a2028ad9d84d97878f0831a2dfffd356.ppt

- Количество слайдов: 47

20 - 1 Process Cost Accounting Chapter 20 Power. Point Authors: Susan Coomer Galbreath, Ph. D. , CPA Charles W. Caldwell, D. B. A. , CMA Jon A. Booker, Ph. D. , CPA, CIA Cynthia J. Rooney, Ph. D. , CPA Copyright © 2013 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

20 - 1 Process Cost Accounting Chapter 20 Power. Point Authors: Susan Coomer Galbreath, Ph. D. , CPA Charles W. Caldwell, D. B. A. , CMA Jon A. Booker, Ph. D. , CPA, CIA Cynthia J. Rooney, Ph. D. , CPA Copyright © 2013 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

20 - 2 C 1 Process Operations § Used for production of small, identical, low-cost items. § Mass produced in automated continuous production process. § Costs cannot be directly traced to each unit of product.

20 - 2 C 1 Process Operations § Used for production of small, identical, low-cost items. § Mass produced in automated continuous production process. § Costs cannot be directly traced to each unit of product.

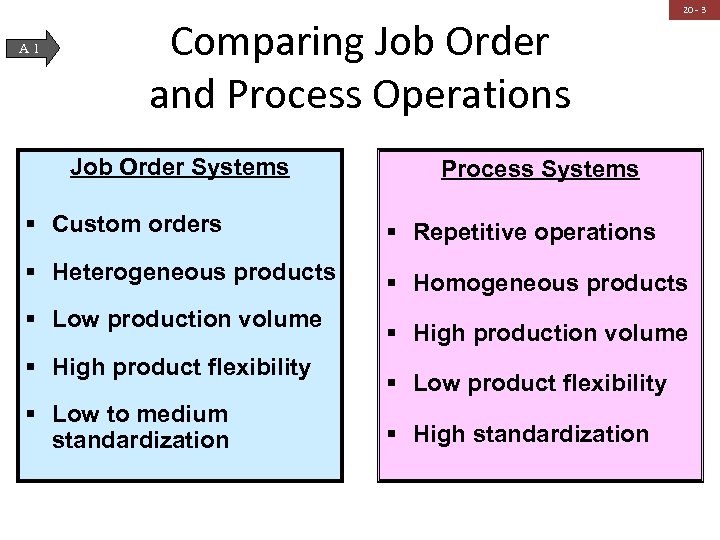

A 1 Comparing Job Order and Process Operations Job Order Systems 20 - 3 Process Systems § Custom orders § Repetitive operations § Heterogeneous products § Homogeneous products § Low production volume § High product flexibility § Low to medium standardization § High production volume § Low product flexibility § High standardization

A 1 Comparing Job Order and Process Operations Job Order Systems 20 - 3 Process Systems § Custom orders § Repetitive operations § Heterogeneous products § Homogeneous products § Low production volume § High product flexibility § Low to medium standardization § High production volume § Low product flexibility § High standardization

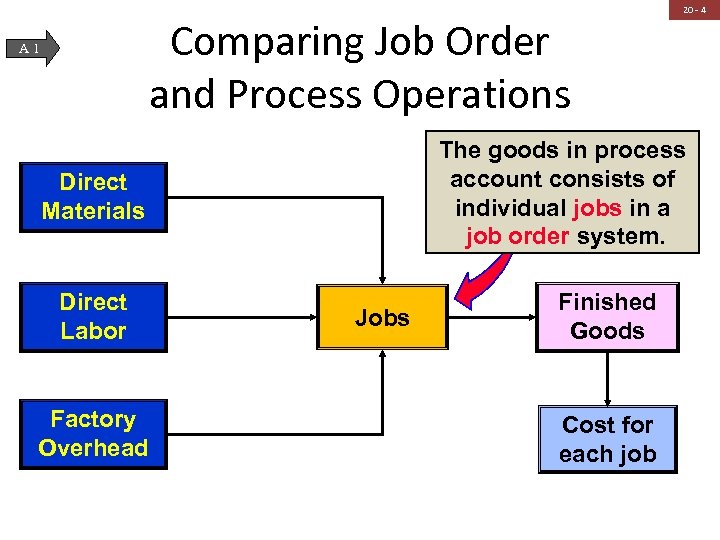

Comparing Job Order and Process Operations A 1 The goods in process account consists of individual jobs in a job order system. Direct Materials Direct Labor Factory Overhead 20 - 4 Jobs Finished Goods Cost for each job

Comparing Job Order and Process Operations A 1 The goods in process account consists of individual jobs in a job order system. Direct Materials Direct Labor Factory Overhead 20 - 4 Jobs Finished Goods Cost for each job

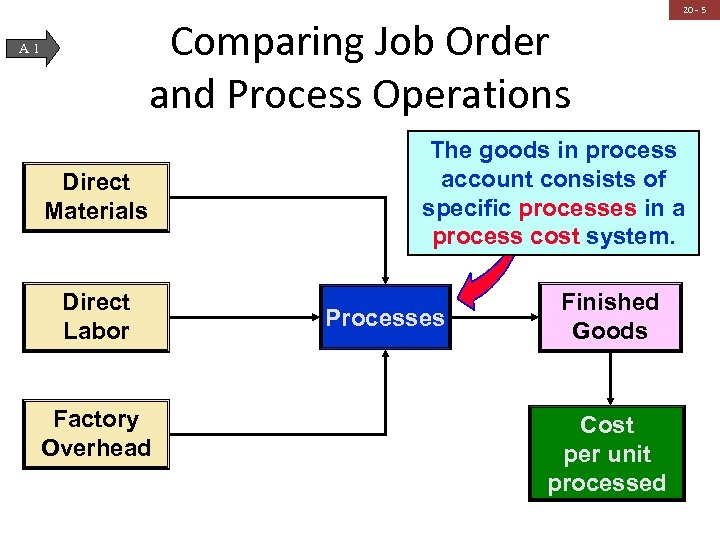

Comparing Job Order and Process Operations A 1 Direct Materials Direct Labor Factory Overhead 20 - 5 The goods in process account consists of specific processes in a process cost system. Processes Finished Goods Cost per unit processed

Comparing Job Order and Process Operations A 1 Direct Materials Direct Labor Factory Overhead 20 - 5 The goods in process account consists of specific processes in a process cost system. Processes Finished Goods Cost per unit processed

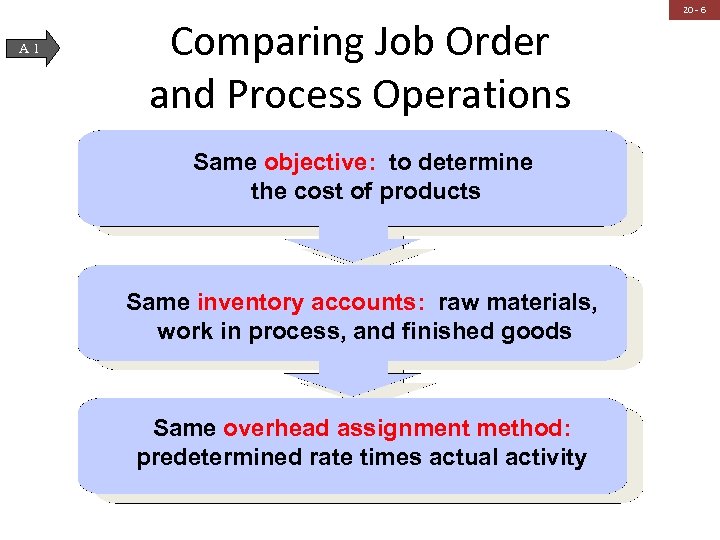

A 1 Comparing Job Order and Process Operations Same objective: to determine the cost of products Same inventory accounts: raw materials, work in process, and finished goods Same overhead assignment method: predetermined rate times actual activity 20 - 6

A 1 Comparing Job Order and Process Operations Same objective: to determine the cost of products Same inventory accounts: raw materials, work in process, and finished goods Same overhead assignment method: predetermined rate times actual activity 20 - 6

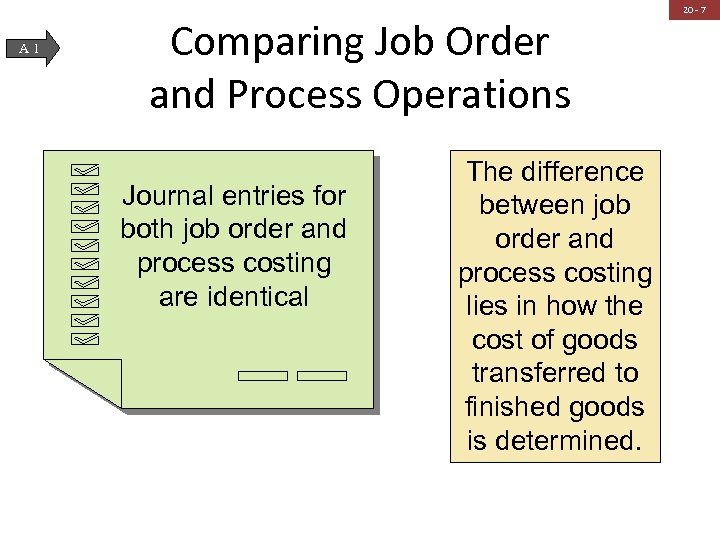

A 1 Comparing Job Order and Process Operations Journal entries for both job order and process costing are identical The difference between job order and process costing lies in how the cost of goods transferred to finished goods is determined. 20 - 7

A 1 Comparing Job Order and Process Operations Journal entries for both job order and process costing are identical The difference between job order and process costing lies in how the cost of goods transferred to finished goods is determined. 20 - 7

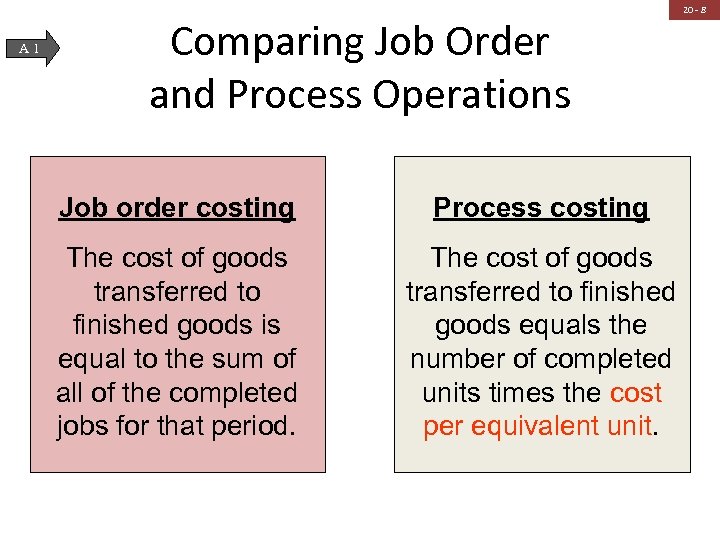

A 1 Comparing Job Order and Process Operations 20 - 8 Job order costing Process costing The cost of goods transferred to finished goods is equal to the sum of all of the completed jobs for that period. The cost of goods transferred to finished goods equals the number of completed units times the cost per equivalent unit.

A 1 Comparing Job Order and Process Operations 20 - 8 Job order costing Process costing The cost of goods transferred to finished goods is equal to the sum of all of the completed jobs for that period. The cost of goods transferred to finished goods equals the number of completed units times the cost per equivalent unit.

A 1 Gen. X Company ─ An Illustration Gen. X makes a product called Profen in a process cost system. 20 - 9

A 1 Gen. X Company ─ An Illustration Gen. X makes a product called Profen in a process cost system. 20 - 9

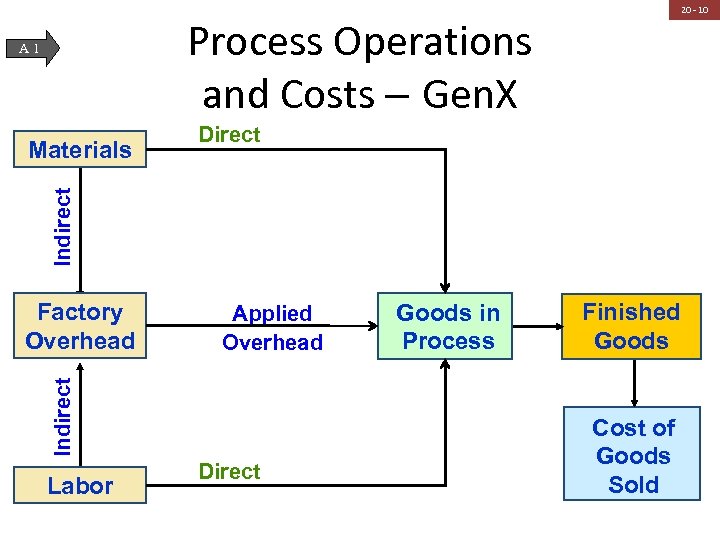

20 - 10 Process Operations and Costs – Gen. X A 1 Indirect Materials Direct Applied Overhead Indirect Factory Overhead Labor Direct Goods in Process Finished Goods Cost of Goods Sold

20 - 10 Process Operations and Costs – Gen. X A 1 Indirect Materials Direct Applied Overhead Indirect Factory Overhead Labor Direct Goods in Process Finished Goods Cost of Goods Sold

20 - 11 C 2 Equivalent Units of Production Costs are accumulated for a period of time by process or department. Unit cost is computed by dividing the accumulated costs by the number of equivalent units produced in the period.

20 - 11 C 2 Equivalent Units of Production Costs are accumulated for a period of time by process or department. Unit cost is computed by dividing the accumulated costs by the number of equivalent units produced in the period.

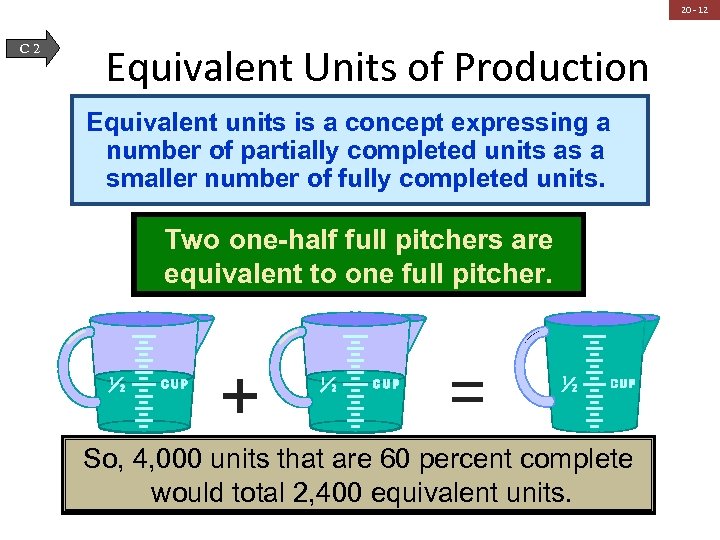

20 - 12 C 2 Equivalent Units of Production Equivalent units is a concept expressing a number of partially completed units as a smaller number of fully completed units. Two one-half full pitchers are equivalent to one full pitcher. + = So, 4, 000 units that are 60 percent complete would total 2, 400 equivalent units.

20 - 12 C 2 Equivalent Units of Production Equivalent units is a concept expressing a number of partially completed units as a smaller number of fully completed units. Two one-half full pitchers are equivalent to one full pitcher. + = So, 4, 000 units that are 60 percent complete would total 2, 400 equivalent units.

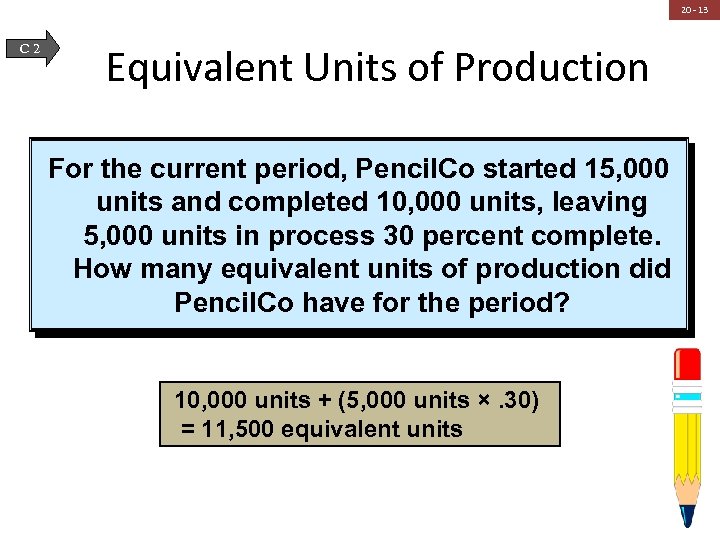

20 - 13 C 2 Equivalent Units of Production For the current period, Pencil. Co started 15, 000 units and completed 10, 000 units, leaving 5, 000 units in process 30 percent complete. How many equivalent units of production did Pencil. Co have for the period? 10, 000 units + (5, 000 units ×. 30) = 11, 500 equivalent units

20 - 13 C 2 Equivalent Units of Production For the current period, Pencil. Co started 15, 000 units and completed 10, 000 units, leaving 5, 000 units in process 30 percent complete. How many equivalent units of production did Pencil. Co have for the period? 10, 000 units + (5, 000 units ×. 30) = 11, 500 equivalent units

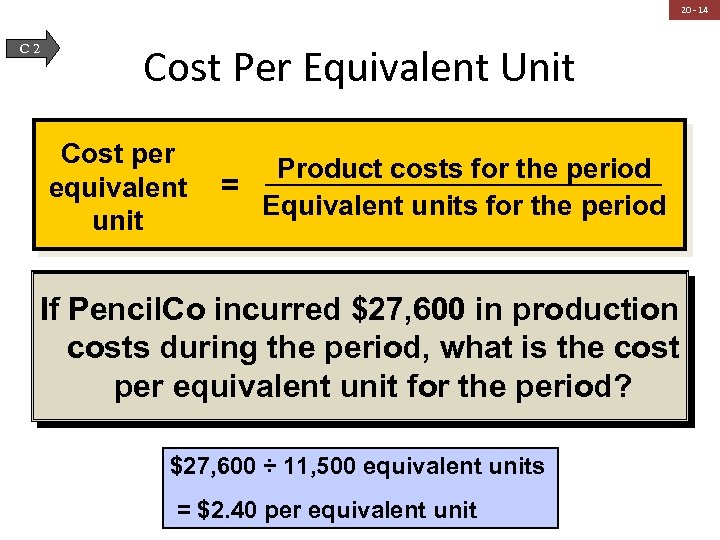

20 - 14 C 2 Cost Per Equivalent Unit Cost per equivalent unit Product costs for the period = Equivalent units for the period If Pencil. Co incurred $27, 600 in production costs during the period, what is the cost per equivalent unit for the period? $27, 600 ÷ 11, 500 equivalent units = $2. 40 per equivalent unit

20 - 14 C 2 Cost Per Equivalent Unit Cost per equivalent unit Product costs for the period = Equivalent units for the period If Pencil. Co incurred $27, 600 in production costs during the period, what is the cost per equivalent unit for the period? $27, 600 ÷ 11, 500 equivalent units = $2. 40 per equivalent unit

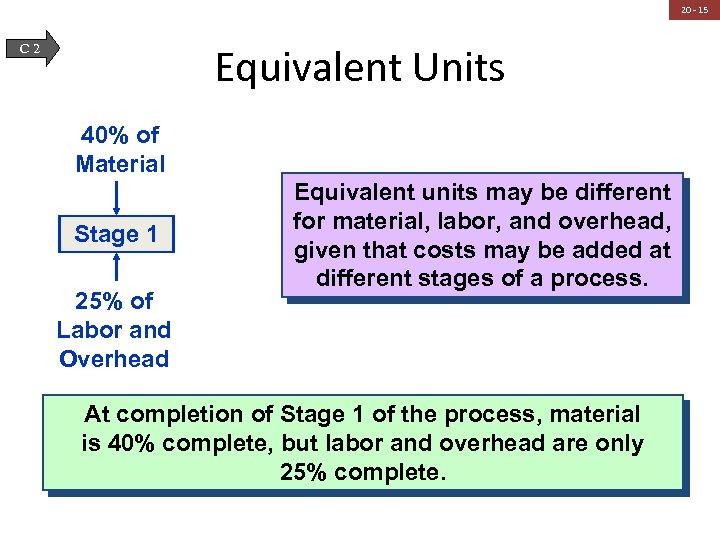

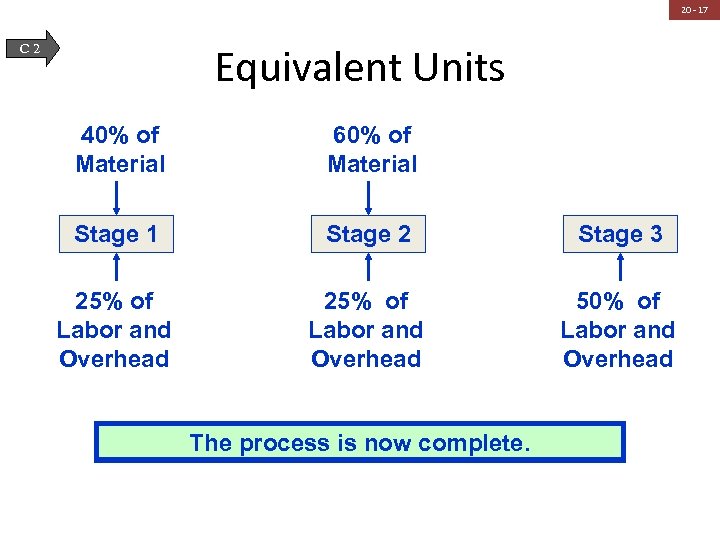

20 - 15 Equivalent Units C 2 40% of Material Stage 1 25% of Labor and Overhead Equivalent units may be different for material, labor, and overhead, given that costs may be added at different stages of a process. At completion of Stage 1 of the process, material is 40% complete, but labor and overhead are only 25% complete.

20 - 15 Equivalent Units C 2 40% of Material Stage 1 25% of Labor and Overhead Equivalent units may be different for material, labor, and overhead, given that costs may be added at different stages of a process. At completion of Stage 1 of the process, material is 40% complete, but labor and overhead are only 25% complete.

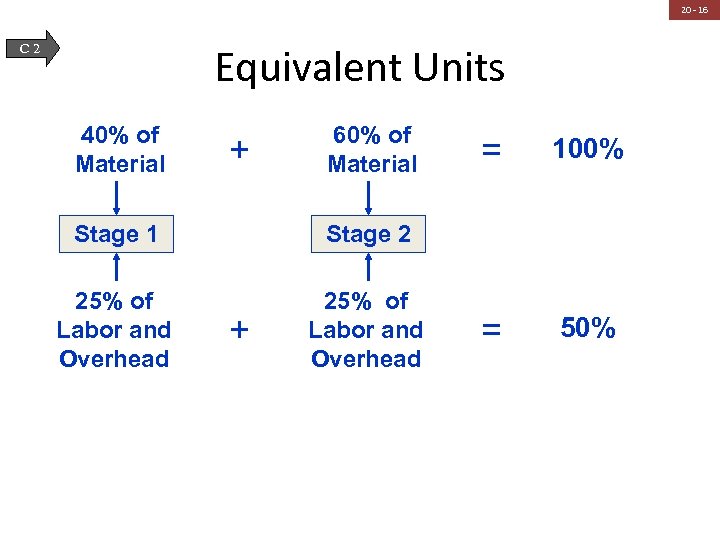

20 - 16 Equivalent Units C 2 40% of Material + 60% of Material Stage 1 25% of Labor and Overhead 100% = 50% Stage 2 25% of Labor and Overhead = +

20 - 16 Equivalent Units C 2 40% of Material + 60% of Material Stage 1 25% of Labor and Overhead 100% = 50% Stage 2 25% of Labor and Overhead = +

20 - 17 Equivalent Units C 2 40% of Material 60% of Material Stage 1 Stage 2 Stage 3 25% of Labor and Overhead 50% of Labor and Overhead The process is now complete.

20 - 17 Equivalent Units C 2 40% of Material 60% of Material Stage 1 Stage 2 Stage 3 25% of Labor and Overhead 50% of Labor and Overhead The process is now complete.

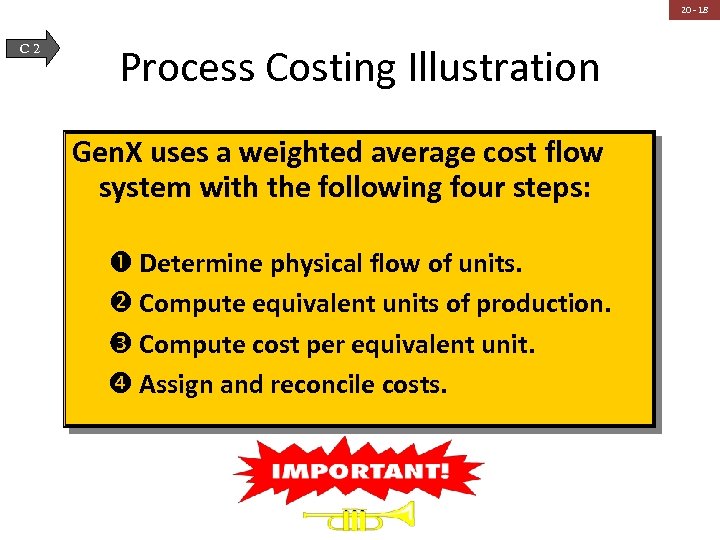

20 - 18 C 2 Process Costing Illustration Gen. X uses a weighted average cost flow system with the following four steps: Determine physical flow of units. Compute equivalent units of production. Compute cost per equivalent unit. Assign and reconcile costs.

20 - 18 C 2 Process Costing Illustration Gen. X uses a weighted average cost flow system with the following four steps: Determine physical flow of units. Compute equivalent units of production. Compute cost per equivalent unit. Assign and reconcile costs.

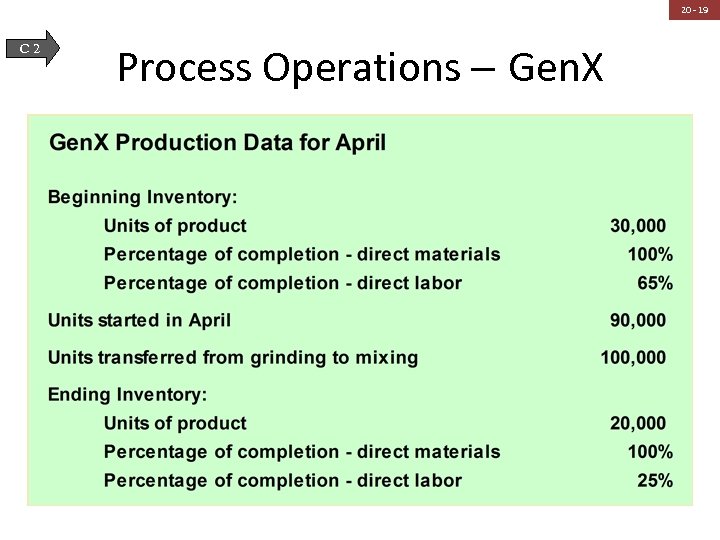

20 - 19 C 2 Process Operations – Gen. X

20 - 19 C 2 Process Operations – Gen. X

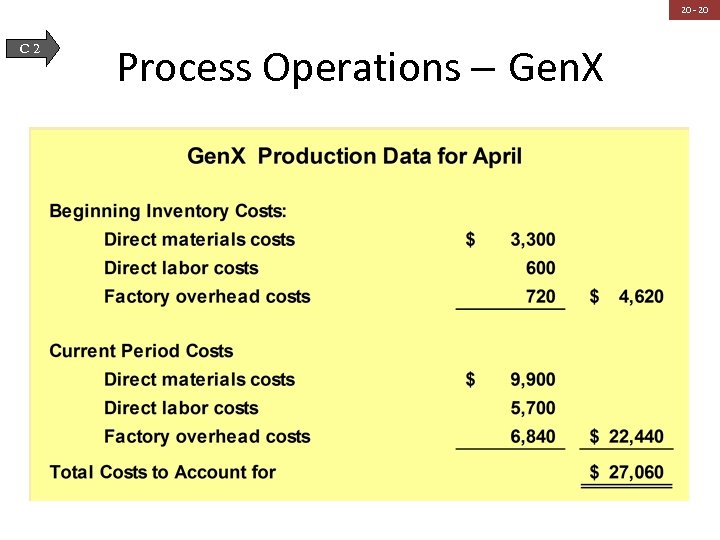

20 - 20 C 2 Process Operations – Gen. X

20 - 20 C 2 Process Operations – Gen. X

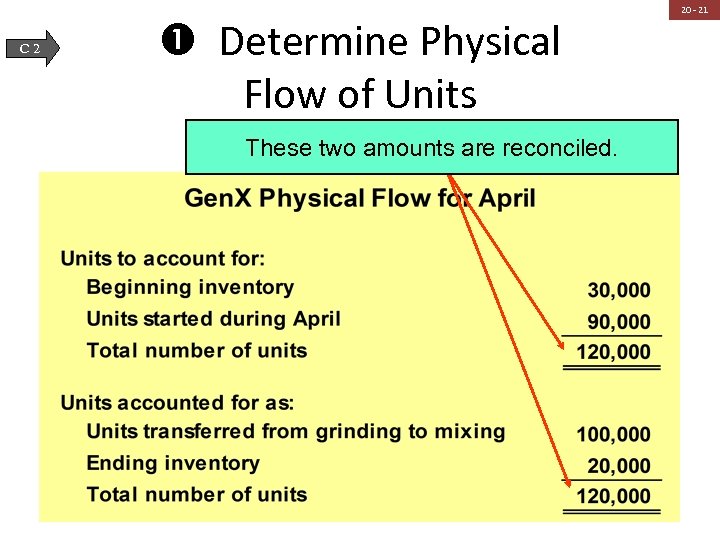

C 2 Determine Physical Flow of Units These two amounts are reconciled. 20 - 21

C 2 Determine Physical Flow of Units These two amounts are reconciled. 20 - 21

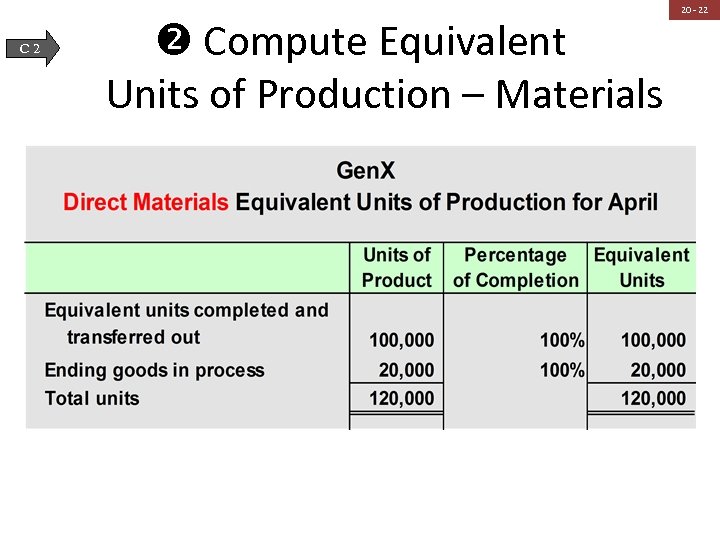

C 2 Compute Equivalent Units of Production – Materials 20 - 22

C 2 Compute Equivalent Units of Production – Materials 20 - 22

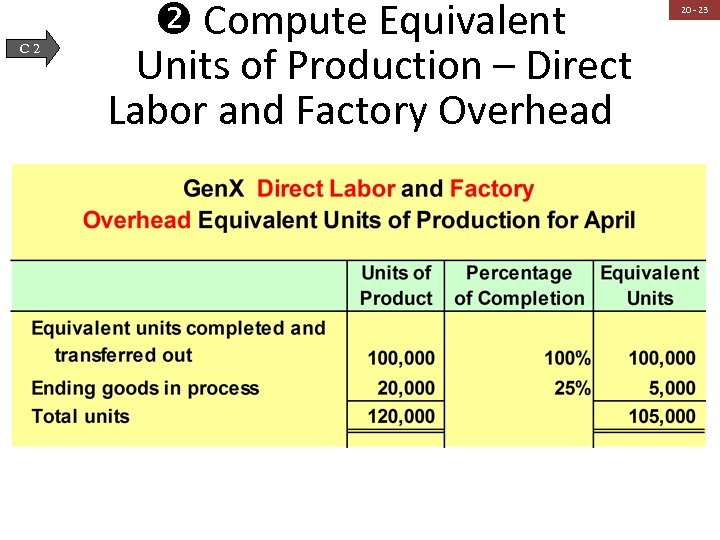

C 2 Compute Equivalent Units of Production – Direct Labor and Factory Overhead 20 - 23

C 2 Compute Equivalent Units of Production – Direct Labor and Factory Overhead 20 - 23

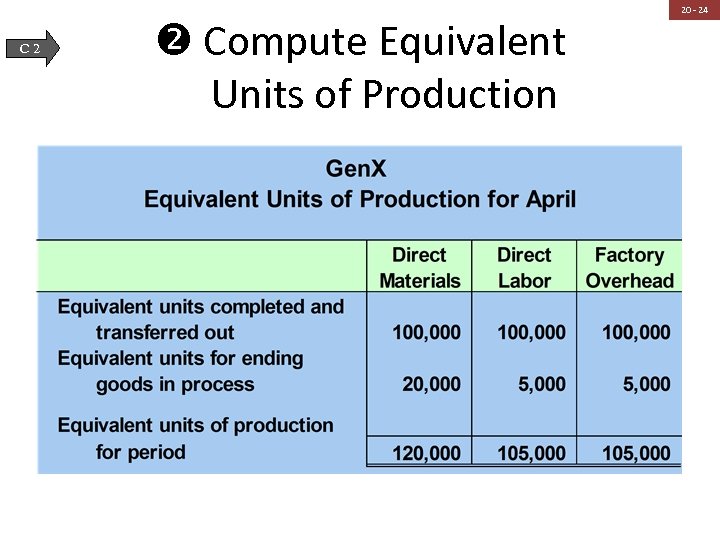

C 2 Compute Equivalent Units of Production 20 - 24

C 2 Compute Equivalent Units of Production 20 - 24

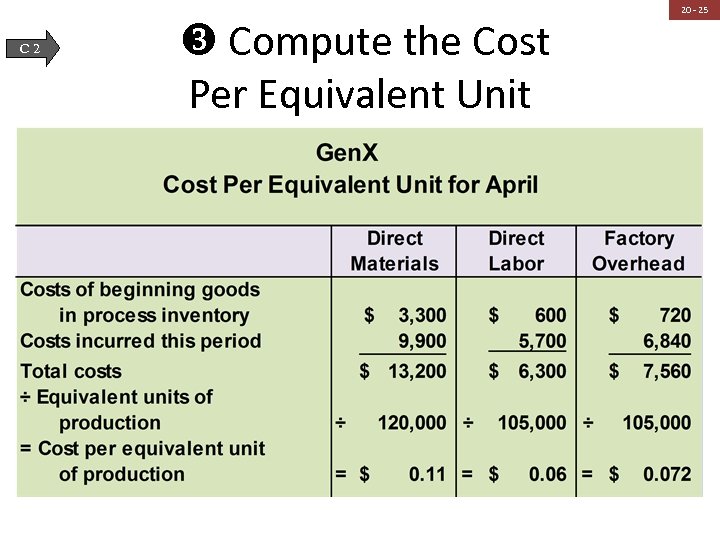

C 2 Compute the Cost Per Equivalent Unit 20 - 25

C 2 Compute the Cost Per Equivalent Unit 20 - 25

20 - 26 C 2 Assign and Reconcile Costs In the cost reconciliation, we will account for all costs incurred by assigning unit costs to the: A. 100, 000 units transferred out. B. 20, 000 units remaining in ending inventory.

20 - 26 C 2 Assign and Reconcile Costs In the cost reconciliation, we will account for all costs incurred by assigning unit costs to the: A. 100, 000 units transferred out. B. 20, 000 units remaining in ending inventory.

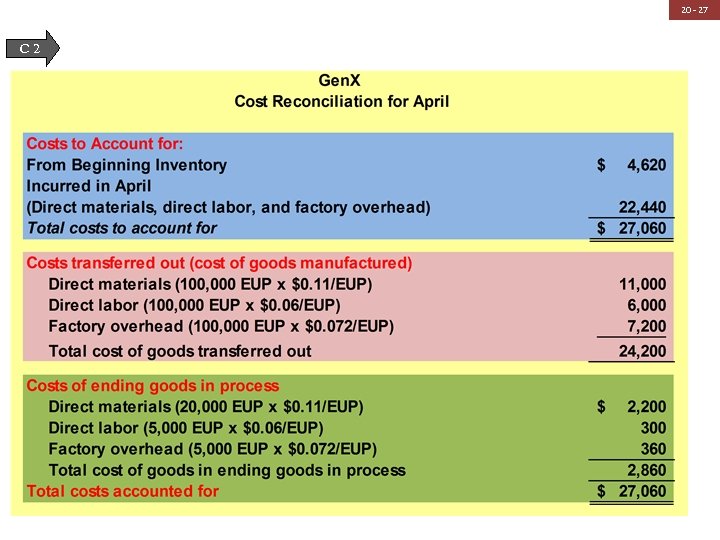

20 - 27 C 2

20 - 27 C 2

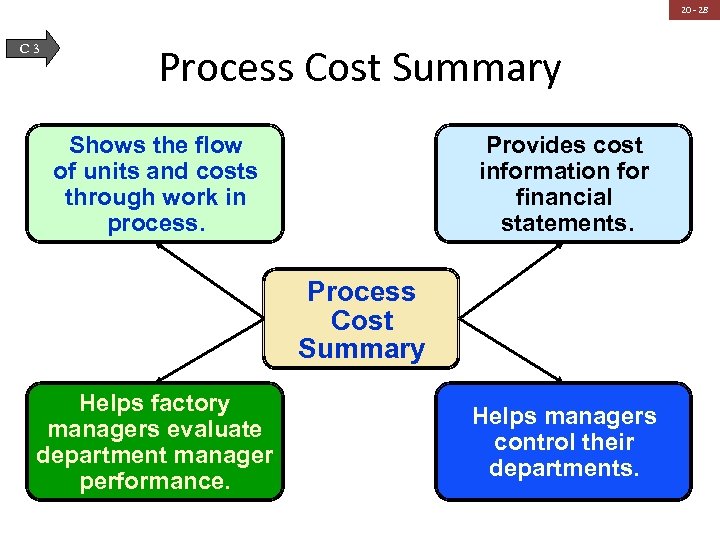

20 - 28 C 3 Process Cost Summary Shows the flow of units and costs through work in process. Provides cost information for financial statements. Process Cost Summary Helps factory managers evaluate department manager performance. Helps managers control their departments.

20 - 28 C 3 Process Cost Summary Shows the flow of units and costs through work in process. Provides cost information for financial statements. Process Cost Summary Helps factory managers evaluate department manager performance. Helps managers control their departments.

20 - 29 C 3 Process Cost Summary We will illustrate the process cost summary for Gen. X in three sections: § Costs charged to production. § Equivalent units of production and cost per equivalent unit. § Cost assignment and reconciliation

20 - 29 C 3 Process Cost Summary We will illustrate the process cost summary for Gen. X in three sections: § Costs charged to production. § Equivalent units of production and cost per equivalent unit. § Cost assignment and reconciliation

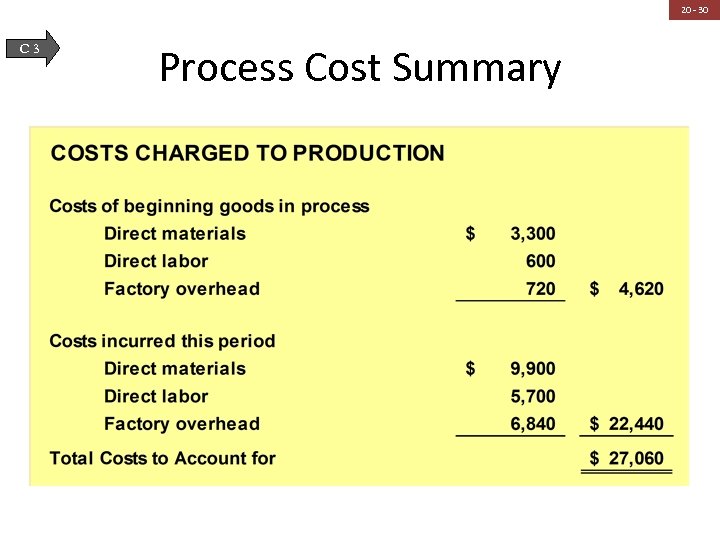

20 - 30 C 3 Process Cost Summary

20 - 30 C 3 Process Cost Summary

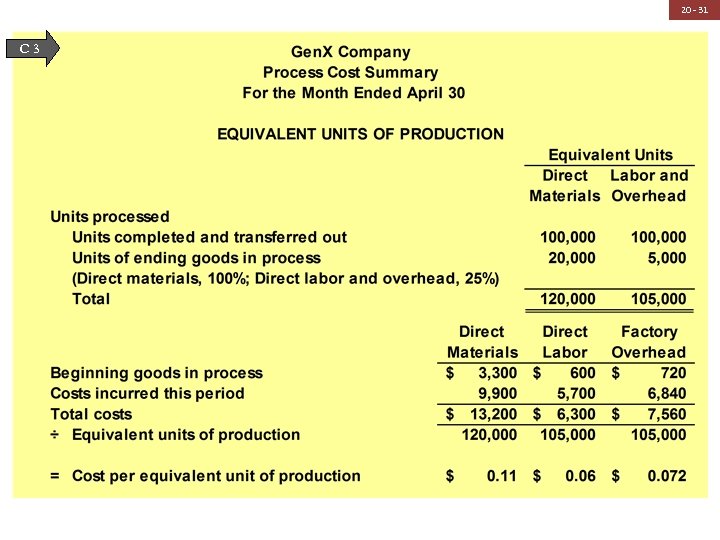

20 - 31 C 3 Process Cost Summary

20 - 31 C 3 Process Cost Summary

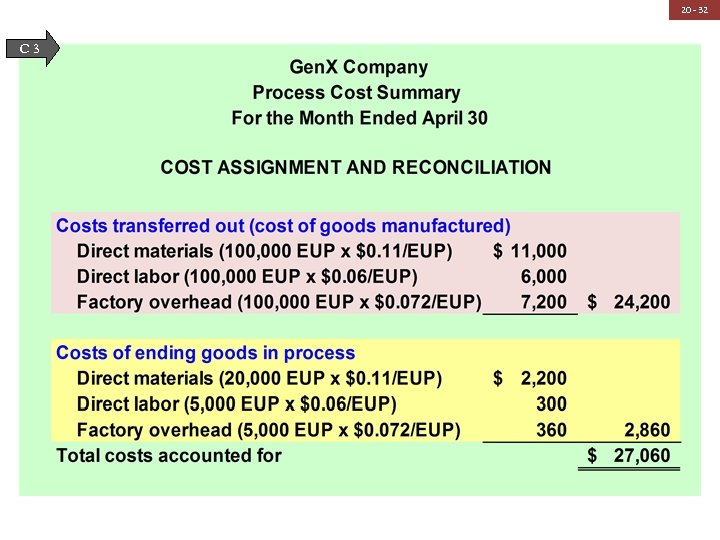

20 - 32 C 3 Process Cost Summary

20 - 32 C 3 Process Cost Summary

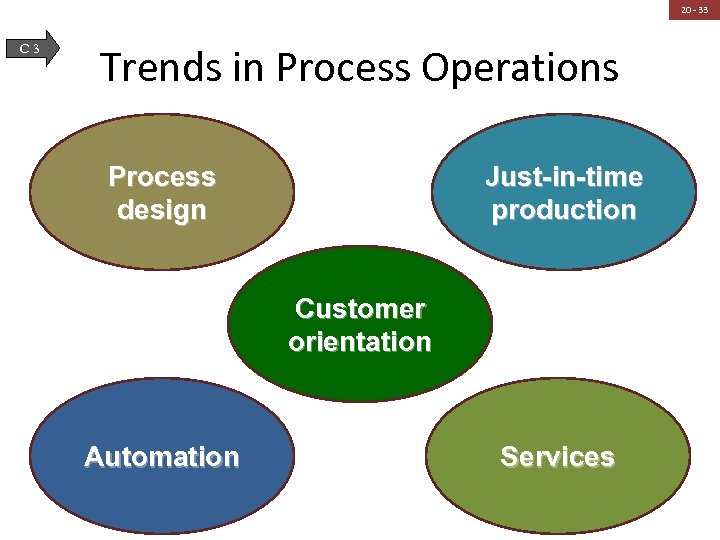

20 - 33 C 3 Trends in Process Operations Process design Just-in-time production Customer orientation Automation Services

20 - 33 C 3 Trends in Process Operations Process design Just-in-time production Customer orientation Automation Services

20 - 34 Global View As part of a series of global environmental goals, Anheuser-Busch In. Bev set targets to reduce its water usage. To meet these goals, the company followed recent trends in process operations, including extensive redesign of production processes and the use of advanced technology to increase efficiency at wastewater treatment plants. As a result, water usage decreased by almost 37 percent.

20 - 34 Global View As part of a series of global environmental goals, Anheuser-Busch In. Bev set targets to reduce its water usage. To meet these goals, the company followed recent trends in process operations, including extensive redesign of production processes and the use of advanced technology to increase efficiency at wastewater treatment plants. As a result, water usage decreased by almost 37 percent.

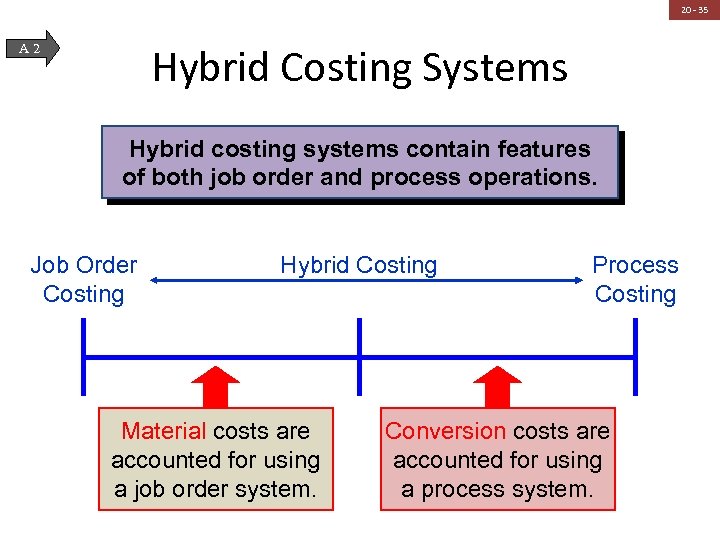

20 - 35 Hybrid Costing Systems A 2 Hybrid costing systems contain features of both job order and process operations. Job Order Costing Hybrid Costing Material costs are accounted for using a job order system. Process Costing Conversion costs are accounted for using a process system.

20 - 35 Hybrid Costing Systems A 2 Hybrid costing systems contain features of both job order and process operations. Job Order Costing Hybrid Costing Material costs are accounted for using a job order system. Process Costing Conversion costs are accounted for using a process system.

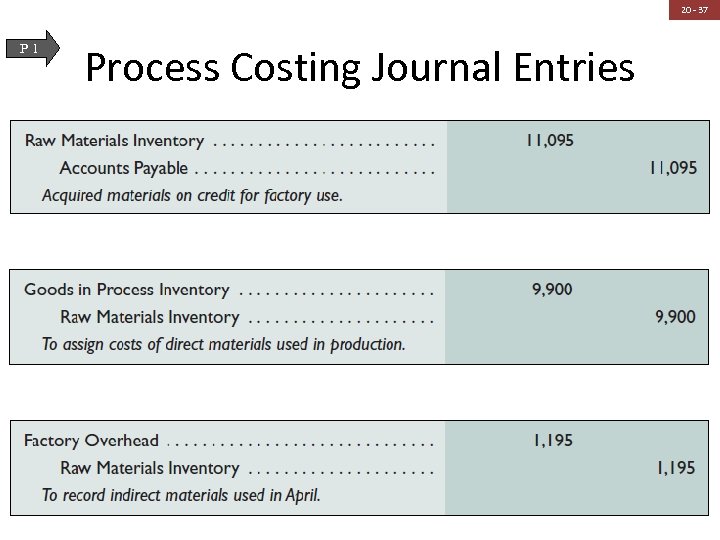

20 - 36 Process Costing Journal Entries Let’s look at the accounting journal entries for the process cost system at Gen. X.

20 - 36 Process Costing Journal Entries Let’s look at the accounting journal entries for the process cost system at Gen. X.

20 - 37 P 1 Process Costing Journal Entries

20 - 37 P 1 Process Costing Journal Entries

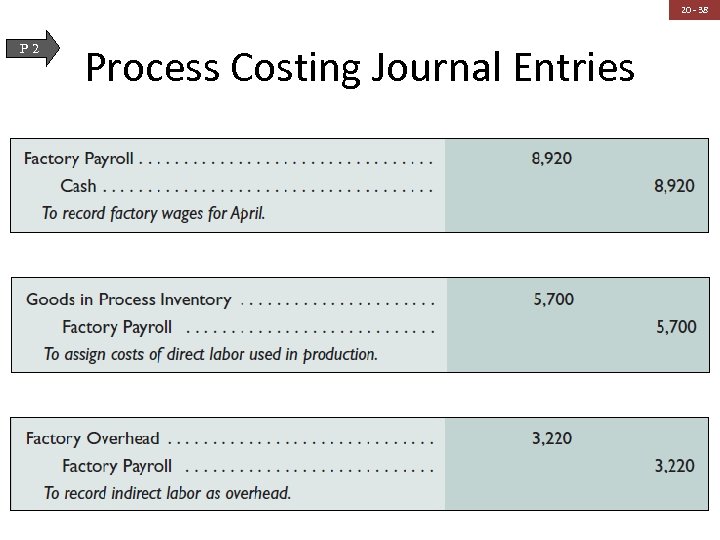

20 - 38 P 2 Process Costing Journal Entries

20 - 38 P 2 Process Costing Journal Entries

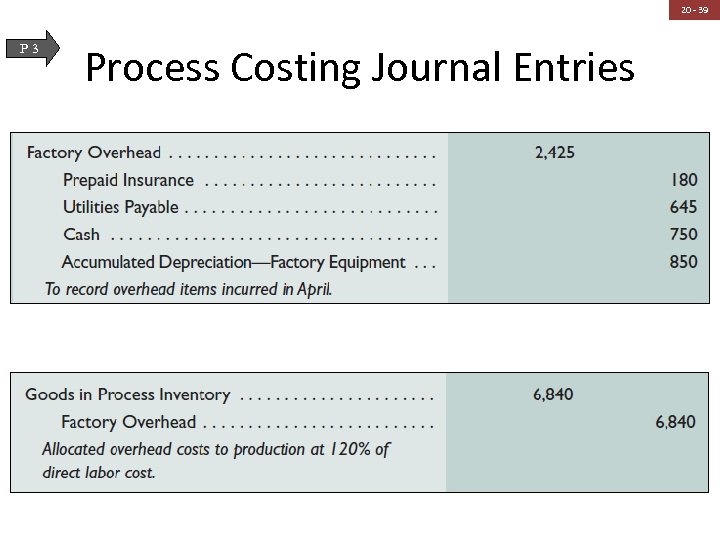

20 - 39 P 3 Process Costing Journal Entries

20 - 39 P 3 Process Costing Journal Entries

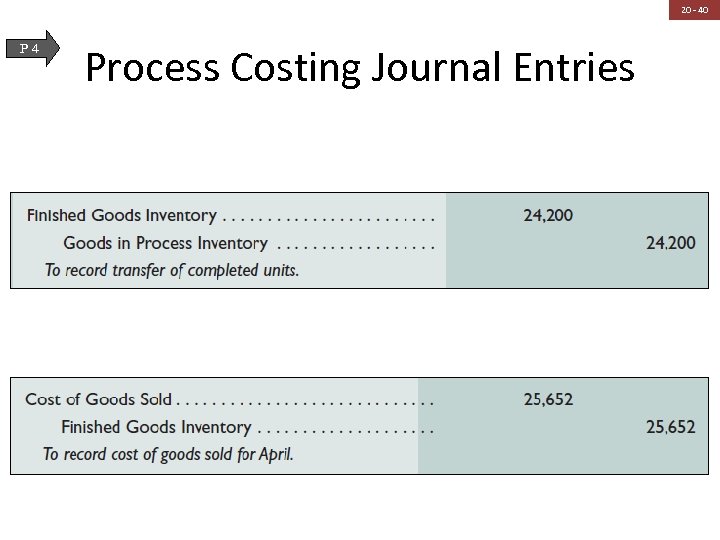

20 - 40 P 4 Process Costing Journal Entries

20 - 40 P 4 Process Costing Journal Entries

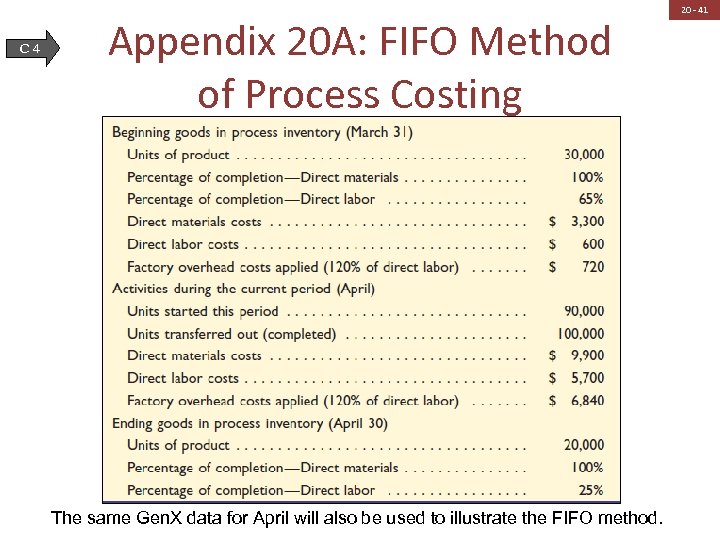

C 4 Appendix 20 A: FIFO Method of Process Costing The same Gen. X data for April will also be used to illustrate the FIFO method. 20 - 41

C 4 Appendix 20 A: FIFO Method of Process Costing The same Gen. X data for April will also be used to illustrate the FIFO method. 20 - 41

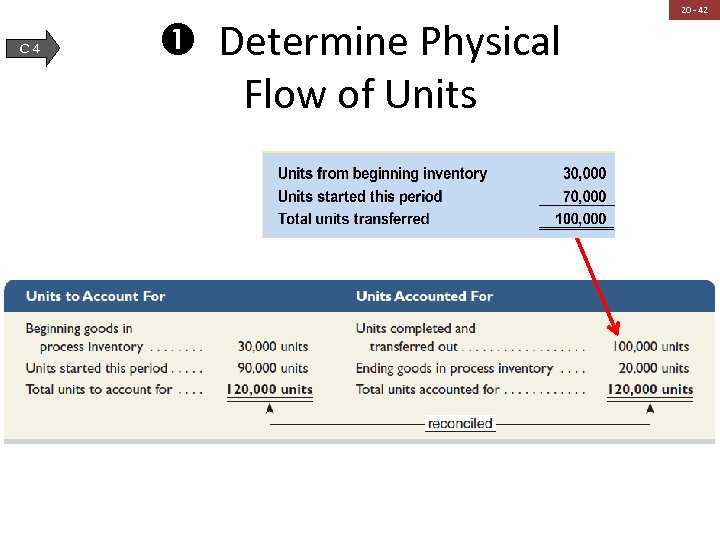

C 4 Determine Physical Flow of Units 20 - 42

C 4 Determine Physical Flow of Units 20 - 42

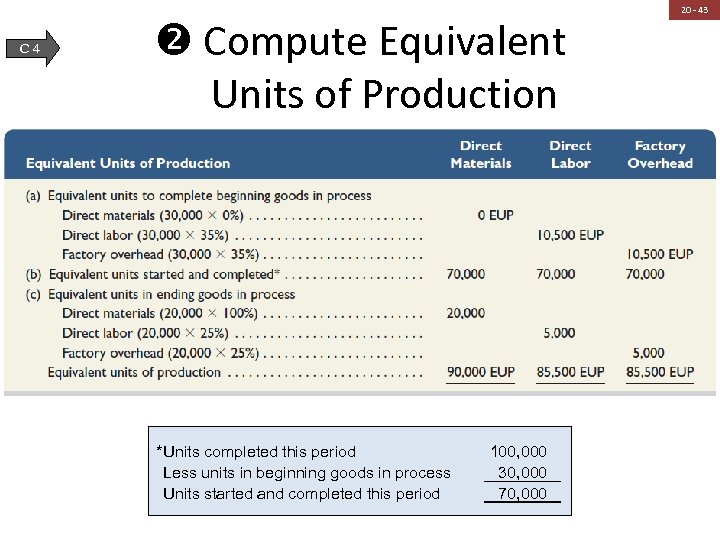

Compute Equivalent Units of Production C 4 *Units completed this period Less units in beginning goods in process Units started and completed this period 100, 000 30, 000 70, 000 20 - 43

Compute Equivalent Units of Production C 4 *Units completed this period Less units in beginning goods in process Units started and completed this period 100, 000 30, 000 70, 000 20 - 43

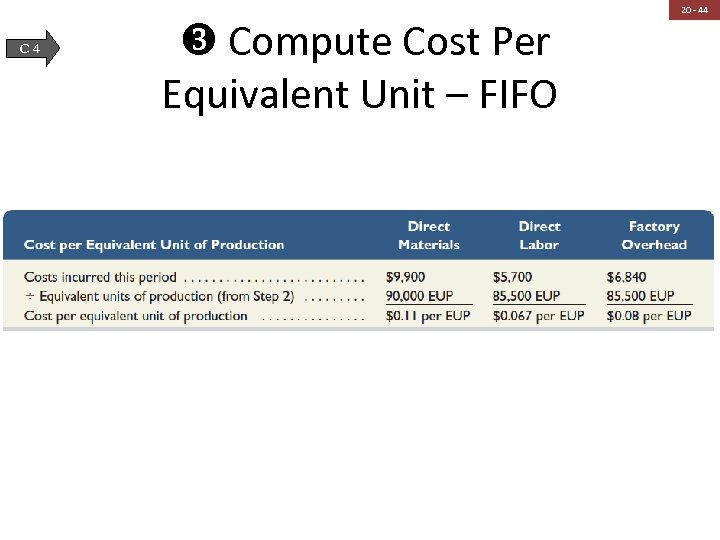

C 4 Compute Cost Per Equivalent Unit – FIFO 20 - 44

C 4 Compute Cost Per Equivalent Unit – FIFO 20 - 44

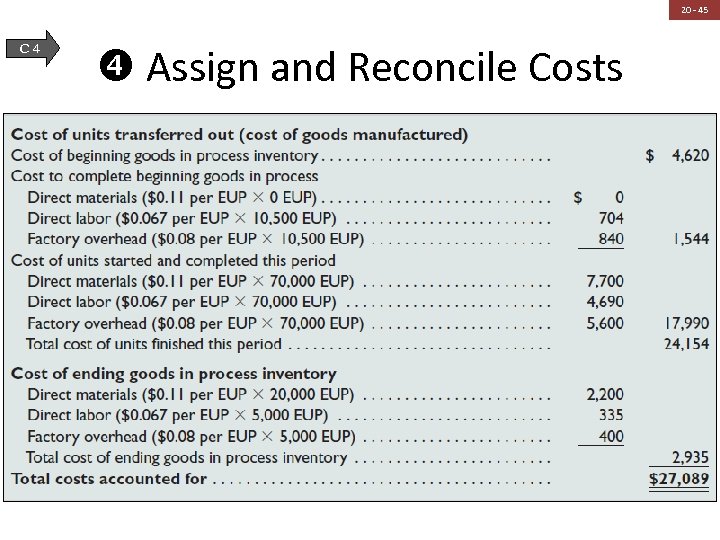

20 - 45 C 4 Assign and Reconcile Costs

20 - 45 C 4 Assign and Reconcile Costs

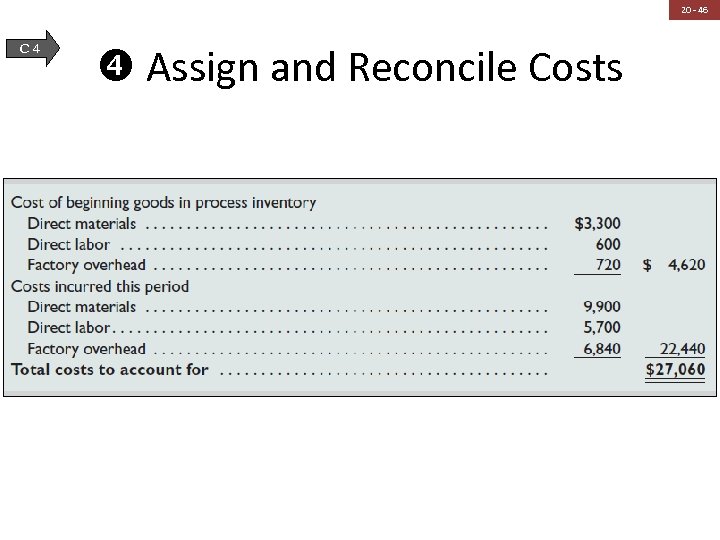

20 - 46 C 4 Assign and Reconcile Costs

20 - 46 C 4 Assign and Reconcile Costs

20 - 47 End of Chapter 20

20 - 47 End of Chapter 20