e83a8e572d8c4c481ec9c11cbd1c30fa.ppt

- Количество слайдов: 68

1 RISK MANAGEMENT FOR METALWORKING INDUSTRY A TRAINING FOR THE METALWORKING INDUSTRY © 2008 All Rights Reserved

1 RISK MANAGEMENT FOR METALWORKING INDUSTRY A TRAINING FOR THE METALWORKING INDUSTRY © 2008 All Rights Reserved

2 Table of Contents We will introduce the following topics to you: q Background for Risk Assessment q How to Conduct Risk Assessment • Risk Assessment Team • Hazard Identification • Control Measures • Evaluation of Risk Levels q Maintenance of Risk Assessment q Exercise © 2008 All Rights Reserved

2 Table of Contents We will introduce the following topics to you: q Background for Risk Assessment q How to Conduct Risk Assessment • Risk Assessment Team • Hazard Identification • Control Measures • Evaluation of Risk Levels q Maintenance of Risk Assessment q Exercise © 2008 All Rights Reserved

3 Background for Risk Assessment © 2008 All Rights Reserved

3 Background for Risk Assessment © 2008 All Rights Reserved

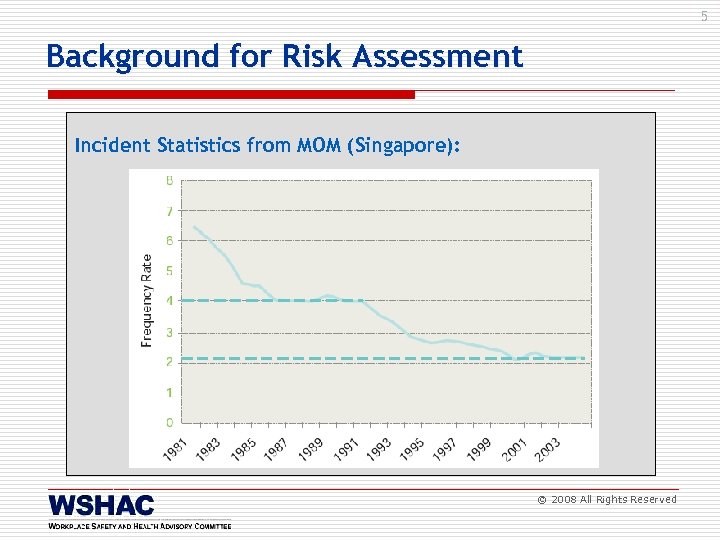

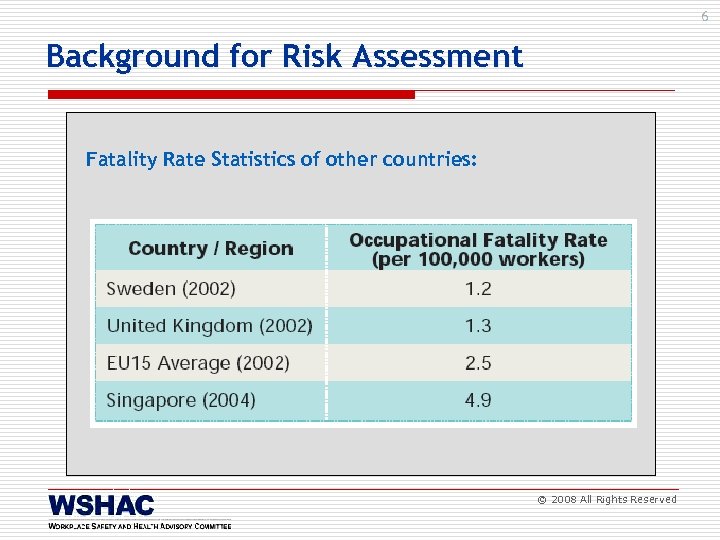

4 Background for Risk Assessment The WSH (Risk Management) Regulation was introduced because: v Since 2000, incident rate maintained constant around 2. 2 per 1, 000 man-hour worked v Gaps in WSH performance with other developed countries v Target to halve the number of work-related fatalities to 2. 5/100, 000 workers by 2015 © 2008 All Rights Reserved

4 Background for Risk Assessment The WSH (Risk Management) Regulation was introduced because: v Since 2000, incident rate maintained constant around 2. 2 per 1, 000 man-hour worked v Gaps in WSH performance with other developed countries v Target to halve the number of work-related fatalities to 2. 5/100, 000 workers by 2015 © 2008 All Rights Reserved

5 Background for Risk Assessment Incident Statistics from MOM (Singapore): © 2008 All Rights Reserved

5 Background for Risk Assessment Incident Statistics from MOM (Singapore): © 2008 All Rights Reserved

6 Background for Risk Assessment Fatality Rate Statistics of other countries: © 2008 All Rights Reserved

6 Background for Risk Assessment Fatality Rate Statistics of other countries: © 2008 All Rights Reserved

7 Legal Requirements Risk assessment is important because: Ø It is required by the law, e. g. Workplace Safety and Health (Risk Management) Regulations Ø It helps the stakeholders to eliminate, reduce or mitigate hazards Ø It keeps employees safe in their workplace © 2008 All Rights Reserved

7 Legal Requirements Risk assessment is important because: Ø It is required by the law, e. g. Workplace Safety and Health (Risk Management) Regulations Ø It helps the stakeholders to eliminate, reduce or mitigate hazards Ø It keeps employees safe in their workplace © 2008 All Rights Reserved

8 Legal Requirements The framework for the new Workplace Safety and Health Act and its regulations is to: Ø Reduce risks at source Ø Take greater industry ownership of WSH outcomes Ø To prevent accidents through higher penalties for poor safety management For effective control of risk, risk assessment must be communicated to relevant parties. © 2008 All Rights Reserved

8 Legal Requirements The framework for the new Workplace Safety and Health Act and its regulations is to: Ø Reduce risks at source Ø Take greater industry ownership of WSH outcomes Ø To prevent accidents through higher penalties for poor safety management For effective control of risk, risk assessment must be communicated to relevant parties. © 2008 All Rights Reserved

9 How to Conduct Risk Assessment © 2008 All Rights Reserved

9 How to Conduct Risk Assessment © 2008 All Rights Reserved

10 Risk Assessment can be done by: § Establishing the risk assessment team § Identifying all the hazards § Identifying all the existing control measures § Evaluating the risk levels § Evaluating whether additional control measures are required © 2008 All Rights Reserved

10 Risk Assessment can be done by: § Establishing the risk assessment team § Identifying all the hazards § Identifying all the existing control measures § Evaluating the risk levels § Evaluating whether additional control measures are required © 2008 All Rights Reserved

11 Team Member Risk Assessment Team consists of: § Team Leader § Management Staff § Process/Facility Engineer § Technical Personnel § Supervisors § Production Operators § Maintenance Staff § Safety Manager/Executive © 2008 All Rights Reserved

11 Team Member Risk Assessment Team consists of: § Team Leader § Management Staff § Process/Facility Engineer § Technical Personnel § Supervisors § Production Operators § Maintenance Staff § Safety Manager/Executive © 2008 All Rights Reserved

12 Responsibilities Employers shall: q Assign a competent person leading the risk assessment team q Ensure that employees are aware of the risk assessment for their work q Provide a register to record findings of risk assessment q Inform all personnel involved about risks in the workplace and means to minimize / eliminate risks q Ensure risk control measures are implemented at the end of risk assessment © 2008 All Rights Reserved

12 Responsibilities Employers shall: q Assign a competent person leading the risk assessment team q Ensure that employees are aware of the risk assessment for their work q Provide a register to record findings of risk assessment q Inform all personnel involved about risks in the workplace and means to minimize / eliminate risks q Ensure risk control measures are implemented at the end of risk assessment © 2008 All Rights Reserved

13 Responsibilities Employers shall: q Keep the risk assessment record for inspection for at least 3 years and submit it to Commissioner for Workplace Safety and Health if required q Review and update the risk assessment at least once every 3 years or earlier if there is significant change to work or process q Develop and implement safe work procedures for works that poses safety and health risks to workers q Keep a written description of the safe work procedures and produce this to the inspector for inspection when required © 2008 All Rights Reserved

13 Responsibilities Employers shall: q Keep the risk assessment record for inspection for at least 3 years and submit it to Commissioner for Workplace Safety and Health if required q Review and update the risk assessment at least once every 3 years or earlier if there is significant change to work or process q Develop and implement safe work procedures for works that poses safety and health risks to workers q Keep a written description of the safe work procedures and produce this to the inspector for inspection when required © 2008 All Rights Reserved

14 Responsibilities Employees shall: q Participate in risk assessments q Adhere to the safe work procedures established to reduce any safety and health risks at the workplace q Inform their supervisors of any shortcomings in the safe work procedures. © 2008 All Rights Reserved

14 Responsibilities Employees shall: q Participate in risk assessments q Adhere to the safe work procedures established to reduce any safety and health risks at the workplace q Inform their supervisors of any shortcomings in the safe work procedures. © 2008 All Rights Reserved

15 Hazard Identification “Hazard” is defined in WSHA as: “Anything with the potential to cause bodily harm or injury, and includes any physical, chemical, biological, mechanical, psychosocial, electrical or ergonomic hazard”. © 2008 All Rights Reserved

15 Hazard Identification “Hazard” is defined in WSHA as: “Anything with the potential to cause bodily harm or injury, and includes any physical, chemical, biological, mechanical, psychosocial, electrical or ergonomic hazard”. © 2008 All Rights Reserved

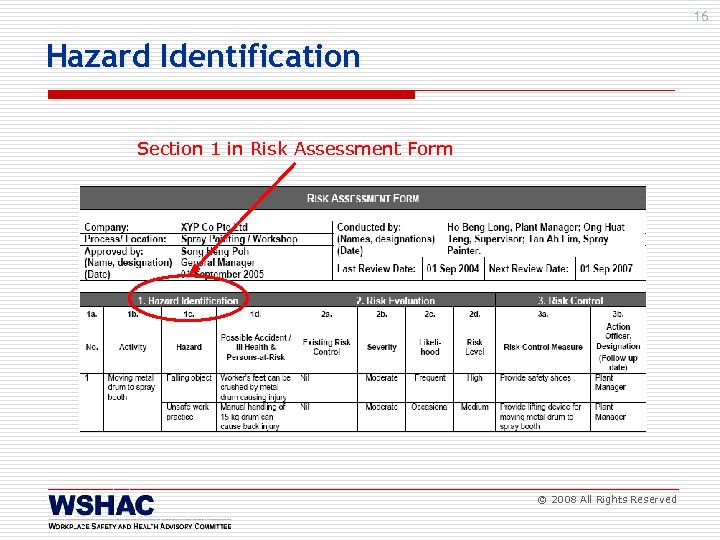

16 Hazard Identification Section 1 in Risk Assessment Form © 2008 All Rights Reserved

16 Hazard Identification Section 1 in Risk Assessment Form © 2008 All Rights Reserved

17 Hazard Identification Steps for Hazard Identification Step 1: Breakdown of activities (1 b) Step 2: Identify the hazards of each step (1 c) Step 3: Identify the consequence(s) of each hazard (1 d) © 2008 All Rights Reserved

17 Hazard Identification Steps for Hazard Identification Step 1: Breakdown of activities (1 b) Step 2: Identify the hazards of each step (1 c) Step 3: Identify the consequence(s) of each hazard (1 d) © 2008 All Rights Reserved

18 Hazard Identification Examples of activities v Metal stamping v Drum painting v Drying of painting in oven v Removal of stuck material from machine v Material shearing v Etc. © 2008 All Rights Reserved

18 Hazard Identification Examples of activities v Metal stamping v Drum painting v Drying of painting in oven v Removal of stuck material from machine v Material shearing v Etc. © 2008 All Rights Reserved

19 Hazard Identification Broad categories of hazards in metalworking industry: Mechanical Noise Electrical Chemical Driving Ergonomics Others © 2008 All Rights Reserved

19 Hazard Identification Broad categories of hazards in metalworking industry: Mechanical Noise Electrical Chemical Driving Ergonomics Others © 2008 All Rights Reserved

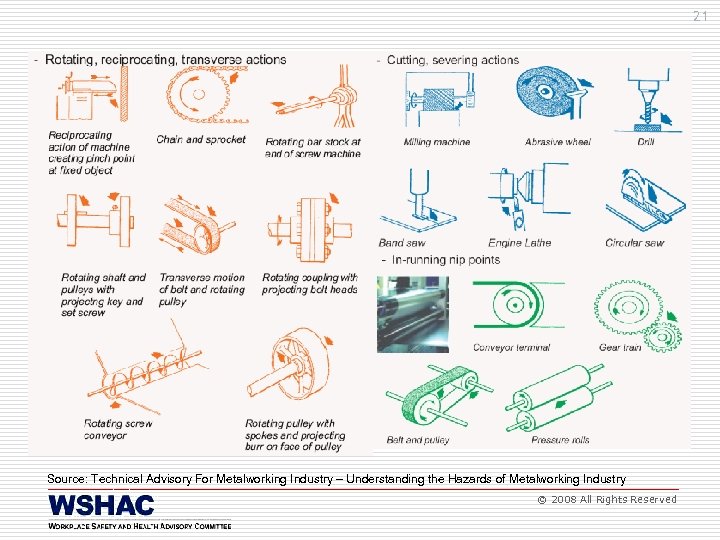

20 Hazard Identification Mechanical Hazards Rotating, reciprocating, transverse actions; Cutting, severing services; In-running nip points. © 2008 All Rights Reserved

20 Hazard Identification Mechanical Hazards Rotating, reciprocating, transverse actions; Cutting, severing services; In-running nip points. © 2008 All Rights Reserved

21 Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

21 Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

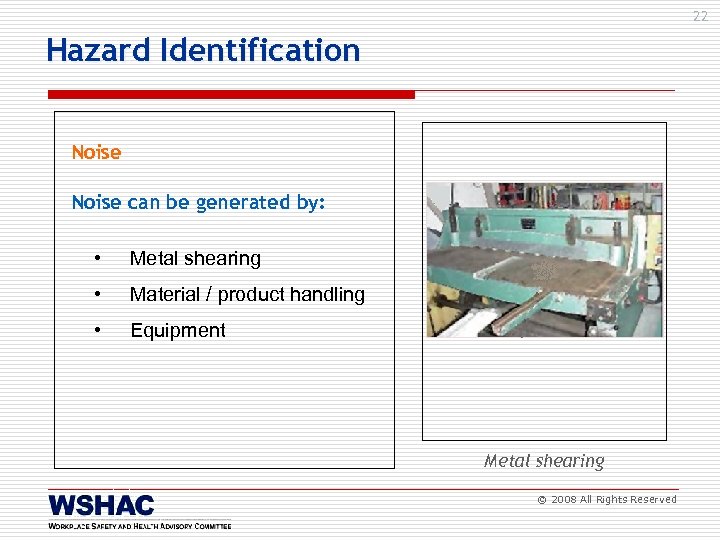

22 Hazard Identification Noise can be generated by: • Metal shearing • Material / product handling • Equipment Metal shearing © 2008 All Rights Reserved

22 Hazard Identification Noise can be generated by: • Metal shearing • Material / product handling • Equipment Metal shearing © 2008 All Rights Reserved

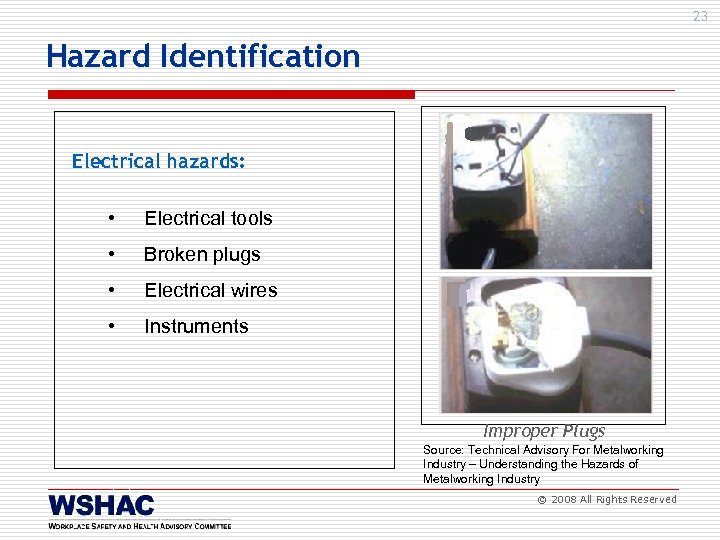

23 Hazard Identification Electrical hazards: • Electrical tools • Broken plugs • Electrical wires • Instruments Improper Plugs Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

23 Hazard Identification Electrical hazards: • Electrical tools • Broken plugs • Electrical wires • Instruments Improper Plugs Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

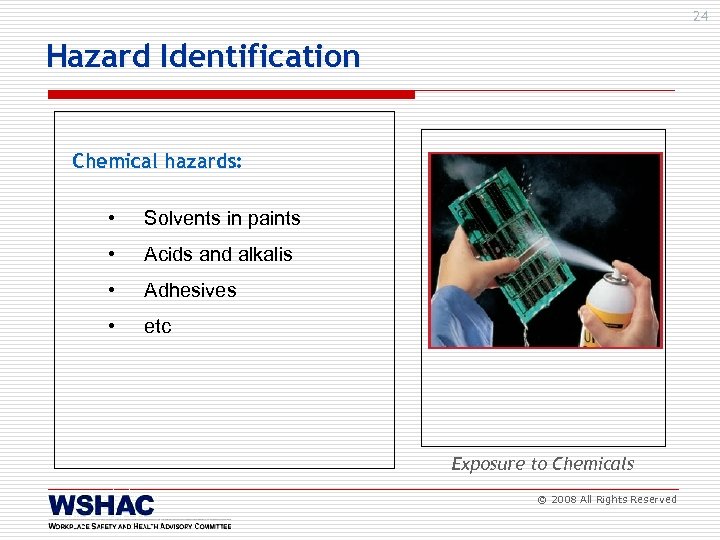

24 Hazard Identification Chemical hazards: • Solvents in paints • Acids and alkalis • Adhesives • etc Exposure to Chemicals © 2008 All Rights Reserved

24 Hazard Identification Chemical hazards: • Solvents in paints • Acids and alkalis • Adhesives • etc Exposure to Chemicals © 2008 All Rights Reserved

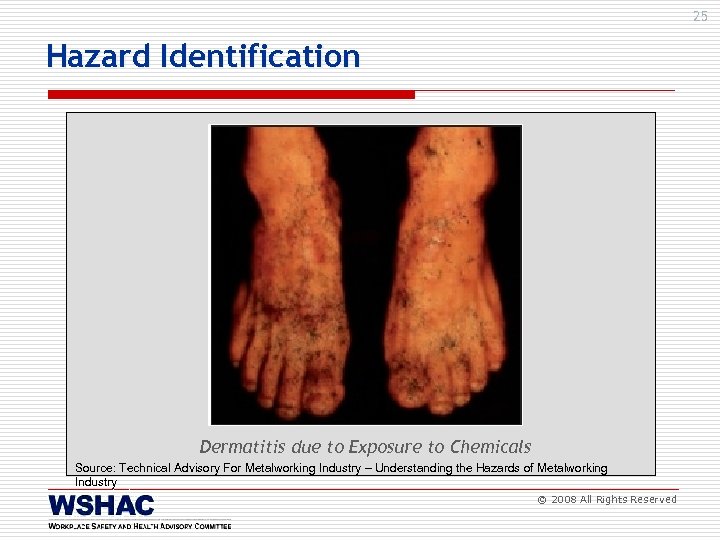

25 Hazard Identification Dermatitis due to Exposure to Chemicals Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

25 Hazard Identification Dermatitis due to Exposure to Chemicals Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

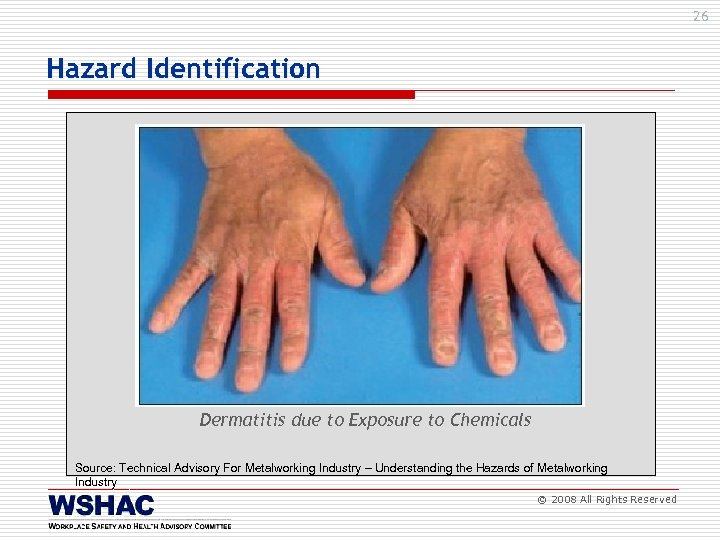

26 Hazard Identification Dermatitis due to Exposure to Chemicals Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

26 Hazard Identification Dermatitis due to Exposure to Chemicals Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

27 Hazard Identification Driving (forklift): • Overloading; • Improper use of forklift; • Over speeding; • Inadequate maintenance • Untrained operator © 2008 All Rights Reserved

27 Hazard Identification Driving (forklift): • Overloading; • Improper use of forklift; • Over speeding; • Inadequate maintenance • Untrained operator © 2008 All Rights Reserved

28 Hazard Identification Source: EIGA Safety Newsletter, SAG NL N° 81/05/E Overturning due to high speed © 2008 All Rights Reserved

28 Hazard Identification Source: EIGA Safety Newsletter, SAG NL N° 81/05/E Overturning due to high speed © 2008 All Rights Reserved

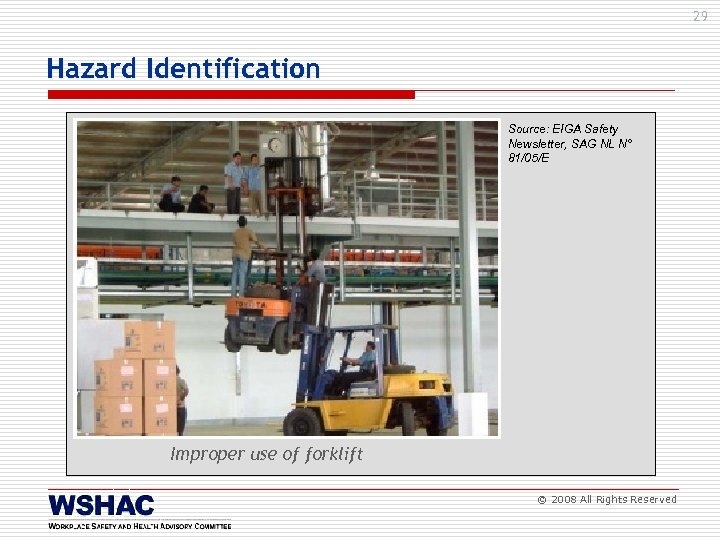

29 Hazard Identification Source: EIGA Safety Newsletter, SAG NL N° 81/05/E Improper use of forklift © 2008 All Rights Reserved

29 Hazard Identification Source: EIGA Safety Newsletter, SAG NL N° 81/05/E Improper use of forklift © 2008 All Rights Reserved

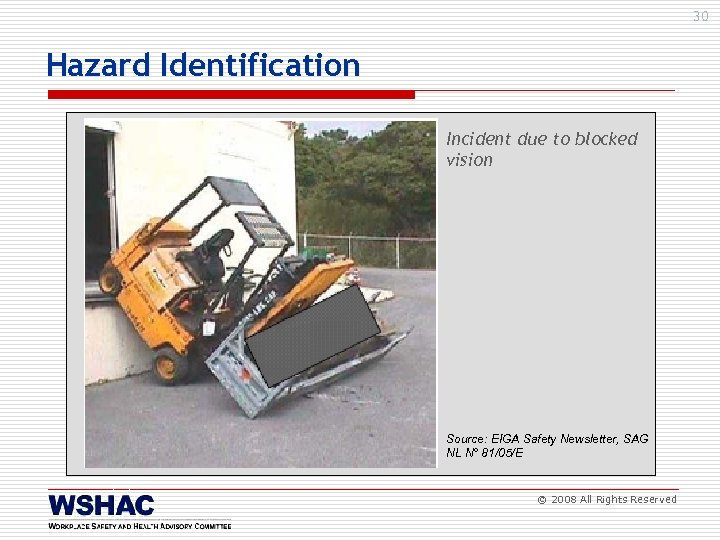

30 Hazard Identification Incident due to blocked vision Source: EIGA Safety Newsletter, SAG NL N° 81/05/E © 2008 All Rights Reserved

30 Hazard Identification Incident due to blocked vision Source: EIGA Safety Newsletter, SAG NL N° 81/05/E © 2008 All Rights Reserved

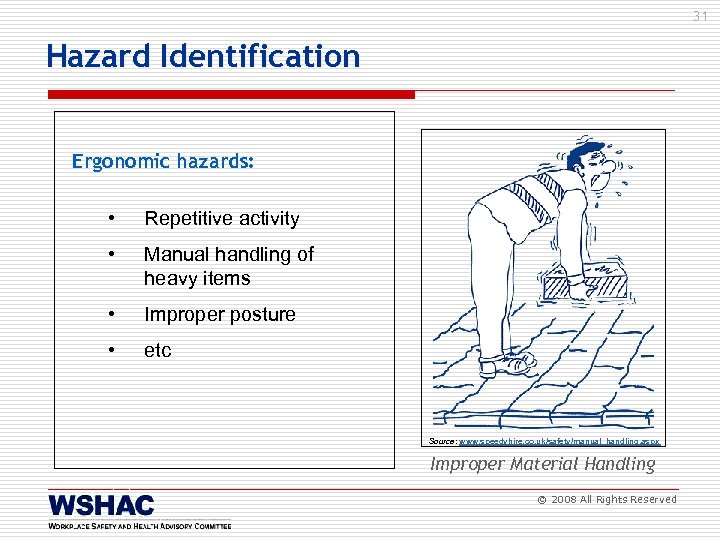

31 Hazard Identification Ergonomic hazards: • Repetitive activity • Manual handling of heavy items • Improper posture • etc Source: www. speedyhire. co. uk/safety/manual_handling. aspx Improper Material Handling © 2008 All Rights Reserved

31 Hazard Identification Ergonomic hazards: • Repetitive activity • Manual handling of heavy items • Improper posture • etc Source: www. speedyhire. co. uk/safety/manual_handling. aspx Improper Material Handling © 2008 All Rights Reserved

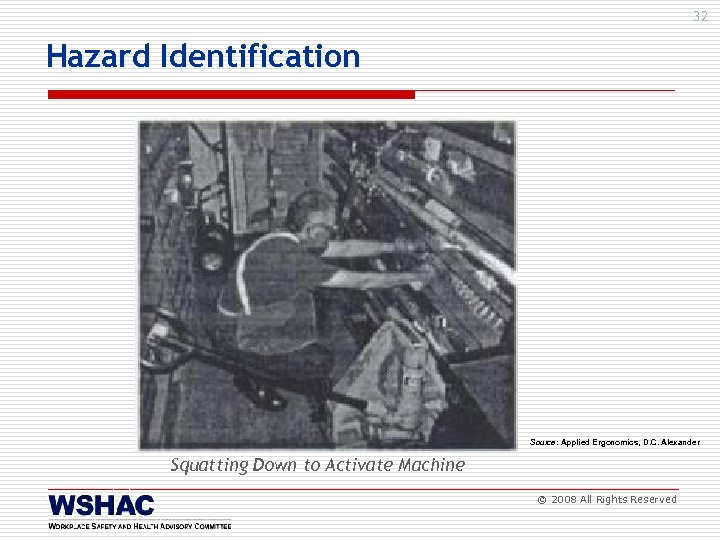

32 Hazard Identification Source: Applied Ergonomics, D. C. Alexander Squatting Down to Activate Machine © 2008 All Rights Reserved

32 Hazard Identification Source: Applied Ergonomics, D. C. Alexander Squatting Down to Activate Machine © 2008 All Rights Reserved

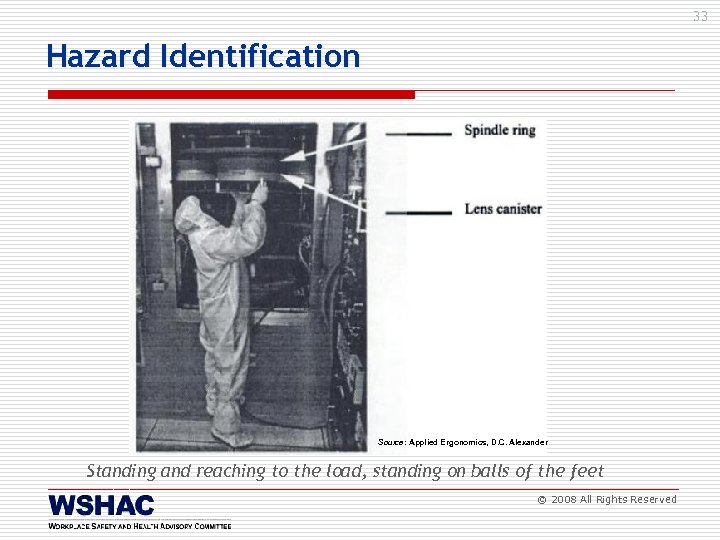

33 Hazard Identification Source: Applied Ergonomics, D. C. Alexander Standing and reaching to the load, standing on balls of the feet © 2008 All Rights Reserved

33 Hazard Identification Source: Applied Ergonomics, D. C. Alexander Standing and reaching to the load, standing on balls of the feet © 2008 All Rights Reserved

34 Hazard Identification Material Loading © 2008 All Rights Reserved

34 Hazard Identification Material Loading © 2008 All Rights Reserved

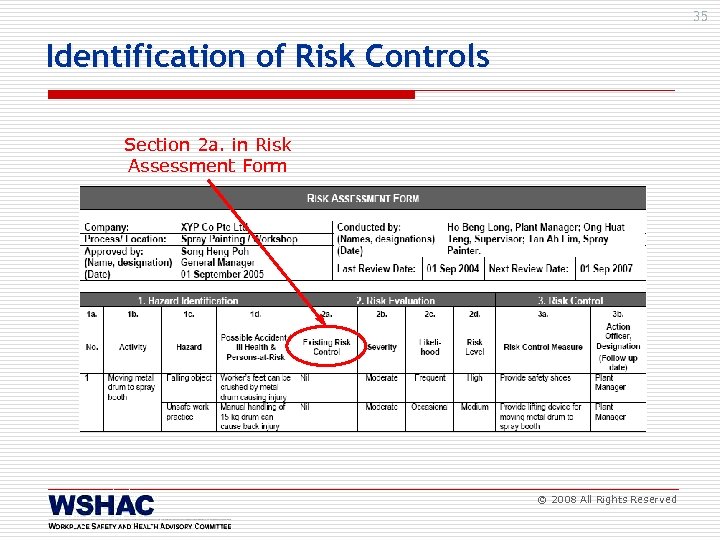

35 Identification of Risk Controls Section 2 a. in Risk Assessment Form © 2008 All Rights Reserved

35 Identification of Risk Controls Section 2 a. in Risk Assessment Form © 2008 All Rights Reserved

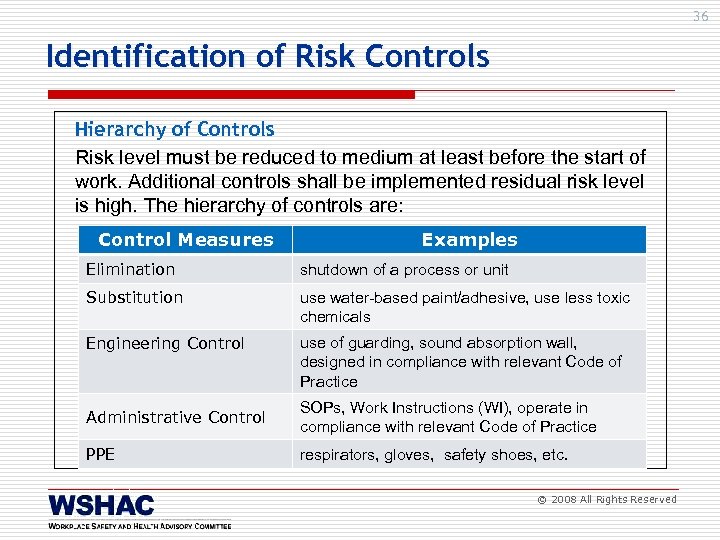

36 Identification of Risk Controls Hierarchy of Controls Risk level must be reduced to medium at least before the start of work. Additional controls shall be implemented residual risk level is high. The hierarchy of controls are: Control Measures Examples Elimination shutdown of a process or unit Substitution use water-based paint/adhesive, use less toxic chemicals Engineering Control use of guarding, sound absorption wall, designed in compliance with relevant Code of Practice Administrative Control SOPs, Work Instructions (WI), operate in compliance with relevant Code of Practice PPE respirators, gloves, safety shoes, etc. © 2008 All Rights Reserved

36 Identification of Risk Controls Hierarchy of Controls Risk level must be reduced to medium at least before the start of work. Additional controls shall be implemented residual risk level is high. The hierarchy of controls are: Control Measures Examples Elimination shutdown of a process or unit Substitution use water-based paint/adhesive, use less toxic chemicals Engineering Control use of guarding, sound absorption wall, designed in compliance with relevant Code of Practice Administrative Control SOPs, Work Instructions (WI), operate in compliance with relevant Code of Practice PPE respirators, gloves, safety shoes, etc. © 2008 All Rights Reserved

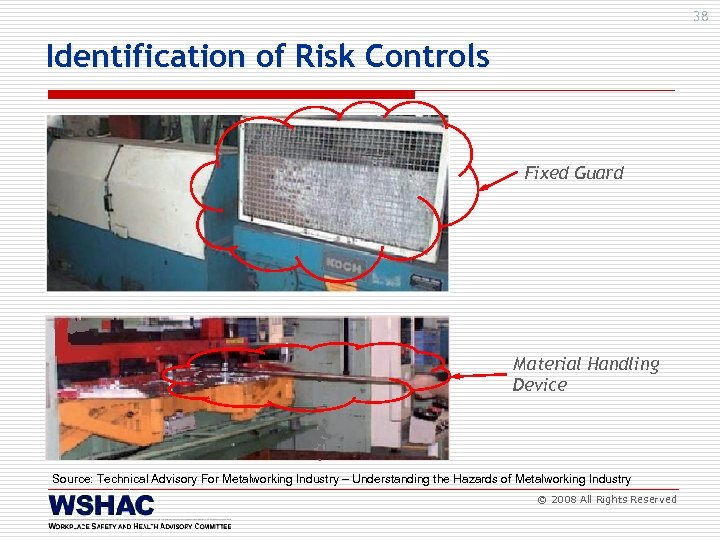

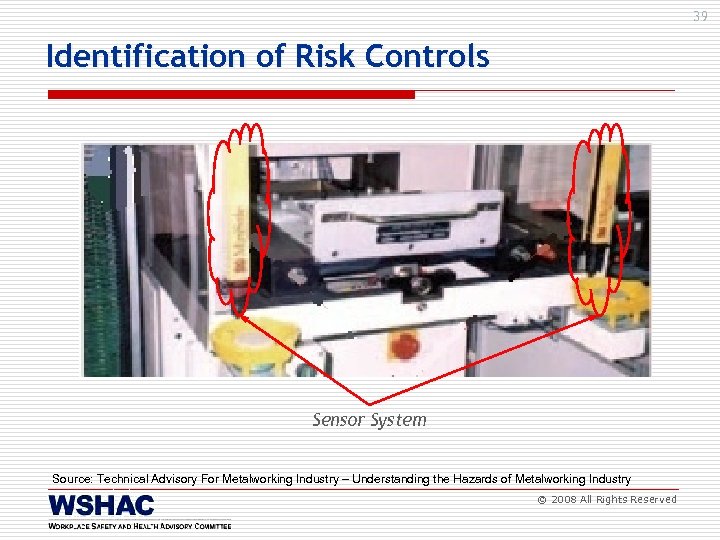

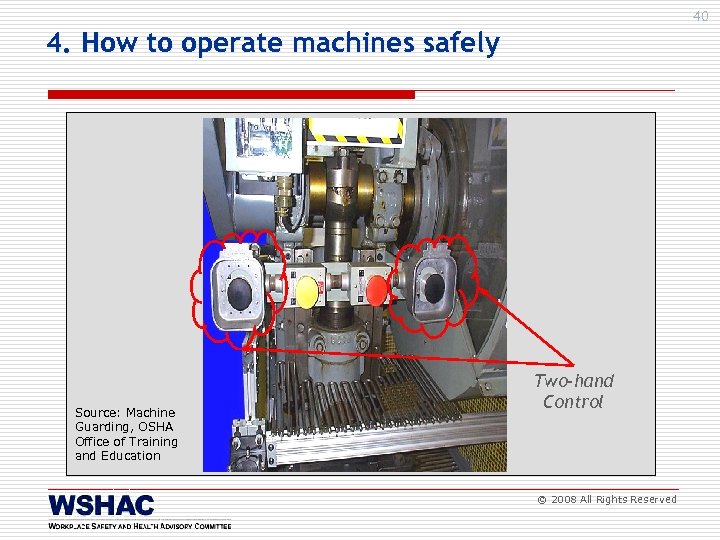

37 Identification of Risk Controls Mechanical hazards: • Machine guarding (engineering control) • Using material handling devices (engineering control) • Two-hand control system (engineering control) • Sensor control system (engineering control) © 2008 All Rights Reserved

37 Identification of Risk Controls Mechanical hazards: • Machine guarding (engineering control) • Using material handling devices (engineering control) • Two-hand control system (engineering control) • Sensor control system (engineering control) © 2008 All Rights Reserved

38 Identification of Risk Controls Fixed Guard Material Handling Device Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

38 Identification of Risk Controls Fixed Guard Material Handling Device Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

39 Identification of Risk Controls Sensor System Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

39 Identification of Risk Controls Sensor System Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

40 4. How to operate machines safely Source: Machine Guarding, OSHA Office of Training and Education Two-hand Control © 2008 All Rights Reserved

40 4. How to operate machines safely Source: Machine Guarding, OSHA Office of Training and Education Two-hand Control © 2008 All Rights Reserved

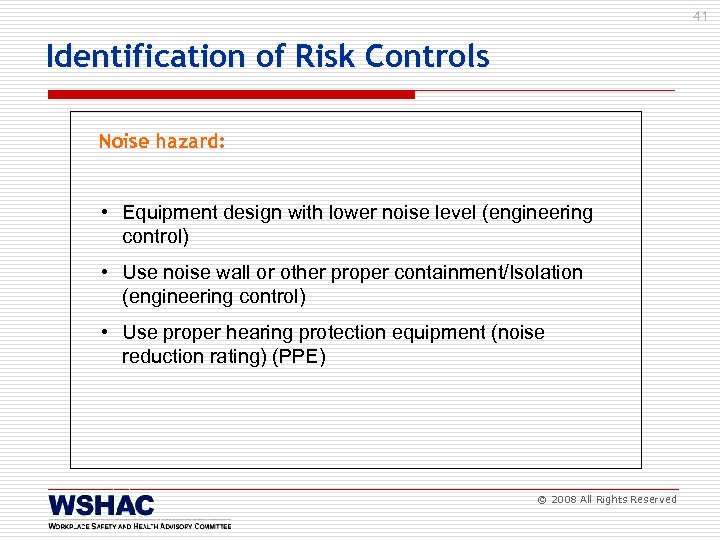

41 Identification of Risk Controls Noise hazard: • Equipment design with lower noise level (engineering control) • Use noise wall or other proper containment/Isolation (engineering control) • Use proper hearing protection equipment (noise reduction rating) (PPE) © 2008 All Rights Reserved

41 Identification of Risk Controls Noise hazard: • Equipment design with lower noise level (engineering control) • Use noise wall or other proper containment/Isolation (engineering control) • Use proper hearing protection equipment (noise reduction rating) (PPE) © 2008 All Rights Reserved

42 Identification of Risk Controls Hearing Protection Equipment Total Enclosure of Machine © 2008 All Rights Reserved

42 Identification of Risk Controls Hearing Protection Equipment Total Enclosure of Machine © 2008 All Rights Reserved

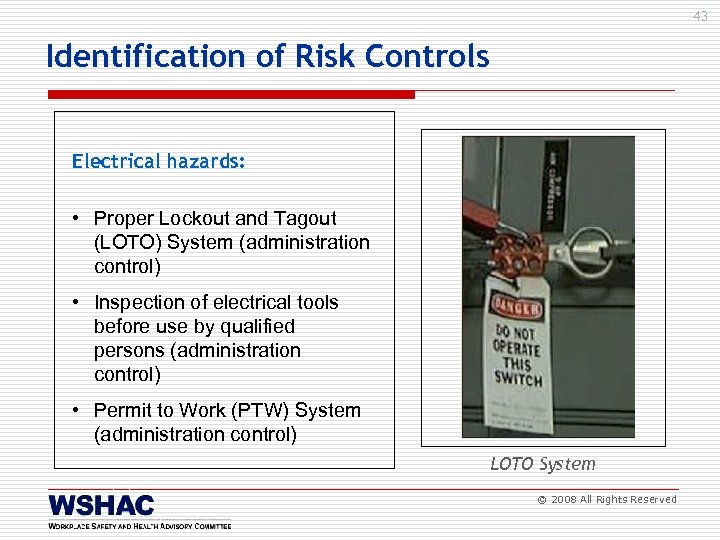

43 Identification of Risk Controls Electrical hazards: • Proper Lockout and Tagout (LOTO) System (administration control) • Inspection of electrical tools before use by qualified persons (administration control) • Permit to Work (PTW) System (administration control) LOTO System © 2008 All Rights Reserved

43 Identification of Risk Controls Electrical hazards: • Proper Lockout and Tagout (LOTO) System (administration control) • Inspection of electrical tools before use by qualified persons (administration control) • Permit to Work (PTW) System (administration control) LOTO System © 2008 All Rights Reserved

44 Identification of Risk Controls Chemical hazards: • Use less toxic chemicals (substitution) • Replace with water-based chemicals (substitution) • Use Local Exhaust Ventilation (LEV) system (engineering control) • Use Safety Data Sheet (SDS) for instructions • Use proper PPE • Regular hygiene monitoring © 2008 All Rights Reserved

44 Identification of Risk Controls Chemical hazards: • Use less toxic chemicals (substitution) • Replace with water-based chemicals (substitution) • Use Local Exhaust Ventilation (LEV) system (engineering control) • Use Safety Data Sheet (SDS) for instructions • Use proper PPE • Regular hygiene monitoring © 2008 All Rights Reserved

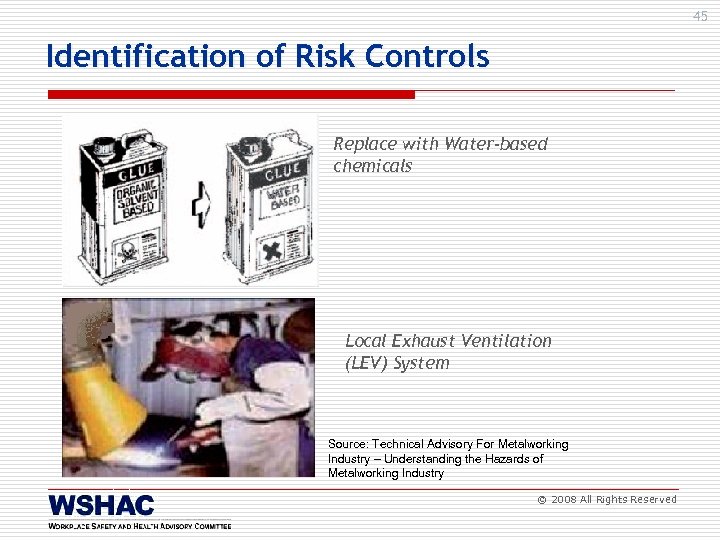

45 Identification of Risk Controls Replace with Water-based chemicals Local Exhaust Ventilation (LEV) System Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

45 Identification of Risk Controls Replace with Water-based chemicals Local Exhaust Ventilation (LEV) System Source: Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry © 2008 All Rights Reserved

46 Identification of Risk Controls Personal Hygiene Monitor Selection of Proper PPE © 2008 All Rights Reserved

46 Identification of Risk Controls Personal Hygiene Monitor Selection of Proper PPE © 2008 All Rights Reserved

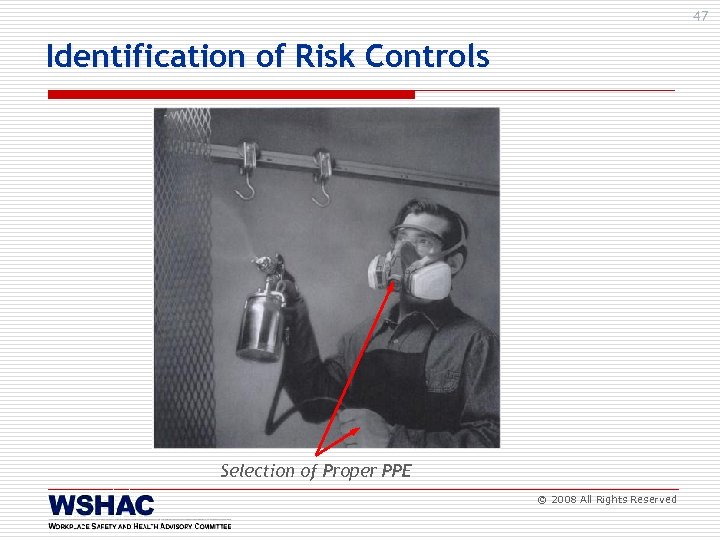

47 Identification of Risk Controls Selection of Proper PPE © 2008 All Rights Reserved

47 Identification of Risk Controls Selection of Proper PPE © 2008 All Rights Reserved

48 Identification of Risk Controls Use of Secondary Containment Use of Spill Control Materials © 2008 All Rights Reserved

48 Identification of Risk Controls Use of Secondary Containment Use of Spill Control Materials © 2008 All Rights Reserved

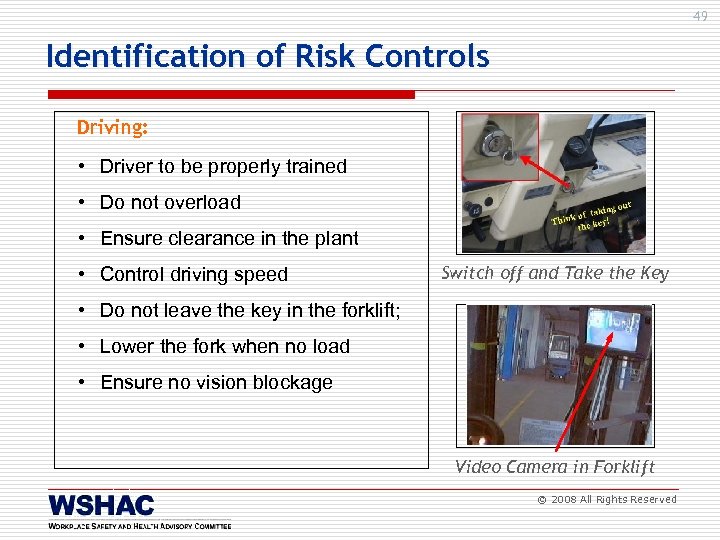

49 Identification of Risk Controls Driving: • Driver to be properly trained • Do not overload • Ensure clearance in the plant • Control driving speed Switch off and Take the Key • Do not leave the key in the forklift; • Lower the fork when no load • Ensure no vision blockage Video Camera in Forklift © 2008 All Rights Reserved

49 Identification of Risk Controls Driving: • Driver to be properly trained • Do not overload • Ensure clearance in the plant • Control driving speed Switch off and Take the Key • Do not leave the key in the forklift; • Lower the fork when no load • Ensure no vision blockage Video Camera in Forklift © 2008 All Rights Reserved

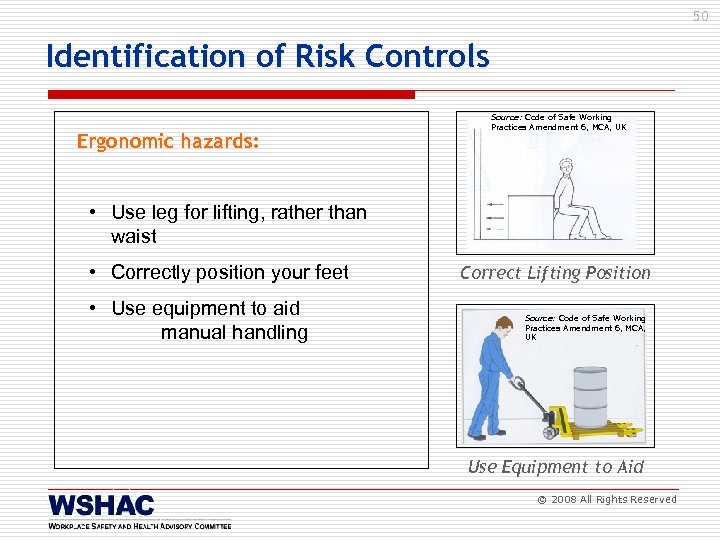

50 Identification of Risk Controls Ergonomic hazards: Source: Code of Safe Working Practices Amendment 6, MCA, UK • Use leg for lifting, rather than waist • Correctly position your feet • Use equipment to aid manual handling Correct Lifting Position Source: Code of Safe Working Practices Amendment 6, MCA, UK Use Equipment to Aid © 2008 All Rights Reserved

50 Identification of Risk Controls Ergonomic hazards: Source: Code of Safe Working Practices Amendment 6, MCA, UK • Use leg for lifting, rather than waist • Correctly position your feet • Use equipment to aid manual handling Correct Lifting Position Source: Code of Safe Working Practices Amendment 6, MCA, UK Use Equipment to Aid © 2008 All Rights Reserved

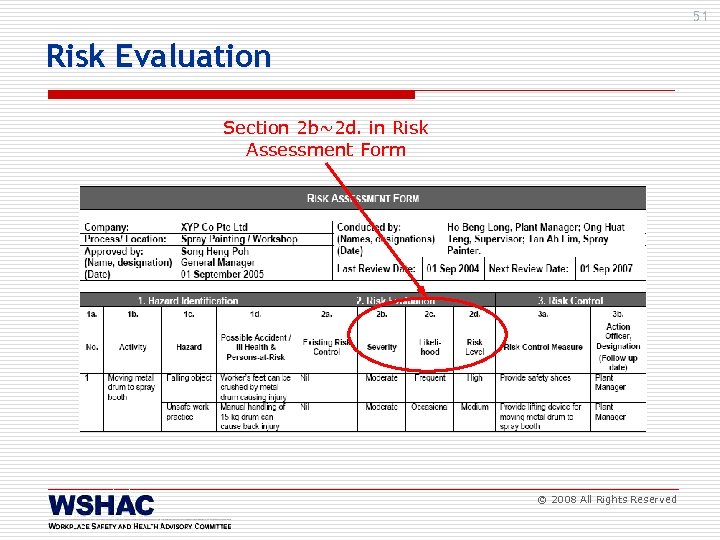

51 Risk Evaluation Section 2 b~2 d. in Risk Assessment Form © 2008 All Rights Reserved

51 Risk Evaluation Section 2 b~2 d. in Risk Assessment Form © 2008 All Rights Reserved

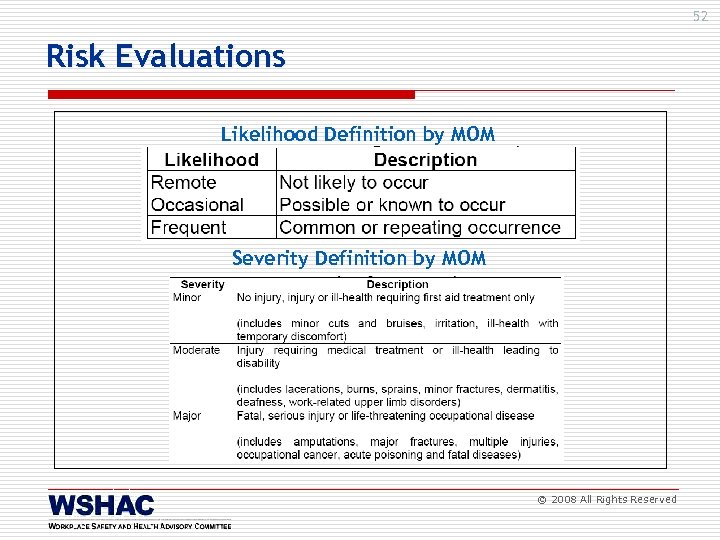

52 Risk Evaluations Likelihood Definition by MOM Severity Definition by MOM © 2008 All Rights Reserved

52 Risk Evaluations Likelihood Definition by MOM Severity Definition by MOM © 2008 All Rights Reserved

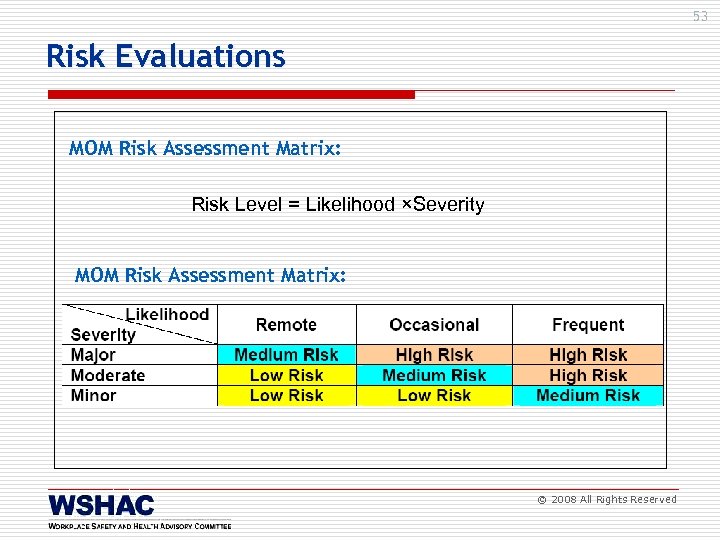

53 Risk Evaluations MOM Risk Assessment Matrix: Risk Level = Likelihood ×Severity MOM Risk Assessment Matrix: © 2008 All Rights Reserved

53 Risk Evaluations MOM Risk Assessment Matrix: Risk Level = Likelihood ×Severity MOM Risk Assessment Matrix: © 2008 All Rights Reserved

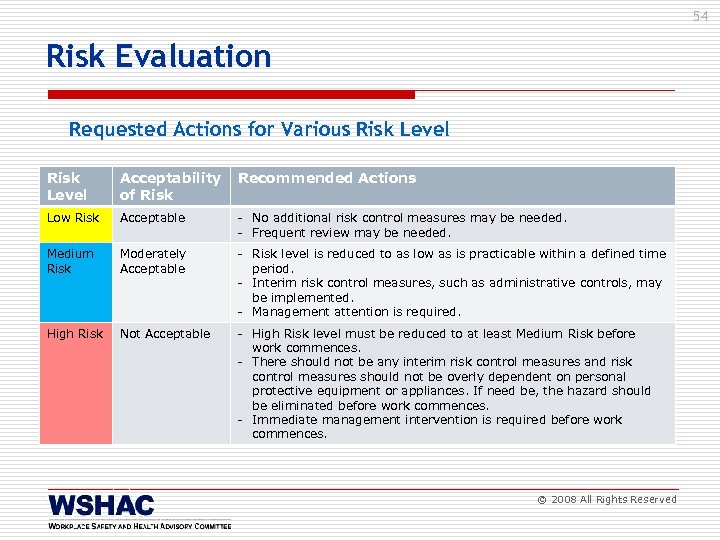

54 Risk Evaluation Requested Actions for Various Risk Level Acceptability of Risk Recommended Actions Low Risk Acceptable - No additional risk control measures may be needed. - Frequent review may be needed. Medium Risk Moderately Acceptable - Risk level is reduced to as low as is practicable within a defined time period. - Interim risk control measures, such as administrative controls, may be implemented. - Management attention is required. High Risk Not Acceptable - High Risk level must be reduced to at least Medium Risk before work commences. - There should not be any interim risk control measures and risk control measures should not be overly dependent on personal protective equipment or appliances. If need be, the hazard should be eliminated before work commences. - Immediate management intervention is required before work commences. © 2008 All Rights Reserved

54 Risk Evaluation Requested Actions for Various Risk Level Acceptability of Risk Recommended Actions Low Risk Acceptable - No additional risk control measures may be needed. - Frequent review may be needed. Medium Risk Moderately Acceptable - Risk level is reduced to as low as is practicable within a defined time period. - Interim risk control measures, such as administrative controls, may be implemented. - Management attention is required. High Risk Not Acceptable - High Risk level must be reduced to at least Medium Risk before work commences. - There should not be any interim risk control measures and risk control measures should not be overly dependent on personal protective equipment or appliances. If need be, the hazard should be eliminated before work commences. - Immediate management intervention is required before work commences. © 2008 All Rights Reserved

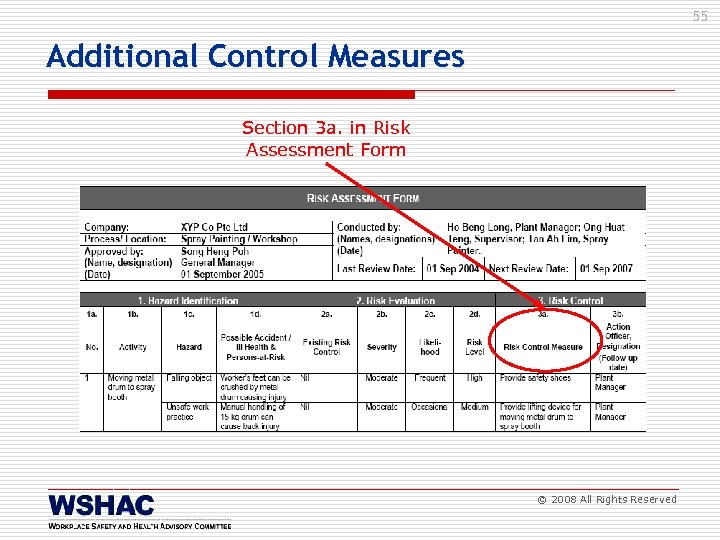

55 Additional Control Measures Section 3 a. in Risk Assessment Form © 2008 All Rights Reserved

55 Additional Control Measures Section 3 a. in Risk Assessment Form © 2008 All Rights Reserved

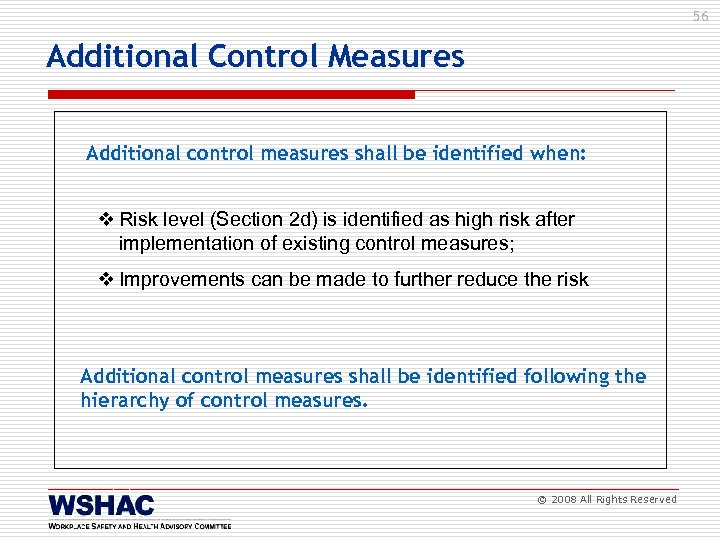

56 Additional Control Measures Additional control measures shall be identified when: v Risk level (Section 2 d) is identified as high risk after implementation of existing control measures; v Improvements can be made to further reduce the risk Additional control measures shall be identified following the hierarchy of control measures. © 2008 All Rights Reserved

56 Additional Control Measures Additional control measures shall be identified when: v Risk level (Section 2 d) is identified as high risk after implementation of existing control measures; v Improvements can be made to further reduce the risk Additional control measures shall be identified following the hierarchy of control measures. © 2008 All Rights Reserved

57 Additional Control Measures Besides the control measures mentioned earlier for each hazard, Safe Work Procedures (administrative control) shall be established and maintained for all works including: ü Routine work: normal daily operation of machines ü Non-routine work (Ad-hoc work): maintenance © 2008 All Rights Reserved

57 Additional Control Measures Besides the control measures mentioned earlier for each hazard, Safe Work Procedures (administrative control) shall be established and maintained for all works including: ü Routine work: normal daily operation of machines ü Non-routine work (Ad-hoc work): maintenance © 2008 All Rights Reserved

58 Additional Control Measures Safe Work Procedures shall be established when other control measures cannot reduce the hazards to a practical level. Examples are as follows: üHot work üPainting ü Manual handling ü Driving safety © 2008 All Rights Reserved

58 Additional Control Measures Safe Work Procedures shall be established when other control measures cannot reduce the hazards to a practical level. Examples are as follows: üHot work üPainting ü Manual handling ü Driving safety © 2008 All Rights Reserved

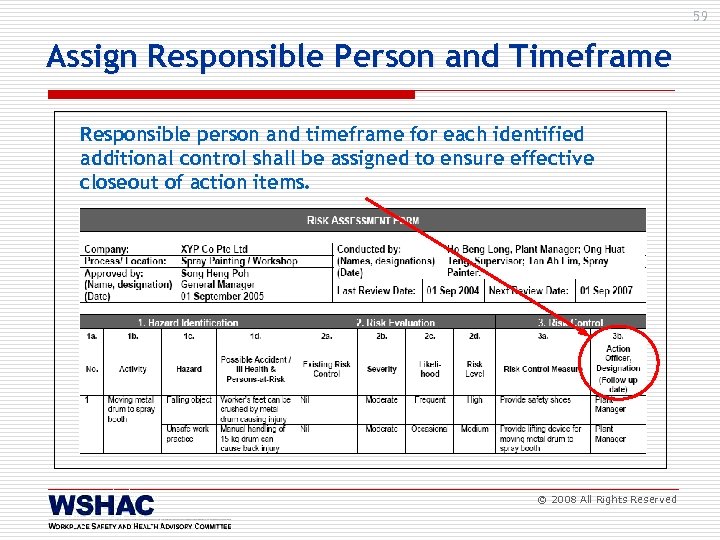

59 Assign Responsible Person and Timeframe Responsible person and timeframe for each identified additional control shall be assigned to ensure effective closeout of action items. © 2008 All Rights Reserved

59 Assign Responsible Person and Timeframe Responsible person and timeframe for each identified additional control shall be assigned to ensure effective closeout of action items. © 2008 All Rights Reserved

60 Maintenance of Risk Assessment © 2008 All Rights Reserved

60 Maintenance of Risk Assessment © 2008 All Rights Reserved

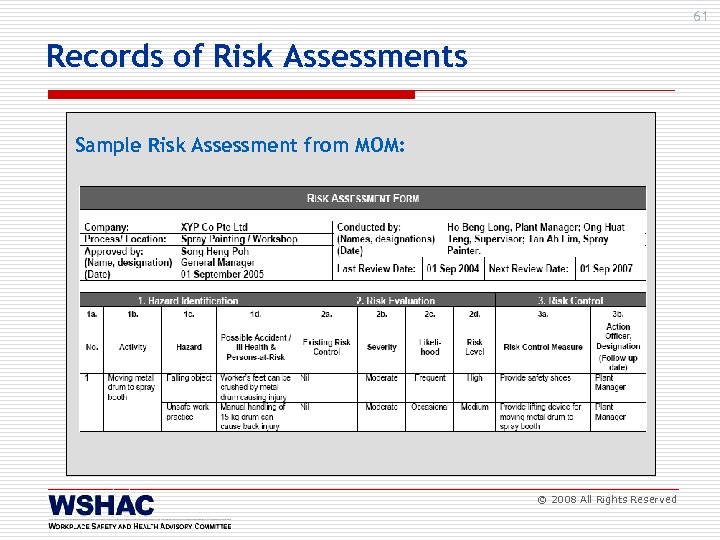

61 Records of Risk Assessments Sample Risk Assessment from MOM: © 2008 All Rights Reserved

61 Records of Risk Assessments Sample Risk Assessment from MOM: © 2008 All Rights Reserved

62 Provision of Information Employer, self-employed person and principal shall inform any person at risk of: • The nature of the risk involved; and • Any measure of safe work procedure implemented. Employer, self-employed person and principal shall inform any person at risk of any change in control measure or safe work procedure. © 2008 All Rights Reserved

62 Provision of Information Employer, self-employed person and principal shall inform any person at risk of: • The nature of the risk involved; and • Any measure of safe work procedure implemented. Employer, self-employed person and principal shall inform any person at risk of any change in control measure or safe work procedure. © 2008 All Rights Reserved

63 Review of Risk Assessments Risk assessment must be done wherever: • New information on safety and health risks surface • There are changes to the area of work or process • There accidents or serious incidents • After a fixed period of time (Max. 3 years) Revised risk assessment must be communicated to relevant parties. © 2008 All Rights Reserved

63 Review of Risk Assessments Risk assessment must be done wherever: • New information on safety and health risks surface • There are changes to the area of work or process • There accidents or serious incidents • After a fixed period of time (Max. 3 years) Revised risk assessment must be communicated to relevant parties. © 2008 All Rights Reserved

64 Review of Risk Assessments The effectiveness of risk control measures can be evaluated by: • Conducting safety inspection or audit on the facility • Obtaining feedback from employees about the measures implemented • Review of statistical data such as accident / incident rate, fatality rate, number of hospitalization, plant down time, etc • Feedback from training assessment / examination © 2008 All Rights Reserved

64 Review of Risk Assessments The effectiveness of risk control measures can be evaluated by: • Conducting safety inspection or audit on the facility • Obtaining feedback from employees about the measures implemented • Review of statistical data such as accident / incident rate, fatality rate, number of hospitalization, plant down time, etc • Feedback from training assessment / examination © 2008 All Rights Reserved

65 Exercises Conduct a risk assessment for your activities in the company. 1. Following the flow provided in the MOM Risk Assessment Form 2. Use the likelihood and severity table from MOM 3. Risk level shall be decided using MOM Risk Assessment Matrix. © 2008 All Rights Reserved

65 Exercises Conduct a risk assessment for your activities in the company. 1. Following the flow provided in the MOM Risk Assessment Form 2. Use the likelihood and severity table from MOM 3. Risk level shall be decided using MOM Risk Assessment Matrix. © 2008 All Rights Reserved

66 Summary After this training, you should have understood: 1. The liability you have in violation of the WSH (Risk Management) Regulations 2. What are the hazards associated with your work? 3. What are the control measures for each hazards? 4. How is risk assessment conducted based on MOM requirements? 5. What should you get involved in risk assessment? © 2008 All Rights Reserved

66 Summary After this training, you should have understood: 1. The liability you have in violation of the WSH (Risk Management) Regulations 2. What are the hazards associated with your work? 3. What are the control measures for each hazards? 4. How is risk assessment conducted based on MOM requirements? 5. What should you get involved in risk assessment? © 2008 All Rights Reserved

67 References: You can find more information from the references below: 1. National OSH Programme-Based Engagement (Pro. BE), Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry. 2. EIGA Safety Newsletter, SAG NL N° 81/05/E. 3. Risk Management: Risk Assessment Guidelines, MOM 4. Guidelines for Noise and Vibration Control, MOM 5. Guidelines on Hearing Conservation Program, MOM 6. Code of Safe Working Practices Amendment 6, MCA, UK 7. Concepts and Techniques of Machine Safeguarding, U. S. Department of Labor, OSHA 3067, 1992 (Revised) © 2008 All Rights Reserved

67 References: You can find more information from the references below: 1. National OSH Programme-Based Engagement (Pro. BE), Technical Advisory For Metalworking Industry – Understanding the Hazards of Metalworking Industry. 2. EIGA Safety Newsletter, SAG NL N° 81/05/E. 3. Risk Management: Risk Assessment Guidelines, MOM 4. Guidelines for Noise and Vibration Control, MOM 5. Guidelines on Hearing Conservation Program, MOM 6. Code of Safe Working Practices Amendment 6, MCA, UK 7. Concepts and Techniques of Machine Safeguarding, U. S. Department of Labor, OSHA 3067, 1992 (Revised) © 2008 All Rights Reserved

68 Thank you! © 2008 All Rights Reserved

68 Thank you! © 2008 All Rights Reserved