1a78115f95cf9363bd3db2f05171f974.ppt

- Количество слайдов: 23

1 Model-Driven CEBAF Setup After the 12 Ge. V Upgrade Dennis Turner WAO 2014 Notice: Authored by Jefferson Science Associates, LLC under U. S. DOE Contract No. DE-AC 05 -06 OR 23177. The U. S. Government retains a nonexclusive, paid-up, irrevocable, world-wide license to publish or reproduce this manuscript for U. S. Government purposes.

Outline • • • Motivation • Path Forward 6 Ge. V CEBAF Overview of 12 Ge. V Upgrade Machine configuration during 6 Ge. V era New operational paradigm developed during 12 Ge. V construction Examples of software tools developed to support the new operational paradigm.

Motivation An accurate accelerator model is critical for accelerator operations, as it enables comparisons of expected and observed beam behavior and helps identify root causes of discrepancy. An infrastructure of tools and procedures that systematically identifies differences between the machine and model will permit convergence that will lead to reductions in tune time, faster recovery from soft failures, and better understanding of CEBAF 12 Ge. V accelerator control and dynamics. CEBAF supports a highly dynamic nuclear physics program. Energy and Pass changes occur rather frequently. In an extreme case, we performed 11 pass changes and 3 energy changes in a one month period. Shorter tune time means more beam time for users. Model-driven setup reduces tune time and improves operational beam quality. The key concepts here are predictability and reproducibility.

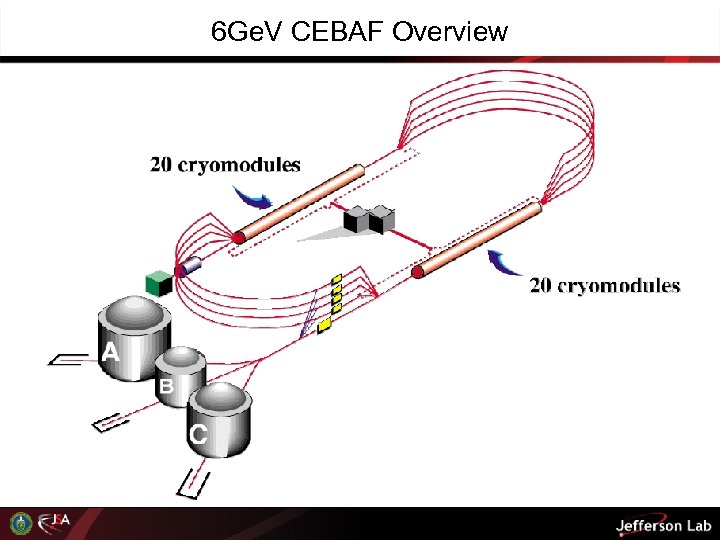

6 Ge. V CEBAF Overview 5 -Pass, 6 Ge. V CW Electron Accelerator Photoinjector; >85% polarization Two 1497 MHz superconducting RF linacs Two Recirculation Arcs Up to 180µA beam current for high data collection rate Simultaneous beam to three experimental halls Dynamic physics program requiring frequent energy and pass changes

6 Ge. V CEBAF Overview

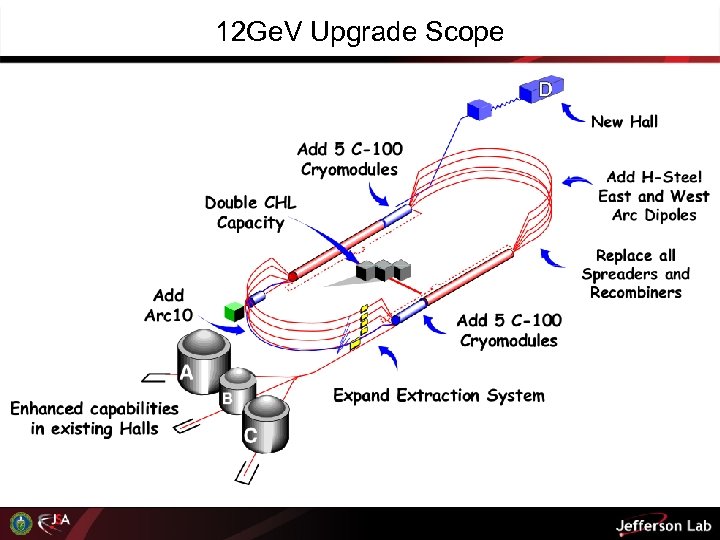

12 Ge. V Upgrade Scope Ten new higher-gradient superconducting RF cryomodules (five per linac). Ten new RF stations to power the 10 new cryomodules. Approximately double the refrigeration capacity. Modifications to the magnets in the recirculation arcs and their power supplies to keep the higher energy beam confined to the existing beam path. Modifications to the extraction system to support the higher energy beams. A tenth arc beamline to provide an extra pass through the North Linac. This additional acceleration pass will bring the beam up to the 12 Ge. V required to accommodate the experimental program in the new hall (Hall D). A new beamline connecting Hall D to the baseline accelerator.

12 Ge. V Upgrade Scope

Machine configuration during the 6 Ge. V era • • Modeled with Opti. M and Art++ • • Tweak, measure, tweak again; “grope & hope”. • No central source for configuration control; occasionally hardware changes did not propagate to operator tools and screens. • No feedback; model was not updated to reflect operational experience. Scaled machine settings from previous configurations to new energy (usually didn't work without much tuning, magnet mapping incomplete) Pass changes could take 4 or more hours, energy changes 8 or more hours. Drastic changes could take many shifts.

Machine configuration for 12 Ge. V The CEBAF Modeling Team was formed specifically to establish tools and procedures for model-driven machine configuration for 12 Ge. V CEBAF. Switched to elegant for modeling (will cover advantages of elegant over Opti. M later) Retrieve machine settings from the model rather than previous configurations ALL magnets were remapped for 12 Ge. V; model can be closer to reality The CEBAF Element Database (CED) was established as a central repository for hardware configuration control and model information. A “feedback loop” has been established such that model discrepancies discovered during commissioning and operation are fed back to the model, thus providing a path for convergence. As an example, during the first 12 Ge. V commissioning run it was noted that Operations needed to excessively tune with the same knobs downstream of Arc 1 after every energy change. This led to the discovery of a dipole body gradient error in the model. The error was corrected, and the excessive tuning was eliminated.

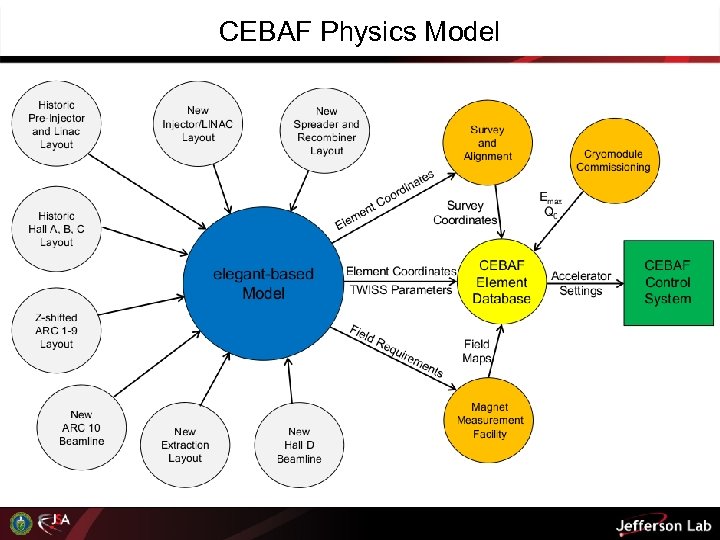

CEBAF Physics Model

elegant (ELEctron Generation ANd Tracking) 6 -D accelerator simulation code that does tracking, optimization, synchrotron radiation, scattering, etc. Developed at APS. Open-source. Compatible with Linux OS used by Operations (Opti. M is Windows only) Actively maintained and continuously improved by the APS team with help from the worldwide accelerator community, whereas Opti. M and Art++ are no longer supported by their primary developers. Large user community, more “industry standard” than Opti. M cannot easily be used in batch mode behind the scenes to drive an "online model" the way that elegant can. elegant also has better (and better tested) functionality to incorporate magnet errors that is an important part of reconciling online modeling with machine measurements. Capable of parallel computing for large scale simulations Interfaces well with the fully developed SDDS infrastructure

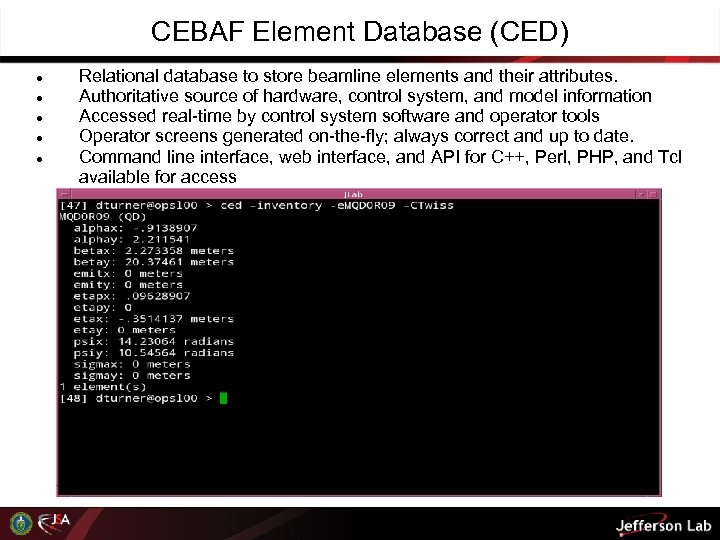

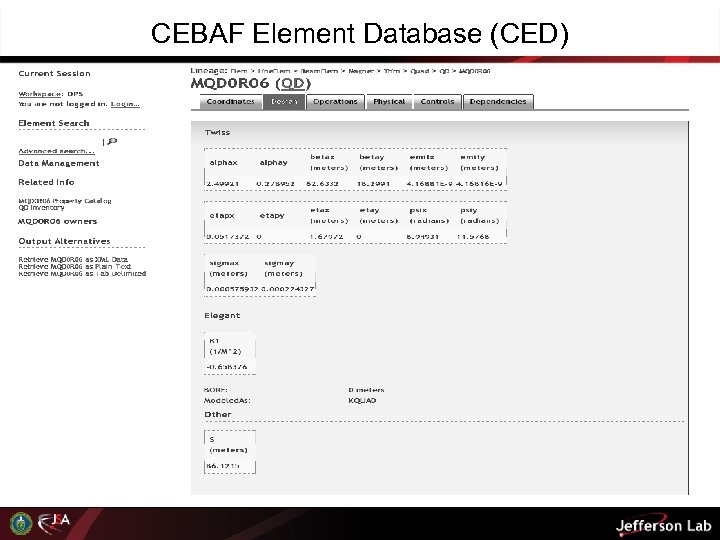

CEBAF Element Database (CED) Relational database to store beamline elements and their attributes. Authoritative source of hardware, control system, and model information Accessed real-time by control system software and operator tools Operator screens generated on-the-fly; always correct and up to date. Command line interface, web interface, and API for C++, Perl, PHP, and Tcl available for access

CEBAF Element Database (CED)

elegant Utilities Library (e. Utilities) Set of Perl modules which provide an object-oriented interface to elegant Provides methods for creating and manipulating elegant lattice and command files Many optics and operator tools built upon e. Utilities. We'll see some examples later.

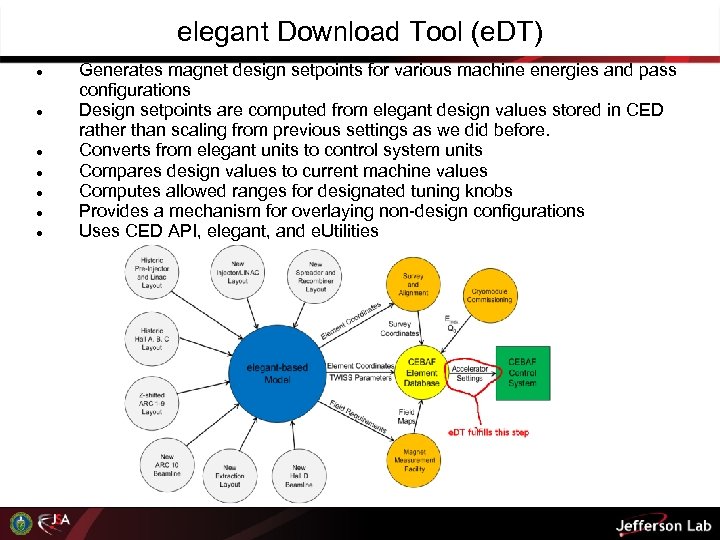

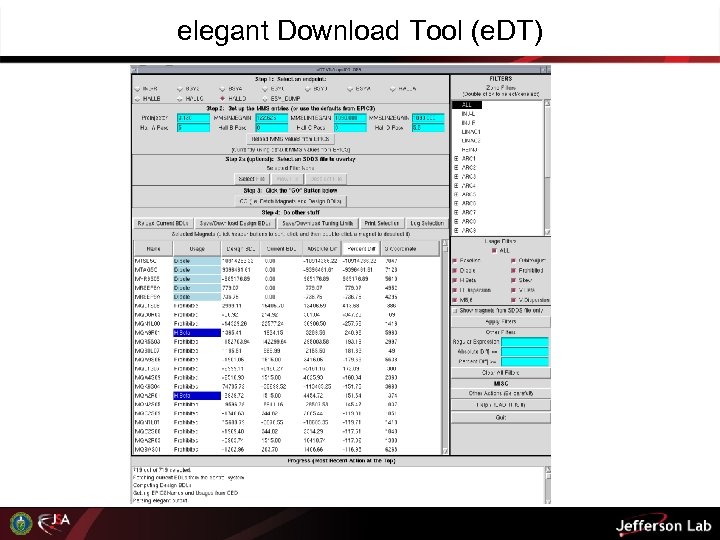

elegant Download Tool (e. DT) Generates magnet design setpoints for various machine energies and pass configurations Design setpoints are computed from elegant design values stored in CED rather than scaling from previous settings as we did before. Converts from elegant units to control system units Compares design values to current machine values Computes allowed ranges for designated tuning knobs Provides a mechanism for overlaying non-design configurations Uses CED API, elegant, and e. Utilities

elegant Download Tool (e. DT)

Quad Scan Utility (qs. Utility) Collects beam size data from wire scans while scanning quadrupole magnets. Computes transverse emittance and Twiss parameters from wire scan data. Produces phase space plots to visualize quality of match. Uses CED and elegant to determine design optics parameters, transport matrices, etc. The previous tool was not transparent to the user. Relied on expert to analyze data offline, after measurements were taken. Sometimes scans did not provide useful data, but it wasn't apparent while the measurements were being taken. The new tool gives “real-time” feedback and provide the user with an immediate indication of measurement quality

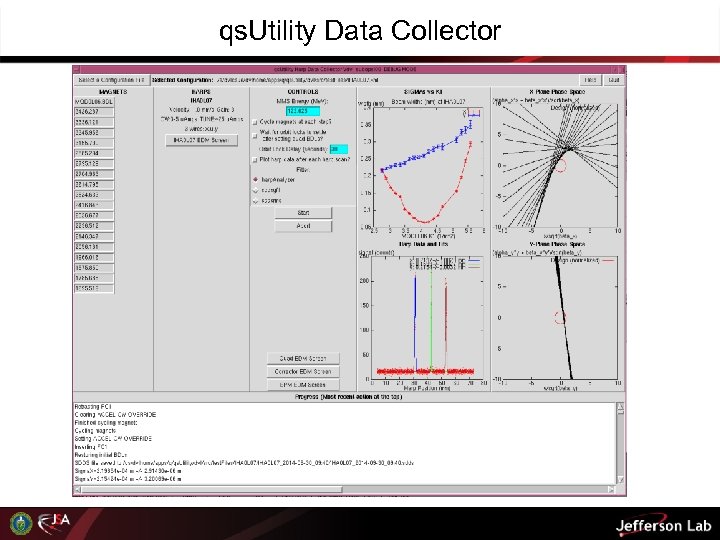

qs. Utility Data Collector

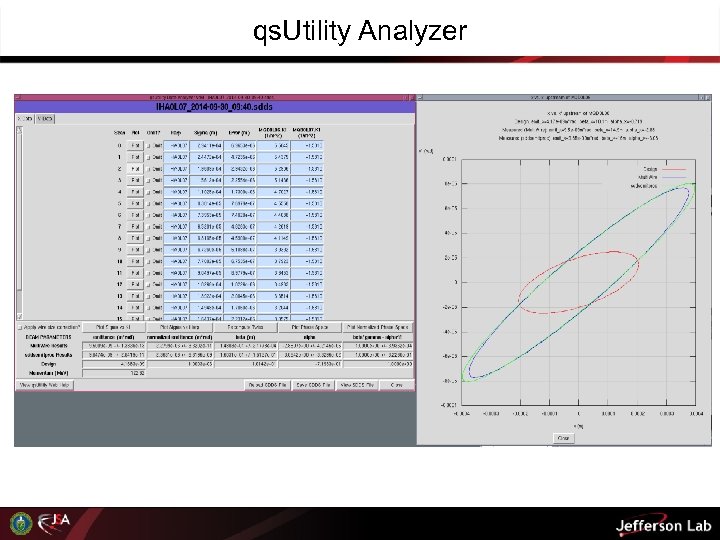

qs. Utility Analyzer

matching. Tool Even with a machine behaving as modeled, sometimes matching is required. For example, beam parameters from the early part of the Injector can vary from run to run or even drift over time, requiring rematching the beam entering the North Linac. This is where matching. Tool will come in handy. The matching. Tool: Takes Twiss parameters measured with qs. Utility as input. Provides automated matching using elegant's built-in optimizer. Given a starting element and matchpoint, matches to design Twiss parameters at a designated matchpoint. Matching used to be performed by optics experts. Each had a different method. matching. Tool provides a consistent method, and operators will be able to perform matching without relying on assistance from optics experts.

matching. Tool

Path Forward The machine and model will converge over the course of 12 Ge. V operations, leading to a measurable reduction in necessary tune time for new machine configurations, and improved CEBAF operational beam quality. As we gain more experience with the new machine and operational paradigm, we will streamline our tools and procedures for more efficient machine operation

Questions? This material is based upon work supported by the U. S. Department of Energy, Office of Science, Office of Nuclear Physics under contract DE-AC 05 -06 OR 23177

1a78115f95cf9363bd3db2f05171f974.ppt