8ce24b11671da06ede26d5aa10cff8e9.ppt

- Количество слайдов: 38

1 Session 1 Introduction to the Field of Operations Management

1 Session 1 Introduction to the Field of Operations Management

2 OBJECTIVES Operations Management Why Study Operations Management? Transformation Processes Defined Operations as a Service The Importance of Operations Management Historical Development of OM Current Issues in OM

2 OBJECTIVES Operations Management Why Study Operations Management? Transformation Processes Defined Operations as a Service The Importance of Operations Management Historical Development of OM Current Issues in OM

3 What is Operations Management? Defined Operations management (OM) is defined as the design, operation, and improvement of the systems that create and deliver the firm’s primary products and services

3 What is Operations Management? Defined Operations management (OM) is defined as the design, operation, and improvement of the systems that create and deliver the firm’s primary products and services

4 Why Study Operations Management? Systematic Approach to Org. Processes Business Education Operations Management Cross-Functional Applications Career Opportunities

4 Why Study Operations Management? Systematic Approach to Org. Processes Business Education Operations Management Cross-Functional Applications Career Opportunities

5 What is a Transformation Process? Defined A transformation process is defined as a use of resources to transform inputs into some desired outputs

5 What is a Transformation Process? Defined A transformation process is defined as a use of resources to transform inputs into some desired outputs

6 Transformations Physical----------manufacturing Locational---------transportation Exchange---------retailing Storage-----------warehousing Physiological-------health care Informational-----telecommunications

6 Transformations Physical----------manufacturing Locational---------transportation Exchange---------retailing Storage-----------warehousing Physiological-------health care Informational-----telecommunications

7 What is a Service and What is a Good? “If you drop it on your foot, it won’t hurt you. ” (Good or service? ) “Services never include goods and goods never include services. ” (True or false? ) https: //www. youtube. com/watch? v=RLEZk 8 s. Ge. ZQ

7 What is a Service and What is a Good? “If you drop it on your foot, it won’t hurt you. ” (Good or service? ) “Services never include goods and goods never include services. ” (True or false? ) https: //www. youtube. com/watch? v=RLEZk 8 s. Ge. ZQ

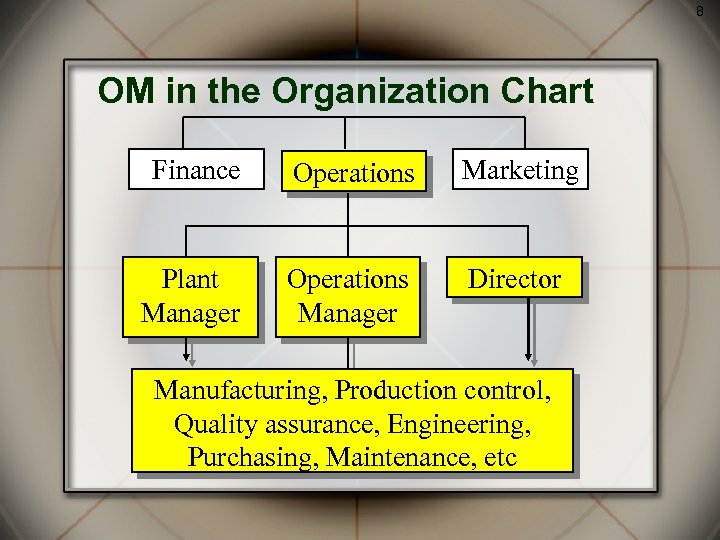

8 OM in the Organization Chart Finance Operations Marketing Plant Manager Operations Manager Director Manufacturing, Production control, Quality assurance, Engineering, Purchasing, Maintenance, etc

8 OM in the Organization Chart Finance Operations Marketing Plant Manager Operations Manager Director Manufacturing, Production control, Quality assurance, Engineering, Purchasing, Maintenance, etc

9 Core Services Defined Core services are basic things that customers want from products they purchase

9 Core Services Defined Core services are basic things that customers want from products they purchase

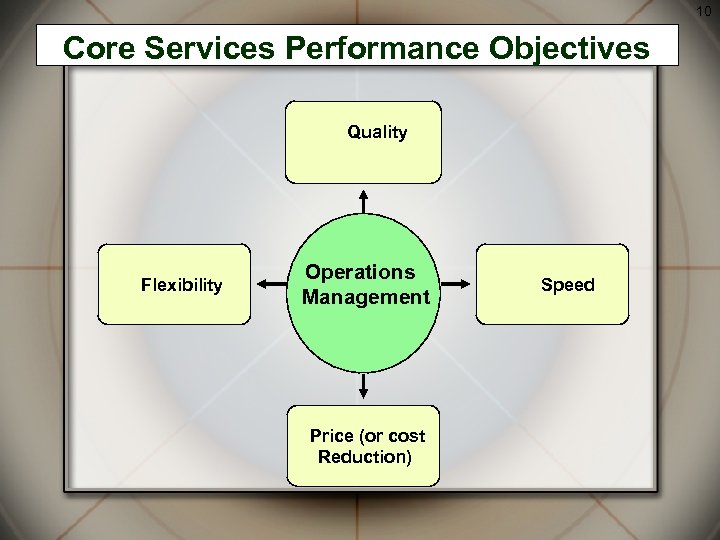

10 Core Services Performance Objectives Quality Flexibility Operations Management Price (or cost Reduction) Speed

10 Core Services Performance Objectives Quality Flexibility Operations Management Price (or cost Reduction) Speed

11 Value-Added Services Defined Value-added services differentiate the organization from competitors and build relationships that bind customers to the firm in a positive way

11 Value-Added Services Defined Value-added services differentiate the organization from competitors and build relationships that bind customers to the firm in a positive way

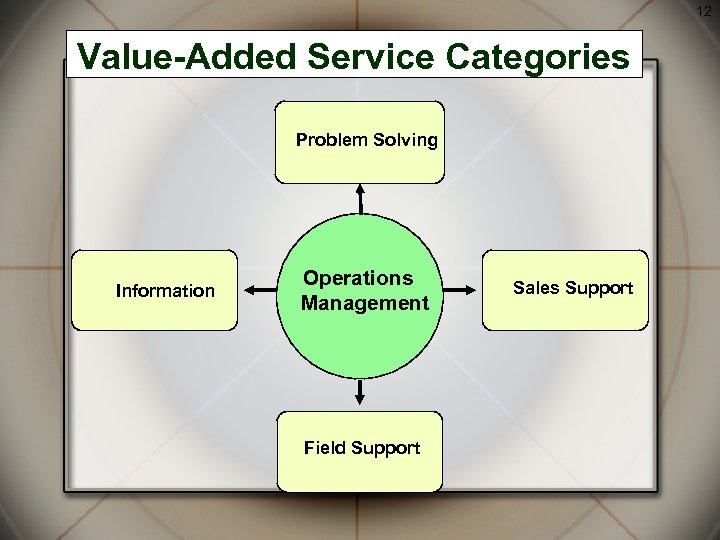

12 Value-Added Service Categories Problem Solving Information Operations Management Field Support Sales Support

12 Value-Added Service Categories Problem Solving Information Operations Management Field Support Sales Support

13 The Importance of Operations Management Synergies must exist with other functional areas of the organization Operations account for 60 -80% of the direct expenses that burden a firm’s profit.

13 The Importance of Operations Management Synergies must exist with other functional areas of the organization Operations account for 60 -80% of the direct expenses that burden a firm’s profit.

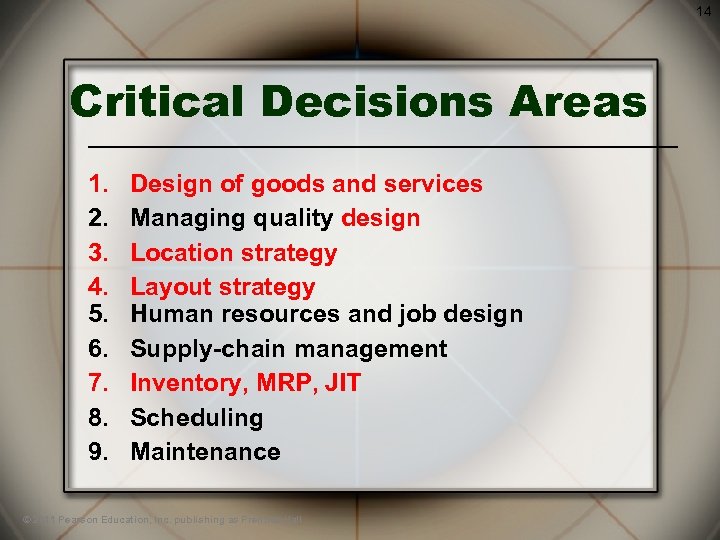

14 Critical Decisions Areas 1. 2. 3. 4. 5. 6. 7. 8. 9. Design of goods and services Managing quality design Location strategy Layout strategy Human resources and job design Supply-chain management Inventory, MRP, JIT Scheduling Maintenance © 2011 Pearson Education, Inc. publishing as Prentice Hall

14 Critical Decisions Areas 1. 2. 3. 4. 5. 6. 7. 8. 9. Design of goods and services Managing quality design Location strategy Layout strategy Human resources and job design Supply-chain management Inventory, MRP, JIT Scheduling Maintenance © 2011 Pearson Education, Inc. publishing as Prentice Hall

15 The Critical Decisions 1. Design of goods and services – What good or service should we offer? – How should we design these products and services? 2. Managing quality – How do we define quality? – Who is responsible for quality? © 2011 Pearson Education, Inc. publishing as Prentice Hall

15 The Critical Decisions 1. Design of goods and services – What good or service should we offer? – How should we design these products and services? 2. Managing quality – How do we define quality? – Who is responsible for quality? © 2011 Pearson Education, Inc. publishing as Prentice Hall

16 The Critical Decisions 3. Process and capacity design – What process and what capacity will these products require? – What equipment and technology is necessary for these processes? 4. Location strategy – Where should we put the facility? – On what criteria should we base the location decision? Table 1. 2 (cont. ) © 2011 Pearson Education, Inc. publishing as Prentice Hall

16 The Critical Decisions 3. Process and capacity design – What process and what capacity will these products require? – What equipment and technology is necessary for these processes? 4. Location strategy – Where should we put the facility? – On what criteria should we base the location decision? Table 1. 2 (cont. ) © 2011 Pearson Education, Inc. publishing as Prentice Hall

17 The Critical Decisions 5. Layout strategy – How should we arrange the facility? – How large must the facility be to meet our plan? 6. Human resources and job design – How do we provide a reasonable work environment? – How much can we expect our employees to produce? Table 1. 2 (cont. ) © 2011 Pearson Education, Inc. publishing as Prentice Hall

17 The Critical Decisions 5. Layout strategy – How should we arrange the facility? – How large must the facility be to meet our plan? 6. Human resources and job design – How do we provide a reasonable work environment? – How much can we expect our employees to produce? Table 1. 2 (cont. ) © 2011 Pearson Education, Inc. publishing as Prentice Hall

18 The Critical Decisions 7. Supply-chain management – Should we make or buy this component? – Who should be our suppliers and how can we integrate them into our strategy? 8. Inventory, material requirements planning, and JIT – How much inventory of each item should we have? – When do we re-order? © 2011 Pearson Education, Inc. publishing as Prentice Hall

18 The Critical Decisions 7. Supply-chain management – Should we make or buy this component? – Who should be our suppliers and how can we integrate them into our strategy? 8. Inventory, material requirements planning, and JIT – How much inventory of each item should we have? – When do we re-order? © 2011 Pearson Education, Inc. publishing as Prentice Hall

19 The Critical Decisions 9. Intermediate and short–term scheduling – Are we better off keeping people on the payroll during slowdowns? – Which jobs do we perform next? 10. Maintenance – How do we build reliability into our processes? – Who is responsible for maintenance? © 2011 Pearson Education, Inc. publishing as Prentice Hall

19 The Critical Decisions 9. Intermediate and short–term scheduling – Are we better off keeping people on the payroll during slowdowns? – Which jobs do we perform next? 10. Maintenance – How do we build reliability into our processes? – Who is responsible for maintenance? © 2011 Pearson Education, Inc. publishing as Prentice Hall

20 Historical Development of OM JIT and TQC Manufacturing Strategy Paradigm Service Quality and Productivity Total Quality Management and Quality Certification

20 Historical Development of OM JIT and TQC Manufacturing Strategy Paradigm Service Quality and Productivity Total Quality Management and Quality Certification

21 Historical Development of OM (cont’d) Business Process Reengineering Supply Chain Management Electronic Commerce

21 Historical Development of OM (cont’d) Business Process Reengineering Supply Chain Management Electronic Commerce

22 Current Issues in OM Coordinate the relationships between mutually supportive but separate organizations. Optimizing global supplier, production, and distribution networks. Increased co-production of goods and services

22 Current Issues in OM Coordinate the relationships between mutually supportive but separate organizations. Optimizing global supplier, production, and distribution networks. Increased co-production of goods and services

23 Current Issues in OM (cont’d) Managing the customer’s experience during the service encounter Raising the awareness of operations as a significant competitive weapon

23 Current Issues in OM (cont’d) Managing the customer’s experience during the service encounter Raising the awareness of operations as a significant competitive weapon

24 New Challenges in OM From To u Local or national focus u Global focus u Batch shipments u Just-in-time u Low bid purchasing u Supply-chain partnering u Lengthy product development u Rapid product development, alliances u Standard products u Mass customization u Job specialization u Empowered employees, teams

24 New Challenges in OM From To u Local or national focus u Global focus u Batch shipments u Just-in-time u Low bid purchasing u Supply-chain partnering u Lengthy product development u Rapid product development, alliances u Standard products u Mass customization u Job specialization u Empowered employees, teams

25 Characteristics of Goods u Tangible product u Consistent product definition u Production usually separate from consumption u Can be inventoried u Low customer interaction

25 Characteristics of Goods u Tangible product u Consistent product definition u Production usually separate from consumption u Can be inventoried u Low customer interaction

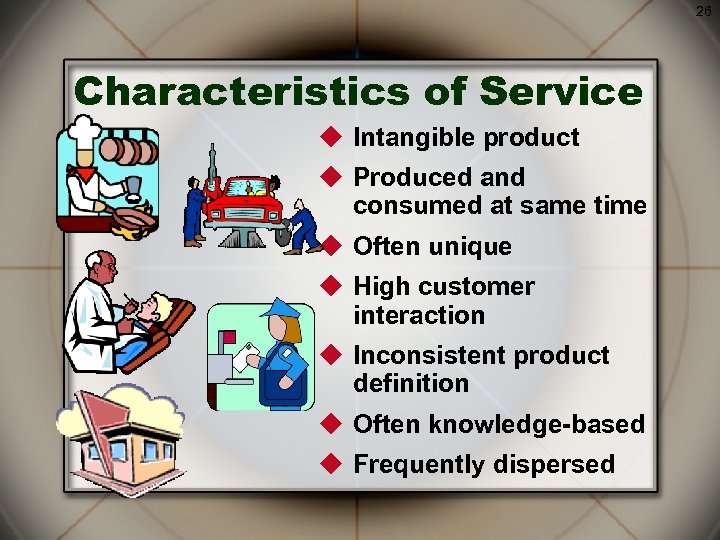

26 Characteristics of Service u Intangible product u Produced and consumed at same time u Often unique u High customer interaction u Inconsistent product definition u Often knowledge-based u Frequently dispersed

26 Characteristics of Service u Intangible product u Produced and consumed at same time u Often unique u High customer interaction u Inconsistent product definition u Often knowledge-based u Frequently dispersed

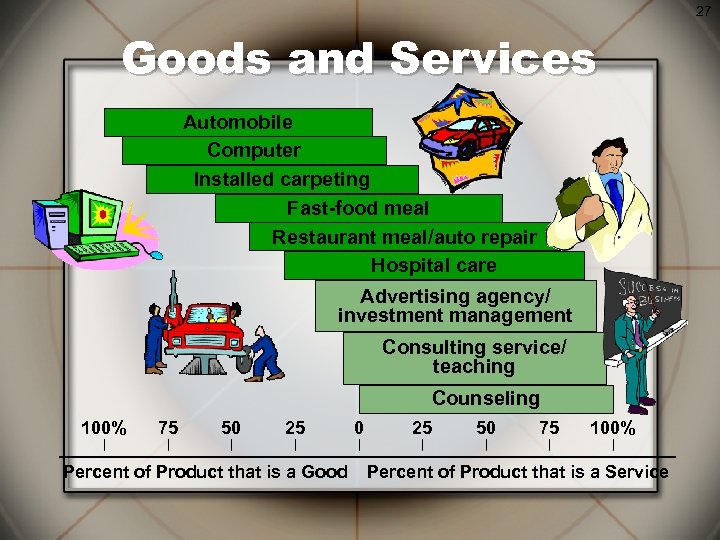

27 Goods and Services Automobile Computer Installed carpeting Fast-food meal Restaurant meal/auto repair Hospital care Advertising agency/ investment management Consulting service/ teaching Counseling 100% | 75 | 50 | 25 | Percent of Product that is a Good 0 | 25 | 50 | 75 | 100% | Percent of Product that is a Service

27 Goods and Services Automobile Computer Installed carpeting Fast-food meal Restaurant meal/auto repair Hospital care Advertising agency/ investment management Consulting service/ teaching Counseling 100% | 75 | 50 | 25 | Percent of Product that is a Good 0 | 25 | 50 | 75 | 100% | Percent of Product that is a Service

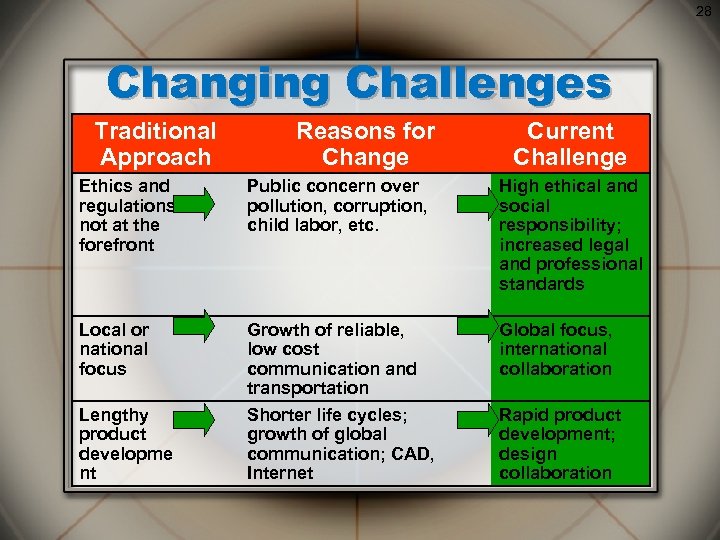

28 Changing Challenges Traditional Approach Reasons for Change Current Challenge Ethics and regulations not at the forefront Public concern over pollution, corruption, child labor, etc. High ethical and social responsibility; increased legal and professional standards Local or national focus Growth of reliable, low cost communication and transportation Shorter life cycles; growth of global communication; CAD, Internet Global focus, international collaboration Lengthy product developme nt Rapid product development; design collaboration

28 Changing Challenges Traditional Approach Reasons for Change Current Challenge Ethics and regulations not at the forefront Public concern over pollution, corruption, child labor, etc. High ethical and social responsibility; increased legal and professional standards Local or national focus Growth of reliable, low cost communication and transportation Shorter life cycles; growth of global communication; CAD, Internet Global focus, international collaboration Lengthy product developme nt Rapid product development; design collaboration

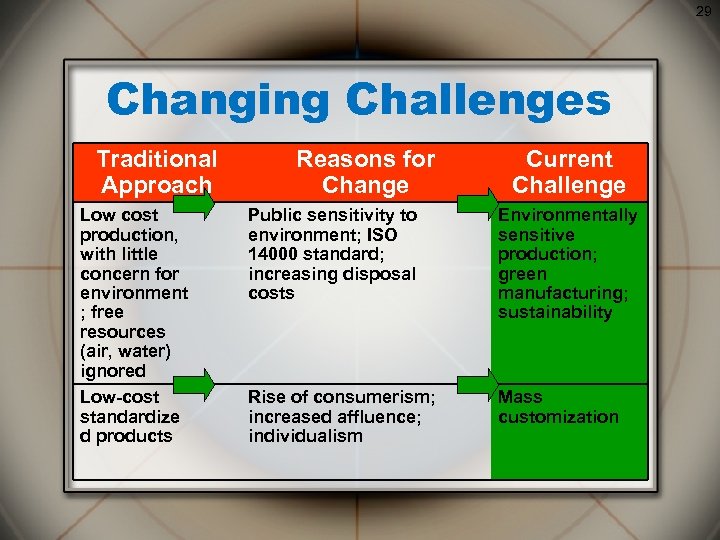

29 Changing Challenges Traditional Approach Low cost production, with little concern for environment ; free resources (air, water) ignored Low-cost standardize d products Reasons for Change Current Challenge Public sensitivity to environment; ISO 14000 standard; increasing disposal costs Environmentally sensitive production; green manufacturing; sustainability Rise of consumerism; increased affluence; individualism Mass customization

29 Changing Challenges Traditional Approach Low cost production, with little concern for environment ; free resources (air, water) ignored Low-cost standardize d products Reasons for Change Current Challenge Public sensitivity to environment; ISO 14000 standard; increasing disposal costs Environmentally sensitive production; green manufacturing; sustainability Rise of consumerism; increased affluence; individualism Mass customization

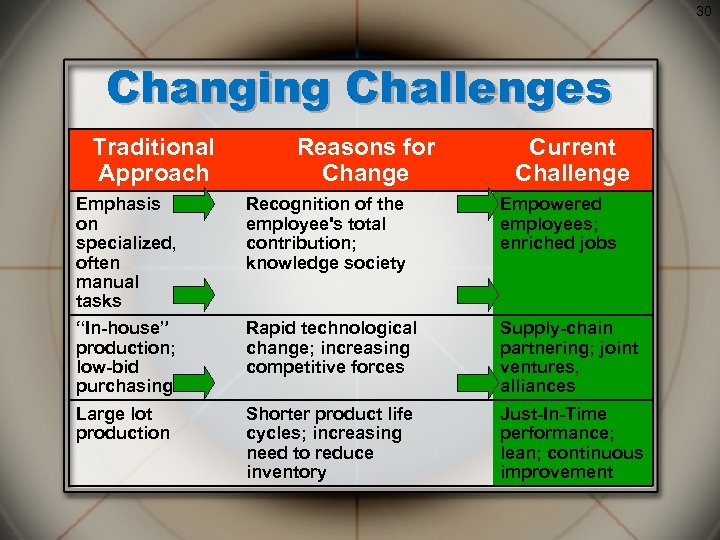

30 Changing Challenges Traditional Approach Reasons for Change Current Challenge Emphasis on specialized, often manual tasks “In-house” production; low-bid purchasing Recognition of the employee's total contribution; knowledge society Empowered employees; enriched jobs Rapid technological change; increasing competitive forces Supply-chain partnering; joint ventures, alliances Large lot production Shorter product life cycles; increasing need to reduce inventory Just-In-Time performance; lean; continuous improvement

30 Changing Challenges Traditional Approach Reasons for Change Current Challenge Emphasis on specialized, often manual tasks “In-house” production; low-bid purchasing Recognition of the employee's total contribution; knowledge society Empowered employees; enriched jobs Rapid technological change; increasing competitive forces Supply-chain partnering; joint ventures, alliances Large lot production Shorter product life cycles; increasing need to reduce inventory Just-In-Time performance; lean; continuous improvement

31 New Trends in OM Ethics Global focus Environmentally sensitive production Rapid product development Mass customization Empowered employees Supply-chain partnering Just-in-time performance © 2011 Pearson Education, Inc. publishing as Prentice Hall

31 New Trends in OM Ethics Global focus Environmentally sensitive production Rapid product development Mass customization Empowered employees Supply-chain partnering Just-in-time performance © 2011 Pearson Education, Inc. publishing as Prentice Hall

32 Productivity Challenge Productivity is the ratio of outputs (goods and services) divided by the inputs (resources such as labor and capital) The objective is to improve productivity! Important Note! Production is a measure of output only and not a measure of efficiency © 2011 Pearson Education, Inc. publishing as Prentice Hall

32 Productivity Challenge Productivity is the ratio of outputs (goods and services) divided by the inputs (resources such as labor and capital) The objective is to improve productivity! Important Note! Production is a measure of output only and not a measure of efficiency © 2011 Pearson Education, Inc. publishing as Prentice Hall

33 Efficiency Versus Effectiveness The difference between efficient and effective is that efficiency refers to how well you do something, whereas effectiveness refers to how useful it is. “Efficiency is doing things right; effectiveness is doing the right things. ” Doing the Right Things is More Important than Doing Things Right

33 Efficiency Versus Effectiveness The difference between efficient and effective is that efficiency refers to how well you do something, whereas effectiveness refers to how useful it is. “Efficiency is doing things right; effectiveness is doing the right things. ” Doing the Right Things is More Important than Doing Things Right

34 Efficiency Versus Effectivenes For example, if a company is not doing well and they decide to train their workforce on a new technology. The training goes really well - they train all their employees in avery short time and tests show they have absorbed the training well. But overall productivity doesn't improve. In this case the company's strategy was efficient but not effective.

34 Efficiency Versus Effectivenes For example, if a company is not doing well and they decide to train their workforce on a new technology. The training goes really well - they train all their employees in avery short time and tests show they have absorbed the training well. But overall productivity doesn't improve. In this case the company's strategy was efficient but not effective.

35 Question Bowl - 1 A major objective of this course is to show smart managers can do which of the following? a. Improve efficiency by lowering costs b. Improve effectiveness by creating value c. Increasing value by reducing prices d. Serving customers well e. All of the above f. Answer: e

35 Question Bowl - 1 A major objective of this course is to show smart managers can do which of the following? a. Improve efficiency by lowering costs b. Improve effectiveness by creating value c. Increasing value by reducing prices d. Serving customers well e. All of the above f. Answer: e

36 Question Bowl - 2 In the Input-Transformation-Output Relationship, a typical “input” for a Department Store is which of the following? a. Displays b. Stocks of goods c. Sales clerks d. All of the above e. None of the above f. Answer: e

36 Question Bowl - 2 In the Input-Transformation-Output Relationship, a typical “input” for a Department Store is which of the following? a. Displays b. Stocks of goods c. Sales clerks d. All of the above e. None of the above f. Answer: e

37 Question Bowl - 3 In which of the following decades did the concept of quality control originate? a. 1920’s b. 1930’s c. 1940’s d. 1950’s e. 1970’s f. Answer: b

37 Question Bowl - 3 In which of the following decades did the concept of quality control originate? a. 1920’s b. 1930’s c. 1940’s d. 1950’s e. 1970’s f. Answer: b

38 End of Session 1

38 End of Session 1