fa46fe515a5812d938840479d8f79538.ppt

- Количество слайдов: 18

12 -ICIT: Going for Gold Jun 26 -27, 2006 12 -ICIT: 02 -01 K Dr Prasert Suttiprasit 1

12 -ICIT: Going for Gold Jun 26 -27, 2006 12 -ICIT: 02 -01 K Dr Prasert Suttiprasit 1

Quality & Food Safety Process Approaches Organizations are more efficient and effective when they use a process approach. o o o Applying a process model concept to incorporate with in the framework of various international standards and quality tools create extremely value-added. The processes must control all activities within the organization. Processes have to eliminate the opportunities for nonconformities and not rely on personnel to catch problems and manage processes. Jun 26 -27, 2006 Dr Prasert Suttiprasit 2

Quality & Food Safety Process Approaches Organizations are more efficient and effective when they use a process approach. o o o Applying a process model concept to incorporate with in the framework of various international standards and quality tools create extremely value-added. The processes must control all activities within the organization. Processes have to eliminate the opportunities for nonconformities and not rely on personnel to catch problems and manage processes. Jun 26 -27, 2006 Dr Prasert Suttiprasit 2

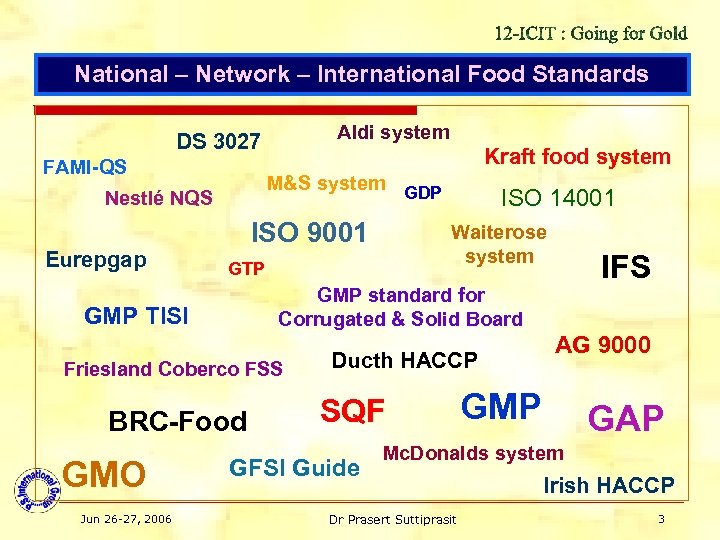

National – Network – International Food Standards Aldi system DS 3027 FAMI-QS M&S system GDP Nestlé NQS Eurepgap Kraft food system ISO 9001 IFS GMP standard for Corrugated & Solid Board Friesland Coberco FSS BRC-Food Jun 26 -27, 2006 Waiterose system GTP GMP TISI GMO ISO 14001 Ducth HACCP SQF GFSI Guide AG 9000 GMP GAP Mc. Donalds system Dr Prasert Suttiprasit Irish HACCP 3

National – Network – International Food Standards Aldi system DS 3027 FAMI-QS M&S system GDP Nestlé NQS Eurepgap Kraft food system ISO 9001 IFS GMP standard for Corrugated & Solid Board Friesland Coberco FSS BRC-Food Jun 26 -27, 2006 Waiterose system GTP GMP TISI GMO ISO 14001 Ducth HACCP SQF GFSI Guide AG 9000 GMP GAP Mc. Donalds system Dr Prasert Suttiprasit Irish HACCP 3

Global/International Food Quality & Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 4

Global/International Food Quality & Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 4

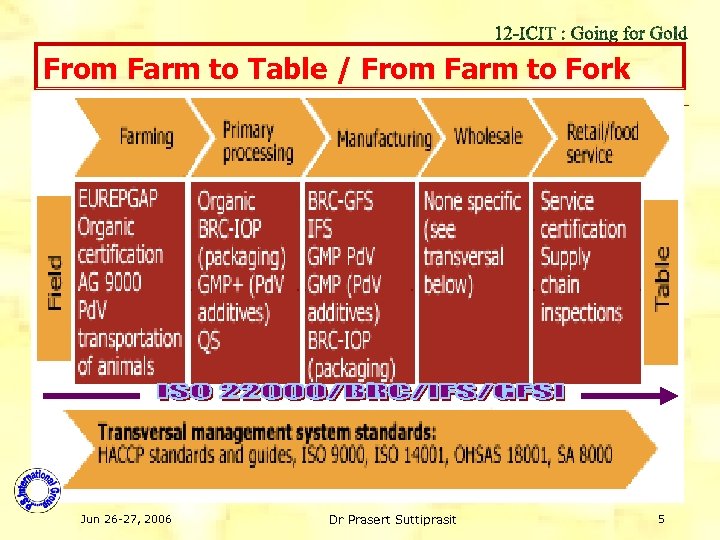

From Farm to Table / From Farm to Fork Jun 26 -27, 2006 Dr Prasert Suttiprasit 5

From Farm to Table / From Farm to Fork Jun 26 -27, 2006 Dr Prasert Suttiprasit 5

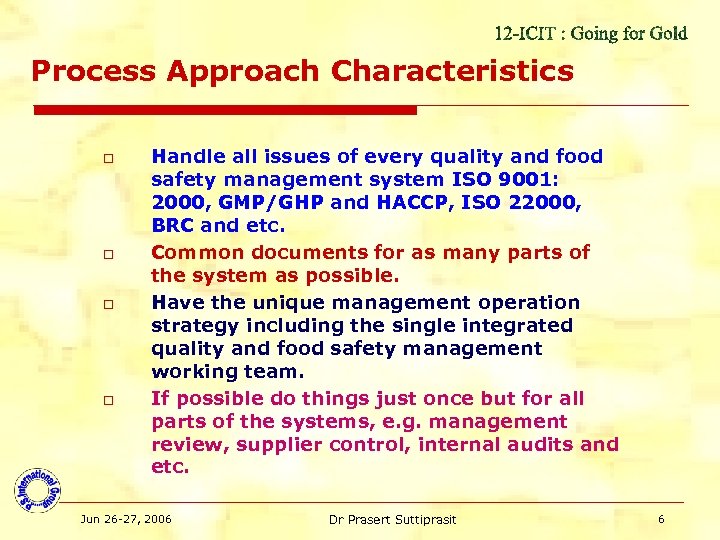

Process Approach Characteristics o o Handle all issues of every quality and food safety management system ISO 9001: 2000, GMP/GHP and HACCP, ISO 22000, BRC and etc. Common documents for as many parts of the system as possible. Have the unique management operation strategy including the single integrated quality and food safety management working team. If possible do things just once but for all parts of the systems, e. g. management review, supplier control, internal audits and etc. Jun 26 -27, 2006 Dr Prasert Suttiprasit 6

Process Approach Characteristics o o Handle all issues of every quality and food safety management system ISO 9001: 2000, GMP/GHP and HACCP, ISO 22000, BRC and etc. Common documents for as many parts of the system as possible. Have the unique management operation strategy including the single integrated quality and food safety management working team. If possible do things just once but for all parts of the systems, e. g. management review, supplier control, internal audits and etc. Jun 26 -27, 2006 Dr Prasert Suttiprasit 6

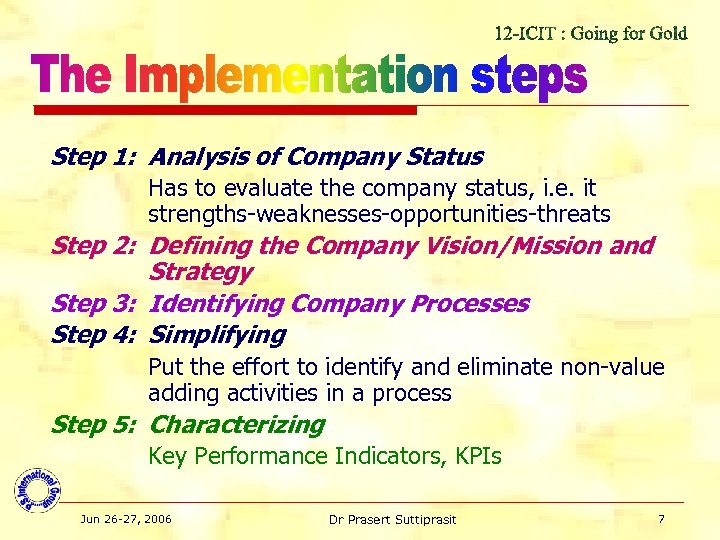

Step 1: Analysis of Company Status Has to evaluate the company status, i. e. it strengths-weaknesses-opportunities-threats Step 2: Defining the Company Vision/Mission and Strategy Step 3: Identifying Company Processes Step 4: Simplifying Put the effort to identify and eliminate non-value adding activities in a process Step 5: Characterizing Key Performance Indicators, KPIs Jun 26 -27, 2006 Dr Prasert Suttiprasit 7

Step 1: Analysis of Company Status Has to evaluate the company status, i. e. it strengths-weaknesses-opportunities-threats Step 2: Defining the Company Vision/Mission and Strategy Step 3: Identifying Company Processes Step 4: Simplifying Put the effort to identify and eliminate non-value adding activities in a process Step 5: Characterizing Key Performance Indicators, KPIs Jun 26 -27, 2006 Dr Prasert Suttiprasit 7

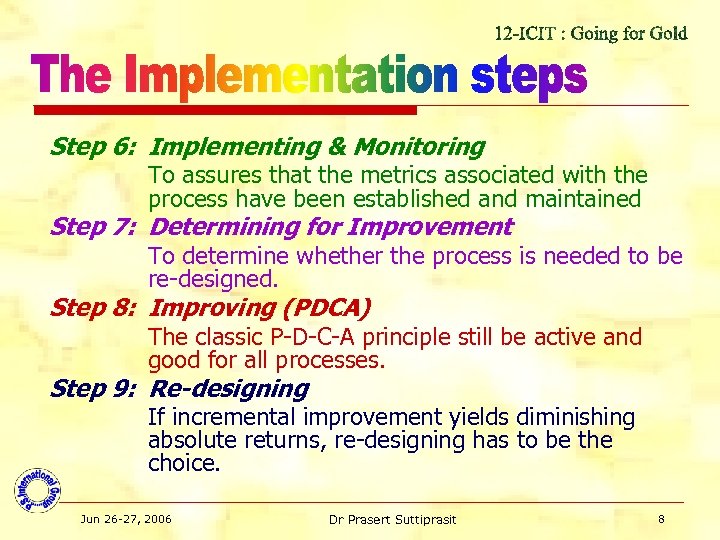

Step 6: Implementing & Monitoring To assures that the metrics associated with the process have been established and maintained Step 7: Determining for Improvement To determine whether the process is needed to be re-designed. Step 8: Improving (PDCA) The classic P-D-C-A principle still be active and good for all processes. Step 9: Re-designing If incremental improvement yields diminishing absolute returns, re-designing has to be the choice. Jun 26 -27, 2006 Dr Prasert Suttiprasit 8

Step 6: Implementing & Monitoring To assures that the metrics associated with the process have been established and maintained Step 7: Determining for Improvement To determine whether the process is needed to be re-designed. Step 8: Improving (PDCA) The classic P-D-C-A principle still be active and good for all processes. Step 9: Re-designing If incremental improvement yields diminishing absolute returns, re-designing has to be the choice. Jun 26 -27, 2006 Dr Prasert Suttiprasit 8

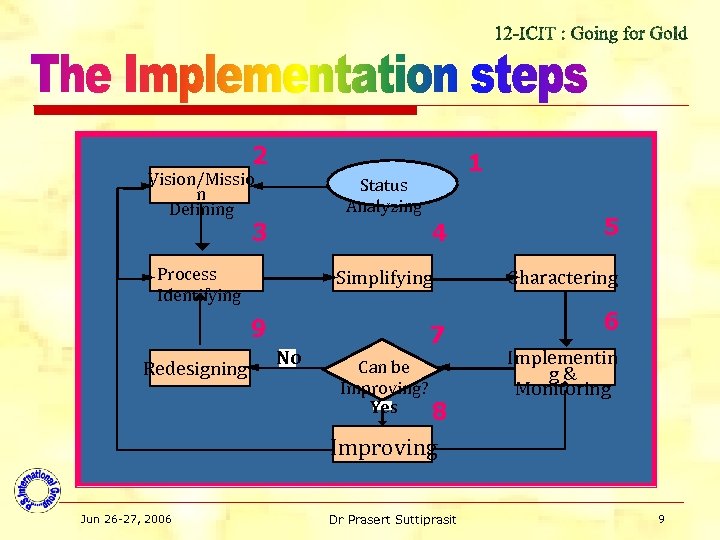

2 1 Vision/Missio n Defining Status Analyzing Process Identifying Simplifying 3 4 9 Redesigning No 7 Can be Improving? Yes 8 5 Charactering 6 Implementin g& Monitoring Improving Jun 26 -27, 2006 Dr Prasert Suttiprasit 9

2 1 Vision/Missio n Defining Status Analyzing Process Identifying Simplifying 3 4 9 Redesigning No 7 Can be Improving? Yes 8 5 Charactering 6 Implementin g& Monitoring Improving Jun 26 -27, 2006 Dr Prasert Suttiprasit 9

Quality & Food Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 10

Quality & Food Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 10

Quality & Food Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 11

Quality & Food Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 11

Quality & Food Safety Standards RECOMMENDED INTERNATIONAL CODE OF PRACTICE GENERAL PRINCIPLES OF FOOD HYGIENE CAC/RCP 1 -1969, Rev. 4 -2003 E Joint FAO/WHO Food Standards Programme CODEX ALIMENTARIUS COMMISSION Jun 26 -27, 2006 Dr Prasert Suttiprasit 12

Quality & Food Safety Standards RECOMMENDED INTERNATIONAL CODE OF PRACTICE GENERAL PRINCIPLES OF FOOD HYGIENE CAC/RCP 1 -1969, Rev. 4 -2003 E Joint FAO/WHO Food Standards Programme CODEX ALIMENTARIUS COMMISSION Jun 26 -27, 2006 Dr Prasert Suttiprasit 12

Quality & Food Safety Standards Managing Food Safety: A Manual for the Voluntary Use of HACCP Principles for Operators of Food Service and Retail Establishments Additional copies are available from: Office of Compliance Division of Cooperative Programs (HFS-625) Center for Food Safety and Applied Nutrition Food and Drug Administration 5100 Paint Branch Parkway College Park, MD 20740 (Tel) 301 -436 -2350 U. S. Department of Health and Human Services Food and Drug Administration Center for Food Safety and Applied Nutrition [July 2005] Jun 26 -27, 2006 Dr Prasert Suttiprasit 13

Quality & Food Safety Standards Managing Food Safety: A Manual for the Voluntary Use of HACCP Principles for Operators of Food Service and Retail Establishments Additional copies are available from: Office of Compliance Division of Cooperative Programs (HFS-625) Center for Food Safety and Applied Nutrition Food and Drug Administration 5100 Paint Branch Parkway College Park, MD 20740 (Tel) 301 -436 -2350 U. S. Department of Health and Human Services Food and Drug Administration Center for Food Safety and Applied Nutrition [July 2005] Jun 26 -27, 2006 Dr Prasert Suttiprasit 13

Quality & Food Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 14

Quality & Food Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 14

Quality & Food Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 15

Quality & Food Safety Standards Jun 26 -27, 2006 Dr Prasert Suttiprasit 15

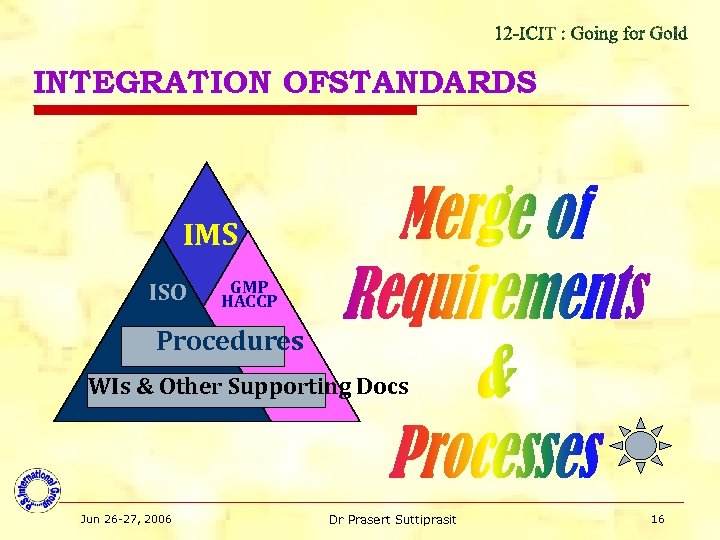

INTEGRATION OFSTANDARDS IMS ISO GMP HACCP Procedures WIs & Other Supporting Docs Jun 26 -27, 2006 Dr Prasert Suttiprasit 16

INTEGRATION OFSTANDARDS IMS ISO GMP HACCP Procedures WIs & Other Supporting Docs Jun 26 -27, 2006 Dr Prasert Suttiprasit 16

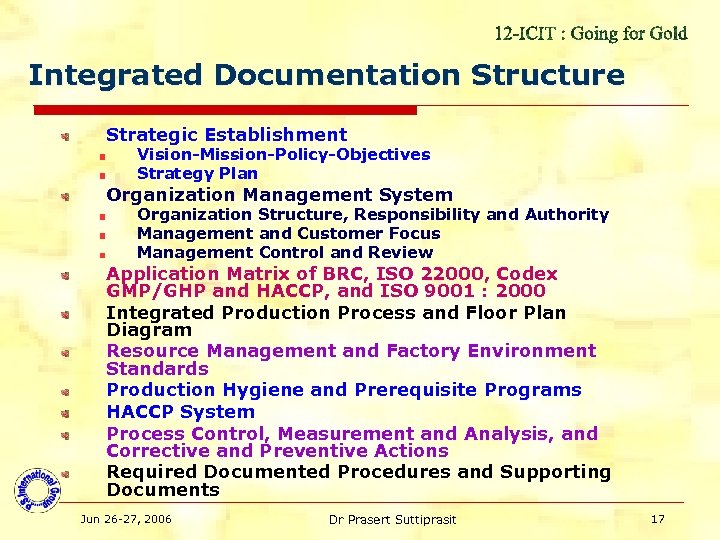

Integrated Documentation Structure Strategic Establishment Vision-Mission-Policy-Objectives Strategy Plan Organization Management System Organization Structure, Responsibility and Authority Management and Customer Focus Management Control and Review Application Matrix of BRC, ISO 22000, Codex GMP/GHP and HACCP, and ISO 9001 : 2000 Integrated Production Process and Floor Plan Diagram Resource Management and Factory Environment Standards Production Hygiene and Prerequisite Programs HACCP System Process Control, Measurement and Analysis, and Corrective and Preventive Actions Required Documented Procedures and Supporting Documents Jun 26 -27, 2006 Dr Prasert Suttiprasit 17

Integrated Documentation Structure Strategic Establishment Vision-Mission-Policy-Objectives Strategy Plan Organization Management System Organization Structure, Responsibility and Authority Management and Customer Focus Management Control and Review Application Matrix of BRC, ISO 22000, Codex GMP/GHP and HACCP, and ISO 9001 : 2000 Integrated Production Process and Floor Plan Diagram Resource Management and Factory Environment Standards Production Hygiene and Prerequisite Programs HACCP System Process Control, Measurement and Analysis, and Corrective and Preventive Actions Required Documented Procedures and Supporting Documents Jun 26 -27, 2006 Dr Prasert Suttiprasit 17

Jun 26 -27, 2006 Dr Prasert Suttiprasit 18

Jun 26 -27, 2006 Dr Prasert Suttiprasit 18