1 RCS Presentation Content: Modular design

- Размер: 7.2 Mегабайта

- Количество слайдов: 25

Описание презентации 1 RCS Presentation Content: Modular design по слайдам

1 RCS Presentation Content: Modular design Rig Feature & Benefits CAN technology What is RCS? Advanced Drilling System Man Machine Interface Options Software

1 RCS Presentation Content: Modular design Rig Feature & Benefits CAN technology What is RCS? Advanced Drilling System Man Machine Interface Options Software

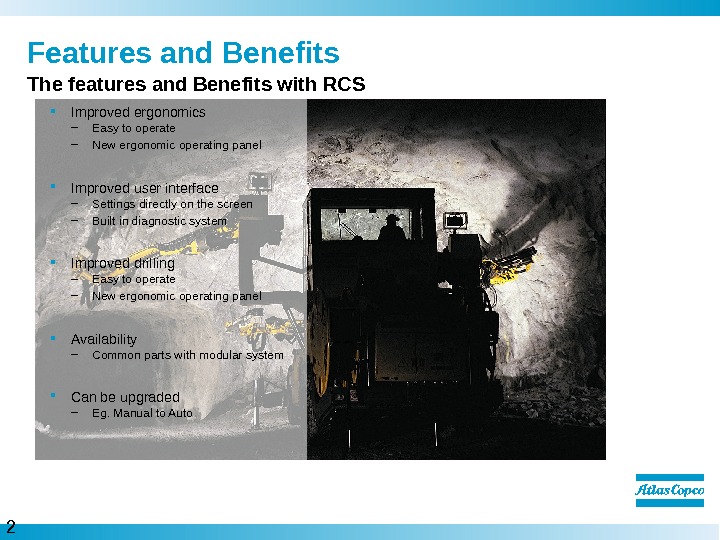

2 Features and Benefits Improved ergonomics – Easy to operate – New ergonomic operating panel Improved user interface – Settings directly on the screen – Built in diagnostic system Improved drilling – Easy to operate – New ergonomic operating panel Availability – Common parts with modular system Can be upgraded – Eg. Manual to Auto. The features and Benefits with RCS

2 Features and Benefits Improved ergonomics – Easy to operate – New ergonomic operating panel Improved user interface – Settings directly on the screen – Built in diagnostic system Improved drilling – Easy to operate – New ergonomic operating panel Availability – Common parts with modular system Can be upgraded – Eg. Manual to Auto. The features and Benefits with RCS

3 CANBUS Technology Controller Area Network Display Operators panel Application module Fuse box PC-Card I/O Module Plugs Cables

3 CANBUS Technology Controller Area Network Display Operators panel Application module Fuse box PC-Card I/O Module Plugs Cables

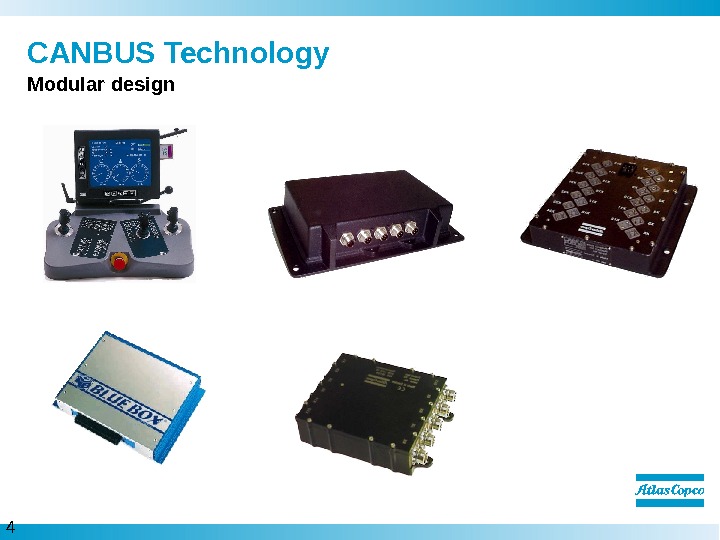

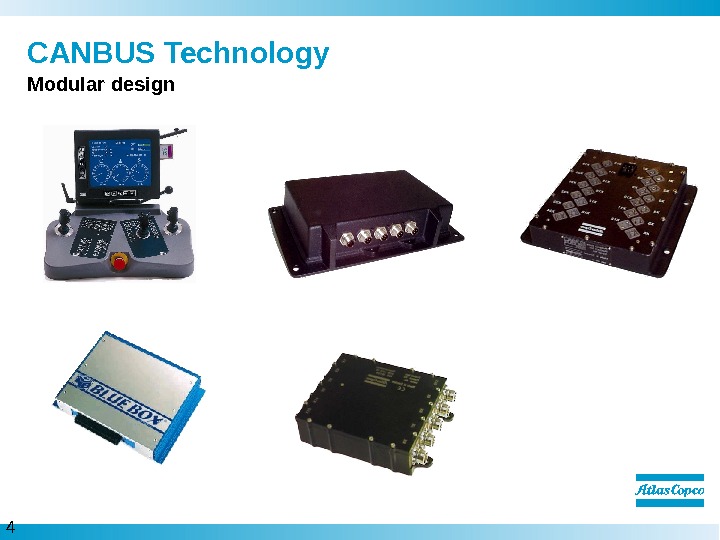

4 CANBUS Technology Modular design

4 CANBUS Technology Modular design

5 CANBUS Technology International Standard ISO – Automobile industry – Forest machinery – Textile industry Modular design Less cabling More functions Flexible and Stable. General about CANBUS

5 CANBUS Technology International Standard ISO – Automobile industry – Forest machinery – Textile industry Modular design Less cabling More functions Flexible and Stable. General about CANBUS

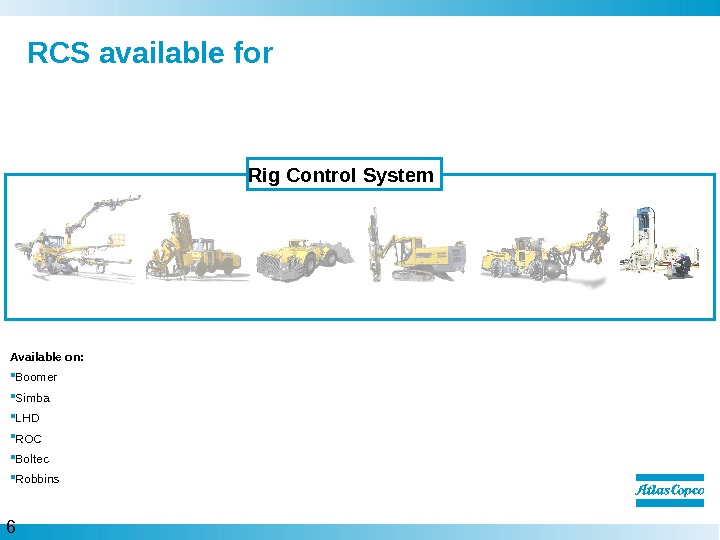

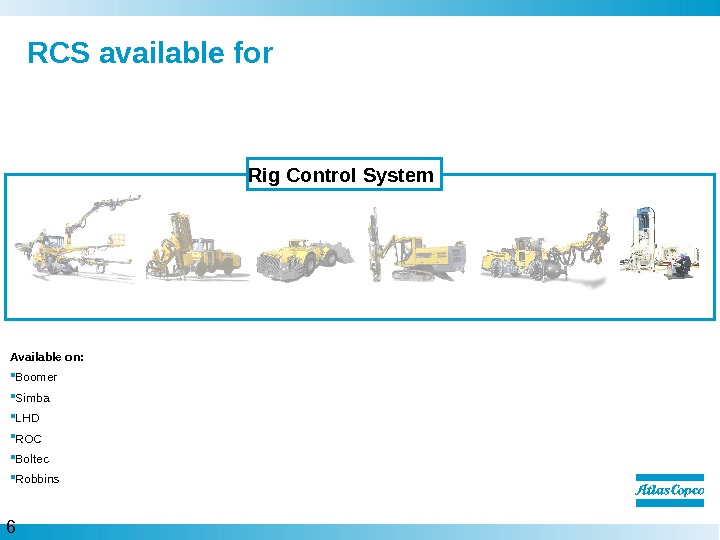

6 RCS available for Rig Control System Available on: Boomer Simba LHD ROC Boltec Robbins

6 RCS available for Rig Control System Available on: Boomer Simba LHD ROC Boltec Robbins

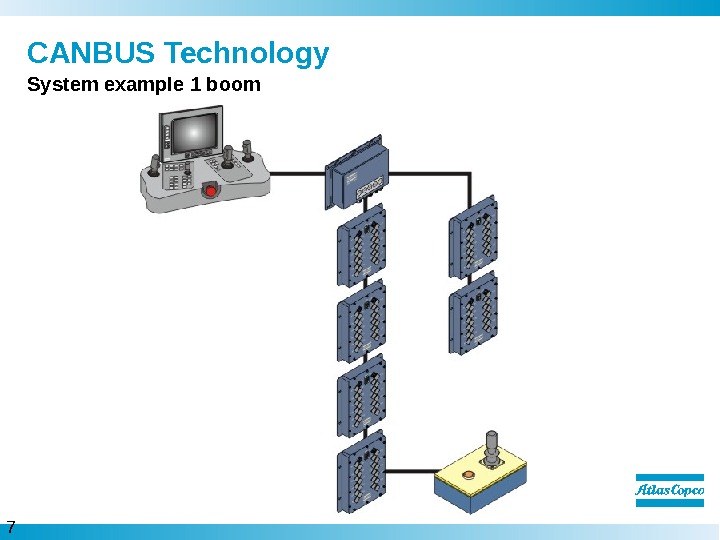

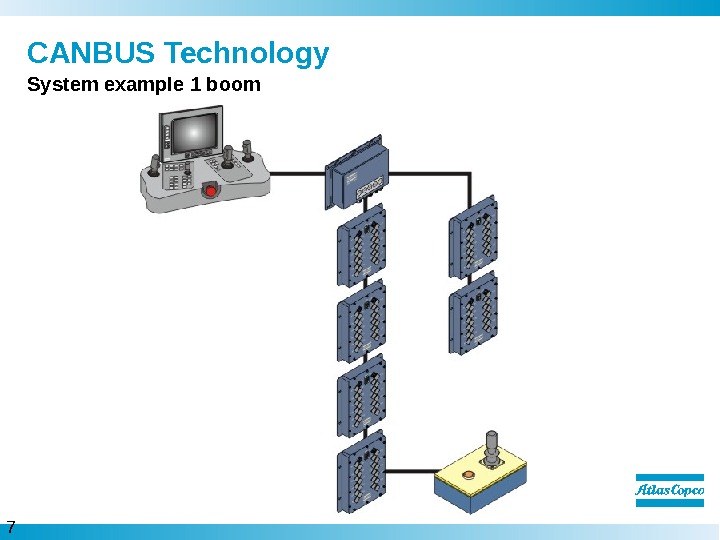

7 CANBUS Technology System example 1 boom

7 CANBUS Technology System example 1 boom

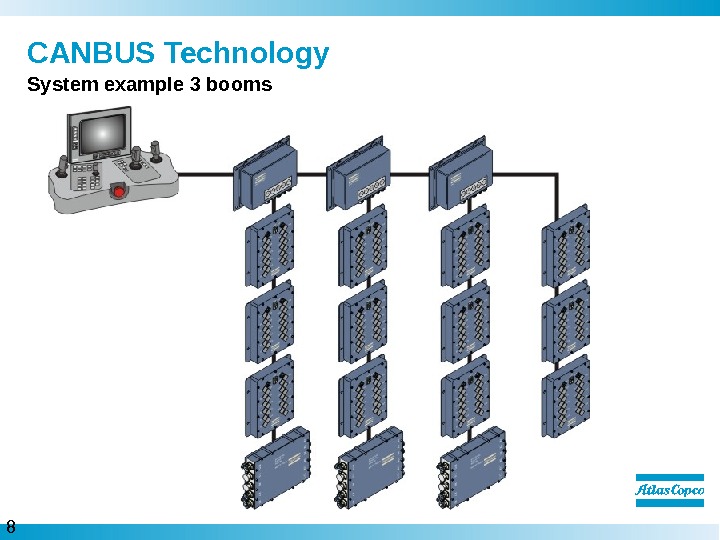

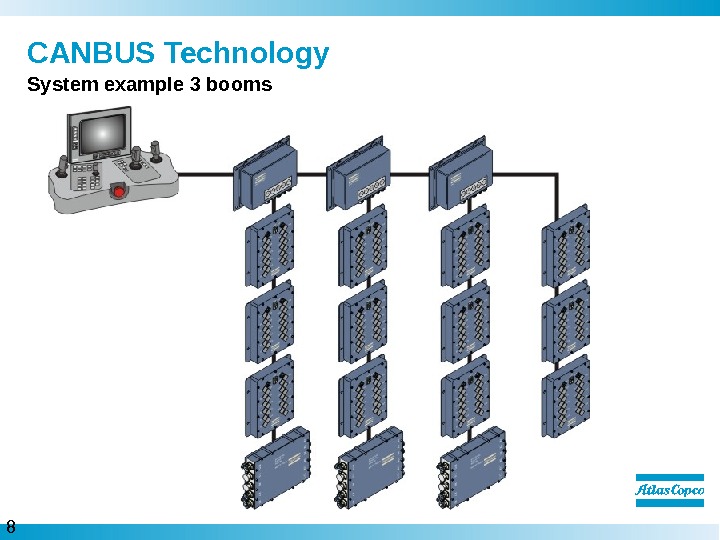

8 CANBUS Technology System example 3 booms

8 CANBUS Technology System example 3 booms

9 What is RCS? RCS – Rig Control System Software. Man Machine Interface Options. Advanced Drill Control

9 What is RCS? RCS – Rig Control System Software. Man Machine Interface Options. Advanced Drill Control

1 0 Advanced Drill Control. C o n t r o l i n g a n d M o n i t o r i n g

1 0 Advanced Drill Control. C o n t r o l i n g a n d M o n i t o r i n g

1 1 Improved cabin layout – Improved operator ergonomics – Increased visibility and space – Gauges and instruments are replaced the display unit – No hydraulics in the cabin – Easy operation. Man Machine Interface Features

1 1 Improved cabin layout – Improved operator ergonomics – Increased visibility and space – Gauges and instruments are replaced the display unit – No hydraulics in the cabin – Easy operation. Man Machine Interface Features

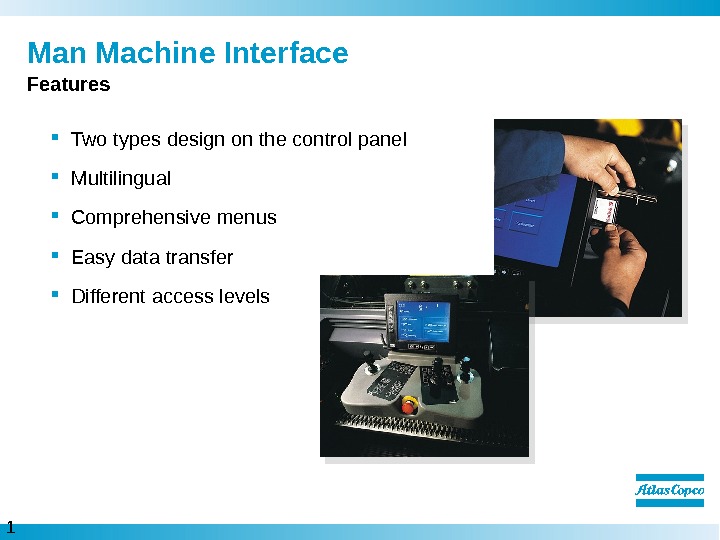

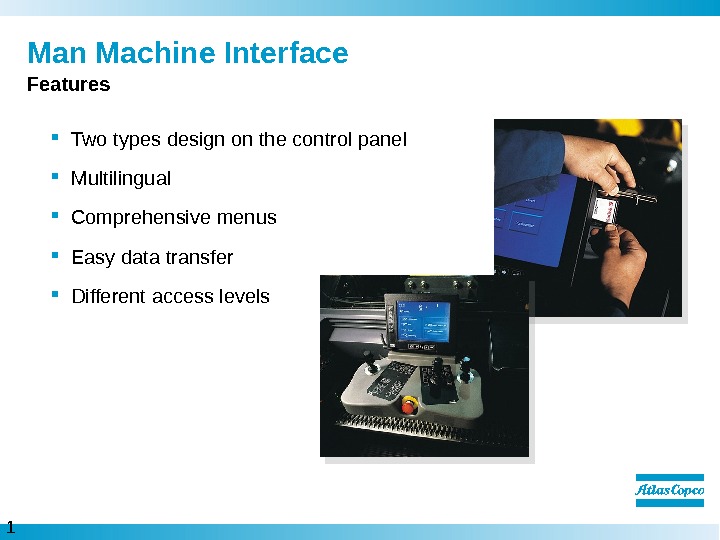

1 2 Man Machine Interface Two types design on the control panel Multilingual Comprehensive menus Easy data transfer Different access levels. Features

1 2 Man Machine Interface Two types design on the control panel Multilingual Comprehensive menus Easy data transfer Different access levels. Features

1 3 Man Machine Interface Preferred settings Pre-settings for different bit types Built-in self diagnostic system Integrated drilling system On screen display of system information. Features

1 3 Man Machine Interface Preferred settings Pre-settings for different bit types Built-in self diagnostic system Integrated drilling system On screen display of system information. Features

1 4 Man Machine Interface Instantaneous monitoring of engine load Instantaneous monitoring of engine consumption Instantaneous monitoring of engine status. Features

1 4 Man Machine Interface Instantaneous monitoring of engine load Instantaneous monitoring of engine consumption Instantaneous monitoring of engine status. Features

1 5 Self Diagnostic System Completely integrated into the RCS On screen display of system information Digital dashboard Warnings and stop. Features

1 5 Self Diagnostic System Completely integrated into the RCS On screen display of system information Digital dashboard Warnings and stop. Features

1 6 Self Diagnostic System Features

1 6 Self Diagnostic System Features

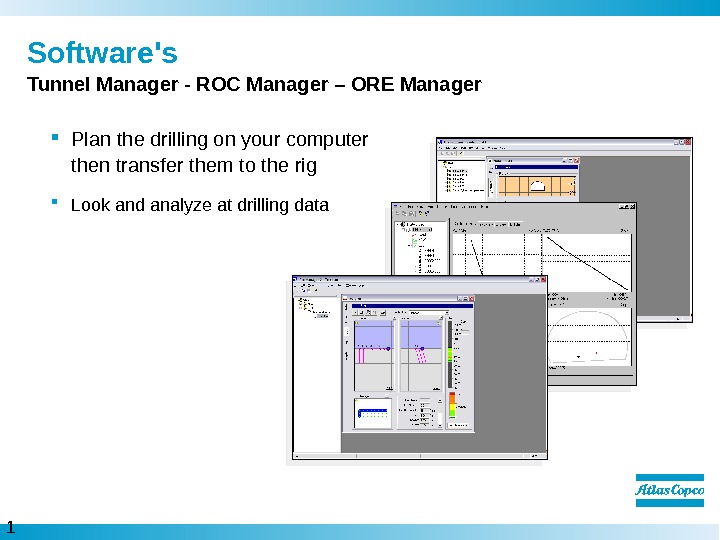

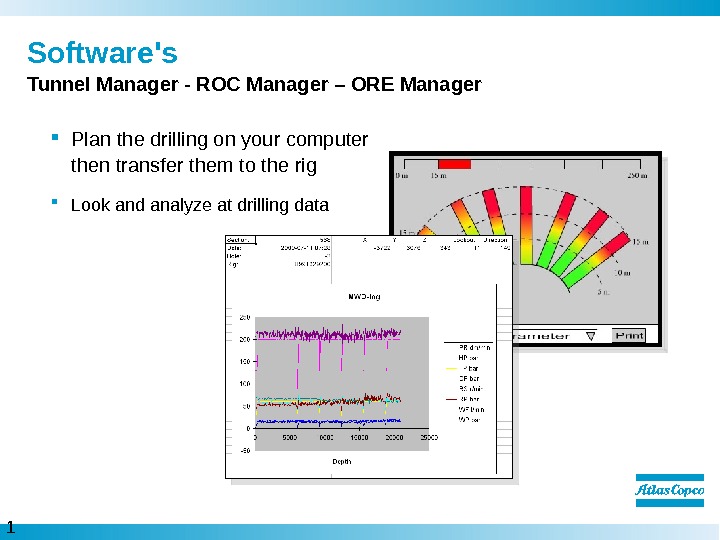

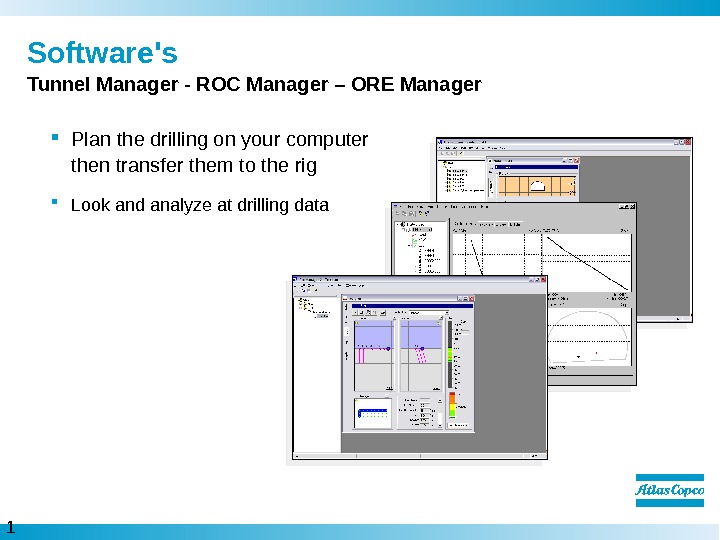

1 7 Software’s Plan the drilling on your computer then transfer them to the rig Look and analyze at drilling data Tunnel Manager — ROC Manager – ORE Manager

1 7 Software’s Plan the drilling on your computer then transfer them to the rig Look and analyze at drilling data Tunnel Manager — ROC Manager – ORE Manager

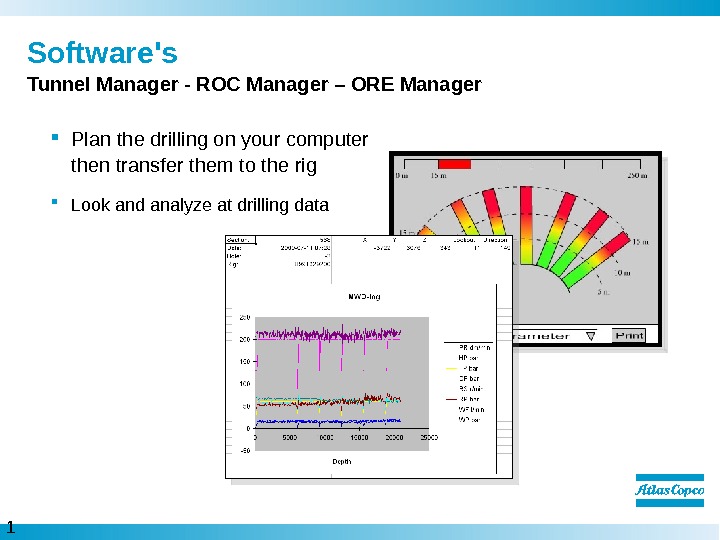

1 8 Software’s Plan the drilling on your computer then transfer them to the rig Look and analyze at drilling data Tunnel Manager — ROC Manager – ORE Manager

1 8 Software’s Plan the drilling on your computer then transfer them to the rig Look and analyze at drilling data Tunnel Manager — ROC Manager – ORE Manager

1 9 RCS Functionality ABC Basic ABC Regular ABC Total. Boomer

1 9 RCS Functionality ABC Basic ABC Regular ABC Total. Boomer

2 0 RCS Functionality Manual alignment of the boom & feed Feed angle displayed on the screen No drill pattern support No logging function. ABC Basic

2 0 RCS Functionality Manual alignment of the boom & feed Feed angle displayed on the screen No drill pattern support No logging function. ABC Basic

2 1 RCS Functionality Drilling pattern created in the office (TM) and transferred to the rig on a PC card Drill hole position and look-out distance shown on the display Feed position and feed look-out distance shown on the display Selected boom and feed moved manually. ABC Regular

2 1 RCS Functionality Drilling pattern created in the office (TM) and transferred to the rig on a PC card Drill hole position and look-out distance shown on the display Feed position and feed look-out distance shown on the display Selected boom and feed moved manually. ABC Regular

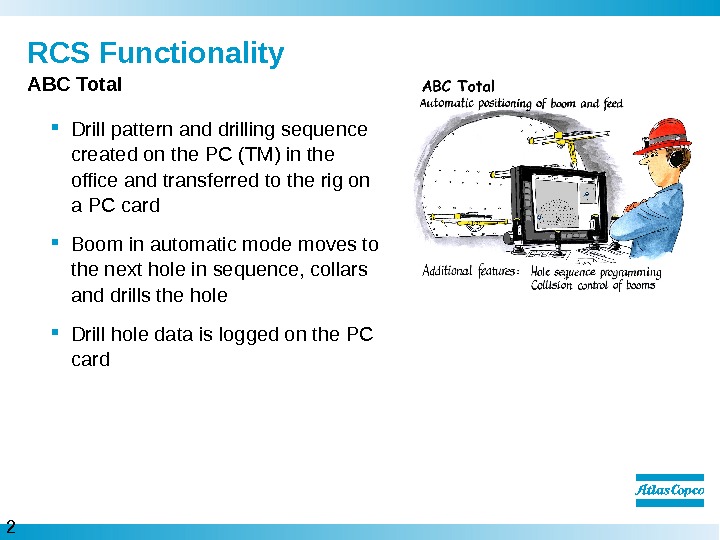

2 2 RCS Functionality Drill pattern and drilling sequence created on the PC (TM) in the office and transferred to the rig on a PC card Boom in automatic mode moves to the next hole in sequence, collars and drills the hole Drill hole data is logged on the PC card. ABC Total

2 2 RCS Functionality Drill pattern and drilling sequence created on the PC (TM) in the office and transferred to the rig on a PC card Boom in automatic mode moves to the next hole in sequence, collars and drills the hole Drill hole data is logged on the PC card. ABC Total

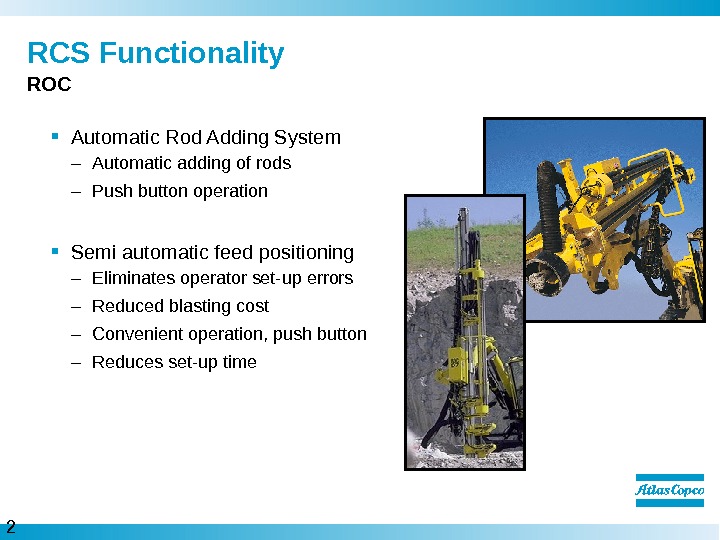

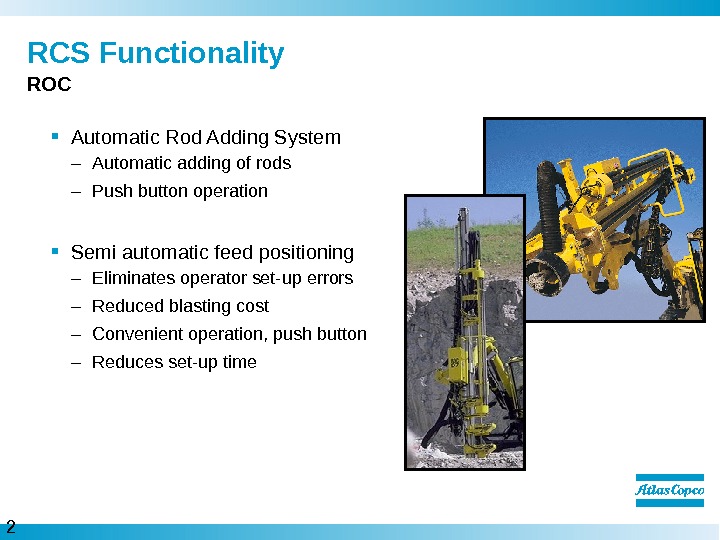

2 3 RCS Functionality ROC Automatic Rod Adding System – Automatic adding of rods – Push button operation Semi automatic feed positioning – Eliminates operator set-up errors – Reduced blasting cost – Convenient operation, push button – Reduces set-up time

2 3 RCS Functionality ROC Automatic Rod Adding System – Automatic adding of rods – Push button operation Semi automatic feed positioning – Eliminates operator set-up errors – Reduced blasting cost – Convenient operation, push button – Reduces set-up time

2 4 We are committed to your superior productivity through interaction and innovation.

2 4 We are committed to your superior productivity through interaction and innovation.