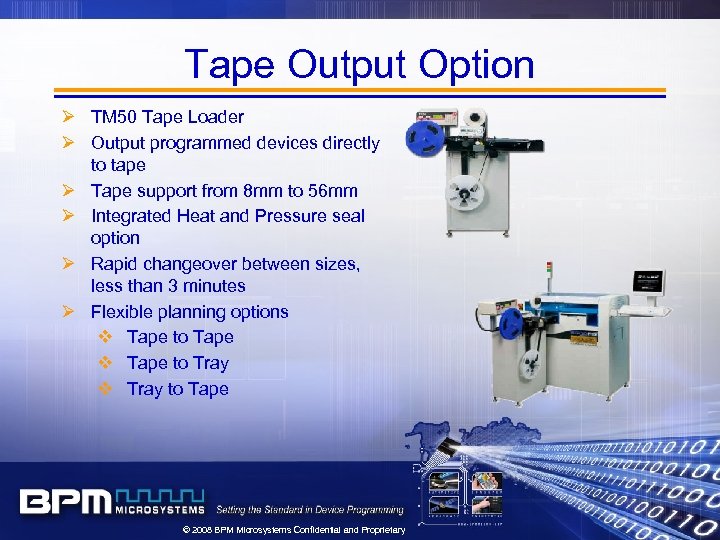

Tape Output Option Ø TM 50 Tape Loader Ø Output programmed devices directly to tape Ø Tape support from 8 mm to 56 mm Ø Integrated Heat and Pressure seal option Ø Rapid changeover between sizes, less than 3 minutes Ø Flexible planning options v Tape to Tape v Tape to Tray v Tray to Tape © 2008 BPM Microsystems Confidential and Proprietary

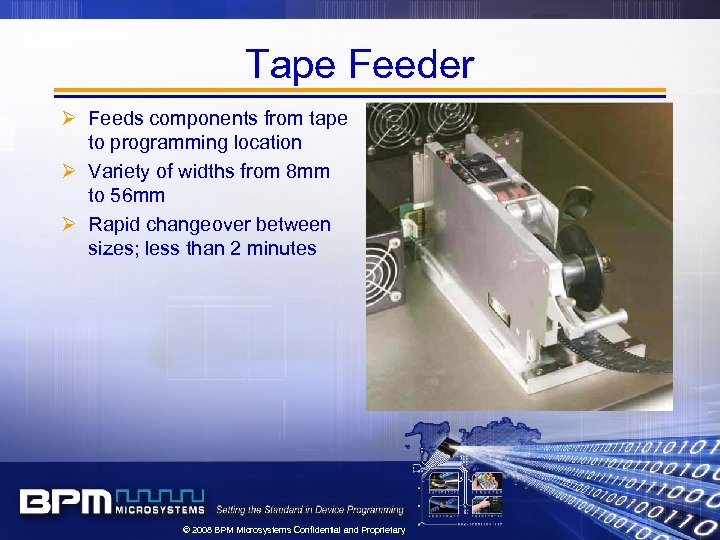

Tape Feeder Ø Feeds components from tape to programming location Ø Variety of widths from 8 mm to 56 mm Ø Rapid changeover between sizes; less than 2 minutes © 2008 BPM Microsystems Confidential and Proprietary

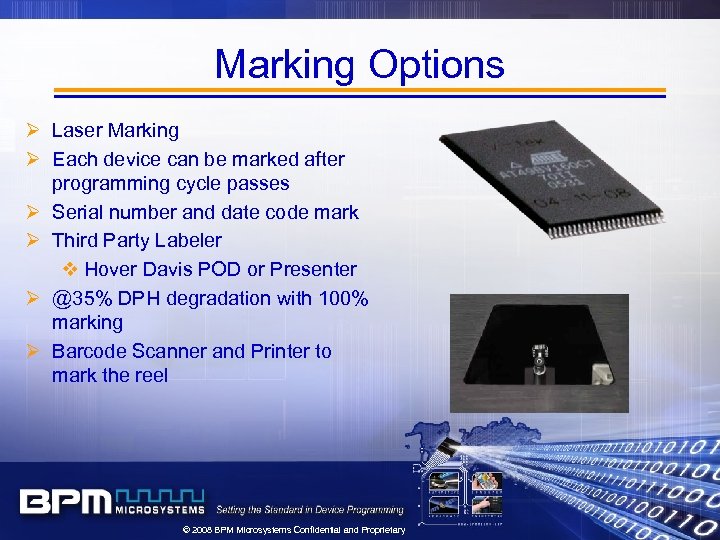

Marking Options Ø Laser Marking Ø Each device can be marked after programming cycle passes Ø Serial number and date code mark Ø Third Party Labeler v Hover Davis POD or Presenter Ø @35% DPH degradation with 100% marking Ø Barcode Scanner and Printer to mark the reel © 2008 BPM Microsystems Confidential and Proprietary

Device Support Ø New support process can range from 2 days to 3 weeks+ Ø Support Process dependent on v Sample availability v Programming Specs v BBM Requirements (NAND) v Socket Availability Ø BPM Device Support Guaranteed Delivery Program v Standard Support Process v Expedited Option v New Devices released daily v Web Requests with automated updates via email © 2008 BPM Microsystems Confidential and Proprietary

Device Support Ø Support Costs v “Free” as part of…. * Software Support Agreement * Strategic Support * Proactive Semihouse Agreements v Fee based $295 + depending upon the complexity Ø Keys to new Device Support v Visibility, Samples, Specs v Open Communication between Customer, BPM, Semihouse v Package and Socket Selection is critical v “Design for programmability” v Bad Block Management Defined Upstream © 2008 BPM Microsystems Confidential and Proprietary

Socket Cards Ø Can program with one, two, three or four socket cards Ø Only single socket card purchase for first article qualification Ø Easy to remove and store with less space Ø Active, Pass and Fail LED status indicators on each individual socket card Ø Auto-start on continuity check option Ø Controlled impedance path for signal integrity © 2008 BPM Microsystems Confidential and Proprietary

Socket Options Ø Burn in test Sockets v Low Cost v Often pre-qualified by semihouse v Reduced Time to Market v Through hole typical Ø High Performance Sockets v 50 K cycles v Surface Mount typical v Favorable Cost/Performance ratio Ø High Insertion Count v 100 K + cycles v Pogo pin contacts v Suitable for high volume/stable design applications © 2008 BPM Microsystems Confidential and Proprietary

Socket Providers Ø Ø Ø Yamaichi Wells CTI 3 M Anteres Comtech Enplas ØHigh Insertion Count Pogo Socket © 2008 BPM Microsystems Confidential and Proprietary

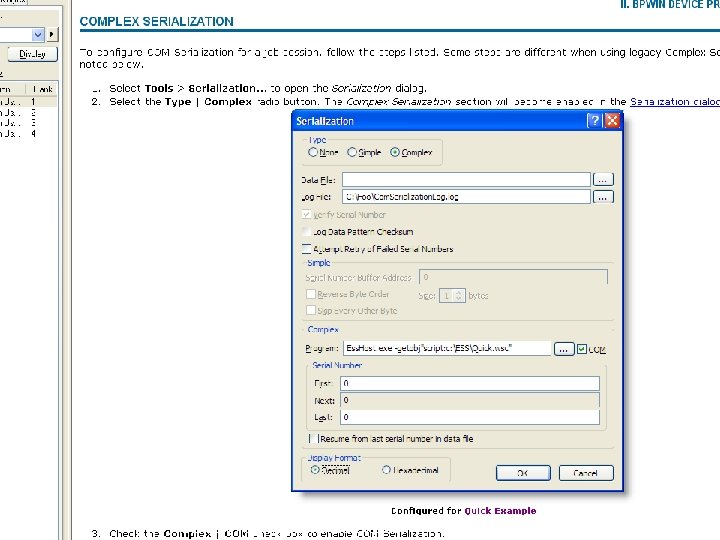

BPWin Software Ø Ø All BPM platforms use standard BPWin software Includes Algorithms and Base Code Auto. Launcher Tool for BPWin revision Control Production Security and Job setup v Operator Mode v Supervisor Mode v Job Protection v Simple Serialization v Complex Com-Serialization v Compatible with MS Windows Account-Based Security Ø Monitor and Control BPWin with API Ø Job. Master for full control of programming jobs Ø 1 year software included, renewed only as needed © 2008 BPM Microsystems Confidential and Proprietary

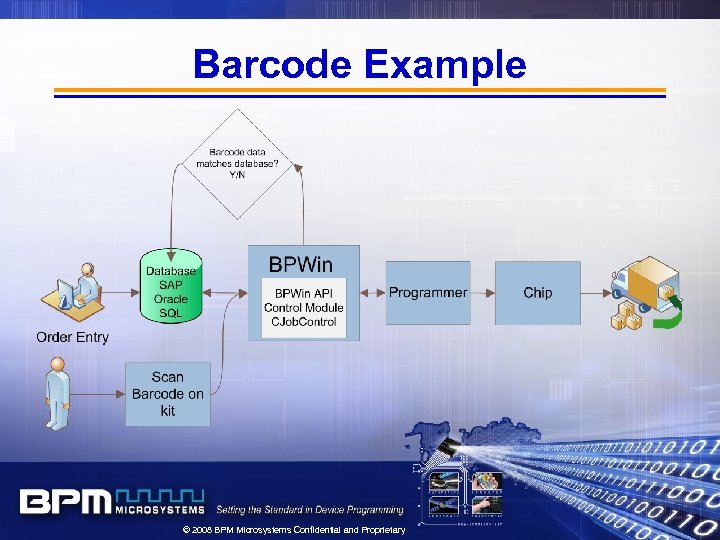

API Job Monitor & Control Ø BPWin API gives customers the ability to control the inputs to all programming equipment and monitor output data Ø BPWin API works with all BPM programming equipment running BPWin © 2008 BPM Microsystems Confidential and Proprietary Courtesy of Action Circuits UK

API Features Ø Language independent API (Labview, C++, Java. Script, C#, VB 6, VB. net, etc…) Ø Ability to interface with any enterprise specific database (SAP, SQL, Excel, or any language supporting COM) Ø Useful for control automation, verification, auditing and logging functions of BPWin Ø Fully integrated, stable and supported with new versions of BPWin software © 2008 BPM Microsystems Confidential and Proprietary

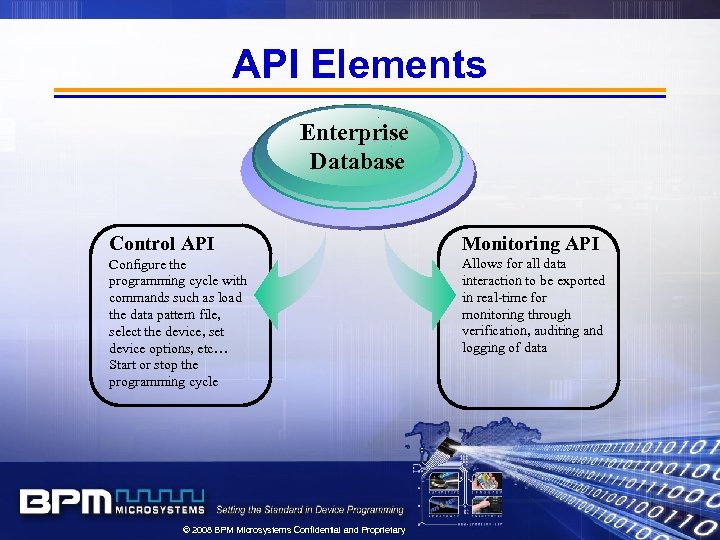

API Elements Enterprise Database Control API Monitoring API Configure the programming cycle with commands such as load the data pattern file, select the device, set device options, etc… Start or stop the programming cycle Allows for all data interaction to be exported in real-time for monitoring through verification, auditing and logging of data © 2008 BPM Microsystems Confidential and Proprietary

Control Applications Ø Automated entry of device configurations and Job Master creation directly from enterprise database eliminating human entry errors. Ø Just in time programming setup without creation of Job. Master files. Ø Mass updating of Job. Master files for global process changes. Ø Integration of tray or reel barcode verify © 2008 BPM Microsystems Confidential and Proprietary

Barcode Example © 2008 BPM Microsystems Confidential and Proprietary

Programming Methods © 2008 BPM Microsystems Confidential and Proprietary

Choices Ø Outsourced programming. v. Offered by component distributors and dedicated programming centers. Ø In-house programming. v. Programming in the same building as the manufacturing process. © 2008 BPM Microsystems Confidential and Proprietary

Programming Center Photo Courtesy of Avnet Germany © 2008 BPM Microsystems Confidential and Proprietary

Outsourced Programming Upside Ø Costs of programming are billed to the job at hand costs do not need to be spread over multiple jobs. Ø Keeps programming quality control out of current quality overhead costs. Ø No capital expenditure or consumable items are needed. Ø Limitations on scrap liability. © 2008 BPM Microsystems Confidential and Proprietary

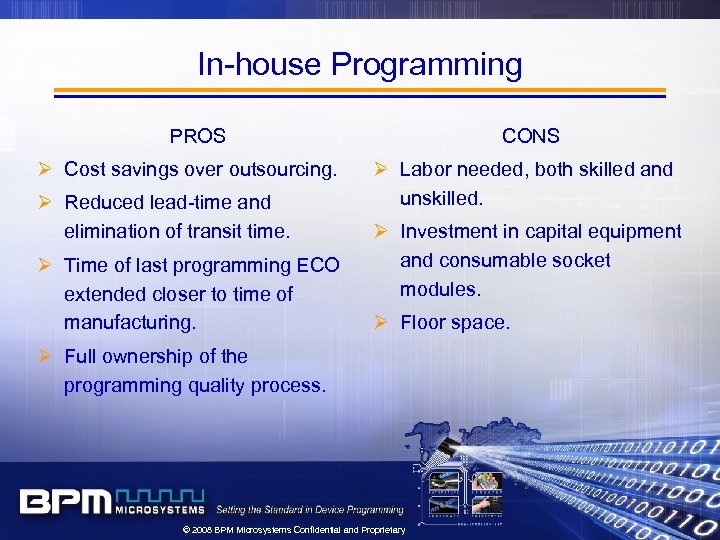

In-house Programming PROS Ø Cost savings over outsourcing. Ø Reduced lead-time and elimination of transit time. Ø Time of last programming ECO extended closer to time of manufacturing. CONS Ø Labor needed, both skilled and unskilled. Ø Investment in capital equipment and consumable socket modules. Ø Floor space. Ø Full ownership of the programming quality process. © 2008 BPM Microsystems Confidential and Proprietary

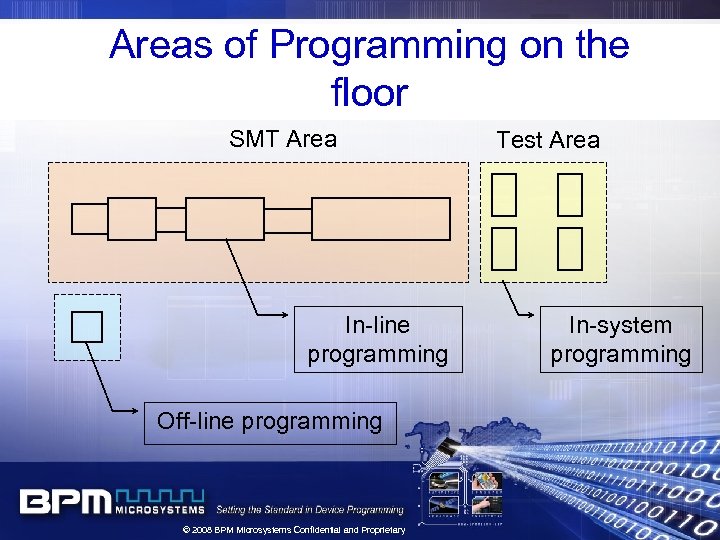

Options for In-house Programming Ø Off-line programming (method of BPM Products) v Devices are programmed prior to solder on the board. Typically done in a specific programming area near the SMT line. Ø In-line programming v The Road Runner product from Data I/O is the only in-line product on the market today. Attaches to two feeder bays on an SMT machine Ø In-system programming v Programming chips after they have been soldered to the board through a JTAG or serial port connection. Ø In-circuit programming v Programming chips after they have been soldered to the board on the board at the bed of nails in-circuit tester. © 2008 BPM Microsystems Confidential and Proprietary

Areas of Programming on the floor SMT Area In-line programming Off-line programming © 2008 BPM Microsystems Confidential and Proprietary Test Area In-system programming

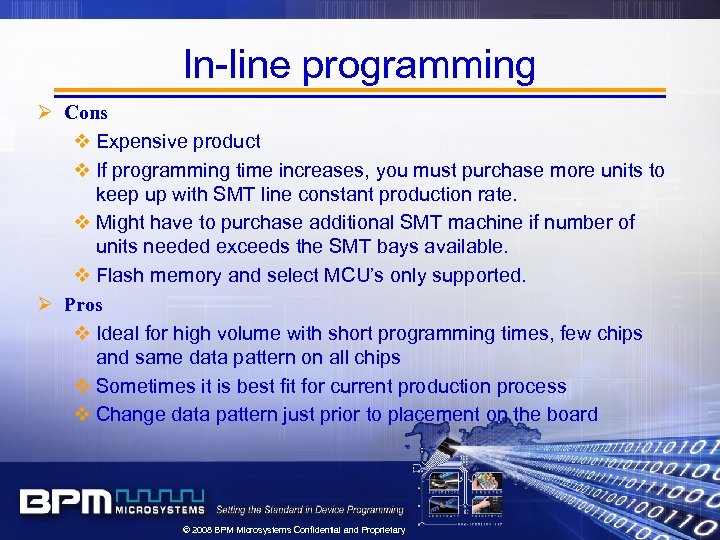

In-line programming Ø Cons v Expensive product v If programming time increases, you must purchase more units to keep up with SMT line constant production rate. v Might have to purchase additional SMT machine if number of units needed exceeds the SMT bays available. v Flash memory and select MCU’s only supported. Ø Pros v Ideal for high volume with short programming times, few chips and same data pattern on all chips v Sometimes it is best fit for current production process v Change data pattern just prior to placement on the board © 2008 BPM Microsystems Confidential and Proprietary

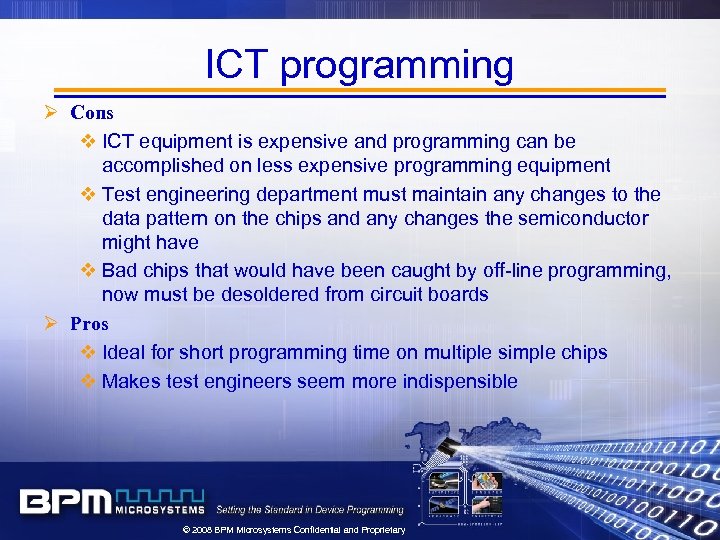

ICT programming Ø Cons v ICT equipment is expensive and programming can be accomplished on less expensive programming equipment v Test engineering department must maintain any changes to the data pattern on the chips and any changes the semiconductor might have v Bad chips that would have been caught by off-line programming, now must be desoldered from circuit boards Ø Pros v Ideal for short programming time on multiple simple chips v Makes test engineers seem more indispensible © 2008 BPM Microsystems Confidential and Proprietary

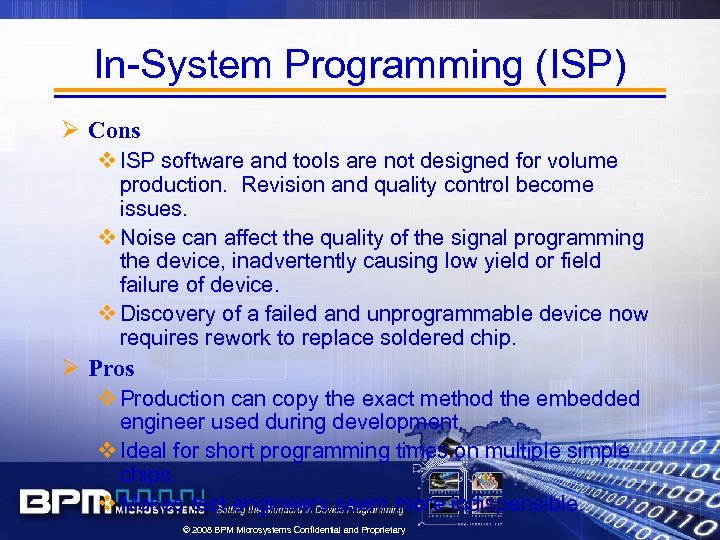

In-System Programming (ISP) Ø Cons v ISP software and tools are not designed for volume production. Revision and quality control become issues. v Noise can affect the quality of the signal programming the device, inadvertently causing low yield or field failure of device. v Discovery of a failed and unprogrammable device now requires rework to replace soldered chip. Ø Pros v Production can copy the exact method the embedded engineer used during development. v Ideal for short programming times on multiple simple chips. v Makes test engineers seem more indispensible. © 2008 BPM Microsystems Confidential and Proprietary

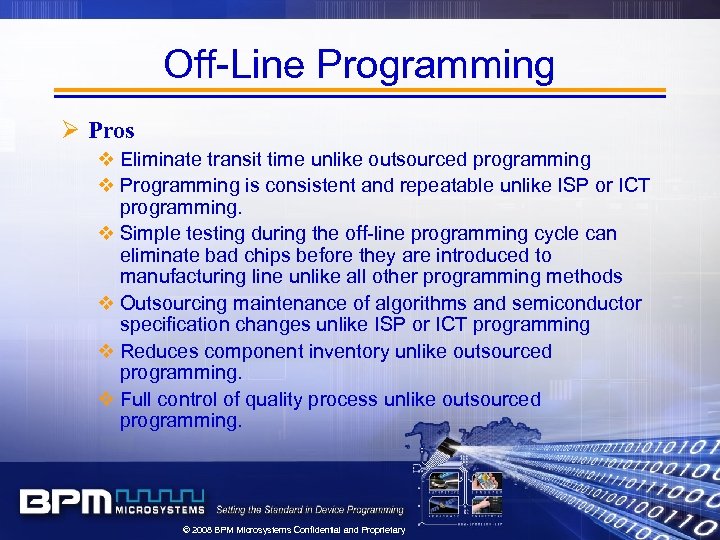

Off-Line Programming Ø Pros v Eliminate transit time unlike outsourced programming v Programming is consistent and repeatable unlike ISP or ICT programming. v Simple testing during the off-line programming cycle can eliminate bad chips before they are introduced to manufacturing line unlike all other programming methods v Outsourcing maintenance of algorithms and semiconductor specification changes unlike ISP or ICT programming v Reduces component inventory unlike outsourced programming. v Full control of quality process unlike outsourced programming. © 2008 BPM Microsystems Confidential and Proprietary

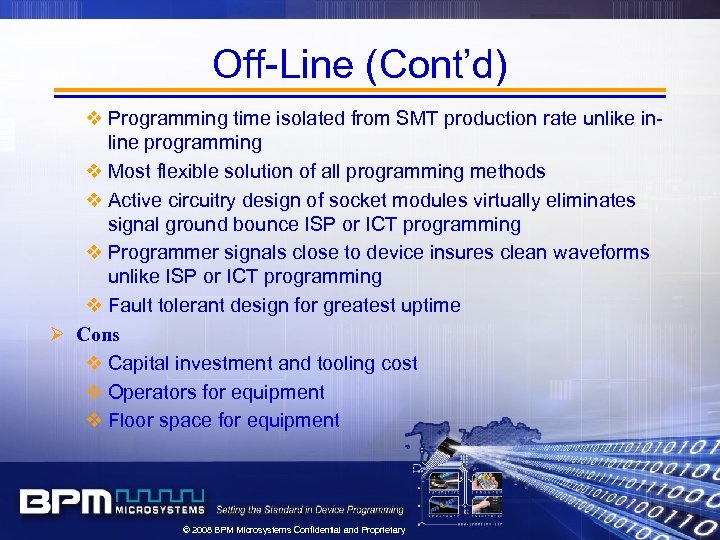

Off-Line (Cont’d) v Programming time isolated from SMT production rate unlike inline programming v Most flexible solution of all programming methods v Active circuitry design of socket modules virtually eliminates signal ground bounce ISP or ICT programming v Programmer signals close to device insures clean waveforms unlike ISP or ICT programming v Fault tolerant design for greatest uptime Ø Cons v Capital investment and tooling cost v Operators for equipment v Floor space for equipment © 2008 BPM Microsystems Confidential and Proprietary

Programming Methods Ø Off-line programming method offers the highest flexibility and lowest cost for device for general programming applications Ø Other methods win only in specialized programming applications. © 2008 BPM Microsystems Confidential and Proprietary

The Issue of Quality in Device Programming © 2008 BPM Microsystems Confidential and Proprietary

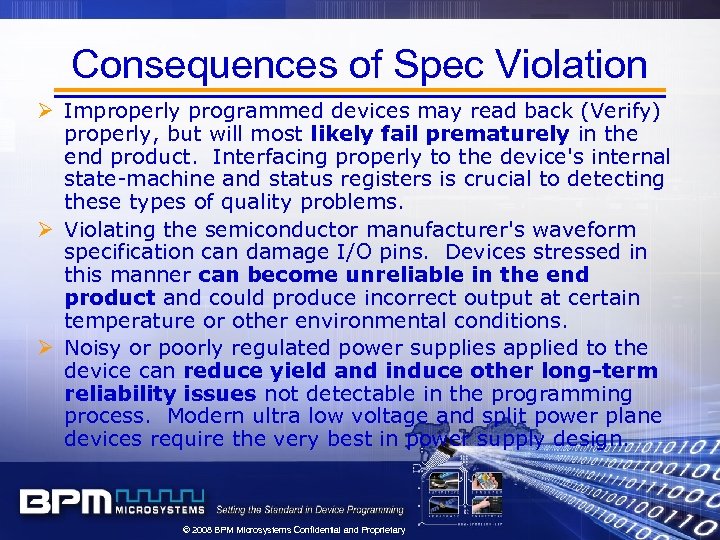

Consequences of Spec Violation Ø Improperly programmed devices may read back (Verify) properly, but will most likely fail prematurely in the end product. Interfacing properly to the device's internal state-machine and status registers is crucial to detecting these types of quality problems. Ø Violating the semiconductor manufacturer's waveform specification can damage I/O pins. Devices stressed in this manner can become unreliable in the end product and could produce incorrect output at certain temperature or other environmental conditions. Ø Noisy or poorly regulated power supplies applied to the device can reduce yield and induce other long-term reliability issues not detectable in the programming process. Modern ultra low voltage and split power plane devices require the very best in power supply design. © 2008 BPM Microsystems Confidential and Proprietary

Results of Spec violation Ø The end result of Spec Violation: v. A lower amount of good and usable programmable devices per programming batch (i. e. low yield) v. Increase in field failures resulting in the end product being returned for repair. Ø Both results are measurable financial burdens to customers. BPM programmers always adheres to the specifications of the semiconductor manufacturers. © 2008 BPM Microsystems Confidential and Proprietary

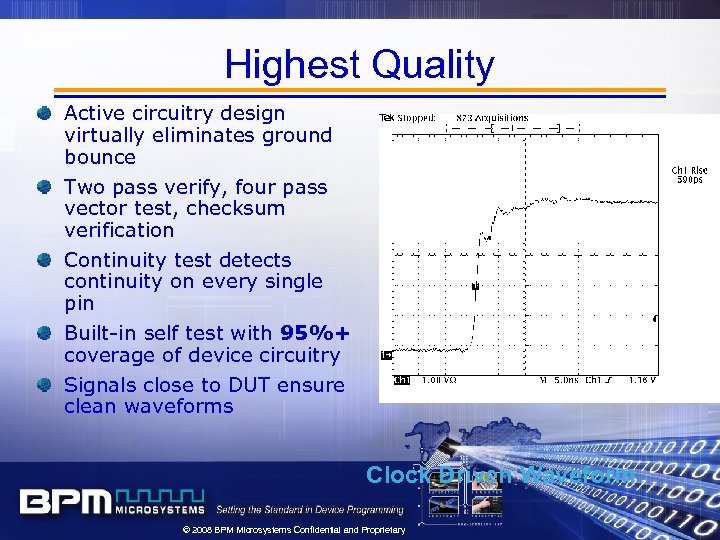

Highest Quality Active circuitry design virtually eliminates ground bounce Two pass verify, four pass vector test, checksum verification Continuity test detects continuity on every single pin Built-in self test with 95%+ coverage of device circuitry Signals close to DUT ensure clean waveforms Clock Driven Waveform © 2008 BPM Microsystems Confidential and Proprietary

Customers Ask… How can a device that passes a verification cycle actually be improperly programmed? A common analogy used to answer this is the final test of an automobile at the factory. If in the final test, the engine’s revolutions per minute go above the red line mark for several minutes, the car still passes its final test and is shipped off and sold. The internal damage would not be visible to the final test performed at the factory. The car would most likely have engine trouble sooner than a car that did not go through the same stress. Devices can be stressed in this same manner if the programming equipment does not follow the exact specification provided by the manufacturer. Ultimately, the importance of quality of device programming depends on the application. At one extreme, might be a child’s toy that is given away in a Happy Meal. You would not expect a field failure in that product to bring much notice. On the other extreme, that same chip might go into a satellite system application. Obviously, the repair on a satellite comes at a much higher cost. All electronic equipment produced falls somewhere in between these two extremes. BPM programming equipment is designed for customers who care about quality. Customers who are not aware or do not value this quality will always find BPM equipment priced higher than they are willing to pay. © 2008 BPM Microsystems Confidential and Proprietary

BPM’s Quality Advantages Ø BPM takes full responsibility of algorithm production and maintenance and guarantees conformance with manufacturers programming specification Ø Change notifications are sent when algorithms are updated or changed. Immediate updates available. Ø Apply signal straight to the chip with less noise and higher yield Ø Bad parts are discarded before solder process which means less rework of boards. © 2008 BPM Microsystems Confidential and Proprietary

RIM –NAND Support © 2008 BPM Microsystems Confidential and Proprietary

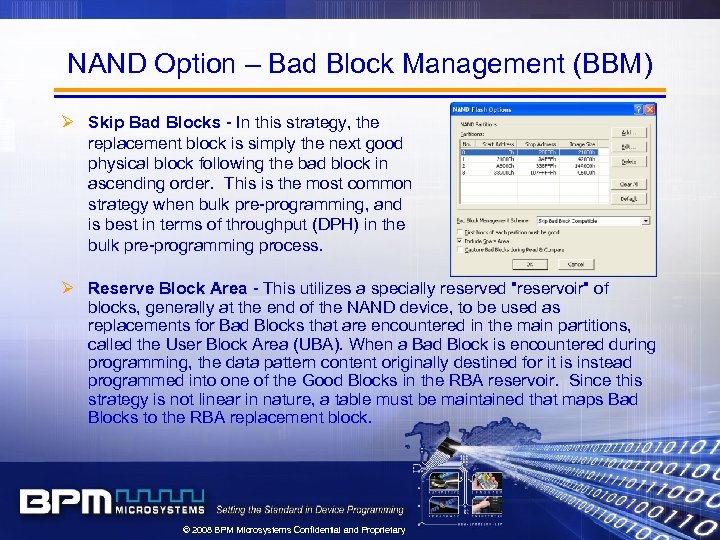

NAND Option – Bad Block Management (BBM) Ø Skip Bad Blocks - In this strategy, the replacement block is simply the next good physical block following the bad block in ascending order. This is the most common strategy when bulk pre-programming, and is best in terms of throughput (DPH) in the bulk pre-programming process. Ø Reserve Block Area - This utilizes a specially reserved "reservoir" of blocks, generally at the end of the NAND device, to be used as replacements for Bad Blocks that are encountered in the main partitions, called the User Block Area (UBA). When a Bad Block is encountered during programming, the data pattern content originally destined for it is instead programmed into one of the Good Blocks in the RBA reservoir. Since this strategy is not linear in nature, a table must be maintained that maps Bad Blocks to the RBA replacement block. © 2008 BPM Microsystems Confidential and Proprietary

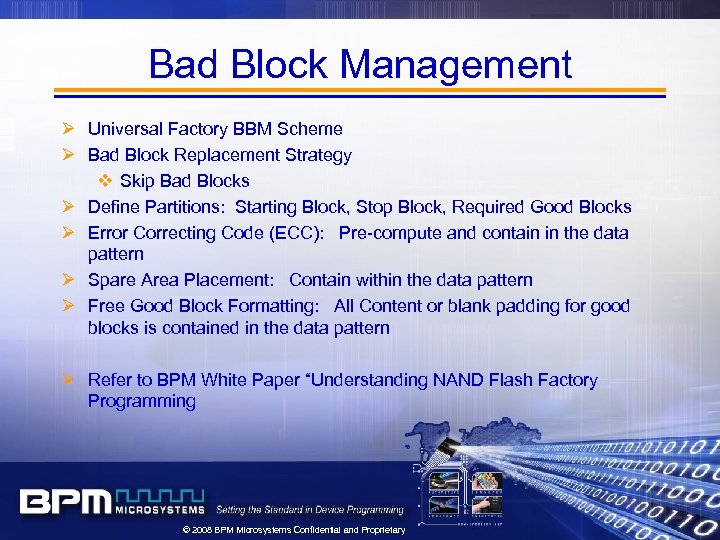

Bad Block Management Ø Universal Factory BBM Scheme Ø Bad Block Replacement Strategy v Skip Bad Blocks Ø Define Partitions: Starting Block, Stop Block, Required Good Blocks Ø Error Correcting Code (ECC): Pre-compute and contain in the data pattern Ø Spare Area Placement: Contain within the data pattern Ø Free Good Block Formatting: All Content or blank padding for good blocks is contained in the data pattern Ø Refer to BPM White Paper “Understanding NAND Flash Factory Programming © 2008 BPM Microsystems Confidential and Proprietary

Why BPM Programming Solutions? Ø Performance v Most Versatile Universal Programming Systems in the World v Highest Performance Flash Memory Platform v One BPM platform may produce more than multiple machines from the competitor Ø Quality and Reliability v All device support is released to the exacting standards of the semiconductor manufacturer v High Quality = High Yield v High Quality = Low Scrap Rate v High Quality = Reduced Rework Ø Return on Investment v High Throughput and Longevity mean lowest total cost per device © 2008 BPM Microsystems Confidential and Proprietary

Why BPM Programming Solutions? Ø Company Stability v BPM is 100% dedicated to device programming v We have the products and expertise to be here long term Ø Protect Intellectual Property IP Security v BPM respects all customer Intellectual Property Ø Establish first or second source Ø Advanced Software Features v Intelligent systems v Easy operator training v Intuitive platform Ø Global Support and Existing Installed Base v Share programming volume with component distributors and programming centers © 2008 BPM Microsystems Confidential and Proprietary

Why BPM Programming Solutions? Ø Ø Ø Ø Ø Performance Return on Investment Company Stability Protect Intellectual Property IP Security Establish first or second source for Advanced Features Global Support Existing Installed Base Complete Solutions for Complex Problems © 2008 BPM Microsystems Confidential and Proprietary

Thank You © 2008 BPM Microsystems Confidential and Proprietary

407f3d7b97b05ded395d36ac8e180154.ppt