814328d2d878231bbf40503e362c0644.ppt

- Количество слайдов: 31

1

Process Automation Integration Utilizing ABB’s 800 x. A and OPC

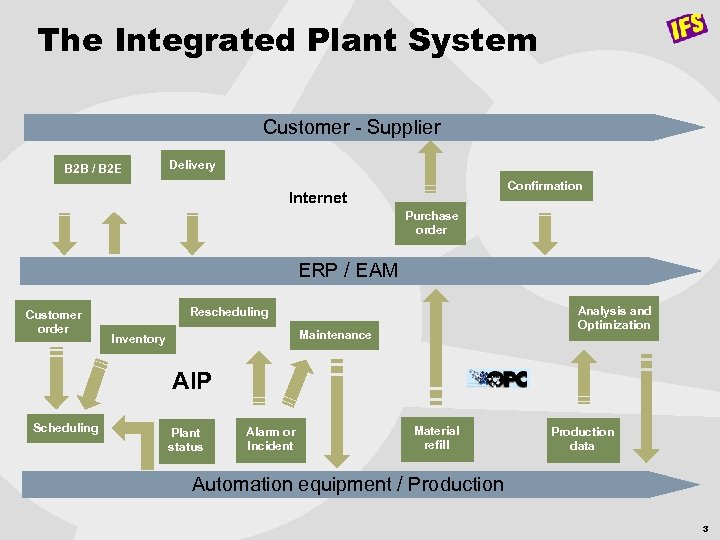

The Integrated Plant System Customer - Supplier B 2 B / B 2 E Delivery Confirmation Internet Purchase order ERP / EAM Customer order Analysis and Optimization Rescheduling Maintenance Inventory AIP Scheduling Plant status Alarm or Incident Material refill Production data Automation equipment / Production 3

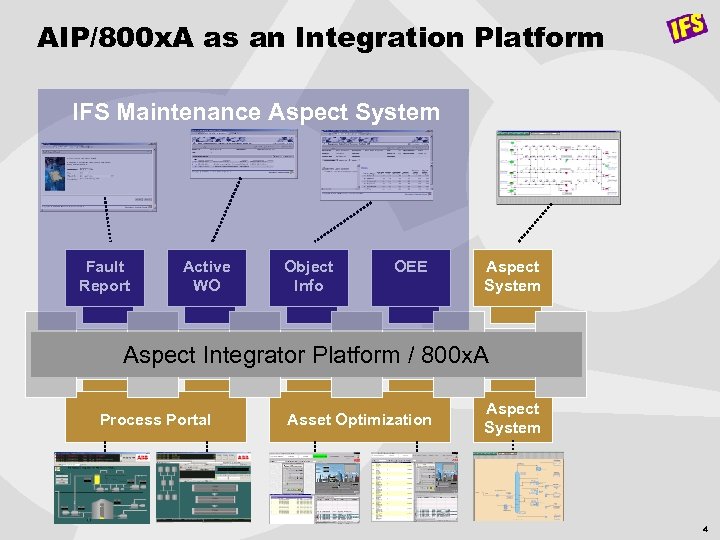

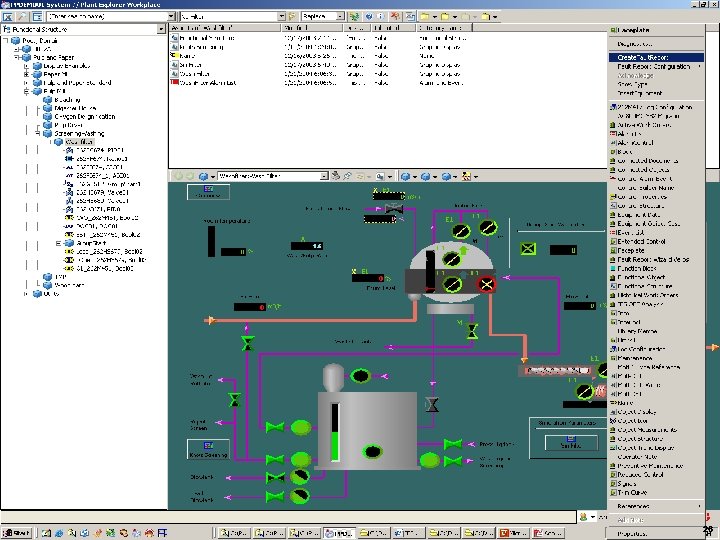

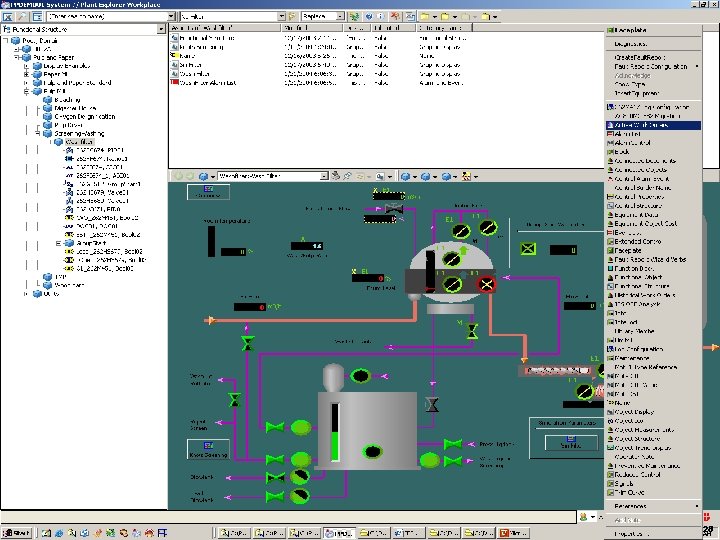

AIP/800 x. A as an Integration Platform IFS Maintenance Aspect System Fault Report Active WO Object Info OEE Aspect System Aspect Integrator Platform / 800 x. A Process Portal Asset Optimization Aspect System 4

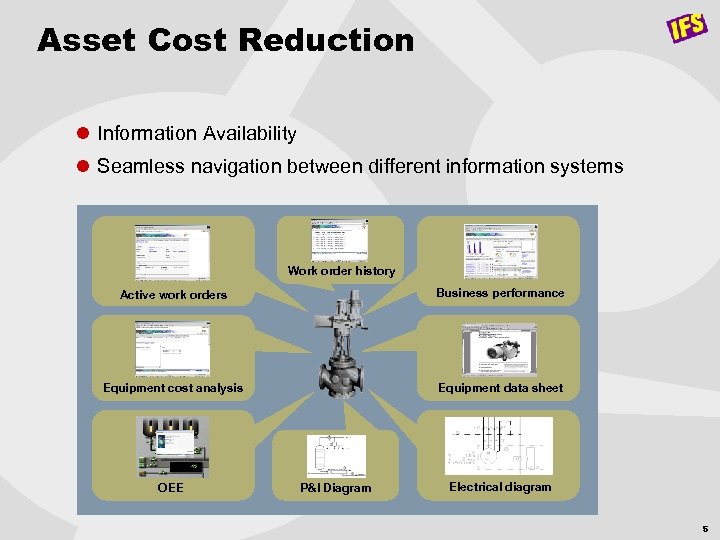

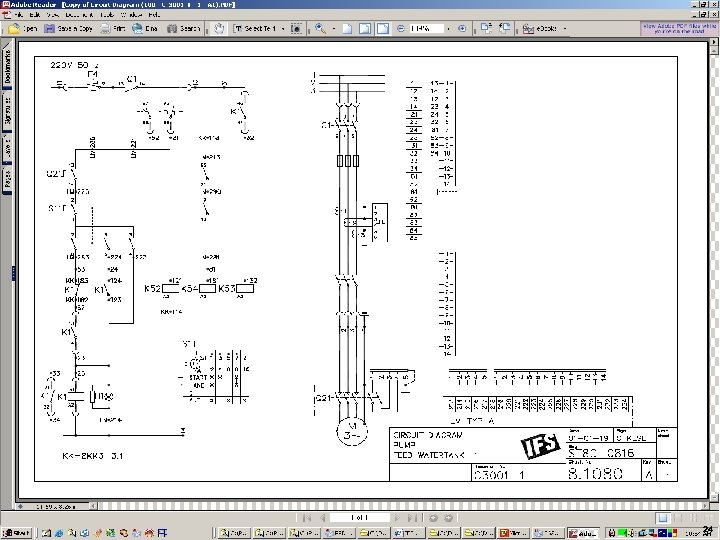

Asset Cost Reduction l Information Availability l Seamless navigation between different information systems Work order history Active work orders Business performance Equipment cost analysis Equipment data sheet OEE P&I Diagram Electrical diagram 5

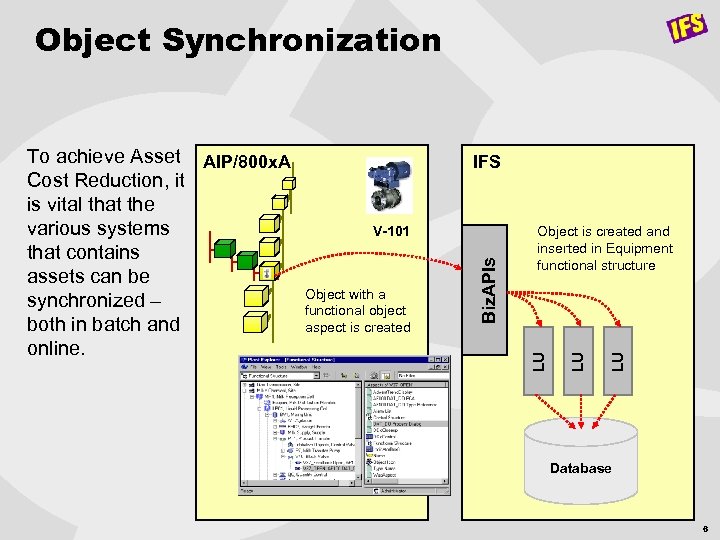

Object Synchronization IFS LU LU Object with a functional object aspect is created Object is created and inserted in Equipment functional structure LU V-101 Biz. APIs To achieve Asset AIP/800 x. A Cost Reduction, it is vital that the various systems that contains assets can be synchronized – both in batch and online. Database 6

Condition-based Maintenance Calendar-based PM could be compared to a man that visits his doctor once a month and asks him to open up his stomach to see if everything looks good. With the risk of forgetting his scalpel or infecting the wound before stitching the stomach together again, the doctor usually says it looks alright. The goal should be to let the factory – as well as men – ask for maintenance when it is needed. 7

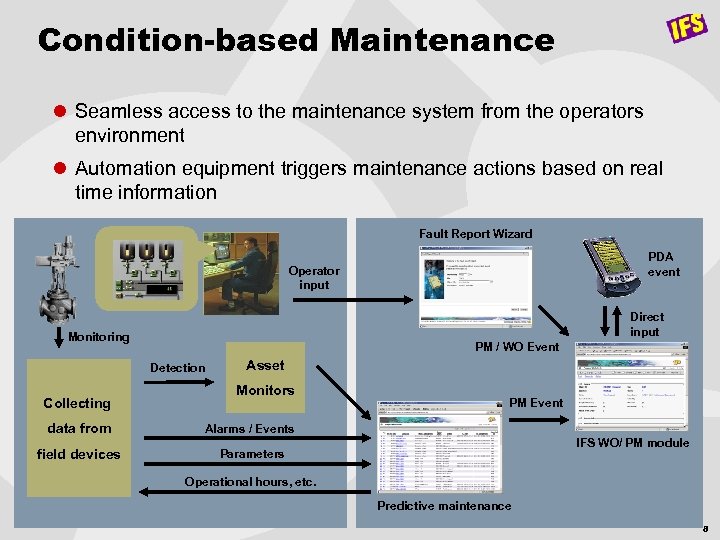

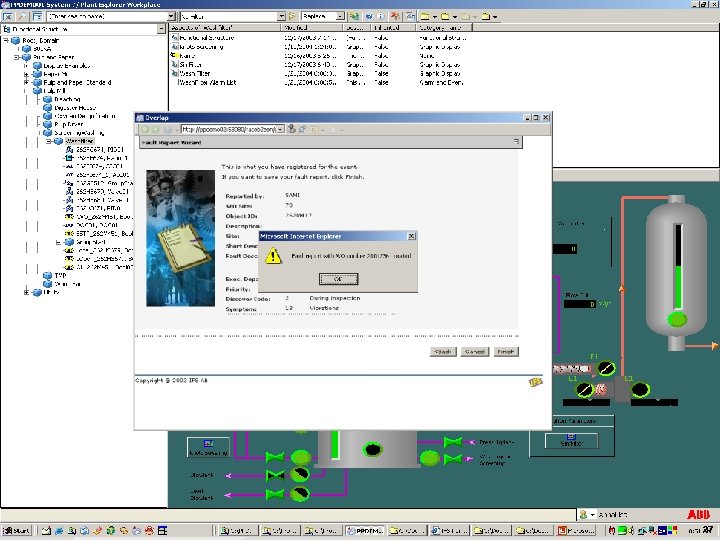

Condition-based Maintenance l Seamless access to the maintenance system from the operators environment l Automation equipment triggers maintenance actions based on real time information Fault Report Wizard PDA event Operator input Direct input Monitoring PM / WO Event Detection Collecting Asset Monitors data from Alarms / Events field devices PM Event Parameters IFS WO/ PM module Operational hours, etc. Predictive maintenance 8

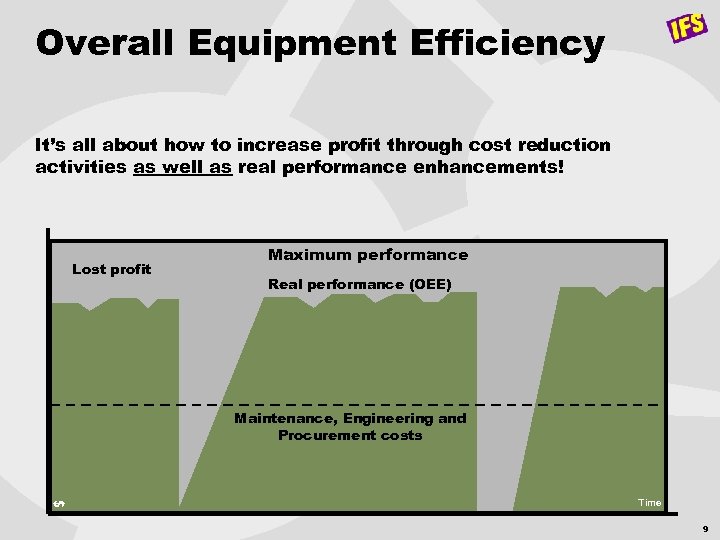

Overall Equipment Efficiency It’s all about how to increase profit through cost reduction activities as well as real performance enhancements! Lost profit Maximum performance Real performance (OEE) Maintenance, Engineering and Procurement costs $ Time 9

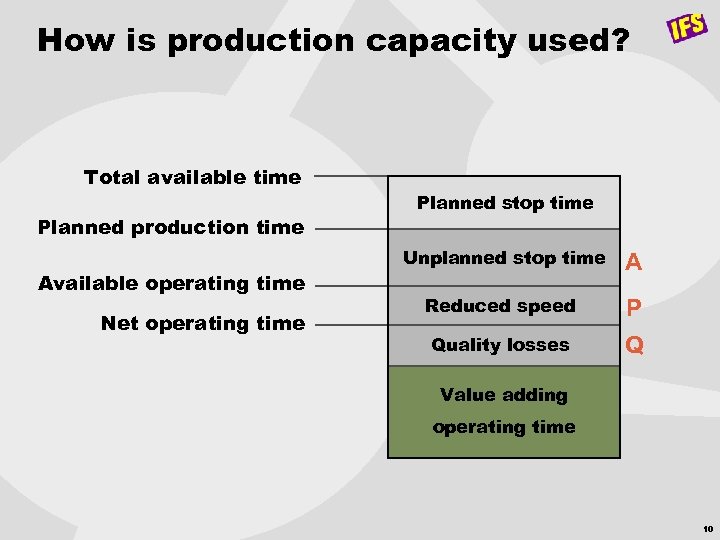

How is production capacity used? Total available time Planned production time Available operating time Net operating time Planned stop time Unplanned stop time A Reduced speed P Quality losses Q Value adding operating time 10

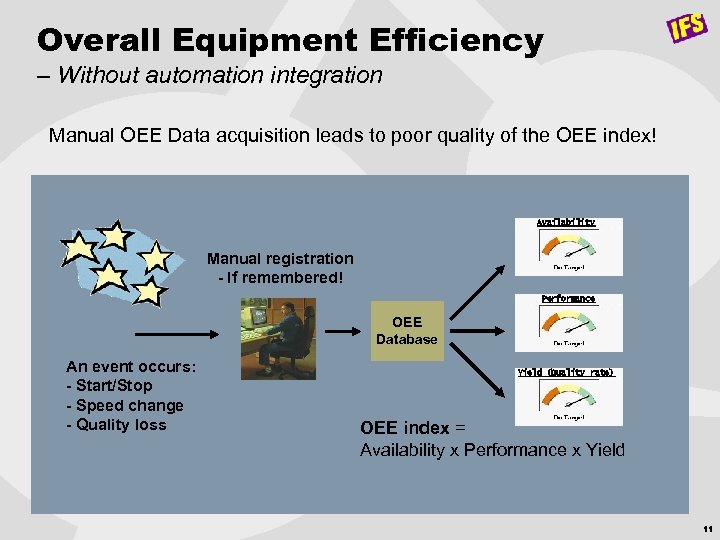

Overall Equipment Efficiency – Without automation integration Manual OEE Data acquisition leads to poor quality of the OEE index! Availability Manual registration - If remembered! Performance OEE Database An event occurs: - Start/Stop - Speed change - Quality loss Yield (Quality rate) OEE index = Availability x Performance x Yield 11

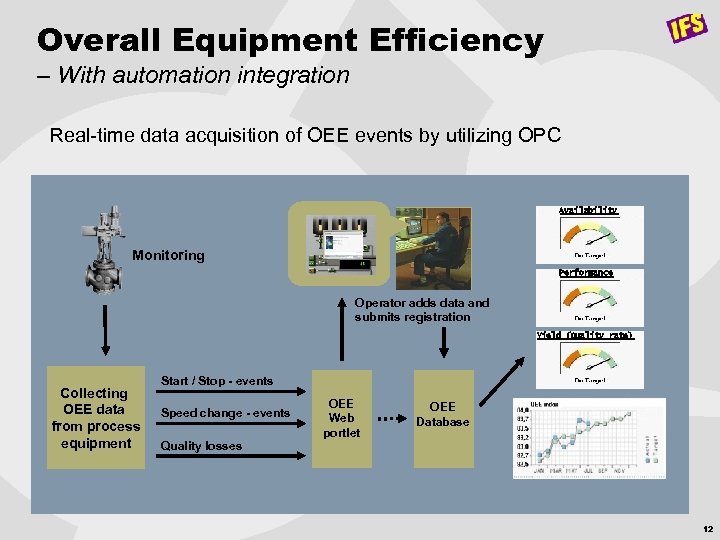

Overall Equipment Efficiency – With automation integration Real-time data acquisition of OEE events by utilizing OPC Availability Monitoring Performance Operator adds data and submits registration Yield (Quality rate) Collecting OEE data from process equipment Start / Stop - events Speed change - events Quality losses OEE Web portlet OEE Database 12

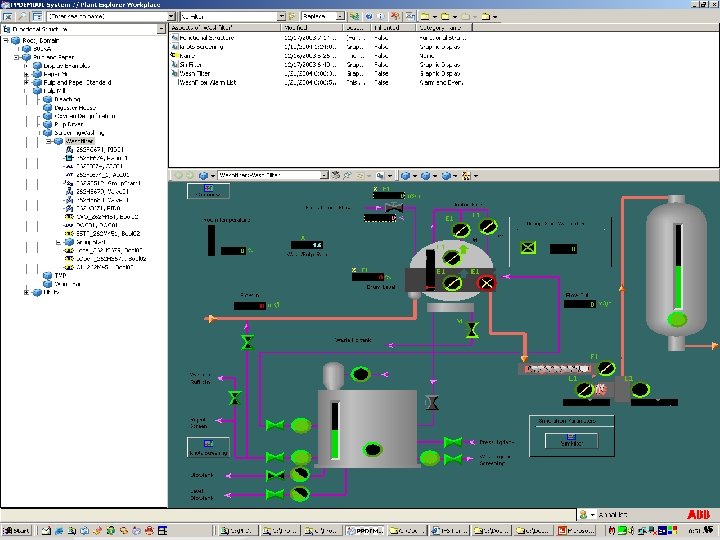

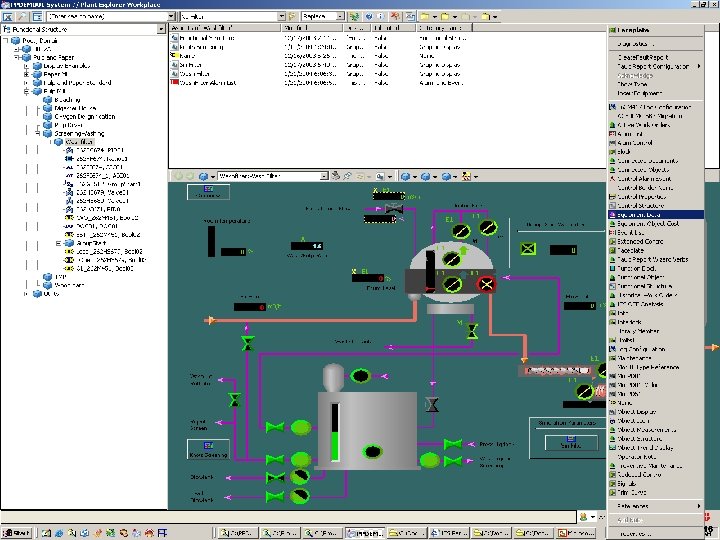

Demo Integrated Plant System Level 1: Connectivity 13

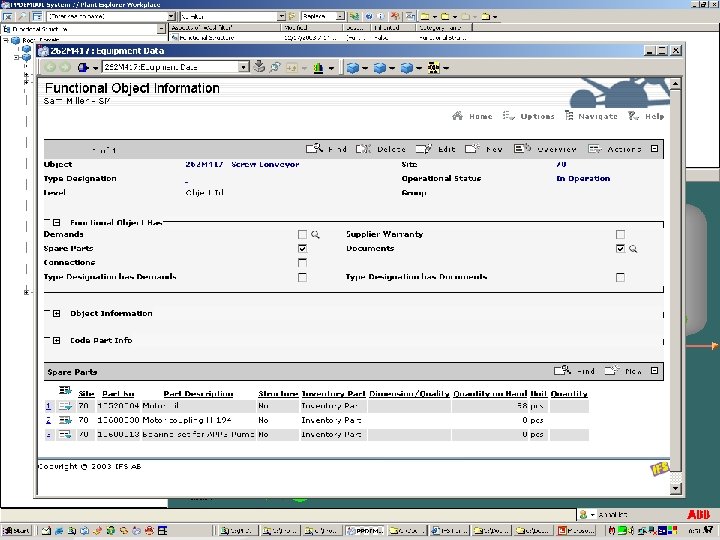

Asset Information – Demands, Spare parts, Inventory

15

16

17

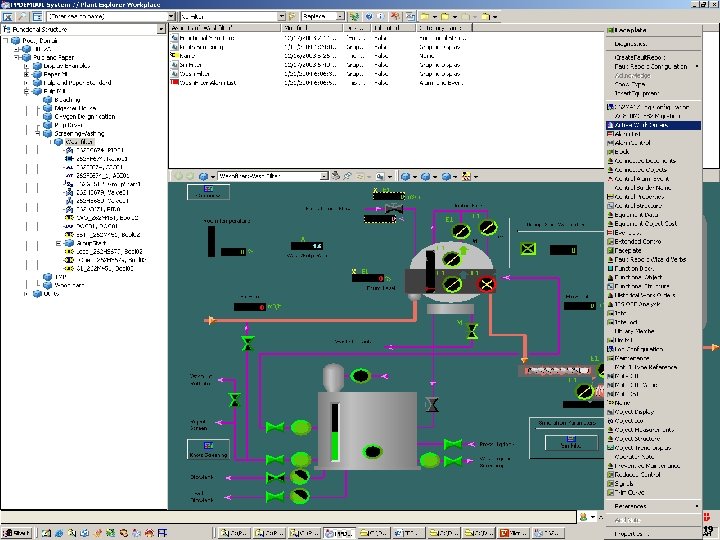

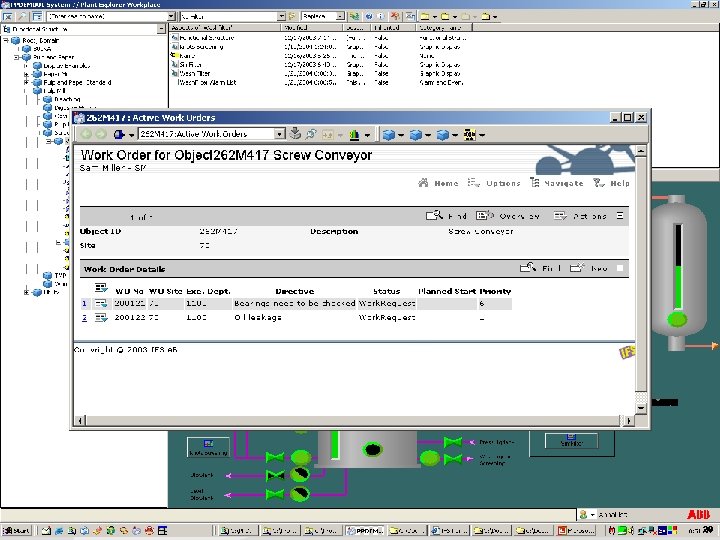

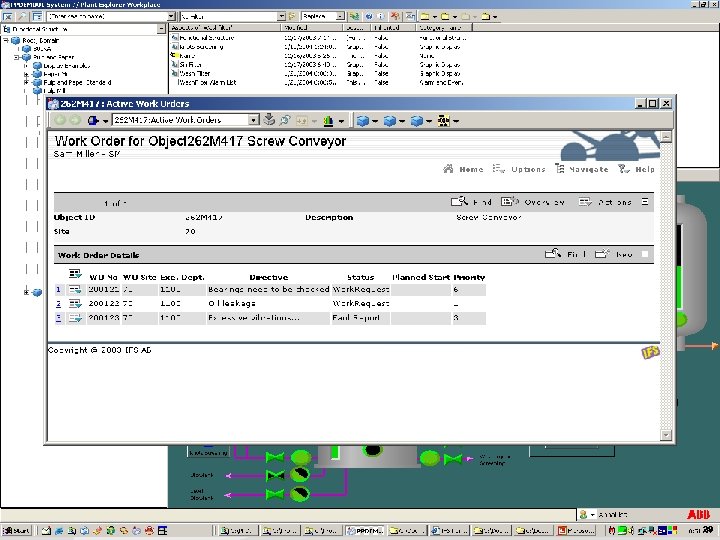

Work Order Planning

19

20

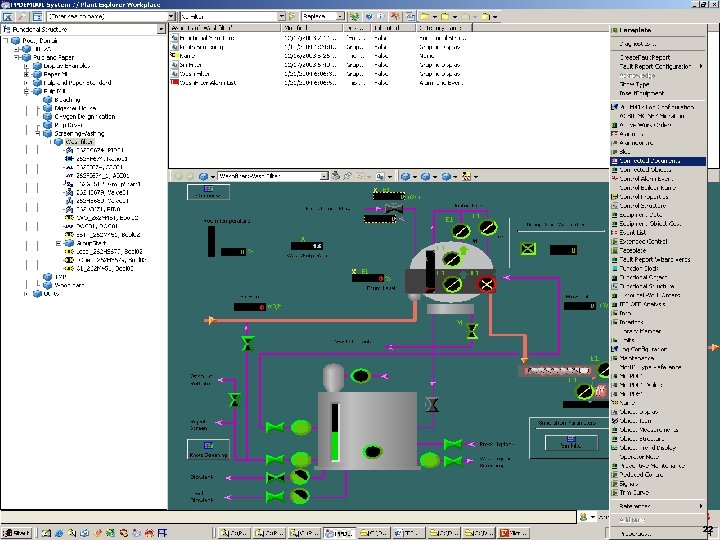

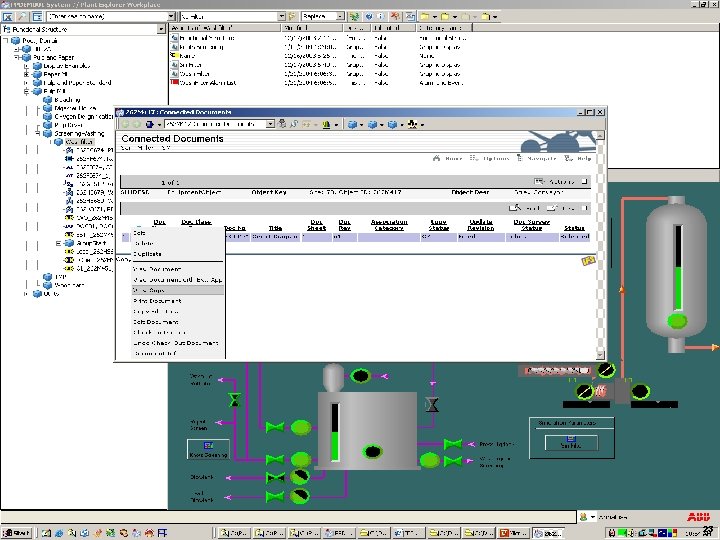

Document Management

22

23

24

Fault Reporting

26

27

28

29

Read More? 30

31

814328d2d878231bbf40503e362c0644.ppt