2 Sensors and transducers

2 Sensors and transducers

2 Sensors and transducers The term sensor is used for an element which produces a signal relating to the quantity being measured. The term transducer is often used in place of the term sensor. Transducers are defined as elements that when subject to some physical change experience a related change.

2 Sensors and transducers The term sensor is used for an element which produces a signal relating to the quantity being measured. The term transducer is often used in place of the term sensor. Transducers are defined as elements that when subject to some physical change experience a related change.

Performance terminology Range and span The range of a transducer defines the limits between which the input can vary. The span is the maximum value of the input minus the minimum value.

Performance terminology Range and span The range of a transducer defines the limits between which the input can vary. The span is the maximum value of the input minus the minimum value.

Performance terminology Error Error is the difference between the result of the measurement and the true value of the quantity being measured. Error = measured value - true value Accuracy Accuracy is the extent to which the value indicated by a measurement system might be wrong.

Performance terminology Error Error is the difference between the result of the measurement and the true value of the quantity being measured. Error = measured value - true value Accuracy Accuracy is the extent to which the value indicated by a measurement system might be wrong.

Performance terminology Sensitivity The sensitivity is the relationship indicating how much output you get per unit input, i.e. ouput/input. For example, a resistance thermometer may have a sensitivity of 0.5 WC.

Performance terminology Sensitivity The sensitivity is the relationship indicating how much output you get per unit input, i.e. ouput/input. For example, a resistance thermometer may have a sensitivity of 0.5 WC.

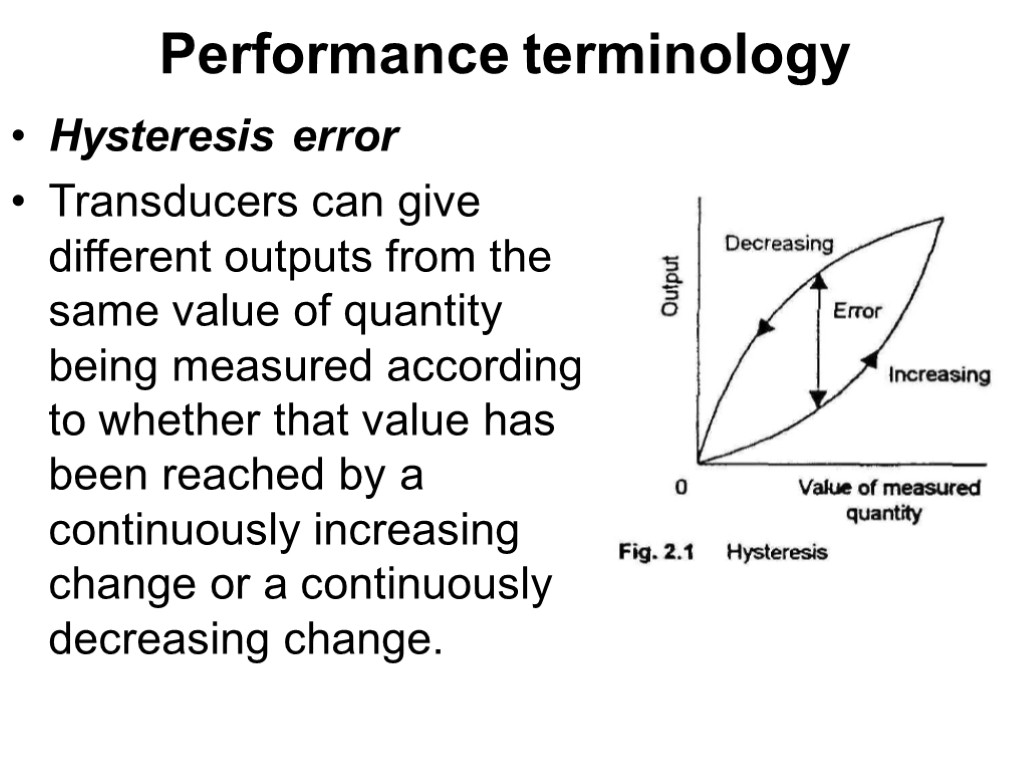

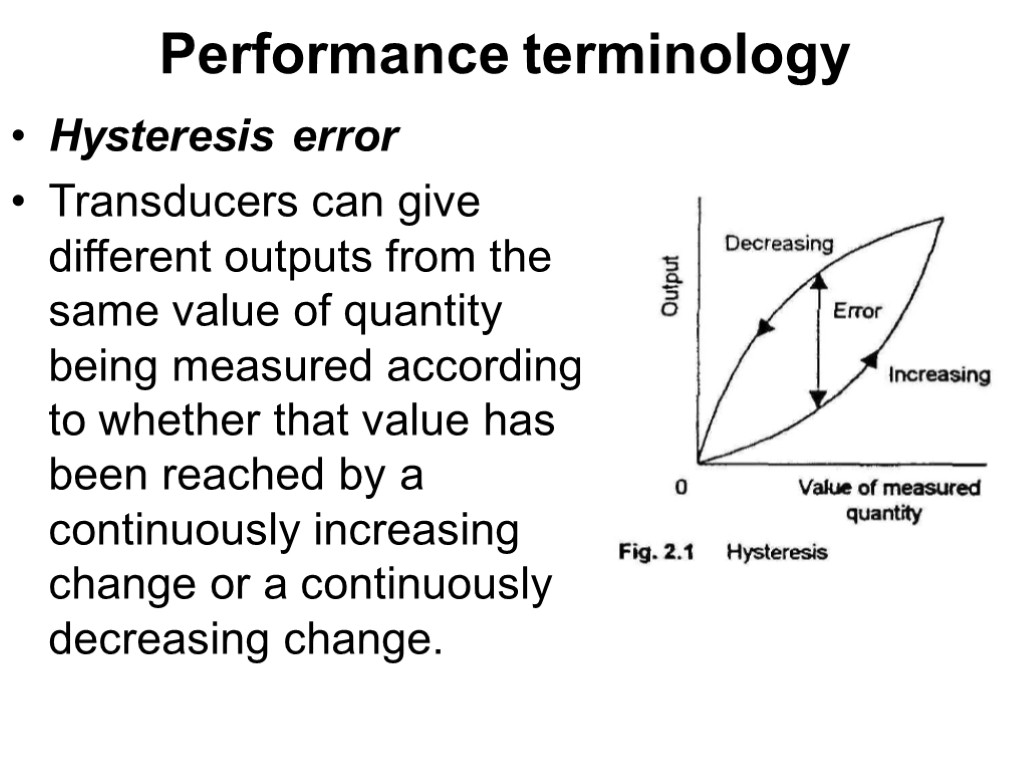

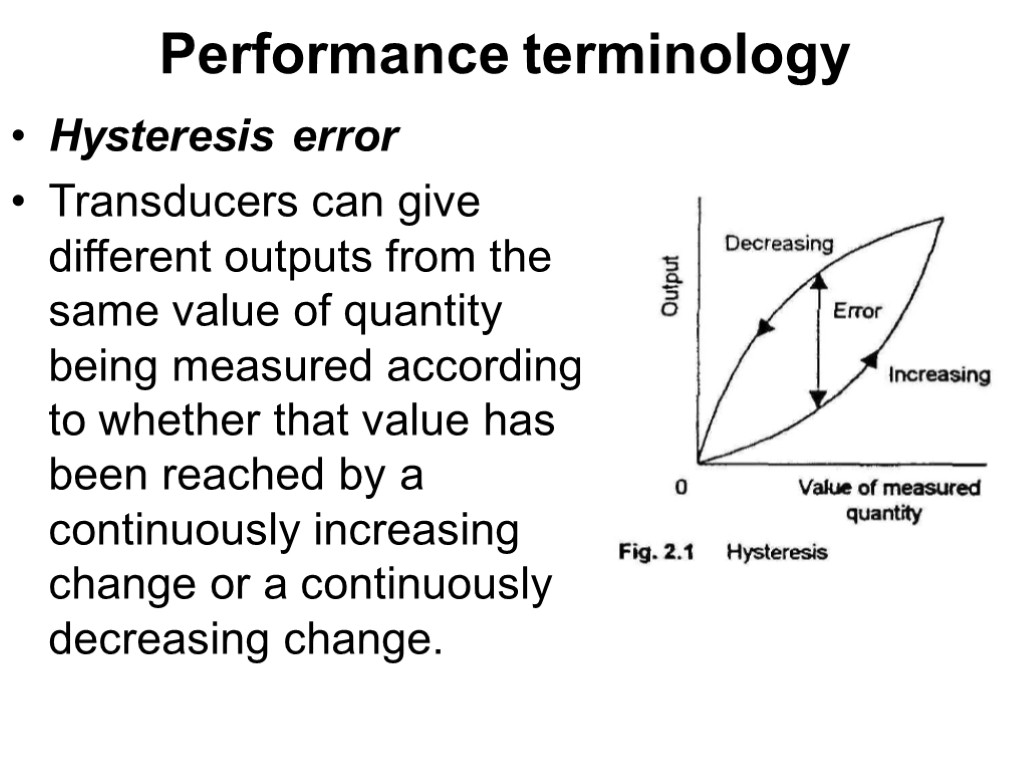

Performance terminology Hysteresis error Transducers can give different outputs from the same value of quantity being measured according to whether that value has been reached by a continuously increasing change or a continuously decreasing change.

Performance terminology Hysteresis error Transducers can give different outputs from the same value of quantity being measured according to whether that value has been reached by a continuously increasing change or a continuously decreasing change.

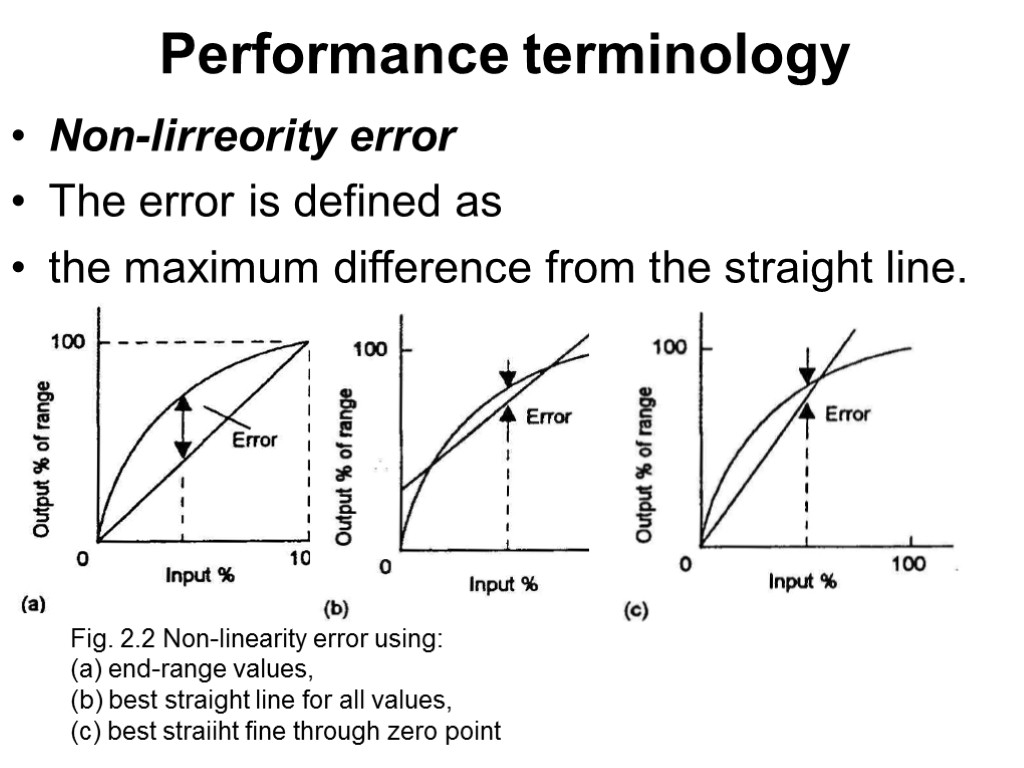

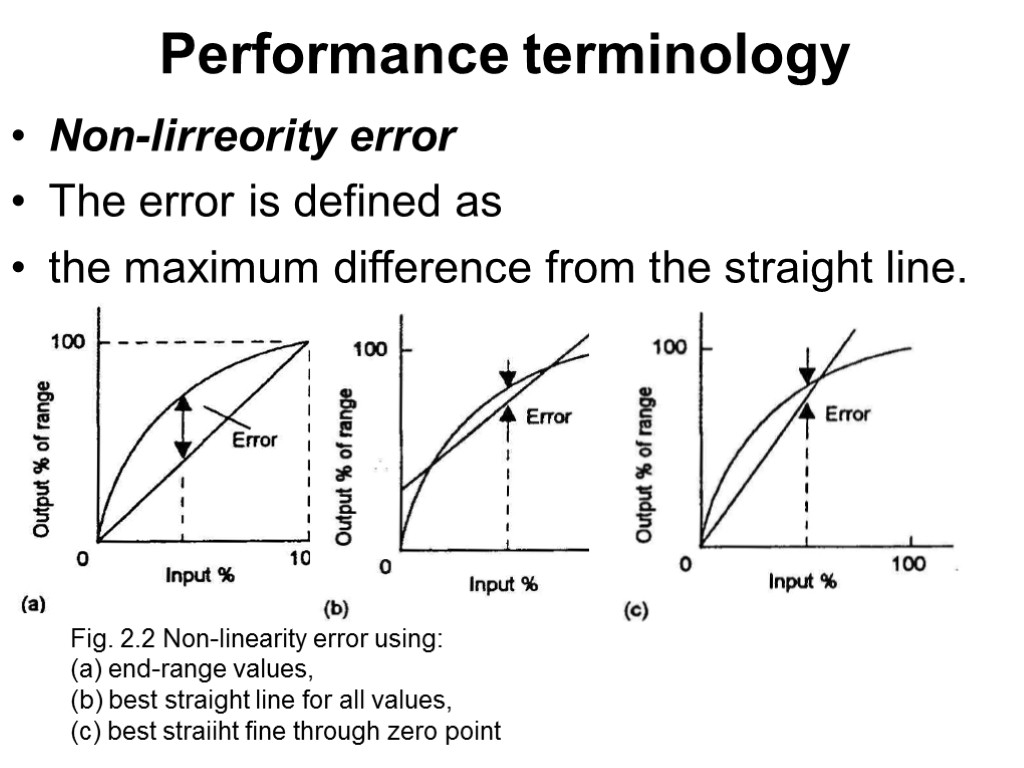

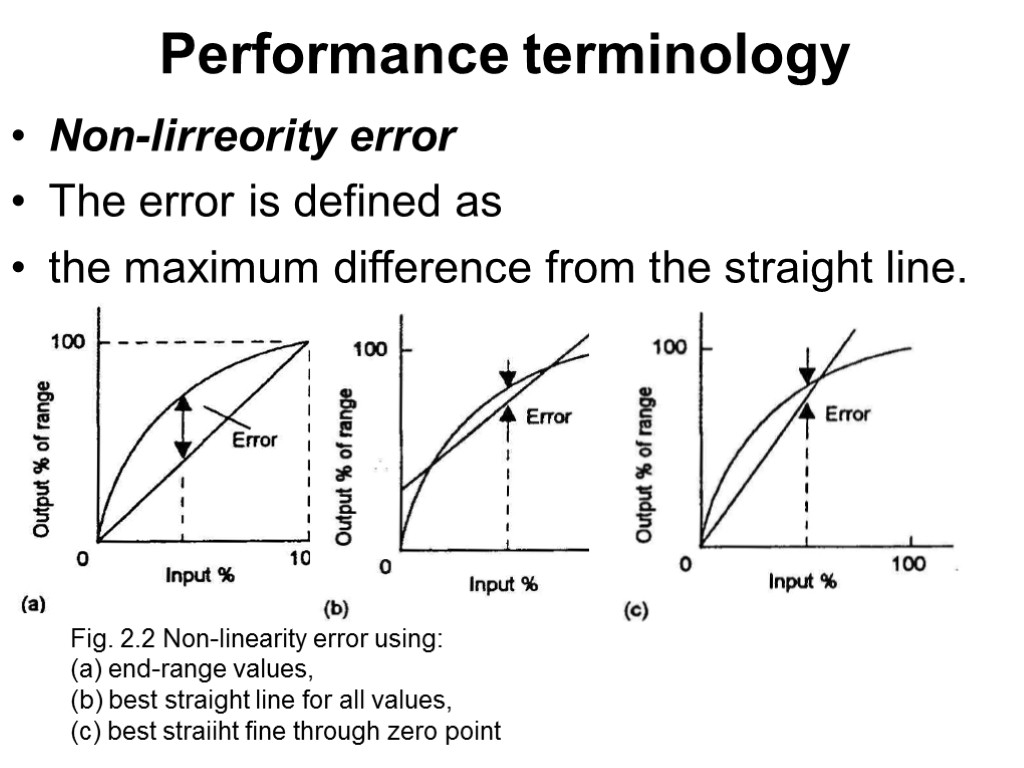

Performance terminology Non-lirreority error The error is defined as the maximum difference from the straight line. . Fig. 2.2 Non-linearity error using: (a) end-range values, (b) best straight line for all values, (c) best straiiht fine through zero point

Performance terminology Non-lirreority error The error is defined as the maximum difference from the straight line. . Fig. 2.2 Non-linearity error using: (a) end-range values, (b) best straight line for all values, (c) best straiiht fine through zero point

Performance terminology Stability The stability of a transducer is its ability to give the same output when used to measure a constant input over a period of time. Drift The term drift is often used to describe the change in output that occurs over time. .

Performance terminology Stability The stability of a transducer is its ability to give the same output when used to measure a constant input over a period of time. Drift The term drift is often used to describe the change in output that occurs over time. .

Performance terminology Dead band/tirne The dead band or dead space of a transducer is the range of input values for which there is no output. Resolution The resolution is the smallest change in the input value that will produce an observable change in the output . .

Performance terminology Dead band/tirne The dead band or dead space of a transducer is the range of input values for which there is no output. Resolution The resolution is the smallest change in the input value that will produce an observable change in the output . .

Specification of a strain gauge pressure transducer: Ranges: 70 to 1000 kPa, 2000 to 70 000 kPa Supply voltage: 10 V d.c. or a.c. r.m.s. Full range output: 40 mV Non-linearity and hysteresis: i0.5% full range output Temperature range: -54°C to + 120°C when operating Thermal zero shift: 0.030% full range outputPC

Specification of a strain gauge pressure transducer: Ranges: 70 to 1000 kPa, 2000 to 70 000 kPa Supply voltage: 10 V d.c. or a.c. r.m.s. Full range output: 40 mV Non-linearity and hysteresis: i0.5% full range output Temperature range: -54°C to + 120°C when operating Thermal zero shift: 0.030% full range outputPC

Static and dynamic haracteristics The static characteristics are the values given when steady-state conditions occur, i.e. the values given when the transducer has settled down after having received some input. The dynamic characteristics refer to the behaviour between the time that the input value changes and the time that the value given by the transducer settles down to the steady-state value.

Static and dynamic haracteristics The static characteristics are the values given when steady-state conditions occur, i.e. the values given when the transducer has settled down after having received some input. The dynamic characteristics refer to the behaviour between the time that the input value changes and the time that the value given by the transducer settles down to the steady-state value.

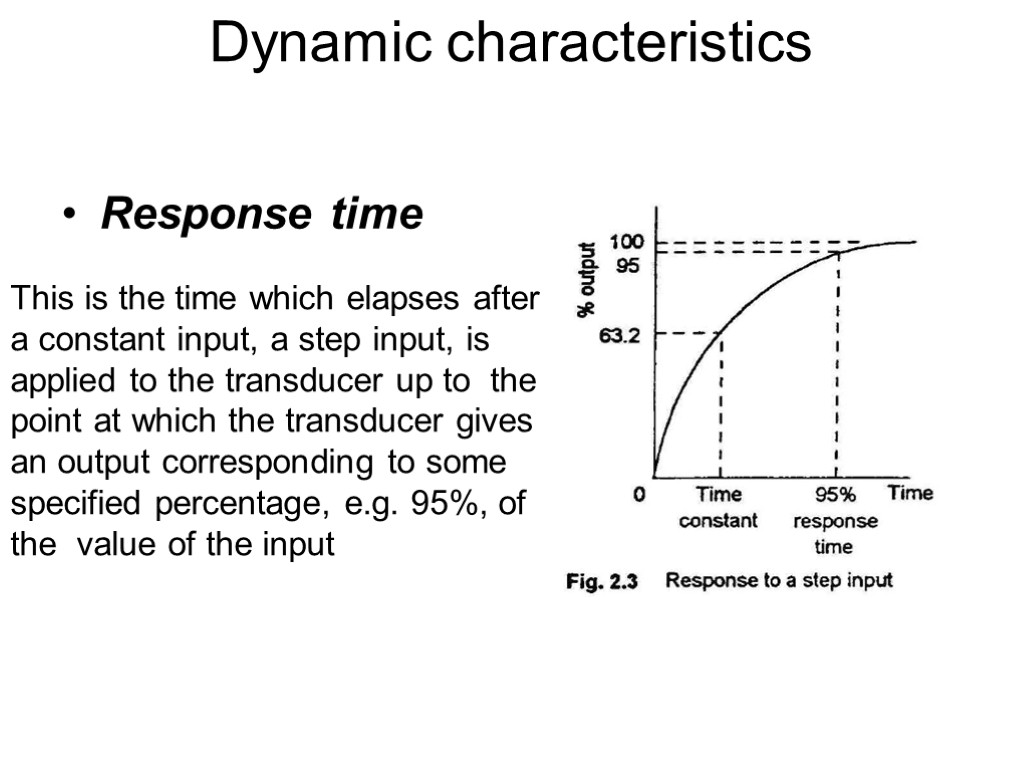

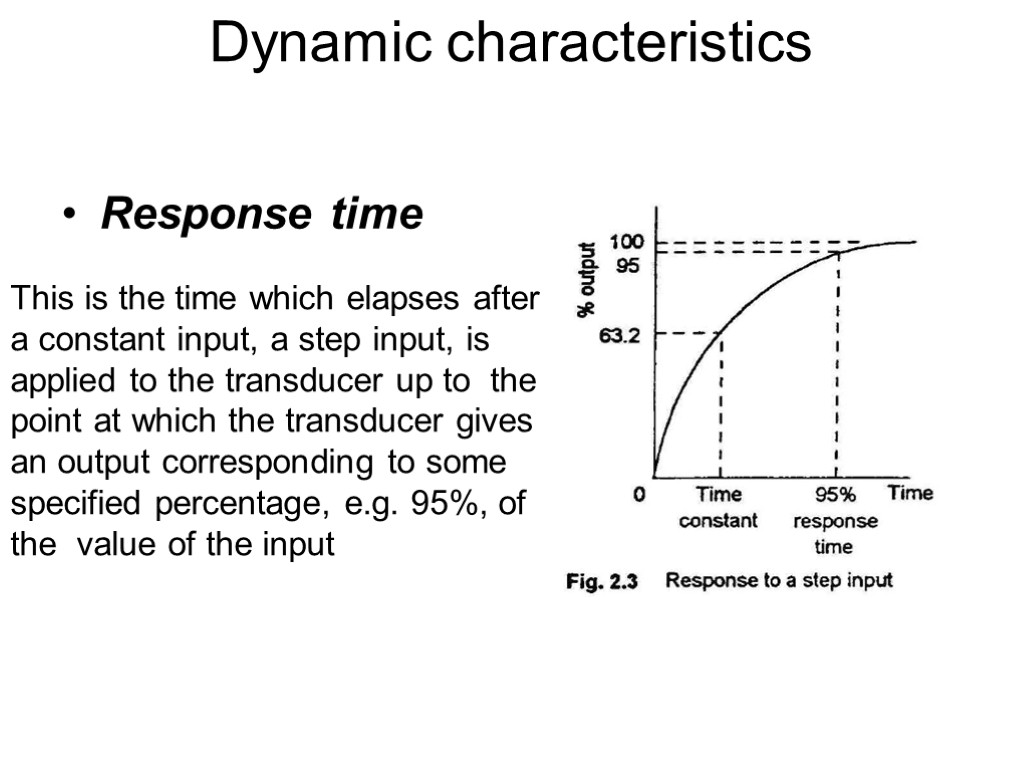

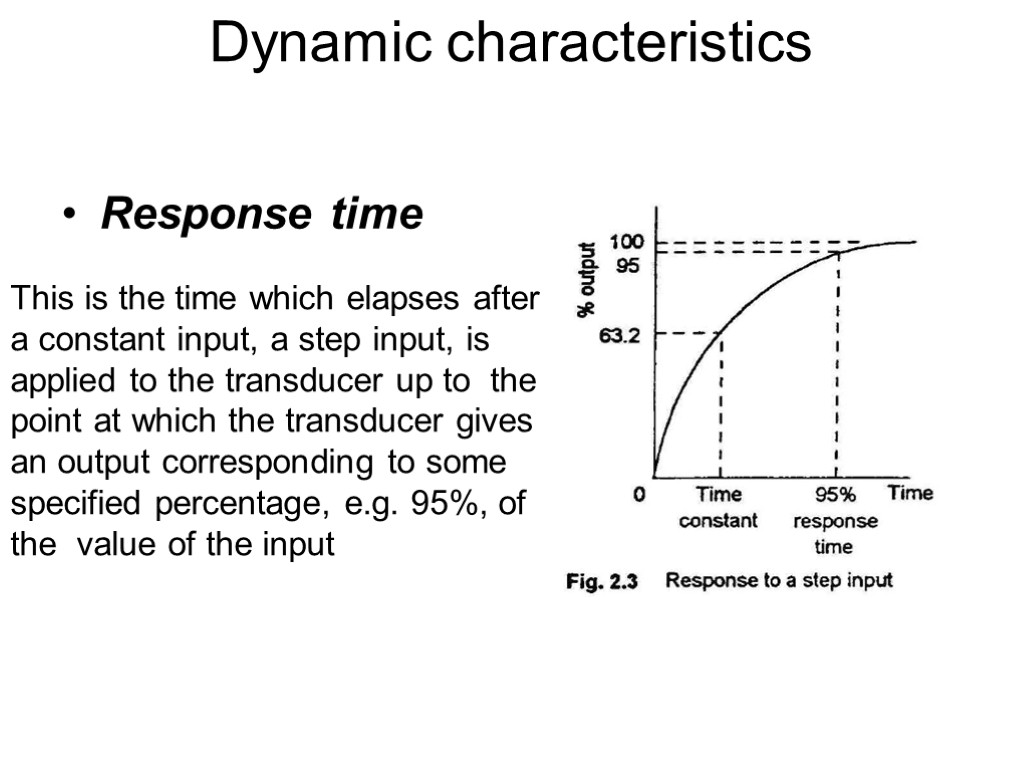

Dynamic characteristics Response time This is the time which elapses after a constant input, a step input, is applied to the transducer up to the point at which the transducer gives an output corresponding to some specified percentage, e.g. 95%, of the value of the input

Dynamic characteristics Response time This is the time which elapses after a constant input, a step input, is applied to the transducer up to the point at which the transducer gives an output corresponding to some specified percentage, e.g. 95%, of the value of the input

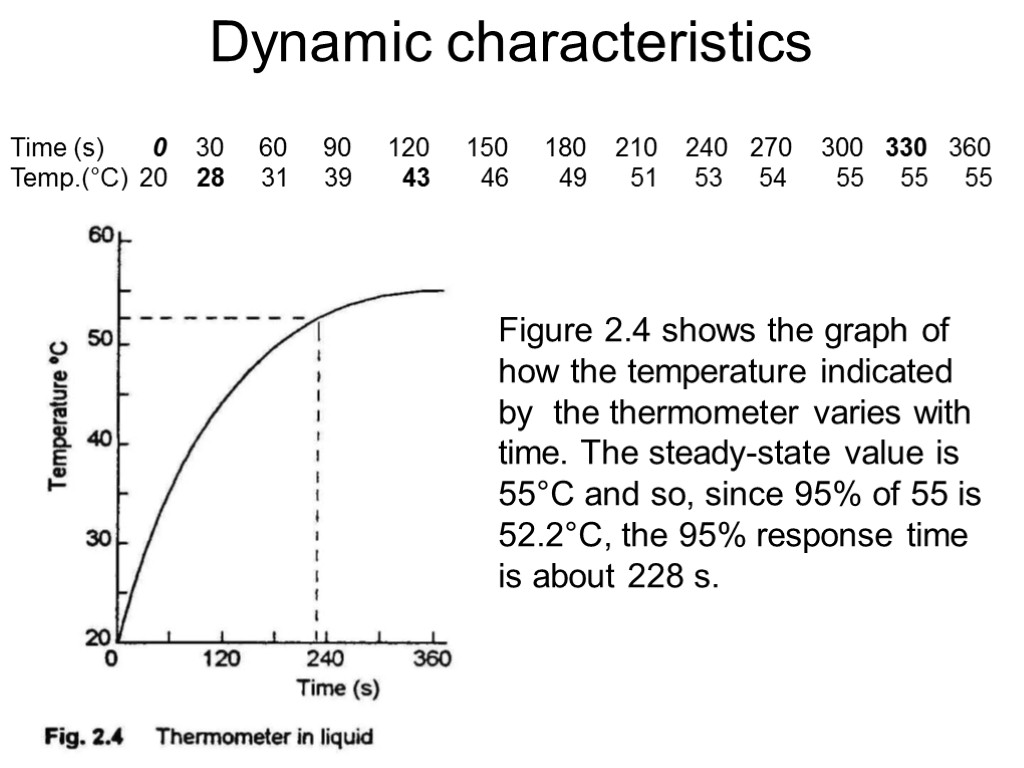

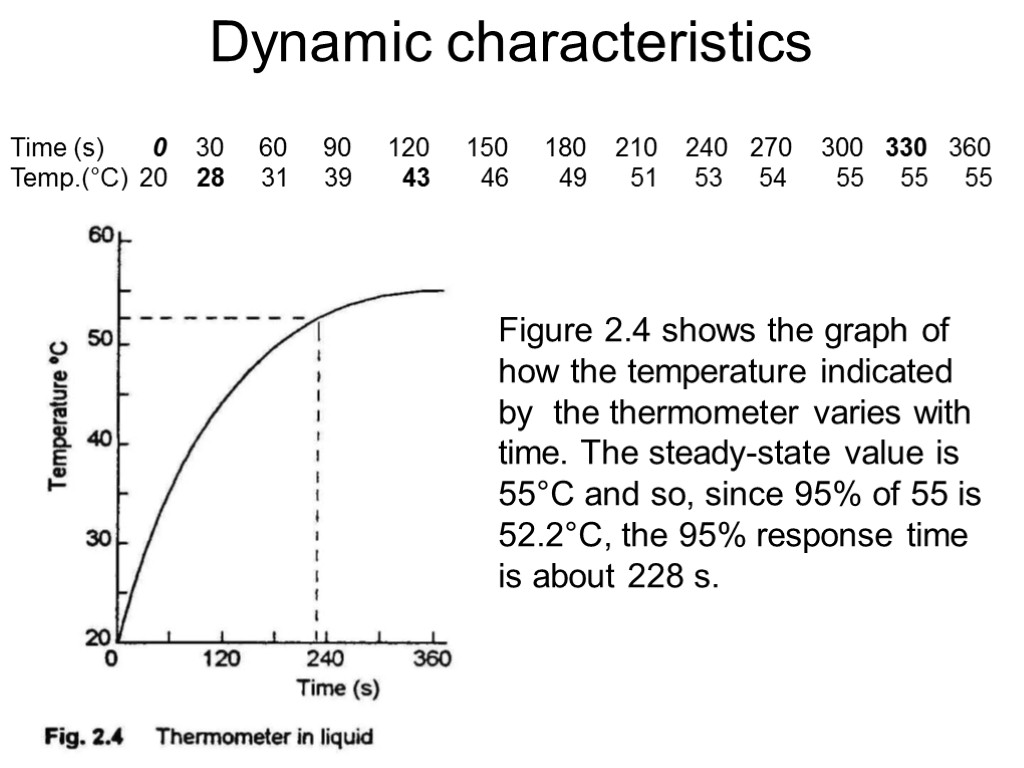

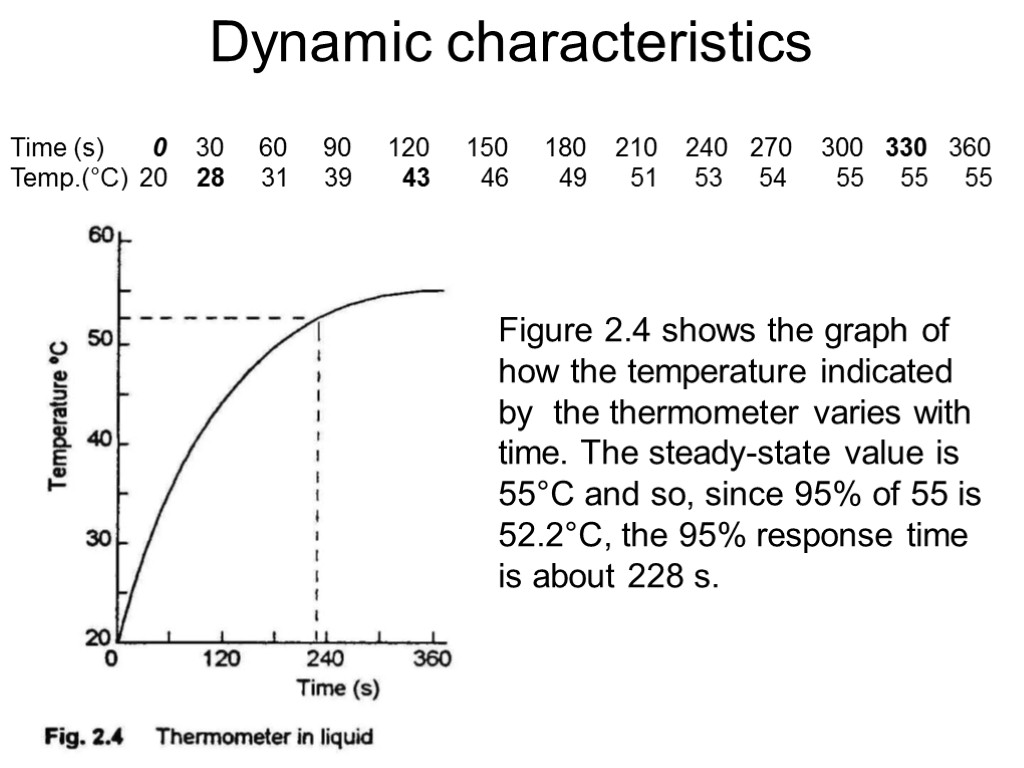

Dynamic characteristics Time (s) 0 30 60 90 120 150 180 210 240 270 300 330 360 Temp.(°C) 20 28 31 39 43 46 49 51 53 54 55 55 55 Figure 2.4 shows the graph of how the temperature indicated by the thermometer varies with time. The steady-state value is 55°C and so, since 95% of 55 is 52.2°C, the 95% response time is about 228 s.

Dynamic characteristics Time (s) 0 30 60 90 120 150 180 210 240 270 300 330 360 Temp.(°C) 20 28 31 39 43 46 49 51 53 54 55 55 55 Figure 2.4 shows the graph of how the temperature indicated by the thermometer varies with time. The steady-state value is 55°C and so, since 95% of 55 is 52.2°C, the 95% response time is about 228 s.