6db5caaf0e09f234ca78be70b0c565f1.ppt

- Количество слайдов: 23

2005/06 Safety Monitors Presentation to Gas Transmission Workstream, 5 January 2006

2005/06 Safety Monitors Presentation to Gas Transmission Workstream, 5 January 2006

Safety Monitors – background Define levels of storage that must be maintained through the winter period ® Introduced in 2004 to replace ‘Top-up’ ® ‘Top-up’ focused on maintaining security of supply: Safety Monitors focus is public safety ® Requirement of National Grid Gas’ Safety Case that action is taken to ensure storage stocks do not fall below the Safety Monitor levels - these decay as the winter progress ®

Safety Monitors – background Define levels of storage that must be maintained through the winter period ® Introduced in 2004 to replace ‘Top-up’ ® ‘Top-up’ focused on maintaining security of supply: Safety Monitors focus is public safety ® Requirement of National Grid Gas’ Safety Case that action is taken to ensure storage stocks do not fall below the Safety Monitor levels - these decay as the winter progress ®

Gas Safety (Management) Regulations 1996 ® ® Requires anyone conveying gas in a network to prepare a Safety Case and for the Safety Case to be accepted by the HSE The Safety Case must contain particulars which describe arrangements for a number of items listed in Schedule 1 These are high level requirements which must be described in detail in the Safety Case – GS(M)R does not define how a specific requirement is to be met. The relevant requirement in Schedule 1 is clause 16 ® 16 - Particulars to demonstrate that the duty holder has established adequate arrangements to minimise the risk of a supply emergency, where a “supply emergency" means an emergency endangering persons and arising from a loss of pressure in a network or any part thereof

Gas Safety (Management) Regulations 1996 ® ® Requires anyone conveying gas in a network to prepare a Safety Case and for the Safety Case to be accepted by the HSE The Safety Case must contain particulars which describe arrangements for a number of items listed in Schedule 1 These are high level requirements which must be described in detail in the Safety Case – GS(M)R does not define how a specific requirement is to be met. The relevant requirement in Schedule 1 is clause 16 ® 16 - Particulars to demonstrate that the duty holder has established adequate arrangements to minimise the risk of a supply emergency, where a “supply emergency" means an emergency endangering persons and arising from a loss of pressure in a network or any part thereof

GS(M)R Safety Monitors ® ® The GS(M)R Safety monitor arrangements form part of National Grid’s detailed demonstration that it has arrangements in place to minimise the risk of a supply emergency They address the risk posed by the possibility of insufficient storage being available for a 1 in 50 duration winter The arrangements have been accepted by the HSE as discharging our responsibility in this area and we have a legal obligation to follow those arrangements Any change in arrangements would constitute a material change to the Safety Case and National Grid would have to present a case which demonstrated that the new arrangements were at least as safe as the current arrangements

GS(M)R Safety Monitors ® ® The GS(M)R Safety monitor arrangements form part of National Grid’s detailed demonstration that it has arrangements in place to minimise the risk of a supply emergency They address the risk posed by the possibility of insufficient storage being available for a 1 in 50 duration winter The arrangements have been accepted by the HSE as discharging our responsibility in this area and we have a legal obligation to follow those arrangements Any change in arrangements would constitute a material change to the Safety Case and National Grid would have to present a case which demonstrated that the new arrangements were at least as safe as the current arrangements

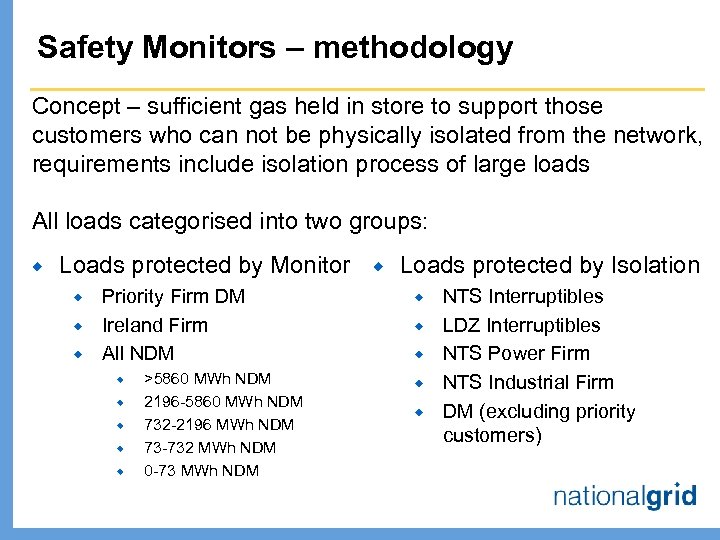

Safety Monitors – methodology Concept – sufficient gas held in store to support those customers who can not be physically isolated from the network, requirements include isolation process of large loads All loads categorised into two groups: ® Loads protected by Monitor ® ® ® Priority Firm DM Ireland Firm All NDM ® ® ® >5860 MWh NDM 2196 -5860 MWh NDM 732 -2196 MWh NDM 73 -732 MWh NDM 0 -73 MWh NDM ® Loads protected by Isolation ® ® ® NTS Interruptibles LDZ Interruptibles NTS Power Firm NTS Industrial Firm DM (excluding priority customers)

Safety Monitors – methodology Concept – sufficient gas held in store to support those customers who can not be physically isolated from the network, requirements include isolation process of large loads All loads categorised into two groups: ® Loads protected by Monitor ® ® ® Priority Firm DM Ireland Firm All NDM ® ® ® >5860 MWh NDM 2196 -5860 MWh NDM 732 -2196 MWh NDM 73 -732 MWh NDM 0 -73 MWh NDM ® Loads protected by Isolation ® ® ® NTS Interruptibles LDZ Interruptibles NTS Power Firm NTS Industrial Firm DM (excluding priority customers)

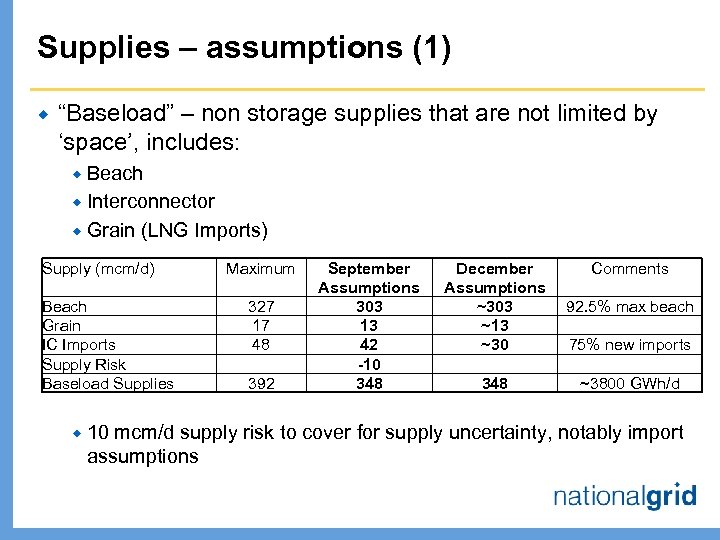

Supplies – assumptions (1) ® “Baseload” – non storage supplies that are not limited by ‘space’, includes: ® Beach ® Interconnector ® Grain (LNG Imports) Supply (mcm/d) Beach Grain IC Imports Supply Risk Baseload Supplies ® 10 Maximum 327 17 48 392 September Assumptions 303 13 42 -10 348 December Assumptions ~303 ~13 ~30 Comments 92. 5% max beach 348 ~3800 GWh/d 75% new imports mcm/d supply risk to cover for supply uncertainty, notably import assumptions

Supplies – assumptions (1) ® “Baseload” – non storage supplies that are not limited by ‘space’, includes: ® Beach ® Interconnector ® Grain (LNG Imports) Supply (mcm/d) Beach Grain IC Imports Supply Risk Baseload Supplies ® 10 Maximum 327 17 48 392 September Assumptions 303 13 42 -10 348 December Assumptions ~303 ~13 ~30 Comments 92. 5% max beach 348 ~3800 GWh/d 75% new imports mcm/d supply risk to cover for supply uncertainty, notably import assumptions

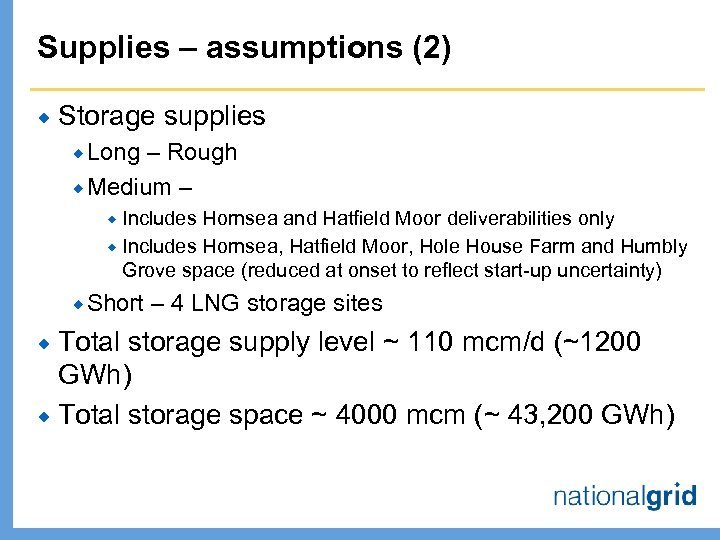

Supplies – assumptions (2) ® Storage supplies ® Long – Rough ® Medium – Includes Hornsea and Hatfield Moor deliverabilities only ® Includes Hornsea, Hatfield Moor, Hole House Farm and Humbly Grove space (reduced at onset to reflect start-up uncertainty) ® ® Short – 4 LNG storage sites Total storage supply level ~ 110 mcm/d (~1200 GWh) ® Total storage space ~ 4000 mcm (~ 43, 200 GWh) ®

Supplies – assumptions (2) ® Storage supplies ® Long – Rough ® Medium – Includes Hornsea and Hatfield Moor deliverabilities only ® Includes Hornsea, Hatfield Moor, Hole House Farm and Humbly Grove space (reduced at onset to reflect start-up uncertainty) ® ® Short – 4 LNG storage sites Total storage supply level ~ 110 mcm/d (~1200 GWh) ® Total storage space ~ 4000 mcm (~ 43, 200 GWh) ®

Supply / demand component – loads protected by monitor

Supply / demand component – loads protected by monitor

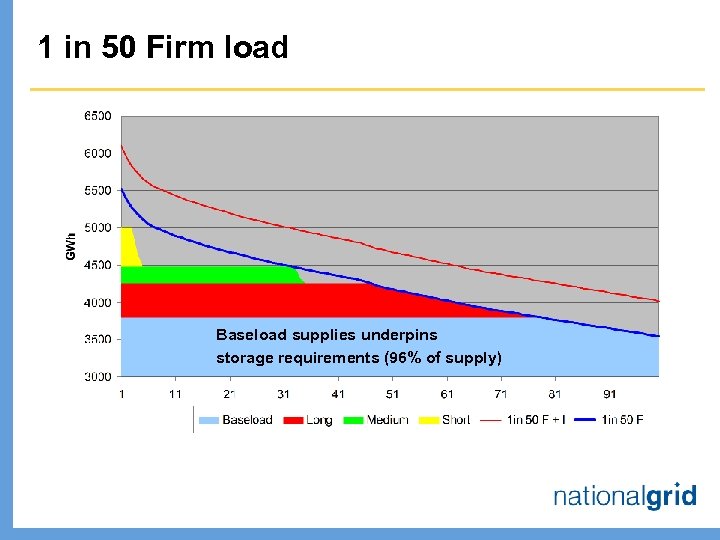

1 in 50 Firm load Baseload supplies underpins storage requirements (96% of supply)

1 in 50 Firm load Baseload supplies underpins storage requirements (96% of supply)

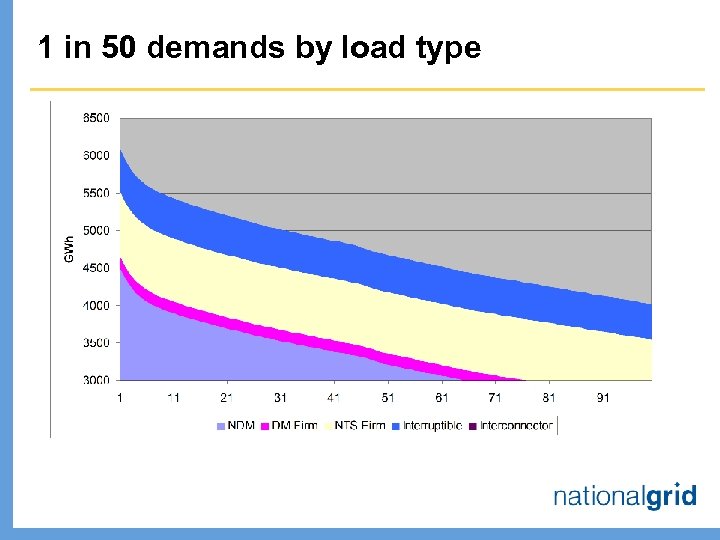

1 in 50 demands by load type

1 in 50 demands by load type

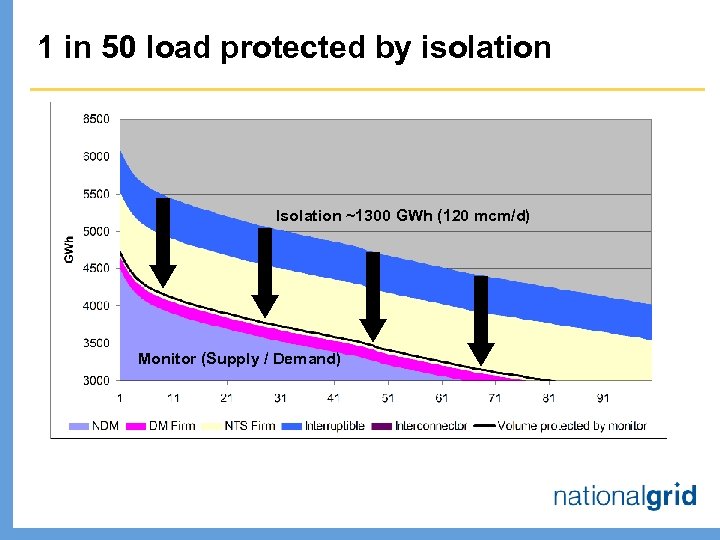

1 in 50 load protected by isolation Isolation ~1300 GWh (120 mcm/d) Monitor (Supply / Demand)

1 in 50 load protected by isolation Isolation ~1300 GWh (120 mcm/d) Monitor (Supply / Demand)

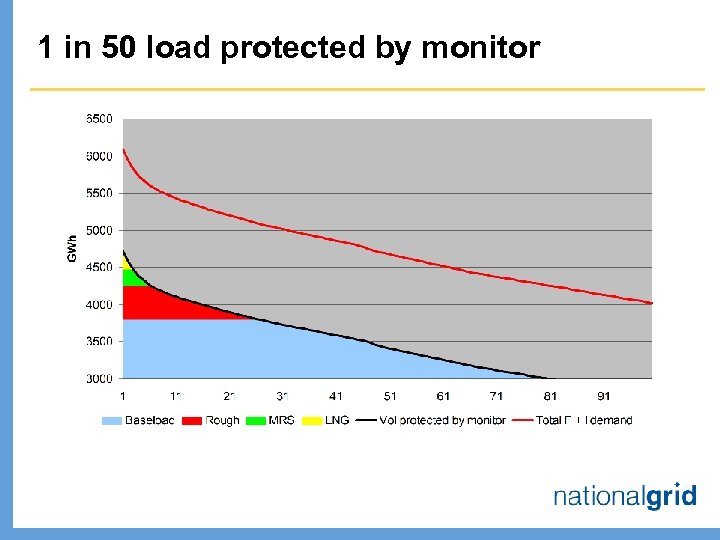

1 in 50 load protected by monitor

1 in 50 load protected by monitor

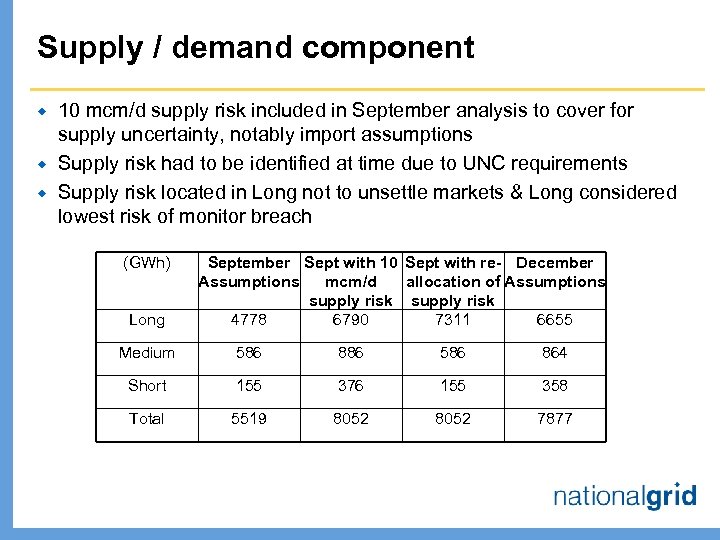

Supply / demand component ® ® ® 10 mcm/d supply risk included in September analysis to cover for supply uncertainty, notably import assumptions Supply risk had to be identified at time due to UNC requirements Supply risk located in Long not to unsettle markets & Long considered lowest risk of monitor breach (GWh) Long September Sept with 10 Sept with re- December Assumptions mcm/d allocation of Assumptions supply risk 4778 6790 7311 6655 Medium 586 886 586 864 Short 155 376 155 358 Total 5519 8052 7877

Supply / demand component ® ® ® 10 mcm/d supply risk included in September analysis to cover for supply uncertainty, notably import assumptions Supply risk had to be identified at time due to UNC requirements Supply risk located in Long not to unsettle markets & Long considered lowest risk of monitor breach (GWh) Long September Sept with 10 Sept with re- December Assumptions mcm/d allocation of Assumptions supply risk 4778 6790 7311 6655 Medium 586 886 586 864 Short 155 376 155 358 Total 5519 8052 7877

Non - supply / demand component – load protected by isolation

Non - supply / demand component – load protected by isolation

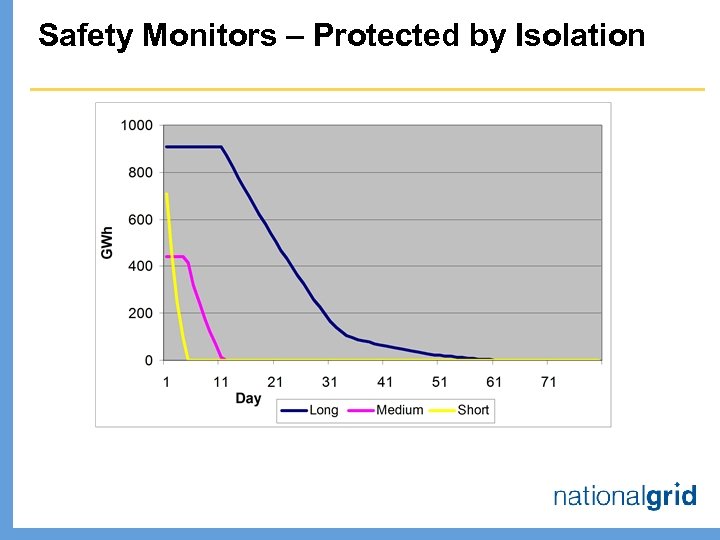

Safety Monitors – Protected by Isolation

Safety Monitors – Protected by Isolation

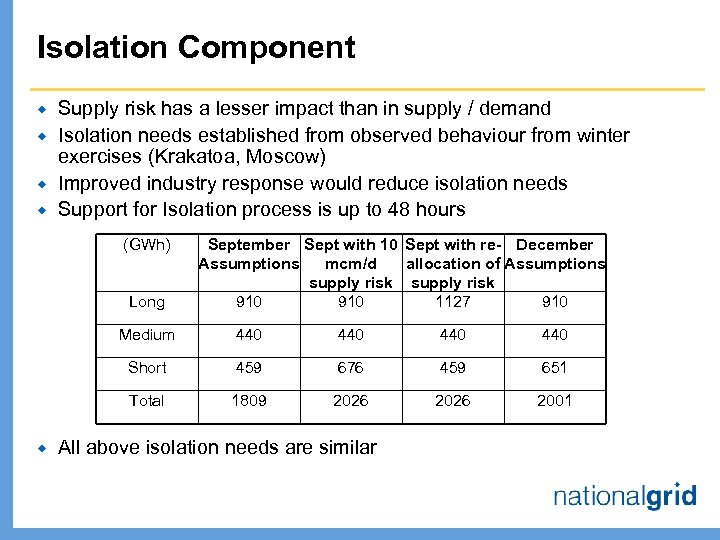

Isolation Component ® ® Supply risk has a lesser impact than in supply / demand Isolation needs established from observed behaviour from winter exercises (Krakatoa, Moscow) Improved industry response would reduce isolation needs Support for Isolation process is up to 48 hours (GWh) Long September Sept with 10 Sept with re- December Assumptions mcm/d allocation of Assumptions supply risk 910 1127 910 Medium 440 440 Short 459 676 459 651 Total ® 440 1809 2026 2001 All above isolation needs are similar

Isolation Component ® ® Supply risk has a lesser impact than in supply / demand Isolation needs established from observed behaviour from winter exercises (Krakatoa, Moscow) Improved industry response would reduce isolation needs Support for Isolation process is up to 48 hours (GWh) Long September Sept with 10 Sept with re- December Assumptions mcm/d allocation of Assumptions supply risk 910 1127 910 Medium 440 440 Short 459 676 459 651 Total ® 440 1809 2026 2001 All above isolation needs are similar

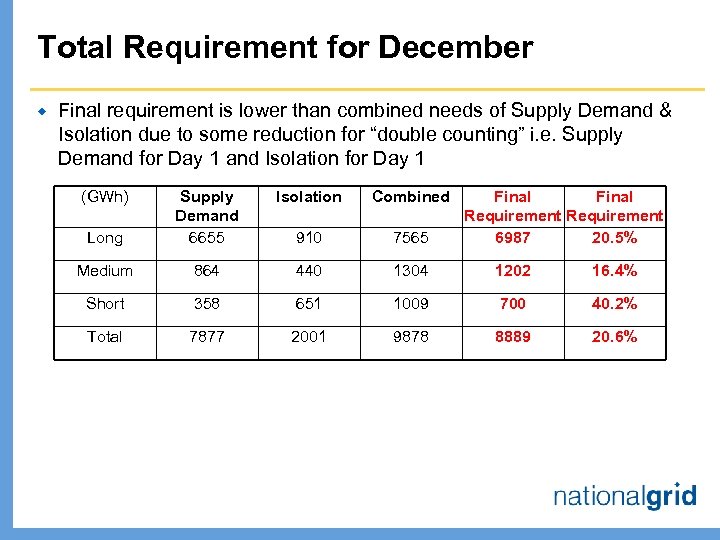

Total Requirement for December ® Final requirement is lower than combined needs of Supply Demand & Isolation due to some reduction for “double counting” i. e. Supply Demand for Day 1 and Isolation for Day 1 (GWh) Isolation Combined Long Supply Demand 6655 Final Requirement 6987 20. 5% 910 7565 Medium 864 440 1304 1202 16. 4% Short 358 651 1009 700 40. 2% Total 7877 2001 9878 8889 20. 6%

Total Requirement for December ® Final requirement is lower than combined needs of Supply Demand & Isolation due to some reduction for “double counting” i. e. Supply Demand for Day 1 and Isolation for Day 1 (GWh) Isolation Combined Long Supply Demand 6655 Final Requirement 6987 20. 5% 910 7565 Medium 864 440 1304 1202 16. 4% Short 358 651 1009 700 40. 2% Total 7877 2001 9878 8889 20. 6%

Monitor profiles

Monitor profiles

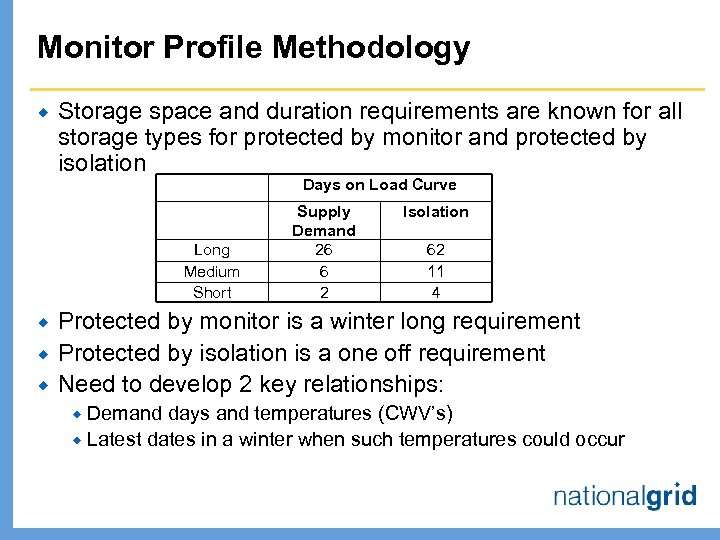

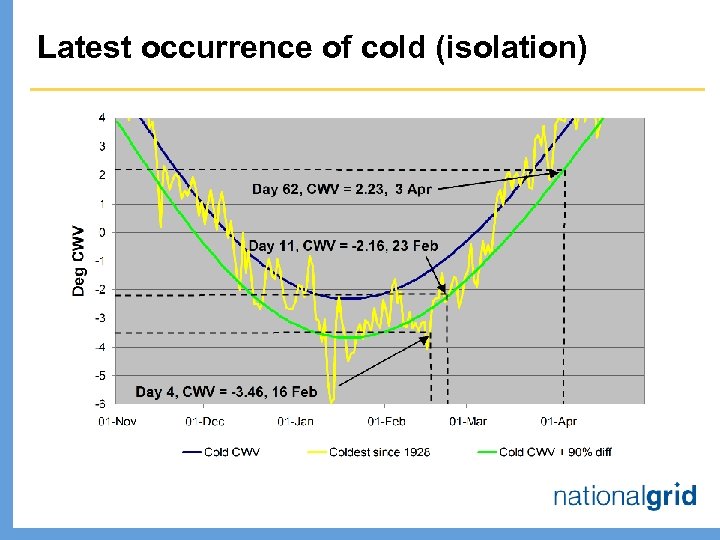

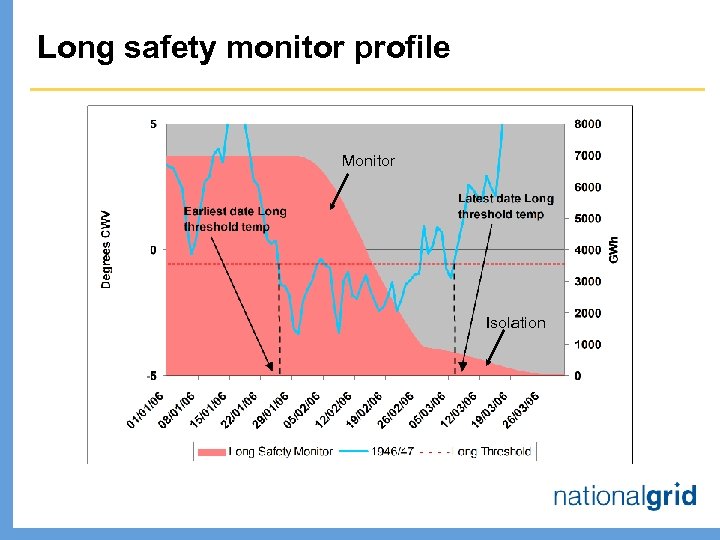

Monitor Profile Methodology ® Storage space and duration requirements are known for all storage types for protected by monitor and protected by isolation Days on Load Curve Long Medium Short ® ® ® Supply Demand 26 6 2 Isolation 62 11 4 Protected by monitor is a winter long requirement Protected by isolation is a one off requirement Need to develop 2 key relationships: ® Demand days and temperatures (CWV’s) ® Latest dates in a winter when such temperatures could occur

Monitor Profile Methodology ® Storage space and duration requirements are known for all storage types for protected by monitor and protected by isolation Days on Load Curve Long Medium Short ® ® ® Supply Demand 26 6 2 Isolation 62 11 4 Protected by monitor is a winter long requirement Protected by isolation is a one off requirement Need to develop 2 key relationships: ® Demand days and temperatures (CWV’s) ® Latest dates in a winter when such temperatures could occur

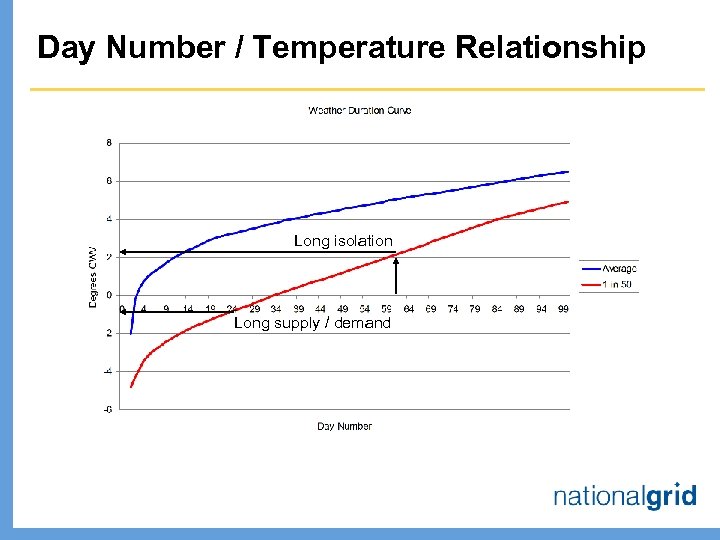

Day Number / Temperature Relationship Long isolation Long supply / demand

Day Number / Temperature Relationship Long isolation Long supply / demand

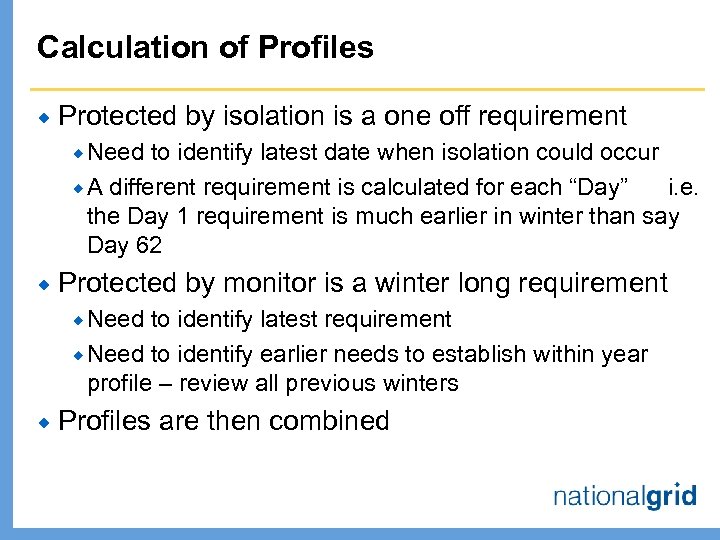

Calculation of Profiles ® Protected by isolation is a one off requirement ® Need to identify latest date when isolation could occur ® A different requirement is calculated for each “Day” i. e. the Day 1 requirement is much earlier in winter than say Day 62 ® Protected by monitor is a winter long requirement ® Need to identify latest requirement ® Need to identify earlier needs to establish within year profile – review all previous winters ® Profiles are then combined

Calculation of Profiles ® Protected by isolation is a one off requirement ® Need to identify latest date when isolation could occur ® A different requirement is calculated for each “Day” i. e. the Day 1 requirement is much earlier in winter than say Day 62 ® Protected by monitor is a winter long requirement ® Need to identify latest requirement ® Need to identify earlier needs to establish within year profile – review all previous winters ® Profiles are then combined

Latest occurrence of cold (isolation)

Latest occurrence of cold (isolation)

Long safety monitor profile Monitor Isolation

Long safety monitor profile Monitor Isolation