21959030413154953d666b0ade774969.ppt

- Количество слайдов: 44

10 Supply Chain Integration Power. Point Slides by Jeff Heyl Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall. For Operations Management, 9 e by Krajewski/Ritzman/Malhotra © 2010 Pearson Education 10 – 1

Supply Chain Integration l The effective coordination of supply chain processes through the seamless flow of information up and down the supply chain l A river that flows from raw material suppliers to consumers u Upstream u Downstream l Mitigating the effects of supply chain disruptions 10 – 2 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

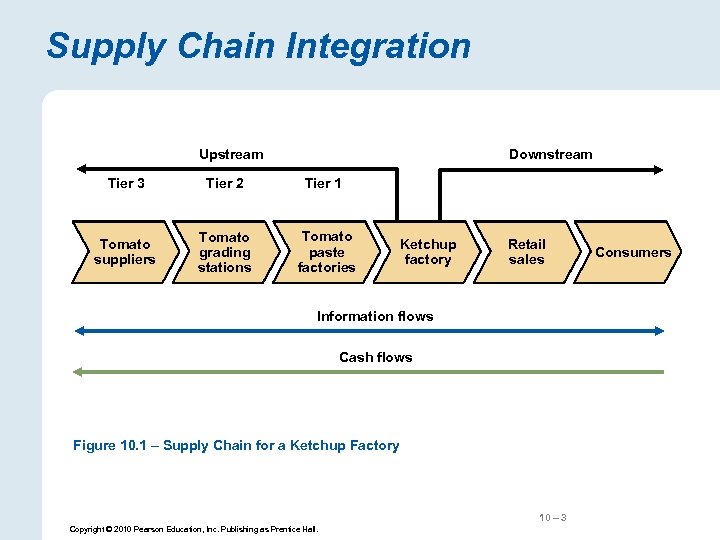

Supply Chain Integration Upstream Downstream Tier 3 Tier 2 Tier 1 Tomato suppliers Tomato grading stations Tomato paste factories Ketchup factory Retail sales Information flows Cash flows Figure 10. 1 – Supply Chain for a Ketchup Factory 10 – 3 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall. Consumers

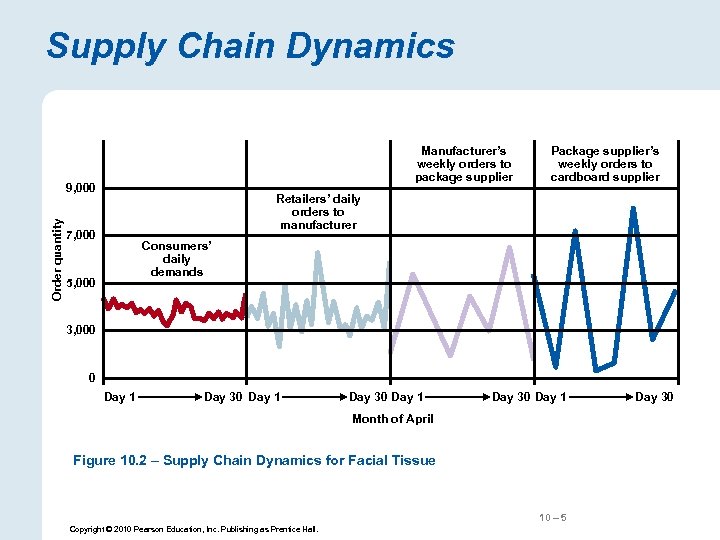

Supply Chain Dynamics l Bullwhip effect u Upstream members must react to the demand u Slightest change in customer demand can ripple through the entire chain l External causes l Internal causes 10 – 4 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Supply Chain Dynamics Manufacturer’s weekly orders to package supplier Order quantity 9, 000 Package supplier’s weekly orders to cardboard supplier Retailers’ daily orders to manufacturer 7, 000 Consumers’ daily demands 5, 000 3, 000 0 Day 1 Day 30 Day 1 Month of April Figure 10. 2 – Supply Chain Dynamics for Facial Tissue 10 – 5 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall. Day 30

Supply Chain Dynamics l Integrated supply chains u High degree of functional and organizational integration minimizes disruptions u Integration must include linkages between the firm, its suppliers, and its customers u SCOR model n Plan n Source n Make n Deliver n Return 10 – 6 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

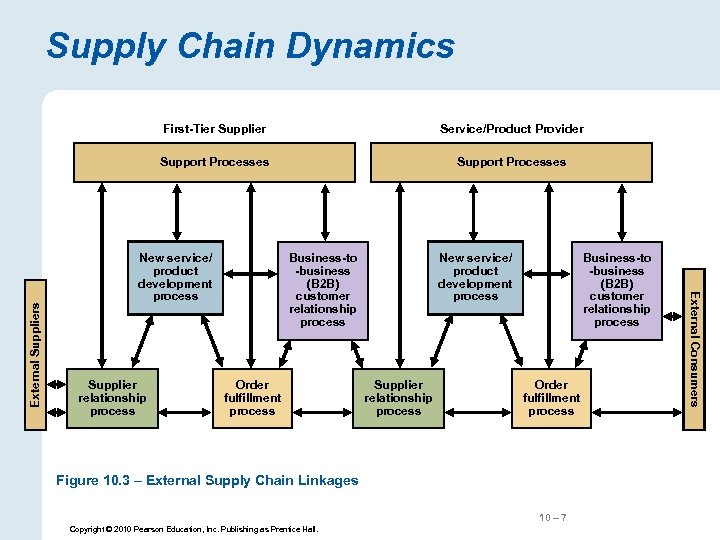

Supply Chain Dynamics Service/Product Provider Support Processes New service/ product development process Supplier relationship process Business-to -business (B 2 B) customer relationship process Order fulfillment process Figure 10. 3 – External Supply Chain Linkages 10 – 7 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall. External Consumers External Suppliers First-Tier Supplier

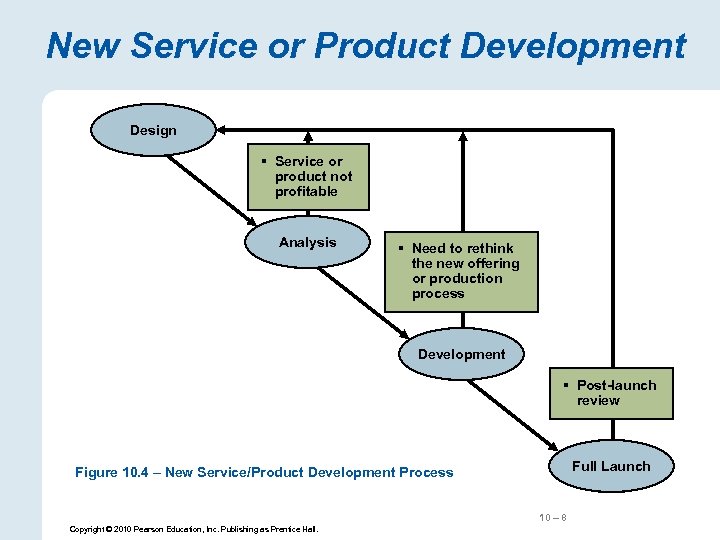

New Service or Product Development Design § Service or product not profitable Analysis § Need to rethink the new offering or production process Development § Post-launch review Full Launch Figure 10. 4 – New Service/Product Development Process 10 – 8 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

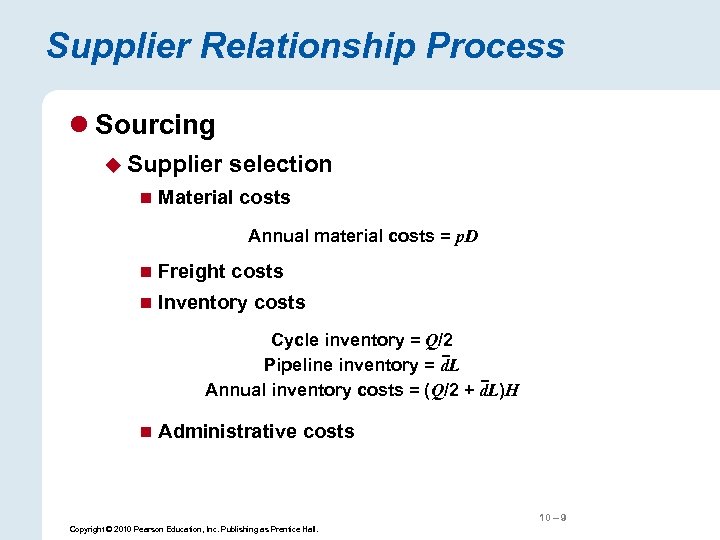

Supplier Relationship Process l Sourcing u Supplier n selection Material costs Annual material costs = p. D n Freight costs n Inventory costs Cycle inventory = Q/2 Pipeline inventory = d. L Annual inventory costs = (Q/2 + d. L)H n Administrative costs 10 – 9 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

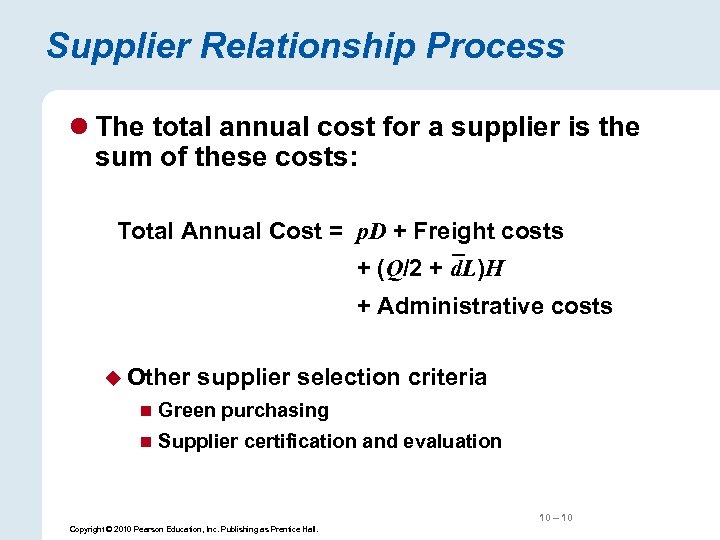

Supplier Relationship Process l The total annual cost for a supplier is the sum of these costs: Total Annual Cost = p. D + Freight costs + (Q/2 + d. L)H + Administrative costs u Other supplier selection criteria n Green purchasing n Supplier certification and evaluation 10 – 10 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

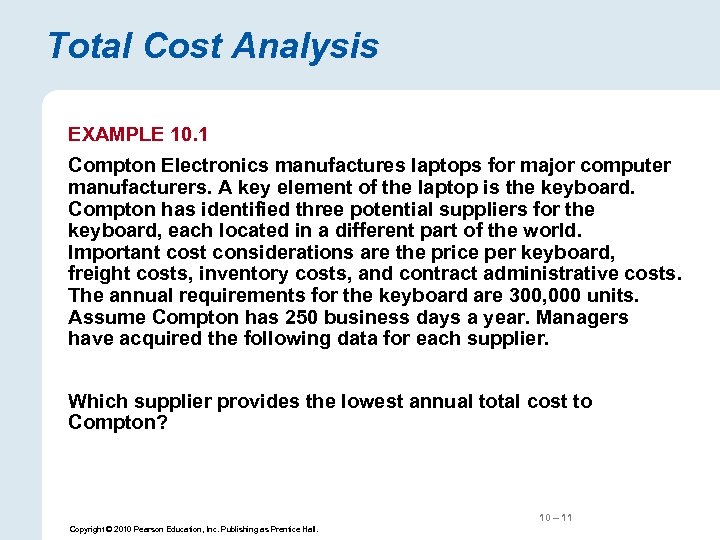

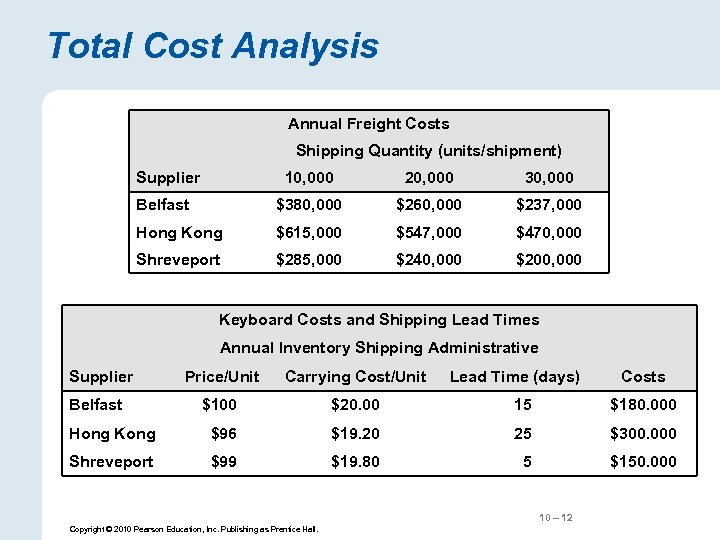

Total Cost Analysis EXAMPLE 10. 1 Compton Electronics manufactures laptops for major computer manufacturers. A key element of the laptop is the keyboard. Compton has identified three potential suppliers for the keyboard, each located in a different part of the world. Important cost considerations are the price per keyboard, freight costs, inventory costs, and contract administrative costs. The annual requirements for the keyboard are 300, 000 units. Assume Compton has 250 business days a year. Managers have acquired the following data for each supplier. Which supplier provides the lowest annual total cost to Compton? 10 – 11 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Total Cost Analysis Annual Freight Costs Shipping Quantity (units/shipment) Supplier 10, 000 20, 000 30, 000 Belfast $380, 000 $260, 000 $237, 000 Hong Kong $615, 000 $547, 000 $470, 000 Shreveport $285, 000 $240, 000 $200, 000 Keyboard Costs and Shipping Lead Times Annual Inventory Shipping Administrative Supplier Price/Unit Carrying Cost/Unit $100 $20. 00 15 $180. 000 Hong Kong $96 $19. 20 25 $300. 000 Shreveport $99 $19. 80 5 $150. 000 Belfast Lead Time (days) 10 – 12 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall. Costs

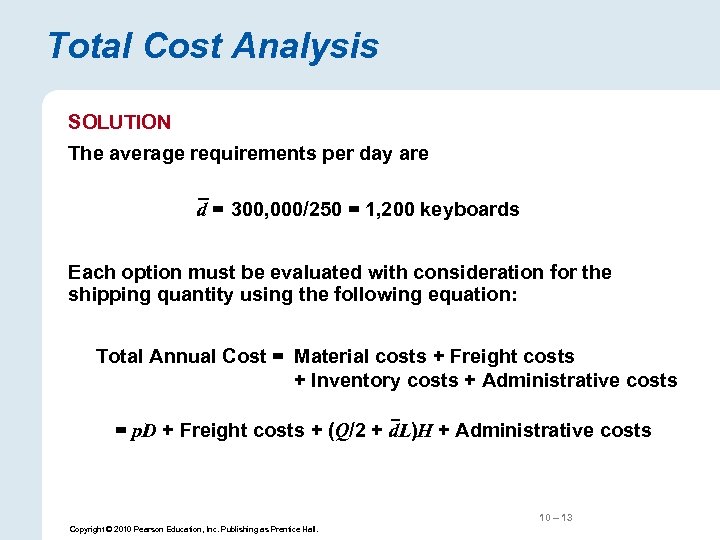

Total Cost Analysis SOLUTION The average requirements per day are d = 300, 000/250 = 1, 200 keyboards Each option must be evaluated with consideration for the shipping quantity using the following equation: Total Annual Cost = Material costs + Freight costs + Inventory costs + Administrative costs = p. D + Freight costs + (Q/2 + d. L)H + Administrative costs 10 – 13 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

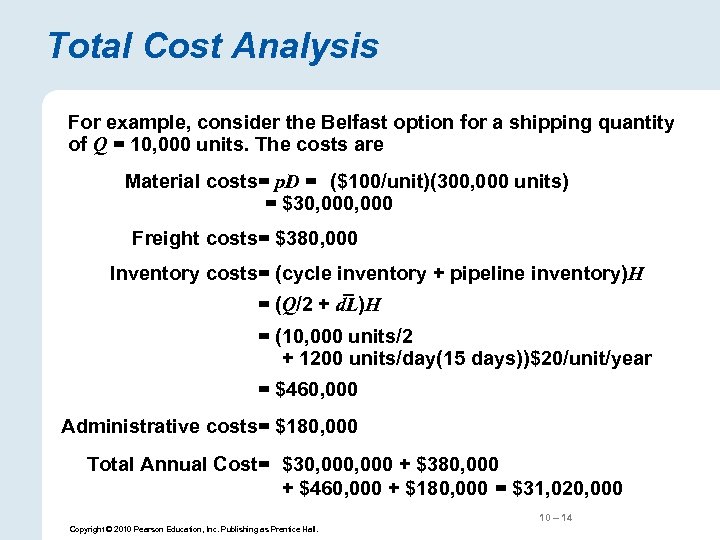

Total Cost Analysis For example, consider the Belfast option for a shipping quantity of Q = 10, 000 units. The costs are Material costs= p. D = ($100/unit)(300, 000 units) = $30, 000 Freight costs= $380, 000 Inventory costs= (cycle inventory + pipeline inventory)H = (Q/2 + d. L)H = (10, 000 units/2 + 1200 units/day(15 days))$20/unit/year = $460, 000 Administrative costs= $180, 000 Total Annual Cost= $30, 000 + $380, 000 + $460, 000 + $180, 000 = $31, 020, 000 10 – 14 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Total Cost Analysis The total costs for all three shipping quantity options are similarly calculated and are contained in the following table. Total Annual Costs for the Keyboard Suppliers Shipping Quantity Supplier 10, 000 20, 000 30, 000 Belfast Hong Kong Shreveport 10 – 15 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

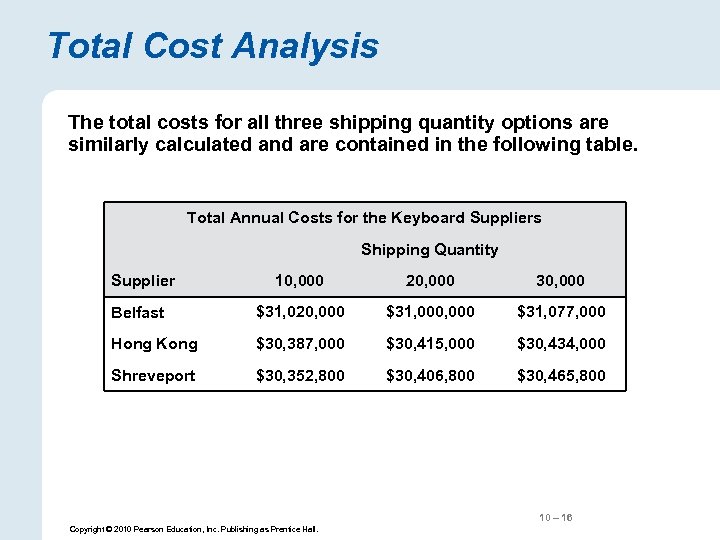

Total Cost Analysis The total costs for all three shipping quantity options are similarly calculated and are contained in the following table. Total Annual Costs for the Keyboard Suppliers Shipping Quantity Supplier 10, 000 20, 000 30, 000 Belfast $31, 020, 000 $31, 077, 000 Hong Kong $30, 387, 000 $30, 415, 000 $30, 434, 000 Shreveport $30, 352, 800 $30, 406, 800 $30, 465, 800 10 – 16 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

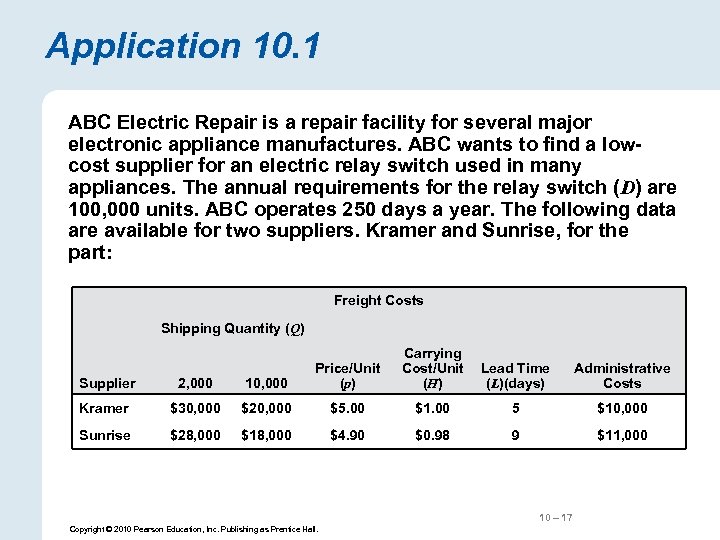

Application 10. 1 ABC Electric Repair is a repair facility for several major electronic appliance manufactures. ABC wants to find a lowcost supplier for an electric relay switch used in many appliances. The annual requirements for the relay switch (D) are 100, 000 units. ABC operates 250 days a year. The following data are available for two suppliers. Kramer and Sunrise, for the part: Freight Costs Shipping Quantity (Q) Supplier 2, 000 10, 000 Price/Unit (p) Carrying Cost/Unit (H) Kramer $30, 000 $20, 000 $5. 00 $1. 00 5 $10, 000 Sunrise $28, 000 $18, 000 $4. 90 $0. 98 9 $11, 000 Lead Time (L)(days) Administrative Costs 10 – 17 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

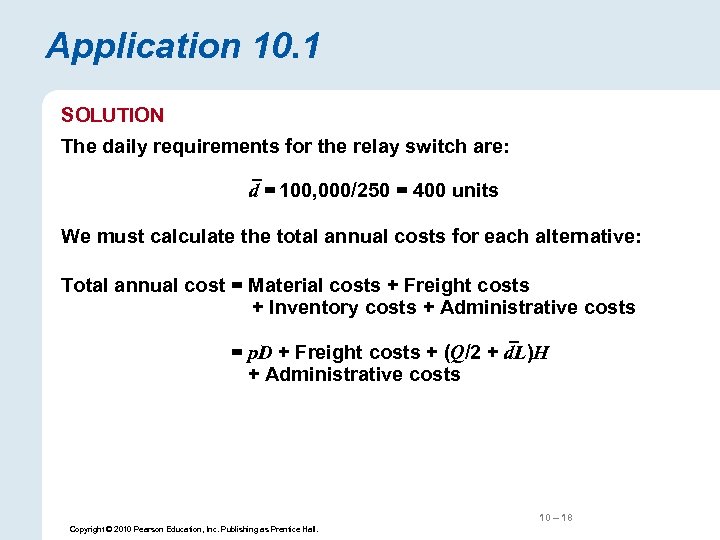

Application 10. 1 SOLUTION The daily requirements for the relay switch are: d = 100, 000/250 = 400 units We must calculate the total annual costs for each alternative: Total annual cost = Material costs + Freight costs + Inventory costs + Administrative costs = p. D + Freight costs + (Q/2 + d. L)H + Administrative costs 10 – 18 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

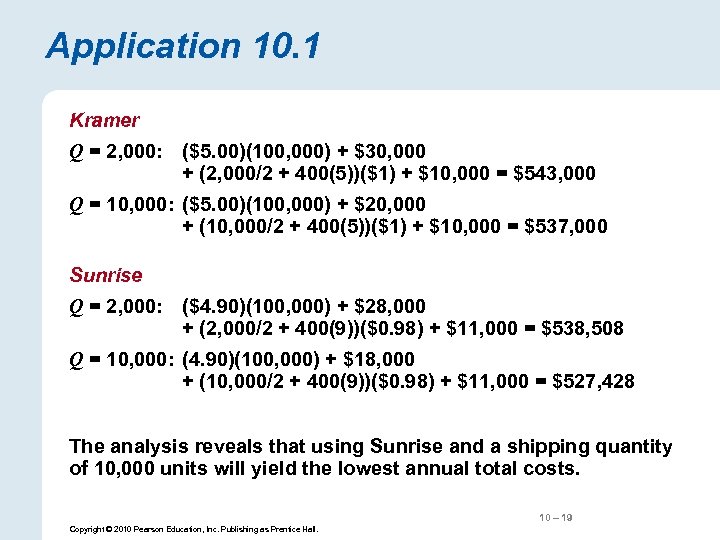

Application 10. 1 Kramer Q = 2, 000: ($5. 00)(100, 000) + $30, 000 + (2, 000/2 + 400(5))($1) + $10, 000 = $543, 000 Q = 10, 000: ($5. 00)(100, 000) + $20, 000 + (10, 000/2 + 400(5))($1) + $10, 000 = $537, 000 Sunrise Q = 2, 000: ($4. 90)(100, 000) + $28, 000 + (2, 000/2 + 400(9))($0. 98) + $11, 000 = $538, 508 Q = 10, 000: (4. 90)(100, 000) + $18, 000 + (10, 000/2 + 400(9))($0. 98) + $11, 000 = $527, 428 The analysis reveals that using Sunrise and a shipping quantity of 10, 000 units will yield the lowest annual total costs. 10 – 19 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

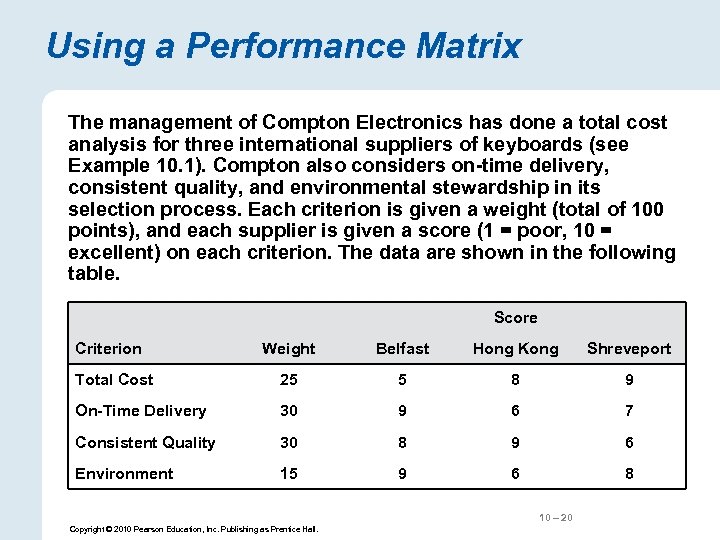

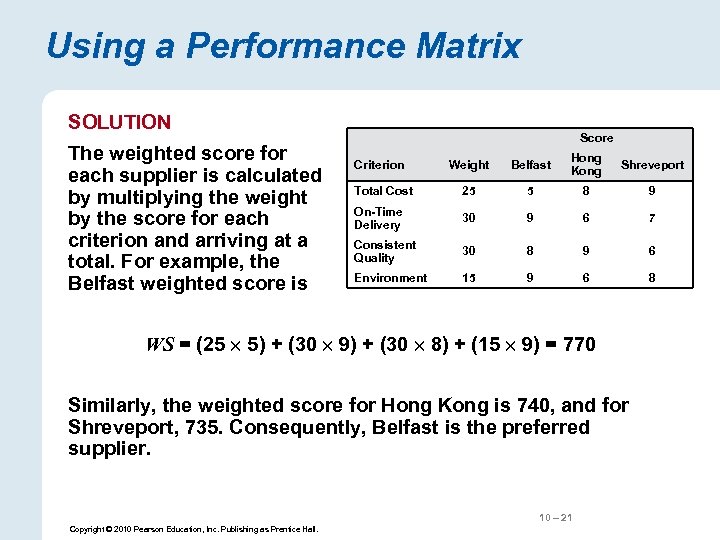

Using a Performance Matrix The management of Compton Electronics has done a total cost analysis for three international suppliers of keyboards (see Example 10. 1). Compton also considers on-time delivery, consistent quality, and environmental stewardship in its selection process. Each criterion is given a weight (total of 100 points), and each supplier is given a score (1 = poor, 10 = excellent) on each criterion. The data are shown in the following table. Score Criterion Weight Belfast Hong Kong Shreveport Total Cost 25 5 8 9 On-Time Delivery 30 9 6 7 Consistent Quality 30 8 9 6 Environment 15 9 6 8 10 – 20 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Using a Performance Matrix SOLUTION The weighted score for each supplier is calculated by multiplying the weight by the score for each criterion and arriving at a total. For example, the Belfast weighted score is Score Weight Belfast Hong Kong Shreveport Total Cost 25 5 8 9 On-Time Delivery 30 9 6 7 Consistent Quality 30 8 9 6 Environment 15 9 6 8 Criterion WS = (25 5) + (30 9) + (30 8) + (15 9) = 770 Similarly, the weighted score for Hong Kong is 740, and for Shreveport, 735. Consequently, Belfast is the preferred supplier. 10 – 21 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

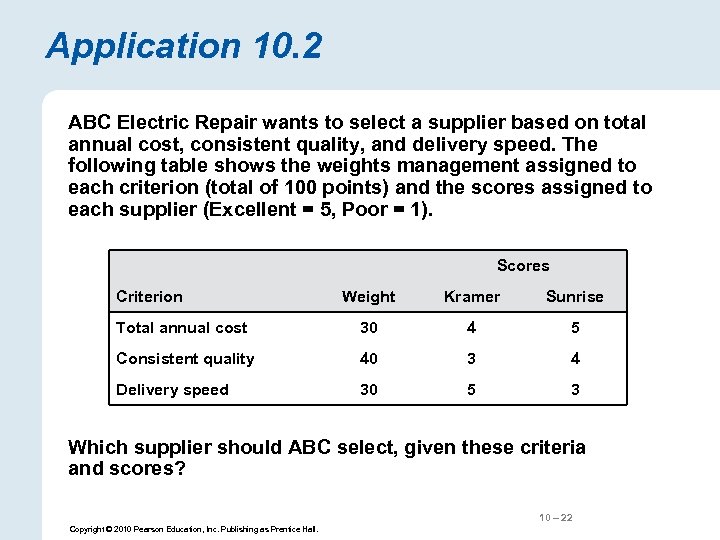

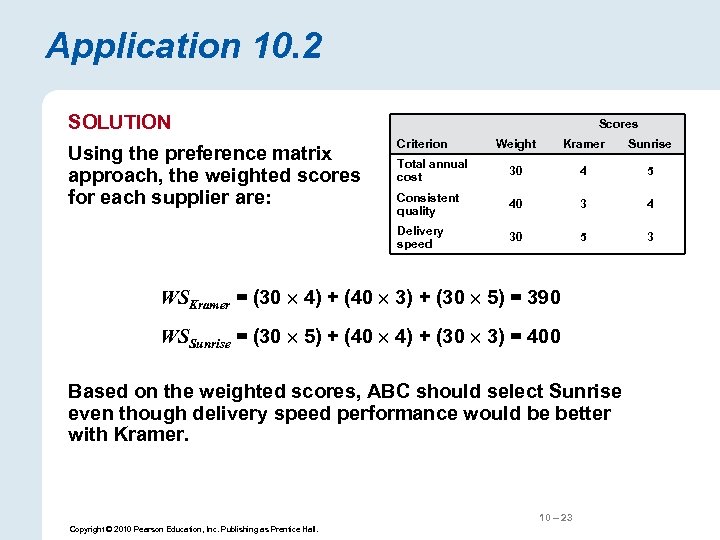

Application 10. 2 ABC Electric Repair wants to select a supplier based on total annual cost, consistent quality, and delivery speed. The following table shows the weights management assigned to each criterion (total of 100 points) and the scores assigned to each supplier (Excellent = 5, Poor = 1). Scores Criterion Weight Kramer Sunrise Total annual cost 30 4 5 Consistent quality 40 3 4 Delivery speed 30 5 3 Which supplier should ABC select, given these criteria and scores? 10 – 22 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Application 10. 2 SOLUTION Scores Weight Kramer Sunrise Total annual cost 30 4 5 Consistent quality 40 3 4 Delivery speed Using the preference matrix approach, the weighted scores for each supplier are: Criterion 30 5 3 WSKramer = (30 4) + (40 3) + (30 5) = 390 WSSunrise = (30 5) + (40 4) + (30 3) = 400 Based on the weighted scores, ABC should select Sunrise even though delivery speed performance would be better with Kramer. 10 – 23 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Supplier Relationship Process l Design collaboration u Early supplier involvement u Presourcing u Value analysis l Negotiation u Obtain an effective contract that meets the price, quality, and delivery requirements u Competitive orientation u Cooperative orientation 10 – 24 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Supplier Relationship Process l Buying u Procurement of the service or material from the supplier u e-purchasing u Loss of control l Information exchange u Radio frequency identification (RFID) u Vendor managed inventories (VMI) 10 – 25 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Order Fulfillment Process l Customer demand planning u Facilitates collaboration u Demand forecasts l Supply planning u u u Inventory management Operations planning and scheduling Resource planning l Production l Logistics u u u Ownership Facility location Mode selection Capacity Cross-docking 10 – 26 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

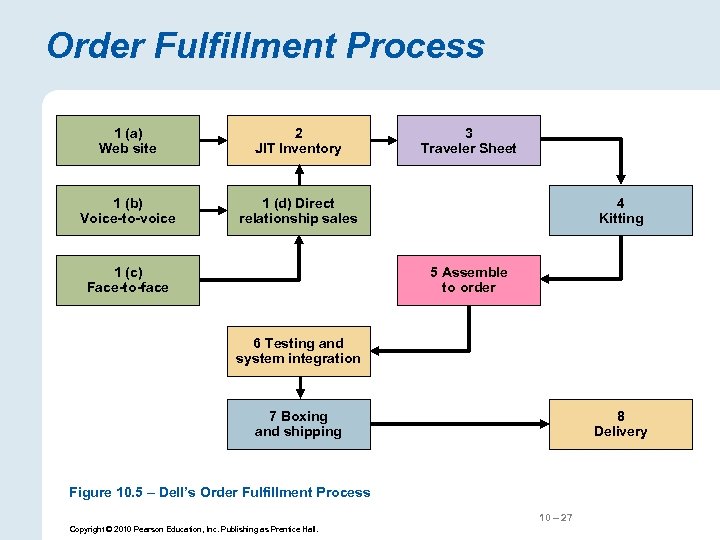

Order Fulfillment Process 1 (a) Web site 2 JIT Inventory 1 (b) Voice-to-voice 1 (d) Direct relationship sales 1 (c) Face-to-face 3 Traveler Sheet 4 Kitting 5 Assemble to order 6 Testing and system integration 7 Boxing and shipping 8 Delivery Figure 10. 5 – Dell’s Order Fulfillment Process 10 – 27 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

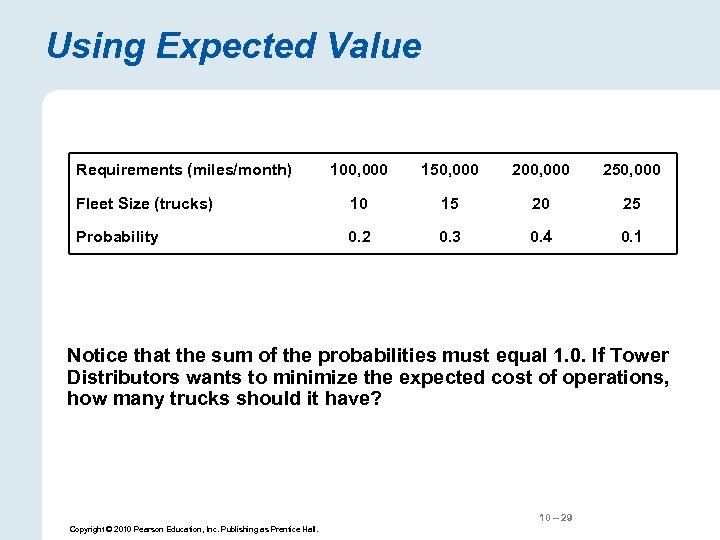

Using Expected Value EXAMPLE 10. 3 Tower Distributors provides logistical services to local manufacturers. Tower picks up products from the manufacturers, takes them to its distribution center, and then assembles shipments to retailers in the region. Tower needs to build a new distribution center; consequently, it needs to make a decision on how many trucks to have. The monthly amortized capital cost of ownership is $2, 100 per truck. Operating variable costs are $1 per mile for each truck owned by Tower. If capacity is exceeded in any month, Tower can rent trucks at $2 per mile. Each truck Tower owns can be used 10, 000 miles per month. The requirements for the trucks, however, are uncertain. Managers have estimated the following probabilities for several possible demand levels and corresponding fleet sizes. 10 – 28 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Using Expected Value Requirements (miles/month) 100, 000 150, 000 200, 000 250, 000 Fleet Size (trucks) 10 15 20 25 Probability 0. 2 0. 3 0. 4 0. 1 Notice that the sum of the probabilities must equal 1. 0. If Tower Distributors wants to minimize the expected cost of operations, how many trucks should it have? 10 – 29 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

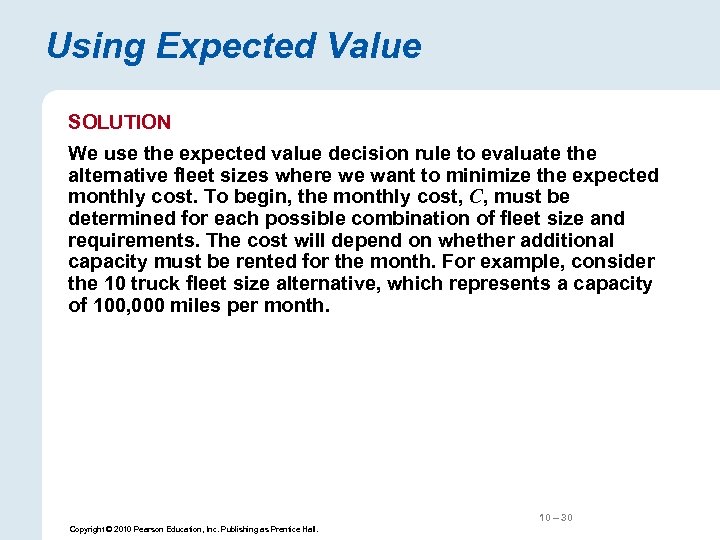

Using Expected Value SOLUTION We use the expected value decision rule to evaluate the alternative fleet sizes where we want to minimize the expected monthly cost. To begin, the monthly cost, C, must be determined for each possible combination of fleet size and requirements. The cost will depend on whether additional capacity must be rented for the month. For example, consider the 10 truck fleet size alternative, which represents a capacity of 100, 000 miles per month. 10 – 30 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

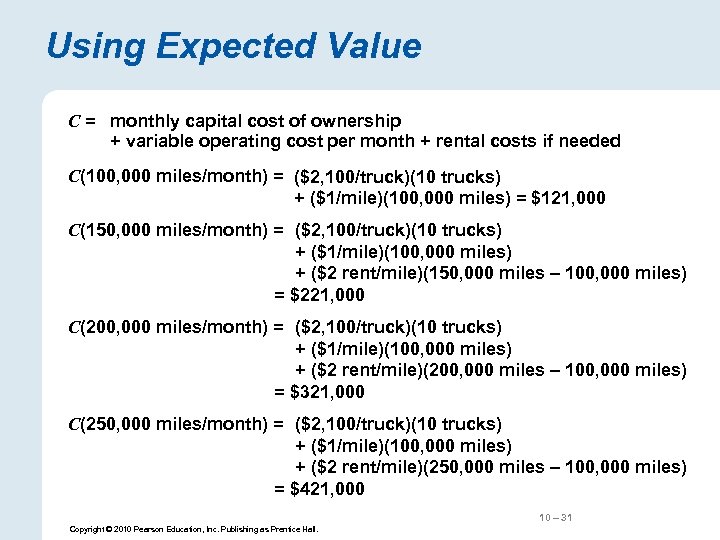

Using Expected Value C = monthly capital cost of ownership + variable operating cost per month + rental costs if needed C(100, 000 miles/month) = ($2, 100/truck)(10 trucks) + ($1/mile)(100, 000 miles) = $121, 000 C(150, 000 miles/month) = ($2, 100/truck)(10 trucks) + ($1/mile)(100, 000 miles) + ($2 rent/mile)(150, 000 miles – 100, 000 miles) = $221, 000 C(200, 000 miles/month) = ($2, 100/truck)(10 trucks) + ($1/mile)(100, 000 miles) + ($2 rent/mile)(200, 000 miles – 100, 000 miles) = $321, 000 C(250, 000 miles/month) = ($2, 100/truck)(10 trucks) + ($1/mile)(100, 000 miles) + ($2 rent/mile)(250, 000 miles – 100, 000 miles) = $421, 000 10 – 31 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

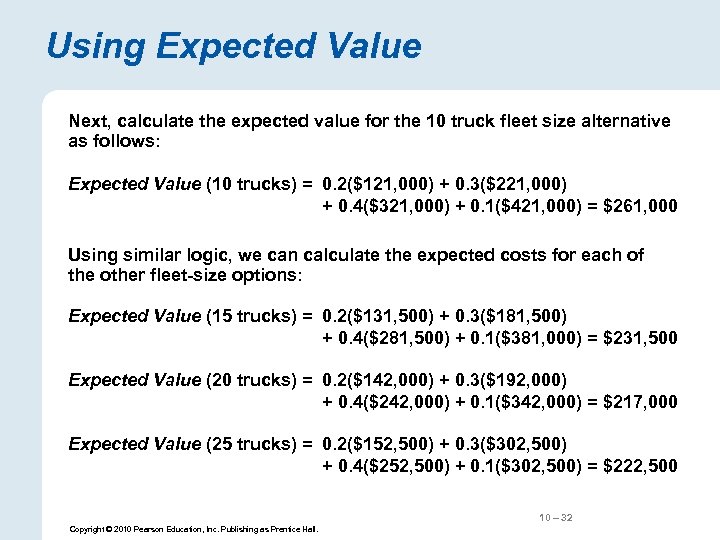

Using Expected Value Next, calculate the expected value for the 10 truck fleet size alternative as follows: Expected Value (10 trucks) = 0. 2($121, 000) + 0. 3($221, 000) + 0. 4($321, 000) + 0. 1($421, 000) = $261, 000 Using similar logic, we can calculate the expected costs for each of the other fleet-size options: Expected Value (15 trucks) = 0. 2($131, 500) + 0. 3($181, 500) + 0. 4($281, 500) + 0. 1($381, 000) = $231, 500 Expected Value (20 trucks) = 0. 2($142, 000) + 0. 3($192, 000) + 0. 4($242, 000) + 0. 1($342, 000) = $217, 000 Expected Value (25 trucks) = 0. 2($152, 500) + 0. 3($302, 500) + 0. 4($252, 500) + 0. 1($302, 500) = $222, 500 10 – 32 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

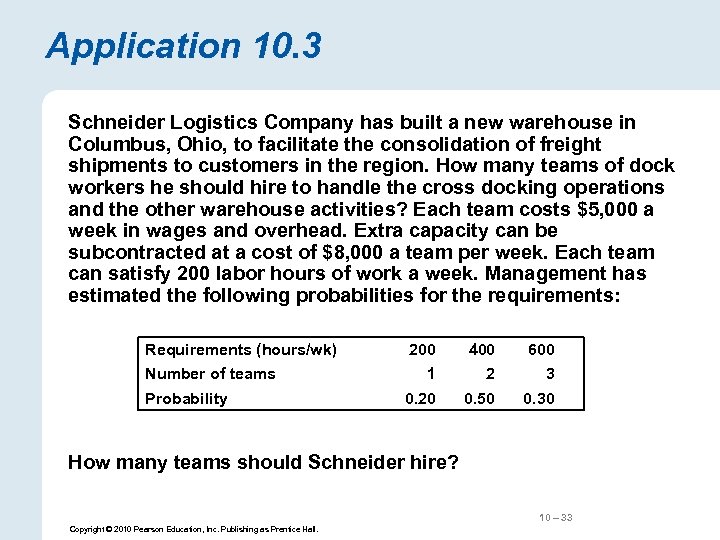

Application 10. 3 Schneider Logistics Company has built a new warehouse in Columbus, Ohio, to facilitate the consolidation of freight shipments to customers in the region. How many teams of dock workers he should hire to handle the cross docking operations and the other warehouse activities? Each team costs $5, 000 a week in wages and overhead. Extra capacity can be subcontracted at a cost of $8, 000 a team per week. Each team can satisfy 200 labor hours of work a week. Management has estimated the following probabilities for the requirements: Requirements (hours/wk) Number of teams Probability 200 400 600 1 2 3 0. 20 0. 50 0. 30 How many teams should Schneider hire? 10 – 33 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

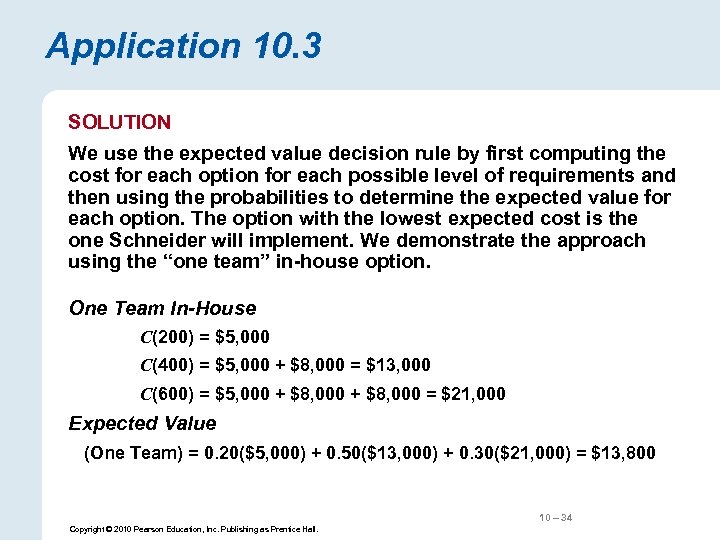

Application 10. 3 SOLUTION We use the expected value decision rule by first computing the cost for each option for each possible level of requirements and then using the probabilities to determine the expected value for each option. The option with the lowest expected cost is the one Schneider will implement. We demonstrate the approach using the “one team” in-house option. One Team In-House C(200) = $5, 000 C(400) = $5, 000 + $8, 000 = $13, 000 C(600) = $5, 000 + $8, 000 = $21, 000 Expected Value (One Team) = 0. 20($5, 000) + 0. 50($13, 000) + 0. 30($21, 000) = $13, 800 10 – 34 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

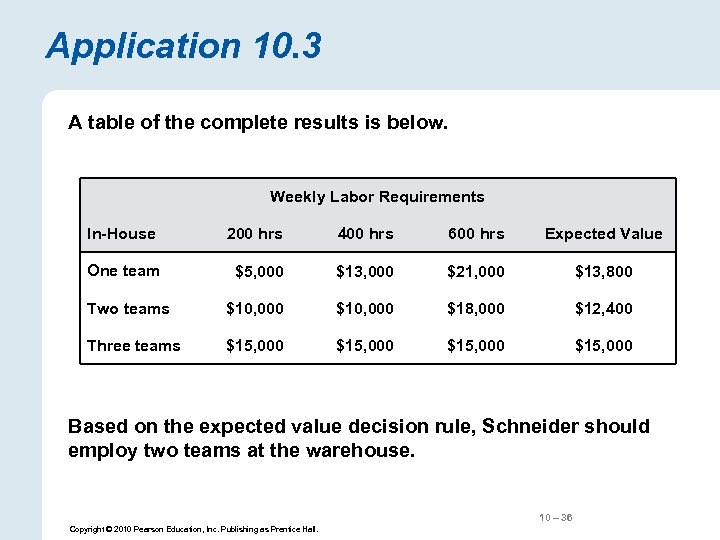

Application 10. 3 A table of the complete results is below. Weekly Labor Requirements In-House 200 hrs 400 hrs 600 hrs Expected Value One team Two teams Three teams 10 – 35 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Application 10. 3 A table of the complete results is below. Weekly Labor Requirements In-House 200 hrs 400 hrs 600 hrs Expected Value One team $5, 000 $13, 000 $21, 000 $13, 800 Two teams $10, 000 $18, 000 $12, 400 Three teams $15, 000 Based on the expected value decision rule, Schneider should employ two teams at the warehouse. 10 – 36 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

The Customer Relationship Process l Customer relationship management (CRM) programs identify, attract, and build relationships with customers l Marketing u Electronic commerce (e-commerce) u Business-to-Consumer (B 2 C) systems u Business-to-Business (B 2 B) systems 10 – 37 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

The Customer Relationship Process l Order placement u Execute a sale, register the specifics, confirm acceptance, and track progress u Internet provides advantage l Customer service u Helps customers with answers to questions, resolves problems, and, provides general information u Call centers 10 – 38 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Levers for Improved Supply Chain Performance l The levers u Sharing data u Collaborative activities u Reduce replenishment lead times u Reduce order lot sizes u Ration short supplies u Use everyday low pricing (EDLP) u Be cooperative and trustworthy 10 – 39 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

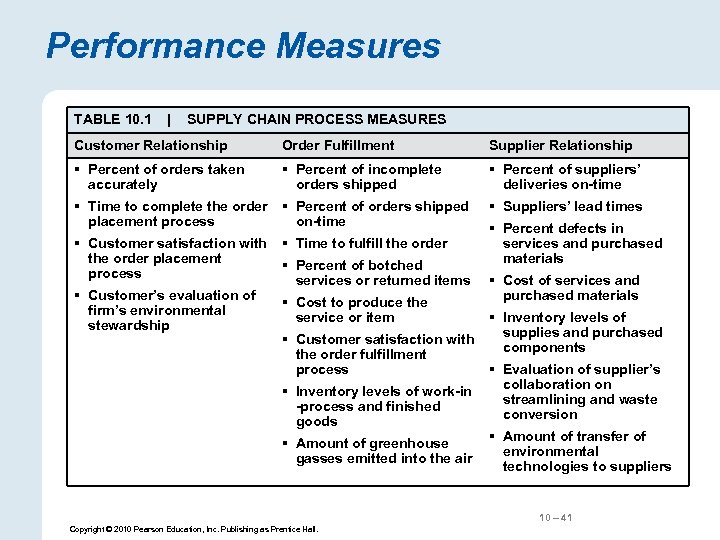

Levers for Improved Supply Chain Performance l Performance measures u Costs u Time u Quality u Environmental impact 10 – 40 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Performance Measures TABLE 10. 1 | SUPPLY CHAIN PROCESS MEASURES Customer Relationship Order Fulfillment Supplier Relationship § Percent of orders taken accurately § Percent of incomplete orders shipped § Percent of suppliers’ deliveries on-time § Time to complete the order § Percent of orders shipped placement process on-time § Customer satisfaction with the order placement process § Time to fulfill the order § Customer’s evaluation of firm’s environmental stewardship § Cost to produce the service or item § Percent of botched services or returned items § Suppliers’ lead times § Percent defects in services and purchased materials § Cost of services and purchased materials § Inventory levels of supplies and purchased § Customer satisfaction with components the order fulfillment process § Inventory levels of work-in -process and finished goods § Amount of greenhouse gasses emitted into the air § Evaluation of supplier’s collaboration on streamlining and waste conversion § Amount of transfer of environmental technologies to suppliers 10 – 41 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

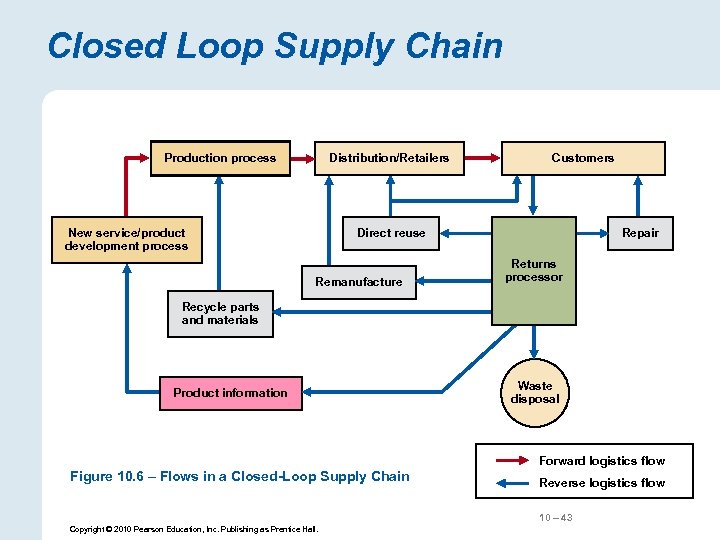

Supply Chains and the Environment l Sustainability u Environmental stewardship u Environmental protection u Productivity improvement u Risk minimization u Innovation l Reverse logistics u Planning, implementing, and controlling flows from consumption back to origin u Closed-loop supply chain 10 – 42 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

Closed Loop Supply Chain Production process Distribution/Retailers New service/product development process Customers Direct reuse Remanufacture Repair Returns processor Recycle parts and materials Product information Waste disposal Forward logistics flow Figure 10. 6 – Flows in a Closed-Loop Supply Chain Reverse logistics flow 10 – 43 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

10 – 44 Copyright © 2010 Pearson Education, Inc. Publishing as Prentice Hall.

21959030413154953d666b0ade774969.ppt