3127b1e4f5714f4641f48dbf61933b70.ppt

- Количество слайдов: 13

2001 ASME/API Gas-Lift Workshop Testing and Modeling Gas-Lift Valves by Ken Decker, Decker Technology Cleon Dunham, Oilfield Automation Consulting Feb. 6, 2001 ASME/API Gas-Lift Workshop 1

2001 ASME/API Gas-Lift Workshop Testing and Modeling Gas-Lift Valves by Ken Decker, Decker Technology Cleon Dunham, Oilfield Automation Consulting Feb. 6, 2001 ASME/API Gas-Lift Workshop 1

Testing and Modeling Gas-Lift Valves Outline • • Gas-lift valves are important API Recommended Practice 11 V 2 Gas-lift Valve Performance Clearinghouse (VPC) VPC members Valves tested by VPC Typical VPC results How member companies use VPC results Future plans Feb. 6, 2001 ASME/API Gas-Lift Workshop 2

Testing and Modeling Gas-Lift Valves Outline • • Gas-lift valves are important API Recommended Practice 11 V 2 Gas-lift Valve Performance Clearinghouse (VPC) VPC members Valves tested by VPC Typical VPC results How member companies use VPC results Future plans Feb. 6, 2001 ASME/API Gas-Lift Workshop 2

Gas-Lift Valves Are Important Gas-lift valves are needed to: • Allow gas-lift wells to unload (work down) to the desired operating depth • Remain open and transmit enough gas to allow transfer to the next valve • Remain in good condition during unloading – Not be eroded by completion fluid • Close and remain closed when lifting from deeper – Not leak – Not allow well fluids to back flow into the annulus • Re-open when needed for re-start (kick off) Feb. 6, 2001 ASME/API Gas-Lift Workshop 3

Gas-Lift Valves Are Important Gas-lift valves are needed to: • Allow gas-lift wells to unload (work down) to the desired operating depth • Remain open and transmit enough gas to allow transfer to the next valve • Remain in good condition during unloading – Not be eroded by completion fluid • Close and remain closed when lifting from deeper – Not leak – Not allow well fluids to back flow into the annulus • Re-open when needed for re-start (kick off) Feb. 6, 2001 ASME/API Gas-Lift Workshop 3

API Recommended Practice 11 V 2 Prior to API RP 11 V 2: • Gas-lift valve open/close calculations based on steady state force/balance equation • Gas passage based on Thornhill-Craver – These didn't represent real performance in dynamic operation – Gas-lift designers were forced to use rules of thumb • API RP 11 V 2 published in January, 1995 – Provided standards for gas-lift valve testing & modeling – But offered no specific process to implement these standards on a routine basis Feb. 6, 2001 ASME/API Gas-Lift Workshop 4

API Recommended Practice 11 V 2 Prior to API RP 11 V 2: • Gas-lift valve open/close calculations based on steady state force/balance equation • Gas passage based on Thornhill-Craver – These didn't represent real performance in dynamic operation – Gas-lift designers were forced to use rules of thumb • API RP 11 V 2 published in January, 1995 – Provided standards for gas-lift valve testing & modeling – But offered no specific process to implement these standards on a routine basis Feb. 6, 2001 ASME/API Gas-Lift Workshop 4

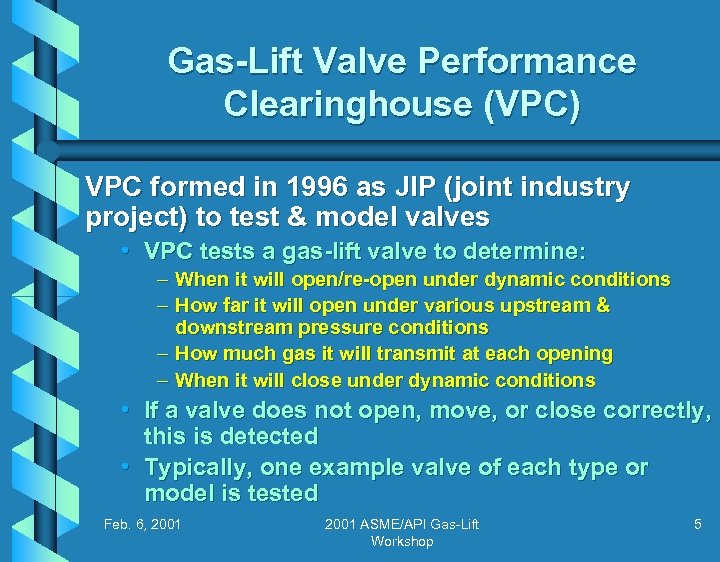

Gas-Lift Valve Performance Clearinghouse (VPC) VPC formed in 1996 as JIP (joint industry project) to test & model valves • VPC tests a gas-lift valve to determine: – When it will open/re-open under dynamic conditions – How far it will open under various upstream & downstream pressure conditions – How much gas it will transmit at each opening – When it will close under dynamic conditions • If a valve does not open, move, or close correctly, this is detected • Typically, one example valve of each type or model is tested Feb. 6, 2001 ASME/API Gas-Lift Workshop 5

Gas-Lift Valve Performance Clearinghouse (VPC) VPC formed in 1996 as JIP (joint industry project) to test & model valves • VPC tests a gas-lift valve to determine: – When it will open/re-open under dynamic conditions – How far it will open under various upstream & downstream pressure conditions – How much gas it will transmit at each opening – When it will close under dynamic conditions • If a valve does not open, move, or close correctly, this is detected • Typically, one example valve of each type or model is tested Feb. 6, 2001 ASME/API Gas-Lift Workshop 5

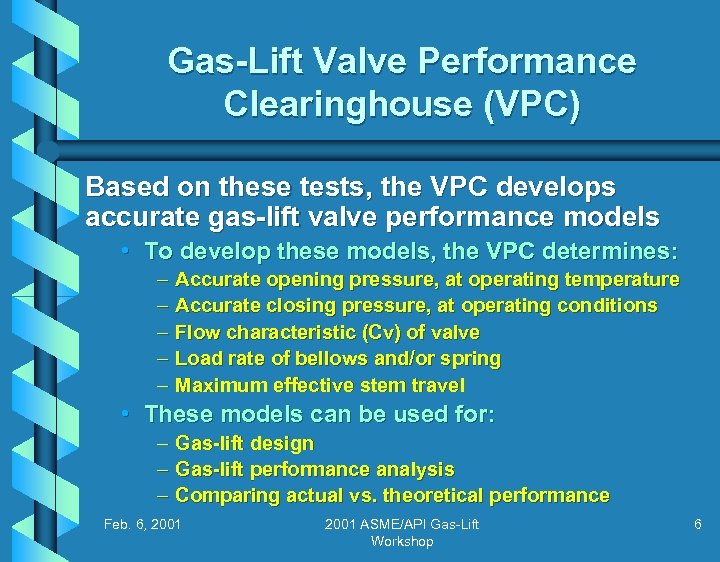

Gas-Lift Valve Performance Clearinghouse (VPC) Based on these tests, the VPC develops accurate gas-lift valve performance models • To develop these models, the VPC determines: – Accurate opening pressure, at operating temperature – Accurate closing pressure, at operating conditions – Flow characteristic (Cv) of valve – Load rate of bellows and/or spring – Maximum effective stem travel • These models can be used for: – Gas-lift design – Gas-lift performance analysis – Comparing actual vs. theoretical performance Feb. 6, 2001 ASME/API Gas-Lift Workshop 6

Gas-Lift Valve Performance Clearinghouse (VPC) Based on these tests, the VPC develops accurate gas-lift valve performance models • To develop these models, the VPC determines: – Accurate opening pressure, at operating temperature – Accurate closing pressure, at operating conditions – Flow characteristic (Cv) of valve – Load rate of bellows and/or spring – Maximum effective stem travel • These models can be used for: – Gas-lift design – Gas-lift performance analysis – Comparing actual vs. theoretical performance Feb. 6, 2001 ASME/API Gas-Lift Workshop 6

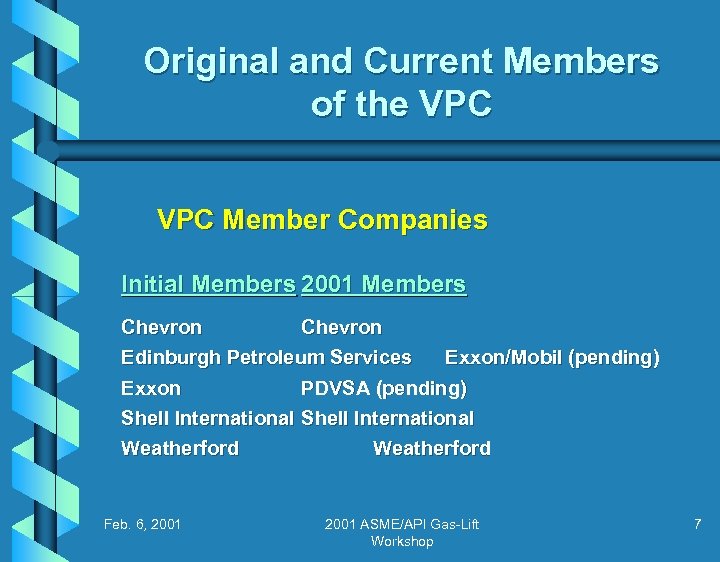

Original and Current Members of the VPC Member Companies Initial Members 2001 Members Chevron Edinburgh Petroleum Services Exxon/Mobil (pending) PDVSA (pending) Exxon Shell International Weatherford Feb. 6, 2001 Weatherford 2001 ASME/API Gas-Lift Workshop 7

Original and Current Members of the VPC Member Companies Initial Members 2001 Members Chevron Edinburgh Petroleum Services Exxon/Mobil (pending) PDVSA (pending) Exxon Shell International Weatherford Feb. 6, 2001 Weatherford 2001 ASME/API Gas-Lift Workshop 7

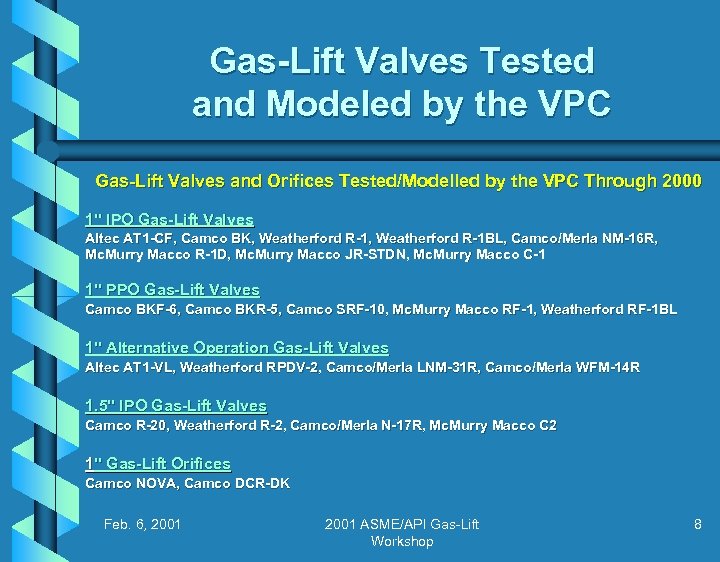

Gas-Lift Valves Tested and Modeled by the VPC Gas-Lift Valves and Orifices Tested/Modelled by the VPC Through 2000 1" IPO Gas-Lift Valves Altec AT 1 -CF, Camco BK, Weatherford R-1 BL, Camco/Merla NM-16 R, Mc. Murry Macco R-1 D, Mc. Murry Macco JR-STDN, Mc. Murry Macco C-1 1" PPO Gas-Lift Valves Camco BKF-6, Camco BKR-5, Camco SRF-10, Mc. Murry Macco RF-1, Weatherford RF-1 BL 1" Alternative Operation Gas-Lift Valves Altec AT 1 -VL, Weatherford RPDV-2, Camco/Merla LNM-31 R, Camco/Merla WFM-14 R 1. 5" IPO Gas-Lift Valves Camco R-20, Weatherford R-2, Camco/Merla N-17 R, Mc. Murry Macco C 2 1" Gas-Lift Orifices Camco NOVA, Camco DCR-DK Feb. 6, 2001 ASME/API Gas-Lift Workshop 8

Gas-Lift Valves Tested and Modeled by the VPC Gas-Lift Valves and Orifices Tested/Modelled by the VPC Through 2000 1" IPO Gas-Lift Valves Altec AT 1 -CF, Camco BK, Weatherford R-1 BL, Camco/Merla NM-16 R, Mc. Murry Macco R-1 D, Mc. Murry Macco JR-STDN, Mc. Murry Macco C-1 1" PPO Gas-Lift Valves Camco BKF-6, Camco BKR-5, Camco SRF-10, Mc. Murry Macco RF-1, Weatherford RF-1 BL 1" Alternative Operation Gas-Lift Valves Altec AT 1 -VL, Weatherford RPDV-2, Camco/Merla LNM-31 R, Camco/Merla WFM-14 R 1. 5" IPO Gas-Lift Valves Camco R-20, Weatherford R-2, Camco/Merla N-17 R, Mc. Murry Macco C 2 1" Gas-Lift Orifices Camco NOVA, Camco DCR-DK Feb. 6, 2001 ASME/API Gas-Lift Workshop 8

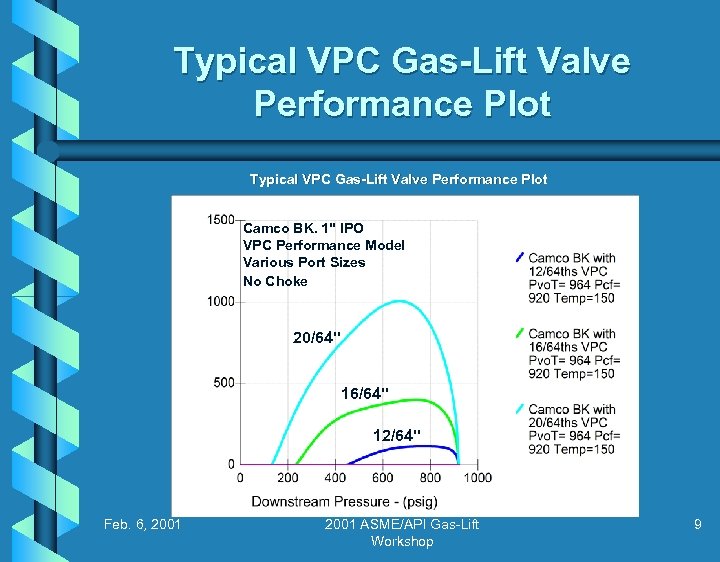

Typical VPC Gas-Lift Valve Performance Plot Camco BK. 1" IPO VPC Performance Model Various Port Sizes No Choke 20/64" 16/64" 12/64" Feb. 6, 2001 ASME/API Gas-Lift Workshop 9

Typical VPC Gas-Lift Valve Performance Plot Camco BK. 1" IPO VPC Performance Model Various Port Sizes No Choke 20/64" 16/64" 12/64" Feb. 6, 2001 ASME/API Gas-Lift Workshop 9

How Member Companies Use VPC Results For example, in Shell: • Only gas-lift valves that have been tested and modeled by the VPC are recommended for use – Any valve found to be inadequate is not recommended for use • VPC gas-lift valve models have been implemented in Win. GLUE – They are used in gas-lift design & performance analysis • In some cases, valves that have been found to be inadequate have been redesigned or replace by the manufacturer – This is clearly a win/win for all concerned Feb. 6, 2001 ASME/API Gas-Lift Workshop 10

How Member Companies Use VPC Results For example, in Shell: • Only gas-lift valves that have been tested and modeled by the VPC are recommended for use – Any valve found to be inadequate is not recommended for use • VPC gas-lift valve models have been implemented in Win. GLUE – They are used in gas-lift design & performance analysis • In some cases, valves that have been found to be inadequate have been redesigned or replace by the manufacturer – This is clearly a win/win for all concerned Feb. 6, 2001 ASME/API Gas-Lift Workshop 10

Future Plans of the VPC In 2001 and beyond, the VPC members have agreed to: • Continue gas-lift valve testing and modeling – Valves/orifices nominated by users – Selected new valves – Several valves of a type/model to check for consistency • Conduct appropriate evaluations – Potential for erosion during unloading – Effect of chokes on erosion potential – Potential life cycle of bellows – Impact of various metallurgies Feb. 6, 2001 ASME/API Gas-Lift Workshop 11

Future Plans of the VPC In 2001 and beyond, the VPC members have agreed to: • Continue gas-lift valve testing and modeling – Valves/orifices nominated by users – Selected new valves – Several valves of a type/model to check for consistency • Conduct appropriate evaluations – Potential for erosion during unloading – Effect of chokes on erosion potential – Potential life cycle of bellows – Impact of various metallurgies Feb. 6, 2001 ASME/API Gas-Lift Workshop 11

Other Companies are Welcome to Join the VPC The VPC is a "joint industry project. " • It is funded and controlled by its members – It is not a profit making organization – Its purpose is to advance gas-lift performance through improved gas-lift valve understanding – Any gas-lift operator or service company is welcome – The VPC meets annually, usually in October, to agree on the budget and plan for the next year • Member companies have found great value in: – Having accurate, reliable information on their valves – Having accurate performance models of their valves – Being able to screen out valves that are not satisfactory Feb. 6, 2001 ASME/API Gas-Lift Workshop 12

Other Companies are Welcome to Join the VPC The VPC is a "joint industry project. " • It is funded and controlled by its members – It is not a profit making organization – Its purpose is to advance gas-lift performance through improved gas-lift valve understanding – Any gas-lift operator or service company is welcome – The VPC meets annually, usually in October, to agree on the budget and plan for the next year • Member companies have found great value in: – Having accurate, reliable information on their valves – Having accurate performance models of their valves – Being able to screen out valves that are not satisfactory Feb. 6, 2001 ASME/API Gas-Lift Workshop 12

Testing and Modeling Gas-Lift Valves Conclusions • Most gas-lift wells require gas-lift valves to lift effectively • Valves do not perform as previously assumed – The steady state force balance equation is not sufficient – Thornhill-Craver can not accurately predict gas passage • To effectively design and analyze gas-lift wells, we must understand gas-lift valve performance – API RP 11 V 2 provides the needed standards – The VPC provides the mechanism to implement these standards for the industry Feb. 6, 2001 ASME/API Gas-Lift Workshop 13

Testing and Modeling Gas-Lift Valves Conclusions • Most gas-lift wells require gas-lift valves to lift effectively • Valves do not perform as previously assumed – The steady state force balance equation is not sufficient – Thornhill-Craver can not accurately predict gas passage • To effectively design and analyze gas-lift wells, we must understand gas-lift valve performance – API RP 11 V 2 provides the needed standards – The VPC provides the mechanism to implement these standards for the industry Feb. 6, 2001 ASME/API Gas-Lift Workshop 13