e4bdc4c448d8fac6c5d7e2ffda67224b.ppt

- Количество слайдов: 57

11 Supply Chain Management Mc. Graw-Hill/Irwin Copyright © 2007 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

11 Supply Chain Management Mc. Graw-Hill/Irwin Copyright © 2007 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

Learning Objectives § § § § Explain what a supply chain is. Explain the need to manage a supply chain and the potential benefits of doing so. Explain the increasing importance of outsourcing. State the objective of supply chain management. List the elements of supply chain management. Identify the strategic, tactical, and operations issues in supply chain management. Describe the bullwhip effect and the reasons why it occurs. 2

Learning Objectives § § § § Explain what a supply chain is. Explain the need to manage a supply chain and the potential benefits of doing so. Explain the increasing importance of outsourcing. State the objective of supply chain management. List the elements of supply chain management. Identify the strategic, tactical, and operations issues in supply chain management. Describe the bullwhip effect and the reasons why it occurs. 2

Learning Objectives § § § § Explain the value of strategic partnering. Discuss the critical importance of information exchange across a supply chain. Outline the key steps, and potential challenges, in creating an effective supply chain. Explain the importance of the purchasing function in business organizations. Describe the responsibilities of purchasing. Explain the term value analysis. Identify several guidelines for ethical behavior in purchasing. 3

Learning Objectives § § § § Explain the value of strategic partnering. Discuss the critical importance of information exchange across a supply chain. Outline the key steps, and potential challenges, in creating an effective supply chain. Explain the importance of the purchasing function in business organizations. Describe the responsibilities of purchasing. Explain the term value analysis. Identify several guidelines for ethical behavior in purchasing. 3

Supply Chain Management § Supply Chain: the sequence of organizations - their facilities, functions, and activities - that are involved in producing and delivering a product or service. Sometimes referred to as value chains 4

Supply Chain Management § Supply Chain: the sequence of organizations - their facilities, functions, and activities - that are involved in producing and delivering a product or service. Sometimes referred to as value chains 4

Facilities § § § Warehouses Factories Processing centers Distribution centers Retail outlets Offices 5

Facilities § § § Warehouses Factories Processing centers Distribution centers Retail outlets Offices 5

Functions and Activities § § § § Forecasting Purchasing Inventory management Information management Quality assurance Scheduling Production and delivery Customer service 6

Functions and Activities § § § § Forecasting Purchasing Inventory management Information management Quality assurance Scheduling Production and delivery Customer service 6

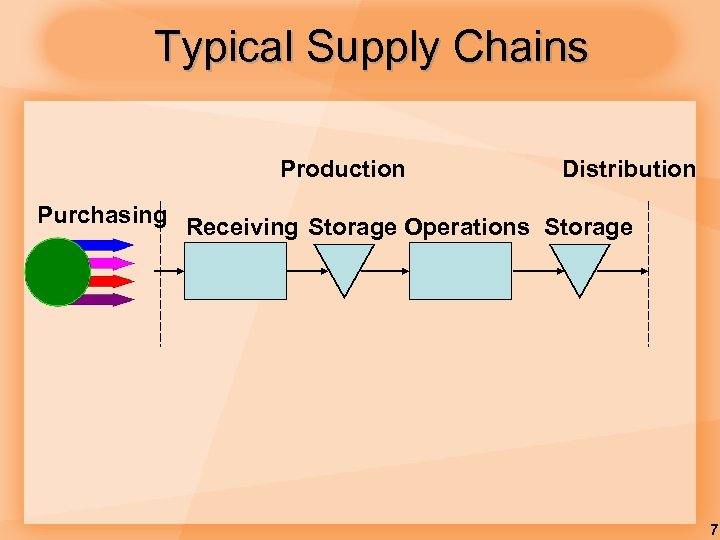

Typical Supply Chains Production Distribution Purchasing Receiving Storage Operations Storage 7

Typical Supply Chains Production Distribution Purchasing Receiving Storage Operations Storage 7

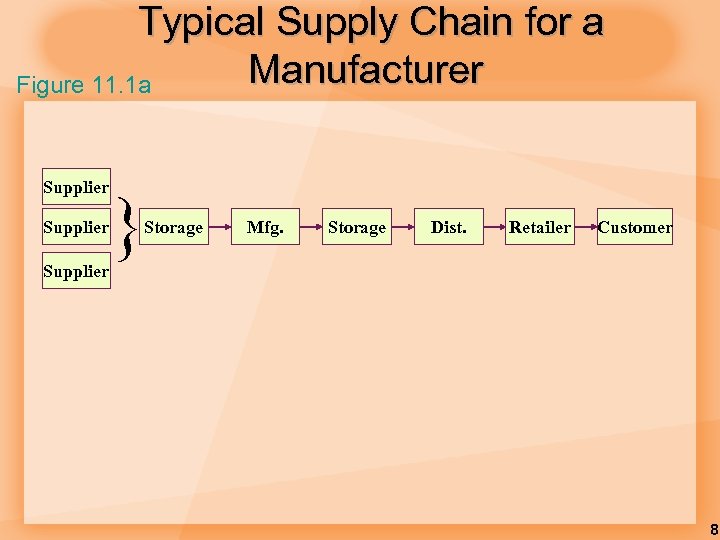

Typical Supply Chain for a Manufacturer Figure 11. 1 a Supplier } Storage Mfg. Storage Dist. Retailer Customer 8

Typical Supply Chain for a Manufacturer Figure 11. 1 a Supplier } Storage Mfg. Storage Dist. Retailer Customer 8

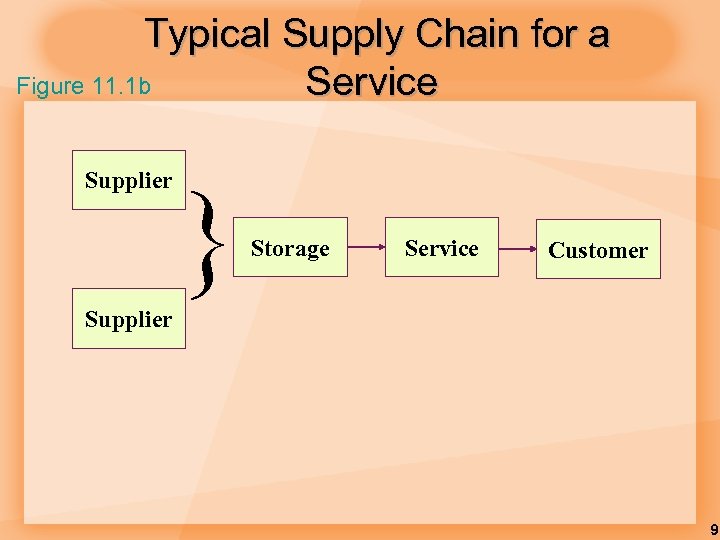

Typical Supply Chain for a Figure 11. 1 b Service Supplier } Storage Service Customer Supplier 9

Typical Supply Chain for a Figure 11. 1 b Service Supplier } Storage Service Customer Supplier 9

Need for Supply Chain Management 1. Improve operations 2. Increasing levels of outsourcing 3. Increasing transportation costs 4. Competitive pressures 5. Increasing globalization 6. Increasing importance of e-commerce 7. Complexity of supply chains 8. Manage inventories 10

Need for Supply Chain Management 1. Improve operations 2. Increasing levels of outsourcing 3. Increasing transportation costs 4. Competitive pressures 5. Increasing globalization 6. Increasing importance of e-commerce 7. Complexity of supply chains 8. Manage inventories 10

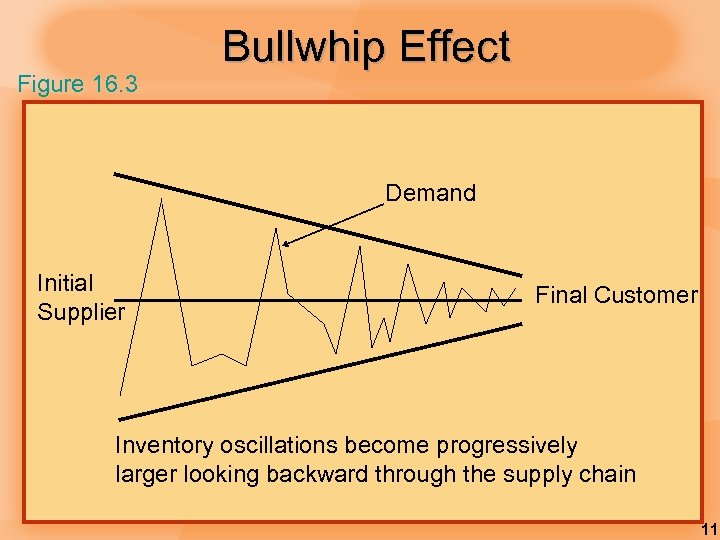

Figure 16. 3 Bullwhip Effect Demand Initial Supplier Final Customer Inventory oscillations become progressively larger looking backward through the supply chain 11

Figure 16. 3 Bullwhip Effect Demand Initial Supplier Final Customer Inventory oscillations become progressively larger looking backward through the supply chain 11

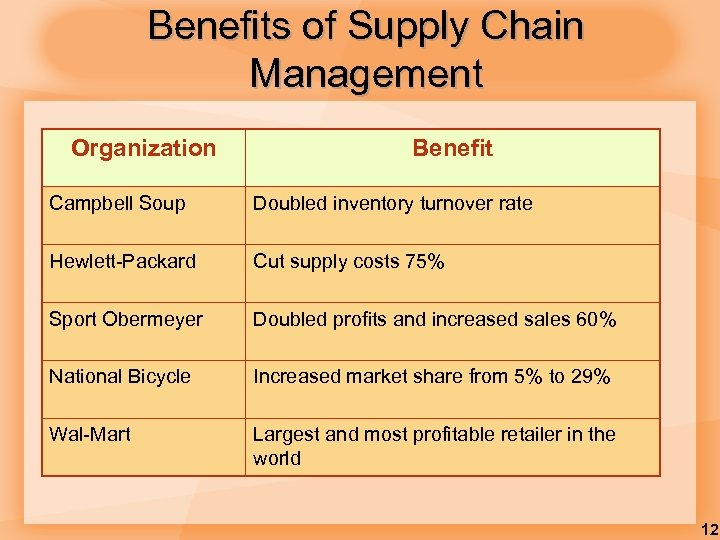

Benefits of Supply Chain Management Organization Benefit Campbell Soup Doubled inventory turnover rate Hewlett-Packard Cut supply costs 75% Sport Obermeyer Doubled profits and increased sales 60% National Bicycle Increased market share from 5% to 29% Wal-Mart Largest and most profitable retailer in the world 12

Benefits of Supply Chain Management Organization Benefit Campbell Soup Doubled inventory turnover rate Hewlett-Packard Cut supply costs 75% Sport Obermeyer Doubled profits and increased sales 60% National Bicycle Increased market share from 5% to 29% Wal-Mart Largest and most profitable retailer in the world 12

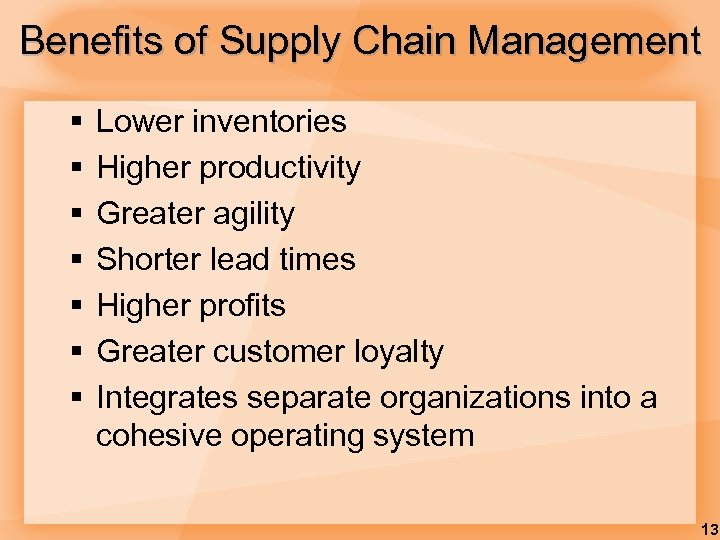

Benefits of Supply Chain Management § § § § Lower inventories Higher productivity Greater agility Shorter lead times Higher profits Greater customer loyalty Integrates separate organizations into a cohesive operating system 13

Benefits of Supply Chain Management § § § § Lower inventories Higher productivity Greater agility Shorter lead times Higher profits Greater customer loyalty Integrates separate organizations into a cohesive operating system 13

Global Supply Chains § Increasing more complex § § § § Language Culture Currency fluctuations Political Transportation costs Local capabilities Finance and economics Environmental 14

Global Supply Chains § Increasing more complex § § § § Language Culture Currency fluctuations Political Transportation costs Local capabilities Finance and economics Environmental 14

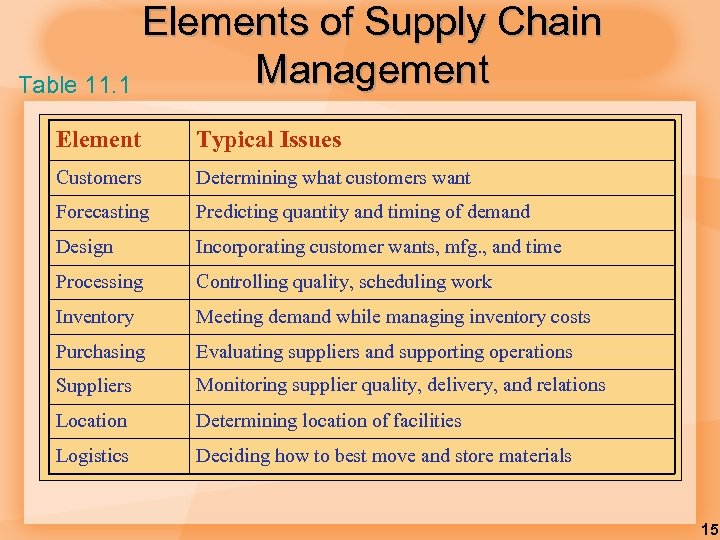

Elements of Supply Chain Management Table 11. 1 Element Typical Issues Customers Determining what customers want Forecasting Predicting quantity and timing of demand Design Incorporating customer wants, mfg. , and time Processing Controlling quality, scheduling work Inventory Meeting demand while managing inventory costs Purchasing Evaluating suppliers and supporting operations Suppliers Monitoring supplier quality, delivery, and relations Location Determining location of facilities Logistics Deciding how to best move and store materials 15

Elements of Supply Chain Management Table 11. 1 Element Typical Issues Customers Determining what customers want Forecasting Predicting quantity and timing of demand Design Incorporating customer wants, mfg. , and time Processing Controlling quality, scheduling work Inventory Meeting demand while managing inventory costs Purchasing Evaluating suppliers and supporting operations Suppliers Monitoring supplier quality, delivery, and relations Location Determining location of facilities Logistics Deciding how to best move and store materials 15

Strategic or Operational § Two types of decisions in supply chain management § Strategic – design and policy § Operational – day-today activities § Major decisions areas § § Location Production Inventory Distribution 16

Strategic or Operational § Two types of decisions in supply chain management § Strategic – design and policy § Operational – day-today activities § Major decisions areas § § Location Production Inventory Distribution 16

Logistics § Refers to the movement of materials and information within a facility and to incoming and outgoing shipments of goods and materials in a supply chain 17

Logistics § Refers to the movement of materials and information within a facility and to incoming and outgoing shipments of goods and materials in a supply chain 17

Logistics • Movement within the facility • Incoming and outgoing shipments • Bar coding • EDI • Distribution • JIT Deliveries 0 214800 232087768 18

Logistics • Movement within the facility • Incoming and outgoing shipments • Bar coding • EDI • Distribution • JIT Deliveries 0 214800 232087768 18

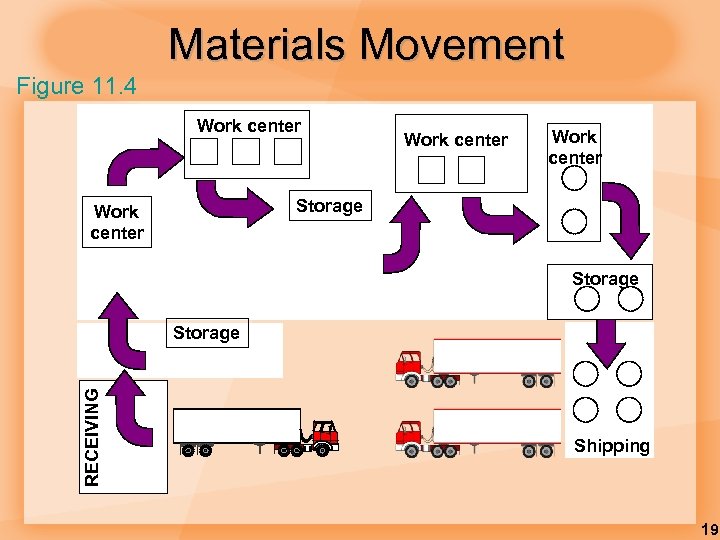

Materials Movement Figure 11. 4 Work center Storage RECEIVING Storage Shipping 19

Materials Movement Figure 11. 4 Work center Storage RECEIVING Storage Shipping 19

Distribution Requirements Planning § Distribution requirements planning (DRP) is a system for inventory management and distribution planning § Extends the concepts of MRPII 20

Distribution Requirements Planning § Distribution requirements planning (DRP) is a system for inventory management and distribution planning § Extends the concepts of MRPII 20

Uses of DRP § Management uses DRP to plan and coordinate: § § § Transportation Warehousing Workers Equipment Financial flows 21

Uses of DRP § Management uses DRP to plan and coordinate: § § § Transportation Warehousing Workers Equipment Financial flows 21

E-Business § E-Business: the use of electronic technology to facilitate business transactions § Applications include § § Internet buying and selling E-mail Order and shipment tracking Electronic data interchange 22

E-Business § E-Business: the use of electronic technology to facilitate business transactions § Applications include § § Internet buying and selling E-mail Order and shipment tracking Electronic data interchange 22

Advantages E-Business § Companies can: § § § § Have a global presence Improve competitiveness and quality Analyze customer interests Collect detailed information Shorten supply chain response times Realize substantial cost savings Create virtual companies Level the playing field for small companies 23

Advantages E-Business § Companies can: § § § § Have a global presence Improve competitiveness and quality Analyze customer interests Collect detailed information Shorten supply chain response times Realize substantial cost savings Create virtual companies Level the playing field for small companies 23

Disadvantages of E-Business § Customer expectations § Order quickly -> fast delivery § Order fulfillment § Order rate often exceeds ability to fulfill it § Inventory holding § Outsourcing loss of control § Internal holding costs 24

Disadvantages of E-Business § Customer expectations § Order quickly -> fast delivery § Order fulfillment § Order rate often exceeds ability to fulfill it § Inventory holding § Outsourcing loss of control § Internal holding costs 24

Reverse Logistics § Reverse logistics – the backward flow of goods returned to the supply chain § Processing returned goods § Sorting, examining/testing, restocking, repairing § Reconditioning, recycling, disposing § Gatekeeping – screening goods to prevent incorrect acceptance of goods § Avoidance – finding ways to minimize the number of items that are returned 25

Reverse Logistics § Reverse logistics – the backward flow of goods returned to the supply chain § Processing returned goods § Sorting, examining/testing, restocking, repairing § Reconditioning, recycling, disposing § Gatekeeping – screening goods to prevent incorrect acceptance of goods § Avoidance – finding ways to minimize the number of items that are returned 25

Effective Supply Chain § Requires linking the market, distribution channels processes, and suppliers § Supply chain should enable members to: § Share forecasts § Determine the status of orders in real time § Access inventory data of partners 26

Effective Supply Chain § Requires linking the market, distribution channels processes, and suppliers § Supply chain should enable members to: § Share forecasts § Determine the status of orders in real time § Access inventory data of partners 26

Successful Supply Chain § Trust among trading partners § Effective communications § Supply chain visibility § Event-management capability § The ability to detect and respond to unplanned events § Performance metrics 27

Successful Supply Chain § Trust among trading partners § Effective communications § Supply chain visibility § Event-management capability § The ability to detect and respond to unplanned events § Performance metrics 27

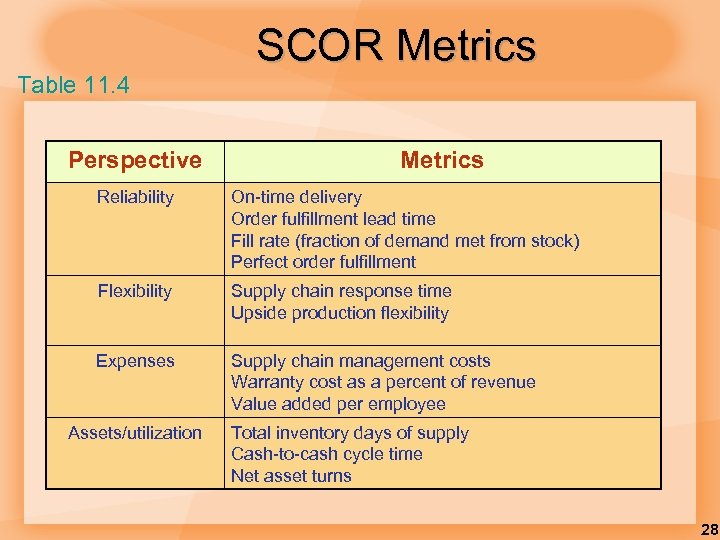

Table 11. 4 Perspective SCOR Metrics Reliability On-time delivery Order fulfillment lead time Fill rate (fraction of demand met from stock) Perfect order fulfillment Flexibility Supply chain response time Upside production flexibility Expenses Supply chain management costs Warranty cost as a percent of revenue Value added per employee Assets/utilization Total inventory days of supply Cash-to-cash cycle time Net asset turns 28

Table 11. 4 Perspective SCOR Metrics Reliability On-time delivery Order fulfillment lead time Fill rate (fraction of demand met from stock) Perfect order fulfillment Flexibility Supply chain response time Upside production flexibility Expenses Supply chain management costs Warranty cost as a percent of revenue Value added per employee Assets/utilization Total inventory days of supply Cash-to-cash cycle time Net asset turns 28

RFID Technology § Used to track goods in supply chain § RFID tag attached to object § Similar to bar codes but uses radio frequency to transmit product information to receiver § RFID eliminates need for manual counting and bar code scanning 29

RFID Technology § Used to track goods in supply chain § RFID tag attached to object § Similar to bar codes but uses radio frequency to transmit product information to receiver § RFID eliminates need for manual counting and bar code scanning 29

CPFR § Collaborative Planning, Forecasting, and Replenishment § Focuses on information sharing among trading partners § Forecasts can be frozen and then converted into a shipping plan § Eliminates typical order processing 30

CPFR § Collaborative Planning, Forecasting, and Replenishment § Focuses on information sharing among trading partners § Forecasts can be frozen and then converted into a shipping plan § Eliminates typical order processing 30

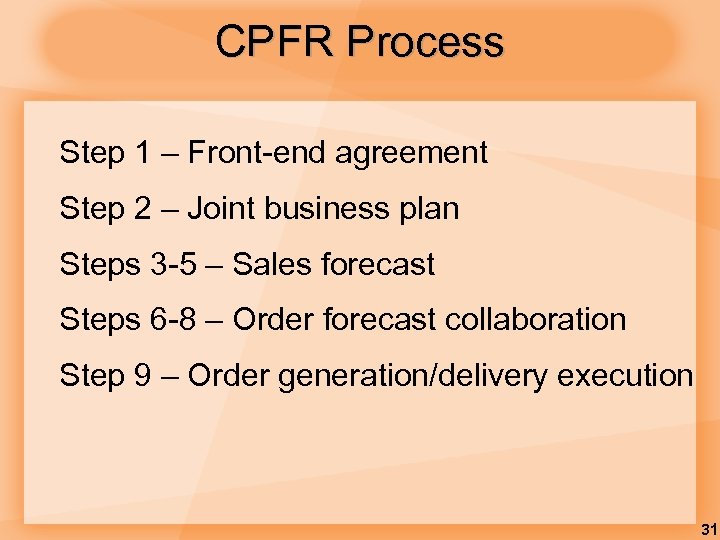

CPFR Process Step 1 – Front-end agreement Step 2 – Joint business plan Steps 3 -5 – Sales forecast Steps 6 -8 – Order forecast collaboration Step 9 – Order generation/delivery execution 31

CPFR Process Step 1 – Front-end agreement Step 2 – Joint business plan Steps 3 -5 – Sales forecast Steps 6 -8 – Order forecast collaboration Step 9 – Order generation/delivery execution 31

CPFR Results § Nabisco and Wegmans § 50% increase in category sales § Wal-mart and Sara Lee § 14% reduction in store-level inventory § 32% increase in sales § Kimberly-Clark and Kmart § Increased category sales that exceeded market growth 32

CPFR Results § Nabisco and Wegmans § 50% increase in category sales § Wal-mart and Sara Lee § 14% reduction in store-level inventory § 32% increase in sales § Kimberly-Clark and Kmart § Increased category sales that exceeded market growth 32

Creating an Effective Supply Chain 1. Develop strategic objectives and tactics 2. Integrate and coordinate activities in the internal supply chain 3. Coordinate activities with suppliers with customers 4. Coordinate planning and execution across the supply chain 5. Form strategic partnerships 33

Creating an Effective Supply Chain 1. Develop strategic objectives and tactics 2. Integrate and coordinate activities in the internal supply chain 3. Coordinate activities with suppliers with customers 4. Coordinate planning and execution across the supply chain 5. Form strategic partnerships 33

Supply Chain Performance Drivers 1. Quality 2. Cost 3. Flexibility 4. Velocity 5. Customer service 34

Supply Chain Performance Drivers 1. Quality 2. Cost 3. Flexibility 4. Velocity 5. Customer service 34

Velocity § Inventory velocity § The rate at which inventory(material) goes through the supply chain § Information velocity § The rate at which information is communicated in a supply chain 35

Velocity § Inventory velocity § The rate at which inventory(material) goes through the supply chain § Information velocity § The rate at which information is communicated in a supply chain 35

Challenges § Barriers to integration of organizations § Getting top management on board § Dealing with trade-offs § Small businesses § Variability and uncertainty § Long lead times 36

Challenges § Barriers to integration of organizations § Getting top management on board § Dealing with trade-offs § Small businesses § Variability and uncertainty § Long lead times 36

Trade-offs 1. Lot-size-inventory § Bullwhip effect 2. Inventory-transportation costs § Cross-docking 3. Lead time-transportation costs 4. Product variety-inventory § Delayed differentiation 5. Cost-customer service § Disintermediation 37

Trade-offs 1. Lot-size-inventory § Bullwhip effect 2. Inventory-transportation costs § Cross-docking 3. Lead time-transportation costs 4. Product variety-inventory § Delayed differentiation 5. Cost-customer service § Disintermediation 37

Trade-offs § Bullwhip effect § Inventories are progressively larger moving backward through the supply chain § Cross-docking § Goods arriving at a warehouse from a supplier are unloaded from the supplier’s truck and loaded onto outbound trucks § Avoids warehouse storage 38

Trade-offs § Bullwhip effect § Inventories are progressively larger moving backward through the supply chain § Cross-docking § Goods arriving at a warehouse from a supplier are unloaded from the supplier’s truck and loaded onto outbound trucks § Avoids warehouse storage 38

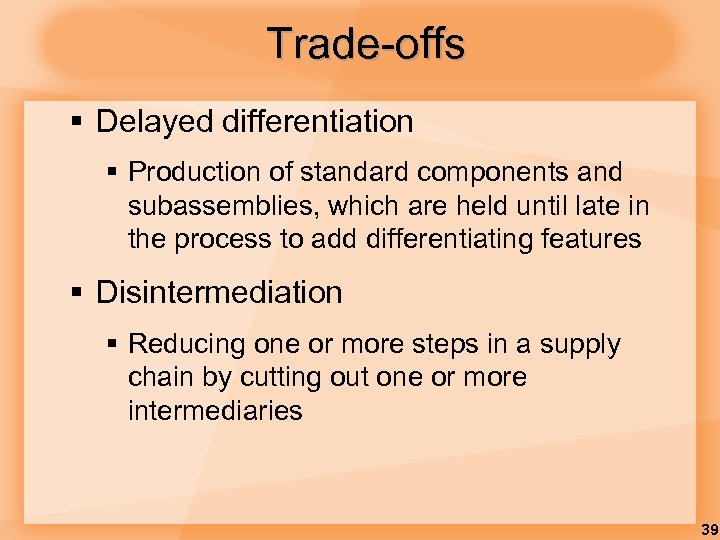

Trade-offs § Delayed differentiation § Production of standard components and subassemblies, which are held until late in the process to add differentiating features § Disintermediation § Reducing one or more steps in a supply chain by cutting out one or more intermediaries 39

Trade-offs § Delayed differentiation § Production of standard components and subassemblies, which are held until late in the process to add differentiating features § Disintermediation § Reducing one or more steps in a supply chain by cutting out one or more intermediaries 39

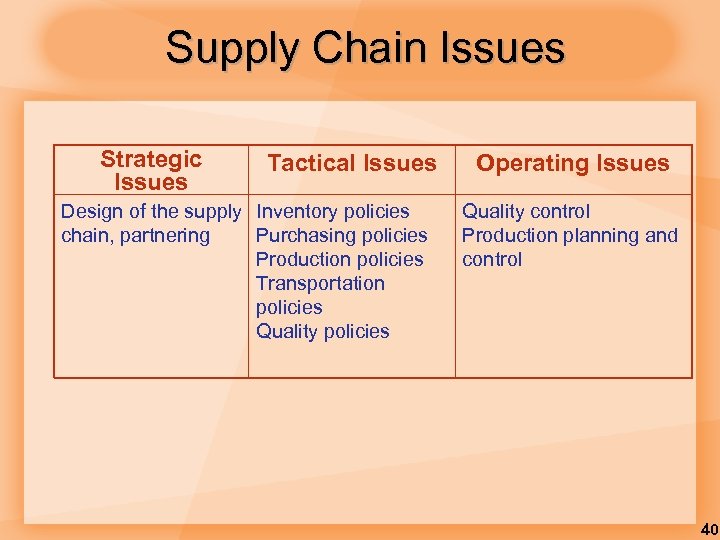

Supply Chain Issues Strategic Issues Tactical Issues Design of the supply Inventory policies chain, partnering Purchasing policies Production policies Transportation policies Quality policies Operating Issues Quality control Production planning and control 40

Supply Chain Issues Strategic Issues Tactical Issues Design of the supply Inventory policies chain, partnering Purchasing policies Production policies Transportation policies Quality policies Operating Issues Quality control Production planning and control 40

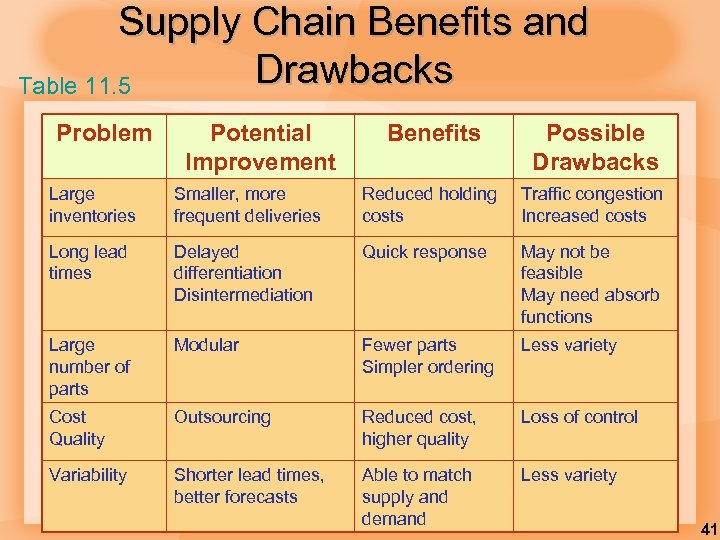

Supply Chain Benefits and Drawbacks Table 11. 5 Problem Potential Improvement Benefits Possible Drawbacks Large inventories Smaller, more frequent deliveries Reduced holding costs Traffic congestion Increased costs Long lead times Delayed differentiation Disintermediation Quick response May not be feasible May need absorb functions Large number of parts Modular Fewer parts Simpler ordering Less variety Cost Quality Outsourcing Reduced cost, higher quality Loss of control Variability Shorter lead times, better forecasts Able to match supply and demand Less variety 41

Supply Chain Benefits and Drawbacks Table 11. 5 Problem Potential Improvement Benefits Possible Drawbacks Large inventories Smaller, more frequent deliveries Reduced holding costs Traffic congestion Increased costs Long lead times Delayed differentiation Disintermediation Quick response May not be feasible May need absorb functions Large number of parts Modular Fewer parts Simpler ordering Less variety Cost Quality Outsourcing Reduced cost, higher quality Loss of control Variability Shorter lead times, better forecasts Able to match supply and demand Less variety 41

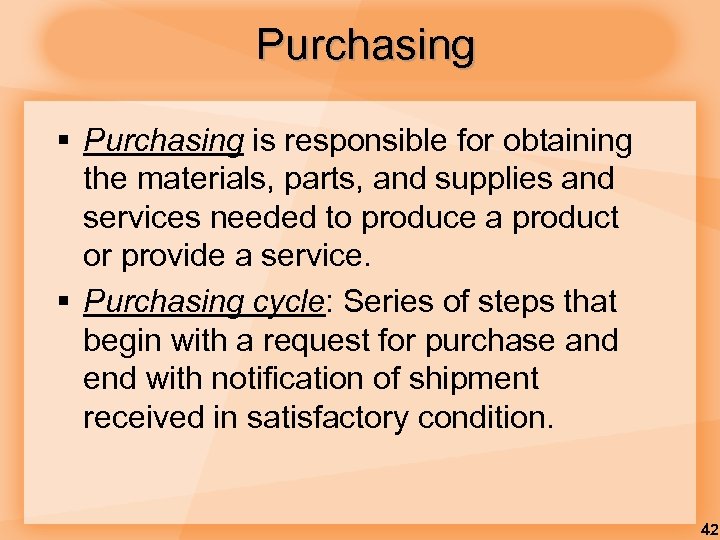

Purchasing § Purchasing is responsible for obtaining the materials, parts, and supplies and services needed to produce a product or provide a service. § Purchasing cycle: Series of steps that begin with a request for purchase and end with notification of shipment received in satisfactory condition. 42

Purchasing § Purchasing is responsible for obtaining the materials, parts, and supplies and services needed to produce a product or provide a service. § Purchasing cycle: Series of steps that begin with a request for purchase and end with notification of shipment received in satisfactory condition. 42

Goal of Purchasing § Develop and implement purchasing plans for products and services that support operations strategies 43

Goal of Purchasing § Develop and implement purchasing plans for products and services that support operations strategies 43

Duties of Purchasing § Identifying sources of supply § Negotiating contracts § Maintaining a database of suppliers § Obtaining goods and services § Managing supplies 44

Duties of Purchasing § Identifying sources of supply § Negotiating contracts § Maintaining a database of suppliers § Obtaining goods and services § Managing supplies 44

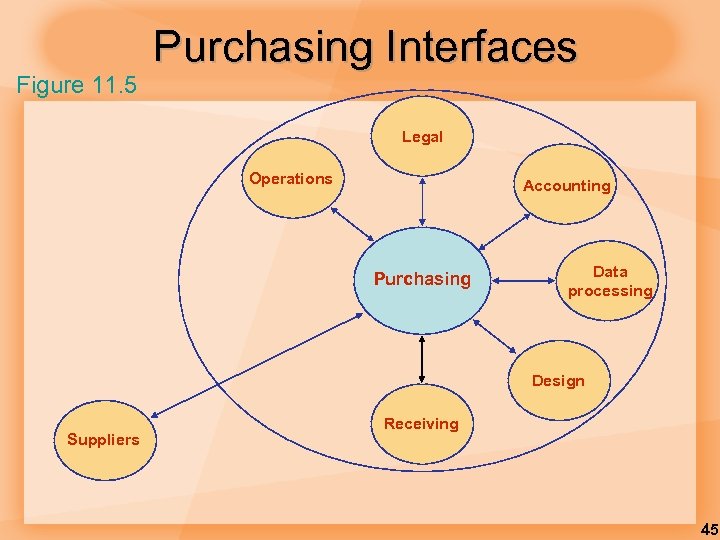

Figure 11. 5 Purchasing Interfaces Legal Operations Accounting Purchasing Data processing Design Suppliers Receiving 45

Figure 11. 5 Purchasing Interfaces Legal Operations Accounting Purchasing Data processing Design Suppliers Receiving 45

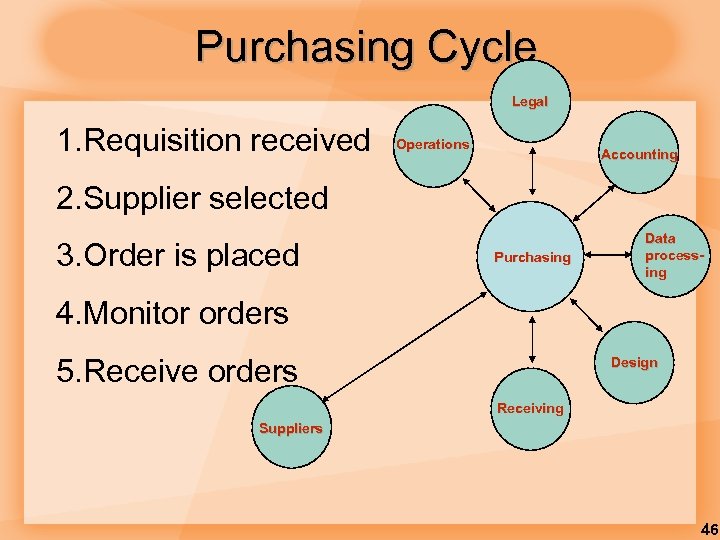

Purchasing Cycle Legal 1. Requisition received Operations Accounting 2. Supplier selected 3. Order is placed Purchasing Data processing 4. Monitor orders 5. Receive orders Design Receiving Suppliers 46

Purchasing Cycle Legal 1. Requisition received Operations Accounting 2. Supplier selected 3. Order is placed Purchasing Data processing 4. Monitor orders 5. Receive orders Design Receiving Suppliers 46

Value Analysis vs. Outsourcing § Value analysis § Examination of the function of purchased parts and materials in an effort to reduce cost and/or improve performance 47

Value Analysis vs. Outsourcing § Value analysis § Examination of the function of purchased parts and materials in an effort to reduce cost and/or improve performance 47

Centralized vs Decentralized Purchasing § Centralized purchasing § Purchasing is handled by one special department § Decentralized purchasing § Individual departments or separate locations handle their own purchasing requirements 48

Centralized vs Decentralized Purchasing § Centralized purchasing § Purchasing is handled by one special department § Decentralized purchasing § Individual departments or separate locations handle their own purchasing requirements 48

Suppliers § Choosing suppliers § Evaluating sources of supply § Supplier audits § Supplier certification § Supplier relationships § Supplier partnerships 49

Suppliers § Choosing suppliers § Evaluating sources of supply § Supplier audits § Supplier certification § Supplier relationships § Supplier partnerships 49

Factors in Choosing a Supplier § § Quality and quality assurance Flexibility Location Price 50

Factors in Choosing a Supplier § § Quality and quality assurance Flexibility Location Price 50

Factors in Choosing a Supplier (cont’d) § § Product or service changes Reputation and financial stability Lead times and on-time delivery Other accounts 51

Factors in Choosing a Supplier (cont’d) § § Product or service changes Reputation and financial stability Lead times and on-time delivery Other accounts 51

Evaluating Sources of Supply § Vendor analysis: Evaluating the sources of supply in terms of price, quality, reputation, and service 52

Evaluating Sources of Supply § Vendor analysis: Evaluating the sources of supply in terms of price, quality, reputation, and service 52

Evaluating Sources of Supply § Vendor analysis - evaluating the sources of supply in terms of § § § Price Quality Services Location Inventory policy Flexibility 53

Evaluating Sources of Supply § Vendor analysis - evaluating the sources of supply in terms of § § § Price Quality Services Location Inventory policy Flexibility 53

Supplier as a Partner Table 11. 9 Aspect Adversary Partner Number of suppliers Many One or a few Length of relationship May be brief Long-term Low price Major consideration Moderately important Reliability May not be high High Openness Low High Quality May be unreliable; buyer inspects At the source; vendor certified Volume of business May be low High Flexibility Relatively low Relatively high Location Widely dispersed Nearness is important 54

Supplier as a Partner Table 11. 9 Aspect Adversary Partner Number of suppliers Many One or a few Length of relationship May be brief Long-term Low price Major consideration Moderately important Reliability May not be high High Openness Low High Quality May be unreliable; buyer inspects At the source; vendor certified Volume of business May be low High Flexibility Relatively low Relatively high Location Widely dispersed Nearness is important 54

Supplier Partnerships § Ideas from suppliers could lead to improved competitiveness 1. Reduce cost of making the purchase 2. Reduce transportation costs 3. Reduce production costs 4. Improve product quality 5. Improve product design 6. Reduce time to market 7. Improve customer satisfaction 8. Reduce inventory costs 9. Introduce new products or services 55

Supplier Partnerships § Ideas from suppliers could lead to improved competitiveness 1. Reduce cost of making the purchase 2. Reduce transportation costs 3. Reduce production costs 4. Improve product quality 5. Improve product design 6. Reduce time to market 7. Improve customer satisfaction 8. Reduce inventory costs 9. Introduce new products or services 55

Critical Issues § Strategic importance § § § Cost Quality Agility Customer service Competitive advantage § Technology management § Benefits § Risks 56

Critical Issues § Strategic importance § § § Cost Quality Agility Customer service Competitive advantage § Technology management § Benefits § Risks 56

Critical Issues § Purchasing function § § Increased outsourcing Increased conversion to lean production Just-in-time deliveries Globalization 57

Critical Issues § Purchasing function § § Increased outsourcing Increased conversion to lean production Just-in-time deliveries Globalization 57