2eeb36199bac44514a35ca738748bfa4.ppt

- Количество слайдов: 32

20 Dec. , ‘ 04 Production of Gaseous Detector Elements u History EST-DEM R. De Oliveira of Gas Detectors in Workshop u Fabrication of GEM Detectors u Fabrication of Micro-megas u Readout Circuits u Other Detectors

20 Dec. , ‘ 04 Production of Gaseous Detector Elements u History EST-DEM R. De Oliveira of Gas Detectors in Workshop u Fabrication of GEM Detectors u Fabrication of Micro-megas u Readout Circuits u Other Detectors

20 Dec. , ‘ 04 History of Gas Detectors in Workshop EST-DEM R. De Oliveira ‘ 96: first GEM about 50 x 50 mm with a gain of 10. ‘ 97: first GEM 100 x 100 mm with gain of 10000. ‘ 98 - ‘ 99: first GEM 400 x 400 mm; 1 D and 2 D readouts; first micro-groove and micro-well detectors. ‘ 00: first 3 D GEM readout; first 1 D readout for Micro-megas in COMPASS. ‘ 01: first PIXEL GEM readout; first 2 D Micro-megas readout. ‘ 03: first PIXEL Micro-megas readout.

20 Dec. , ‘ 04 History of Gas Detectors in Workshop EST-DEM R. De Oliveira ‘ 96: first GEM about 50 x 50 mm with a gain of 10. ‘ 97: first GEM 100 x 100 mm with gain of 10000. ‘ 98 - ‘ 99: first GEM 400 x 400 mm; 1 D and 2 D readouts; first micro-groove and micro-well detectors. ‘ 00: first 3 D GEM readout; first 1 D readout for Micro-megas in COMPASS. ‘ 01: first PIXEL GEM readout; first 2 D Micro-megas readout. ‘ 03: first PIXEL Micro-megas readout.

20 Dec. , ‘ 04 Fabrication of GEM Detector u Theory of Operation u Cross-section of GEM u Manufacturing Process u Examples u GEM Capabilities u How to Buy a GEM? Around 500 GEMs produced per year in CERN. EST-DEM R. De Oliveira

20 Dec. , ‘ 04 Fabrication of GEM Detector u Theory of Operation u Cross-section of GEM u Manufacturing Process u Examples u GEM Capabilities u How to Buy a GEM? Around 500 GEMs produced per year in CERN. EST-DEM R. De Oliveira

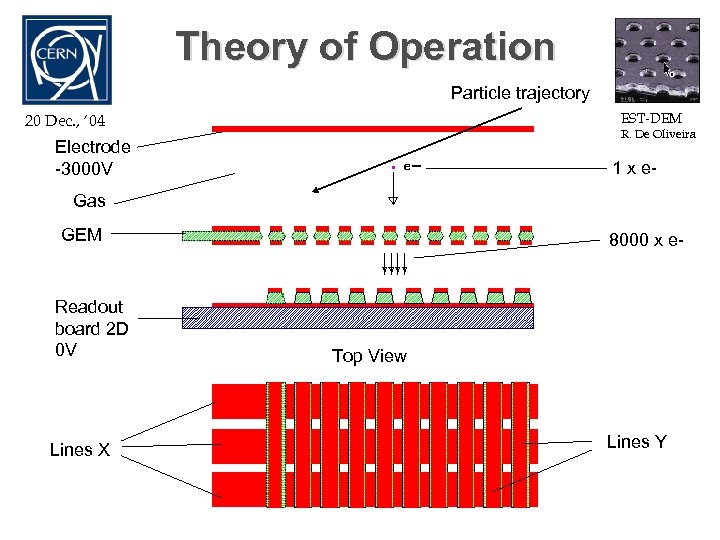

Theory of Operation Particle trajectory EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Electrode -3000 V 1 x e- Gas GEM Readout board 2 D 0 V Lines X 8000 x e- Top View Lines Y

Theory of Operation Particle trajectory EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Electrode -3000 V 1 x e- Gas GEM Readout board 2 D 0 V Lines X 8000 x e- Top View Lines Y

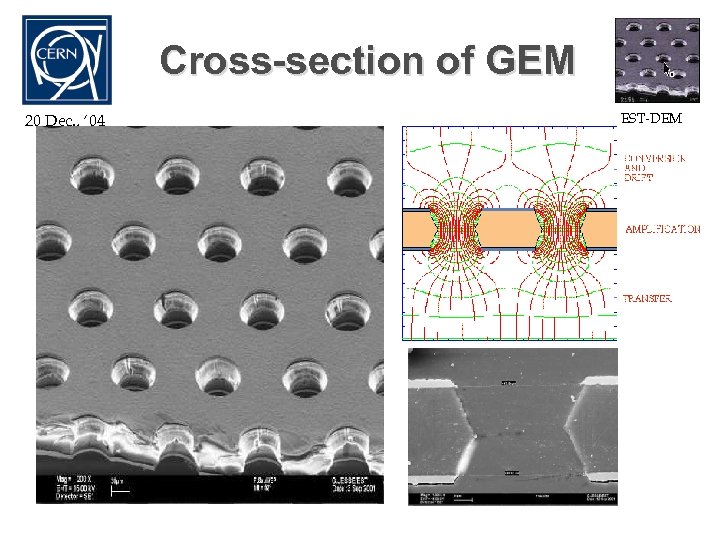

Cross-section of GEM 20 Dec. , ‘ 04 EST-DEM R. De Oliveira

Cross-section of GEM 20 Dec. , ‘ 04 EST-DEM R. De Oliveira

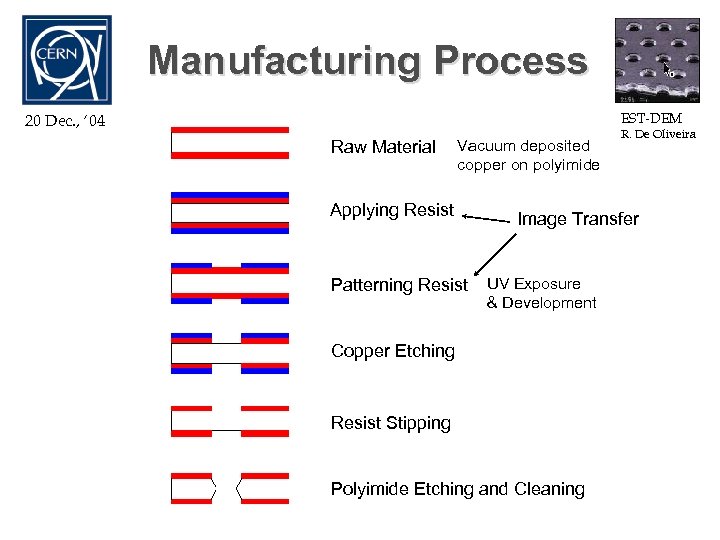

Manufacturing Process EST-DEM 20 Dec. , ‘ 04 Raw Material Vacuum deposited copper on polyimide Applying Resist Patterning Resist R. De Oliveira Image Transfer UV Exposure & Development Copper Etching Resist Stipping Polyimide Etching and Cleaning

Manufacturing Process EST-DEM 20 Dec. , ‘ 04 Raw Material Vacuum deposited copper on polyimide Applying Resist Patterning Resist R. De Oliveira Image Transfer UV Exposure & Development Copper Etching Resist Stipping Polyimide Etching and Cleaning

Manufacturing Process EST-DEM 20 Dec. , ‘ 04 u Image transfer with film pocket R. De Oliveira u Copper Etching in a Drawer Machine

Manufacturing Process EST-DEM 20 Dec. , ‘ 04 u Image transfer with film pocket R. De Oliveira u Copper Etching in a Drawer Machine

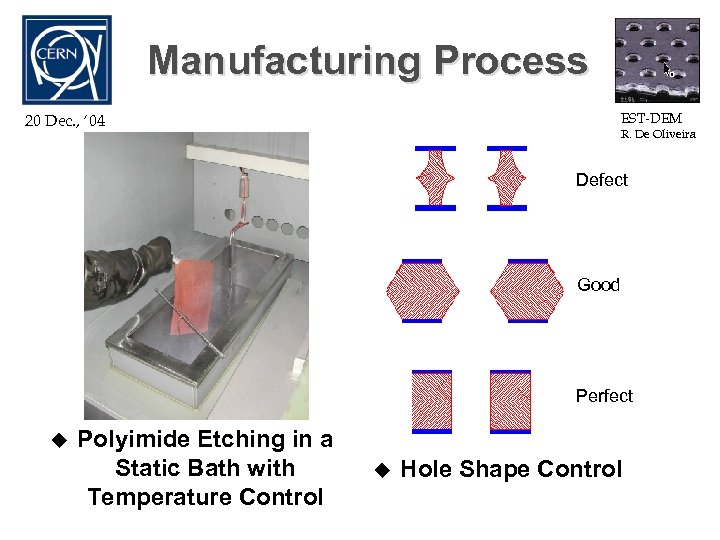

Manufacturing Process EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Defect Good Perfect u Polyimide Etching in a Static Bath with Temperature Control u Hole Shape Control

Manufacturing Process EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Defect Good Perfect u Polyimide Etching in a Static Bath with Temperature Control u Hole Shape Control

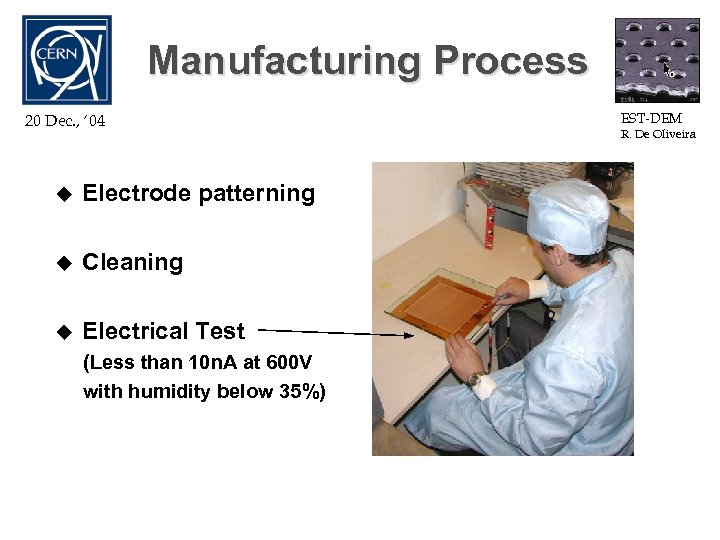

Manufacturing Process 20 Dec. , ‘ 04 u Electrode patterning u Cleaning u Electrical Test (Less than 10 n. A at 600 V with humidity below 35%) EST-DEM R. De Oliveira

Manufacturing Process 20 Dec. , ‘ 04 u Electrode patterning u Cleaning u Electrical Test (Less than 10 n. A at 600 V with humidity below 35%) EST-DEM R. De Oliveira

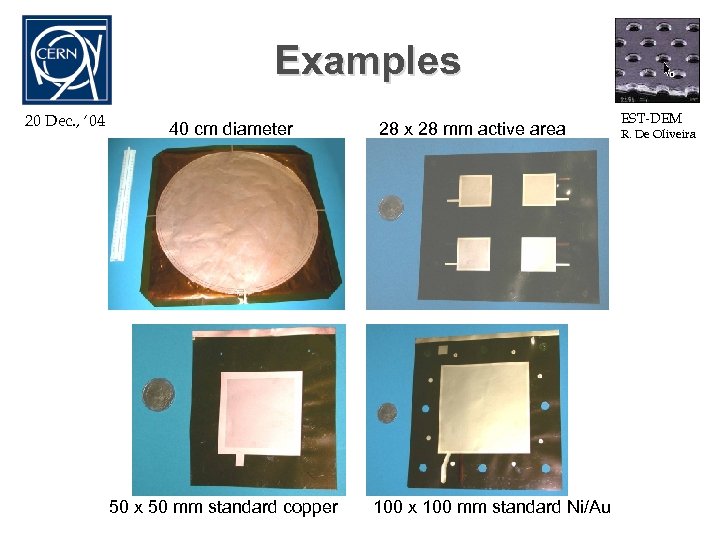

Examples 20 Dec. , ‘ 04 40 cm diameter 50 x 50 mm standard copper 28 x 28 mm active area 100 x 100 mm standard Ni/Au EST-DEM R. De Oliveira

Examples 20 Dec. , ‘ 04 40 cm diameter 50 x 50 mm standard copper 28 x 28 mm active area 100 x 100 mm standard Ni/Au EST-DEM R. De Oliveira

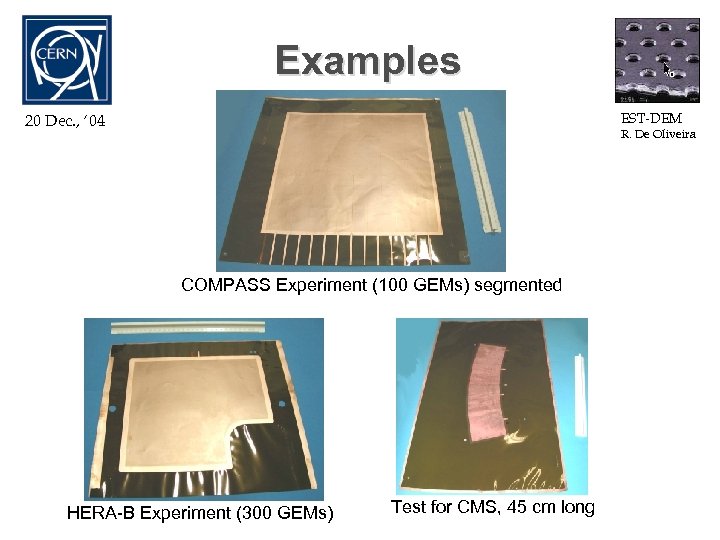

Examples EST-DEM 20 Dec. , ‘ 04 R. De Oliveira COMPASS Experiment (100 GEMs) segmented HERA-B Experiment (300 GEMs) Test for CMS, 45 cm long

Examples EST-DEM 20 Dec. , ‘ 04 R. De Oliveira COMPASS Experiment (100 GEMs) segmented HERA-B Experiment (300 GEMs) Test for CMS, 45 cm long

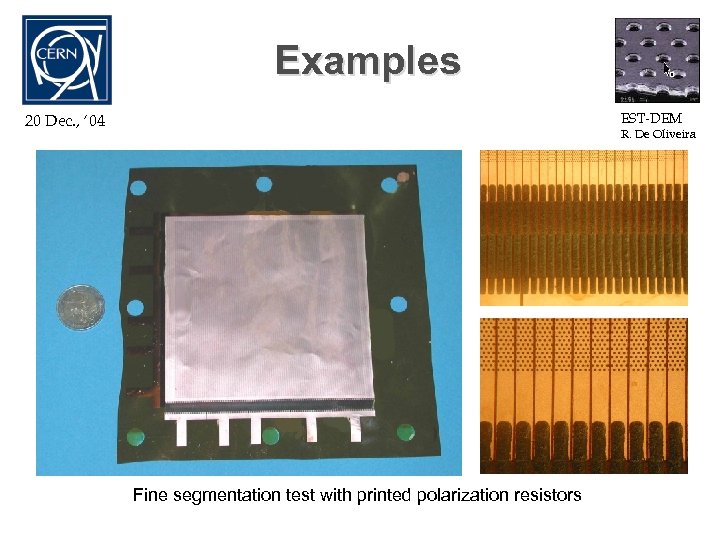

Examples EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Fine segmentation test with printed polarization resistors

Examples EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Fine segmentation test with printed polarization resistors

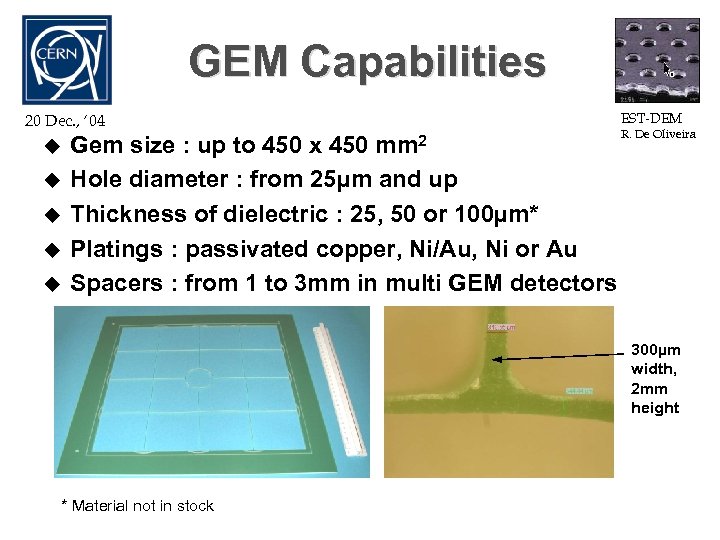

GEM Capabilities EST-DEM 20 Dec. , ‘ 04 u u u mm 2 Gem size : up to 450 x 450 Hole diameter : from 25µm and up Thickness of dielectric : 25, 50 or 100µm* Platings : passivated copper, Ni/Au, Ni or Au Spacers : from 1 to 3 mm in multi GEM detectors R. De Oliveira 300µm width, 2 mm height * Material not in stock

GEM Capabilities EST-DEM 20 Dec. , ‘ 04 u u u mm 2 Gem size : up to 450 x 450 Hole diameter : from 25µm and up Thickness of dielectric : 25, 50 or 100µm* Platings : passivated copper, Ni/Au, Ni or Au Spacers : from 1 to 3 mm in multi GEM detectors R. De Oliveira 300µm width, 2 mm height * Material not in stock

How to Buy a GEM? EST-DEM 20 Dec. , ‘ 04 R. De Oliveira http: //www. cern. ch/dem/products/gem u standard products : 100 x 100 mm active area u 50 x 50 mm active area u with or without frame u passivated copper or Ni/Au u u non-standard workshop products : please contact the

How to Buy a GEM? EST-DEM 20 Dec. , ‘ 04 R. De Oliveira http: //www. cern. ch/dem/products/gem u standard products : 100 x 100 mm active area u 50 x 50 mm active area u with or without frame u passivated copper or Ni/Au u u non-standard workshop products : please contact the

20 Dec. , ‘ 04 Fabrication of Micro-megas Micro. Megas: u u Theory of Operation Manufacturing Process Possibilities Examples Bulk Micro. Megas: u u u Manufacturing Process Possibilities Examples EST-DEM R. De Oliveira

20 Dec. , ‘ 04 Fabrication of Micro-megas Micro. Megas: u u Theory of Operation Manufacturing Process Possibilities Examples Bulk Micro. Megas: u u u Manufacturing Process Possibilities Examples EST-DEM R. De Oliveira

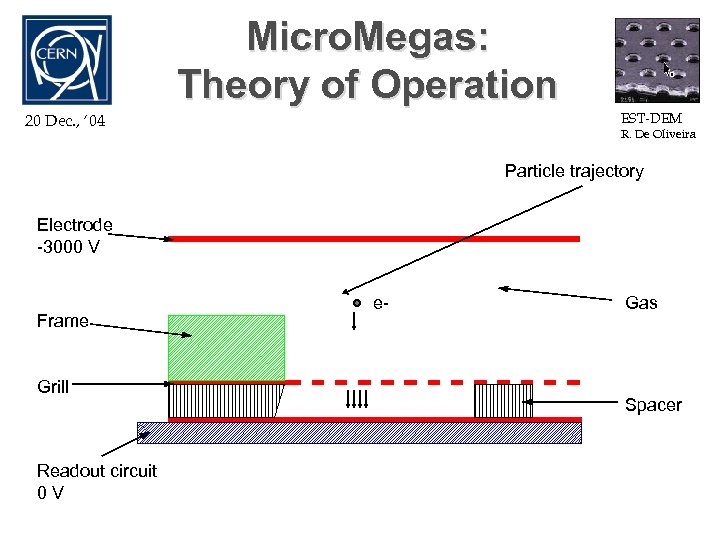

Micro. Megas: Theory of Operation EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Particle trajectory Electrode -3000 V Frame Grill Readout circuit 0 V e- Gas Spacer

Micro. Megas: Theory of Operation EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Particle trajectory Electrode -3000 V Frame Grill Readout circuit 0 V e- Gas Spacer

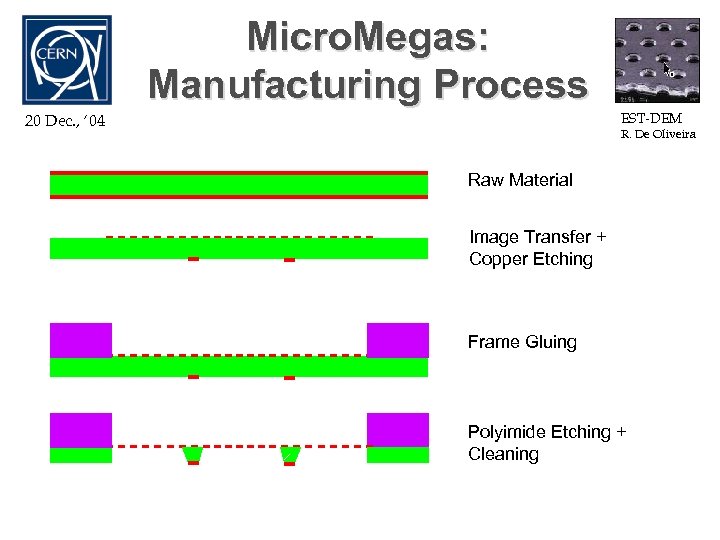

Micro. Megas: Manufacturing Process EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Raw Material Image Transfer + Copper Etching Frame Gluing Polyimide Etching + Cleaning

Micro. Megas: Manufacturing Process EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Raw Material Image Transfer + Copper Etching Frame Gluing Polyimide Etching + Cleaning

Micro. Megas: Possibilities EST-DEM 20 Dec. , ‘ 04 u Size of the grill : R. De Oliveira max 40 cm diameter u Bigger sizes under development u u Pattern u Metals : mini 500 mesh, 1000 under study : copper, nickel, titanium u Spacers : on the grill : 25 or 50µm thick (polyimide) u on the readout : from 50µm to 0. 5 mm (modified epoxy) u

Micro. Megas: Possibilities EST-DEM 20 Dec. , ‘ 04 u Size of the grill : R. De Oliveira max 40 cm diameter u Bigger sizes under development u u Pattern u Metals : mini 500 mesh, 1000 under study : copper, nickel, titanium u Spacers : on the grill : 25 or 50µm thick (polyimide) u on the readout : from 50µm to 0. 5 mm (modified epoxy) u

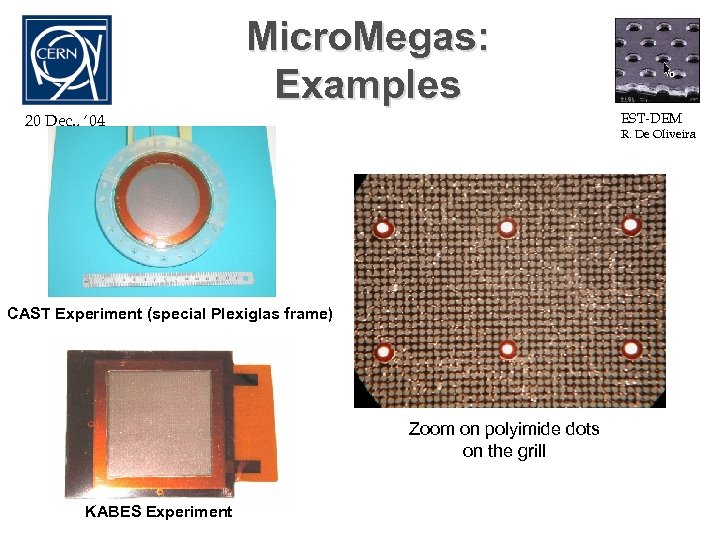

Micro. Megas: Examples EST-DEM 20 Dec. , ‘ 04 R. De Oliveira CAST Experiment (special Plexiglas frame) Zoom on polyimide dots on the grill KABES Experiment

Micro. Megas: Examples EST-DEM 20 Dec. , ‘ 04 R. De Oliveira CAST Experiment (special Plexiglas frame) Zoom on polyimide dots on the grill KABES Experiment

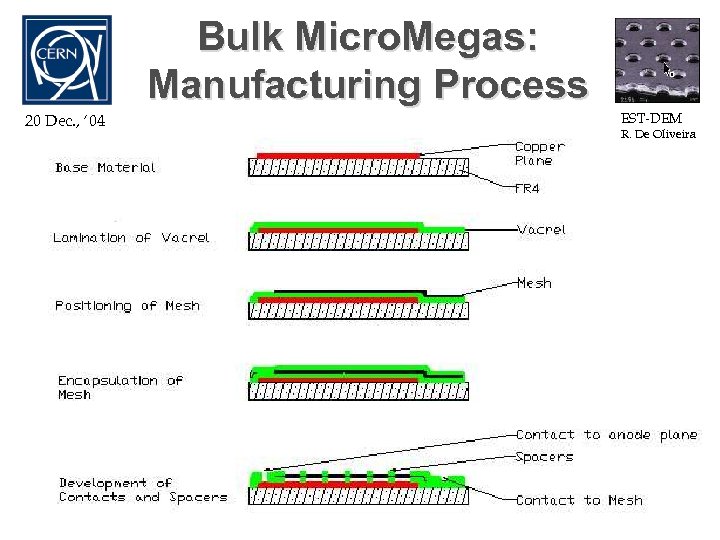

Bulk Micro. Megas: Manufacturing Process 20 Dec. , ‘ 04 EST-DEM R. De Oliveira

Bulk Micro. Megas: Manufacturing Process 20 Dec. , ‘ 04 EST-DEM R. De Oliveira

Bulk Micro. Megas: Possibilities EST-DEM 20 Dec. , ‘ 04 u R. De Oliveira Size of the bulk: u max 40 cm u Pattern : mini 600 mesh u Metals: stainless steel u Spacers: u u 75µm height (150µm, 225µm…), modified epoxy Multi grid systems (under study)

Bulk Micro. Megas: Possibilities EST-DEM 20 Dec. , ‘ 04 u R. De Oliveira Size of the bulk: u max 40 cm u Pattern : mini 600 mesh u Metals: stainless steel u Spacers: u u 75µm height (150µm, 225µm…), modified epoxy Multi grid systems (under study)

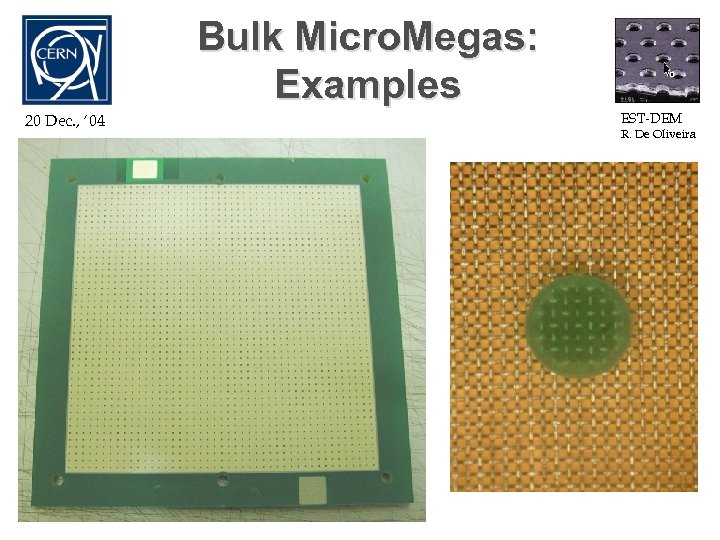

Bulk Micro. Megas: Examples 20 Dec. , ‘ 04 EST-DEM R. De Oliveira

Bulk Micro. Megas: Examples 20 Dec. , ‘ 04 EST-DEM R. De Oliveira

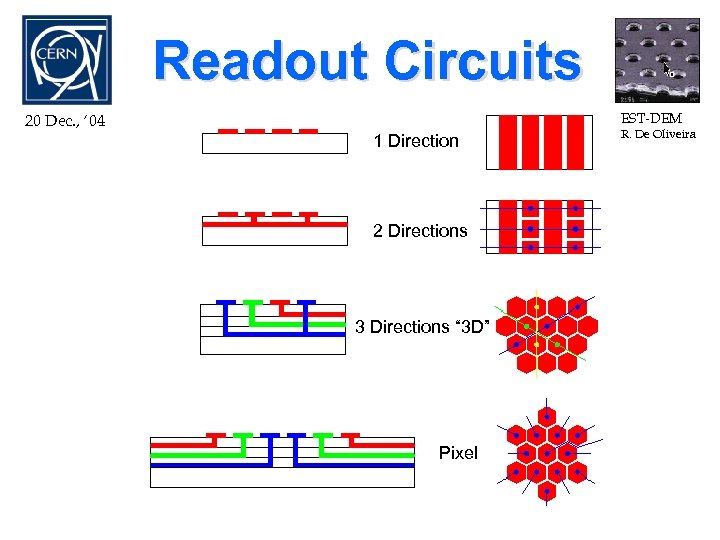

Readout Circuits 20 Dec. , ‘ 04 EST-DEM 1 Direction 2 Directions 3 Directions “ 3 D” Pixel R. De Oliveira

Readout Circuits 20 Dec. , ‘ 04 EST-DEM 1 Direction 2 Directions 3 Directions “ 3 D” Pixel R. De Oliveira

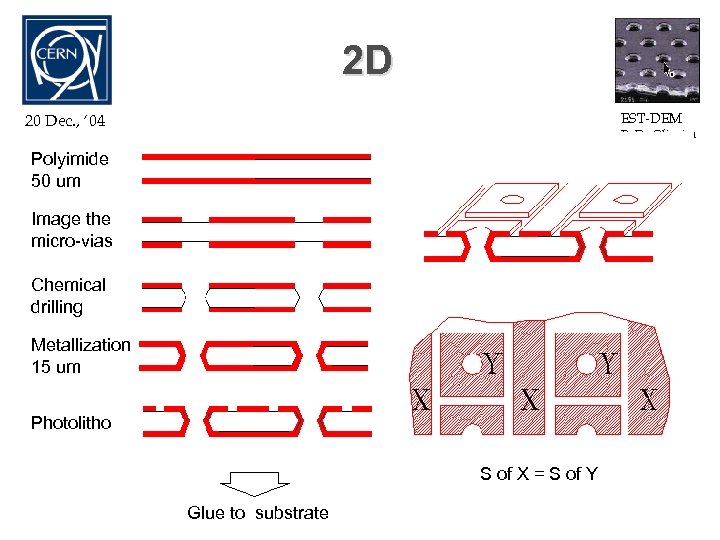

2 D EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Polyimide 50 um Image the micro-vias Chemical drilling Metallization 15 um Photolitho S of X = S of Y Glue to substrate

2 D EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Polyimide 50 um Image the micro-vias Chemical drilling Metallization 15 um Photolitho S of X = S of Y Glue to substrate

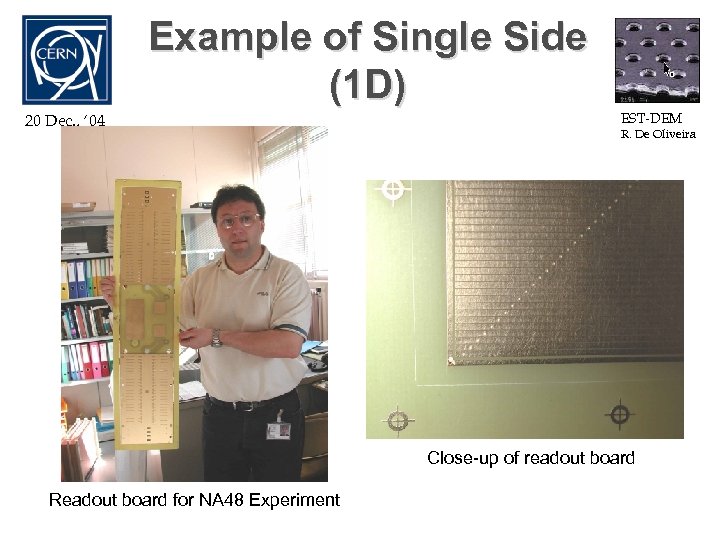

Example of Single Side (1 D) 20 Dec. , ‘ 04 EST-DEM R. De Oliveira Close-up of readout board Readout board for NA 48 Experiment

Example of Single Side (1 D) 20 Dec. , ‘ 04 EST-DEM R. De Oliveira Close-up of readout board Readout board for NA 48 Experiment

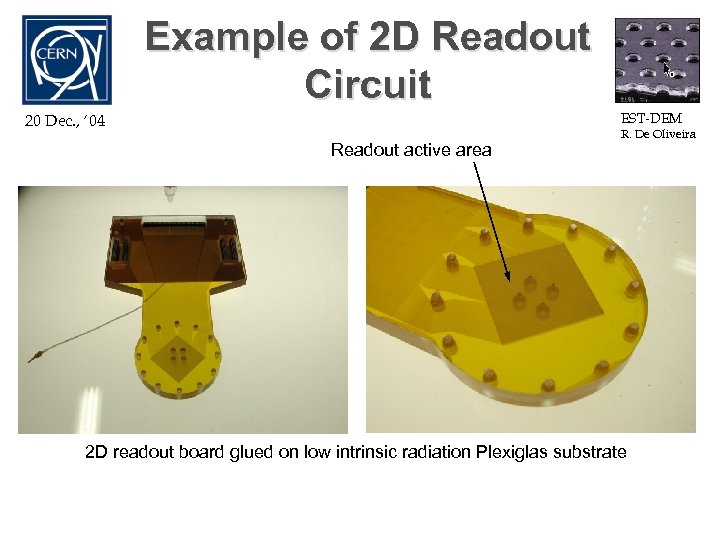

Example of 2 D Readout Circuit EST-DEM 20 Dec. , ‘ 04 Readout active area R. De Oliveira 2 D readout board glued on low intrinsic radiation Plexiglas substrate

Example of 2 D Readout Circuit EST-DEM 20 Dec. , ‘ 04 Readout active area R. De Oliveira 2 D readout board glued on low intrinsic radiation Plexiglas substrate

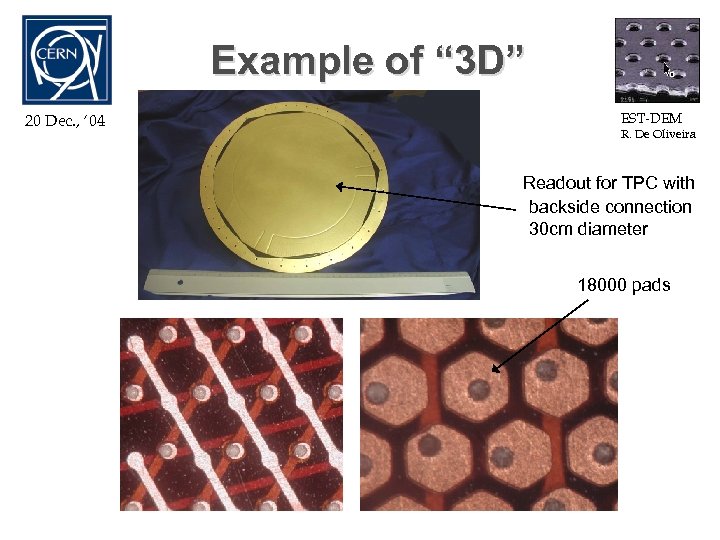

Example of “ 3 D” 20 Dec. , ‘ 04 EST-DEM R. De Oliveira Readout for TPC with backside connection 30 cm diameter 18000 pads

Example of “ 3 D” 20 Dec. , ‘ 04 EST-DEM R. De Oliveira Readout for TPC with backside connection 30 cm diameter 18000 pads

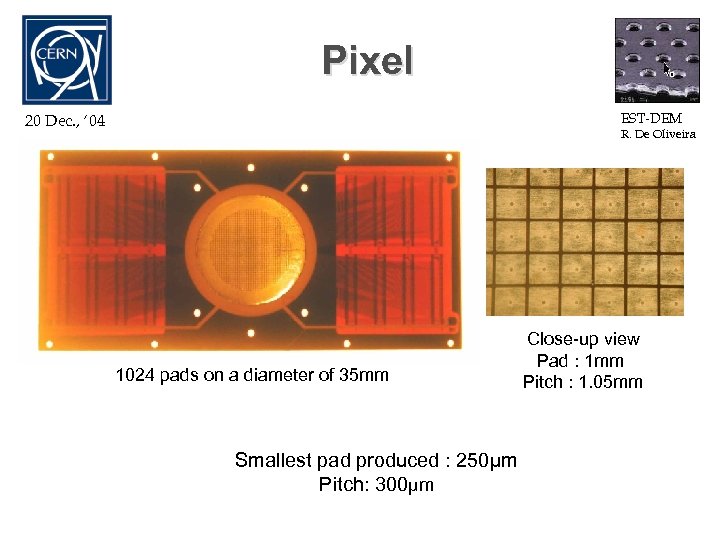

Pixel EST-DEM 20 Dec. , ‘ 04 R. De Oliveira 1024 pads on a diameter of 35 mm Smallest pad produced : 250µm Pitch: 300µm Close-up view Pad : 1 mm Pitch : 1. 05 mm

Pixel EST-DEM 20 Dec. , ‘ 04 R. De Oliveira 1024 pads on a diameter of 35 mm Smallest pad produced : 250µm Pitch: 300µm Close-up view Pad : 1 mm Pitch : 1. 05 mm

Readout Possibilities EST-DEM 20 Dec. , ‘ 04 u Supporting materials : FR 4 u Metals u u Flexible u u Low : without substrate mass : Carbon composite intrinsic radiation : Plexiglas u Kevlar Composite u R. De Oliveira

Readout Possibilities EST-DEM 20 Dec. , ‘ 04 u Supporting materials : FR 4 u Metals u u Flexible u u Low : without substrate mass : Carbon composite intrinsic radiation : Plexiglas u Kevlar Composite u R. De Oliveira

Other Detectors EST-DEM 20 Dec. , ‘ 04 R. De Oliveira u Micro-groove u Micro-well * * * R. Bellazzini group, INFN-Pisa, and University of Pisa

Other Detectors EST-DEM 20 Dec. , ‘ 04 R. De Oliveira u Micro-groove u Micro-well * * * R. Bellazzini group, INFN-Pisa, and University of Pisa

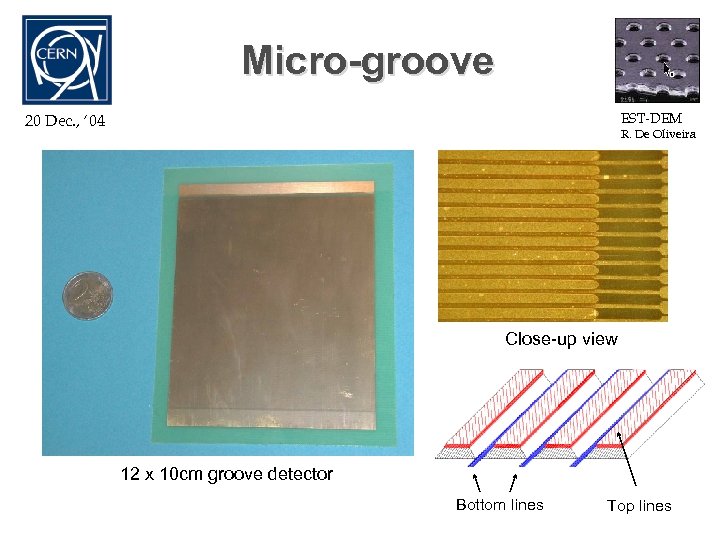

Micro-groove EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Close-up view 12 x 10 cm groove detector Bottom lines Top lines

Micro-groove EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Close-up view 12 x 10 cm groove detector Bottom lines Top lines

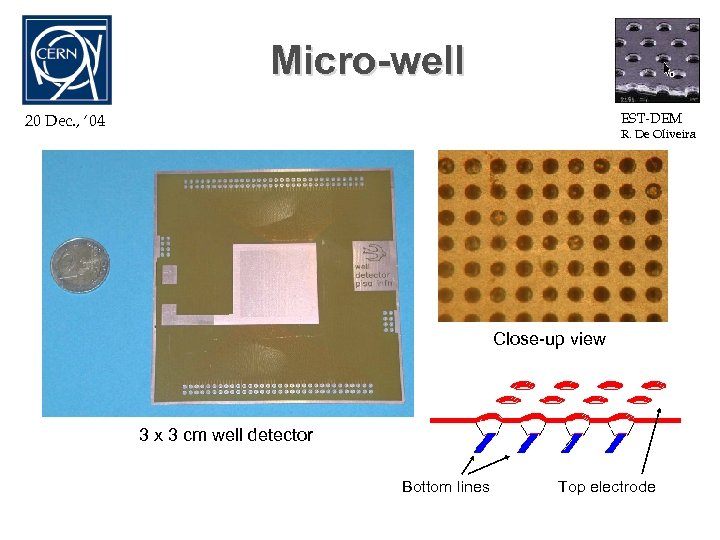

Micro-well EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Close-up view 3 x 3 cm well detector Bottom lines Top electrode

Micro-well EST-DEM 20 Dec. , ‘ 04 R. De Oliveira Close-up view 3 x 3 cm well detector Bottom lines Top electrode