005456f191387ac94e4ff3de2d909047.ppt

- Количество слайдов: 69

2007 DOE Biomass Program Review EERC Center for Biomass Utilization® Chris J. Zygarlicke and Bruce C. Folkedahl Energy & Environmental Research Center University of North Dakota August 15– 16, 2007

Overview Time Line • FY 05 project start date October 2005 • 82% complete Budget • Total project funding FY 05 • DOE $992, 000 • Nonfed. Cost Share $350, 000 FY 06 Funded Office of Science FY 07 Request $1, 000 Barriers • Developing and validating technologies for future biorefineries using corn, vegetable and crop oil, agricultural residues, and perennial crop feedstocks. • Overcoming market barriers by detailing end-to-end process integration, risk of pioneer technology, and plant economics through technology demonstration. Partners Stage • See next two slides.

Overview (cont. ) – Partners • • • • Agricultural Utilization Research Institute Ankur Scientific United Soybean Board Technical Crops International North Dakota Corn Utilization/Corn Council Minnesota Corn Growers Association Ensyn Technologies, Inc. City of Grand Forks North Dakota Department of Commerce Division of Community Services Chippewa Valley Ethanol Company ND State Board of Agricultural Research and Education North Dakota Soybean Council University of North Dakota Chemical Engineering Department ND Corn Utilization Council CANSOLV Technologies South Dakota Soybean Research and Promotion Council • Energy & Environmental Research Center • BBI International • Bio-Renewable Group • Fremont Industries Inc. • Initiative for Renewable Energy and the Environment • Pinnacle Engineering • Vidir Biomass Inc. • Wanzek Construction • Zeton Inc. • Great River Energy • Fagen Inc. • MDU Resources Group Inc. • Minnesota Power • North Dakota Department of Agriculture • North Dakota Forest Service • Otter Tail Power Company • Touchstone Energy Cooperatives of North Dakota

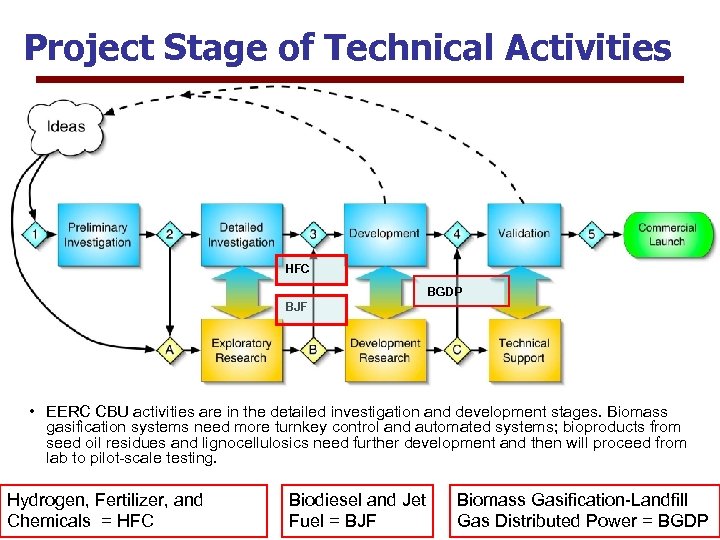

Project Stage of Technical Activities HFC BGDP BJF • EERC CBU activities are in the detailed investigation and development stages. Biomass gasification systems need more turnkey control and automated systems; bioproducts from seed oil residues and lignocellulosics need further development and then will proceed from lab to pilot-scale testing. Hydrogen, Fertilizer, and Chemicals = HFC Biodiesel and Jet Fuel = BJF Biomass Gasification-Landfill Gas Distributed Power = BGDP

Project Goals and Objectives • To develop and promote the use of biomass for production of biopower, biofuels, and bioproducts ü A program with several technical and educational activities ü Not just one research topic

Activities Within EERC CBU – 2005 • Activity 1 – Management and Strategic Studies • Activity 2 – Biomass Gasification and Distributed Power Production • Activity 3 – Novel High-Cetane Oxygenates from Waste Glycerol from Biodiesel Plants • Activity 4 – Utilization of Cuphea Oil for Biodiesel Production • Activity 5 – Process Integration for Economic Hydrogen Production from Ethanol • Activity 6 – Biojet Fuel Cold-Flow Improvement • Activity 7 – Urea Fertilizer Production from Ethanol Coproduct Carbon Dioxide • Activity 8 – Chemical Feedstocks from Lignocellulosic Pyrolysis • Activity 9 – Landfill Methane for Microturbine Power • Activity 10 – Biodiesel Education and Outreach

Approach • • Utilize cash cost share from industry partners for all tasks to not only ensure relevance to marketplace but to enhance the overall investment of DOE in the projects. Illuminate multiple pathways for biomass utilization: – Heat and power production through small-scale biomass gasification. – Novel oil seed feedstock development such as Cuphea oil. – High-value-added bioproducts to replace petroleumderived products such as polyamines and polyamides. – Outreach and education to accelerate market acceptance of bioproducts and technologies.

Activity 2 – Biomass Gasification and Distributed Power Production Goals Publish gas quality data from various biomass fuels such as wood, switchgrass, wheat straw, flax, sunflower hulls, nut shells, and stoker-grade coal. This supports the Biomass R&D Initiative to integrate technology R&D programs to foster a domestic bioindustry producing fuels, products, and power. Objectives Procure gasification system. Install and conduct testing. Publish results in journals and present at a major conference. Scope of Work Task 1 – Procure Gasifier (Task 1 is complete) Task 2 – Installation of Equipment and Data Acquisition (Task 2 is under way) Task 3 – Complete testing Task 4 – Publish – Conference and Journal (Abstract to Power. Gen 07) Expected completion date is December 31, 2007.

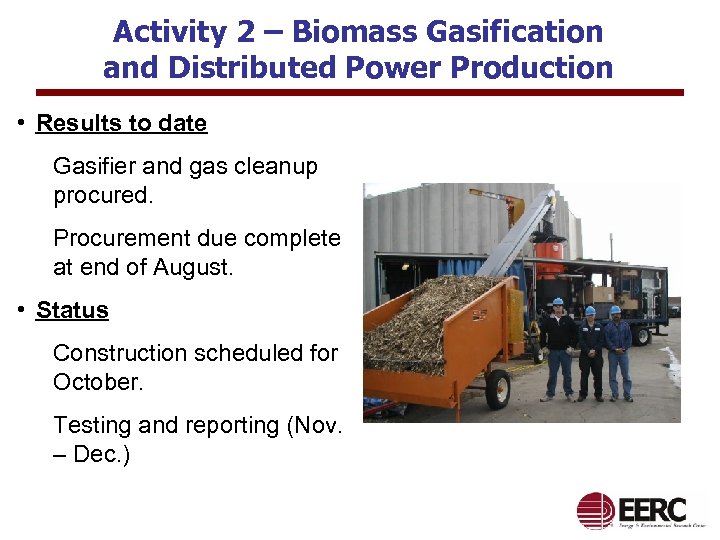

Activity 2 – Biomass Gasification and Distributed Power Production • Results to date Gasifier and gas cleanup procured. Procurement due complete at end of August. • Status Construction scheduled for October. Testing and reporting (Nov. – Dec. )

Activity 3 – Novel High-Cetane Oxygenates from Glycerol from Biodiesel Plants • Goal – Develop a process for converting biodiesel coproduct glycerin to highcetane diesel fuel additives. Additives will be evaluated based on cetane, cold-flow, and other key performance parameters. – Supports DOE plan for reductions in production costs along the biomass supply chain for bio-based fuels and products to effectively compete in these markets Image Source: http: //en. wikipedia. org/wiki/Biodiesel

Activity 3 – Novel High-Cetane Oxygenates from Glycerol from Biodiesel Plants • Objectives – Catalyst development: synthesize a variety of solid acid catalysts and test with pure and impure glycerol in batch initially and subsequently in continuous reactors. – Glycerol (pure and impure) conversion into acetals and subsequently to a variety of acetal esters and ethers in batch and continuous reactors. Cetane and CFP testing of blends. – Optimization of synthesis catalysts and conditions.

Activity 3 – Novel High-Cetane Oxygenates from Glycerol from Biodiesel Plants • Results to date Preparation of target oxygenate candidates for testing. Four samples – structurally different – Conversion of glycerol from biodiesel processes to dioxolane intermediates. – Conversion of dioxolanes to hydrocarbon-soluble oxygenates (three prepared for testing – one more in progress). Status Evaluation to give indications of effect of structure on fuel properties will be completed in October 2007. Blending cetane number and cold-filter plugging point (Both performed by independent testing lab – Magellan Labs. )

Activity 4 – Utilization of Cuphea Oils for Biodiesel Production • Goal – Develop a biodiesel with coldflow properties equivalent to or better than those of petroleum diesel. This supports the DOE feedstock development and utilization goals for diversified feedstocks for biofuels production. • Objectives – Characterize Cuphea oil and Cuphea biodiesel product www. wiu. edu/Alt. Crops/cuphea. htm

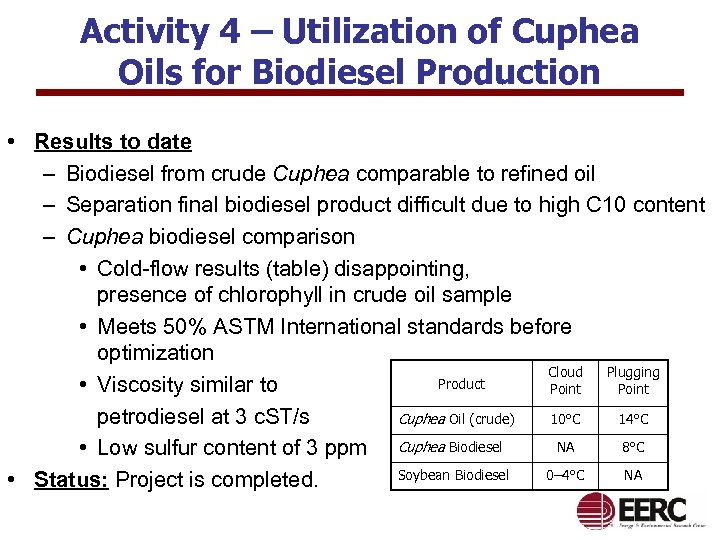

Activity 4 – Utilization of Cuphea Oils for Biodiesel Production • Results to date – Biodiesel from crude Cuphea comparable to refined oil – Separation final biodiesel product difficult due to high C 10 content – Cuphea biodiesel comparison • Cold-flow results (table) disappointing, presence of chlorophyll in crude oil sample • Meets 50% ASTM International standards before optimization Cloud Plugging Product • Viscosity similar to Point petrodiesel at 3 c. ST/s Cuphea Oil (crude) 10°C 14°C NA 8°C • Low sulfur content of 3 ppm Cuphea Biodiesel Soybean Biodiesel 0– 4°C NA • Status: Project is completed.

Activity 5 – Process Integration for Economical Hydrogen Production from Ethanol • • Goal – Demonstrate on a pilot scale the continuous production of a hydrogen gas stream from a partially distilled ethanol product. – This supports the DOE Program’s overarching strategic goal to develop costcompetitive biomass technologies to enable the production of biofuels nationwide and reduce dependence on oil through the creation of a new domestic bioindustry. Objectives – Characterize operational conditions for the various ethanol feedstock alternatives and develop pilot-scale experimental design. – Pilot-scale parametric testing by the EERC and H 2 Gen to evaluate hydrogen production from selected ethanol feedstock and liquid fuels. – Economic analysis of hydrogen production from partially distilled ethanol, fuel-grade ethanol, and other viable feedstocks.

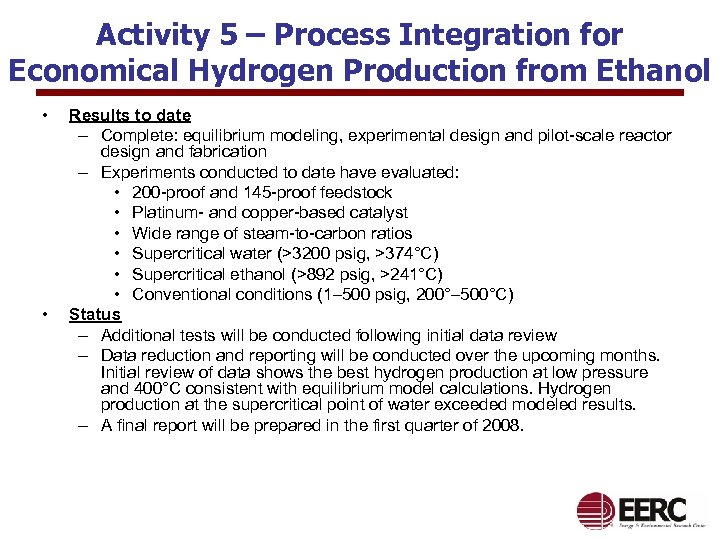

Activity 5 – Process Integration for Economical Hydrogen Production from Ethanol • • Results to date – Complete: equilibrium modeling, experimental design and pilot-scale reactor design and fabrication – Experiments conducted to date have evaluated: • 200 -proof and 145 -proof feedstock • Platinum- and copper-based catalyst • Wide range of steam-to-carbon ratios • Supercritical water (>3200 psig, >374°C) • Supercritical ethanol (>892 psig, >241°C) • Conventional conditions (1– 500 psig, 200°– 500°C) Status – Additional tests will be conducted following initial data review – Data reduction and reporting will be conducted over the upcoming months. Initial review of data shows the best hydrogen production at low pressure and 400°C consistent with equilibrium model calculations. Hydrogen production at the supercritical point of water exceeded modeled results. – A final report will be prepared in the first quarter of 2008.

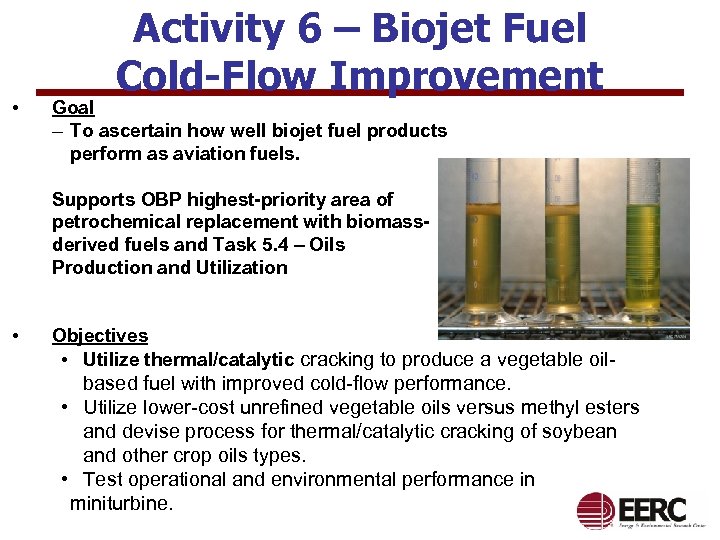

• Activity 6 – Biojet Fuel Cold-Flow Improvement Goal – To ascertain how well biojet fuel products perform as aviation fuels. Supports OBP highest-priority area of petrochemical replacement with biomassderived fuels and Task 5. 4 – Oils Production and Utilization • Objectives • Utilize thermal/catalytic cracking to produce a vegetable oil- based fuel with improved cold-flow performance. • Utilize lower-cost unrefined vegetable oils versus methyl esters and devise process for thermal/catalytic cracking of soybean and other crop oils types. • Test operational and environmental performance in miniturbine.

Activity 6 – Biojet Fuel Cold-Flow Improvement • Results to Date – Purchased and installed microturbine, now being used for fuel evaluation – Generated 15 gallons each of biojet fuel from two different feedstock sources – 0. 6 gallons per day – Cloud point, pour point, flash point, D-86 curves, heating values determined – Unknowns in chemical composition reduced. Over 100 compounds identified. • Status – In-house long-term fuels testing in the microturbine – Extensive corrosion coupon and stability testing – Additional fuels property testing

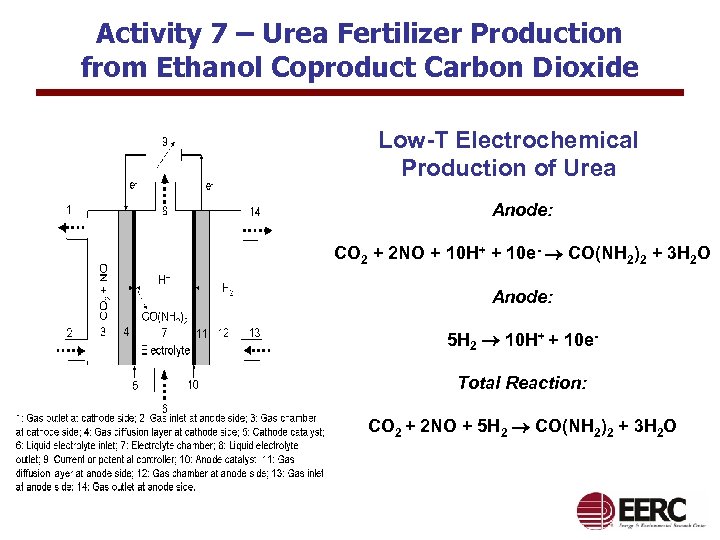

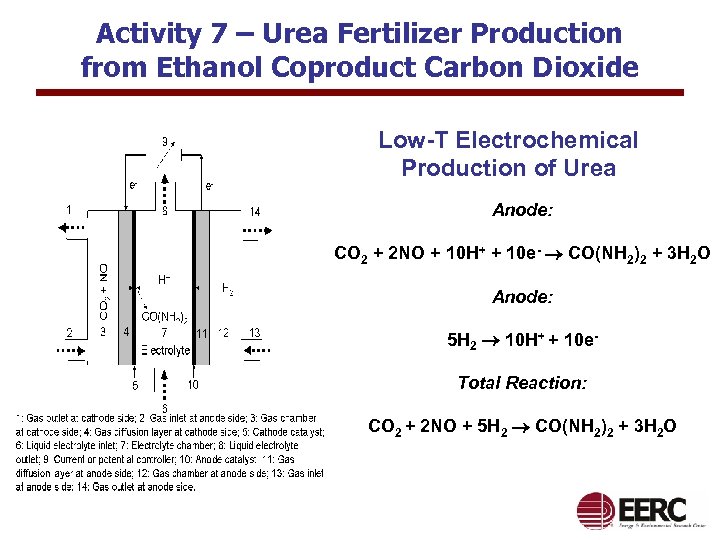

Activity 7 – Urea Fertilizer Production from Ethanol Coproduct Carbon Dioxide Low-T Electrochemical Production of Urea Anode: CO 2 + 2 NO + 10 H+ + 10 e- CO(NH 2)2 + 3 H 2 O Anode: 5 H 2 10 H+ + 10 e. Total Reaction: CO 2 + 2 NO + 5 H 2 CO(NH 2)2 + 3 H 2 O

Activity 7 – Achievements • Demonstrated urea production at room temperature and atmospheric pressure, which is characterized by a product composition comprising approximately 70% ammonia and 30% urea with a total current efficiency of around 80% under the optimized conditions. • Prepared draft provisional patent. • Proposed a mechanism for the formation of urea and coproduct ammonia and developed strategies to improve urea selectivity. • Proposed a novel electrochemical approach to directly produce solid urea without the need of costly purification. • Completed preliminary economy analysis for the urea process. • Completed the final report.

Activity 8 – Chemical Feedstocks from Lignocellulosic Pyrolysis Bio-Oil • Goal – Produce and evaluate bioproducts from pyrolysis oils to supplant petroleum-derived products. Supports DOE goal of biorefinery bioproducts technology advancement. • Objectives – Using hydroxyacetaldehyde (HA) extracted from commercial bio-oil provided by project partner Ensyn Renewables, produce and evaluate polyamines and polyamides potential for application in enhanced oil recovery (EOR). • Results to date – Polyamines and polyamides produced from bio HA – Demonstrated on the bench scale the technical viability of using HAderived polymers to mediate the viscosity of aqueous “polymer flooding” solutions in EOR applications. Status: Complete.

Activity 9 – Landfill Methane for Microturbine Power • Goal – Evaluate the Grand Forks landfill site for gas production, and determine the most cost-effective and efficient method to prepare the gas for microturbine use. – Publish results, provide an economic case study, and provide an educational tool for university students. • Objectives – Assessment of the landfill site for gas production. – Develop a methane gas observation well profile and characterize the gas. – Investigate more cost-effective, efficient, and aggressive means to prepare the gas for microturbine use (moisture, siloxane, and nonmethane gas removal). – Develop and deliver the overall return-on-investment for this system.

Activity 9 – Landfill Methane for Microturbine Power • Results – 2. 4 to 2. 5 M tons of waste currently in place (3. 4 M tons projected by 2009) – 400 to 600 scfm gas production potential for the site – 1. 5 - to 2. 0 -MW gross power generation capacity for the total gas flow – 1. 0 - to 1. 5 -MW net power generation after parasitic loads – 7. 0 to 10. 5 MWh annual electricity generation potential assuming 80% annual capacity factor • Status – Project complete

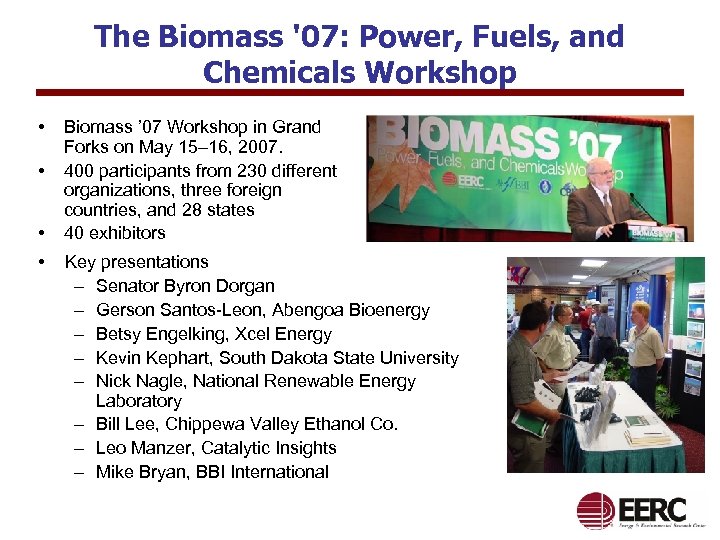

The Biomass '07: Power, Fuels, and Chemicals Workshop • • Biomass ’ 07 Workshop in Grand Forks on May 15– 16, 2007. 400 participants from 230 different organizations, three foreign countries, and 28 states 40 exhibitors Key presentations – Senator Byron Dorgan – Gerson Santos-Leon, Abengoa Bioenergy – Betsy Engelking, Xcel Energy – Kevin Kephart, South Dakota State University – Nick Nagle, National Renewable Energy Laboratory – Bill Lee, Chippewa Valley Ethanol Co. – Leo Manzer, Catalytic Insights – Mike Bryan, BBI International

Biodiesel Workshop Series – North Dakota and the South Dakota • Crop oils and feedstocks, refining process, transportation and distribution, marketing, government incentives, and fleet programs. • 140 attendees for three workshops in North and South Dakota. • Presentations made by EERC, NDSU Department of Plant Sciences, Northern Canola Growers Association, NDSU Ag & Biosystems Engineering, ND Department of Agriculture, the National Biodiesel Board, the City of Brooklyn Park (MN), the City of Fargo, the SD Department of Transportation, and the SD Soybean Research & Promotion Council.

Success Factors and Showstoppers • Distributed 150 -k. W biomass gasifier for multiple biomass feedstocks – Gas-cleaning system completed – Automated char separation and handling completed – Several feedstock types converted successfully – Demo plant installed • Landfill gas microturbine electricity – Determination of adequate feedstock for megawatt output – Good economics for microturbine in cold climate – Needs demo or small commercial testing • Development of by-products from ethanol and cellulose biomass – Successful production of hydrogen from wet ethanol (70%– 80% yield) using novel high-pressure on-demand ethanol reforming process – Assurance of a hydrogen economy necessary for economical hydrogen production at ethanol plants to go forward – Electrochemical approach to converting ethanol to urea-ammonia fertilizer, requires proving of lowcost nitrogen source – Hydroxyacetaldehyde (HA) chemical feedstock from biomass-derived pyrolysis bio-oil has good promise, but optimized pyrolysis system for HA production needs high-risk pilot-scale development and proving. • Development of biodiesel or “green” diesel – Direct thermal cracking holds great promise, but product separation may prove too costly – Availability of crop oils critical and dependent on agronomics – High-cetane oxygenates from glycerol requires stability in assured low glycerol costs and renewable incentive. • Outreach and education events reached high numbers, excellent demographics, and great media exposure for total success.

Future Work • Biomass gasification for distributed power – 12 -month demonstration of tar control, char handling automation, gas cleaning, and power generation on multiple feedstocks • Improved cold-flow biojet fuel – final assessment by fuel experts at Wright–Patterson AFB. • Hydrogen from ethanol – complete full process integration study and economics for hydrogen production from ethanol. • Complete lab-scale testing of integrated urea electrochemical synthesis using reagent-grade CO 2 and nitrite/nitrate, optimization of the electrochemical synthesis to determine process economics and paths forward. • Biomass '08 International Conference in Minneapolis, Minnesota, in April 2008 and Biomass '08 Technical Workshop in Grand Forks in July 2008.

Summary • All activities in the EERC CBU have Industry cost share to ensure market relevance and leverage DOE funding. • Activities in the EERC CBU contribute to the DOE goals of reducing dependance on imported oil and reduction of greenhouse gas emissions through the development of technologies that enhance the economics of biopower, bioproducts and biofuels. • CBU has been successful at building upon past successes to further technologies from bench and lab scale to pilot scale and ultimately to demonstation scale. – Cost-effective distributed biomass gasification for power production • Outreach and education have marketed DOE work in biofuels and energy in the Northern Great Plains. – Workshop participation grows from 80 to over 400 attendees – Biofuels expand from 2 plants to 8 plants

Additional Slides

Goals • Develop technologies for converting feedstocks into cost-competitive commodity liquid fuels, like ethanol, as well as products and power and to raise public and industry awareness of biomass products and technologies to accelerate marketplace success. Objectives • Develop and validate a robust 150 -k. W-sized biomass gasifier for multiple biomass feedstocks, clean gas formulation and electricity generation, and determine feasibility of landfill gas capture for microturbine-based electricity generation in cold climate. • Development of by-products from ethanol and cellulose biomass including highpressure on-demand ethanol reforming process for hydrogen, an electrochemical approach to converting ethanol to urea-ammonia fertilizer, and hydroxyacetaldehyde (HA) chemical feedstock from biomass-derived pyrolysis bio-oil. • Development of biodiesel or “green” diesel crop oils, direct thermal cracking of crop oils compatible jet fuel, and exploring novel high-cetane oxygenates from biodiesel by-product glycerol. • Conduct multiple outreach and education events for biomass technologies, in general and specifically, for biodiesel utilization.

Milestones • All research projects running to completion by 3/31/2008 with a final report for 2004 and 2005 projects. Critical Milestones • Task 1 – Management and Strategic Studies • Task 2 – Biomass Gasification for Distributed Power – Demo of tar control, automation December 2007 • Task 3 – Novel High-Cetane Oxygenates from Waste Glycerol from Biodiesel Production – Production of Oxygenates November 2007 • Task 4 – Utilization of Cuphea Oils for Biodiesel Production – Complete biodiesel production and analyses June 2007 • Task 5 – Process Integration for Economic Hydrogen Production from Ethanol – Complete pilot-scale ethanol parametric testing December 2007

Milestones – Continued Critical Milestones • Task 6 – Biojet Fuel Cold-Flow Improvement – Wright–Patterson AFB assessment of fuel June 2007 • Task 7 – Urea Fertilizer Production from Ethanol Coproduct Carbon Dioxide – Demonstrated electrochemical production of nitric oxide-derived urea March 2007 • Task 8 – Chemical Feedstocks from Lignocellulosic Pyrolysis – Production of hydroxyacetaldehyde-derived agent for polymer-flood enhanced oil recovery and demonstration of effectiveness February 2007 • Task 9 – Landfill Methane for Microturbine Power – Profiled the Grand Forks, ND, municipal landfill site in terms of gas quantity and quality. Based on this information, evaluated the most economical methods to pretreat the lower gas volumes for a cogeneration demonstration in a microturnbine on a small landfill site. June 2007 • Task 10 – Biodiesel Education and Outreach – North Dakota and South Dakota Biodiesel workshops March 2007

Publications and Presentations • • • Zygarlicke, C. J. ; Schmidt, D. D. Development of an Industrial-Scale Biomass Gasification Power Plant. In Proceedings of the 14 th European Biomass Conference & Exhibition: Biomass for Energy Industry and Climate Protection; Paris, France, Oct 17– 21, 2005. Schmidt, D. D. ; Zygarlicke, C. J. Biomass Gasification for Small (150 -k. We) Power Commercialization Application. Presented at the 30 th International Technical Conference on Coal Utilization & Fuels Systems, Clearwater, FL, April 17– 21, 2005. Olson, E. S. ; Sharma, R. K. ; Aulich, T. R. ; Freel, B. ; Boulard, D. ; von Keitz, M. A Fast-Pyrolysis Biorefinery for the Northern Great Plains; Final Report for Great Plains Institute for Sustainable Development; EERC Publication 2006 -EERC-01 -05; Energy & Environmental Research Center: Grand Forks, ND, Jan 2006. Corporan, E. ; Reich, R. ; Monroig, O; De. Witt, M. J. ; Aulich, T. ; Mann, M. ; Seames, W. Impacts of Biodiesel on Pollutant Emissions of a JP-8 -Fueled Turbine Engine. J. Air Waste Manage. Assoc. 2005, 55 (7), 940– 949. Aulich, T. R. ; Olson, ES. ; Sharma, R. K. Isolation of Succinic Acid from Fermentation Broths; Final Report (Oct 10, 2003 – April 30, 2005) for Minnesota Corn Research & Promotion Council, South Dakota Corn Utilization Council, and North Dakota Growers Association; EERC Publication 2004 -EERC-06 -07; Energy & Environmental Research Center: Grand Forks, ND, June 2005. Olson, E. S. ; Sharma, R. K. ; Aulich, T. R. The Higher Alcohols Biorefinery II: Conversion of Ethanol to High Cetane Diesel Additives. Presented at the 26 th Symposium on Biotechnology for Fuels and Chemicals, Chattanooga, TN, May 9– 12, 2004. Olson, E. S. ; Sharma, R. K. ; Aulich, T. R. The Higher-Alcohols Biorefinery: Improvement of the Catalyst for Ethanol Conversion. Appl. Biochem. Biotechnol. 2004, 113– 116, 913– 932. Olson, E. S. ; Sharma, R. K. ; Aulich, T. R. ; Timpe R. C. Ester Fuels and Chemicals from Biomass. Appl. Biochem. Biotechno. 2003, 105– 108, 843– 851.

Results of EERC CBU® 2005 • Activity 2 – Biomass Gasification and Distributed Power Production • Activity 3 – Novel High-Cetane Oxygenates from Waste Glycerol from Biodiesel Plants • Activity 4 – Utilization of Cuphea Oil for Biodiesel Production • Activity 5 – Process Integration for Economic Hydrogen Production from Ethanol • Activity 6 – Biojet Fuel Cold-Flow Improvement • Activity 7 – Urea Fertilizer Production from Ethanol Coproduct Carbon Dioxide • Activity 8 – Chemical Feedstocks from Lignocellulosic Pyrolysis • Activity 9 – Landfill Methane for Microturbine Power • Activity 10 – Biodiesel Education and Outreach

Activity 2 – Biomass Gasification and Distributed Power Production Goals Publish gas quality data from various biomass fuels such as wood, switchgrass, wheat straw, flax, sunflower hulls, nut shells, and stoker-grade coal. Objectives Procure gasification system. Install and conduct testing. Publish results in journals and present at a major conference. Scope of Work Task 1 – Procure Gasifier (Task 1 is complete. ) Task 2 – Installation of Equipment and Data Acquisition (Task 2 is under way. ) Task 3 – Complete testing Task 4 – Publish – Conference and Journal (Abstract to Power. Gen 07) Expected completion date is December 31, 2007

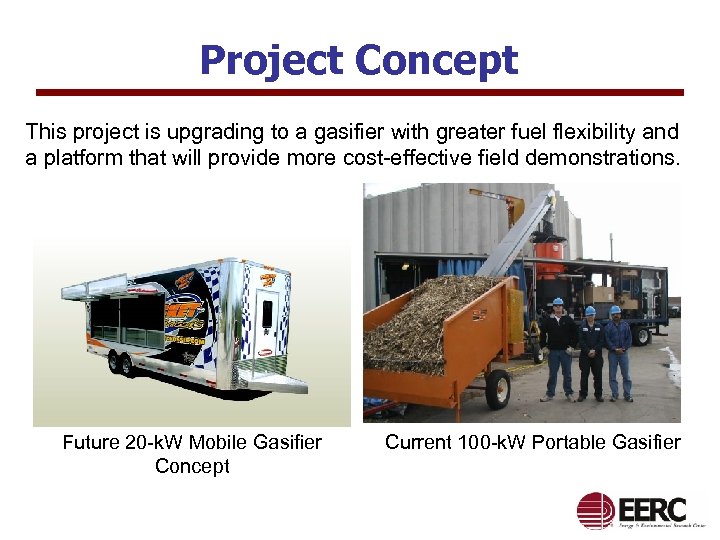

Project Concept This project is upgrading to a gasifier with greater fuel flexibility and a platform that will provide more cost-effective field demonstrations. Future 20 -k. W Mobile Gasifier Concept Current 100 -k. W Portable Gasifier

Current Status • Gasifier and gas cleanup procured (equipment delivered). • Engineering and procurement in progress. • Procurement due complete at end of August. • Construction scheduled for October. • Testing and reporting (Nov. – Dec. )

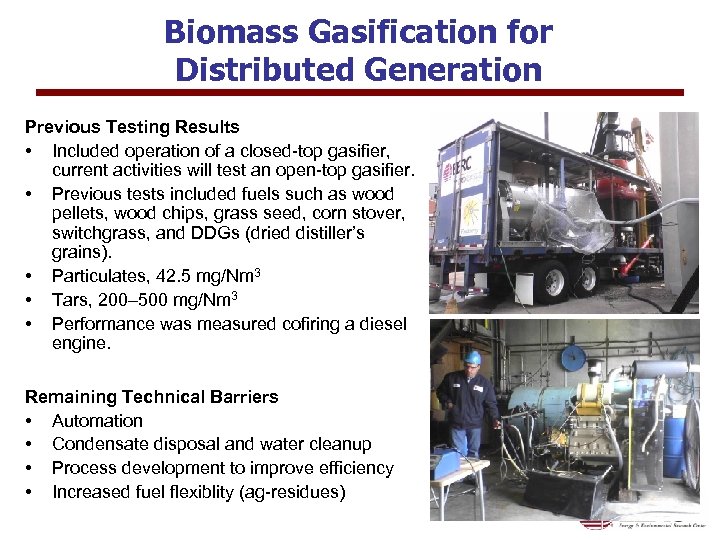

Biomass Gasification for Distributed Generation Previous Testing Results • Included operation of a closed-top gasifier, current activities will test an open-top gasifier. • Previous tests included fuels such as wood pellets, wood chips, grass seed, corn stover, switchgrass, and DDGs (dried distiller’s grains). • Particulates, 42. 5 mg/Nm 3 • Tars, 200– 500 mg/Nm 3 • Performance was measured cofiring a diesel engine. Remaining Technical Barriers • Automation • Condensate disposal and water cleanup • Process development to improve efficiency • Increased fuel flexiblity (ag-residues)

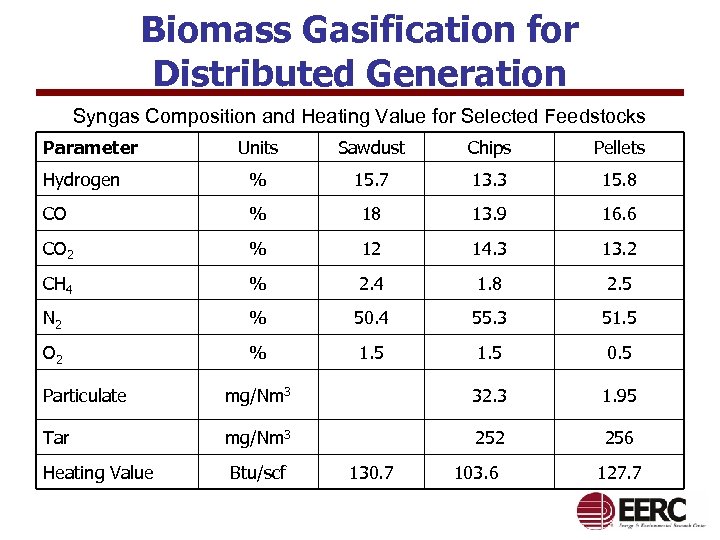

Biomass Gasification for Distributed Generation Syngas Composition and Heating Value for Selected Feedstocks Parameter Units Sawdust Chips Pellets Hydrogen % 15. 7 13. 3 15. 8 CO % 18 13. 9 16. 6 CO 2 % 12 14. 3 13. 2 CH 4 % 2. 4 1. 8 2. 5 N 2 % 50. 4 55. 3 51. 5 O 2 % 1. 5 0. 5 Particulate mg/Nm 3 32. 3 1. 95 Tar mg/Nm 3 252 256 Heating Value Btu/scf 130. 7 103. 6 127. 7

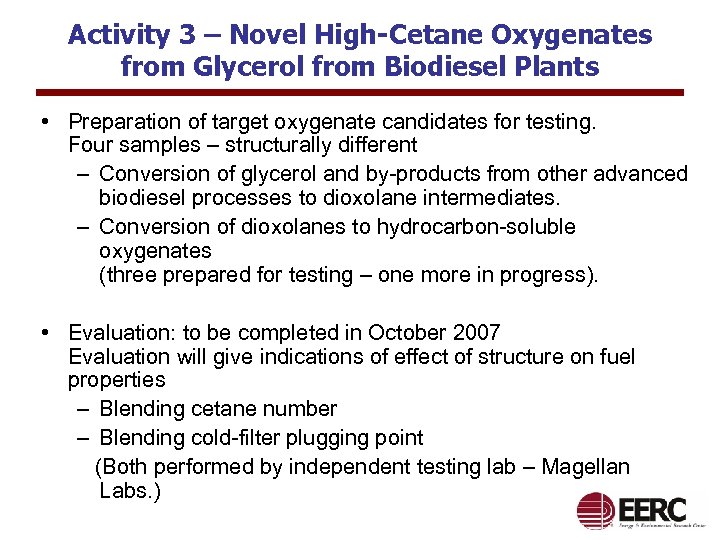

Activity 3 – Novel High-Cetane Oxygenates from Glycerol from Biodiesel Plants • Preparation of target oxygenate candidates for testing. Four samples – structurally different – Conversion of glycerol and by-products from other advanced biodiesel processes to dioxolane intermediates. – Conversion of dioxolanes to hydrocarbon-soluble oxygenates (three prepared for testing – one more in progress). • Evaluation: to be completed in October 2007 Evaluation will give indications of effect of structure on fuel properties – Blending cetane number – Blending cold-filter plugging point (Both performed by independent testing lab – Magellan Labs. )

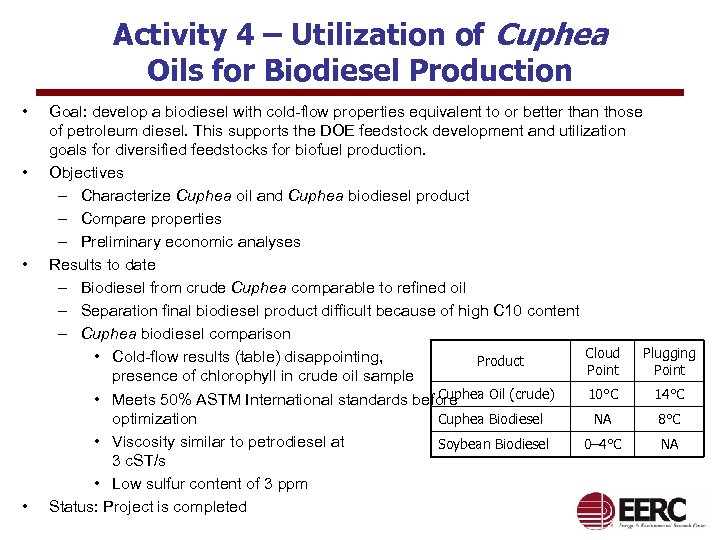

Activity 4 – Utilization of Cuphea Oils for Biodiesel Production • • Goal: develop a biodiesel with cold-flow properties equivalent to or better than those of petroleum diesel. This supports the DOE feedstock development and utilization goals for diversified feedstocks for biofuel production. Objectives – Characterize Cuphea oil and Cuphea biodiesel product – Compare properties – Preliminary economic analyses Results to date – Biodiesel from crude Cuphea comparable to refined oil – Separation final biodiesel product difficult because of high C 10 content – Cuphea biodiesel comparison Cloud Plugging • Cold-flow results (table) disappointing, Product Point presence of chlorophyll in crude oil sample Cuphea Oil (crude) 10°C 14°C • Meets 50% ASTM International standards before Cuphea Biodiesel NA 8°C optimization • Viscosity similar to petrodiesel at Soybean Biodiesel 0– 4°C NA 3 c. ST/s • Low sulfur content of 3 ppm Status: Project is completed

Activity 5 – Process Integration for Economical Hydrogen Production from Ethanol • EERC project objectives: – Demonstrate, on a pilot scale, the production of a fuel cell-grade hydrogen gas stream from ethanol. – Further quantify the economic impact of integrating hydrogen production with an ethanol-processing facility. – Evaluate the potential for highpressure reforming for on-demand hydrogen production.

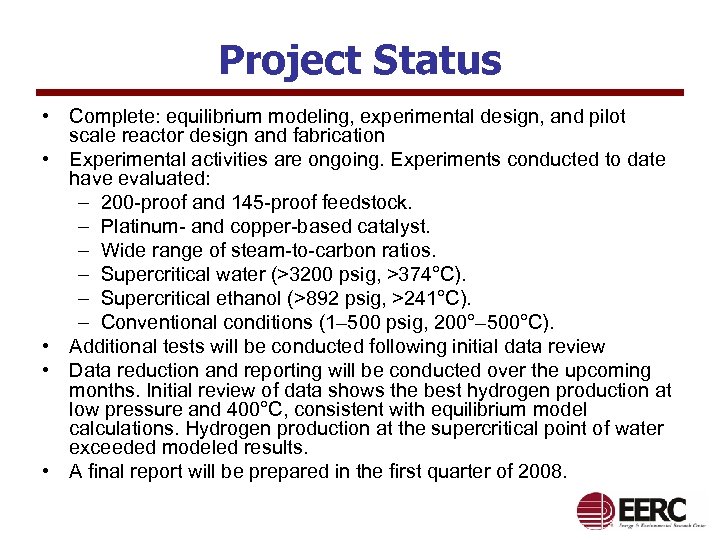

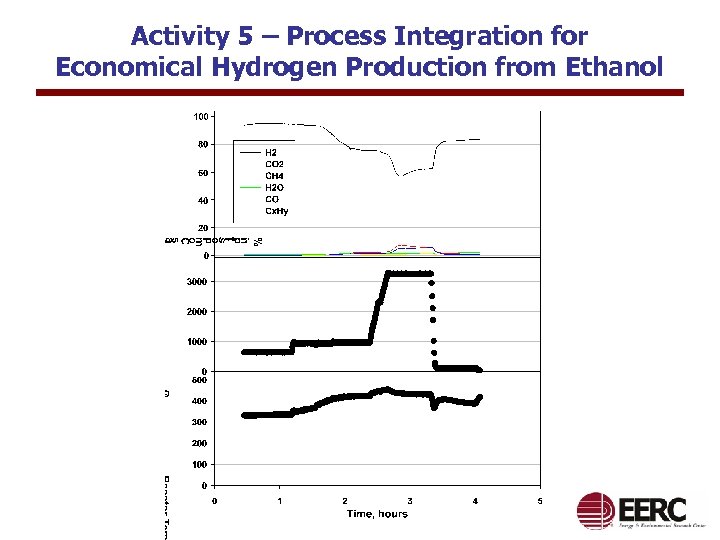

Project Status • Complete: equilibrium modeling, experimental design, and pilot scale reactor design and fabrication • Experimental activities are ongoing. Experiments conducted to date have evaluated: – 200 -proof and 145 -proof feedstock. – Platinum- and copper-based catalyst. – Wide range of steam-to-carbon ratios. – Supercritical water (>3200 psig, >374°C). – Supercritical ethanol (>892 psig, >241°C). – Conventional conditions (1– 500 psig, 200°– 500°C). • Additional tests will be conducted following initial data review • Data reduction and reporting will be conducted over the upcoming months. Initial review of data shows the best hydrogen production at low pressure and 400°C, consistent with equilibrium model calculations. Hydrogen production at the supercritical point of water exceeded modeled results. • A final report will be prepared in the first quarter of 2008.

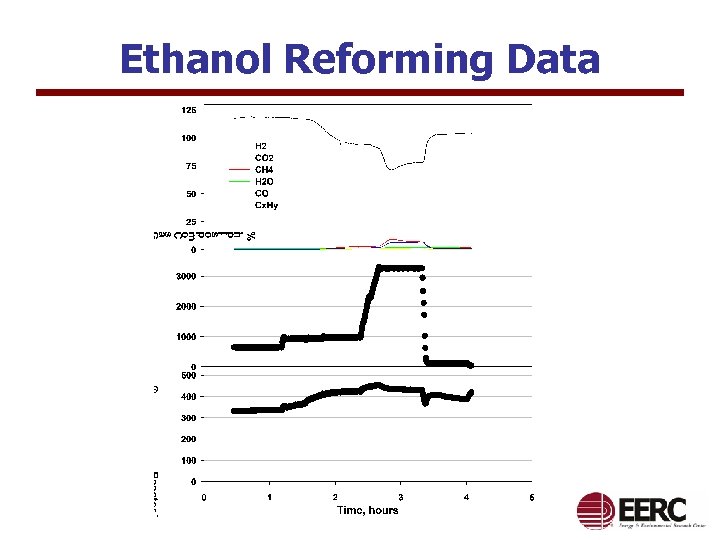

Ethanol Reforming Data

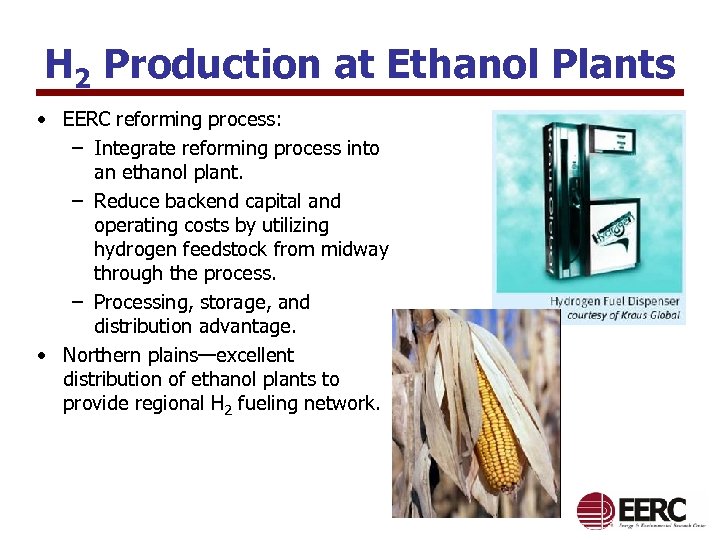

H 2 Production at Ethanol Plants • EERC reforming process: – Integrate reforming process into an ethanol plant. – Reduce backend capital and operating costs by utilizing hydrogen feedstock from midway through the process. – Processing, storage, and distribution advantage. • Northern plains—excellent distribution of ethanol plants to provide regional H 2 fueling network.

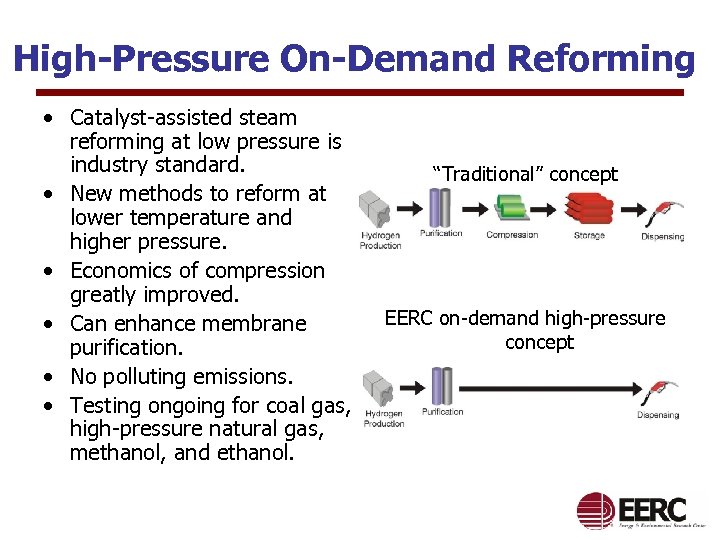

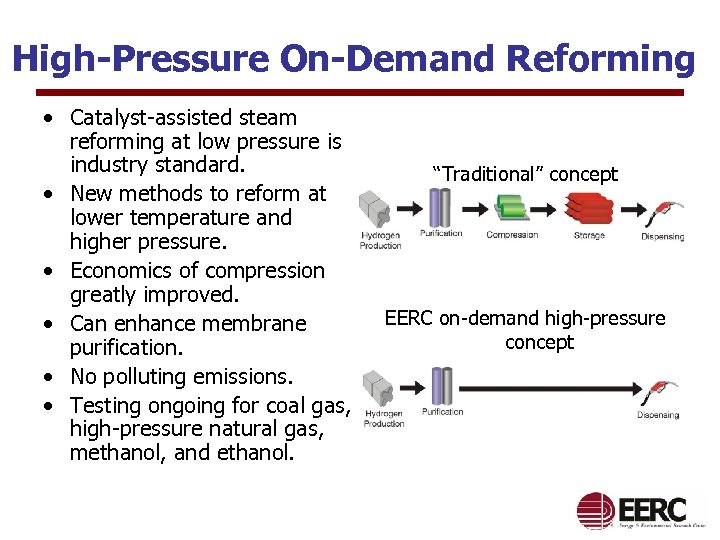

High-Pressure On-Demand Reforming • Catalyst-assisted steam reforming at low pressure is industry standard. • New methods to reform at lower temperature and higher pressure. • Economics of compression greatly improved. • Can enhance membrane purification. • No polluting emissions. • Testing ongoing for coal gas, high-pressure natural gas, methanol, and ethanol. “Traditional” concept EERC on-demand high-pressure concept

Activity 5 – Partners • • North Dakota Corn Utilization Council Minnesota Corn Research & Promotion Council Chippewa Valley Ethanol Company H 2 Gen Innovations Inc.

Background • 2002 catalytic partial oxidation of ethanol – Evaluated effect of O 2, H 2 O, and denaturant on hydrogen production – Demonstrated 25 mol% hydrogen with addition of 10 mol% O 2 and 50 mol% H 2 O • 2004 integrated facility concept – Bench-scale ethanol reforming – Preliminary economic evaluation – Equilibrium modeling

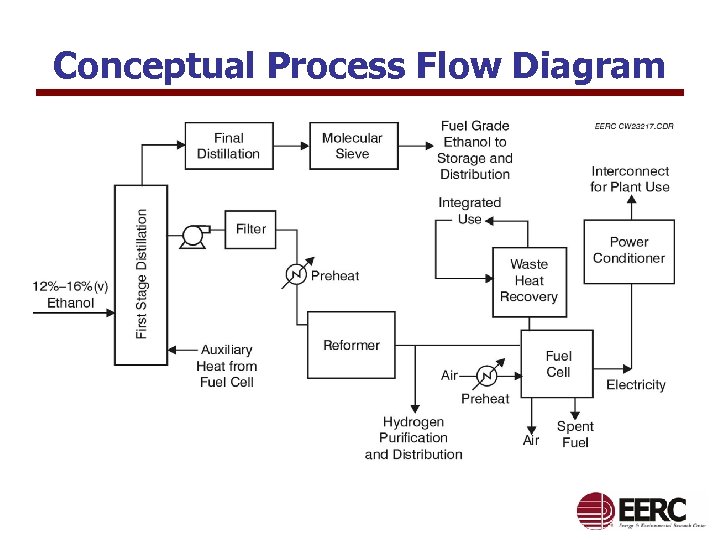

Conceptual Process Flow Diagram

H 2 Production at Ethanol Plants • EERC reforming process: – Integrate reforming process into an ethanol plant. – Reduce backend capital and operating costs by utilizing hydrogen feedstock from midway through the process. – Processing, storage, and distribution advantage. • Northern plains—excellent distribution of ethanol plants to provide regional H 2 fueling network.

High-Pressure On-Demand Reforming • Catalyst-assisted steam reforming at low pressure is industry standard. • New methods to reform at lower temperature and higher pressure. • Economics of compression greatly improved. • Can enhance membrane purification. • No polluting emissions. • Testing ongoing for coal gas, high-pressure natural gas, methanol, and ethanol. “Traditional” concept EERC on-demand high-pressure concept

Activity 5 – Process Integration for Economical Hydrogen Production from Ethanol

Scope of Work • • • Select optimal ethanol feedstock Pilot-scale testing by the EERC Collaborative testing by H 2 Gen (HGM) Optimize process for H 2 production from ethanol Evaluate economics of H 2 production from an integrated process versus distributed fuel-grade ethanol

Activity 6 – Biojet Fuel Cold-Flow Improvement Objective: To ascertain how well the UND biojet fuel products perform as aviation fuels. Motivation: Qualification of Biojet-100 as an acceptable fuel by the FAA and USAF will require extensive testing. Any problems with current fuel need to be solved. Accomplishments: • Purchased and installed microturbine; now being used for fuel evaluation • Generated 15 gallons each of biojet fuel from two different feedstock sources – 0. 6 gallons per day! • Cloud point, pour point, flash point, D-86 curves, heating values determined • Unknowns in chemical composition reduced. Over 100 compounds identified. Future Directions: • In-house long-term fuels testing in the microturbine • Extensive corrosion coupon and stability testing • Additional fuels property testing

Biojet Fuel Cold-Flow Improvement Why are we concerned with cold flow? • Improved cold flow will enable crop oilbased biofuel to be utilized in Northern winter conditions by diesel engines. • Cold flow at − 50°C will use as alternative, renewable jet fuel. • Supports OBP highest-priority area of petrochemical replacement with biomass -derived fuels and Task 5. 4 – Oils Production and Utilization

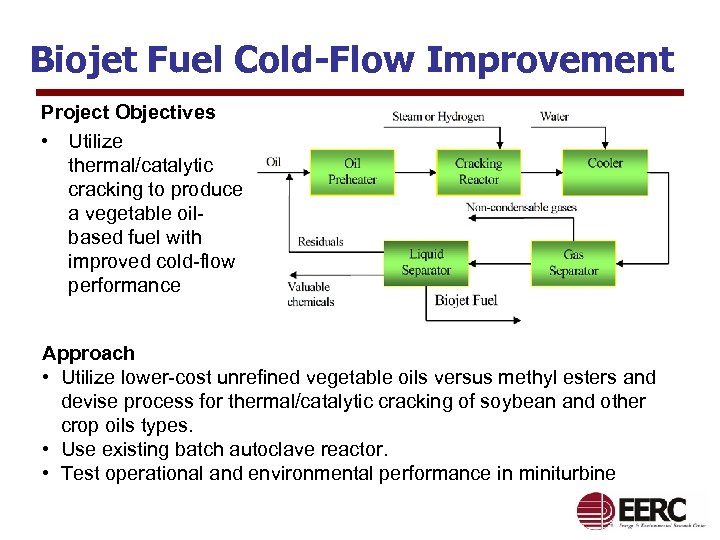

Biojet Fuel Cold-Flow Improvement Project Objectives • Utilize thermal/catalytic cracking to produce a vegetable oilbased fuel with improved cold-flow performance Approach • Utilize lower-cost unrefined vegetable oils versus methyl esters and devise process for thermal/catalytic cracking of soybean and other crop oils types. • Use existing batch autoclave reactor. • Test operational and environmental performance in miniturbine

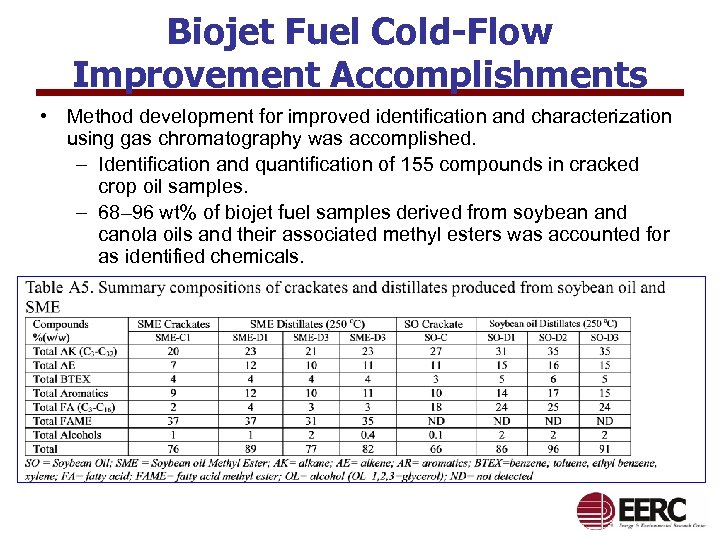

Biojet Fuel Cold-Flow Improvement Accomplishments • Method development for improved identification and characterization using gas chromatography was accomplished. – Identification and quantification of 155 compounds in cracked crop oil samples. – 68– 96 wt% of biojet fuel samples derived from soybean and canola oils and their associated methyl esters was accounted for as identified chemicals.

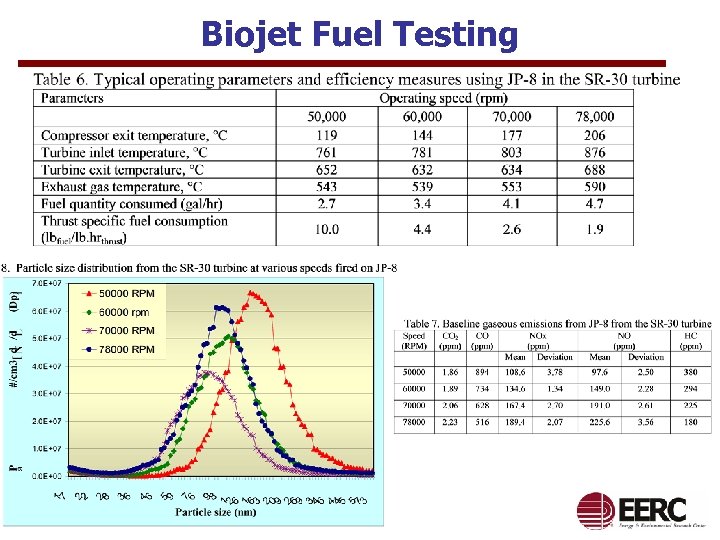

Biojet Fuel Testing

Activity 7 – Urea Fertilizer Production from Ethanol Coproduct Carbon Dioxide Low-T Electrochemical Production of Urea Anode: CO 2 + 2 NO + 10 H+ + 10 e- CO(NH 2)2 + 3 H 2 O Anode: 5 H 2 10 H+ + 10 e. Total Reaction: CO 2 + 2 NO + 5 H 2 CO(NH 2)2 + 3 H 2 O

Activity 7 – Achievements • Demonstrated urea production at room temperature and atmospheric pressure, which is characterized by a product composition comprising approximately 70% ammonia and 30% urea with a total current efficiency of around 80% under the optimized conditions. • Prepared draft provisional patent. • Proposed a mechanism for the formation of urea and coproduct ammonia and developed strategies to improve urea selectivity. • Proposed a novel electrochemical approach to directly produce solid urea without the need of costly purification. • Completed preliminary economy analysis for the urea process. • Completed the final report.

Activity 8 – Chemical Feedstocks from Lignocellulosic Pyrolysis Bio-Oil • Using hydroxyacetaldehyde (HA) extracted from commercial bio-oil provided by project partner Ensyn Renewables, produced several polyamines and polyamides with potential applications in enhanced oil recovery (EOR) • Demonstrated on the bench scale the technical viability of using HA-derived polymers to mediate the viscosity of aqueous “polymer flooding” solutions in EOR applications.

Activity 9 – Landfill Methane for Microturbine Power Project Results • Basic assessment of the landfill site indicates: – 2. 4 to 2. 5 M tons of waste currently in place (3. 4 M tons projected by 2009) – 400 to 600 scfm gas production potential for the site – 1. 5 - to 2. 0 -MW gross power generation capacity for the total gas flow – 1. 0 - to 1. 5 -MW net power generation after parasitic loads – 7. 0 - to 10. 5 -MWh annual electricity generation potential assuming 80% annual capacity factor

Project Results (continued) • Gas analyses for the combined closure Phases* I through IV include siloxane determination, total VOC scan, and major fuel components: – 45%– 52% methane (450– 520 Btu/scf) – Trace H 2 – 35% to 48% CO 2 – 2%– 5% N 2 – 2%– 5% moisture – 400– 500 ppmv total VOCs – 2. 5– 6 ppmv total siloxanes Note: There are currently six closed phases with three more planned by 2009. * Phases are selected areas of the landfill site

Project Results (continued) • Investigation of the technologies to prepare landfill gas for use in a microturbine or ICE has determined that for power generation at LFG sites that have a power generation potential less than 3 -4 MW, no economical systems are currently available to efficiently remove siloxanes and VOCs from the gas stream. • For sites with greater than 3 MW potential, the initial capital cost of gas collection, cleanup and preparation, and power generation equipment can be more than $2 M per MW. • By comparison, our developmental system will target sites with less than 2– 3 MW potential for expected total per MW cost less than the current rate.

Milestones • All research projects running to completion by 3/31/2008 with a final report for 2004 and 2005 projects. Critical Milestones • Task 1 – Management and Strategic Studies • Task 2 – Biomass Gasification for Distributed Power – Demo of tar control, automation, and multiple feedstocks December 2007 • Task 3 – Novel High-Cetane Oxygenates from Waste Glycerol from Biodiesel Production – Production of oxygenates November 2007 • Task 4 – Utilization of Cuphea Oils for Biodiesel Production – Complete biodiesel production and analyses June 2006 • Task 5 – Process Integration for Economic Hydrogen Production from Ethanol

Milestones – Continued Critical Milestones • Task 6 – Biojet Fuel Cold-Flow Improvement – Wright–Patterson AFB Assessment of fuel June 2007 • Task 7 – Urea Fertilizer Production from Ethanol Coproduct Carbon Dioxide – Demonstrated electrochemical production of nitric oxide-derived urea March 2007 • Task 8 – Chemical Feedstocks from Lignocellulosic Pyrolysis – Production of hydroxyacetaldehyde-derived agent for polymer-flood enhanced oil recovery and demonstration of effectiveness February 2007 • Task 9 – Landfill Methane for Microturbine Power – Profiled the Grand Forks, ND, municipal landfill site in terms of gas quantity and quality. Based on this information, evaluated the most economical methods to pretreat the lower gas volumes for a cogeneration demonstration in a microturbine on a small landfill site. June 2007 • Task 10 – Biodiesel Education and Outreach – North Dakota and South Dakota Biodiesel workshops March 2007

The Biomass '07: Power, Fuels, and Chemicals Workshop • Biomass ’ 07 Workshop in Grand Forks on May 15– 16, 2007. • 400 participants from 230 different organizations, three foreign countries, and 28 states • 40 exhibitors • Key presentations – Senator Byron Dorgan – Gerson Santos-Leon, Abengoa Bioenergy – Betsy Engelking, Xcel Energy – Kevin Kephart, South Dakota State University – Nick Nagle, National Renewable Energy Laboratory – Bill Lee, Chippewa Valley Ethanol Co. – Leo Manzer, Catalytic Insights – Mike Bryan, BBI International

Biodiesel Workshop Series – North Dakota and the South Dakota • Crop oils and feedstocks, refining process, transportation and distribution, marketing, government incentives, and fleet programs. • 140 attendees for three workshops in North and South Dakota. • Presentations made by EERC, NDSU Department of Plant Sciences, Northern Canola Growers Association, NDSU Ag & Biosystems Engineering, ND Department of Agriculture, the National Biodiesel Board, the City of Brooklyn Park (MN), the City of Fargo, the SD Department of Transportation, and the SD Soybean Research & Promotion Council.

Future Work • Biomass gasification for distributed power – 12 -month demonstration of tar control, char handling automation, gas cleaning, and power generation on multiple feedstocks • Improved cold-flow biojet fuel – final assessment by fuel experts at Wright–Patterson AFB. • Hydrogen from ethanol – complete full process integration study and economics for hydrogen production from ethanol. • Complete lab-scale testing of integrated urea electrochemical synthesis using reagent-grade CO 2 and nitrite/nitrate, optimization of the electrochemical synthesis to determine process economics and paths forward. • Biomass '08 International Conference in Minneapolis, Minnesota, in April 2008 and Biomass '08 Technical Workshop in Grand Forks in July 2008.

005456f191387ac94e4ff3de2d909047.ppt