743f76abb90deaff7820d66420c89823.ppt

- Количество слайдов: 18

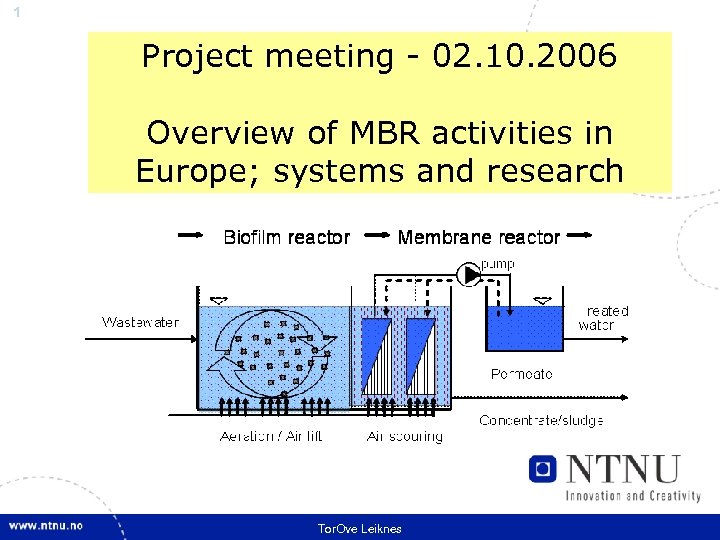

1 Project meeting - 02. 10. 2006 Overview of MBR activities in Europe; systems and research Tor. Ove Leiknes

1 Project meeting - 02. 10. 2006 Overview of MBR activities in Europe; systems and research Tor. Ove Leiknes

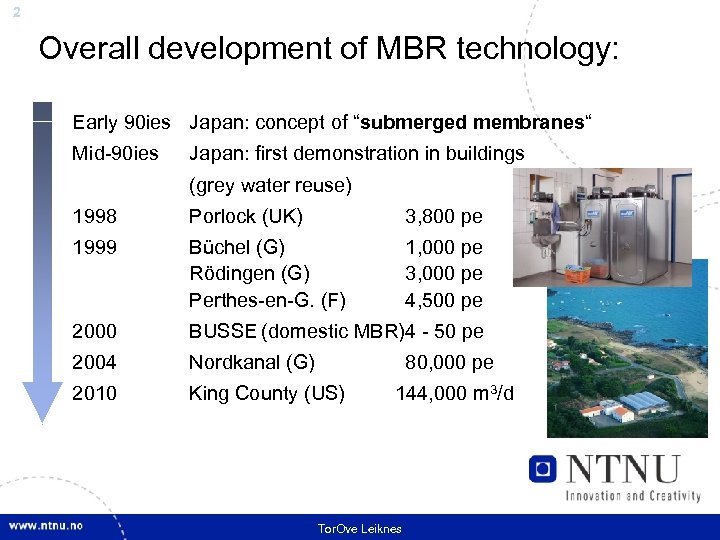

2 Overall development of MBR technology: Early 90 ies Japan: concept of “submerged membranes“ Mid-90 ies Japan: first demonstration in buildings (grey water reuse) 1998 Porlock (UK) 3, 800 pe 1999 Büchel (G) Rödingen (G) Perthes-en-G. (F) 1, 000 pe 3, 000 pe 4, 500 pe 2000 BUSSE (domestic MBR)4 - 50 pe 2004 Nordkanal (G) 2010 King County (US) 144, 000 m 3/d 80, 000 pe Tor. Ove Leiknes

2 Overall development of MBR technology: Early 90 ies Japan: concept of “submerged membranes“ Mid-90 ies Japan: first demonstration in buildings (grey water reuse) 1998 Porlock (UK) 3, 800 pe 1999 Büchel (G) Rödingen (G) Perthes-en-G. (F) 1, 000 pe 3, 000 pe 4, 500 pe 2000 BUSSE (domestic MBR)4 - 50 pe 2004 Nordkanal (G) 2010 King County (US) 144, 000 m 3/d 80, 000 pe Tor. Ove Leiknes

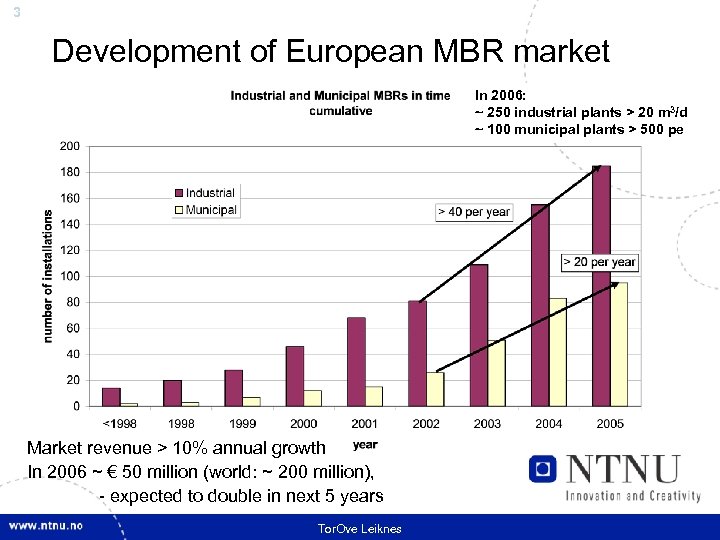

3 Development of European MBR market In 2006: ~ 250 industrial plants > 20 m 3/d ~ 100 municipal plants > 500 pe Market revenue > 10% annual growth In 2006 ~ € 50 million (world: ~ 200 million), - expected to double in next 5 years Tor. Ove Leiknes

3 Development of European MBR market In 2006: ~ 250 industrial plants > 20 m 3/d ~ 100 municipal plants > 500 pe Market revenue > 10% annual growth In 2006 ~ € 50 million (world: ~ 200 million), - expected to double in next 5 years Tor. Ove Leiknes

4 Industrial applications: • • Already considered as “Best Available Technology” Often cost-effective – – – • Cost of membrane system not so relevant due to high load / small throughflow Needs of water recycling RO pretreatment Established in diverse sectors – Food & beverage, cosmetics, chemical, textile, pulp & paper, ship, leachates, automotive, etc Tor. Ove Leiknes

4 Industrial applications: • • Already considered as “Best Available Technology” Often cost-effective – – – • Cost of membrane system not so relevant due to high load / small throughflow Needs of water recycling RO pretreatment Established in diverse sectors – Food & beverage, cosmetics, chemical, textile, pulp & paper, ship, leachates, automotive, etc Tor. Ove Leiknes

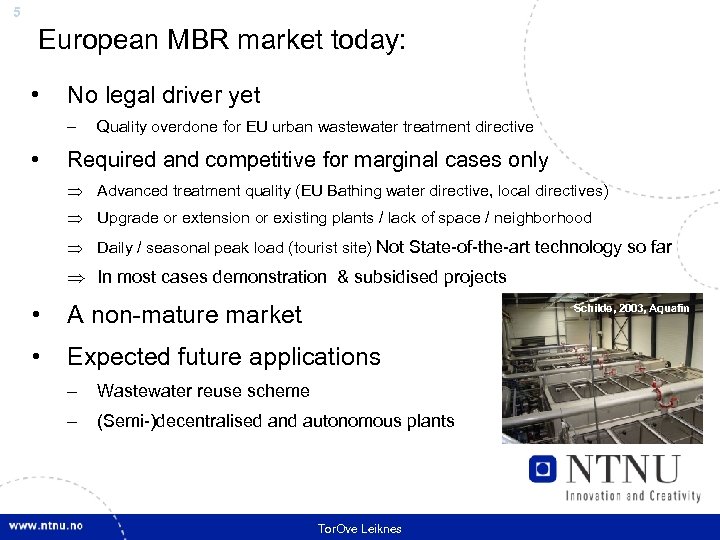

5 European MBR market today: • No legal driver yet – • Quality overdone for EU urban wastewater treatment directive Required and competitive for marginal cases only Þ Advanced treatment quality (EU Bathing water directive, local directives) Þ Upgrade or extension or existing plants / lack of space / neighborhood Þ Daily / seasonal peak load (tourist site) Not State-of-the-art technology so far Þ In most cases demonstration & subsidised projects • A non-mature market • Expected future applications Schilde, 2003, Aquafin – Wastewater reuse scheme – (Semi-)decentralised and autonomous plants Tor. Ove Leiknes

5 European MBR market today: • No legal driver yet – • Quality overdone for EU urban wastewater treatment directive Required and competitive for marginal cases only Þ Advanced treatment quality (EU Bathing water directive, local directives) Þ Upgrade or extension or existing plants / lack of space / neighborhood Þ Daily / seasonal peak load (tourist site) Not State-of-the-art technology so far Þ In most cases demonstration & subsidised projects • A non-mature market • Expected future applications Schilde, 2003, Aquafin – Wastewater reuse scheme – (Semi-)decentralised and autonomous plants Tor. Ove Leiknes

6 Community size EU Market < 50 pe Many ‘young’ companies (8 in Germany) 50 - 2. 000 pe Technological gaps of standardized units 2. 000 - 10. 000 pe Main market: 2 non-EU leaders, ~10 ‘outsiders’ (4 in Germany) 10. 000 - 100. 000 pe Rare applications (mainly retrofitting) > 100. 000 pe Will remain exception worldwide Tor. Ove Leiknes

6 Community size EU Market < 50 pe Many ‘young’ companies (8 in Germany) 50 - 2. 000 pe Technological gaps of standardized units 2. 000 - 10. 000 pe Main market: 2 non-EU leaders, ~10 ‘outsiders’ (4 in Germany) 10. 000 - 100. 000 pe Rare applications (mainly retrofitting) > 100. 000 pe Will remain exception worldwide Tor. Ove Leiknes

7 MBR suppliers: • Zenon • Kubota • Memcor • Mitsubishi Several “newcomers” to EU market: • A 3 (FM) • Puron (HF) • Polymem (HF) • Milleniumpore (Tub) • Inge (multi-channel) Tor. Ove Leiknes

7 MBR suppliers: • Zenon • Kubota • Memcor • Mitsubishi Several “newcomers” to EU market: • A 3 (FM) • Puron (HF) • Polymem (HF) • Milleniumpore (Tub) • Inge (multi-channel) Tor. Ove Leiknes

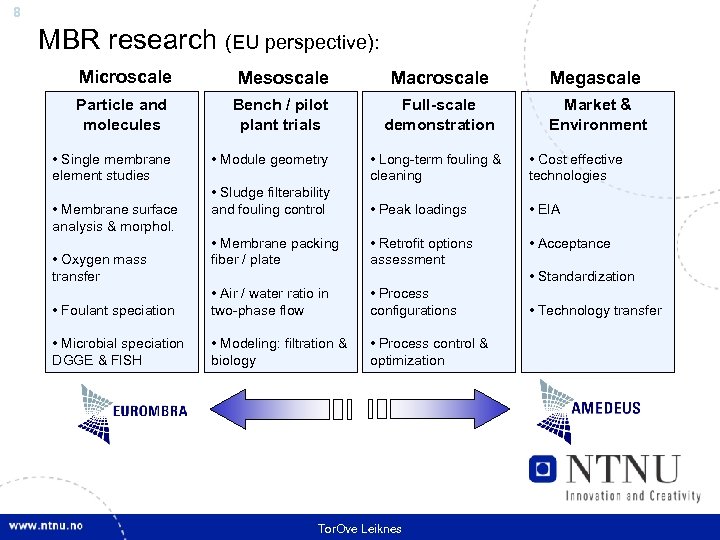

8 MBR research (EU perspective): Microscale Mesoscale Macroscale Megascale Particle and molecules Bench / pilot plant trials Full-scale demonstration Market & Environment • Single membrane element studies • Module geometry • Membrane surface analysis & morphol. • Oxygen mass transfer • Long-term fouling & cleaning • Cost effective technologies • Sludge filterability and fouling control • Peak loadings • EIA • Membrane packing fiber / plate • Retrofit options assessment • Acceptance • Standardization • Foulant speciation • Air / water ratio in two-phase flow • Process configurations • Microbial speciation DGGE & FISH • Modeling: filtration & biology • Process control & optimization Tor. Ove Leiknes • Technology transfer

8 MBR research (EU perspective): Microscale Mesoscale Macroscale Megascale Particle and molecules Bench / pilot plant trials Full-scale demonstration Market & Environment • Single membrane element studies • Module geometry • Membrane surface analysis & morphol. • Oxygen mass transfer • Long-term fouling & cleaning • Cost effective technologies • Sludge filterability and fouling control • Peak loadings • EIA • Membrane packing fiber / plate • Retrofit options assessment • Acceptance • Standardization • Foulant speciation • Air / water ratio in two-phase flow • Process configurations • Microbial speciation DGGE & FISH • Modeling: filtration & biology • Process control & optimization Tor. Ove Leiknes • Technology transfer

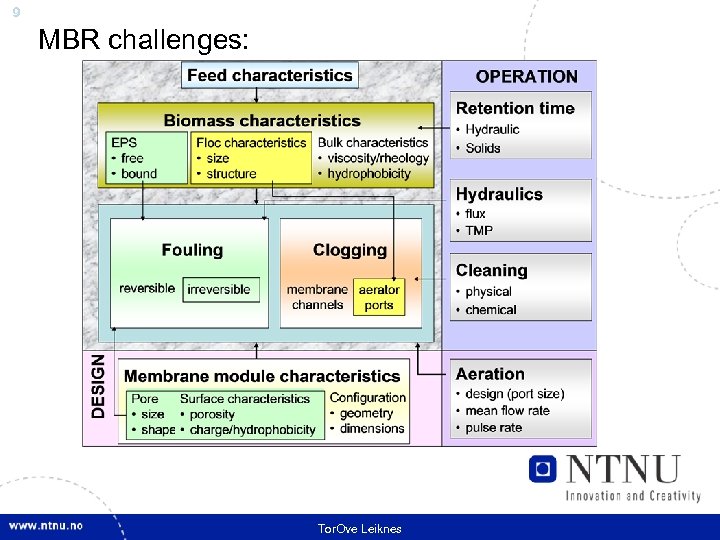

9 MBR challenges: Tor. Ove Leiknes

9 MBR challenges: Tor. Ove Leiknes

10 Central research topics currently in focus Fouling and membrane interaction • • Membrane / fouling characterization methods Qualitative and quantitative analysis of foulants (short and long term) Interaction between foulants and membranes, impact of identified foulants in practice Impact of biological operational parameters, flux, aeration etc Impact of dynamic effects: hydraulic and organic load variation Impacts of and on microbial speciation and diversity Modification of membrane composition, structure and surface Tor. Ove Leiknes

10 Central research topics currently in focus Fouling and membrane interaction • • Membrane / fouling characterization methods Qualitative and quantitative analysis of foulants (short and long term) Interaction between foulants and membranes, impact of identified foulants in practice Impact of biological operational parameters, flux, aeration etc Impact of dynamic effects: hydraulic and organic load variation Impacts of and on microbial speciation and diversity Modification of membrane composition, structure and surface Tor. Ove Leiknes

11 Non-invasive, on-line monitoring of foulants • Biological, physical or chemical sensors • Diverse degrees of sophistication: – Automated MFI on sludge or sludge filtrate – Single-filament or other dedicated test cells as indicator of sludge fouling propensity – Photometric measurement with Flow Injection Analysis – FISH probes to characterize biology and population dynamics – Bi-dimensional fluorometry and Denaturing Gradient Gel Electrophoresis (DGGE) Tor. Ove Leiknes

11 Non-invasive, on-line monitoring of foulants • Biological, physical or chemical sensors • Diverse degrees of sophistication: – Automated MFI on sludge or sludge filtrate – Single-filament or other dedicated test cells as indicator of sludge fouling propensity – Photometric measurement with Flow Injection Analysis – FISH probes to characterize biology and population dynamics – Bi-dimensional fluorometry and Denaturing Gradient Gel Electrophoresis (DGGE) Tor. Ove Leiknes

12 Fouling control through additives • Assumptions: organic fouling occurs through colloids with « unpredictable » occurrence => Additives for physical-chemical removal (flocculents, adsorbents, enzymes, etc) • Strategies of fouling control & flux enhancement with chemical addition with on-line organic foulant sensors – – Rain events – • Daily peaks Seasonal peaks “Compact MBR”: low SRT / low HRT + on-line fouling control Tor. Ove Leiknes

12 Fouling control through additives • Assumptions: organic fouling occurs through colloids with « unpredictable » occurrence => Additives for physical-chemical removal (flocculents, adsorbents, enzymes, etc) • Strategies of fouling control & flux enhancement with chemical addition with on-line organic foulant sensors – – Rain events – • Daily peaks Seasonal peaks “Compact MBR”: low SRT / low HRT + on-line fouling control Tor. Ove Leiknes

13 Optimization of cleaning protocols • • • Maintenance vs. curative cleaning (cleaning-in-place) Reduced chemical consumptions, costs & handling “On-air” cleaning? (also for flat-sheet membranes) Alternatives to chlorine? Oxidants or anti-scaling products? Impact on membrane life-time, accelerating aging tests Module geometry and aeration • • Bi-phasic CFD model for optimization of modules and filtration reactors Impact of module geometry on short and long term fouling behavior and filtration performance Impact of flow pattern and aeration mode on performances Enhanced mass transfer characteristics Tor. Ove Leiknes

13 Optimization of cleaning protocols • • • Maintenance vs. curative cleaning (cleaning-in-place) Reduced chemical consumptions, costs & handling “On-air” cleaning? (also for flat-sheet membranes) Alternatives to chlorine? Oxidants or anti-scaling products? Impact on membrane life-time, accelerating aging tests Module geometry and aeration • • Bi-phasic CFD model for optimization of modules and filtration reactors Impact of module geometry on short and long term fouling behavior and filtration performance Impact of flow pattern and aeration mode on performances Enhanced mass transfer characteristics Tor. Ove Leiknes

14 Concentrate / sludge handling • • • Sludge production Sludge characterization and dewaterability Adapted sludge treatment Impact of extra-cellular polymeric substances Sludge stabilization Process modeling • For improvement of design and operation: – Nutrients removal – Sludge production – Filtration modeling – Fouling prediction – Dynamic modelling (hydraulic and pollutant loads) – Biological models coupled with hydrodynamic models (CFD and residence time distribution) Tor. Ove Leiknes

14 Concentrate / sludge handling • • • Sludge production Sludge characterization and dewaterability Adapted sludge treatment Impact of extra-cellular polymeric substances Sludge stabilization Process modeling • For improvement of design and operation: – Nutrients removal – Sludge production – Filtration modeling – Fouling prediction – Dynamic modelling (hydraulic and pollutant loads) – Biological models coupled with hydrodynamic models (CFD and residence time distribution) Tor. Ove Leiknes

15 Optimization of process configurations • • MBR with or without primary sedimentation? Submerged modules externally or directly in aerated reactor? Dual MBR/CAS for plant retrofitting? Turn-key standardized range of MBR/filtration units? How to best tackle peaks? (biology & filtration) Integrated hydrodynamics of membrane / biological system? Models as predicting tools + pilot- & large-scale validation Process control • Advanced data acquisition, supervision and control system for MBR – – – • Remote advanced control system for small MBR plants (operation diagnostics and alerts) Automization of reporting and maintenance planning Dynamic filtration control for larger plants (“fuzzy-logic” approach) Optimized control strategy of influent split for MBR/CAS in parallel Tor. Ove Leiknes

15 Optimization of process configurations • • MBR with or without primary sedimentation? Submerged modules externally or directly in aerated reactor? Dual MBR/CAS for plant retrofitting? Turn-key standardized range of MBR/filtration units? How to best tackle peaks? (biology & filtration) Integrated hydrodynamics of membrane / biological system? Models as predicting tools + pilot- & large-scale validation Process control • Advanced data acquisition, supervision and control system for MBR – – – • Remote advanced control system for small MBR plants (operation diagnostics and alerts) Automization of reporting and maintenance planning Dynamic filtration control for larger plants (“fuzzy-logic” approach) Optimized control strategy of influent split for MBR/CAS in parallel Tor. Ove Leiknes

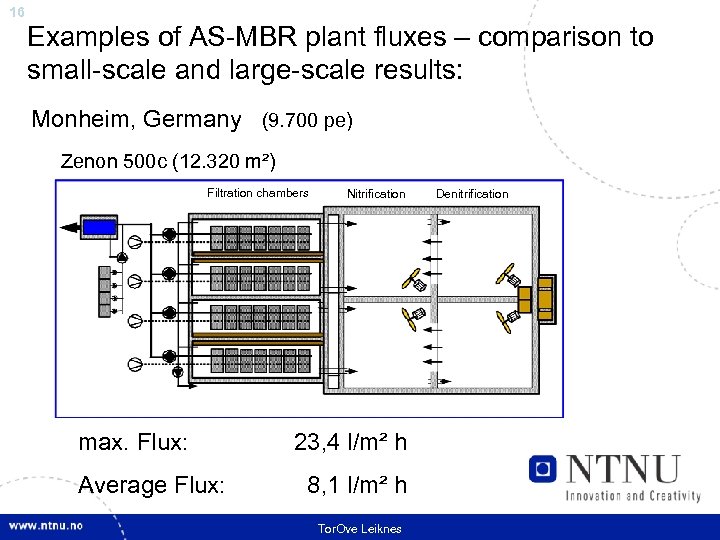

16 Examples of AS-MBR plant fluxes – comparison to small-scale and large-scale results: Monheim, Germany (9. 700 pe) Zenon 500 c (12. 320 m²) Filtration chambers Nitrification max. Flux: 23, 4 l/m² h Average Flux: 8, 1 l/m² h Tor. Ove Leiknes Denitrification

16 Examples of AS-MBR plant fluxes – comparison to small-scale and large-scale results: Monheim, Germany (9. 700 pe) Zenon 500 c (12. 320 m²) Filtration chambers Nitrification max. Flux: 23, 4 l/m² h Average Flux: 8, 1 l/m² h Tor. Ove Leiknes Denitrification

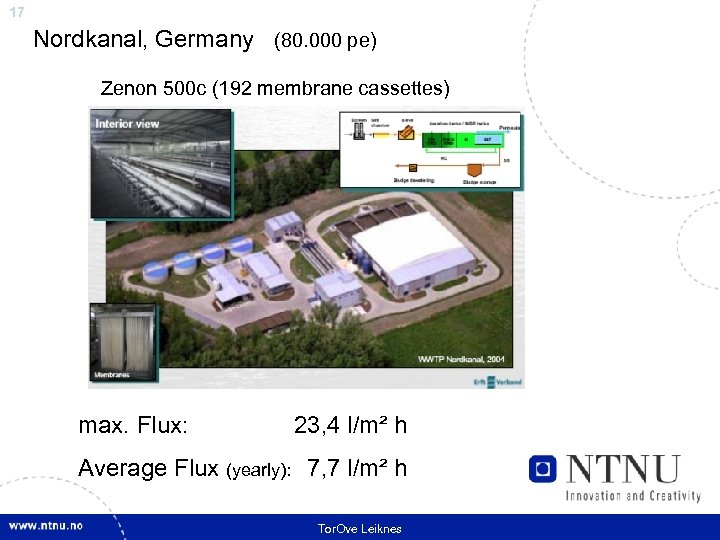

17 Nordkanal, Germany (80. 000 pe) Zenon 500 c (192 membrane cassettes) max. Flux: 23, 4 l/m² h Average Flux (yearly): 7, 7 l/m² h Tor. Ove Leiknes

17 Nordkanal, Germany (80. 000 pe) Zenon 500 c (192 membrane cassettes) max. Flux: 23, 4 l/m² h Average Flux (yearly): 7, 7 l/m² h Tor. Ove Leiknes

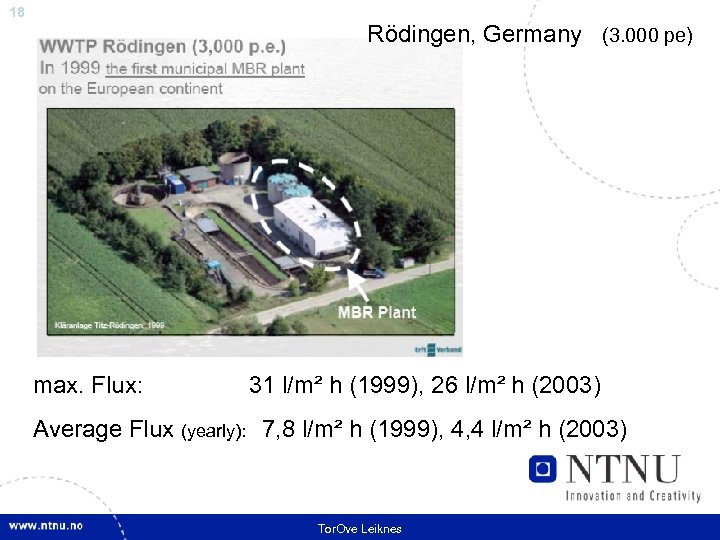

18 Rödingen, Germany (3. 000 pe) max. Flux: 31 l/m² h (1999), 26 l/m² h (2003) Average Flux (yearly): 7, 8 l/m² h (1999), 4, 4 l/m² h (2003) Tor. Ove Leiknes

18 Rödingen, Germany (3. 000 pe) max. Flux: 31 l/m² h (1999), 26 l/m² h (2003) Average Flux (yearly): 7, 8 l/m² h (1999), 4, 4 l/m² h (2003) Tor. Ove Leiknes