1922a25e19c6fa7f81083816ed72af42.ppt

- Количество слайдов: 104

1 Starting Soon: Soil Sampling and Decision Making Using Incremental Sampling Methodology (ISM) - Part 2 u u u Incremental Sampling Methodology Technology Regulatory and Guidance Document (ISM-1, February 2012) - http: //www. itrcweb. org/ism-1/ Download Power. Point file • Clu-in training page at https: //clu-in. org/conf/itrc/ISM/ • Under “Download Training Materials” Using Adobe Connect • Related Links (on right) § Select name of link § Click “Browse To” • Full Screen button near top of page u Follow ITRC

1 Starting Soon: Soil Sampling and Decision Making Using Incremental Sampling Methodology (ISM) - Part 2 u u u Incremental Sampling Methodology Technology Regulatory and Guidance Document (ISM-1, February 2012) - http: //www. itrcweb. org/ism-1/ Download Power. Point file • Clu-in training page at https: //clu-in. org/conf/itrc/ISM/ • Under “Download Training Materials” Using Adobe Connect • Related Links (on right) § Select name of link § Click “Browse To” • Full Screen button near top of page u Follow ITRC

2 Welcome – Thanks for joining this ITRC Training Class Follow ITRC Soil Sampling and Decision Making Using Incremental Sampling Methodology (ISM) Part 2 – Implement, Assess, and Apply Web-Based Document at: http: //www. itrcweb. org/ISM-1/ Incremental Sampling Methodology Technology Regulatory and Guidance Document (ISM-1, February 2012) Sponsored by: Interstate Technology and Regulatory Council (www. itrcweb. org) Hosted by: US EPA Clean Up Information Network (www. cluin. org)

2 Welcome – Thanks for joining this ITRC Training Class Follow ITRC Soil Sampling and Decision Making Using Incremental Sampling Methodology (ISM) Part 2 – Implement, Assess, and Apply Web-Based Document at: http: //www. itrcweb. org/ISM-1/ Incremental Sampling Methodology Technology Regulatory and Guidance Document (ISM-1, February 2012) Sponsored by: Interstate Technology and Regulatory Council (www. itrcweb. org) Hosted by: US EPA Clean Up Information Network (www. cluin. org)

3 Housekeeping u u u Course time is 2¼ hours This event is being recorded Trainers control slides • Want to control your own slides? You can download presentation file on Clu-in training page u Questions and feedback • Throughout training: type in the “Q & A” box • At Q&A breaks: unmute your phone with #6 to ask out loud • At end of class: Feedback form available from last slide § Need confirmation of your participation today? Fill out the feedback form and check box for confirmation email and certificate Copyright 2017 Interstate Technology & Regulatory Council, 50 F Street, NW, Suite 350, Washington, DC 20001

3 Housekeeping u u u Course time is 2¼ hours This event is being recorded Trainers control slides • Want to control your own slides? You can download presentation file on Clu-in training page u Questions and feedback • Throughout training: type in the “Q & A” box • At Q&A breaks: unmute your phone with #6 to ask out loud • At end of class: Feedback form available from last slide § Need confirmation of your participation today? Fill out the feedback form and check box for confirmation email and certificate Copyright 2017 Interstate Technology & Regulatory Council, 50 F Street, NW, Suite 350, Washington, DC 20001

4 ITRC (www. itrcweb. org) – Shaping the Future of Regulatory Acceptance u u u Host organization Network • State regulators Disclaimer • Full version in “Notes” section • Partially funded by the U. S. government § All 50 states, PR, DC § ITRC nor US government • Federal partners warranty material § ITRC nor US government DOE DOD endorse specific products EPA • ITRC materials copyrighted – • ITRC Industry Affiliates Program • Academia • Community stakeholders u Follow ITRC see usage policy u Available from www. itrcweb. org • Technical and regulatory guidance documents • Internet-based and classroom training schedule • More…

4 ITRC (www. itrcweb. org) – Shaping the Future of Regulatory Acceptance u u u Host organization Network • State regulators Disclaimer • Full version in “Notes” section • Partially funded by the U. S. government § All 50 states, PR, DC § ITRC nor US government • Federal partners warranty material § ITRC nor US government DOE DOD endorse specific products EPA • ITRC materials copyrighted – • ITRC Industry Affiliates Program • Academia • Community stakeholders u Follow ITRC see usage policy u Available from www. itrcweb. org • Technical and regulatory guidance documents • Internet-based and classroom training schedule • More…

5 Meet the ITRC Trainers Michael Stroh Mark Bruce Missouri Department of Natural Resources Jefferson City, MO 573 -522 -9902 michael. stroh@ dnr. mo. gov Test. America Inc. North Canton, OH 330 -966 -7267 mark. bruce@ testamericainc. com Jay Clausen Tim Frederick U. S. Army Cold Regions Research and Engineering Laboratory Hanover, NH 603 -646 -4597 Jay. L. Clausen@ usace. army. mil USEPA Region 4 Atlanta, GA 404 -562 -8598 frederick. tim@epa. gov

5 Meet the ITRC Trainers Michael Stroh Mark Bruce Missouri Department of Natural Resources Jefferson City, MO 573 -522 -9902 michael. stroh@ dnr. mo. gov Test. America Inc. North Canton, OH 330 -966 -7267 mark. bruce@ testamericainc. com Jay Clausen Tim Frederick U. S. Army Cold Regions Research and Engineering Laboratory Hanover, NH 603 -646 -4597 Jay. L. Clausen@ usace. army. mil USEPA Region 4 Atlanta, GA 404 -562 -8598 frederick. tim@epa. gov

6 Soil Sampling Data – What Do We All Need? u u u Accuracy Reproducibility Defensibility …. but how do we get it? Incremental Sampling Methodology (ISM) …. . may be your answer…. .

6 Soil Sampling Data – What Do We All Need? u u u Accuracy Reproducibility Defensibility …. but how do we get it? Incremental Sampling Methodology (ISM) …. . may be your answer…. .

7 ISM Goal – A Representative Sample! The primary objective of ISM is to obtain a representative sample having constituents in exactly the same proportions as the entire decision unit. Representative subsampling

7 ISM Goal – A Representative Sample! The primary objective of ISM is to obtain a representative sample having constituents in exactly the same proportions as the entire decision unit. Representative subsampling

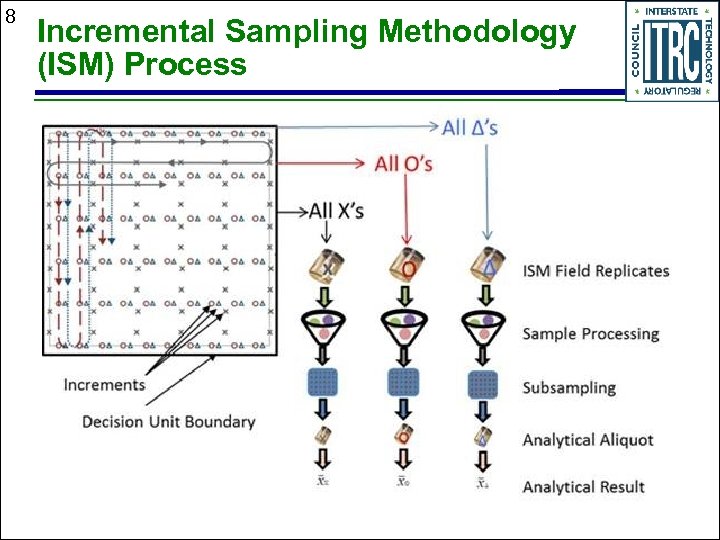

8 Incremental Sampling Methodology (ISM) Process

8 Incremental Sampling Methodology (ISM) Process

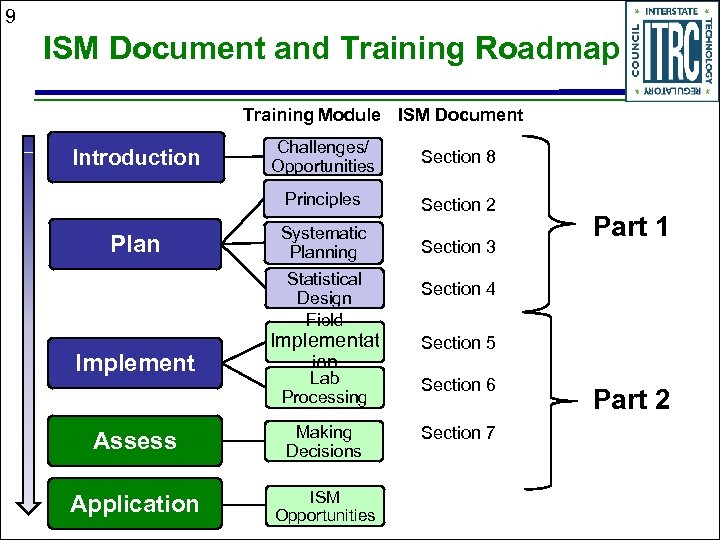

9 ISM Document and Training Roadmap Training Module ISM Document Plan Challenges/ Opportunities Section 8 Principles Introduction Section 2 Systematic Planning Statistical Design Field Implementat ion Section 3 Part 1 Section 4 Section 5 Lab Processing Section 6 Assess Making Decisions Section 7 Application ISM Opportunities Part 2

9 ISM Document and Training Roadmap Training Module ISM Document Plan Challenges/ Opportunities Section 8 Principles Introduction Section 2 Systematic Planning Statistical Design Field Implementat ion Section 3 Part 1 Section 4 Section 5 Lab Processing Section 6 Assess Making Decisions Section 7 Application ISM Opportunities Part 2

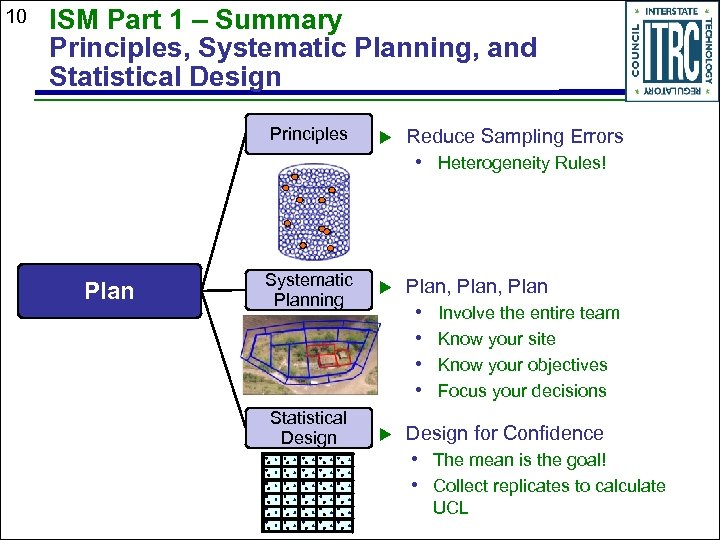

10 ISM Part 1 – Summary Principles, Systematic Planning, and Statistical Design Principles u Reduce Sampling Errors • Heterogeneity Rules! Plan Systematic Planning u Statistical Design u Plan, Plan • • Involve the entire team Know your site Know your objectives Focus your decisions Design for Confidence • The mean is the goal! • Collect replicates to calculate UCL

10 ISM Part 1 – Summary Principles, Systematic Planning, and Statistical Design Principles u Reduce Sampling Errors • Heterogeneity Rules! Plan Systematic Planning u Statistical Design u Plan, Plan • • Involve the entire team Know your site Know your objectives Focus your decisions Design for Confidence • The mean is the goal! • Collect replicates to calculate UCL

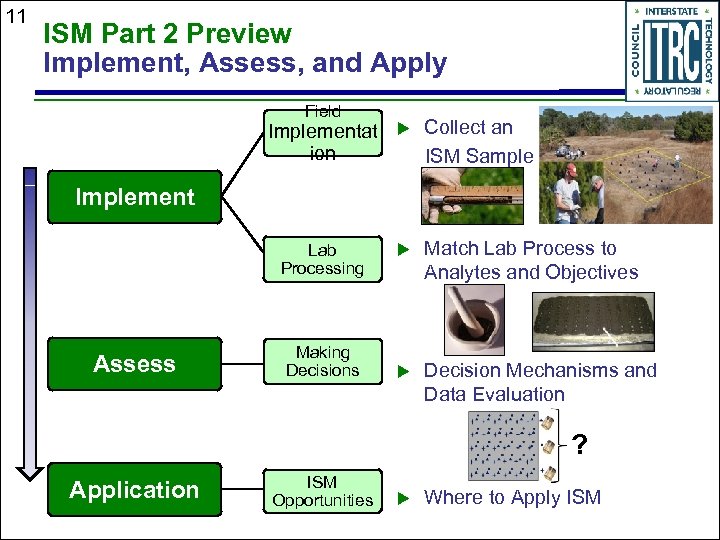

11 ISM Part 2 Preview Implement, Assess, and Apply Field Implementat u Collect an ion ISM Sample Implement Lab Processing Assess Making Decisions u Match Lab Process to Analytes and Objectives u Decision Mechanisms and Data Evaluation ? Application ISM Opportunities u Where to Apply ISM

11 ISM Part 2 Preview Implement, Assess, and Apply Field Implementat u Collect an ion ISM Sample Implement Lab Processing Assess Making Decisions u Match Lab Process to Analytes and Objectives u Decision Mechanisms and Data Evaluation ? Application ISM Opportunities u Where to Apply ISM

12 Field Implementation Learning Objectives Learn how to: u Collect an ISM sample • Understand the similarities and differences between surface and subsurface ISM sampling • Consider issues specific to non-volatile and volatile ISM sampling • Implement and collect ISM replicate samples ITRC, ISM-1, Section 5

12 Field Implementation Learning Objectives Learn how to: u Collect an ISM sample • Understand the similarities and differences between surface and subsurface ISM sampling • Consider issues specific to non-volatile and volatile ISM sampling • Implement and collect ISM replicate samples ITRC, ISM-1, Section 5

13 Key Presentation Topics u u u Sampling design Sampling tools ISM surface/subsurface sampling • Cores and subsampling u Specific contaminant of concern (COC) considerations • Non-volatile and volatile u ISM replicates

13 Key Presentation Topics u u u Sampling design Sampling tools ISM surface/subsurface sampling • Cores and subsampling u Specific contaminant of concern (COC) considerations • Non-volatile and volatile u ISM replicates

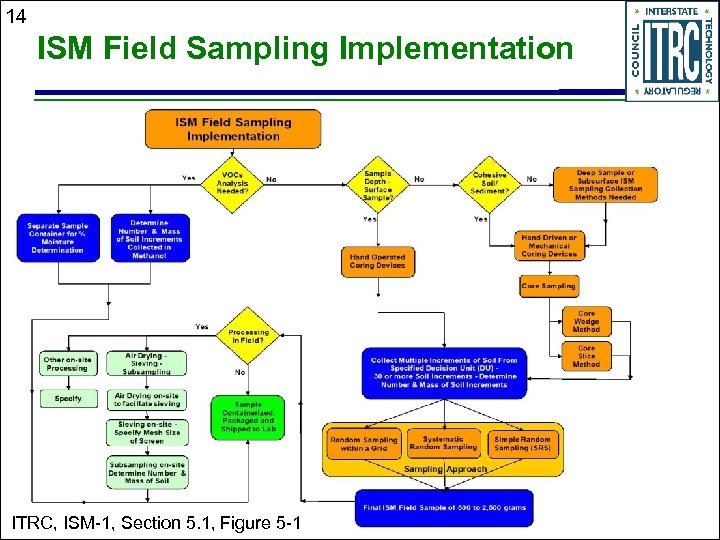

14 ISM Field Sampling Implementation ITRC, ISM-1, Section 5. 1, Figure 5 -1

14 ISM Field Sampling Implementation ITRC, ISM-1, Section 5. 1, Figure 5 -1

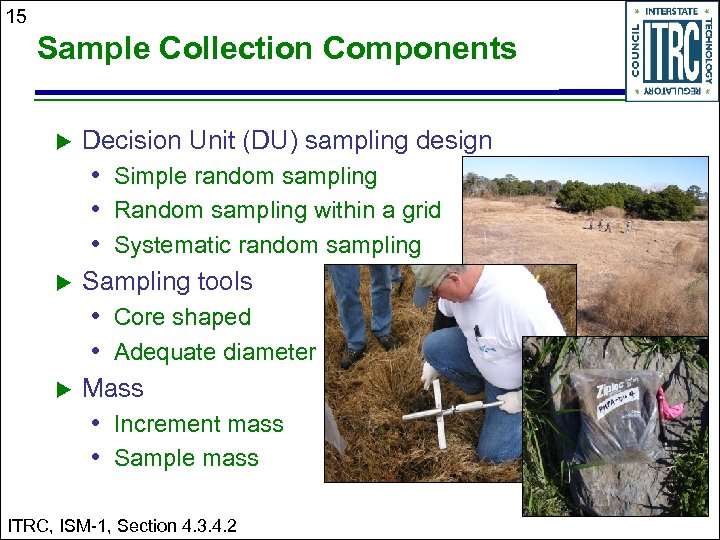

15 Sample Collection Components u Decision Unit (DU) sampling design • Simple random sampling • Random sampling within a grid • Systematic random sampling u Sampling tools • Core shaped • Adequate diameter u Mass • Increment mass • Sample mass ITRC, ISM-1, Section 4. 3. 4. 2

15 Sample Collection Components u Decision Unit (DU) sampling design • Simple random sampling • Random sampling within a grid • Systematic random sampling u Sampling tools • Core shaped • Adequate diameter u Mass • Increment mass • Sample mass ITRC, ISM-1, Section 4. 3. 4. 2

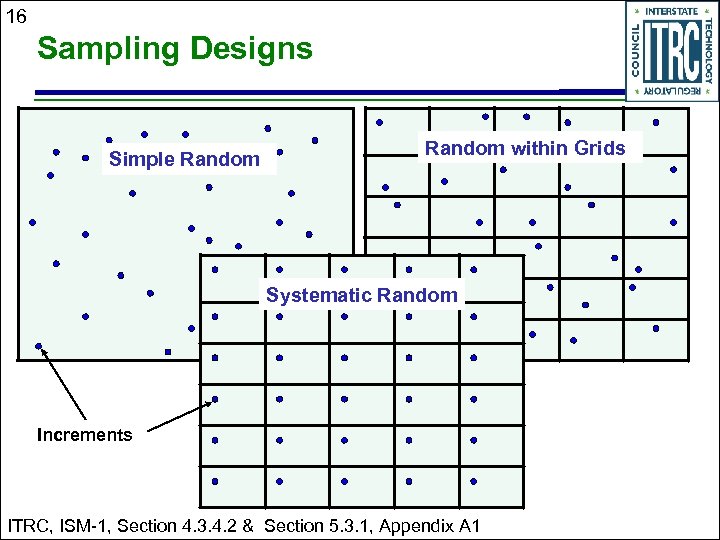

16 Sampling Designs Simple Random within Grids Systematic Random Increments ITRC, ISM-1, Section 4. 3. 4. 2 & Section 5. 3. 1, Appendix A 1

16 Sampling Designs Simple Random within Grids Systematic Random Increments ITRC, ISM-1, Section 4. 3. 4. 2 & Section 5. 3. 1, Appendix A 1

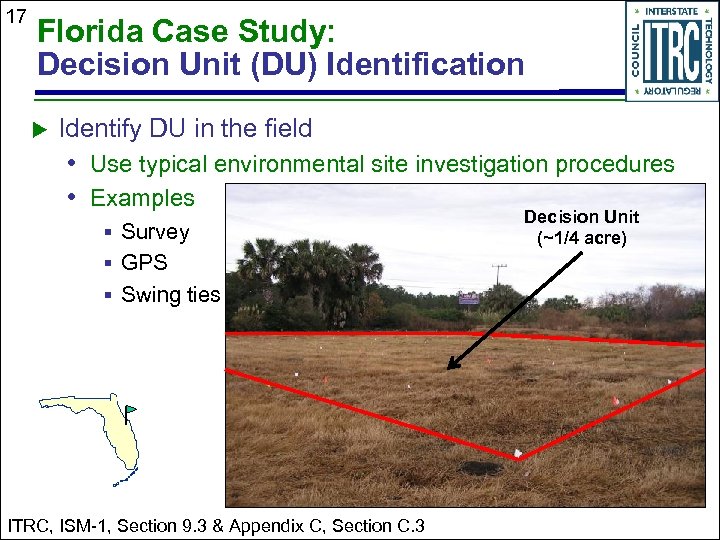

17 Florida Case Study: Decision Unit (DU) Identification u Identify DU in the field • Use typical environmental site investigation procedures • Examples § Survey § GPS § Swing ties ITRC, ISM-1, Section 9. 3 & Appendix C, Section C. 3 Decision Unit (~1/4 acre)

17 Florida Case Study: Decision Unit (DU) Identification u Identify DU in the field • Use typical environmental site investigation procedures • Examples § Survey § GPS § Swing ties ITRC, ISM-1, Section 9. 3 & Appendix C, Section C. 3 Decision Unit (~1/4 acre)

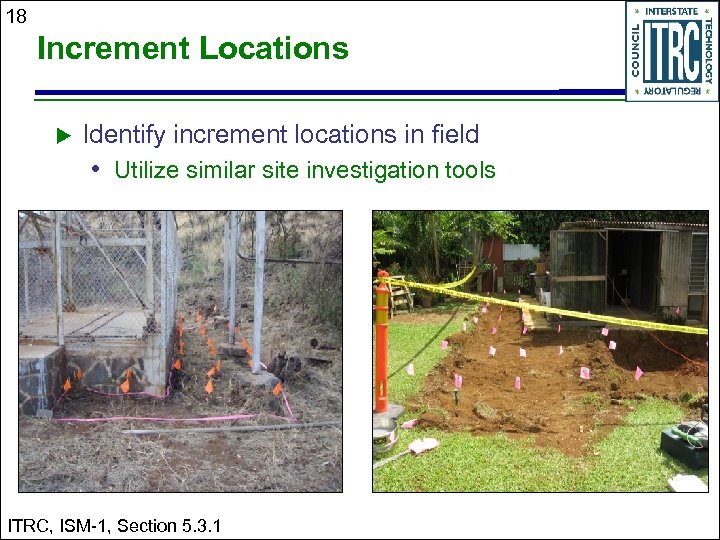

18 Increment Locations u Identify increment locations in field • Utilize similar site investigation tools ITRC, ISM-1, Section 5. 3. 1

18 Increment Locations u Identify increment locations in field • Utilize similar site investigation tools ITRC, ISM-1, Section 5. 3. 1

19 Florida Case Study: Increment Field Determination

19 Florida Case Study: Increment Field Determination

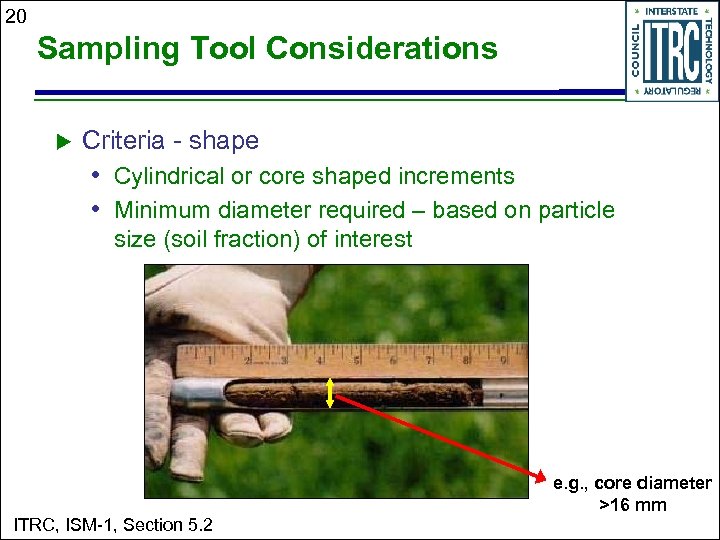

20 Sampling Tool Considerations u Criteria - shape • Cylindrical or core shaped increments • Minimum diameter required – based on particle size (soil fraction) of interest e. g. , core diameter >16 mm ITRC, ISM-1, Section 5. 2

20 Sampling Tool Considerations u Criteria - shape • Cylindrical or core shaped increments • Minimum diameter required – based on particle size (soil fraction) of interest e. g. , core diameter >16 mm ITRC, ISM-1, Section 5. 2

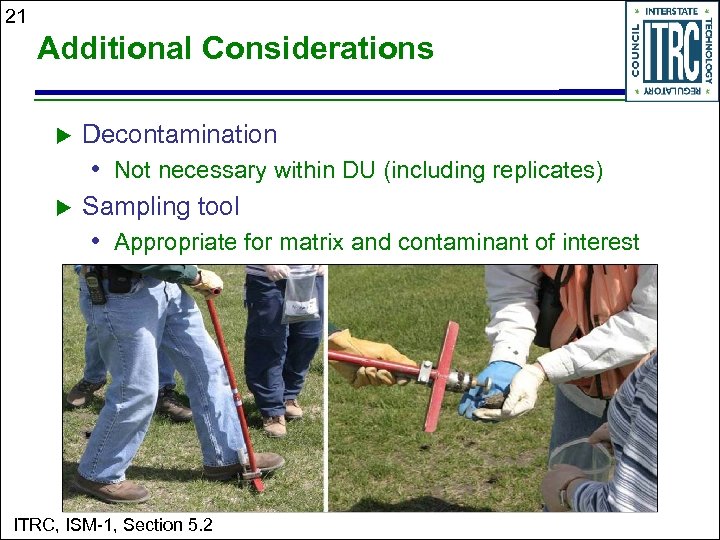

21 Additional Considerations u Decontamination • Not necessary within DU (including replicates) u Sampling tool • Appropriate for matrix and contaminant of interest ITRC, ISM-1, Section 5. 2

21 Additional Considerations u Decontamination • Not necessary within DU (including replicates) u Sampling tool • Appropriate for matrix and contaminant of interest ITRC, ISM-1, Section 5. 2

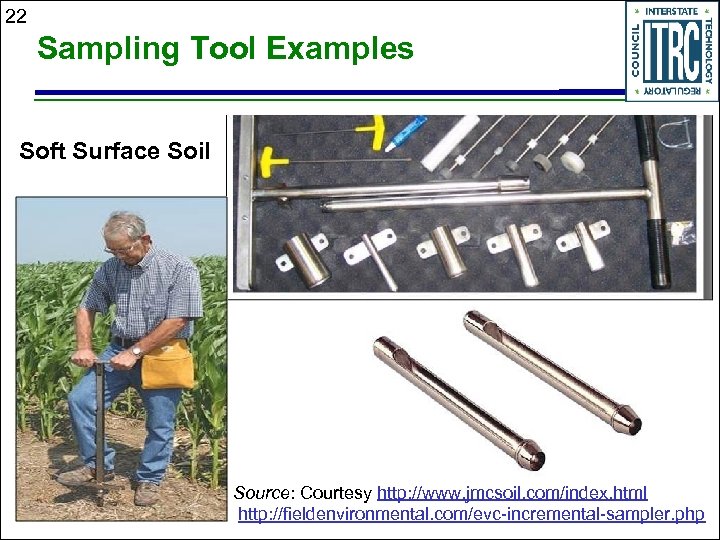

22 Sampling Tool Examples Soft Surface Soil Source: Courtesy http: //www. jmcsoil. com/index. html http: //fieldenvironmental. com/evc-incremental-sampler. php

22 Sampling Tool Examples Soft Surface Soil Source: Courtesy http: //www. jmcsoil. com/index. html http: //fieldenvironmental. com/evc-incremental-sampler. php

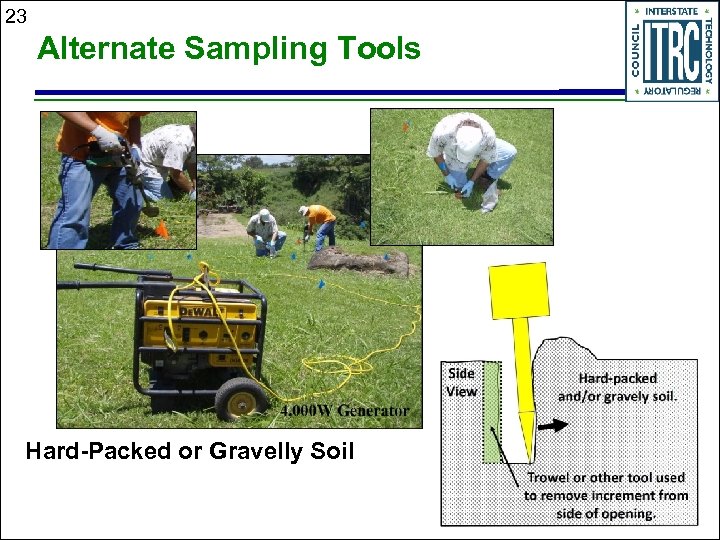

23 Alternate Sampling Tools Hard-Packed or Gravelly Soil

23 Alternate Sampling Tools Hard-Packed or Gravelly Soil

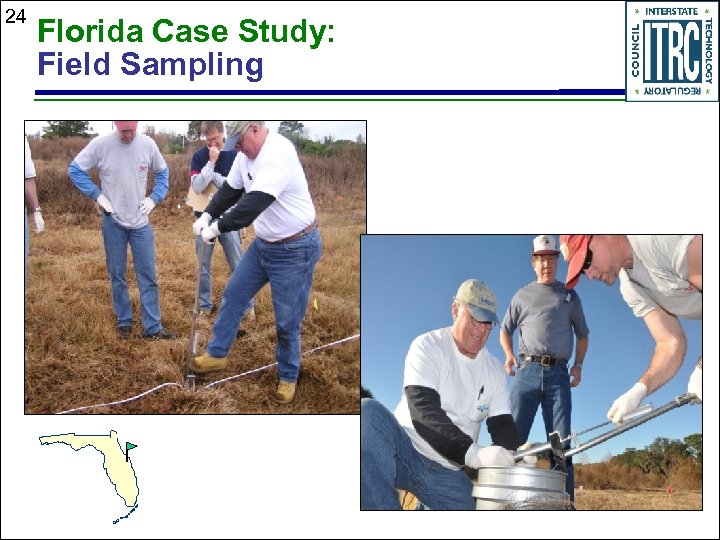

24 Florida Case Study: Field Sampling

24 Florida Case Study: Field Sampling

25 Florida Case Study: “Low Tech” Sampling Tools

25 Florida Case Study: “Low Tech” Sampling Tools

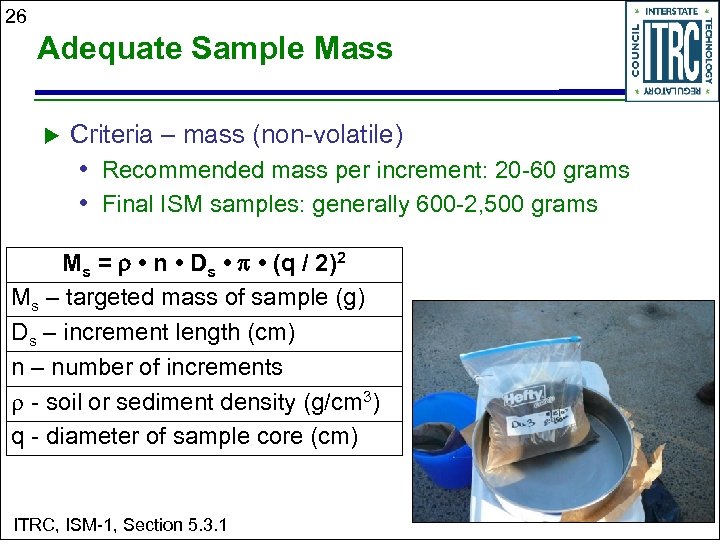

26 Adequate Sample Mass u Criteria – mass (non-volatile) • Recommended mass per increment: 20 -60 grams • Final ISM samples: generally 600 -2, 500 grams Ms = • n • Ds • • (q / 2)2 Ms – targeted mass of sample (g) Ds – increment length (cm) n – number of increments - soil or sediment density (g/cm 3) q - diameter of sample core (cm) ITRC, ISM-1, Section 5. 3. 1

26 Adequate Sample Mass u Criteria – mass (non-volatile) • Recommended mass per increment: 20 -60 grams • Final ISM samples: generally 600 -2, 500 grams Ms = • n • Ds • • (q / 2)2 Ms – targeted mass of sample (g) Ds – increment length (cm) n – number of increments - soil or sediment density (g/cm 3) q - diameter of sample core (cm) ITRC, ISM-1, Section 5. 3. 1

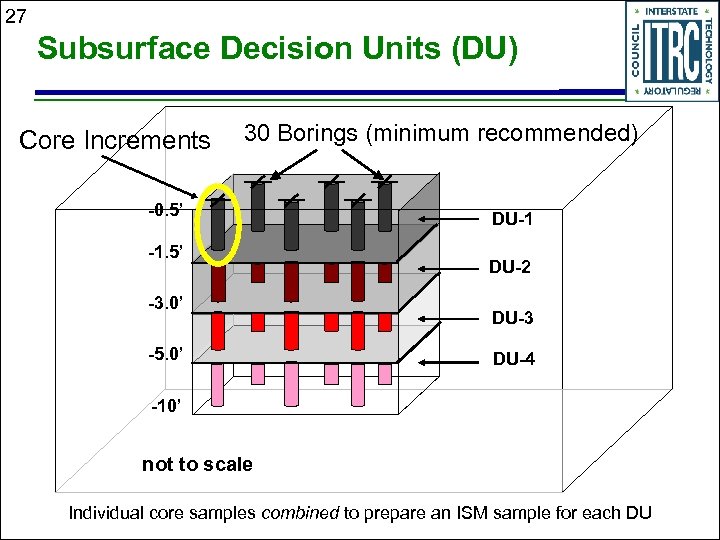

27 Subsurface Decision Units (DU) Core Increments 30 Borings (minimum recommended) -0. 5’ -1. 5’ -3. 0’ -5. 0’ DU-1 DU-2 DU-3 DU-4 -10’ not to scale Individual core samples combined to prepare an ISM sample for each DU

27 Subsurface Decision Units (DU) Core Increments 30 Borings (minimum recommended) -0. 5’ -1. 5’ -3. 0’ -5. 0’ DU-1 DU-2 DU-3 DU-4 -10’ not to scale Individual core samples combined to prepare an ISM sample for each DU

28 Subsurface Sampling Considerations u u Preferred increment – entire core interval Core subsampling alternatives 1. Core wedge 2. Core slice ITRC, ISM-1, Section 5. 3. 2

28 Subsurface Sampling Considerations u u Preferred increment – entire core interval Core subsampling alternatives 1. Core wedge 2. Core slice ITRC, ISM-1, Section 5. 3. 2

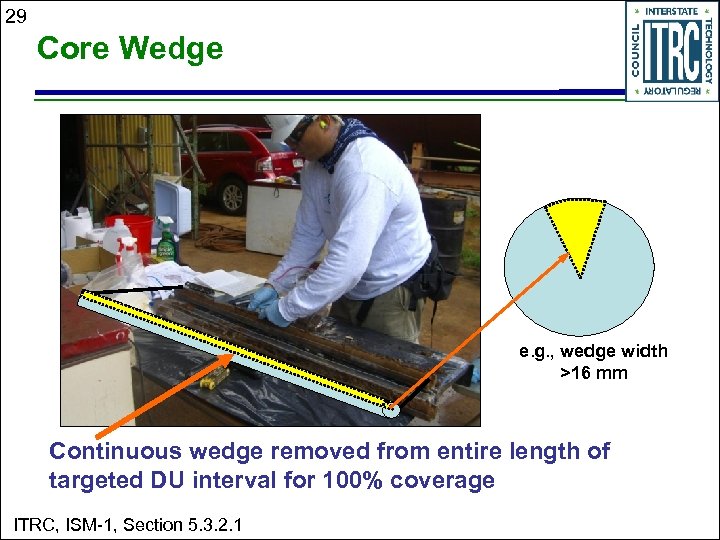

29 Core Wedge e. g. , wedge width >16 mm Continuous wedge removed from entire length of targeted DU interval for 100% coverage ITRC, ISM-1, Section 5. 3. 2. 1

29 Core Wedge e. g. , wedge width >16 mm Continuous wedge removed from entire length of targeted DU interval for 100% coverage ITRC, ISM-1, Section 5. 3. 2. 1

30 Core Slice removed from randomly selected interval length of targeted DU depth ITRC, ISM-1, Section 5. 3. 2. 1

30 Core Slice removed from randomly selected interval length of targeted DU depth ITRC, ISM-1, Section 5. 3. 2. 1

31 Field Processing for Non-Volatiles u u ISM sample processing in a controlled laboratory environment is recommended to reduce error Field processing may be applicable if project specific DQOs can be met ITRC, ISM-1, Section 5. 4. 1

31 Field Processing for Non-Volatiles u u ISM sample processing in a controlled laboratory environment is recommended to reduce error Field processing may be applicable if project specific DQOs can be met ITRC, ISM-1, Section 5. 4. 1

32 Florida Case Study: Non-Volatile ISM Sample Logistics u u Final ISM samples: typically 600 -2, 500 grams or more • Containers, storage, shipping Laboratory • Facilities and equipment for correct processing and subsampling

32 Florida Case Study: Non-Volatile ISM Sample Logistics u u Final ISM samples: typically 600 -2, 500 grams or more • Containers, storage, shipping Laboratory • Facilities and equipment for correct processing and subsampling

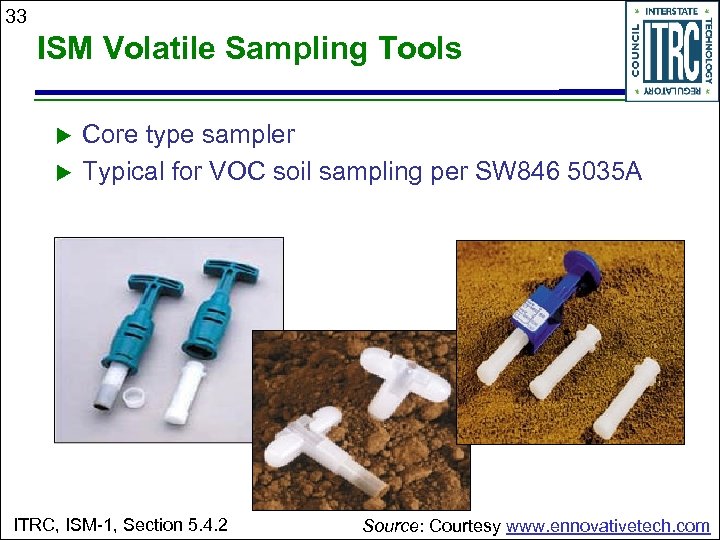

33 ISM Volatile Sampling Tools u u Core type sampler Typical for VOC soil sampling per SW 846 5035 A ITRC, ISM-1, Section 5. 4. 2 Source: Courtesy www. ennovativetech. com

33 ISM Volatile Sampling Tools u u Core type sampler Typical for VOC soil sampling per SW 846 5035 A ITRC, ISM-1, Section 5. 4. 2 Source: Courtesy www. ennovativetech. com

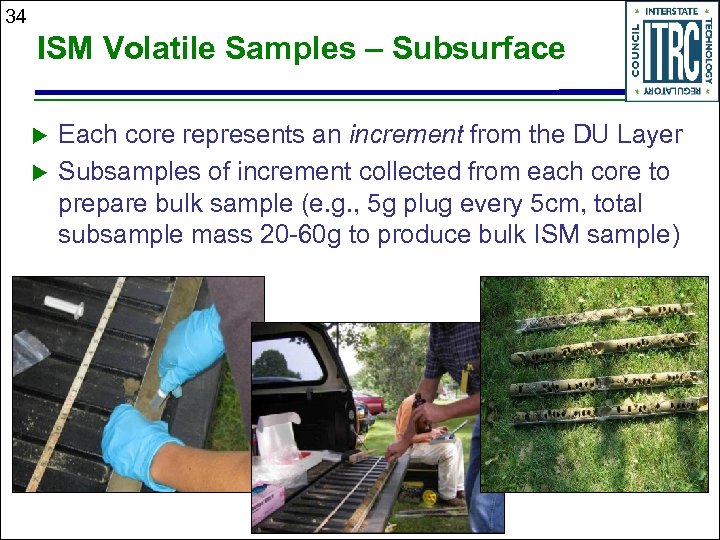

34 ISM Volatile Samples – Subsurface u u Each core represents an increment from the DU Layer Subsamples of increment collected from each core to prepare bulk sample (e. g. , 5 g plug every 5 cm, total subsample mass 20 -60 g to produce bulk ISM sample)

34 ISM Volatile Samples – Subsurface u u Each core represents an increment from the DU Layer Subsamples of increment collected from each core to prepare bulk sample (e. g. , 5 g plug every 5 cm, total subsample mass 20 -60 g to produce bulk ISM sample)

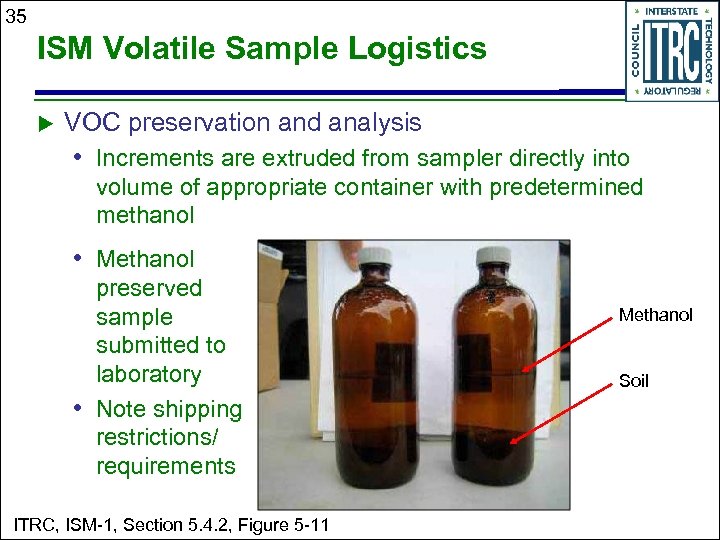

35 ISM Volatile Sample Logistics u VOC preservation and analysis • Increments are extruded from sampler directly into volume of appropriate container with predetermined methanol • Methanol preserved sample submitted to laboratory • Note shipping restrictions/ requirements ITRC, ISM-1, Section 5. 4. 2, Figure 5 -11 Methanol Soil

35 ISM Volatile Sample Logistics u VOC preservation and analysis • Increments are extruded from sampler directly into volume of appropriate container with predetermined methanol • Methanol preserved sample submitted to laboratory • Note shipping restrictions/ requirements ITRC, ISM-1, Section 5. 4. 2, Figure 5 -11 Methanol Soil

36 Replicates Recommended u Increments collected from alternate random locations • Independent samples, not “splits” u Minimum 3 replicate set for statistical evaluations u Additional replicates may be necessary depending on contaminant heterogeneity and project specific DQOs ITRC, ISM-1, Section 5. 3. 5

36 Replicates Recommended u Increments collected from alternate random locations • Independent samples, not “splits” u Minimum 3 replicate set for statistical evaluations u Additional replicates may be necessary depending on contaminant heterogeneity and project specific DQOs ITRC, ISM-1, Section 5. 3. 5

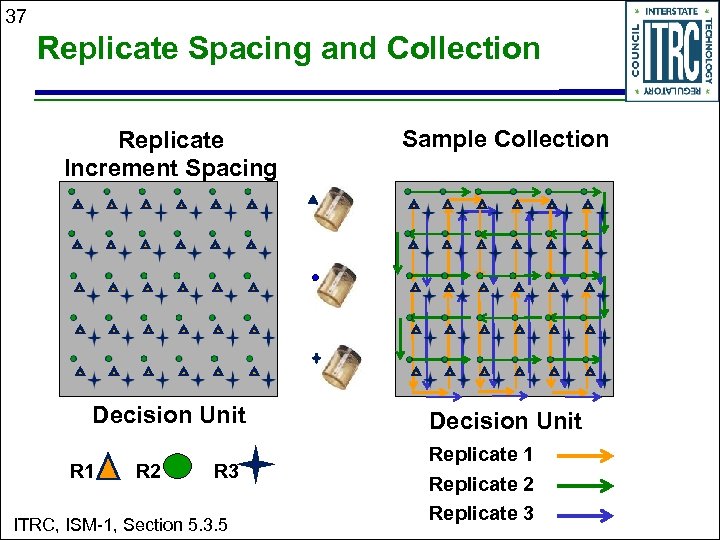

37 Replicate Spacing and Collection Replicate Increment Spacing Sample Collection Decision Unit R 1 R 2 R 3 ITRC, ISM-1, Section 5. 3. 5 Replicate 1 Replicate 2 Replicate 3

37 Replicate Spacing and Collection Replicate Increment Spacing Sample Collection Decision Unit R 1 R 2 R 3 ITRC, ISM-1, Section 5. 3. 5 Replicate 1 Replicate 2 Replicate 3

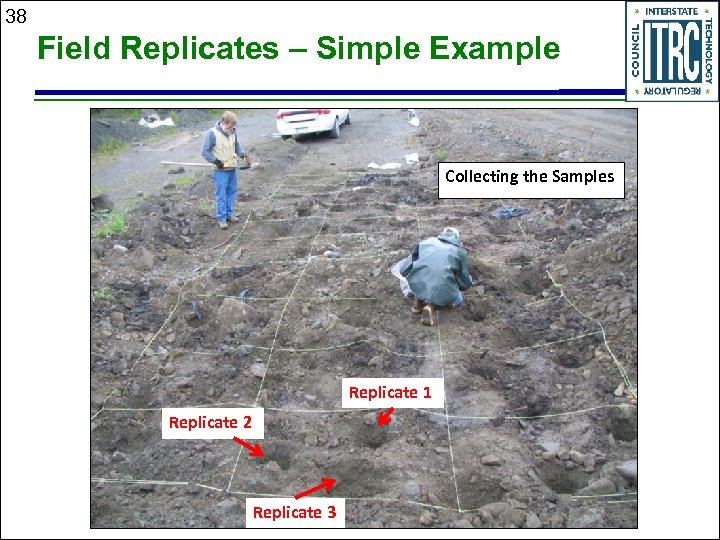

38 Field Replicates – Simple Example Collecting the Samples Replicate 1 Replicate 2 Replicate 3

38 Field Replicates – Simple Example Collecting the Samples Replicate 1 Replicate 2 Replicate 3

39 Replicate/Sampling Reminders u Replicates • • u What type How many Where/when will they be collected How will they be evaluated “Homogenizing” or mixing not necessary • Laboratory processing and subsampling (following module) designed to attain representative analytical sample

39 Replicate/Sampling Reminders u Replicates • • u What type How many Where/when will they be collected How will they be evaluated “Homogenizing” or mixing not necessary • Laboratory processing and subsampling (following module) designed to attain representative analytical sample

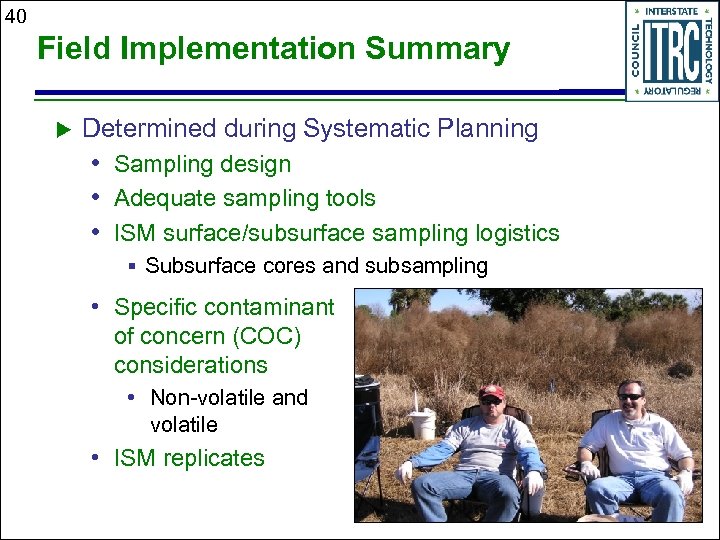

40 Field Implementation Summary u Determined during Systematic Planning • Sampling design • Adequate sampling tools • ISM surface/subsurface sampling logistics § Subsurface cores and subsampling • Specific contaminant of concern (COC) considerations • Non-volatile and volatile • ISM replicates

40 Field Implementation Summary u Determined during Systematic Planning • Sampling design • Adequate sampling tools • ISM surface/subsurface sampling logistics § Subsurface cores and subsampling • Specific contaminant of concern (COC) considerations • Non-volatile and volatile • ISM replicates

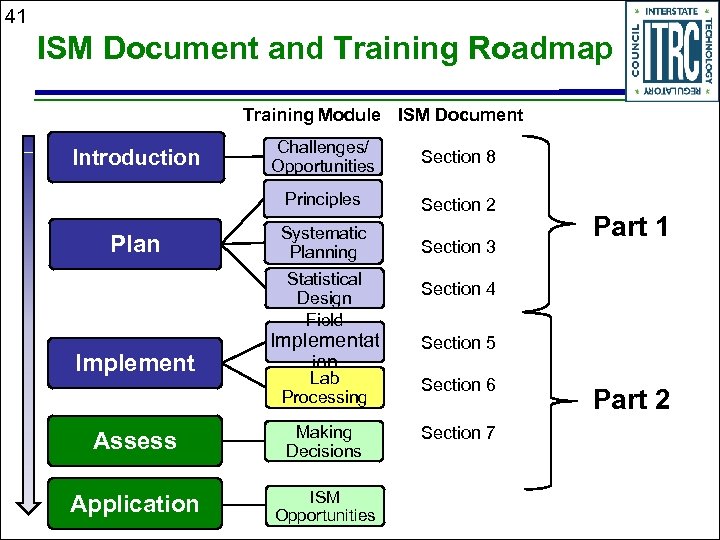

41 ISM Document and Training Roadmap Training Module ISM Document Plan Challenges/ Opportunities Section 8 Principles Introduction Section 2 Systematic Planning Statistical Design Field Implementat ion Section 3 Part 1 Section 4 Section 5 Lab Processing Section 6 Assess Making Decisions Section 7 Application ISM Opportunities Part 2

41 ISM Document and Training Roadmap Training Module ISM Document Plan Challenges/ Opportunities Section 8 Principles Introduction Section 2 Systematic Planning Statistical Design Field Implementat ion Section 3 Part 1 Section 4 Section 5 Lab Processing Section 6 Assess Making Decisions Section 7 Application ISM Opportunities Part 2

42 Laboratory Processing Learning Objectives Learn how to: u Match process options to analytes and data objectives u Manage sample moisture u Select/reduce particle size u Collect subsamples for analysis u Apply Quality Assurance u Examine options for lab certification

42 Laboratory Processing Learning Objectives Learn how to: u Match process options to analytes and data objectives u Manage sample moisture u Select/reduce particle size u Collect subsamples for analysis u Apply Quality Assurance u Examine options for lab certification

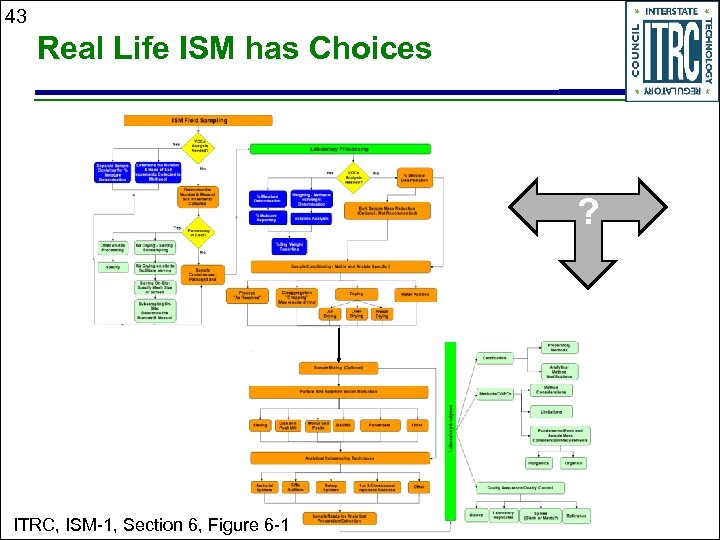

43 Real Life ISM has Choices ? ITRC, ISM-1, Section 6, Figure 6 -1

43 Real Life ISM has Choices ? ITRC, ISM-1, Section 6, Figure 6 -1

44 Analyte-Matrix Driven Options u Pick the right option • More representative subsamples • Better precision u Pick the wrong option • Poor and unknown bias

44 Analyte-Matrix Driven Options u Pick the right option • More representative subsamples • Better precision u Pick the wrong option • Poor and unknown bias

45 Include Lab Processing in Project Planning Lab ITRC, ISM-1, Section 6. 1. 1

45 Include Lab Processing in Project Planning Lab ITRC, ISM-1, Section 6. 1. 1

46 Define the Analytes u u u u u Volatile organics Energetics Metals, Hg PCBs Organochlorine pesticides Phenoxy acid herbicides Petroleum hydrocarbons Semivolatile organics Other

46 Define the Analytes u u u u u Volatile organics Energetics Metals, Hg PCBs Organochlorine pesticides Phenoxy acid herbicides Petroleum hydrocarbons Semivolatile organics Other

47 Coordinate VOC Sampling & Analysis u Use methanol preservation • Methanol transport • Bottle sizes (large, medium, small) u Analytical sensitivity limitations • Higher reporting limits • Selected Ion Monitoring GC-MS § Short analyte lists ITRC, ISM-1, Section 6. 2. 1

47 Coordinate VOC Sampling & Analysis u Use methanol preservation • Methanol transport • Bottle sizes (large, medium, small) u Analytical sensitivity limitations • Higher reporting limits • Selected Ion Monitoring GC-MS § Short analyte lists ITRC, ISM-1, Section 6. 2. 1

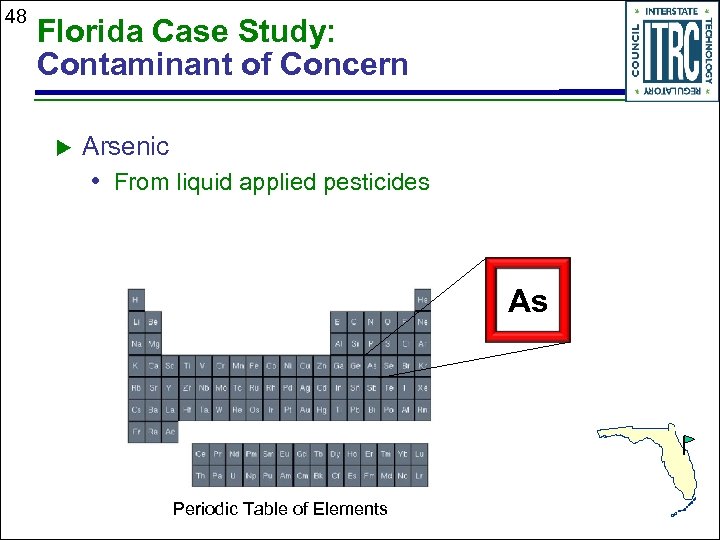

48 Florida Case Study: Contaminant of Concern u Arsenic • From liquid applied pesticides As Periodic Table of Elements

48 Florida Case Study: Contaminant of Concern u Arsenic • From liquid applied pesticides As Periodic Table of Elements

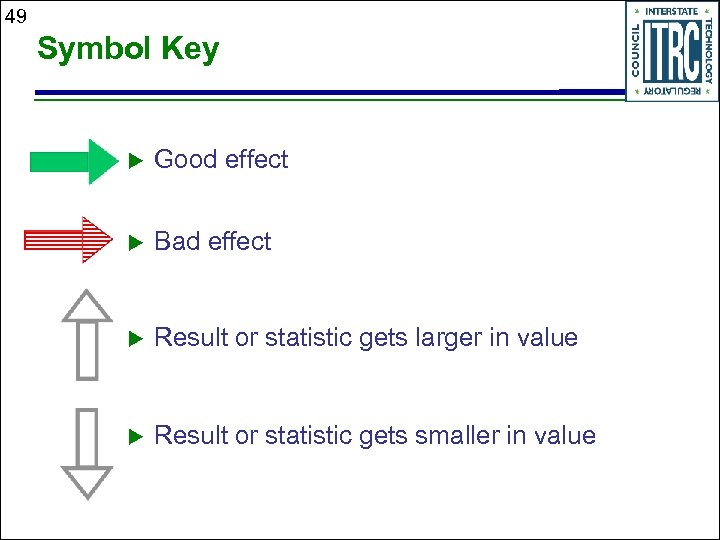

49 Symbol Key u Good effect u Bad effect u Result or statistic gets larger in value u Result or statistic gets smaller in value

49 Symbol Key u Good effect u Bad effect u Result or statistic gets larger in value u Result or statistic gets smaller in value

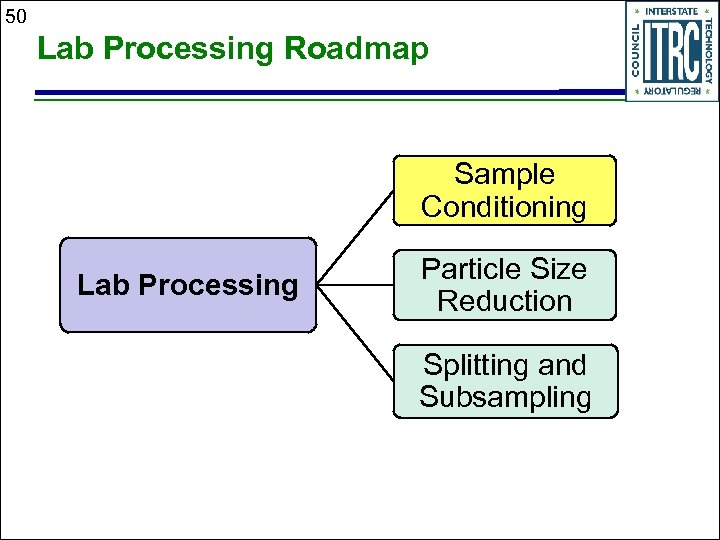

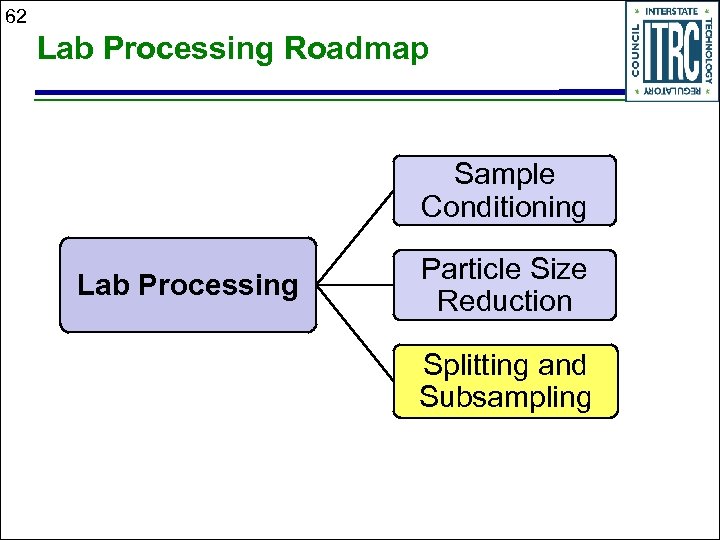

50 Lab Processing Roadmap Sample Conditioning Lab Processing Particle Size Reduction Splitting and Subsampling

50 Lab Processing Roadmap Sample Conditioning Lab Processing Particle Size Reduction Splitting and Subsampling

51 Condition the Sample u Air drying • • Room temperature – most common Ventilation hood Goal: Crushable agglomerates Consider volatilization losses § Boiling point § Binding to soil particles § Potential for Loss Table – Naphthalene – Acenaphthene – Benzo[a]pyrene u Use other options when drying not appropriate ITRC, ISM-1, Section 6. 2. 2. 3

51 Condition the Sample u Air drying • • Room temperature – most common Ventilation hood Goal: Crushable agglomerates Consider volatilization losses § Boiling point § Binding to soil particles § Potential for Loss Table – Naphthalene – Acenaphthene – Benzo[a]pyrene u Use other options when drying not appropriate ITRC, ISM-1, Section 6. 2. 2. 3

52 Florida Case Study: Air Drying Samples u Arsenic • High boiling arsenic species • Volatilization loss not expected ITRC, ISM-1, Section 9, Appendix C

52 Florida Case Study: Air Drying Samples u Arsenic • High boiling arsenic species • Volatilization loss not expected ITRC, ISM-1, Section 9, Appendix C

53 Define Terms: Grinding u u Generic term for soil disaggregation or milling The grinding type or equipment must be specified to select a particular laboratory process

53 Define Terms: Grinding u u Generic term for soil disaggregation or milling The grinding type or equipment must be specified to select a particular laboratory process

54 Define Terms: Disaggregating u Breaking all the soil clumps into individual small particles, but keeping the small pebbles and hard crystalline particles intact ITRC, ISM-1, Section 6. 2. 2. 3

54 Define Terms: Disaggregating u Breaking all the soil clumps into individual small particles, but keeping the small pebbles and hard crystalline particles intact ITRC, ISM-1, Section 6. 2. 2. 3

55 Define Terms: Milling u Complete particle size reduction of all soil components including hard crystalline materials to a defined maximum particle size (e. g. < 75 µm) Picture from USACE-Alan Hewitt ITRC, ISM-1, Section 6. 2. 2. 5

55 Define Terms: Milling u Complete particle size reduction of all soil components including hard crystalline materials to a defined maximum particle size (e. g. < 75 µm) Picture from USACE-Alan Hewitt ITRC, ISM-1, Section 6. 2. 2. 5

56 Florida Case Study: Particle Size Reduction u Disaggregation and sieving • Nugget effect expected to be small § Contaminant exposure sprayed as a liquid u Mill • Puck mill u Comparison study planned

56 Florida Case Study: Particle Size Reduction u Disaggregation and sieving • Nugget effect expected to be small § Contaminant exposure sprayed as a liquid u Mill • Puck mill u Comparison study planned

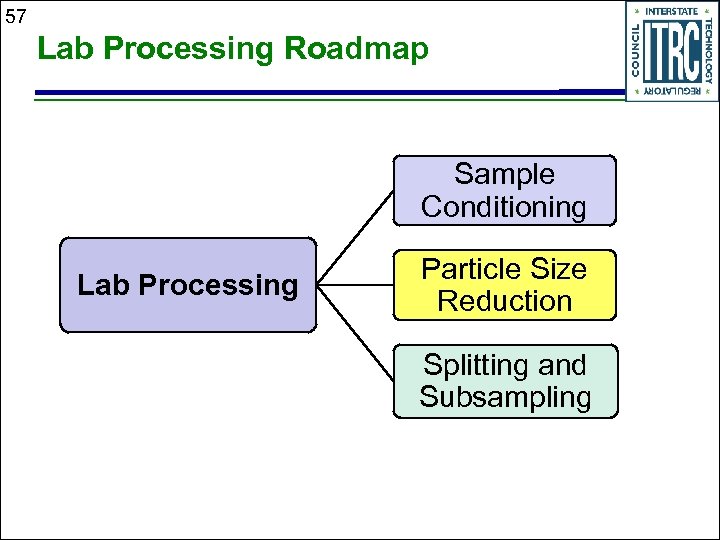

57 Lab Processing Roadmap Sample Conditioning Lab Processing Particle Size Reduction Splitting and Subsampling

57 Lab Processing Roadmap Sample Conditioning Lab Processing Particle Size Reduction Splitting and Subsampling

58 To Mill or Not to Mill? (Particle Size Reduction) u Recommended • Crystalline particles, fibrous threads, paint chips • Energetics, metals u Strengths • Reduces variability • Reduces subsampling error • Facilitates mixing • Improves precision ITRC, ISM-1, Section 6. 2. 2. 5 Picture from USACE-Alan Hewitt

58 To Mill or Not to Mill? (Particle Size Reduction) u Recommended • Crystalline particles, fibrous threads, paint chips • Energetics, metals u Strengths • Reduces variability • Reduces subsampling error • Facilitates mixing • Improves precision ITRC, ISM-1, Section 6. 2. 2. 5 Picture from USACE-Alan Hewitt

59 To Mill or Not to Mill u Not recommended • Volatile, thermally labile, increased “availability” • Examples § Monochloro PCBs, reactive SVOCs, decane, elemental mercury • Limitations § Analyte losses § Metals contamination § Potential high bias to metals risk assessment (pebbles) ITRC, ISM-1, Section 6. 2. 2. 5 If uncertain, do milled & unmilled

59 To Mill or Not to Mill u Not recommended • Volatile, thermally labile, increased “availability” • Examples § Monochloro PCBs, reactive SVOCs, decane, elemental mercury • Limitations § Analyte losses § Metals contamination § Potential high bias to metals risk assessment (pebbles) ITRC, ISM-1, Section 6. 2. 2. 5 If uncertain, do milled & unmilled

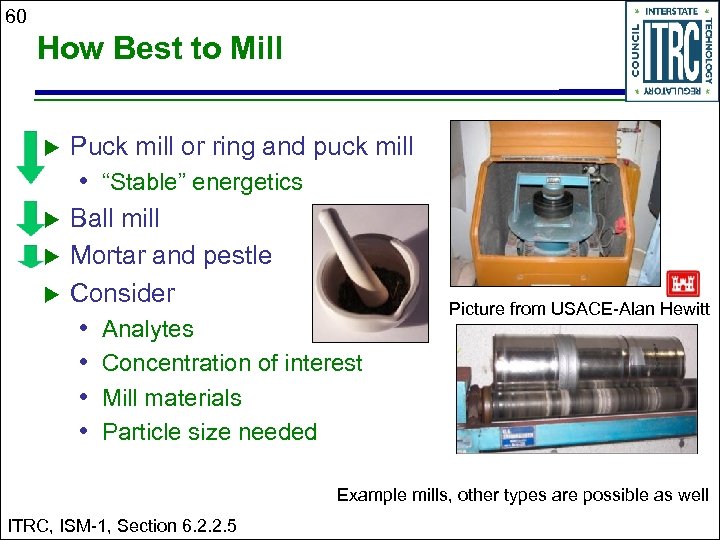

60 How Best to Mill u Puck mill or ring and puck mill • “Stable” energetics u u u Ball mill Mortar and pestle Consider • • Analytes Concentration of interest Mill materials Particle size needed Picture from USACE-Alan Hewitt Example mills, other types are possible as well ITRC, ISM-1, Section 6. 2. 2. 5

60 How Best to Mill u Puck mill or ring and puck mill • “Stable” energetics u u u Ball mill Mortar and pestle Consider • • Analytes Concentration of interest Mill materials Particle size needed Picture from USACE-Alan Hewitt Example mills, other types are possible as well ITRC, ISM-1, Section 6. 2. 2. 5

61 Florida Case Study: Results Confirm Milling Not Needed u Disaggregation and sieving • Nugget effect expected to be small § Contaminant exposure sprayed as a liquid u Mill • Puck mill u Results confirm milling not needed for this part of site • Small precision improvement with milling • No change in mean concentration

61 Florida Case Study: Results Confirm Milling Not Needed u Disaggregation and sieving • Nugget effect expected to be small § Contaminant exposure sprayed as a liquid u Mill • Puck mill u Results confirm milling not needed for this part of site • Small precision improvement with milling • No change in mean concentration

62 Lab Processing Roadmap Sample Conditioning Lab Processing Particle Size Reduction Splitting and Subsampling

62 Lab Processing Roadmap Sample Conditioning Lab Processing Particle Size Reduction Splitting and Subsampling

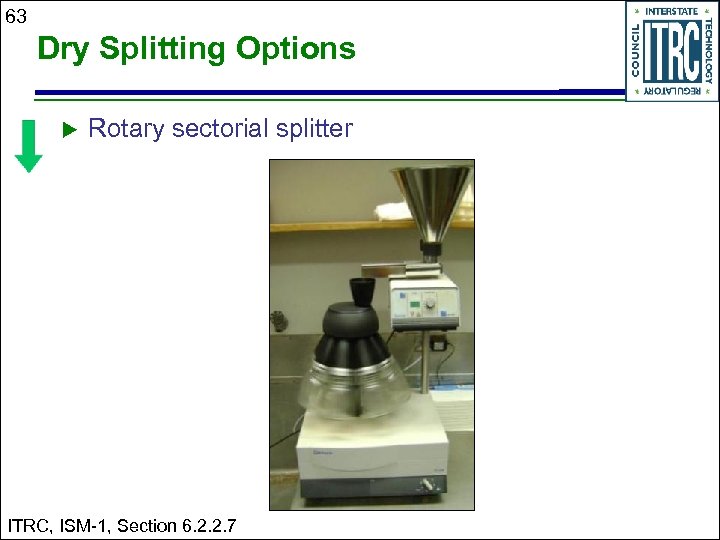

63 Dry Splitting Options u Rotary sectorial splitter ITRC, ISM-1, Section 6. 2. 2. 7

63 Dry Splitting Options u Rotary sectorial splitter ITRC, ISM-1, Section 6. 2. 2. 7

64 Subsampling Options u 2 -Dimensional Japanese Slabcake Dry Wet ITRC, ISM-1, Section 6. 2. 2. 7

64 Subsampling Options u 2 -Dimensional Japanese Slabcake Dry Wet ITRC, ISM-1, Section 6. 2. 2. 7

65 Subsampling Tools Square straight-sided scoops for dry non-cohesive soil u

65 Subsampling Tools Square straight-sided scoops for dry non-cohesive soil u

66 Florida Case Study: Choose Subsampling Process u 2 -D Slabcake Subsampling • Lower cost than sectorial splitter • More representative than “dig a spot”

66 Florida Case Study: Choose Subsampling Process u 2 -D Slabcake Subsampling • Lower cost than sectorial splitter • More representative than “dig a spot”

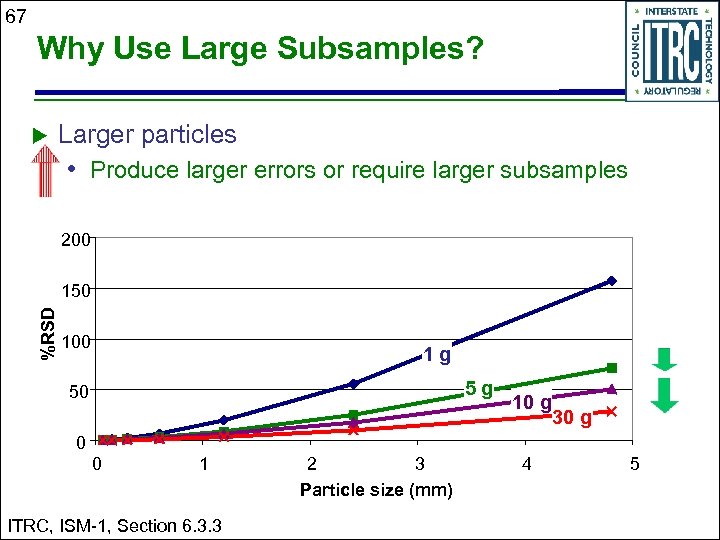

67 Why Use Large Subsamples? u Larger particles • Produce larger errors or require larger subsamples 200 %RSD 150 100 1 g 5 g 50 10 g 30 g 0 0 1 ITRC, ISM-1, Section 6. 3. 3 2 3 Particle size (mm) 4 5

67 Why Use Large Subsamples? u Larger particles • Produce larger errors or require larger subsamples 200 %RSD 150 100 1 g 5 g 50 10 g 30 g 0 0 1 ITRC, ISM-1, Section 6. 3. 3 2 3 Particle size (mm) 4 5

68 Florida Case Study: Nugget Effect Minimal u 2 g subsamples on disaggregated aliquots 2 g subsamples on milled aliquots u Low heterogeneity expected u • Confirmed through replicates

68 Florida Case Study: Nugget Effect Minimal u 2 g subsamples on disaggregated aliquots 2 g subsamples on milled aliquots u Low heterogeneity expected u • Confirmed through replicates

69 Laboratory Quality Control Measures u Laboratory equipment blanks • Limited clean matrices u Laboratory control samples (LCS) and matrix spikes • Practicality of large scale spiking in kg samples § High cost § Limited availability • Introduced post ISM processing into subsample u Subsampling replicates

69 Laboratory Quality Control Measures u Laboratory equipment blanks • Limited clean matrices u Laboratory control samples (LCS) and matrix spikes • Practicality of large scale spiking in kg samples § High cost § Limited availability • Introduced post ISM processing into subsample u Subsampling replicates

70 Florida Case Study: Challenges with “Blank” Samples u Ottawa sand method blank attempted for milling • Metals content of the sand was too variable u Standard preparation batch QC • No laboratory control sample or matrix spike through ISM processes

70 Florida Case Study: Challenges with “Blank” Samples u Ottawa sand method blank attempted for milling • Metals content of the sand was too variable u Standard preparation batch QC • No laboratory control sample or matrix spike through ISM processes

71 Verify Laboratory Certification u National Environmental Laboratory Accreditation Program (NELAP) u Non-NELAP state accreditation u Agency-specific accreditation • Do. D Environmental Laboratory Approval Program ITRC, ISM-1, Section 6. 4. 1

71 Verify Laboratory Certification u National Environmental Laboratory Accreditation Program (NELAP) u Non-NELAP state accreditation u Agency-specific accreditation • Do. D Environmental Laboratory Approval Program ITRC, ISM-1, Section 6. 4. 1

72 Cite Reference Methods u Collecting and Processing of Representative Samples For Energetic Residues in Solid Matrices from Military Training Ranges • USEPA SW-846 Method 8330 B, Appendix A http: //www. epa. gov/osw/hazard/testmethods/pdfs/8330 b. pdf u Metals in Solid Matrices • USACE research effort • Planned SW-846 Method 3050 - Update V? ITRC, ISM-1, Section 6. 4. 1

72 Cite Reference Methods u Collecting and Processing of Representative Samples For Energetic Residues in Solid Matrices from Military Training Ranges • USEPA SW-846 Method 8330 B, Appendix A http: //www. epa. gov/osw/hazard/testmethods/pdfs/8330 b. pdf u Metals in Solid Matrices • USACE research effort • Planned SW-846 Method 3050 - Update V? ITRC, ISM-1, Section 6. 4. 1

73 Use Alternate References u ASTM D 6323 Standard Guide for Laboratory Subsampling of Media Related to Waste Management Activities • ASTM 2003 u Guidance for Obtaining Representative Laboratory Analytical Subsamples from Particulate Laboratory Samples • Gerlach 2003 u Laboratory Standard Operating Procedure ITRC, ISM-1, Section 6. 4. 1

73 Use Alternate References u ASTM D 6323 Standard Guide for Laboratory Subsampling of Media Related to Waste Management Activities • ASTM 2003 u Guidance for Obtaining Representative Laboratory Analytical Subsamples from Particulate Laboratory Samples • Gerlach 2003 u Laboratory Standard Operating Procedure ITRC, ISM-1, Section 6. 4. 1

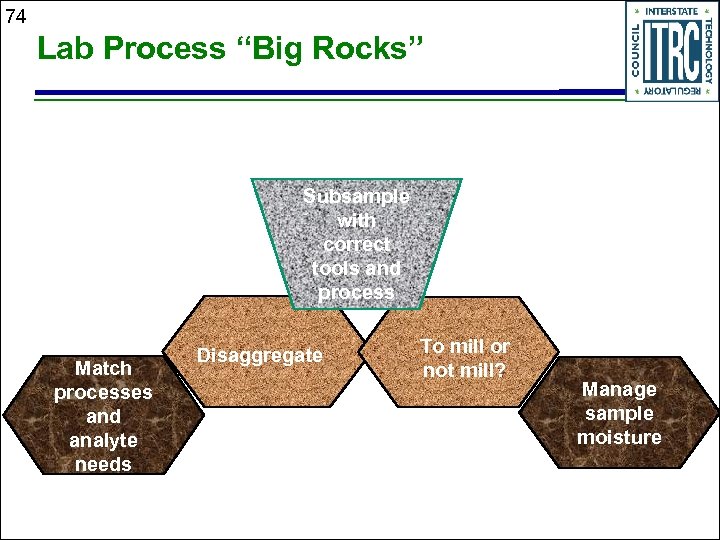

74 Lab Process “Big Rocks” Subsample with correct tools and process Match processes and analyte needs Disaggregate To mill or not mill? Manage sample moisture

74 Lab Process “Big Rocks” Subsample with correct tools and process Match processes and analyte needs Disaggregate To mill or not mill? Manage sample moisture

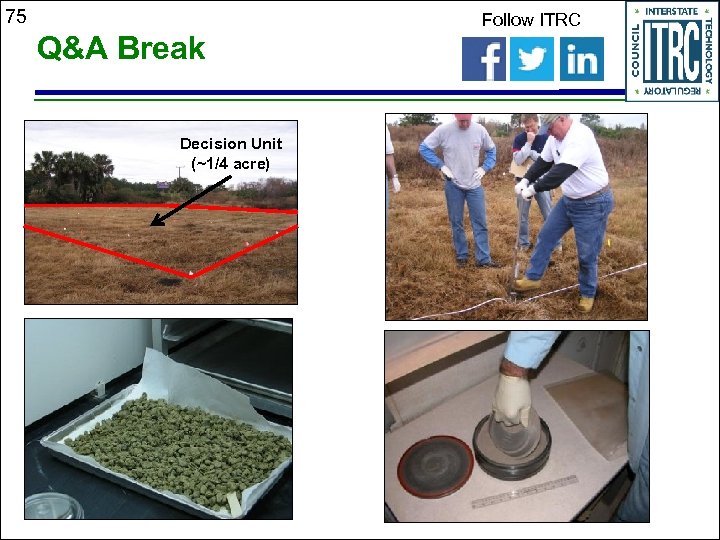

75 Q&A Break Decision Unit (~1/4 acre) Follow ITRC

75 Q&A Break Decision Unit (~1/4 acre) Follow ITRC

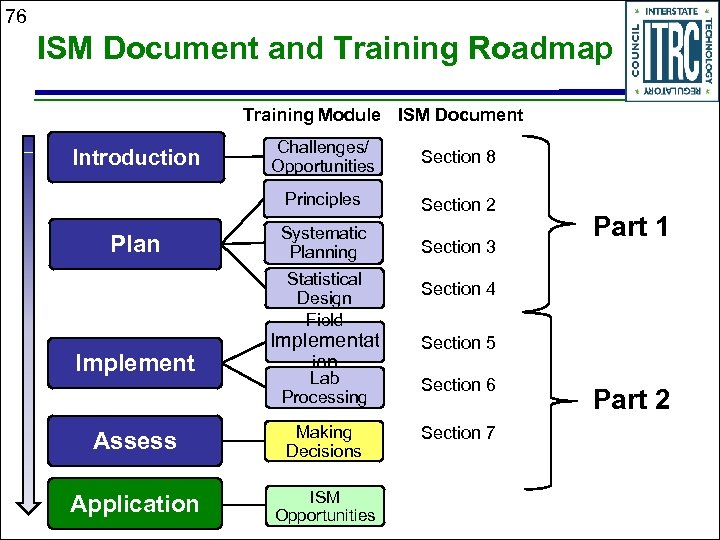

76 ISM Document and Training Roadmap Training Module ISM Document Plan Challenges/ Opportunities Section 8 Principles Introduction Section 2 Systematic Planning Statistical Design Field Implementat ion Section 3 Part 1 Section 4 Section 5 Lab Processing Section 6 Assess Making Decisions Section 7 Application ISM Opportunities Part 2

76 ISM Document and Training Roadmap Training Module ISM Document Plan Challenges/ Opportunities Section 8 Principles Introduction Section 2 Systematic Planning Statistical Design Field Implementat ion Section 3 Part 1 Section 4 Section 5 Lab Processing Section 6 Assess Making Decisions Section 7 Application ISM Opportunities Part 2

77 Making Decisions: Learning Objectives Learn how to: u Use ISM data to make decisions u Evaluate data • Identifying sources of error • Quantify error • Interpret error • Isolate sources of error

77 Making Decisions: Learning Objectives Learn how to: u Use ISM data to make decisions u Evaluate data • Identifying sources of error • Quantify error • Interpret error • Isolate sources of error

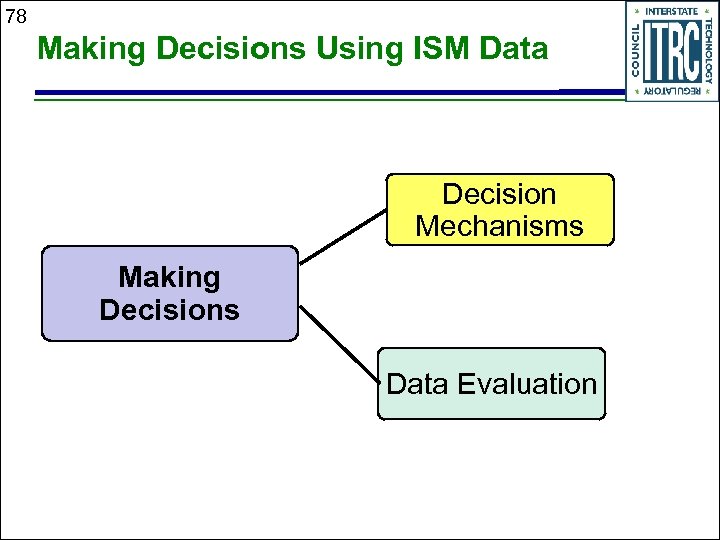

78 Making Decisions Using ISM Data Decision Mechanisms Making Decisions Data Evaluation

78 Making Decisions Using ISM Data Decision Mechanisms Making Decisions Data Evaluation

79 Making Decisions u Decision Mechanism (DM) • Structured approach to making decisions • Identified and agreed upon during Data Quality Objective (DQO) process • 6 common types of DM

79 Making Decisions u Decision Mechanism (DM) • Structured approach to making decisions • Identified and agreed upon during Data Quality Objective (DQO) process • 6 common types of DM

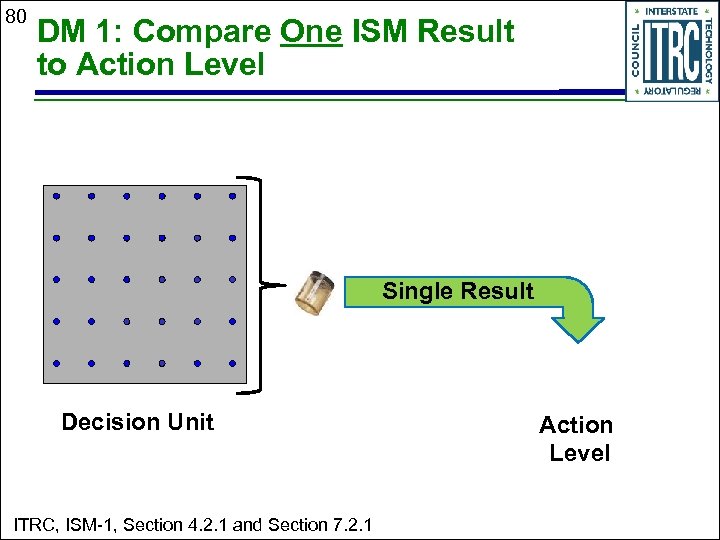

80 DM 1: Compare One ISM Result to Action Level Single Result Decision Unit ITRC, ISM-1, Section 4. 2. 1 and Section 7. 2. 1 Action Level

80 DM 1: Compare One ISM Result to Action Level Single Result Decision Unit ITRC, ISM-1, Section 4. 2. 1 and Section 7. 2. 1 Action Level

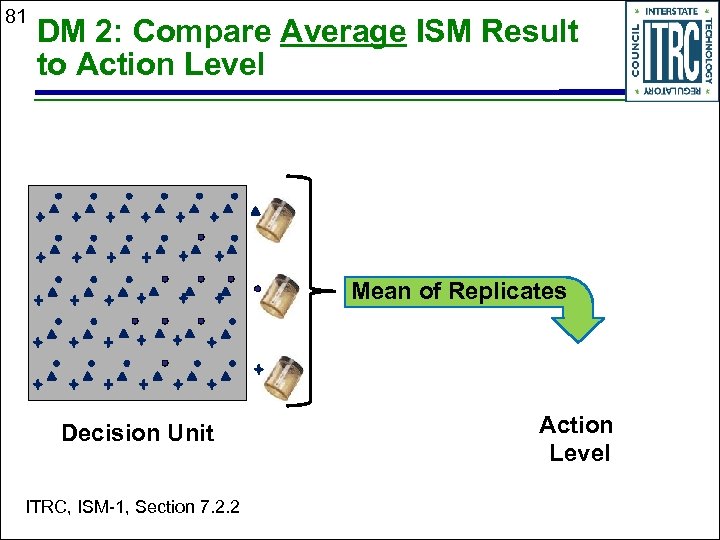

81 DM 2: Compare Average ISM Result to Action Level Mean of Replicates Decision Unit ITRC, ISM-1, Section 7. 2. 2 Action Level

81 DM 2: Compare Average ISM Result to Action Level Mean of Replicates Decision Unit ITRC, ISM-1, Section 7. 2. 2 Action Level

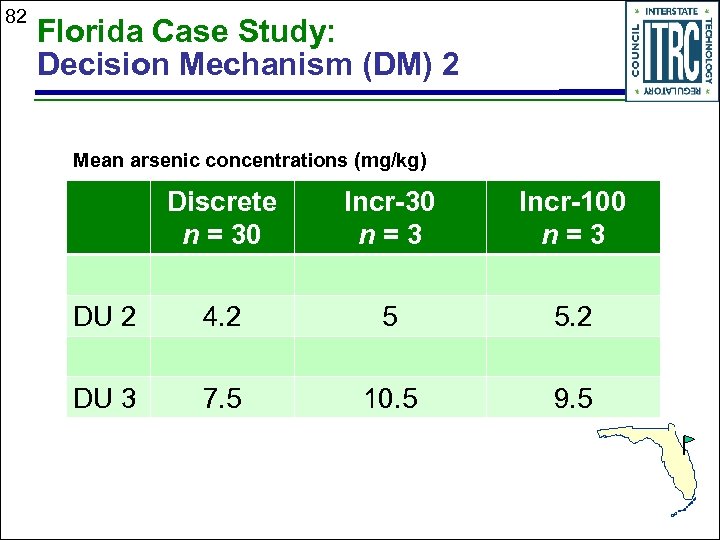

82 Florida Case Study: Decision Mechanism (DM) 2 Mean arsenic concentrations (mg/kg) Discrete n = 30 Incr-30 n=3 Incr-100 n=3 DU 2 4. 2 5 5. 2 DU 3 7. 5 10. 5 9. 5

82 Florida Case Study: Decision Mechanism (DM) 2 Mean arsenic concentrations (mg/kg) Discrete n = 30 Incr-30 n=3 Incr-100 n=3 DU 2 4. 2 5 5. 2 DU 3 7. 5 10. 5 9. 5

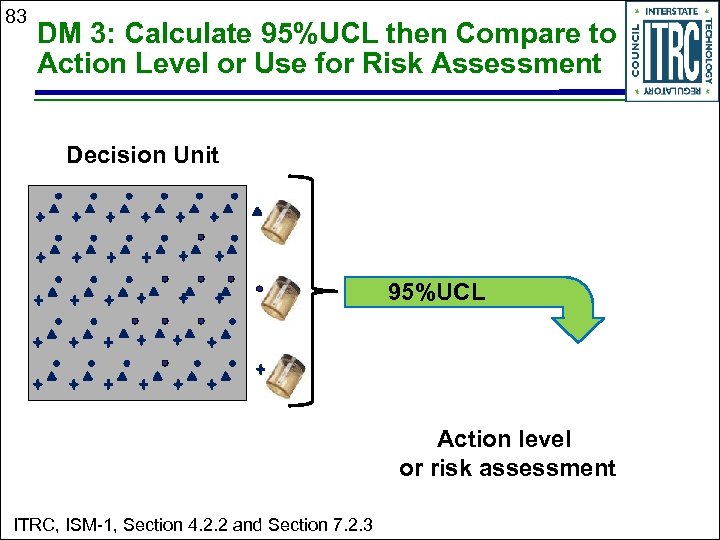

83 DM 3: Calculate 95%UCL then Compare to Action Level or Use for Risk Assessment Decision Unit 95%UCL Action level or risk assessment ITRC, ISM-1, Section 4. 2. 2 and Section 7. 2. 3

83 DM 3: Calculate 95%UCL then Compare to Action Level or Use for Risk Assessment Decision Unit 95%UCL Action level or risk assessment ITRC, ISM-1, Section 4. 2. 2 and Section 7. 2. 3

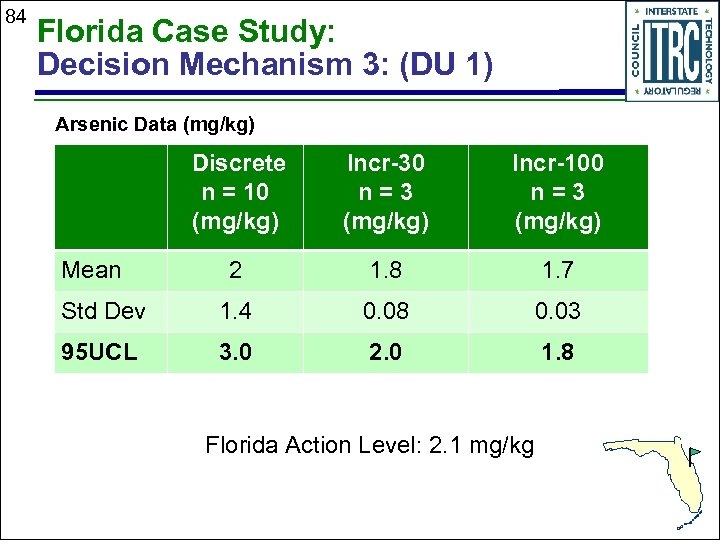

84 Florida Case Study: Decision Mechanism 3: (DU 1) Arsenic Data (mg/kg) Discrete n = 10 (mg/kg) Incr-30 n=3 (mg/kg) Incr-100 n=3 (mg/kg) 2 1. 8 1. 7 Std Dev 1. 4 0. 08 0. 03 95 UCL 3. 0 2. 0 1. 8 Mean Florida Action Level: 2. 1 mg/kg

84 Florida Case Study: Decision Mechanism 3: (DU 1) Arsenic Data (mg/kg) Discrete n = 10 (mg/kg) Incr-30 n=3 (mg/kg) Incr-100 n=3 (mg/kg) 2 1. 8 1. 7 Std Dev 1. 4 0. 08 0. 03 95 UCL 3. 0 2. 0 1. 8 Mean Florida Action Level: 2. 1 mg/kg

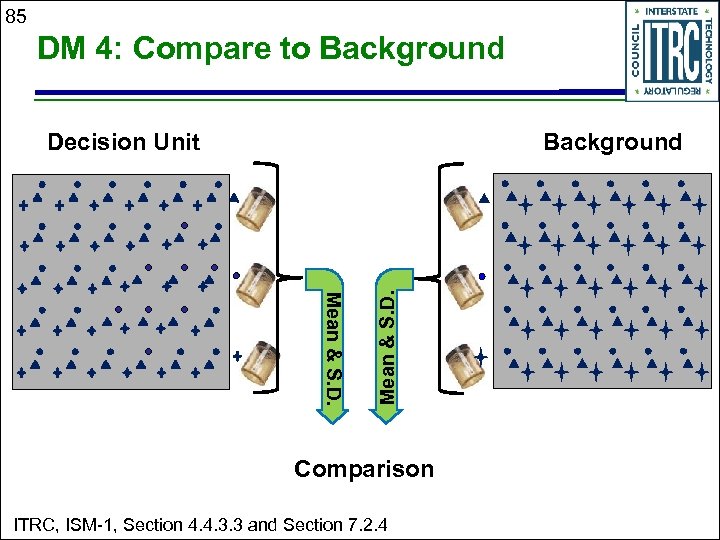

85 DM 4: Compare to Background Decision Unit Mean & S. D. Background Comparison ITRC, ISM-1, Section 4. 4. 3. 3 and Section 7. 2. 4

85 DM 4: Compare to Background Decision Unit Mean & S. D. Background Comparison ITRC, ISM-1, Section 4. 4. 3. 3 and Section 7. 2. 4

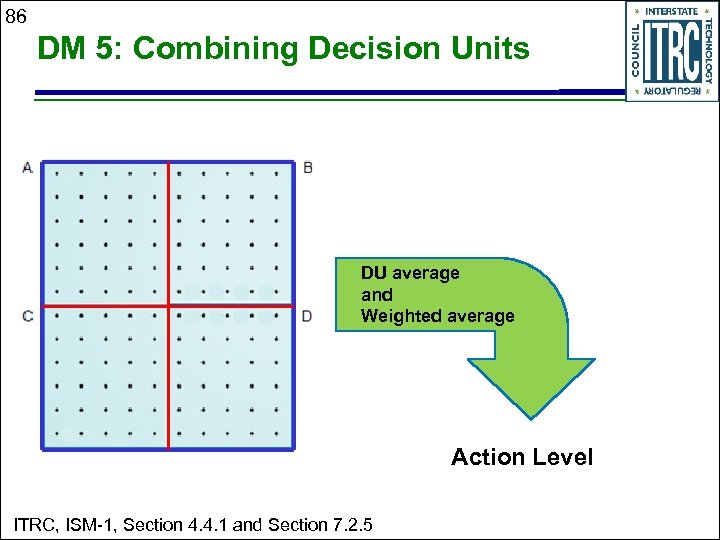

86 DM 5: Combining Decision Units DU average and Weighted average Action Level ITRC, ISM-1, Section 4. 4. 1 and Section 7. 2. 5

86 DM 5: Combining Decision Units DU average and Weighted average Action Level ITRC, ISM-1, Section 4. 4. 1 and Section 7. 2. 5

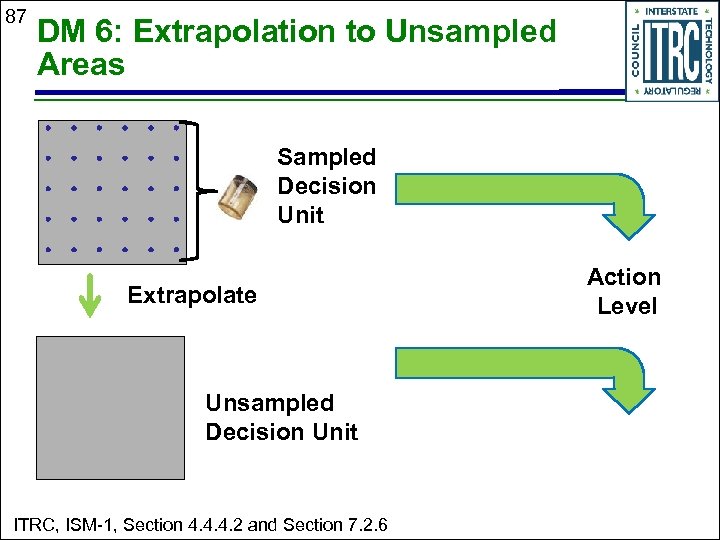

87 DM 6: Extrapolation to Unsampled Areas Sampled Decision Unit Extrapolate Unsampled Decision Unit ITRC, ISM-1, Section 4. 4. 4. 2 and Section 7. 2. 6 Action Level

87 DM 6: Extrapolation to Unsampled Areas Sampled Decision Unit Extrapolate Unsampled Decision Unit ITRC, ISM-1, Section 4. 4. 4. 2 and Section 7. 2. 6 Action Level

88 Making Decisions Using ISM Data Decision Mechanisms Making Decisions Data Evaluation

88 Making Decisions Using ISM Data Decision Mechanisms Making Decisions Data Evaluation

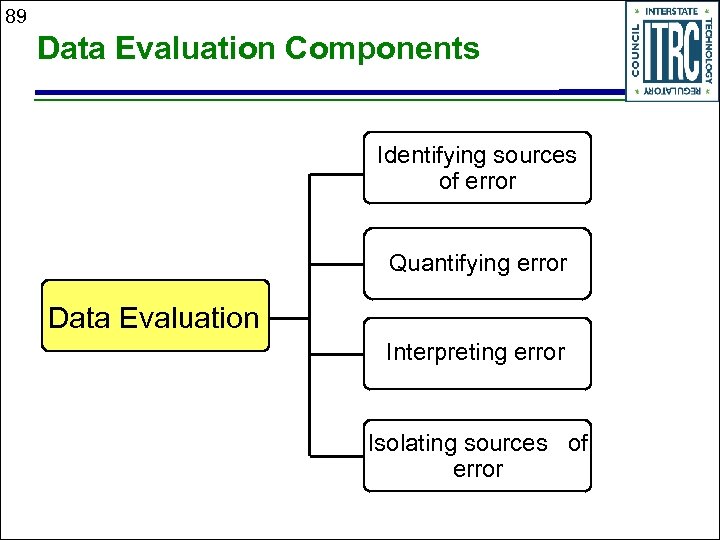

89 Data Evaluation Components Identifying sources of error Quantifying error Data Evaluation Interpreting error Isolating sources of error

89 Data Evaluation Components Identifying sources of error Quantifying error Data Evaluation Interpreting error Isolating sources of error

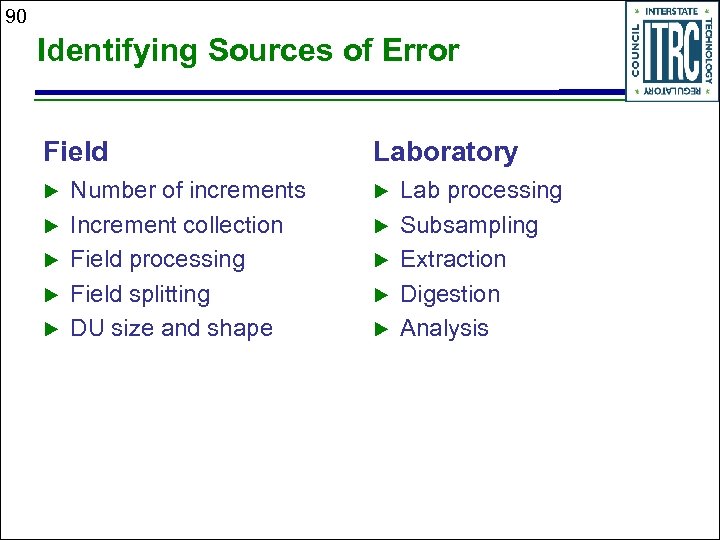

90 Identifying Sources of Error Field u u u Number of increments Increment collection Field processing Field splitting DU size and shape Laboratory u u u Lab processing Subsampling Extraction Digestion Analysis

90 Identifying Sources of Error Field u u u Number of increments Increment collection Field processing Field splitting DU size and shape Laboratory u u u Lab processing Subsampling Extraction Digestion Analysis

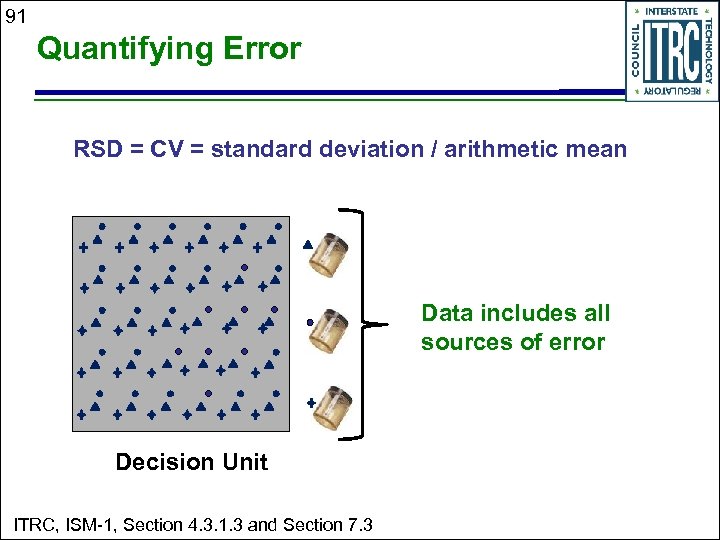

91 Quantifying Error RSD = CV = standard deviation / arithmetic mean Data includes all sources of error Decision Unit ITRC, ISM-1, Section 4. 3. 1. 3 and Section 7. 3

91 Quantifying Error RSD = CV = standard deviation / arithmetic mean Data includes all sources of error Decision Unit ITRC, ISM-1, Section 4. 3. 1. 3 and Section 7. 3

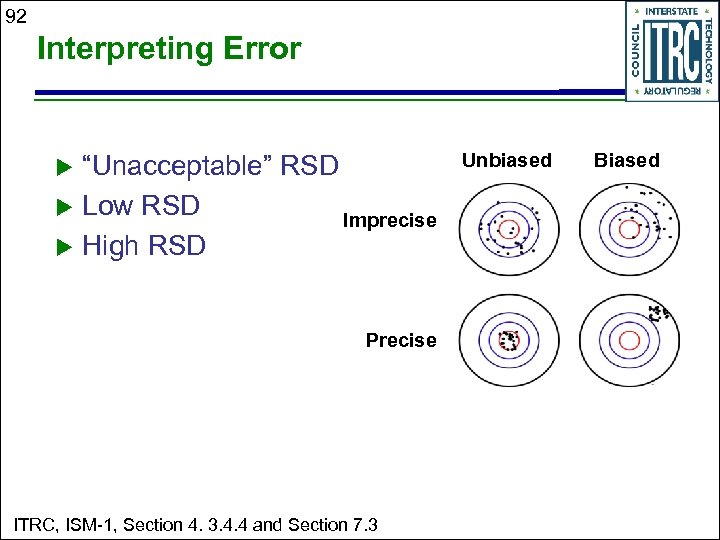

92 Interpreting Error “Unacceptable” RSD u Low RSD Imprecise u High RSD u Precise ITRC, ISM-1, Section 4. 3. 4. 4 and Section 7. 3 Unbiased Biased

92 Interpreting Error “Unacceptable” RSD u Low RSD Imprecise u High RSD u Precise ITRC, ISM-1, Section 4. 3. 4. 4 and Section 7. 3 Unbiased Biased

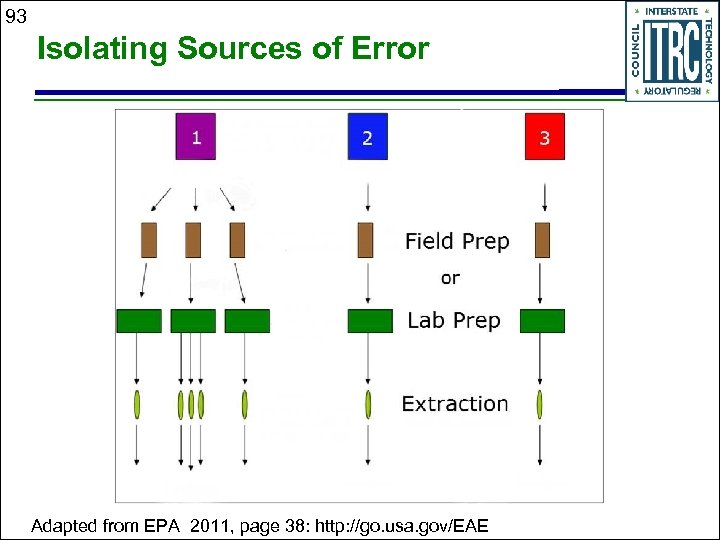

93 Isolating Sources of Error Adapted from EPA 2011, page 38: http: //go. usa. gov/EAE

93 Isolating Sources of Error Adapted from EPA 2011, page 38: http: //go. usa. gov/EAE

94 Making Decisions Using ISM Data Decision Mechanisms Making Decisions Data Evaluation

94 Making Decisions Using ISM Data Decision Mechanisms Making Decisions Data Evaluation

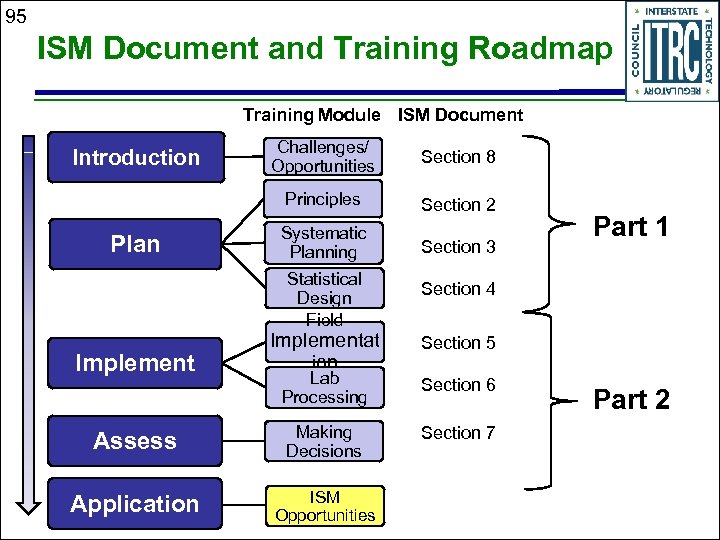

95 ISM Document and Training Roadmap Training Module ISM Document Plan Challenges/ Opportunities Section 8 Principles Introduction Section 2 Systematic Planning Statistical Design Field Implementat ion Section 3 Part 1 Section 4 Section 5 Lab Processing Section 6 Assess Making Decisions Section 7 Application ISM Opportunities Part 2

95 ISM Document and Training Roadmap Training Module ISM Document Plan Challenges/ Opportunities Section 8 Principles Introduction Section 2 Systematic Planning Statistical Design Field Implementat ion Section 3 Part 1 Section 4 Section 5 Lab Processing Section 6 Assess Making Decisions Section 7 Application ISM Opportunities Part 2

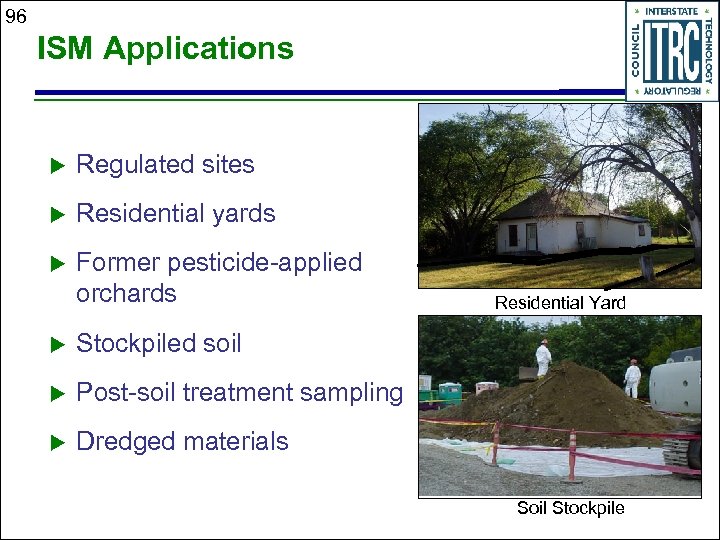

96 ISM Applications u Regulated sites u Residential yards u Former pesticide-applied orchards u Stockpiled soil u Post-soil treatment sampling u Residential Yard Dredged materials Soil Stockpile

96 ISM Applications u Regulated sites u Residential yards u Former pesticide-applied orchards u Stockpiled soil u Post-soil treatment sampling u Residential Yard Dredged materials Soil Stockpile

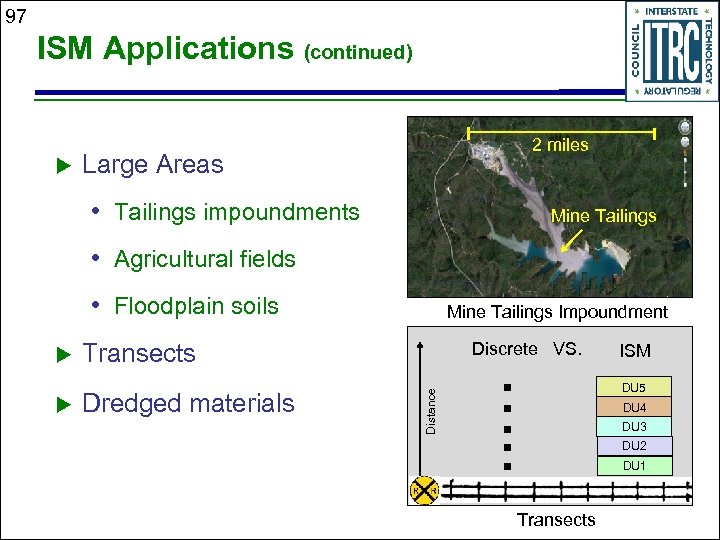

97 ISM Applications (continued) u 2 miles Large Areas • Tailings impoundments Mine Tailings • Agricultural fields • Floodplain soils u Discrete VS. Transects Dredged materials ISM DU 5 Distance u Mine Tailings Impoundment DU 4 DU 3 DU 2 DU 1 Transects

97 ISM Applications (continued) u 2 miles Large Areas • Tailings impoundments Mine Tailings • Agricultural fields • Floodplain soils u Discrete VS. Transects Dredged materials ISM DU 5 Distance u Mine Tailings Impoundment DU 4 DU 3 DU 2 DU 1 Transects

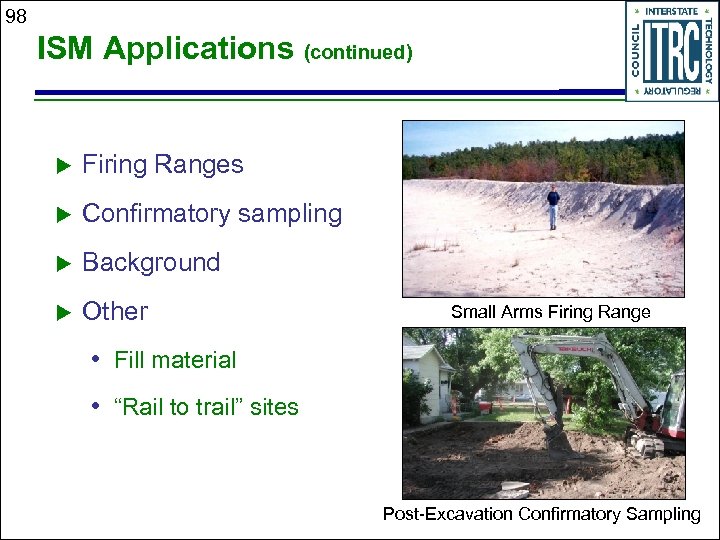

98 ISM Applications (continued) u Firing Ranges u Confirmatory sampling u Background u Other Small Arms Firing Range • Fill material • “Rail to trail” sites Post-Excavation Confirmatory Sampling

98 ISM Applications (continued) u Firing Ranges u Confirmatory sampling u Background u Other Small Arms Firing Range • Fill material • “Rail to trail” sites Post-Excavation Confirmatory Sampling

99 How Does ISM Cost Compare? Elements u Planning u Field Collection u QA/QC Samples u Sample Transport u Sample Processing/Conditioning u Lab Analysis u Overall Sampling/Analysis Portion of Project

99 How Does ISM Cost Compare? Elements u Planning u Field Collection u QA/QC Samples u Sample Transport u Sample Processing/Conditioning u Lab Analysis u Overall Sampling/Analysis Portion of Project

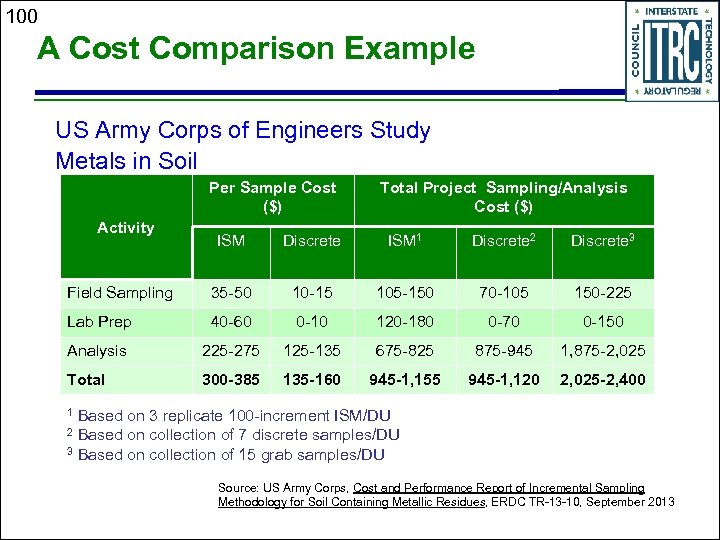

100 A Cost Comparison Example US Army Corps of Engineers Study Metals in Soil Per Sample Cost ($) Activity Total Project Sampling/Analysis Cost ($) ISM Discrete ISM 1 Discrete 2 Discrete 3 Field Sampling 35 -50 10 -15 105 -150 70 -105 150 -225 Lab Prep 40 -60 0 -10 120 -180 0 -70 0 -150 Analysis 225 -275 125 -135 675 -825 875 -945 1, 875 -2, 025 Total 300 -385 135 -160 945 -1, 155 945 -1, 120 2, 025 -2, 400 1 Based on 3 replicate 100 -increment ISM/DU 2 Based on collection of 7 discrete samples/DU 3 Based on collection of 15 grab samples/DU Source: US Army Corps, Cost and Performance Report of Incremental Sampling Methodology for Soil Containing Metallic Residues, ERDC TR-13 -10, September 2013

100 A Cost Comparison Example US Army Corps of Engineers Study Metals in Soil Per Sample Cost ($) Activity Total Project Sampling/Analysis Cost ($) ISM Discrete ISM 1 Discrete 2 Discrete 3 Field Sampling 35 -50 10 -15 105 -150 70 -105 150 -225 Lab Prep 40 -60 0 -10 120 -180 0 -70 0 -150 Analysis 225 -275 125 -135 675 -825 875 -945 1, 875 -2, 025 Total 300 -385 135 -160 945 -1, 155 945 -1, 120 2, 025 -2, 400 1 Based on 3 replicate 100 -increment ISM/DU 2 Based on collection of 7 discrete samples/DU 3 Based on collection of 15 grab samples/DU Source: US Army Corps, Cost and Performance Report of Incremental Sampling Methodology for Soil Containing Metallic Residues, ERDC TR-13 -10, September 2013

101 Bottom Line on Cost Comparisons sy a Measuring the cost difference between ISM and discrete sampling. asy Measuring the cost of making a wrong decision. E E

101 Bottom Line on Cost Comparisons sy a Measuring the cost difference between ISM and discrete sampling. asy Measuring the cost of making a wrong decision. E E

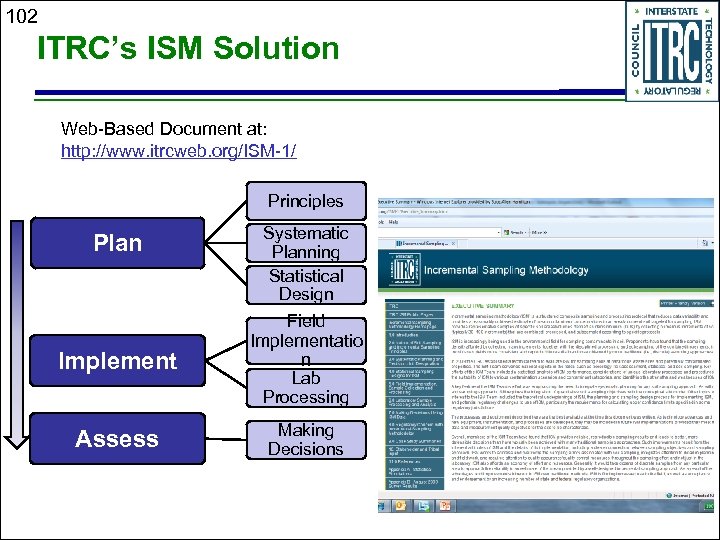

102 ITRC’s ISM Solution Web-Based Document at: http: //www. itrcweb. org/ISM-1/ Principles Plan Systematic Planning Statistical Design Implement Field Implementatio n Lab Processing Assess Making Decisions

102 ITRC’s ISM Solution Web-Based Document at: http: //www. itrcweb. org/ISM-1/ Principles Plan Systematic Planning Statistical Design Implement Field Implementatio n Lab Processing Assess Making Decisions

103 Overview & Wrap-up ISM: u Specifically designed to address short comings of discrete sampling methods u Provides a systematic, science-based approach to site investigation u Increases data representativeness u Provides greater confidence in decision making

103 Overview & Wrap-up ISM: u Specifically designed to address short comings of discrete sampling methods u Provides a systematic, science-based approach to site investigation u Increases data representativeness u Provides greater confidence in decision making

104 Follow ITRC Thank You u 2 nd question and answer break u Links to additional resources • http: //www. clu-in. org/conf/itrc/ISM/resource. cfm u Feedback form – please complete • http: //www. clu-in. org/conf/itrc/ISM/feedback. cfm Need confirmation of your participation today? Fill out the feedback form and check box for confirmation email and certificate.

104 Follow ITRC Thank You u 2 nd question and answer break u Links to additional resources • http: //www. clu-in. org/conf/itrc/ISM/resource. cfm u Feedback form – please complete • http: //www. clu-in. org/conf/itrc/ISM/feedback. cfm Need confirmation of your participation today? Fill out the feedback form and check box for confirmation email and certificate.