1 TFV I Content Introduction History, classification of

32148-v_a_1503_intro_samara.ppt

- Количество слайдов: 17

1 TFV I Content Introduction History, classification of forming process technology Classification of rolling mills and some baiscs Hot rolling of strips Technology, methods, concepts, equipment, optimization Cold rolling of strips Technology, concepts Coating Operational data ……….

1 TFV I Content Introduction History, classification of forming process technology Classification of rolling mills and some baiscs Hot rolling of strips Technology, methods, concepts, equipment, optimization Cold rolling of strips Technology, concepts Coating Operational data ……….

2 2 TU Clausthal Institute of Metallurgy - IMET Prof. Dr.-Ing. Heinz Palkowski Institute of Metallurgy Forming and Processing [email protected] www.imet.tu-clausthal.de/agpal

2 2 TU Clausthal Institute of Metallurgy - IMET Prof. Dr.-Ing. Heinz Palkowski Institute of Metallurgy Forming and Processing [email protected] www.imet.tu-clausthal.de/agpal

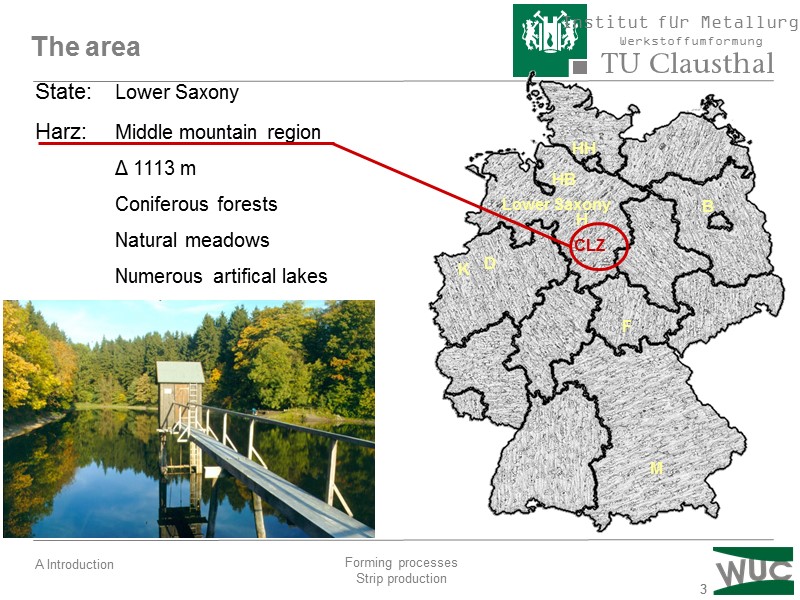

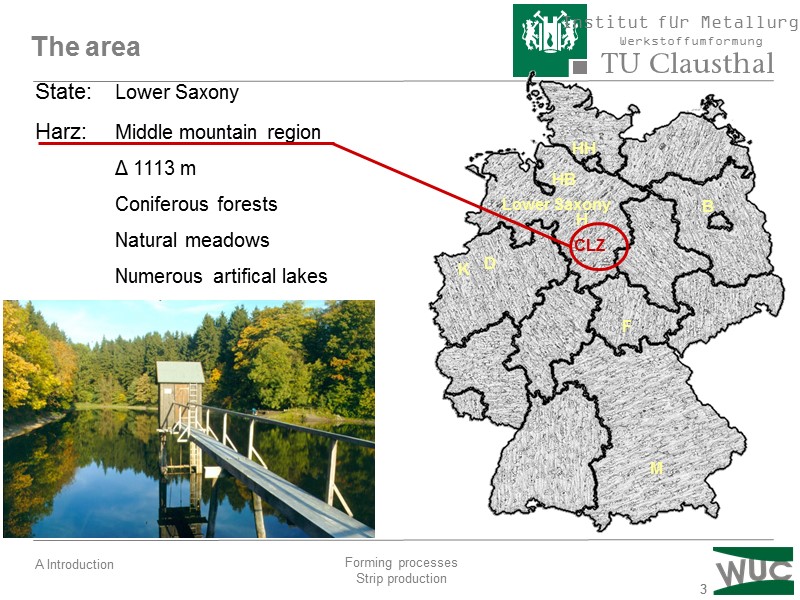

3 3 The area State: Lower Saxony Harz: Middle mountain region Δ 1113 m Coniferous forests Natural meadows Numerous artifical lakes M H HH B D K F HB Lower Saxony

3 3 The area State: Lower Saxony Harz: Middle mountain region Δ 1113 m Coniferous forests Natural meadows Numerous artifical lakes M H HH B D K F HB Lower Saxony

4 4 The town Inhabitants: 18,000 Height: 600 m N.N. Main employer: University All shops (magazines) for daily goods available, but no malls! No train station! Hourly bus connections to/from Goslar (20 km) train to / from Hanover and Braunschweig (1h). Walking distances within the town: Passing through: 45 min To center from any town limit: max. 25 min Student homes to center: max. 15 min Weather in summer time: Changing, rainy periods possible Temperatures (18-28 °C) . Prof. Dr.-Ing. Heinz Palkowski Institute of Metallurgy Forming and Processing [email protected] www.imet.tu-clausthal.de/agpal .

4 4 The town Inhabitants: 18,000 Height: 600 m N.N. Main employer: University All shops (magazines) for daily goods available, but no malls! No train station! Hourly bus connections to/from Goslar (20 km) train to / from Hanover and Braunschweig (1h). Walking distances within the town: Passing through: 45 min To center from any town limit: max. 25 min Student homes to center: max. 15 min Weather in summer time: Changing, rainy periods possible Temperatures (18-28 °C) . Prof. Dr.-Ing. Heinz Palkowski Institute of Metallurgy Forming and Processing [email protected] www.imet.tu-clausthal.de/agpal .

5 5 History 1775 School for Mining and Metallurgy ~ 1930 University ~ 1962 Technical University Faculties - Natural and Material Science - Energy and Economic Science - Mathematics/Informatics and Mech. Engineering No students (WS 14/15): 4.900 Women: 26 % Foreigners: 30 % Material Sciences: 285 Clausthal University of Technology

5 5 History 1775 School for Mining and Metallurgy ~ 1930 University ~ 1962 Technical University Faculties - Natural and Material Science - Energy and Economic Science - Mathematics/Informatics and Mech. Engineering No students (WS 14/15): 4.900 Women: 26 % Foreigners: 30 % Material Sciences: 285 Clausthal University of Technology

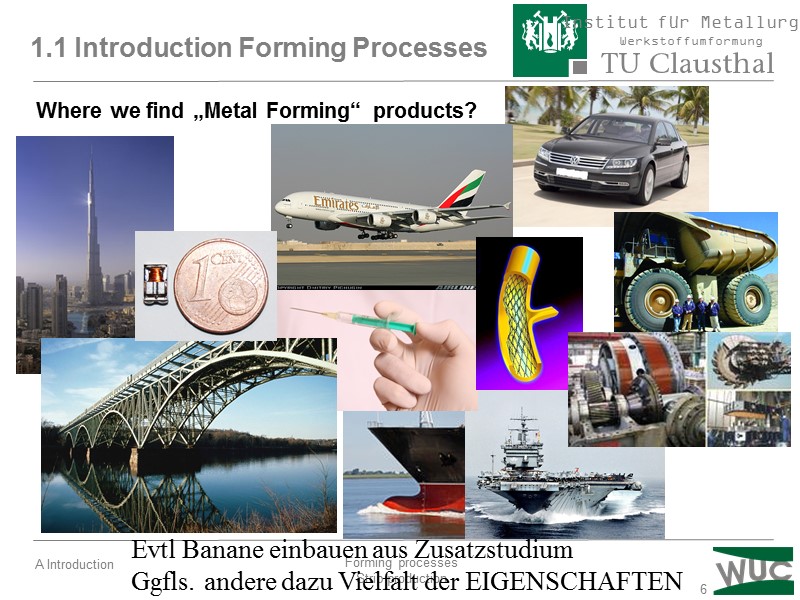

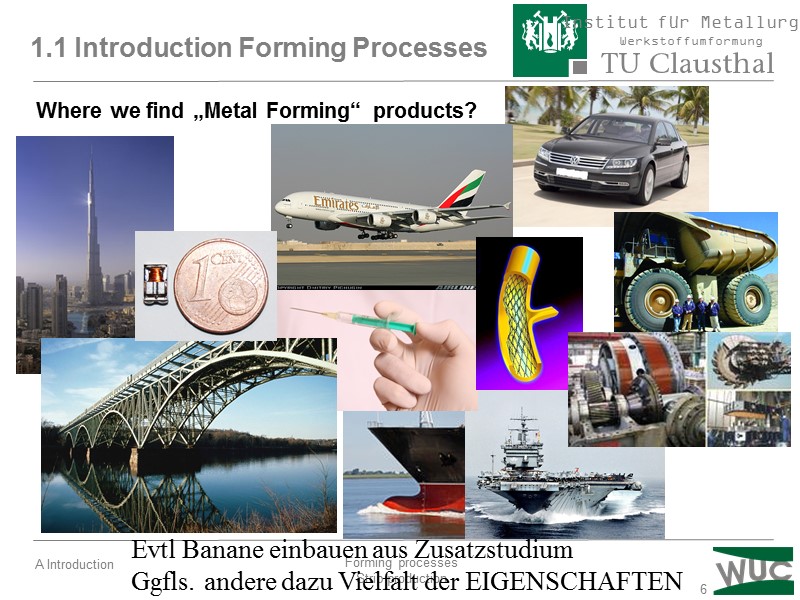

6 1.1 Introduction Forming Processes Evtl Banane einbauen aus Zusatzstudium Ggfls. andere dazu Vielfalt der EIGENSCHAFTEN Where we find „Metal Forming“ products?

6 1.1 Introduction Forming Processes Evtl Banane einbauen aus Zusatzstudium Ggfls. andere dazu Vielfalt der EIGENSCHAFTEN Where we find „Metal Forming“ products?

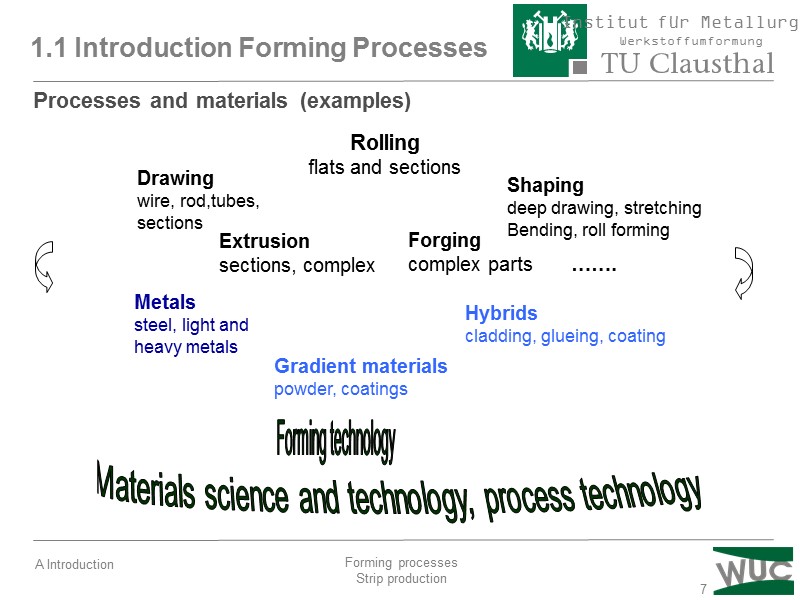

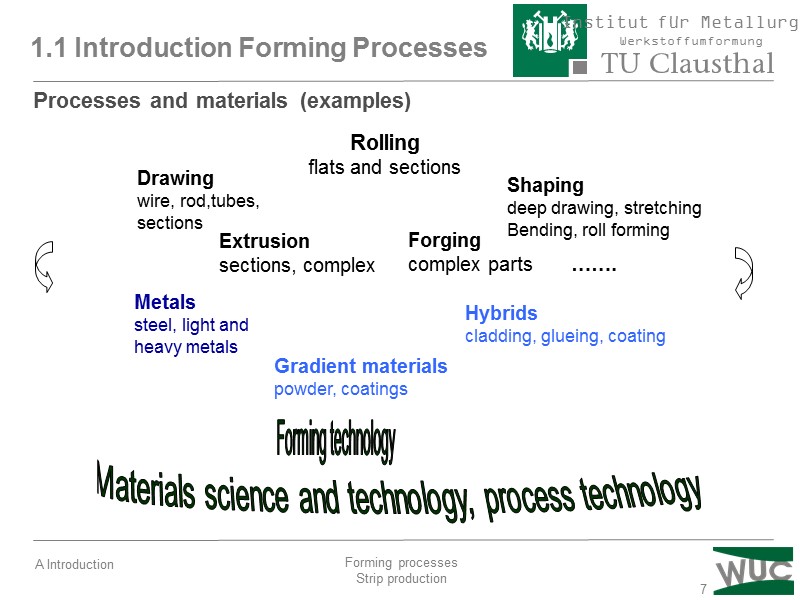

7 Rolling flats and sections Drawing wire, rod,tubes, sections Shaping deep drawing, stretching Bending, roll forming Hybrids cladding, glueing, coating Gradient materials powder, coatings Extrusion sections, complex Metals steel, light and heavy metals Processes and materials (examples) 1.1 Introduction Forming Processes Forging complex parts …….

7 Rolling flats and sections Drawing wire, rod,tubes, sections Shaping deep drawing, stretching Bending, roll forming Hybrids cladding, glueing, coating Gradient materials powder, coatings Extrusion sections, complex Metals steel, light and heavy metals Processes and materials (examples) 1.1 Introduction Forming Processes Forging complex parts …….

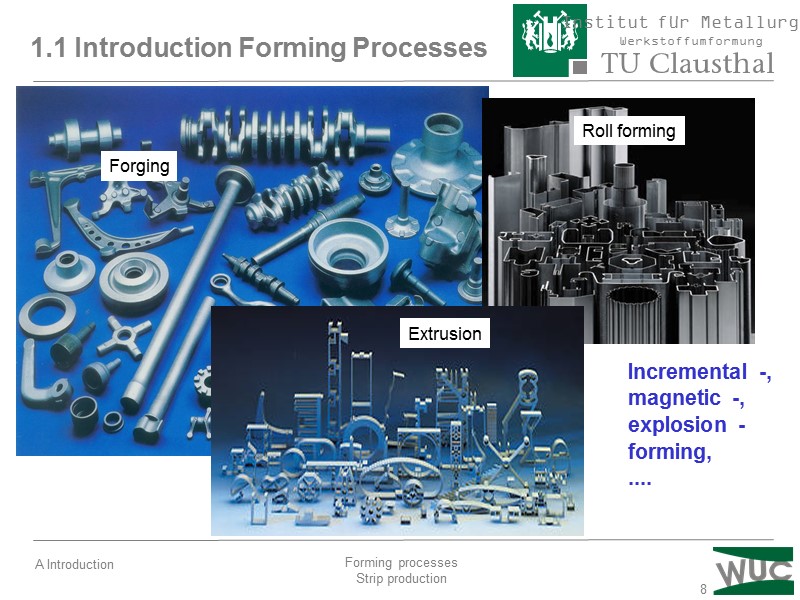

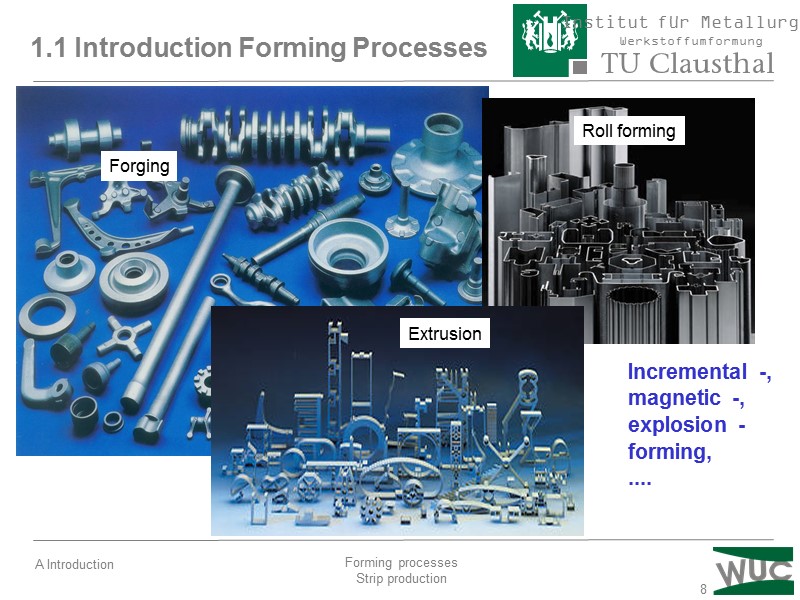

8 Incremental -, magnetic -, explosion - forming, .... 1.1 Introduction Forming Processes

8 Incremental -, magnetic -, explosion - forming, .... 1.1 Introduction Forming Processes

9 1.1 Introduction Forming Processes Controlled plastic deformation in the solid state with mass constancy and material connectivity! What is „Metal Forming“ ?

9 1.1 Introduction Forming Processes Controlled plastic deformation in the solid state with mass constancy and material connectivity! What is „Metal Forming“ ?

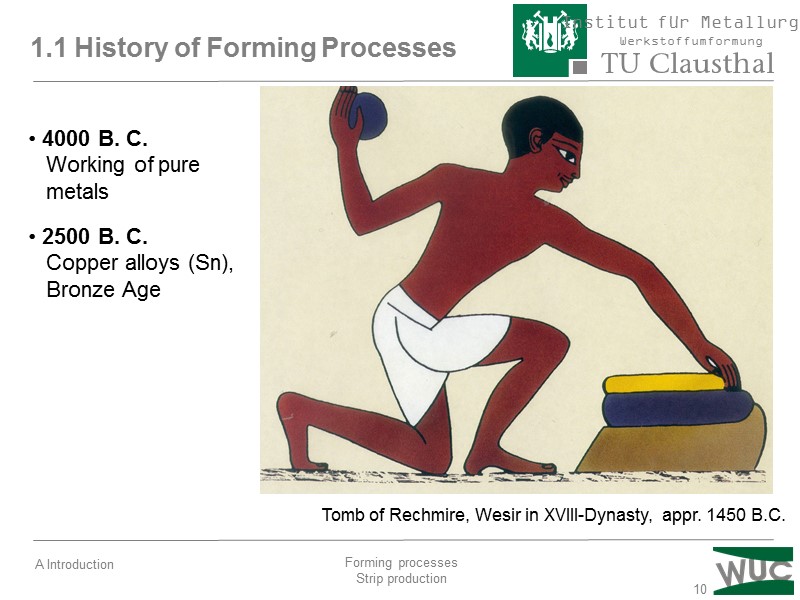

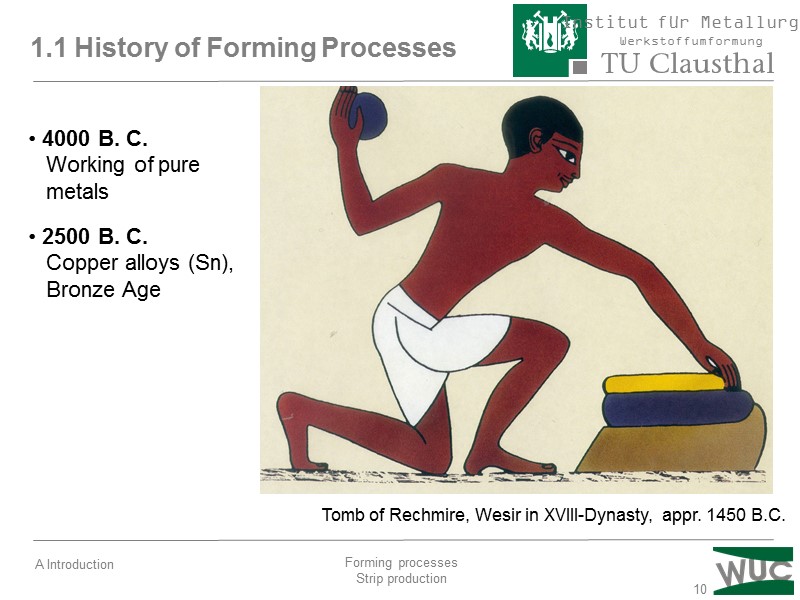

10 1.1 History of Forming Processes 4000 B. C. Working of pure metals 2500 B. C. Copper alloys (Sn), Bronze Age Tomb of Rechmire, Wesir in XVIII-Dynasty, appr. 1450 B.C.

10 1.1 History of Forming Processes 4000 B. C. Working of pure metals 2500 B. C. Copper alloys (Sn), Bronze Age Tomb of Rechmire, Wesir in XVIII-Dynasty, appr. 1450 B.C.

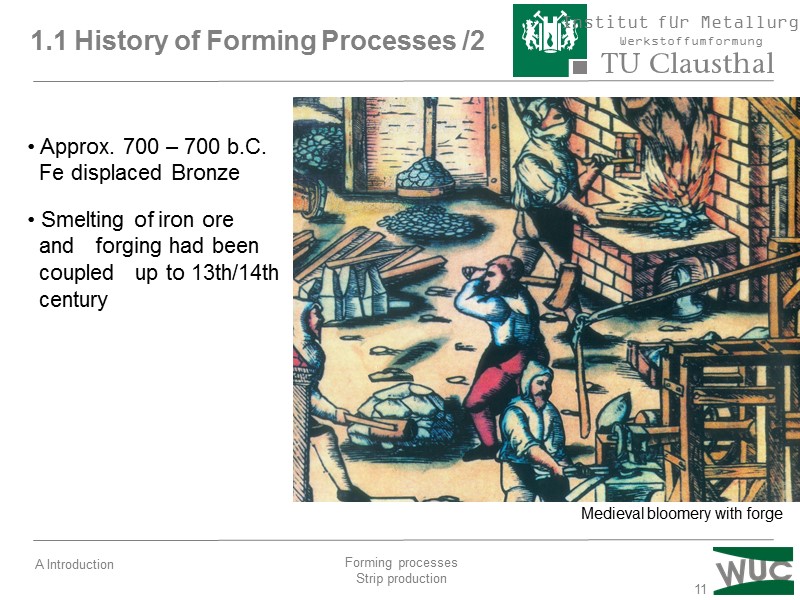

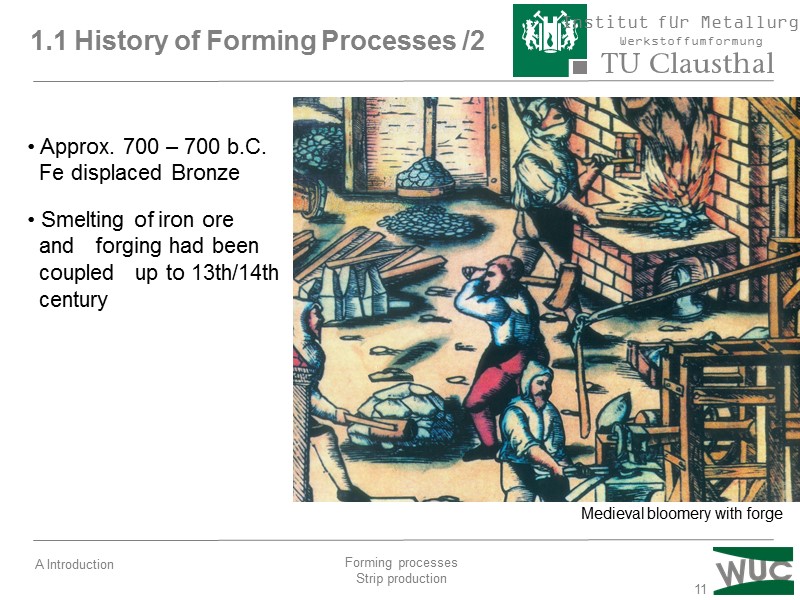

11 1.1 History of Forming Processes /2 Approx. 700 – 700 b.C. Fe displaced Bronze Smelting of iron ore and forging had been coupled up to 13th/14th century Medieval bloomery with forge

11 1.1 History of Forming Processes /2 Approx. 700 – 700 b.C. Fe displaced Bronze Smelting of iron ore and forging had been coupled up to 13th/14th century Medieval bloomery with forge

12 1.1 History of Forming Processes /3

12 1.1 History of Forming Processes /3

13 . 1.1 History of Forming Processes /4 … past and now.

13 . 1.1 History of Forming Processes /4 … past and now.

14 Vorlesungsübersicht 1.3 Classification 1.2 Classification of Forming Primary forming Making a shape for the 1st time out of a melt, gaseous or shapeless solid condition Forming Conversion of a given form under control of geometry by plastic deformation. Continuity of material and mass! Separating Locally cancelled continuity of material (e.g. sawing, milling) Joining Connecting to parts, filling and infiltrating (e.g. welding, sticking) Change of utility (e.g.hardening by heat treatment) properties Coating Applying thin layer on surface ... following forming processes

14 Vorlesungsübersicht 1.3 Classification 1.2 Classification of Forming Primary forming Making a shape for the 1st time out of a melt, gaseous or shapeless solid condition Forming Conversion of a given form under control of geometry by plastic deformation. Continuity of material and mass! Separating Locally cancelled continuity of material (e.g. sawing, milling) Joining Connecting to parts, filling and infiltrating (e.g. welding, sticking) Change of utility (e.g.hardening by heat treatment) properties Coating Applying thin layer on surface ... following forming processes

15 Technische Formgebungsverfahren Vorlesungsübersicht 1.2 Classification of Forming Pressure forming Rolling, open die -, die forming Push-pull forming Drawing, deep drawing, spinning Tensile forming Stretch forming Bending Roll forming to shape, folding Shear forming Torsion processes ... following tensile state

15 Technische Formgebungsverfahren Vorlesungsübersicht 1.2 Classification of Forming Pressure forming Rolling, open die -, die forming Push-pull forming Drawing, deep drawing, spinning Tensile forming Stretch forming Bending Roll forming to shape, folding Shear forming Torsion processes ... following tensile state

16 Vorlesungsübersicht 1.2 Classification of Forming ... following temperature Hot working Energy is added from outside or working with 1st heat above recrystallisation temperature Warm working Material is heated up below it‘s recrystallisation temperature Cold working No heat added from outside Recrystallisation temperatures of some metals: C-steel 550 °C Aluminium 290 °C Copper 200 °C Lead 0 °C

16 Vorlesungsübersicht 1.2 Classification of Forming ... following temperature Hot working Energy is added from outside or working with 1st heat above recrystallisation temperature Warm working Material is heated up below it‘s recrystallisation temperature Cold working No heat added from outside Recrystallisation temperatures of some metals: C-steel 550 °C Aluminium 290 °C Copper 200 °C Lead 0 °C

17 Vorlesungsübersicht 1.2 Classification ... following type of product: Solid forming Upsetting (edging), rolling, drawing, pushing through, twisting, shifting,... Solid and sheet forming Stretching, bending,... Sheet forming Stretch forming, deep drawing,...

17 Vorlesungsübersicht 1.2 Classification ... following type of product: Solid forming Upsetting (edging), rolling, drawing, pushing through, twisting, shifting,... Solid and sheet forming Stretching, bending,... Sheet forming Stretch forming, deep drawing,...