28ede24884c0bb9c277f4088c083998a.ppt

- Количество слайдов: 99

1 Starting Soon: Biochemical Reactors (BCR) for Treating Mining Influenced Water (MIW) u u u Biochemical Reactors (BCR) for Treating Mining Influenced Water (MIW) at http: //www. itrcweb. org/bcr-1/ Download Power. Point file • Clu-in training page at http: //www. clu-in. org/conf/itrc/bcr/ • Under “Download Training Materials” Download flowcharts for reference during the training class • http: //www. cluin. org/conf/itrc/BCR/ITRC-BCRfor. MIWDecision. Flow. pdf u Using Adobe Connect • Related Links (on right) § Select name of link § Click “Browse To” • Full Screen button near top of page

2 Welcome – Thanks for joining this ITRC Training Class Biochemical Reactors (BCR) for Treating Mining Influenced Water (MIW) Sponsored by: Interstate Technology and Regulatory Council (www. itrcweb. org) Hosted by: US EPA Clean Up Information Network (www. cluin. org)

3 Housekeeping u u u Course time is 2¼ hours This event is being recorded Trainers control slides • Want to control your own slides? You can download presentation file on Clu-in training page u Questions and feedback • Throughout training: type in the “Q & A” box • At Q&A breaks: unmute your phone with #6 to ask out loud • At end of class: Feedback form available from last slide § Need confirmation of your participation today? Fill out the feedback form and check box for confirmation email and certificate Copyright 2015 Interstate Technology & Regulatory Council, 50 F Street, NW, Suite 350, Washington, DC 20001

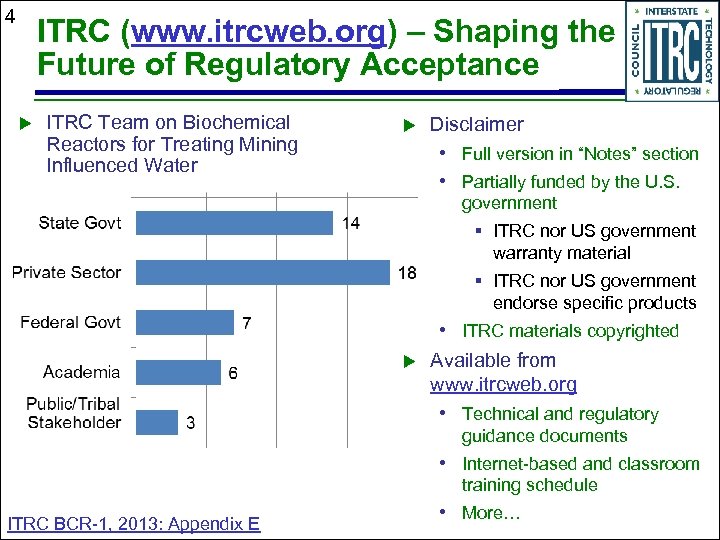

4 ITRC (www. itrcweb. org) – Shaping the Future of Regulatory Acceptance u ITRC Team on Biochemical Reactors for Treating Mining Influenced Water u Disclaimer • Full version in “Notes” section • Partially funded by the U. S. government § ITRC nor US government warranty material § ITRC nor US government endorse specific products • ITRC materials copyrighted u Available from www. itrcweb. org • Technical and regulatory guidance documents • Internet-based and classroom training schedule ITRC BCR-1, 2013: Appendix E • More…

5 Meet the ITRC Trainers Cherri Baysinger Missouri Department of Health and Senior Services Jefferson City, MO 573 -522 -2808 cherri. baysinger @health. mo. gov Paul Eger St Paul, MN 651 -459 -5607 paul. eger @yahoo. com Eduardo Gasca Burns & Mc. Donnell Engineering Company, Inc. Chicago, IL 312 -223 -9599 Egasca @burnsmcd. com Christine Brown California Department of Toxic Substances Control Cypress, CA 714 -484 -5382 cbrown@dtsc. ca. gov

6 Today’s Learning Objectives u At the end of this training, you will be able to…. . • Describe a Biochemical Reactors (BCR) and how it works • Identify when a BCR is applicable to a site • Navigate the ITRC guidance • Use the ITRC guidance as a framework for decision making (apply decision tree)

7 Training Outline u u u BCR basics Determining applicability Designing and implementing a BCR Challenges and solutions Summary ITRC BCR-1, 2013: Section 1

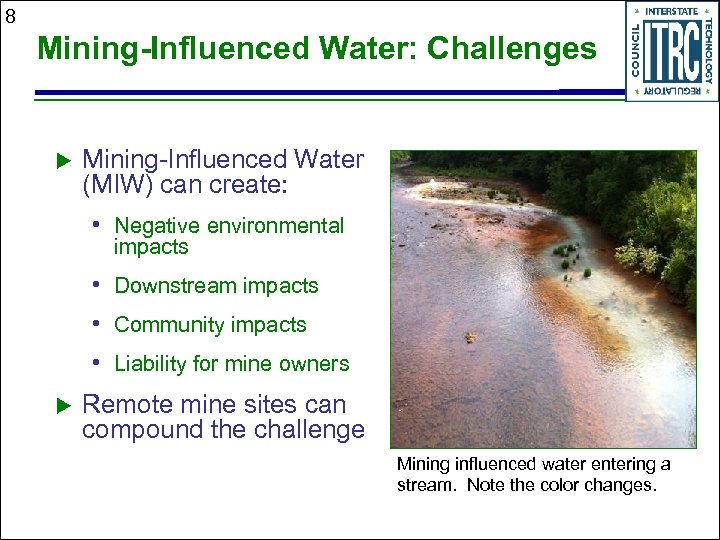

8 Mining-Influenced Water: Challenges u Mining-Influenced Water (MIW) can create: • Negative environmental impacts • Downstream impacts • Community impacts • Liability for mine owners u Remote mine sites can compound the challenge Mining influenced water entering a stream. Note the color changes.

9 One Possible Solution…. u Biochemical Coal Pit Run BCR, PA Reactor (BCR)

10 What is a Biochemical Reactor (BCR)? u …engineered treatment system that uses an organic substrate to drive microbial and chemical reactions to reduce concentration of metals, acidity, and sulfate in MIW. Penn Hill #2 BCR, PA

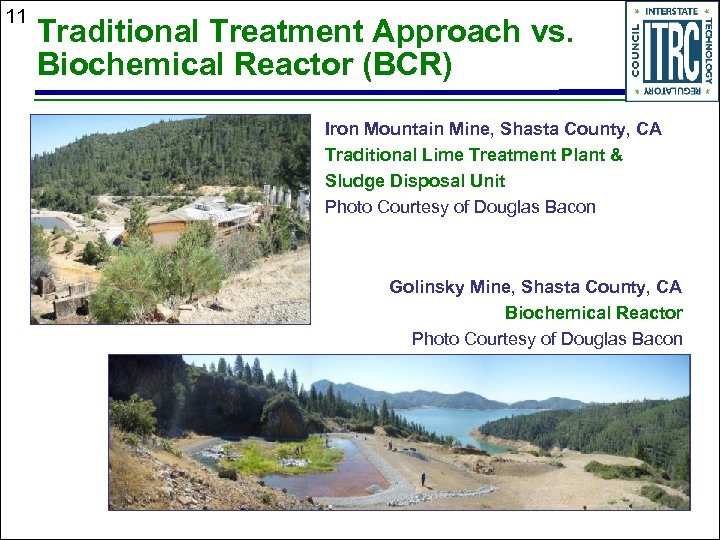

11 Traditional Treatment Approach vs. Biochemical Reactor (BCR) Iron Mountain Mine, Shasta County, CA Traditional Lime Treatment Plant & Sludge Disposal Unit Photo Courtesy of Douglas Bacon Golinsky Mine, Shasta County, CA Biochemical Reactor Photo Courtesy of Douglas Bacon

12 BCRs can be used: u u Various mining sites • Metals • Coal Remote sites • Limited Infrastructure • Extreme conditions u Variable water qualities • p. H • Sulfate • Metals and metalloids Penn Hill #2, PA Mammoth Mine, CA

13 How does a BCR work? Guido Sarducci’s 5 Minute University Intro to BCRs

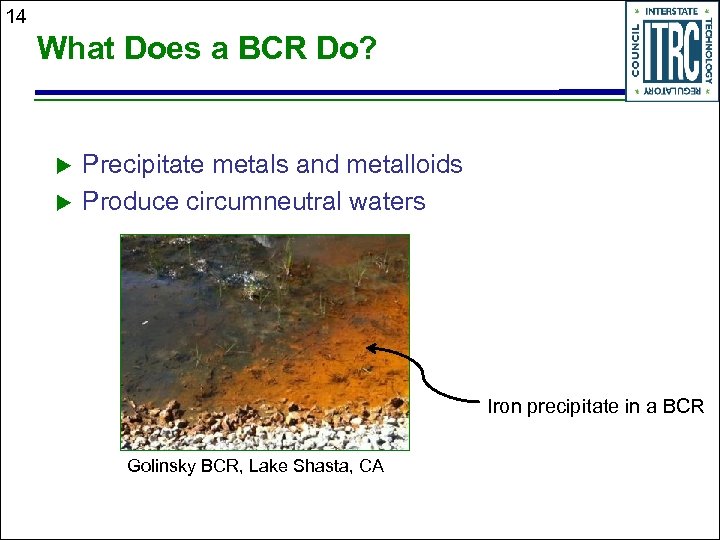

14 What Does a BCR Do? u u Precipitate metals and metalloids Produce circumneutral waters Iron precipitate in a BCR Golinsky BCR, Lake Shasta, CA

15 How Does a BCR Do That? u Sulfate reducing bacteria • Common bacteria • Present in soil • High concentrations in manure Remove sulfate by reducing it to sulfide u Need oxygen free environment, sulfate, and an electron donor • Usually organic compound u Photo of sulfate reducing bacteria

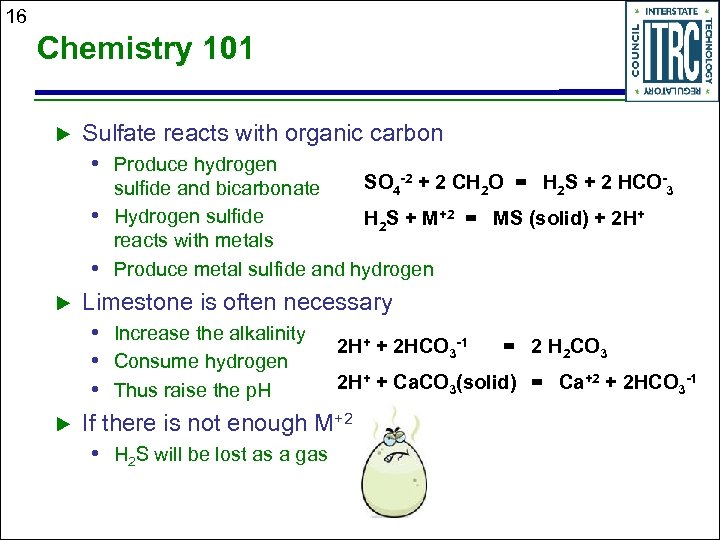

16 Chemistry 101 u Sulfate reacts with organic carbon • Produce hydrogen SO 4 -2 + 2 CH 2 O = H 2 S + 2 HCO-3 sulfide and bicarbonate • Hydrogen sulfide H 2 S + M+2 = MS (solid) + 2 H+ reacts with metals • Produce metal sulfide and hydrogen u u Limestone is often necessary • Increase the alkalinity 2 H+ + 2 HCO 3 -1 = 2 H 2 CO 3 • Consume hydrogen 2 H+ + Ca. CO 3(solid) = Ca+2 + 2 HCO 3 -1 • Thus raise the p. H If there is not enough M+2 • H 2 S will be lost as a gas

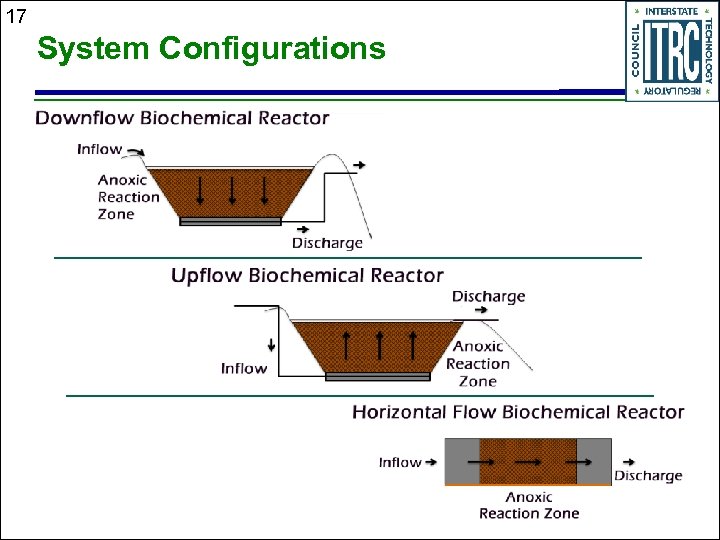

17 System Configurations

18 Advantages u u u u Low energy requirements May be low maintenance if designed properly Can be used in remote situations Removes metals Flexible and versatile Treats wide variety of MIW Will improve ecological function of receiving stream

19 Cautions u u BCRs may not consistently meet strict water quality standards BCRs are not walk away systems Monitoring is required Maintenance may be needed periodically

20 Ask Not What a BCR Can Do For You… …Ask what this guidance can explain for your site TO CLEAN UP MINING-INFLUENCED WATER

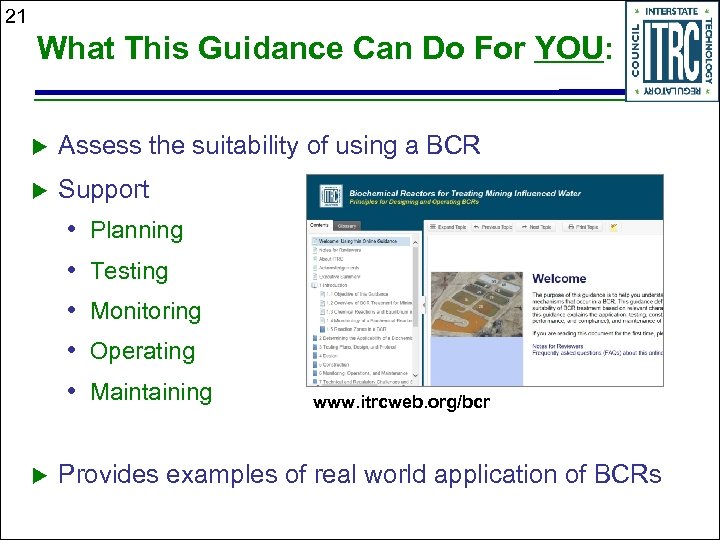

21 What This Guidance Can Do For YOU: u Assess the suitability of using a BCR u Support • • • u Planning Testing Monitoring Operating Maintaining www. itrcweb. org/bcr Provides examples of real world application of BCRs

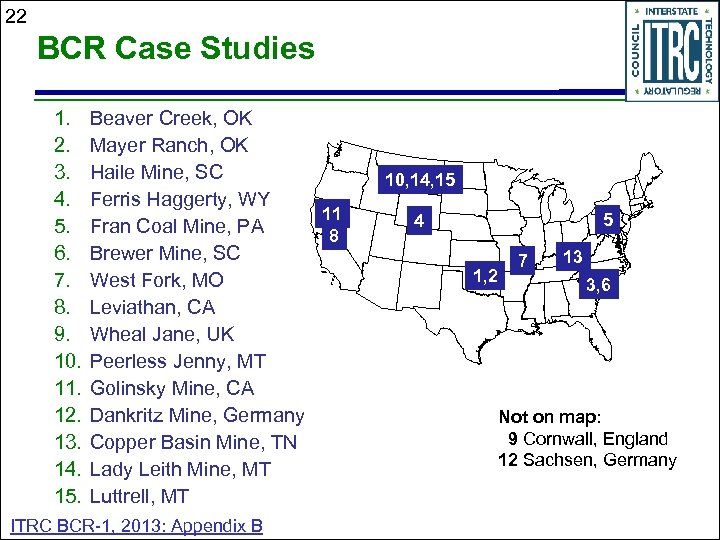

22 BCR Case Studies 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. Beaver Creek, OK Mayer Ranch, OK Haile Mine, SC Ferris Haggerty, WY 11 Fran Coal Mine, PA 8 Brewer Mine, SC West Fork, MO Leviathan, CA Wheal Jane, UK Peerless Jenny, MT Golinsky Mine, CA Dankritz Mine, Germany Copper Basin Mine, TN Lady Leith Mine, MT Luttrell, MT ITRC BCR-1, 2013: Appendix B 10, 14, 15 5 4 1, 2 7 13 3, 6 Not on map: 9 Cornwall, England 12 Sachsen, Germany

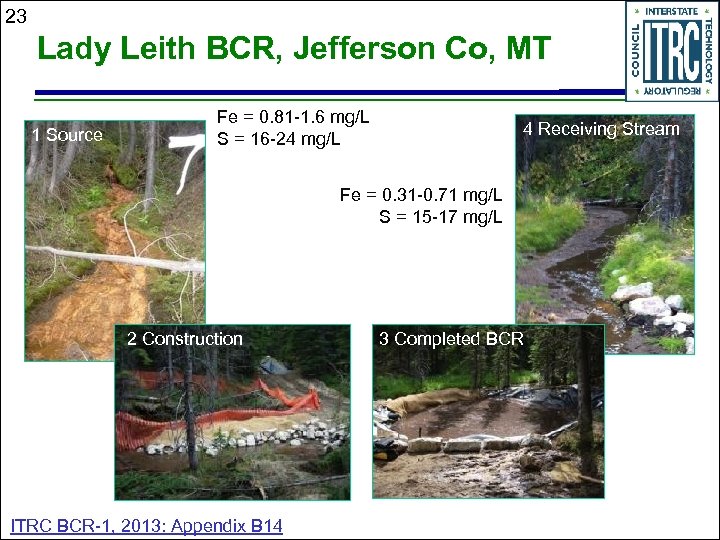

23 Lady Leith BCR, Jefferson Co, MT 1 Source Fe = 0. 81 -1. 6 mg/L S = 16 -24 mg/L 4 Receiving Stream Fe = 0. 31 -0. 71 mg/L S = 15 -17 mg/L 2 Construction ITRC BCR-1, 2013: Appendix B 14 3 Completed BCR

24 Key Messages 1. BCRs are viable alternatives for treating MIW, even in remote areas 2. BCRs are site-specific 3. BCRs are not walk away systems 4. The guidance is a convenient resource when considering a BCR

25 Training Outline u u u BCR basics Determining applicability • Decision tree and BCR selection Designing and implementing a BCR Challenges and solutions Summary ITRC BCR-1, 2013: Section 3

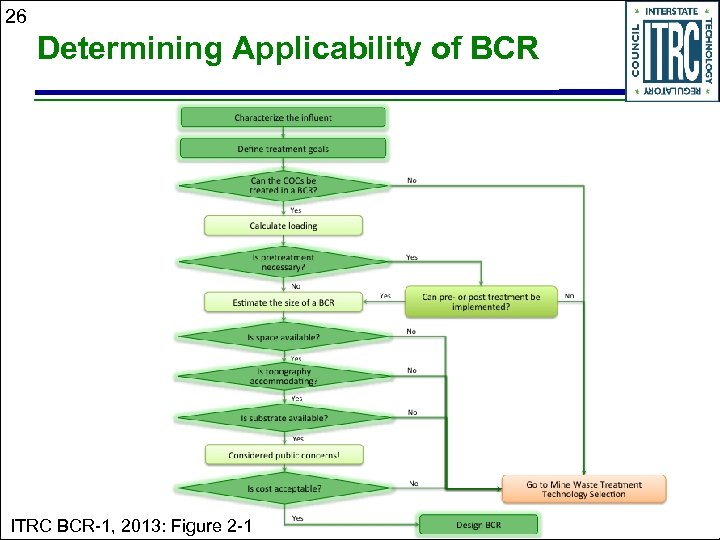

26 Determining Applicability of BCR ITRC BCR-1, 2013: Figure 2 -1

27 Characterize the Influent Characterize the influent Define treatment goals Can the COCs be treated in a BCR?

28 Got Treatment Goals? Characterize the influent Define treatment goals Can the COCs be treated in a BCR? Your friendly local regulator

29 Can the BCR Treat Your Water? Characterize the influent Define treatment goals Can the COCs be treated in a BCR?

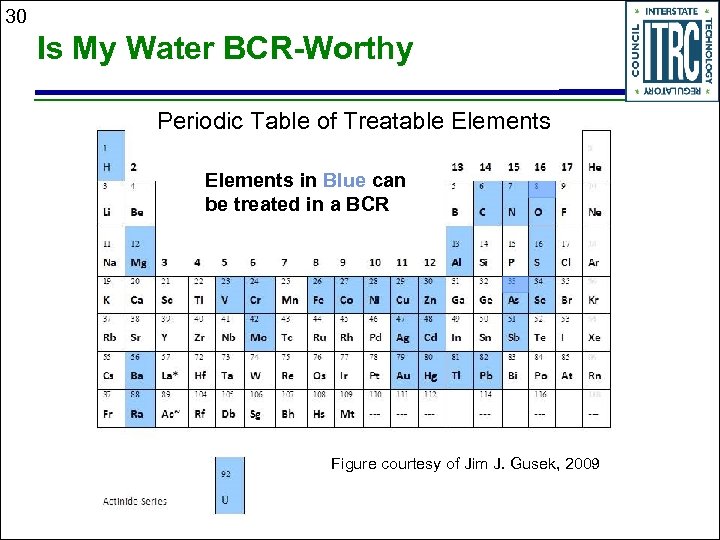

30 Is My Water BCR-Worthy Periodic Table of Treatable Elements in Blue can be treated in a BCR Figure courtesy of Jim J. Gusek, 2009

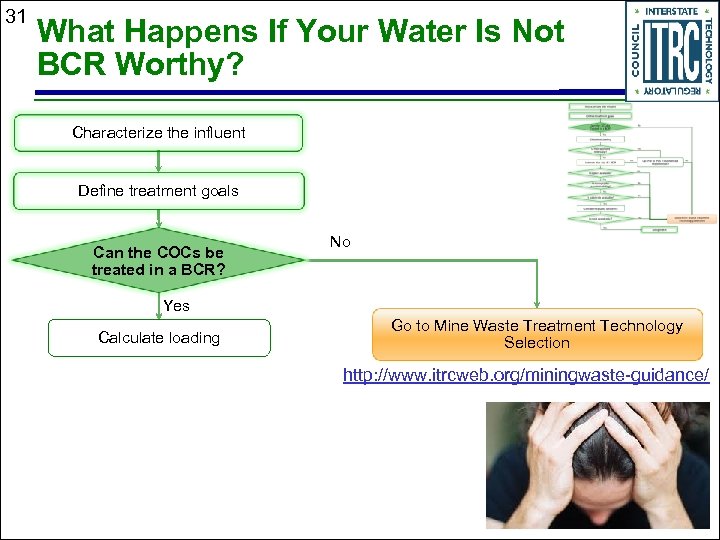

31 What Happens If Your Water Is Not BCR Worthy? Characterize the influent Define treatment goals Can the COCs be treated in a BCR? No Yes Calculate loading Go to Mine Waste Treatment Technology Selection http: //www. itrcweb. org/miningwaste-guidance/

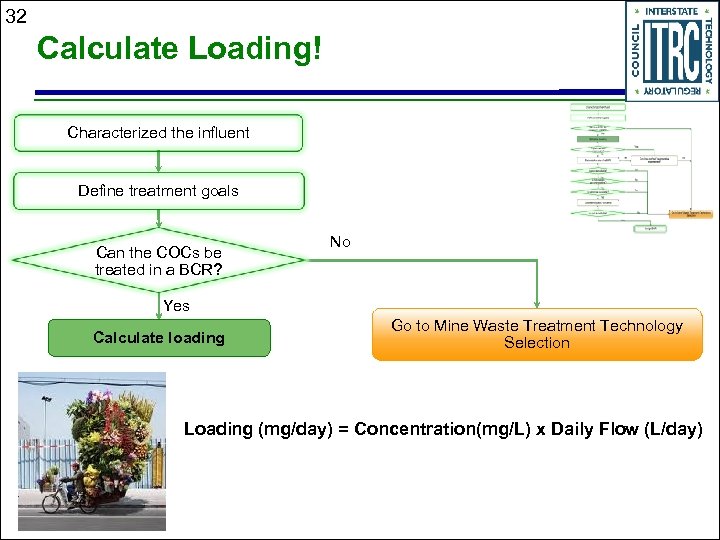

32 Calculate Loading! Characterized the influent Define treatment goals Can the COCs be treated in a BCR? No Yes Calculate loading Go to Mine Waste Treatment Technology Selection Loading (mg/day) = Concentration(mg/L) x Daily Flow (L/day)

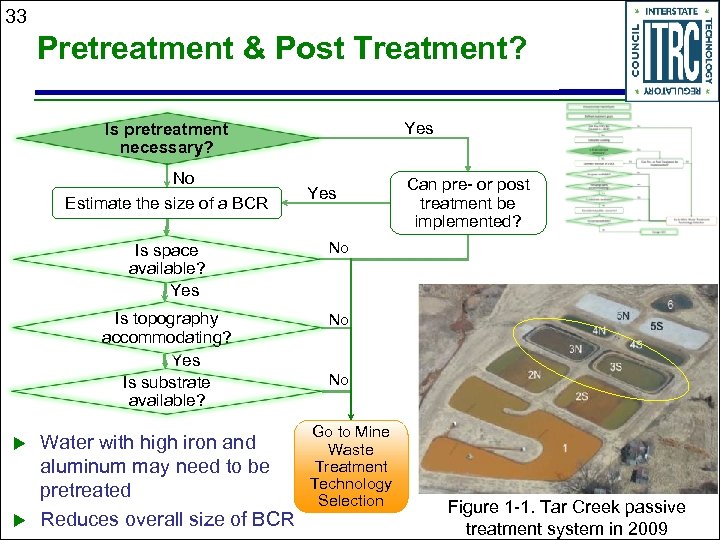

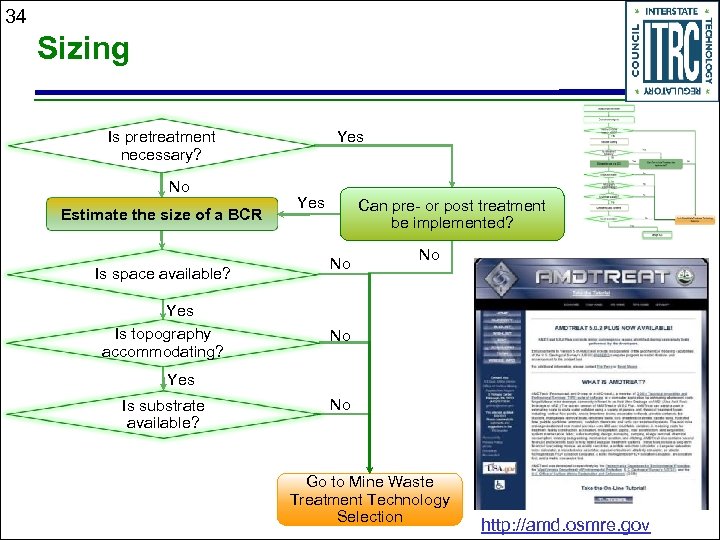

33 Pretreatment & Post Treatment? Yes Is pretreatment necessary? No Estimate the size of a BCR Yes Is space available? Yes u u No No Is topography accommodating? Yes Is substrate available? Can pre- or post treatment be implemented? No Water with high iron and aluminum may need to be pretreated Reduces overall size of BCR No Go to Mine Waste Treatment Technology Selection Figure 1 -1. Tar Creek passive treatment system in 2009

34 Sizing Yes Is pretreatment necessary? No Estimate the size of a BCR Is space available? Yes Is topography accommodating? Yes Can pre- or post treatment be implemented? No No No Yes Is substrate available? No Go to Mine Waste Treatment Technology Selection http: //amd. osmre. gov

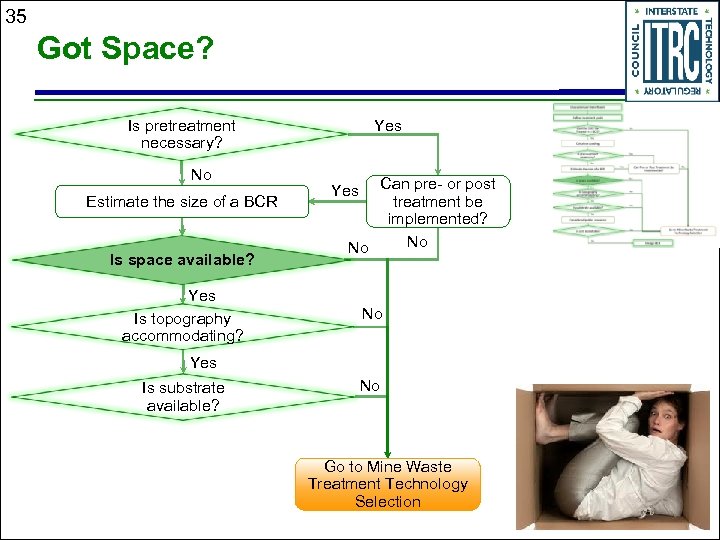

35 Got Space? Yes Is pretreatment necessary? No Estimate the size of a BCR Is space available? Yes Is topography accommodating? Can pre- or post treatment be implemented? No No Yes Is substrate available? No Go to Mine Waste Treatment Technology Selection

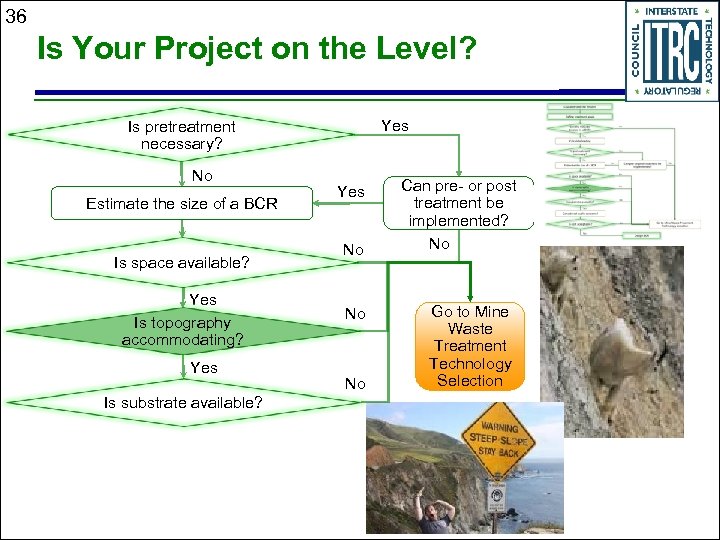

36 Is Your Project on the Level? Yes Is pretreatment necessary? No Estimate the size of a BCR Is space available? Yes Is topography accommodating? Yes Is substrate available? Yes No No No Can pre- or post treatment be implemented? No Go to Mine Waste Treatment Technology Selection

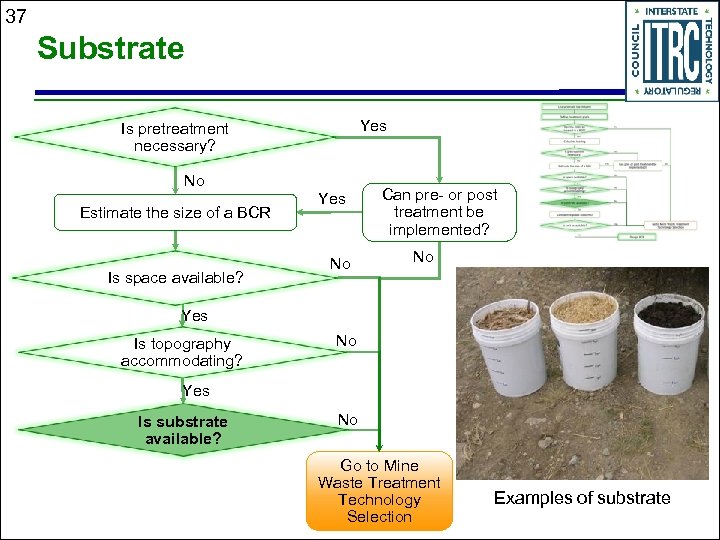

37 Substrate Yes Is pretreatment necessary? No Estimate the size of a BCR Is space available? Yes No Can pre- or post treatment be implemented? No Yes Is topography accommodating? No Yes Is substrate available? No Go to Mine Waste Treatment Technology Selection Examples of substrate

38 How Close to a BCR Would You Live? Consider public concerns Is cost acceptable? Yes No Go to Mine Waste Treatment Technology Selection Design BCR

39 Co$t$ Consider public concerns Is cost acceptable? No Go to Mine Waste Treatment Technology Selection Yes Design BCR

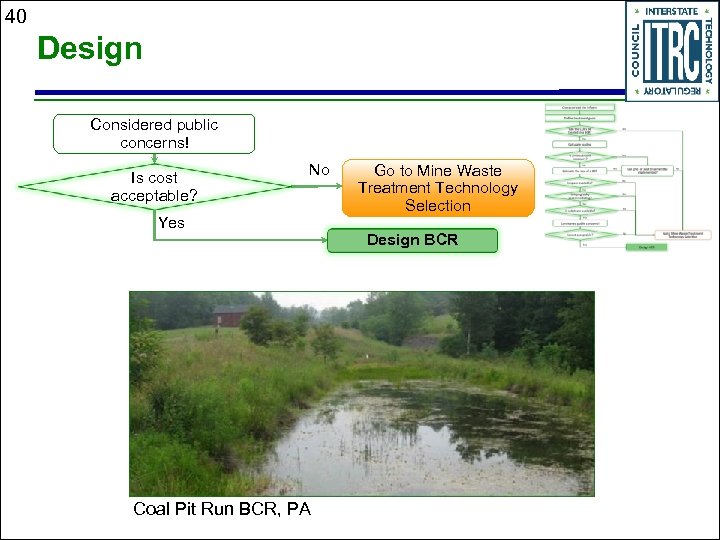

40 Design Considered public concerns! Is cost acceptable? No Yes Coal Pit Run BCR, PA Go to Mine Waste Treatment Technology Selection Design BCR

41 Training Outline u u u BCR basics Determining applicability Designing and implementing a BCR • Testing plans, design, protocol • Design and site-specific costs • Construction • Monitoring, operation, maintenance Challenges and solutions Summary ITRC BCR-1, 2013: Section 3

42 Treatability Testing u What is needed for treatability testing? • Site MIW • Substrates Hay Wood Chips Limestone

43 Substrate Selection u Characteristics of an effective substrate: • Source of long-term carbon source § Electron donor (food/energy source) • Source of short-term carbon source § Electron donor (food/energy source) • • • Source of microbial inoculum Source of alkalinity Good permeability Microbial attachment sites Locally available

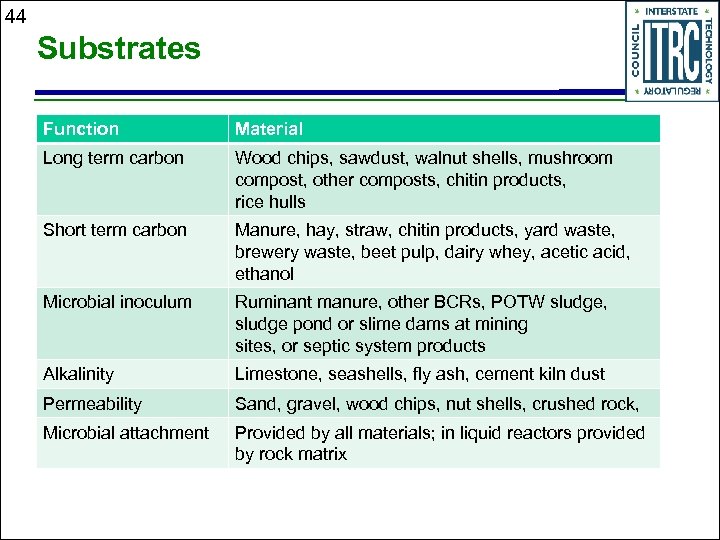

44 Substrates Function Material Long term carbon Wood chips, sawdust, walnut shells, mushroom compost, other composts, chitin products, rice hulls Short term carbon Manure, hay, straw, chitin products, yard waste, brewery waste, beet pulp, dairy whey, acetic acid, ethanol Microbial inoculum Ruminant manure, other BCRs, POTW sludge, sludge pond or slime dams at mining sites, or septic system products Alkalinity Limestone, seashells, fly ash, cement kiln dust Permeability Sand, gravel, wood chips, nut shells, crushed rock, Microbial attachment Provided by all materials; in liquid reactors provided by rock matrix

45 Proof of Principle u Lab test • Screening • Can I treat my water in an anaerobic environment? • What substrate is best?

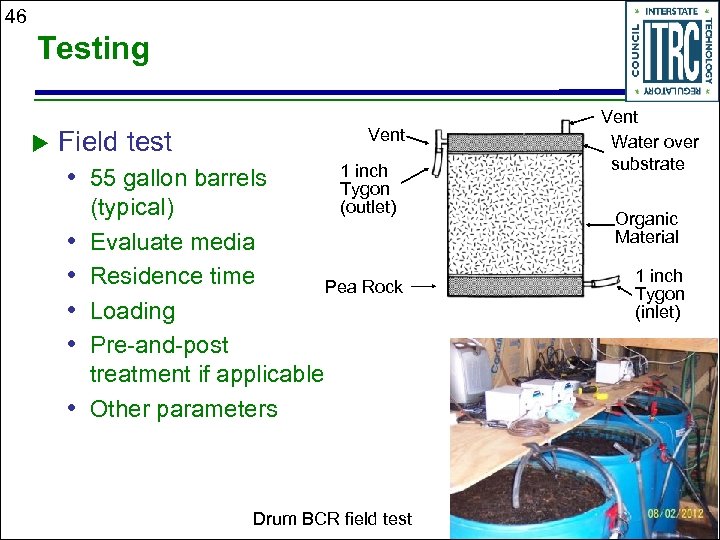

46 Testing u Field test • 55 gallon barrels • • • Vent 1 inch Tygon (outlet) (typical) Evaluate media Residence time Pea Rock Loading Pre-and-post treatment if applicable Other parameters Drum BCR field test Vent Water over substrate Organic Material 1 inch Tygon (inlet)

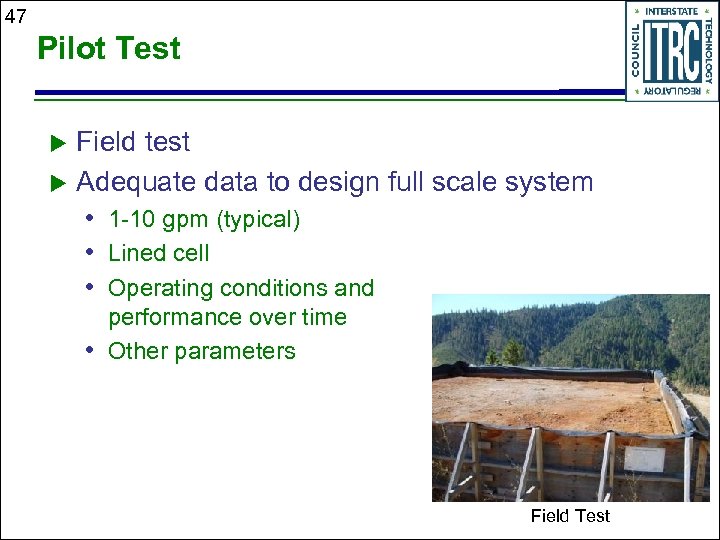

47 Pilot Test Field test u Adequate data to design full scale system • 1 -10 gpm (typical) • Lined cell • Operating conditions and u performance over time • Other parameters Field Test

48 Training Outline u u u BCR basics Determining applicability Designing and implementing a BCR • Testing plans, design, protocol • Design and site-specific costs • Construction • Monitoring, operation, maintenance Challenges and solutions Summary ITRC BCR-1, 2013: Section 4

49 Design

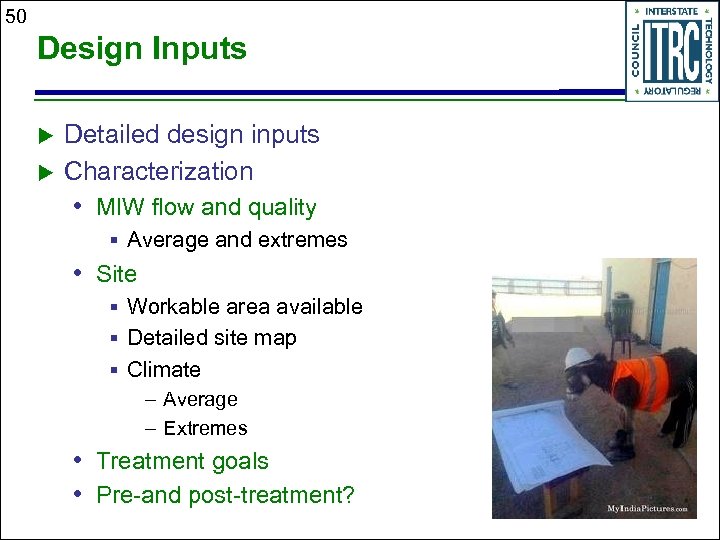

50 Design Inputs u u Detailed design inputs Characterization • MIW flow and quality § Average and extremes • Site § Workable area available § Detailed site map § Climate – Average – Extremes • Treatment goals • Pre-and post-treatment?

51 Performance Data u u Seasonal variability Loading range Residence time Substrate mixture • Thickness • Degradation rate • Metal removal efficiency

52 What Size BCR Do I Need? u Balance the amount of sulfate reduction with the input contaminant load • Total amount of sulfate reduction = volumetric rate of sulfate reduction (mmoles/m 3/day) x volume of reactor (m 3) • Contaminant load = sum of all contaminants in input water (mmoles/day) § Metals (Me+2, Me+3 ; + H+ )= total acidity

53 BCR Size Calculations u Compute total acidity load ( metals + acid) • Use flow and concentrations from characterization Total acidity load = Σ mmole divalent metals (M+2) in input + 1. 5 Σ mmole Al+3, Fe+3 + 0. 5 (1000 x 10 -p. H) u Volumetric sulfate reduction rate • Determined from testing data Volume of reactor(m 3) = total acidity rate (mmole/day) Sulfate reduction rate (mmole/m 3/day)

54 Design Adjustments u Does it fit? • Adjust design if necessary • Volume = area x depth § Maximum depth ~ 6 ft • Bugs on booze? § Supply carbon source as liquid § Ethanol, molasses

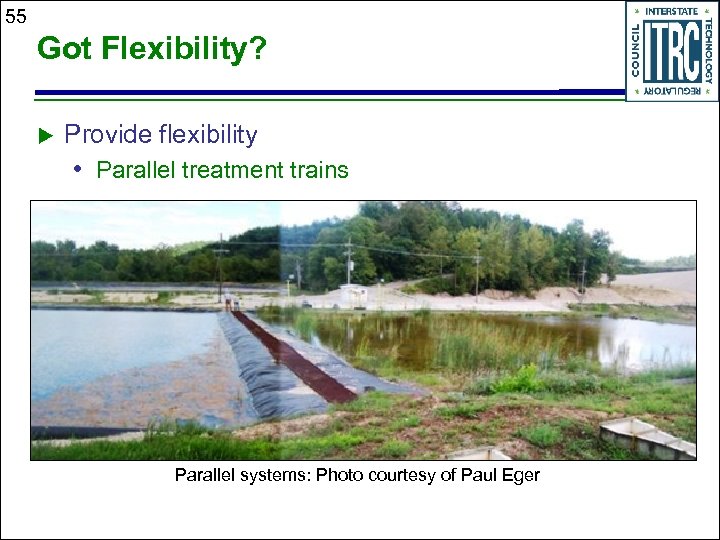

55 Got Flexibility? u Provide flexibility • Parallel treatment trains Parallel systems: Photo courtesy of Paul Eger

56 Need More? u u Appendix C. BCR Calculation Examples AMDTreat (http: //amd. osmre. gov/)

57 The Big Question – How Long Will It Last? u u Typical estimate 10 - 20 years Initial estimates • Carbon consumption • Limestone consumption

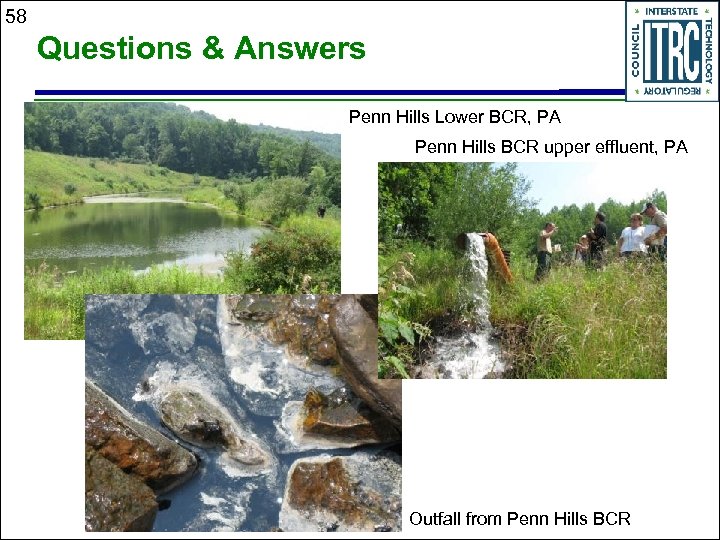

58 Questions & Answers Penn Hills Lower BCR, PA Penn Hills BCR upper effluent, PA Outfall from Penn Hills BCR

59 Training Outline u u u BCR basics Determining applicability Designing and implementing a BCR • Testing plans, design, protocol • Design and site-specific costs • Construction • Monitoring, operation, maintenance Challenges and solutions Summary ITRC BCR-1, 2013: Section 5

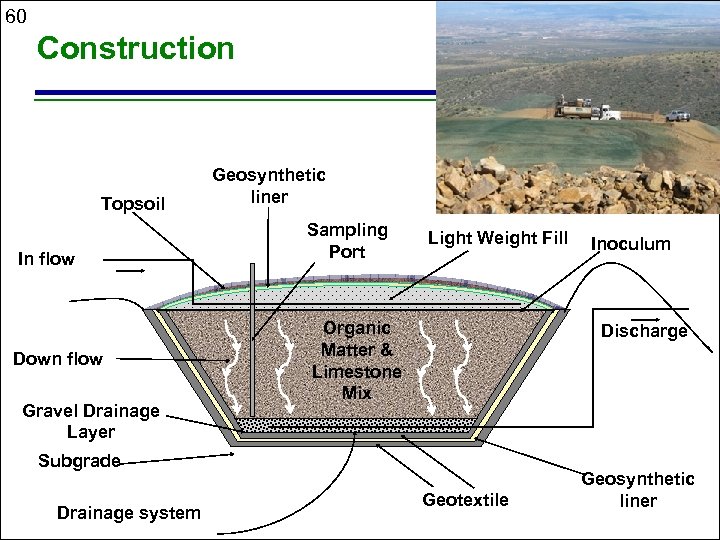

60 Construction Topsoil In flow Down flow Gravel Drainage Layer Geosynthetic liner Sampling Port Light Weight Fill Organic Matter & Organic Matter Limestone & Limestone Mix Discharge Subgrade Drainage system Inoculum Geotextile Geosynthetic liner

61 Sub-grade Preparation Pre-installed effluent pipe Subgrade

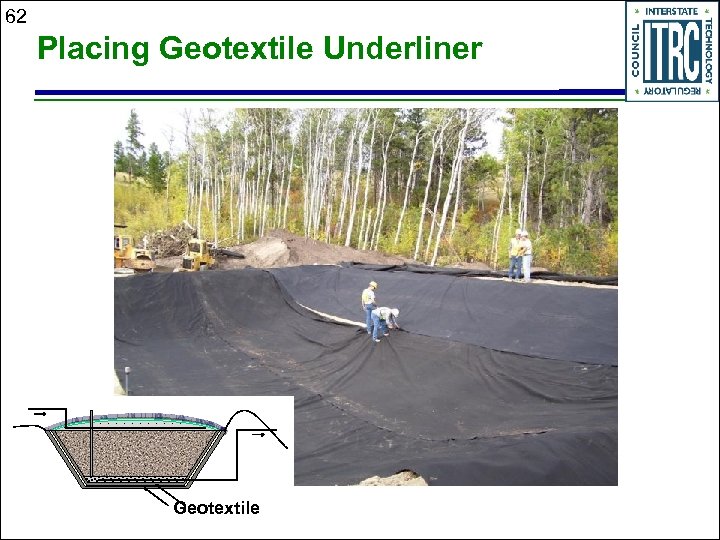

62 Placing Geotextile Underliner Geotextile

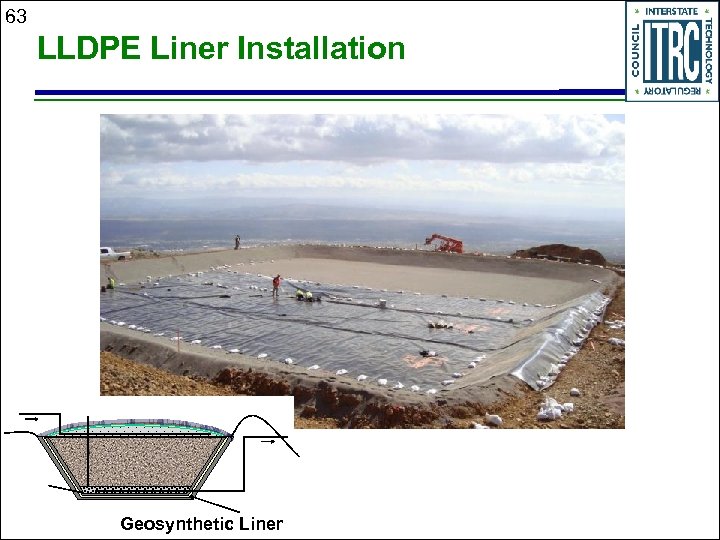

63 LLDPE Liner Installation Geosynthetic Liner

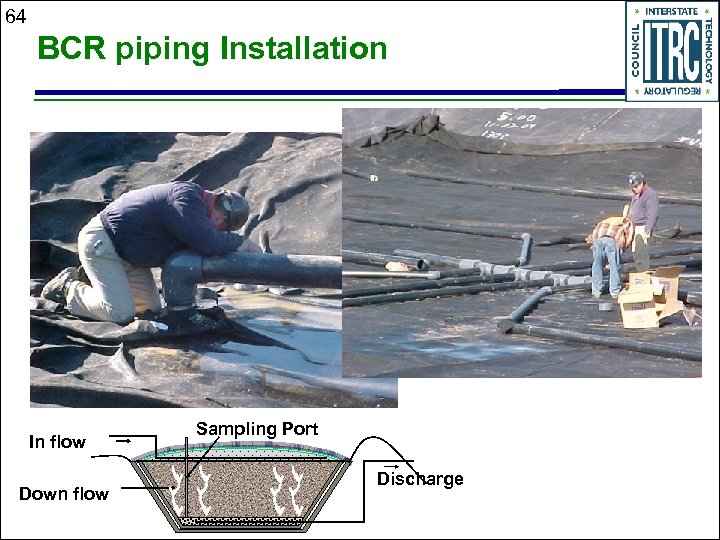

64 BCR piping Installation In flow Down flow Sampling Port Discharge

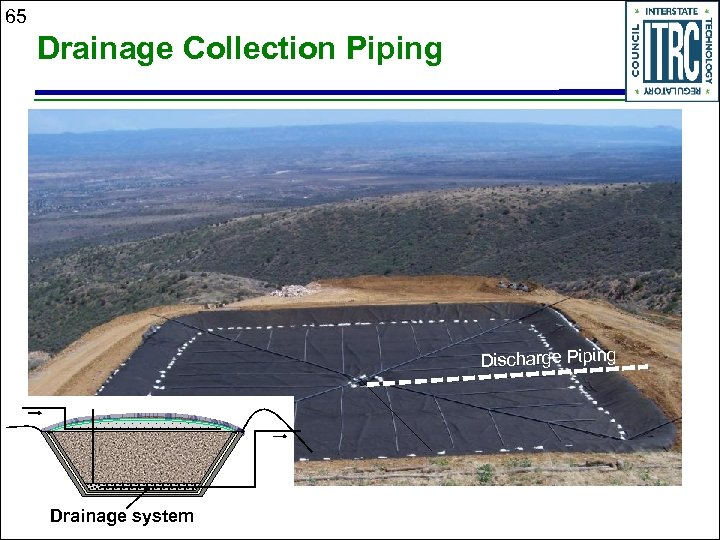

65 Drainage Collection Piping Discharge Piping Drainage system

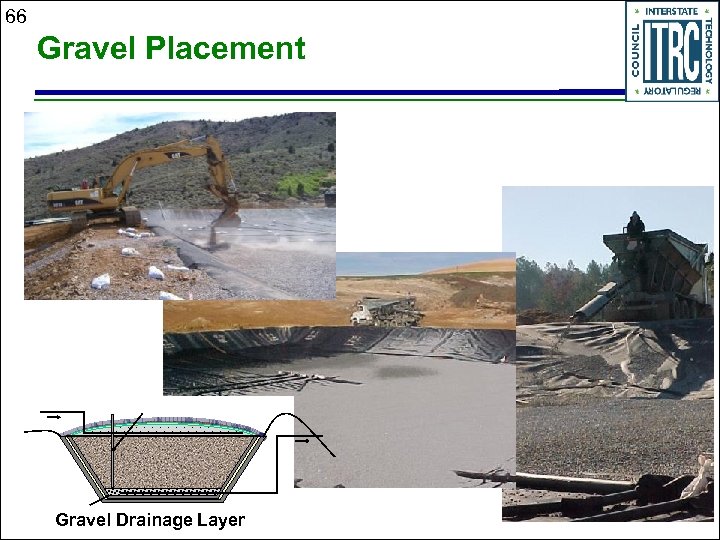

66 Gravel Placement Gravel Drainage Layer

67 Mixing Organic Substrate

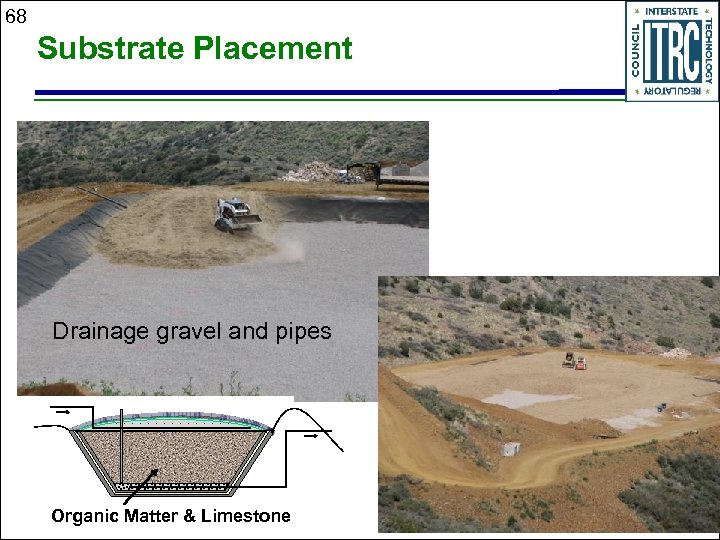

68 Substrate Placement Drainage gravel and pipes Organic Matter & Limestone

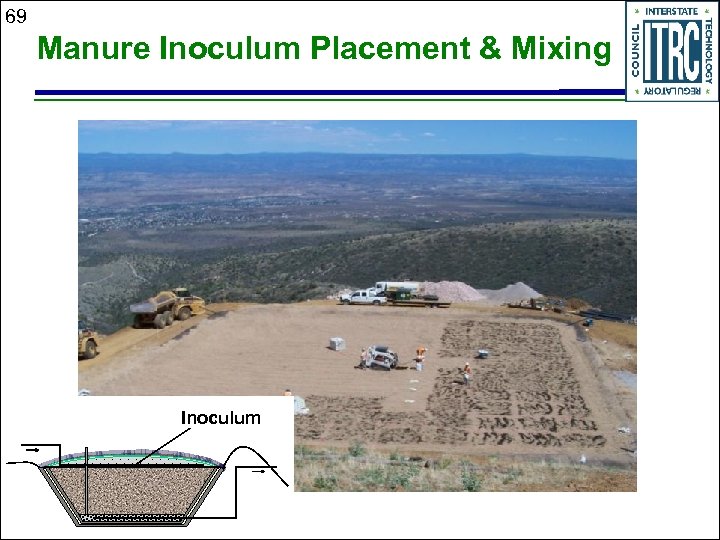

69 Manure Inoculum Placement & Mixing Inoculum

70 Cover Installation Geosynthetic liner

71 Topsoil Light Weight Fill

72 Cover Seeding Hydro-seeding

73 Does It Have To Be So Complex? u Goals • Best Management Practices or National Pollution Discharge Elimination System u u Size Setting We don’t need no stinkin permits!

74 Training Outline u u u BCR basics Determining applicability Designing and implementing a BCR • Testing plans, design, protocol • Design and site-specific costs • Construction • Monitoring, operation, maintenance Challenges and solutions Summary ITRC BCR-1, 2013: Section 6

75 Monitoring, Operation, Maintenance u BCRs designed for • Minimum operation & low maintenance • Low energy/passive u Monitoring Conducted periodically for; • Physical conditions • Performance evaluations • Compliance requirements

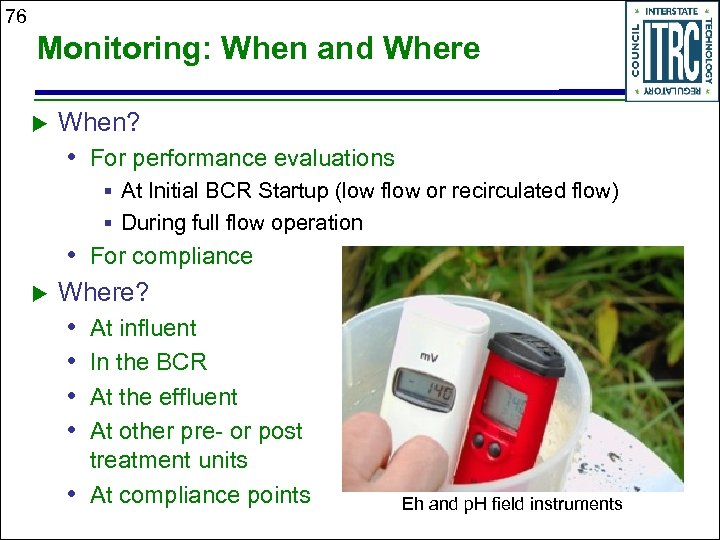

76 Monitoring: When and Where u When? • For performance evaluations § At Initial BCR Startup (low flow or recirculated flow) § During full flow operation • For compliance u Where? • • At influent In the BCR At the effluent At other pre- or post treatment units • At compliance points Eh and p. H field instruments

77 What Do We Monitor at BCRs u Depends on operational phase, function, and regulatory requirements • Performance § Field and laboratory water chemistry, water levels, and flow rates § Visual observations § Odor • Compliance § Regulated parameters (metals, DO, BOD, sulfide, ammonia, TSS, Flow, and other relevant parameters) See: Water chemistry parameters in Section 6. 3

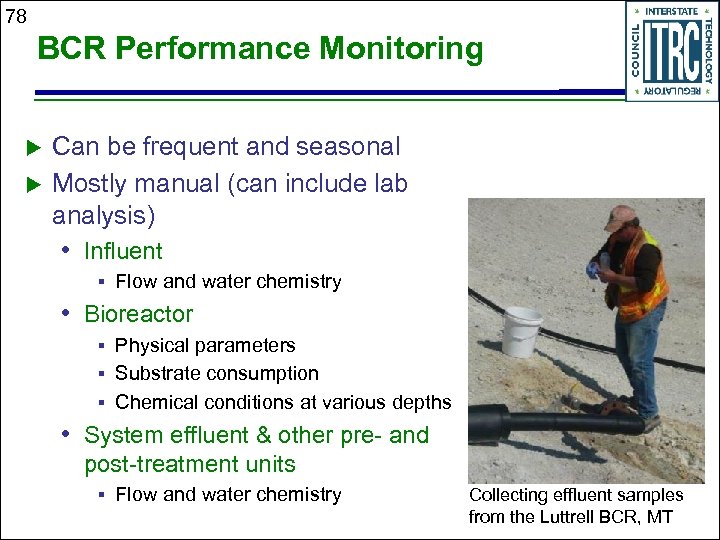

78 BCR Performance Monitoring u u Can be frequent and seasonal Mostly manual (can include lab analysis) • Influent § Flow and water chemistry • Bioreactor § Physical parameters § Substrate consumption § Chemical conditions at various depths • System effluent & other pre- and post-treatment units § Flow and water chemistry Collecting effluent samples from the Luttrell BCR, MT

79 Field Parameters u u Common Field parameters • Flow rate • Temperature, p. H, ORP, DO • Visual observations • Hydrogen sulfide presence Optional field parameters • Iron speciation • Acidity & alkalinity • Sulfide and sulfate • Conductivity Sampling influent flow at Penn Hills BCR, PA

80 Laboratory Parameters u u u u u Metals Sulfate Sulfide Alkalinity BOD/COD TDS/TSS Ammonia Nitrate/nitrite Phosphorous Substrate use

81 Compliance Monitoring u May be subject to multiple regulatory programs • Clean Water Act, • Surface Mining Control and Reclamation Act • NPDES • CERCLA / RCRA • State and County u u Required frequency Required parameters • Site Specific • Metals, BOD, TSS, ammonia, nitrate/nitrite, P, sulfide Effluent p. H and Eh Testing

82 Sample Collection u Sample collection methods • Follow site-specific plan and procedures • Manual and automatic sampling • Field measurement instruments § Portable meters § Permanent meters • Field chemistry kits (HACH, etc. ) • Sample type - grab, composite, incremental Penn Hills influent flow test

83 Sample Analysis u u u Chemicals analysis • Field parameters, methods and purpose (Table 6 -2) • Laboratory parameters, methods and purpose (Table 6 -3) Samples packaging and transportation • Custody procedures • Samples preservation (Table 6 -4) • Samples transportation Samples analysis QA/QC • Duplicates, spikes ITRC BCR-1, 2013 : Figure 6 -2. Automatic wastewater sampler

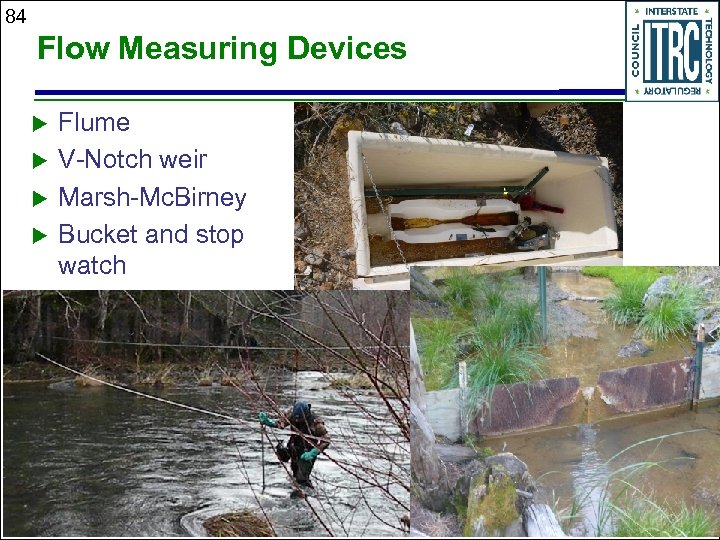

84 Flow Measuring Devices u u Flume V-Notch weir Marsh-Mc. Birney Bucket and stop watch

85 Operations u u BCR will run by itself Periodic Inspection of physical conditions • Visual inspection of system • Flow rates & water level in units, piezometers, • • • gauges and standpipes System integrity (berms, liners, piping) Site access Identify potential short-circuiting of water Drop inlets/outlets, pipes, & weirs If used, check electrical & mechanical equipment (e. g. , pumps) Figure 4 -4. Sampling pipe/piezometer

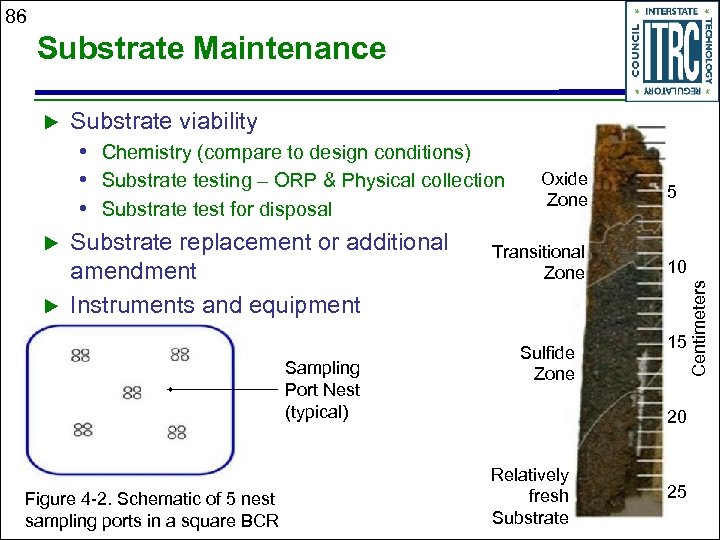

86 Substrate Maintenance u u Substrate viability • Chemistry (compare to design conditions) Oxide • Substrate testing – ORP & Physical collection Zone • Substrate test for disposal Substrate replacement or additional Transitional amendment Zone Instruments and equipment Sampling Port Nest (typical) Figure 4 -2. Schematic of 5 nest sampling ports in a square BCR Sulfide Zone 5 10 15 20 Relatively fresh Substrate 25 Centimeters u

87 Troubleshooting: Chemical Trends u Influent and effluent • Fe, Al, Mn changes u BCR • Increased ORP/Eh and DO u Effluent • Increases in other metals • Less reduced sulfur / increased sulfate • Decreased p. H ITRC BCR-1, 2013: Section 6. 3. 2 Adjustable Elevation Head Weir for BCR Effluent

88 Troubleshooting: Physical Trends u u u Plugging Overflow and flow controls Short circuiting Gas lock-up in BCR Structural integrity • Berms/dikes • Ponds • Liners u Erosion and stormwater management Section 6. 3. 2 in Guidance Golinsky BCR, CA: Photo courtesy of Bruce Marvin

89 Training Outline u u u BCR basics Determining applicability Designing and implementing a BCR Challenges and solutions • Technical challenges • Regulatory challenges • Stakeholder concerns and issues Summary ITRC BCR-1: Section 7, Section 8, Section 9

90 Challenges and Solutions u u Technical Regulatory • Permitting • Water Quality Standards • Disposal of Residual Materials • Wetlands u Stakeholder • Community, tribal concerns • Liability • Use of MIW as a Resource Golinsky Biochemical Reactor, Lake Shasta, CA Photo courtesy of Bruce Marvin

91 Regulatory – Permitting u Permit requirements vary • Location • Project phase § Construction § Operation Construction of the BCR in Park City, UT Photo courtesy Jeff Schoenbacher Park City Municipal Corporation

92 Regulatory – Water Quality Standards u u Set to protect human health and the environment BCRs can meet water quality standards There may be some times when they do not meet standards This must be understood by all! Collecting an effluent sample from BCR discharge point

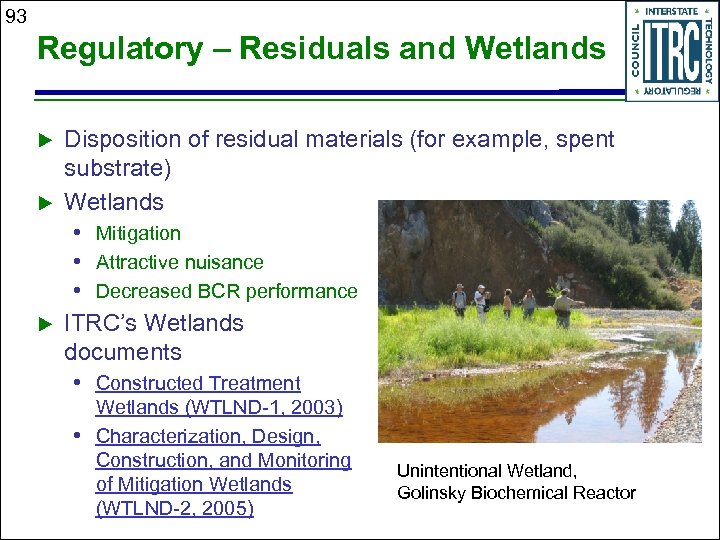

93 Regulatory – Residuals and Wetlands u u u Disposition of residual materials (for example, spent substrate) Wetlands • Mitigation • Attractive nuisance • Decreased BCR performance ITRC’s Wetlands documents • Constructed Treatment Wetlands (WTLND-1, 2003) • Characterization, Design, Construction, and Monitoring of Mitigation Wetlands (WTLND-2, 2005) Unintentional Wetland, Golinsky Biochemical Reactor

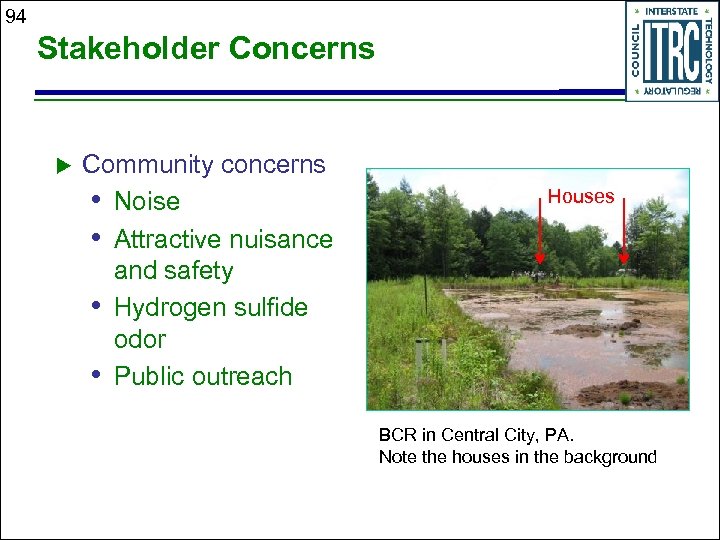

94 Stakeholder Concerns u Community concerns • Noise • Attractive nuisance and safety • Hydrogen sulfide odor • Public outreach Houses BCR in Central City, PA. Note the houses in the background

95 Stakeholder Concerns (cont. ) u Tribal concerns • Clean Water Act Authority u Volunteer groups • Watershed groups • Abandoned mine sites Fran Coal Mine MIW

96 Liability Concerns u u u Liability of Good Samaritans Disposal of spent substrate Effluent compliance • NPDES versus Infiltration or Recharge Sludge Disposal area, Iron Mountain Mine, California The perfect should not be the enemy of the good

97 MIW as an Emerging Resource u u Hydrofracking Electricity production Receiving stream, Lady Leith BCR, Jefferson County MT

98 Key Take Away Messages u u BCRs are viable alternatives for treating MIW, even in remote areas BCRs are site-specific, not one size fits all BCRs are not walk-away systems, but require maintenance and monitoring Web based document is a convenient resource when considering a BCR

99 Thank You for Participating u 2 nd question and answer break u Links to additional resources • http: //www. clu-in. org/conf/itrc/bcr/resource. cfm u Feedback form – please complete • http: //www. clu-in. org/conf/itrc/bcr/feedback. cfm Need confirmation of your participation today? Fill out the feedback form and check box for confirmation email and certificate.

28ede24884c0bb9c277f4088c083998a.ppt