Sensors and transducers_lecture_.ppt

- Количество слайдов: 19

2 Sensors and transducers

2 Sensors and transducers

2 Sensors and transducers • The term sensor is used for an element which produces a signal relating to the quantity being measured. • The term transducer is often used in place of the term sensor. Transducers are defined as elements that when subject to some physical change experience a • related change.

2 Sensors and transducers • The term sensor is used for an element which produces a signal relating to the quantity being measured. • The term transducer is often used in place of the term sensor. Transducers are defined as elements that when subject to some physical change experience a • related change.

Performance terminology • Range and span • The range of a transducer defines the limits between which the input can vary. • • The span is the maximum value of the input minus the minimum value.

Performance terminology • Range and span • The range of a transducer defines the limits between which the input can vary. • • The span is the maximum value of the input minus the minimum value.

Performance terminology • Error is the difference between the result of the measurement and the true value of the quantity being measured. • Error = measured value - true value • Accuracy is the extent to which the value indicated by a measurement system might be wrong.

Performance terminology • Error is the difference between the result of the measurement and the true value of the quantity being measured. • Error = measured value - true value • Accuracy is the extent to which the value indicated by a measurement system might be wrong.

Performance terminology • Sensitivity • The sensitivity is the relationship indicating how much output you get per unit input, i. e. ouput/input. • For example, a resistance thermometer may have a sensitivity of 0. 5 WC.

Performance terminology • Sensitivity • The sensitivity is the relationship indicating how much output you get per unit input, i. e. ouput/input. • For example, a resistance thermometer may have a sensitivity of 0. 5 WC.

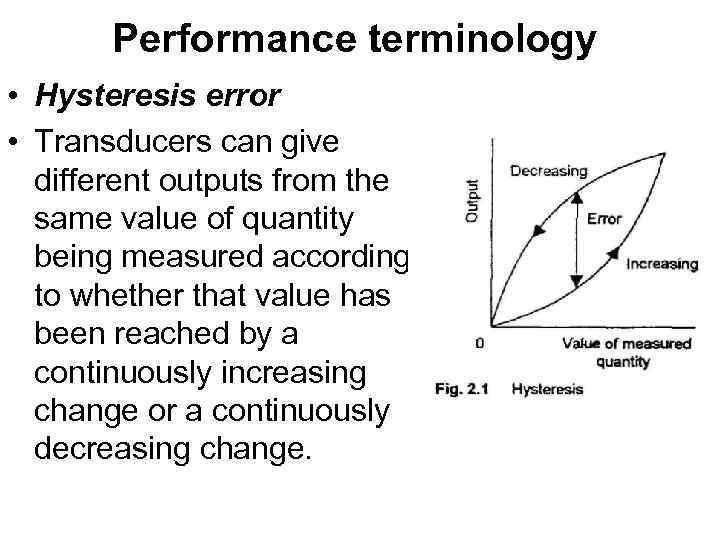

Performance terminology • Hysteresis error • Transducers can give different outputs from the same value of quantity being measured according to whether that value has been reached by a continuously increasing change or a continuously decreasing change.

Performance terminology • Hysteresis error • Transducers can give different outputs from the same value of quantity being measured according to whether that value has been reached by a continuously increasing change or a continuously decreasing change.

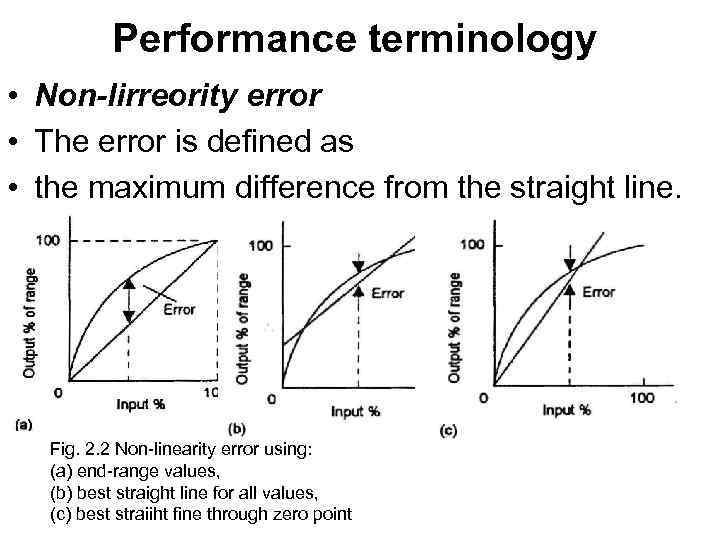

Performance terminology • • Non-lirreority error The error is defined as the maximum difference from the straight line. . Fig. 2. 2 Non-linearity error using: (a) end-range values, (b) best straight line for all values, (c) best straiiht fine through zero point

Performance terminology • • Non-lirreority error The error is defined as the maximum difference from the straight line. . Fig. 2. 2 Non-linearity error using: (a) end-range values, (b) best straight line for all values, (c) best straiiht fine through zero point

Performance terminology • Stability • The stability of a transducer is its ability to give the same output when used to measure a constant input over a period of time. • • Drift • The term drift is often used to describe the • change in output that occurs over time. • .

Performance terminology • Stability • The stability of a transducer is its ability to give the same output when used to measure a constant input over a period of time. • • Drift • The term drift is often used to describe the • change in output that occurs over time. • .

Performance terminology • Dead band/tirne • The dead band or dead space of a transducer • is the range of input values for which there is no output. • Resolution • The resolution is the smallest change in the input value that will produce an observable change in the output • .

Performance terminology • Dead band/tirne • The dead band or dead space of a transducer • is the range of input values for which there is no output. • Resolution • The resolution is the smallest change in the input value that will produce an observable change in the output • .

Specification of a strain gauge pressure transducer: • • Ranges: 70 to 1000 k. Pa, 2000 to 70 000 k. Pa Supply voltage: 10 V d. c. or a. c. r. m. s. Full range output: 40 m. V Non-linearity and hysteresis: i 0. 5% full range output • Temperature range: -54°C to + 120°C when operating • Thermal zero shift: 0. 030% full range output. PC

Specification of a strain gauge pressure transducer: • • Ranges: 70 to 1000 k. Pa, 2000 to 70 000 k. Pa Supply voltage: 10 V d. c. or a. c. r. m. s. Full range output: 40 m. V Non-linearity and hysteresis: i 0. 5% full range output • Temperature range: -54°C to + 120°C when operating • Thermal zero shift: 0. 030% full range output. PC

Static and dynamic haracteristics • The static characteristics are the values given when steady-state conditions occur, i. e. the values given when the transducer has settled down after having received some input. • The dynamic characteristics • refer to the behaviour between the time that the input value changes and the time that the value given by the transducer settles down to the steady-state value.

Static and dynamic haracteristics • The static characteristics are the values given when steady-state conditions occur, i. e. the values given when the transducer has settled down after having received some input. • The dynamic characteristics • refer to the behaviour between the time that the input value changes and the time that the value given by the transducer settles down to the steady-state value.

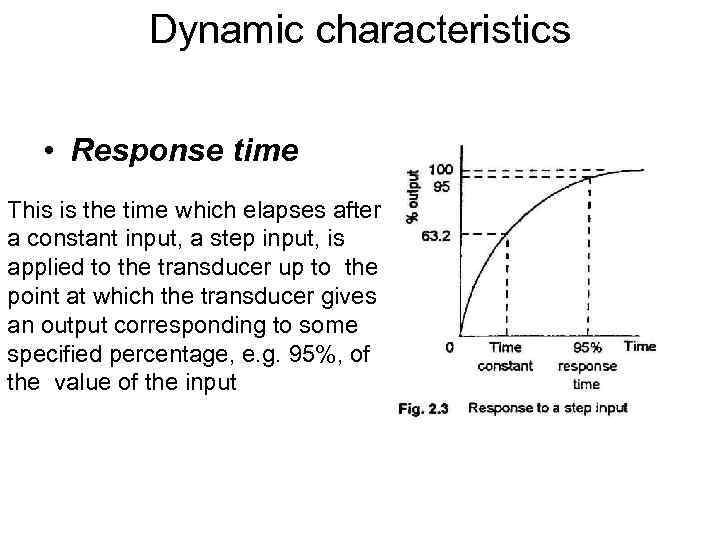

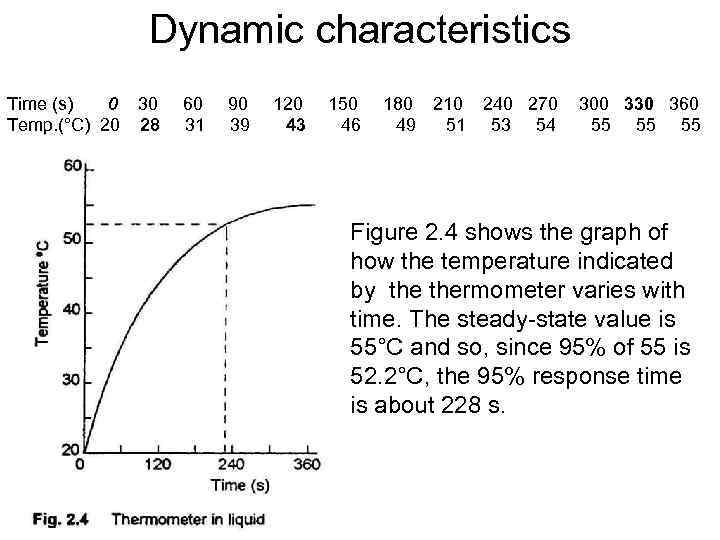

Dynamic characteristics • Response time This is the time which elapses after a constant input, a step input, is applied to the transducer up to the point at which the transducer gives an output corresponding to some specified percentage, e. g. 95%, of the value of the input

Dynamic characteristics • Response time This is the time which elapses after a constant input, a step input, is applied to the transducer up to the point at which the transducer gives an output corresponding to some specified percentage, e. g. 95%, of the value of the input

Dynamic characteristics Time (s) 0 30 Temp. (°C) 20 28 60 31 90 39 120 43 150 46 180 210 240 270 49 51 53 54 300 330 360 55 55 55 Figure 2. 4 shows the graph of how the temperature indicated by thermometer varies with time. The steady-state value is 55°C and so, since 95% of 55 is 52. 2°C, the 95% response time is about 228 s.

Dynamic characteristics Time (s) 0 30 Temp. (°C) 20 28 60 31 90 39 120 43 150 46 180 210 240 270 49 51 53 54 300 330 360 55 55 55 Figure 2. 4 shows the graph of how the temperature indicated by thermometer varies with time. The steady-state value is 55°C and so, since 95% of 55 is 52. 2°C, the 95% response time is about 228 s.