50015e1144ef6f478a252b7588230884.ppt

- Количество слайдов: 41

12 Ge. V Upgrade - Beam Transport Quads & Girders, Arc 10 and Hall D Layout Preliminary Design and Safety Review Quad Girders Michael Bevins May 3, 2007

Outline • • • Introduction & Scope Requirements & Design Philosophy Girder Count - Flavors Girder Layouts Bolted Plate Girder vs Extrusion Safety Considerations Cost Estimates & Schedule Risk Assessment Summary

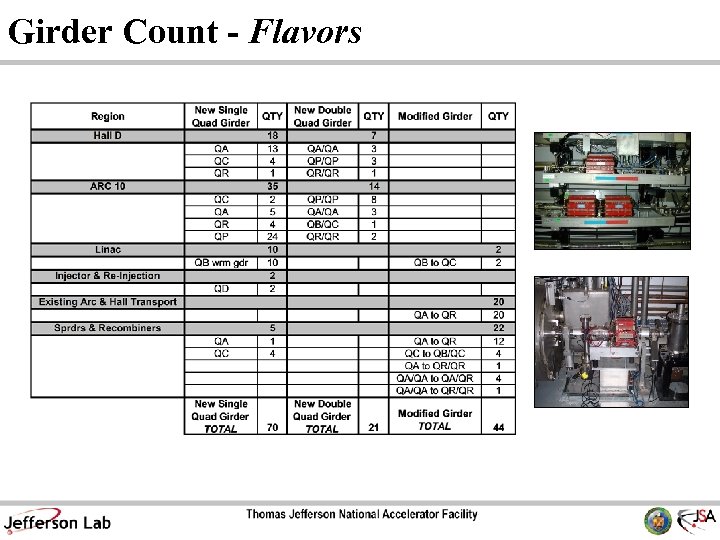

Introduction & Scope • The 12 Ge. V upgrade requires an addition of ~91 quad girders • 74 of the 91 girders will be in the new ARC 10 and Hall D lines • 12 Ge. V field strength requirements force us to modify 44 existing quad girders – Some quads will be replaced with higher strength quads (e. g. , QA to QR) – Some girders will require an additional quad • Songsheet level layouts are being used to identify the number of girder flavors that will be required – We expect a number of custom designs will be needed in the spreader and recombiner regions • Girder requirements, design philosophy, flavors, & cost estimates will be presented today • An alternative to the CEBAF style extruded girder will also be presented

Requirements/Design Philosophy Same as CEBAF. . . • Structural – Support girder elements and maintain alignment during shipping and installation • Alignment – Quad +/- 0. 5 mm in x & y, 1. 0 mm in z – BPM relative to quad +/- 0. 25 mm in x & y • Diagnostics – Girders should support typical suit of diagnostics and correctors • BPM, Harp, Viewer, H & V correctors (BC, BD, …) – Provide means to support electronics packaging and wiring • Vacuum – Provide support for pumps, roughing valves, gauges • Handling – Provide tapped holes for commercial lifting rings • Complete double quad girder weighs ~1200 lbs

Girder Count - Flavors

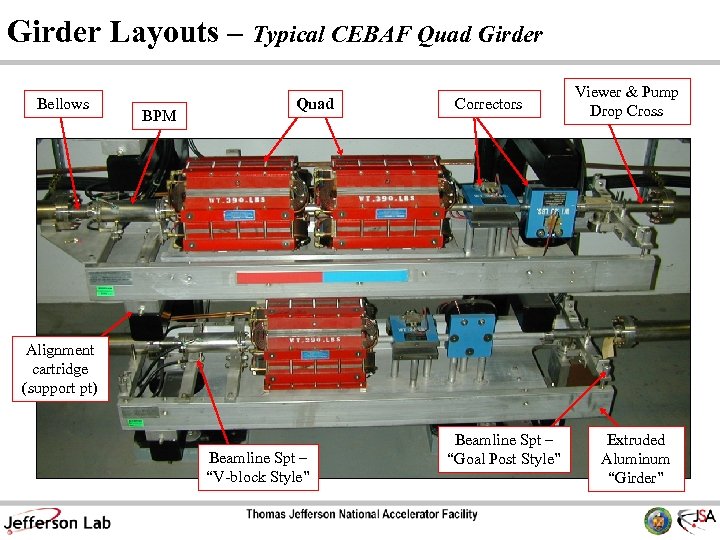

Girder Layouts – Typical CEBAF Quad Girder Bellows BPM Quad Correctors Viewer & Pump Drop Cross Alignment cartridge (support pt) Beamline Spt – “V-block Style” Beamline Spt – “Goal Post Style” Extruded Aluminum “Girder”

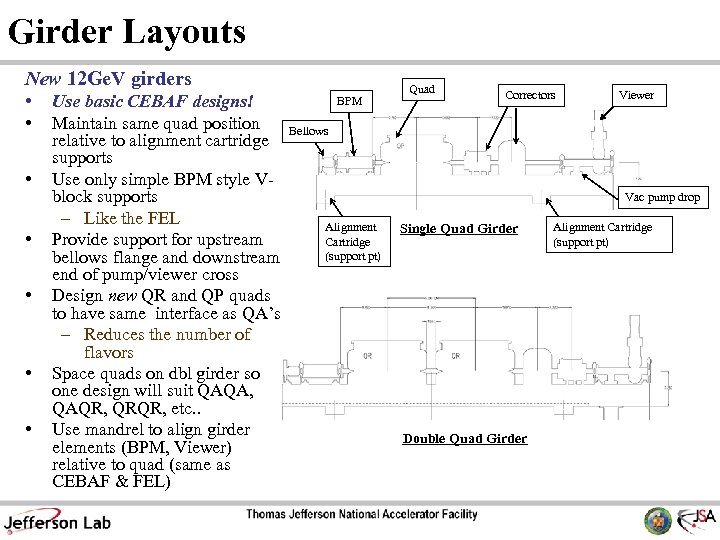

Girder Layouts New 12 Ge. V girders • • Use basic CEBAF designs! Maintain same quad position relative to alignment cartridge supports Use only simple BPM style Vblock supports – Like the FEL Provide support for upstream bellows flange and downstream end of pump/viewer cross Design new QR and QP quads to have same interface as QA’s – Reduces the number of flavors Space quads on dbl girder so one design will suit QAQA, QAQR, QRQR, etc. . Use mandrel to align girder elements (BPM, Viewer) relative to quad (same as CEBAF & FEL) BPM Quad Correctors Viewer Bellows Vac pump drop Alignment Cartridge (support pt) Single Quad Girder Double Quad Girder Alignment Cartridge (support pt)

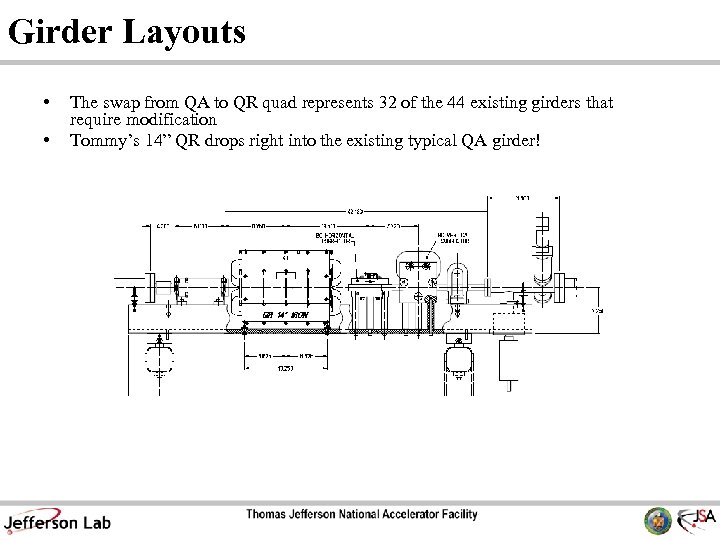

Girder Layouts • • The swap from QA to QR quad represents 32 of the 44 existing girders that require modification Tommy’s 14” QR drops right into the existing typical QA girder!

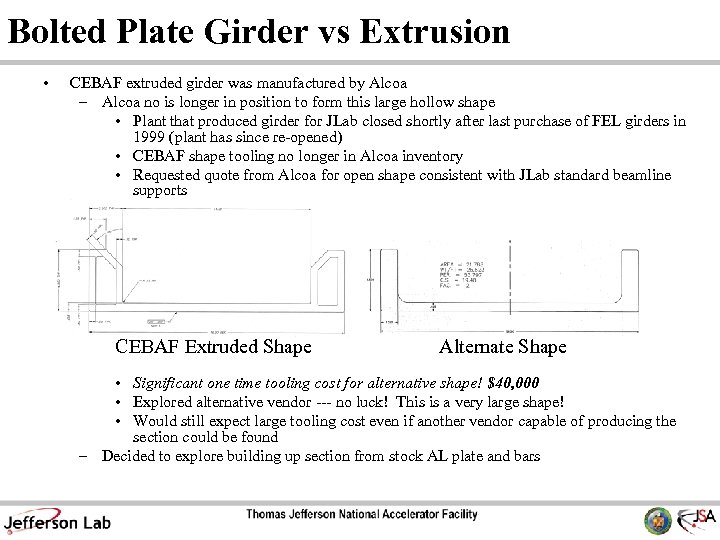

Bolted Plate Girder vs Extrusion • CEBAF extruded girder was manufactured by Alcoa – Alcoa no is longer in position to form this large hollow shape • Plant that produced girder for JLab closed shortly after last purchase of FEL girders in 1999 (plant has since re-opened) • CEBAF shape tooling no longer in Alcoa inventory • Requested quote from Alcoa for open shape consistent with JLab standard beamline supports CEBAF Extruded Shape Alternate Shape • Significant one time tooling cost for alternative shape! $40, 000 • Explored alternative vendor --- no luck! This is a very large shape! • Would still expect large tooling cost even if another vendor capable of producing the section could be found – Decided to explore building up section from stock AL plate and bars

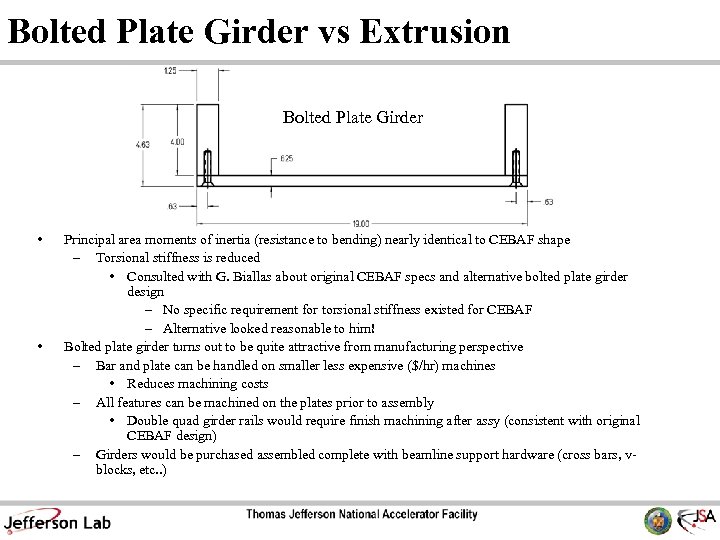

Bolted Plate Girder vs Extrusion Bolted Plate Girder • • Principal area moments of inertia (resistance to bending) nearly identical to CEBAF shape – Torsional stiffness is reduced • Consulted with G. Biallas about original CEBAF specs and alternative bolted plate girder design – No specific requirement for torsional stiffness existed for CEBAF – Alternative looked reasonable to him! Bolted plate girder turns out to be quite attractive from manufacturing perspective – Bar and plate can be handled on smaller less expensive ($/hr) machines • Reduces machining costs – All features can be machined on the plates prior to assembly • Double quad girder rails would require finish machining after assy (consistent with original CEBAF design) – Girders would be purchased assembled complete with beamline support hardware (cross bars, vblocks, etc. . )

Safety Considerations • Personnel Training – Jlab & sub-contractor • Radiation – Designated areas for containment and radiation survey of girders that will be removed from the tunnel • Material handling – Provide provisions for lifting • Electrical Hazards – Package and support electronics, power leads and terminal blocks to control electrical hazards

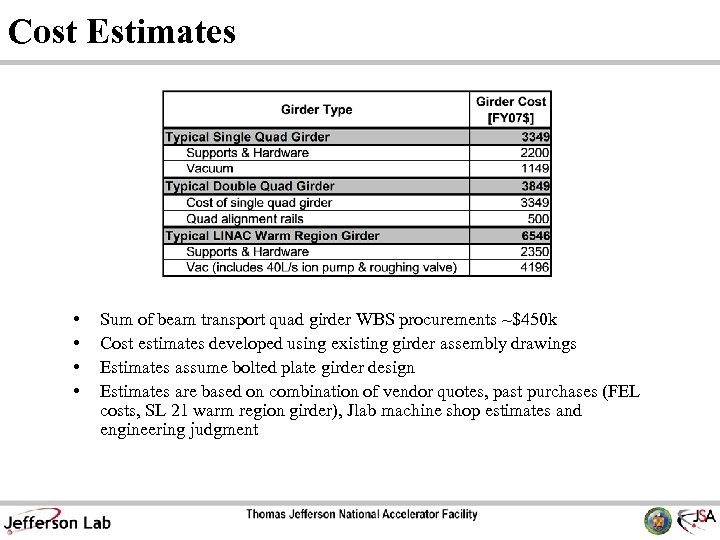

Cost Estimates • • Sum of beam transport quad girder WBS procurements ~$450 k Cost estimates developed using existing girder assembly drawings Estimates assume bolted plate girder design Estimates are based on combination of vendor quotes, past purchases (FEL costs, SL 21 warm region girder), Jlab machine shop estimates and engineering judgment

Schedule • New girder procurements in time to support girder build up prior to major installation down • Modified girder swap out and modifications during major down requires more detailed study • Detailed reuse vs mod vs make plan TBD to optimize cost and schedule savings – Inventory of existing girder extrusion and support hardware as well as a complete accounting of parts that will be removed from modified girders is planed

Risk Assessment • Technical - Low – Girders & Supports – very similar designs exist and are already proven – Alignment - same as existing machine • Procurement Schedule - Low – No long-lead items identified • Cost – Low – Linac warm region girder recently prototyped – Vendor quotes for most vacuum elements • Pumps, valves, spools, diag/pump cross – Good cost estimates for machined parts • Vendor & Jlab shop budgetary estimates • Referenced recent FEL beam transport purchases

Summary • The 12 Ge. V beam transport girder designs are more than 35% complete thus exceeding the goal set to support our DOE External Project Reviews this summer • We will continue to work closely with our friends throughout the lab (safety, CASA, installation, vacuum, alignment, I&C, magnet measurement, operations, procurement & facilities) as we move forward • Detailed design will be complete in 2008 to support assembly and installation schedules • We look forward to comments & recommendations from the committee

12 Ge. V Upgrade - Beam Transport Quads & Girders, Arc 10 and Hall D Layout Preliminary Design and Safety Review Arc 10 & Hall D Michael Bevins May 3, 2007

Outline • Requirements & Specifications • ARC 10 – Elements/Girder Count – Beam Transport Layout – Vacuum Analysis – Highlighted Challenges • Hall D • Safety Considerations • Cost & Risk Assessment • Summary

Requirements & Specifications • Alignment specs – Quads and dioples positioned to +/-0. 5 mm in x & y, +/- 1. 0 mm in z • Vacuum specs – Beam line partial pressure of hydrogen <10 -6 torr – Total average pressure of all other constituents less than 5 x 10 -7 torr – Fabrication, welding, cleaning & handling, and leak checking specs still apply • 22631 -S-001 Fabrication of Ultra-High Vacuum Equipment • 22632 -S-001 Cleaning and Handling of U. H. V. Components • 22633 -S-001 Welding Specification For U. H. V. Components • 22634 -S-001 Helium Leak Test For U. H. V. Components • Note an update and modernization of our vacuum specs is underway

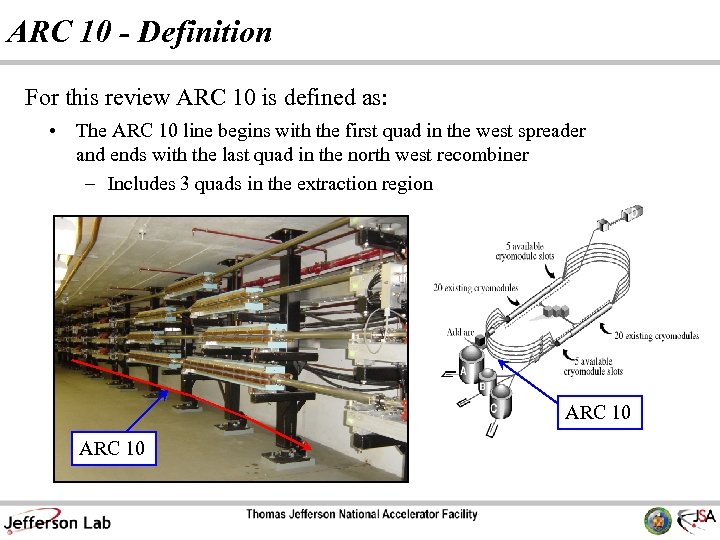

ARC 10 - Definition For this review ARC 10 is defined as: • The ARC 10 line begins with the first quad in the west spreader and ends with the last quad in the north west recombiner – Includes 3 quads in the extraction region ARC 10

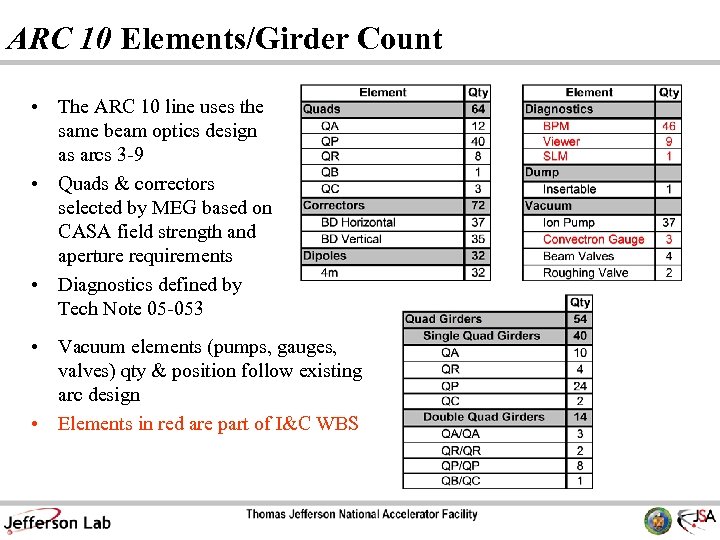

ARC 10 Elements/Girder Count • The ARC 10 line uses the same beam optics design as arcs 3 -9 • Quads & correctors selected by MEG based on CASA field strength and aperture requirements • Diagnostics defined by Tech Note 05 -053 • Vacuum elements (pumps, gauges, valves) qty & position follow existing arc design • Elements in red are part of I&C WBS

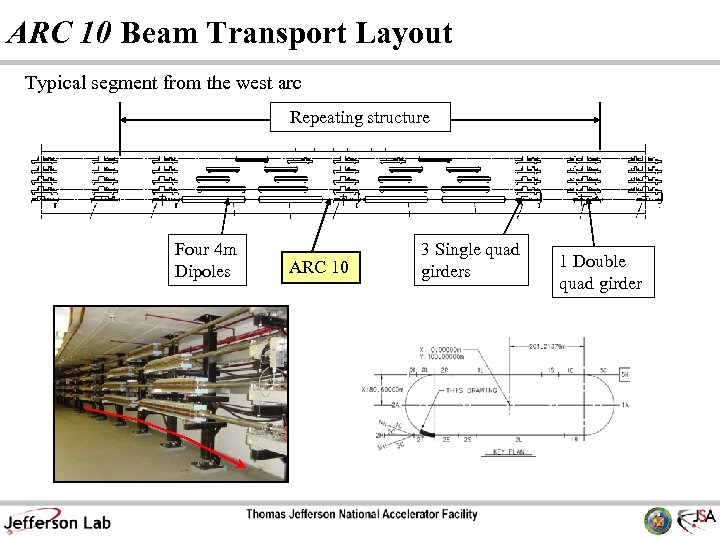

ARC 10 Beam Transport Layout Typical segment from the west arc Repeating structure Four 4 m Dipoles ARC 10 3 Single quad girders 1 Double quad girder

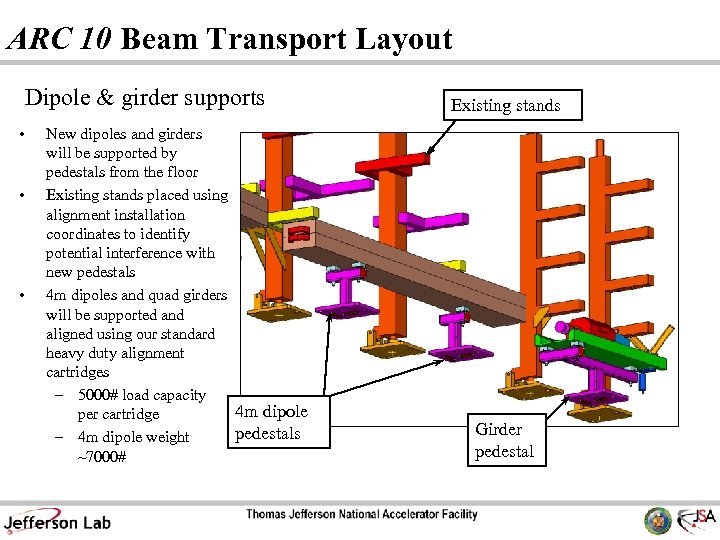

ARC 10 Beam Transport Layout Dipole & girder supports • • • New dipoles and girders will be supported by pedestals from the floor Existing stands placed using alignment installation coordinates to identify potential interference with new pedestals 4 m dipoles and quad girders will be supported and aligned using our standard heavy duty alignment cartridges – 5000# load capacity 4 m dipole per cartridge pedestals – 4 m dipole weight ~7000# Existing stands Girder pedestal

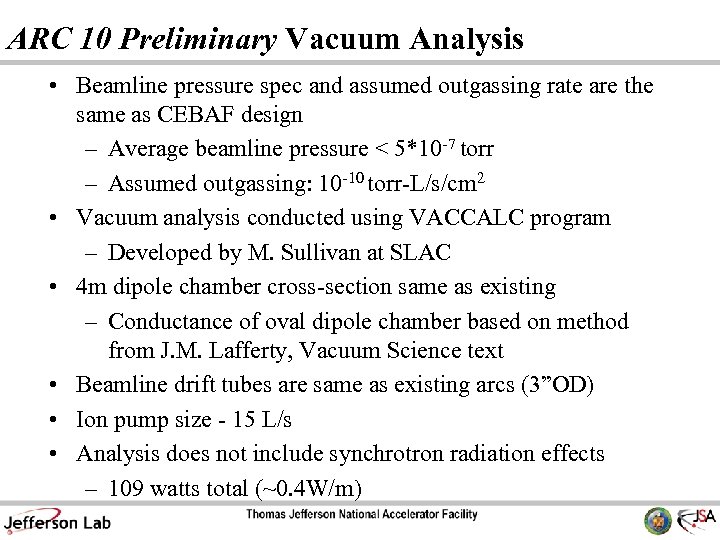

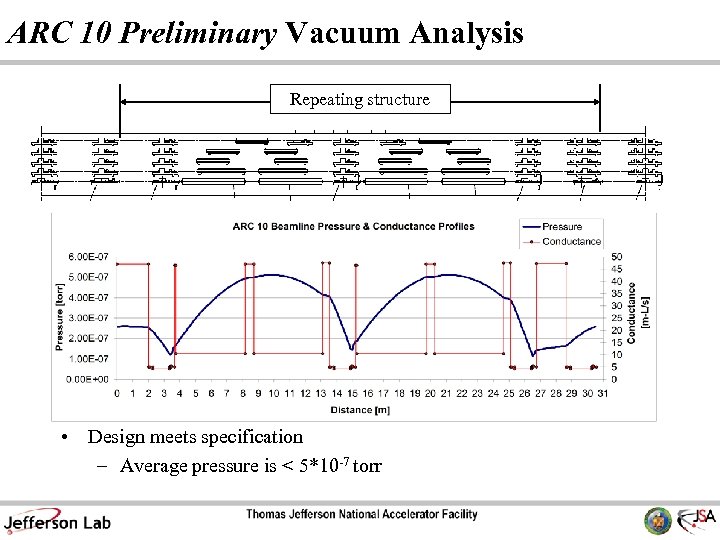

ARC 10 Preliminary Vacuum Analysis • Beamline pressure spec and assumed outgassing rate are the same as CEBAF design – Average beamline pressure < 5*10 -7 torr – Assumed outgassing: 10 -10 torr-L/s/cm 2 • Vacuum analysis conducted using VACCALC program – Developed by M. Sullivan at SLAC • 4 m dipole chamber cross-section same as existing – Conductance of oval dipole chamber based on method from J. M. Lafferty, Vacuum Science text • Beamline drift tubes are same as existing arcs (3”OD) • Ion pump size - 15 L/s • Analysis does not include synchrotron radiation effects – 109 watts total (~0. 4 W/m)

ARC 10 Preliminary Vacuum Analysis Repeating structure • Design meets specification – Average pressure is < 5*10 -7 torr

ARC 10 Highlighted Challenges • Identify interference between the arc 10 line and the existing stands in the extraction and injector/re-injection region – Some of the stands in these regions were modified in the field - documentation is incomplete – Plan to work with the alignment group to obtain as built coordinates of suspect areas

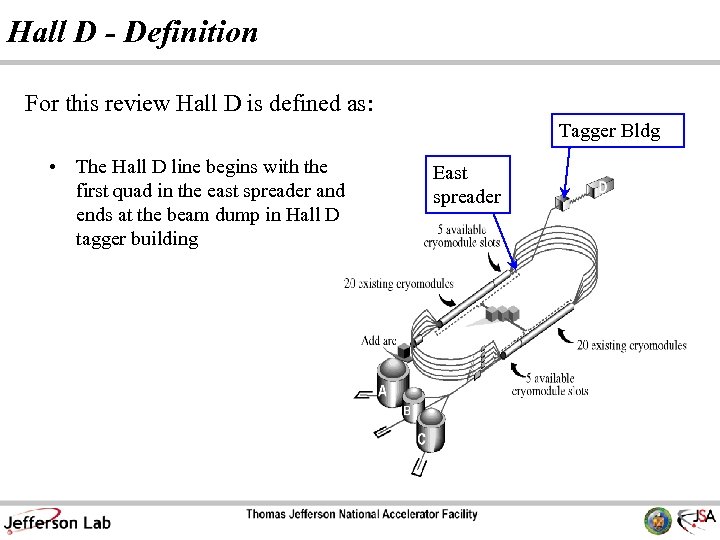

Hall D - Definition For this review Hall D is defined as: Tagger Bldg • The Hall D line begins with the first quad in the east spreader and ends at the beam dump in Hall D tagger building East spreader

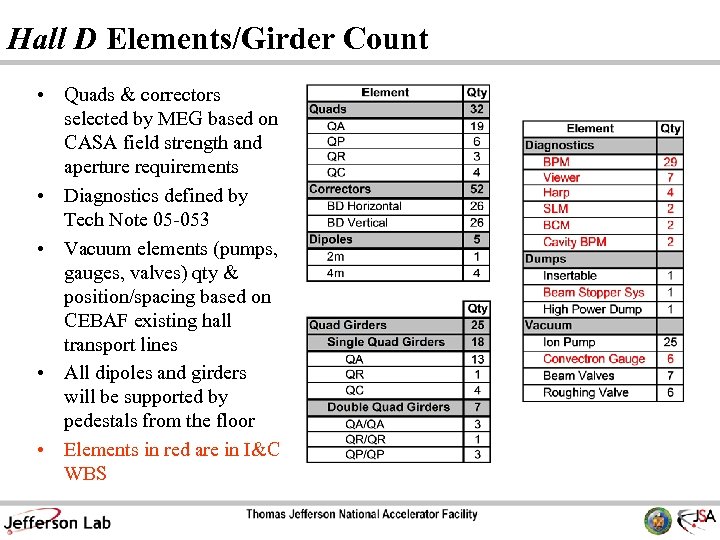

Hall D Elements/Girder Count • Quads & correctors selected by MEG based on CASA field strength and aperture requirements • Diagnostics defined by Tech Note 05 -053 • Vacuum elements (pumps, gauges, valves) qty & position/spacing based on CEBAF existing hall transport lines • All dipoles and girders will be supported by pedestals from the floor • Elements in red are in I&C WBS

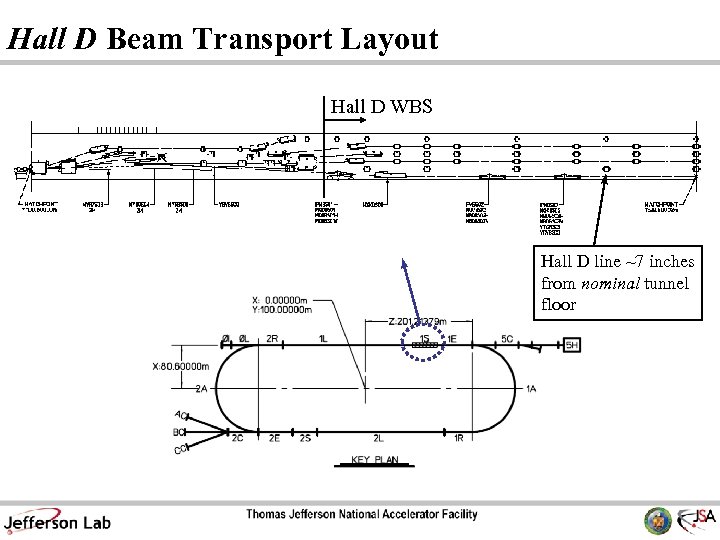

Hall D Beam Transport Layout Hall D WBS Hall D line ~7 inches from nominal tunnel floor

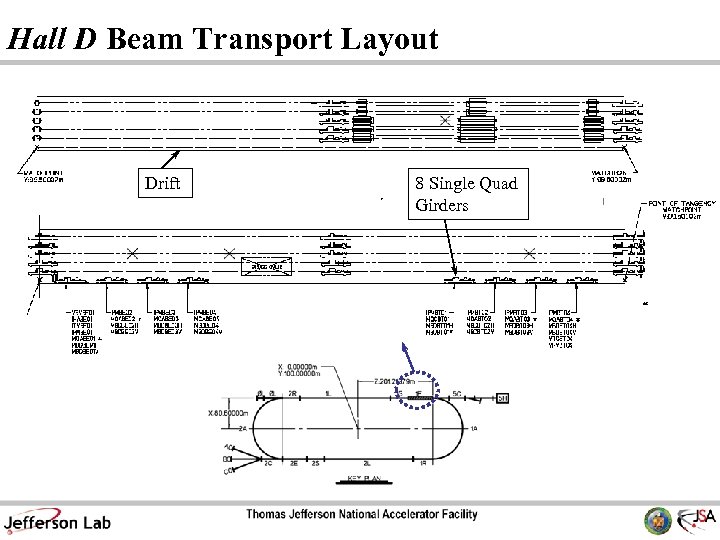

Hall D Beam Transport Layout Drift 8 Single Quad Girders

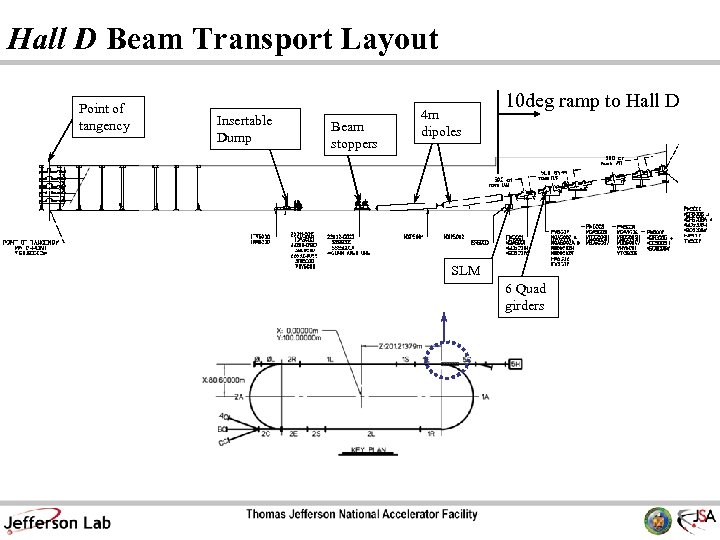

Hall D Beam Transport Layout Point of tangency Insertable Dump Beam stoppers 4 m dipoles 10 deg ramp to Hall D SLM 6 Quad girders

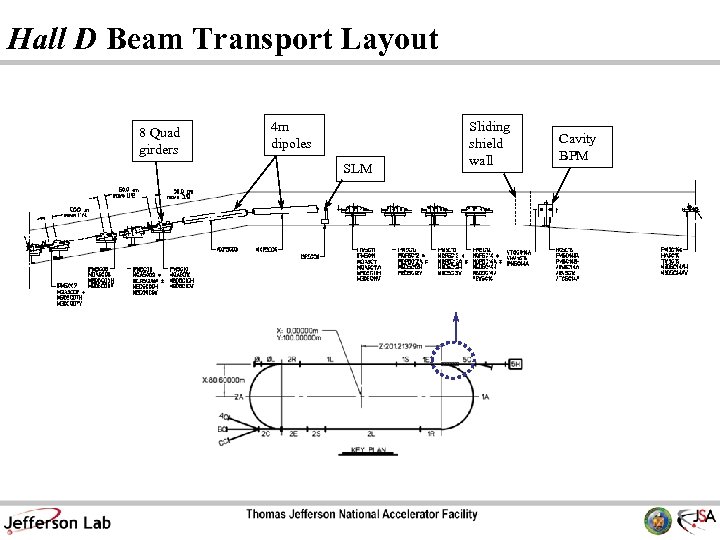

Hall D Beam Transport Layout 8 Quad girders 4 m dipoles SLM Sliding shield wall Cavity BPM

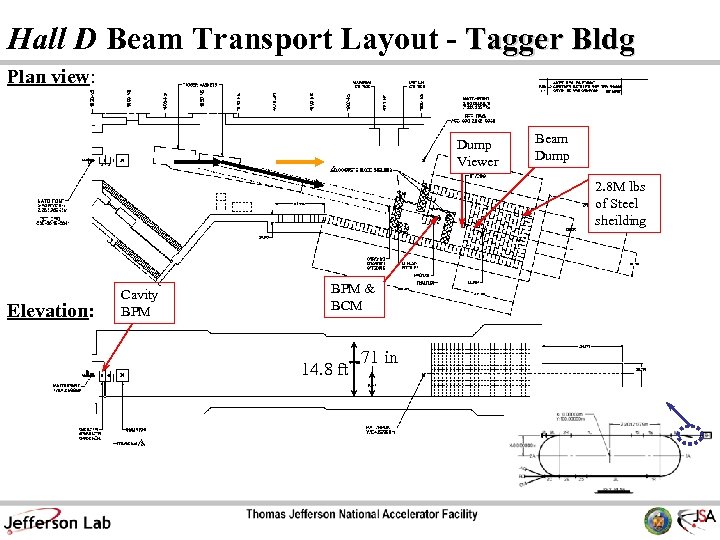

Hall D Beam Transport Layout - Tagger Bldg Plan view: Dump Viewer Beam Dump 2. 8 M lbs of Steel sheilding Elevation: Cavity BPM & BCM 14. 8 ft 71 in

Hall D Preliminary Vacuum Analysis • Beamline pressure spec and assumed outgassing rate are the same as CEBAF design – Average beamline pressure < 5*10 -7 torr – Assumed outgassing: 10 -10 torr-L/s/cm 2 • Vacuum analysis conducted using VACCALC program – Developed by M. Sullivan at SLAC • 4 m dipole chamber cross-section same as existing – Conductance of oval dipole chamber based on method from J. M. Lafferty, Vacuum Science text • Beamline drift tubes are same as existing arcs (3”OD) • Number of pumps based on CEBAF – Detailed analysis TBD

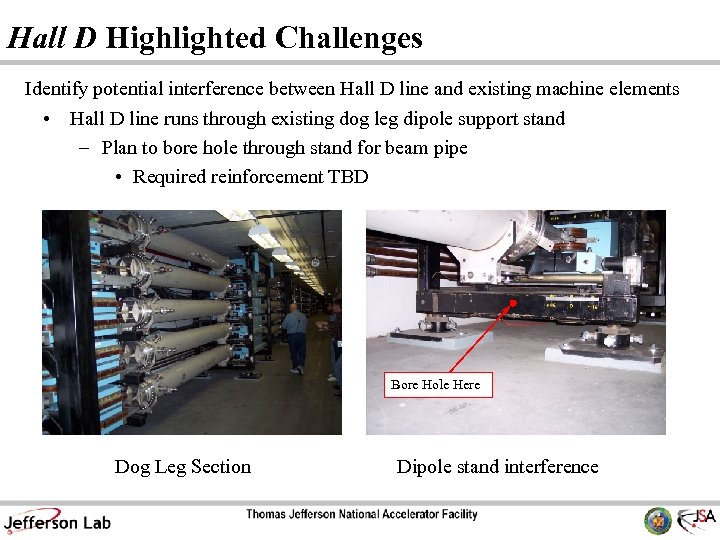

Hall D Highlighted Challenges Identify potential interference between Hall D line and existing machine elements • Hall D line runs through existing dog leg dipole support stand – Plan to bore hole through stand for beam pipe • Required reinforcement TBD Bore Hole Here Dog Leg Section Dipole stand interference

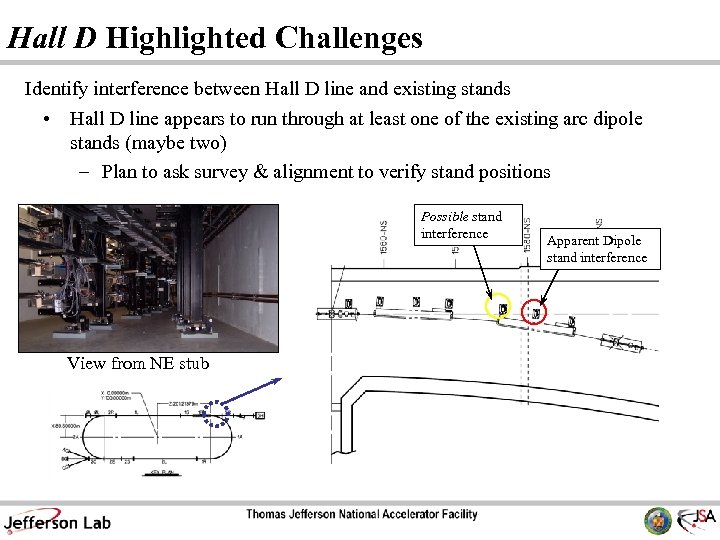

Hall D Highlighted Challenges Identify interference between Hall D line and existing stands • Hall D line appears to run through at least one of the existing arc dipole stands (maybe two) – Plan to ask survey & alignment to verify stand positions Possible stand interference View from NE stub Apparent Dipole stand interference

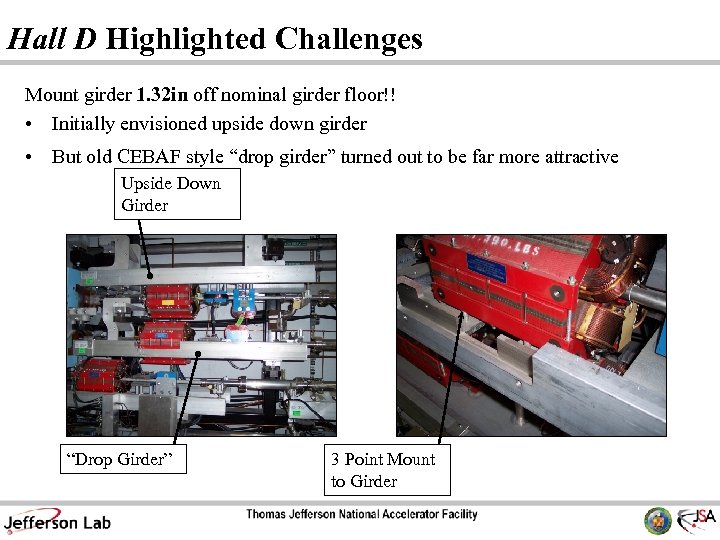

Hall D Highlighted Challenges Mount girder 1. 32 in off nominal girder floor!! • Initially envisioned upside down girder • But old CEBAF style “drop girder” turned out to be far more attractive Upside Down Girder “Drop Girder” 3 Point Mount to Girder

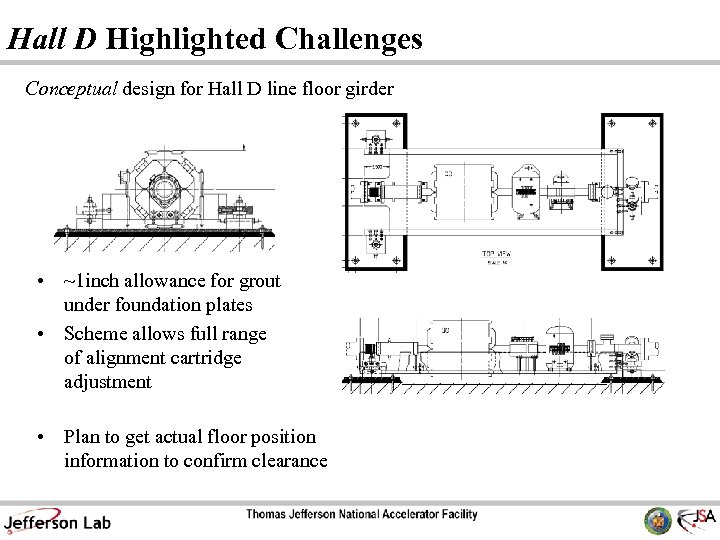

Hall D Highlighted Challenges Conceptual design for Hall D line floor girder • ~1 inch allowance for grout under foundation plates • Scheme allows full range of alignment cartridge adjustment • Plan to get actual floor position information to confirm clearance

Safety Considerations • Personnel Training – Jlab & sub-contractor • Radiation – Removal and relocation of north east stub dump to tagger bldg – Designated areas for containment and radiation survey of materials that will be removed from the tunnel – In situ modification of stands • Coordination with civil and Hall D installation • Material handling – Working on 10 deg slope – Shielding removal and installation • Potential hot work • Electrical Hazards

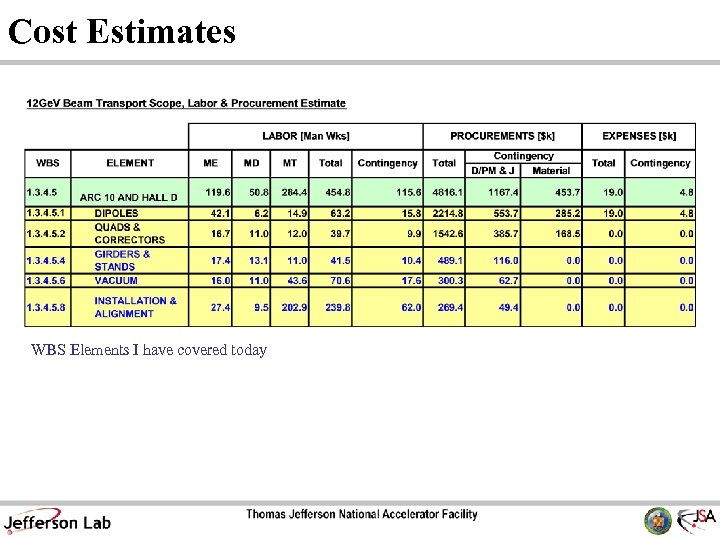

Cost Estimates WBS Elements I have covered today

Risk Assessment • Technical - Low – Girders & Supports – very similar designs exist and are already proven – Vacuum – design consistent with existing machine – Alignment - same as existing machine • Procurement Schedule - Low – No long-lead items identified • Cost – Low – Good girder, stand alignment cartridge cost estimates – Good estimates for vacuum tubes, flanges, pumps, valves

Summary • The arc 10 and hall D beam transport designs are 35% complete thus meeting the goal set to support our DOE External Project Reviews this summer • We will continue to work closely with our friends throughout the lab (safety, CASA, installation, vacuum, alignment, I&C, magnet measurement, operations, procurement & facilities) as we move forward • Detailed design will be complete in 2009 to support assembly and installation schedules • We look forward to comments & recommendations from the committee

50015e1144ef6f478a252b7588230884.ppt