36de09f04a821e70f0b62f45e13b8f03.ppt

- Количество слайдов: 50

1 Chapter 8 Quality Management © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

1 Chapter 8 Quality Management © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

2 OBJECTIVES • Total Quality Management Defined • Quality Specifications and Costs • Six Sigma Quality and Tools • ISO 9000 • External Benchmarking • Service Quality Measurement © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

2 OBJECTIVES • Total Quality Management Defined • Quality Specifications and Costs • Six Sigma Quality and Tools • ISO 9000 • External Benchmarking • Service Quality Measurement © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

3 Total Quality Management (TQM) Defined • Total quality management is defined as managing the entire organization so that it excels on all dimensions of products and services that are important to the customer © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

3 Total Quality Management (TQM) Defined • Total quality management is defined as managing the entire organization so that it excels on all dimensions of products and services that are important to the customer © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

4 Total Quality Management (TQM) • The TQM culture follows the Deming approach: — — Cultural environment for SPC Training employees in the TQM concept Problem solving Design of experiments • TQM is customer (external/internal) driven • TQM is company-wide not QC departments only © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

4 Total Quality Management (TQM) • The TQM culture follows the Deming approach: — — Cultural environment for SPC Training employees in the TQM concept Problem solving Design of experiments • TQM is customer (external/internal) driven • TQM is company-wide not QC departments only © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

5 Culture of TQM • Participative management: — — — Create proper cultural environment Promote team concepts Change of attitude (management and labor) Company versus individual goals Have a long-term focus • TQM is based on an integrated whole — All departments — All functions — All people in the company © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

5 Culture of TQM • Participative management: — — — Create proper cultural environment Promote team concepts Change of attitude (management and labor) Company versus individual goals Have a long-term focus • TQM is based on an integrated whole — All departments — All functions — All people in the company © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

6 TQM Concepts • Interest mostly due to: — Consumer interest in quality—more for their money — Foreign competition — The trade deficit • The goal is customer satisfaction • TQM integrates all function/processes in the company © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

6 TQM Concepts • Interest mostly due to: — Consumer interest in quality—more for their money — Foreign competition — The trade deficit • The goal is customer satisfaction • TQM integrates all function/processes in the company © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

7 Malcolm Baldrige National Quality Award • Initiated in 1987 to promote quality • Foreign competition was rationale • Award set national standards for quality • Designed to promote awareness: — Awareness of quality as competitive weapon — Requirements for quality excellence — Benchmarking: information sharing © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

7 Malcolm Baldrige National Quality Award • Initiated in 1987 to promote quality • Foreign competition was rationale • Award set national standards for quality • Designed to promote awareness: — Awareness of quality as competitive weapon — Requirements for quality excellence — Benchmarking: information sharing © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

8 Quality Specifications • Design quality: — Inherent value of the product marketplace — Strategic decision for the firm — Dimensions include: in the ü Performance, Features, Reliability, Durability, Serviceability, Response, Aesthetics, and Reputation. • Conformance quality: — Degree to which the product or service design specifications are met © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

8 Quality Specifications • Design quality: — Inherent value of the product marketplace — Strategic decision for the firm — Dimensions include: in the ü Performance, Features, Reliability, Durability, Serviceability, Response, Aesthetics, and Reputation. • Conformance quality: — Degree to which the product or service design specifications are met © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

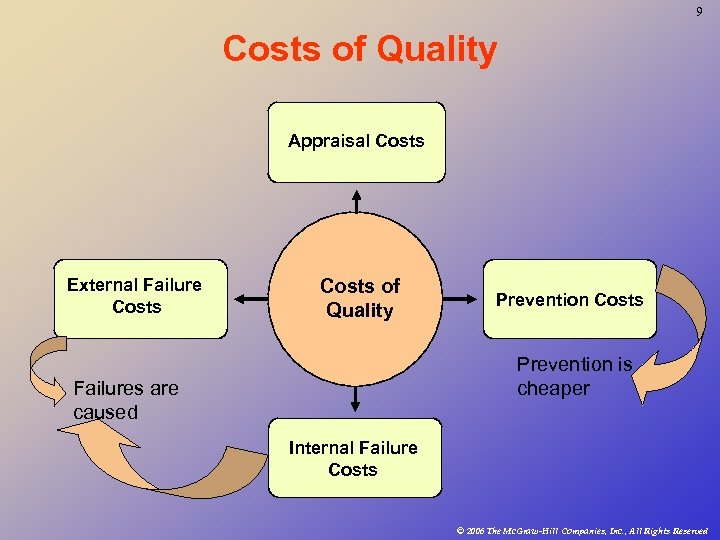

9 Costs of Quality Appraisal Costs External Failure Costs of Quality Prevention Costs Prevention is cheaper Failures are caused Internal Failure Costs © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

9 Costs of Quality Appraisal Costs External Failure Costs of Quality Prevention Costs Prevention is cheaper Failures are caused Internal Failure Costs © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

10 Costs of Quality • Appraisal costs: — — Inspection and testing of purchased materials Inspection and testing of products • Prevention costs: — — Training of employees in quality Quality planning activities • Internal failure costs: — — Costs of scrap and rework Costs of analyzing failures • External failure costs: — — Costs of warrantees Costs of liabilities © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

10 Costs of Quality • Appraisal costs: — — Inspection and testing of purchased materials Inspection and testing of products • Prevention costs: — — Training of employees in quality Quality planning activities • Internal failure costs: — — Costs of scrap and rework Costs of analyzing failures • External failure costs: — — Costs of warrantees Costs of liabilities © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

11 Six Sigma Quality • A philosophy and set of methods companies use to eliminate defects in their products and processes • Seeks to reduce variation in the processes that lead to product defects • The name, “six sigma” refers to the variation that exists within plus or minus three standard deviations of the process outputs © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

11 Six Sigma Quality • A philosophy and set of methods companies use to eliminate defects in their products and processes • Seeks to reduce variation in the processes that lead to product defects • The name, “six sigma” refers to the variation that exists within plus or minus three standard deviations of the process outputs © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

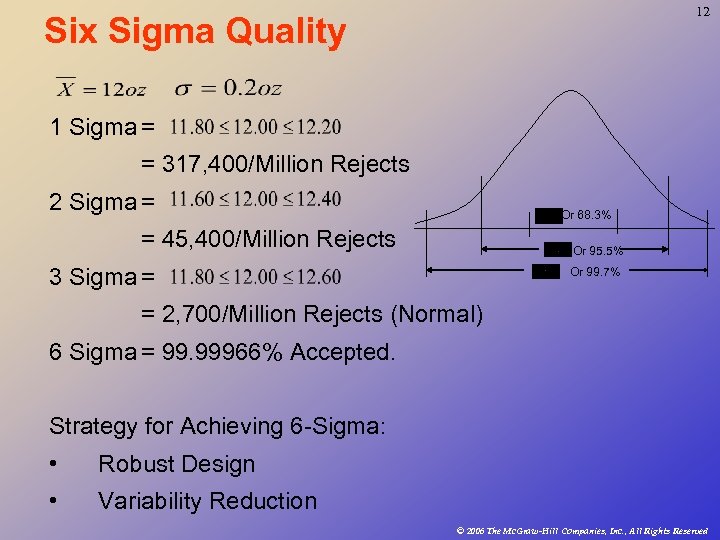

12 Six Sigma Quality 1 Sigma = = 317, 400/Million Rejects 2 Sigma = Or 68. 3% = 45, 400/Million Rejects Or 95. 5% 3 Sigma = Or 99. 7% = 2, 700/Million Rejects (Normal) 6 Sigma = 99. 99966% Accepted. Strategy for Achieving 6 -Sigma: • Robust Design • Variability Reduction © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

12 Six Sigma Quality 1 Sigma = = 317, 400/Million Rejects 2 Sigma = Or 68. 3% = 45, 400/Million Rejects Or 95. 5% 3 Sigma = Or 99. 7% = 2, 700/Million Rejects (Normal) 6 Sigma = 99. 99966% Accepted. Strategy for Achieving 6 -Sigma: • Robust Design • Variability Reduction © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

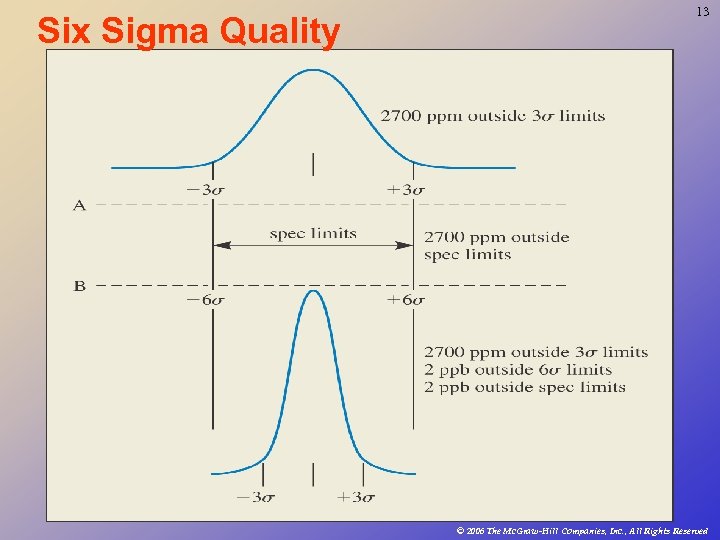

Six Sigma Quality 13 © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Six Sigma Quality 13 © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

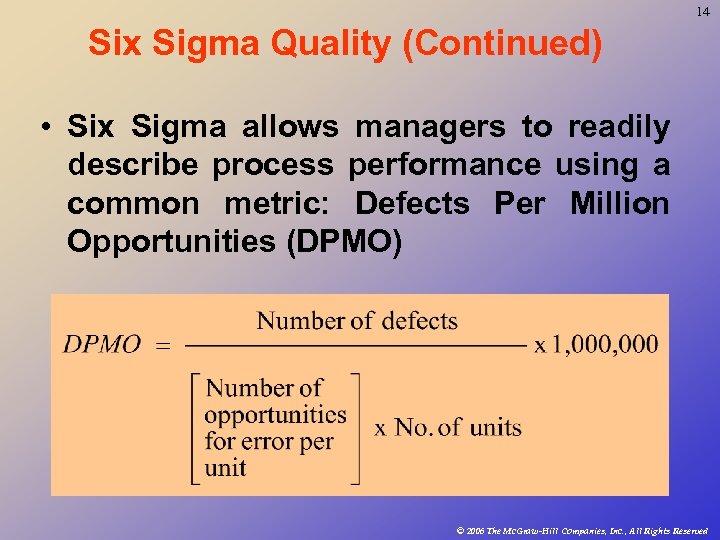

14 Six Sigma Quality (Continued) • Six Sigma allows managers to readily describe process performance using a common metric: Defects Per Million Opportunities (DPMO) © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

14 Six Sigma Quality (Continued) • Six Sigma allows managers to readily describe process performance using a common metric: Defects Per Million Opportunities (DPMO) © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

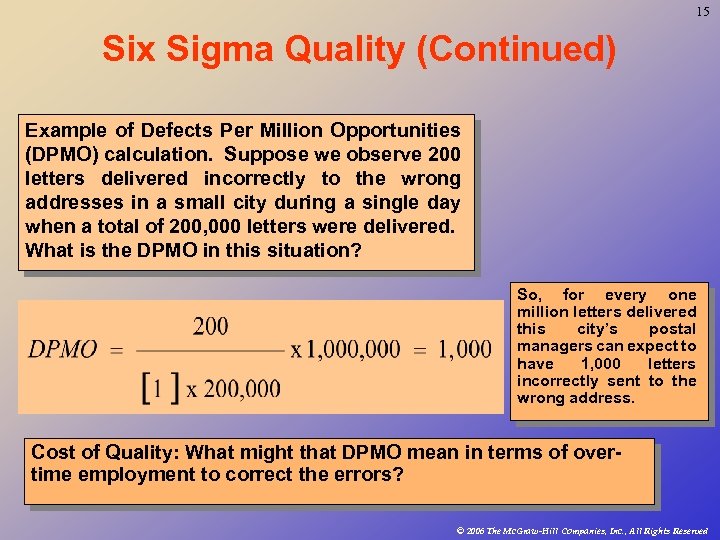

15 Six Sigma Quality (Continued) Example of Defects Per Million Opportunities (DPMO) calculation. Suppose we observe 200 letters delivered incorrectly to the wrong addresses in a small city during a single day when a total of 200, 000 letters were delivered. What is the DPMO in this situation? So, for every one million letters delivered this city’s postal managers can expect to have 1, 000 letters incorrectly sent to the wrong address. Cost of Quality: What might that DPMO mean in terms of overtime employment to correct the errors? © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

15 Six Sigma Quality (Continued) Example of Defects Per Million Opportunities (DPMO) calculation. Suppose we observe 200 letters delivered incorrectly to the wrong addresses in a small city during a single day when a total of 200, 000 letters were delivered. What is the DPMO in this situation? So, for every one million letters delivered this city’s postal managers can expect to have 1, 000 letters incorrectly sent to the wrong address. Cost of Quality: What might that DPMO mean in terms of overtime employment to correct the errors? © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Six Sigma Quality: DMAIC Cycle 16 • Define, Measure, Analyze, Improve, and Control (DMAIC) • Developed by General Electric as a means of focusing effort on quality using a methodological approach • Overall focus of the methodology is to understand achieve what the customer wants • A six-sigma program seeks to reduce the variation in the processes that lead to these defects • DMAIC consists of five steps…. © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Six Sigma Quality: DMAIC Cycle 16 • Define, Measure, Analyze, Improve, and Control (DMAIC) • Developed by General Electric as a means of focusing effort on quality using a methodological approach • Overall focus of the methodology is to understand achieve what the customer wants • A six-sigma program seeks to reduce the variation in the processes that lead to these defects • DMAIC consists of five steps…. © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

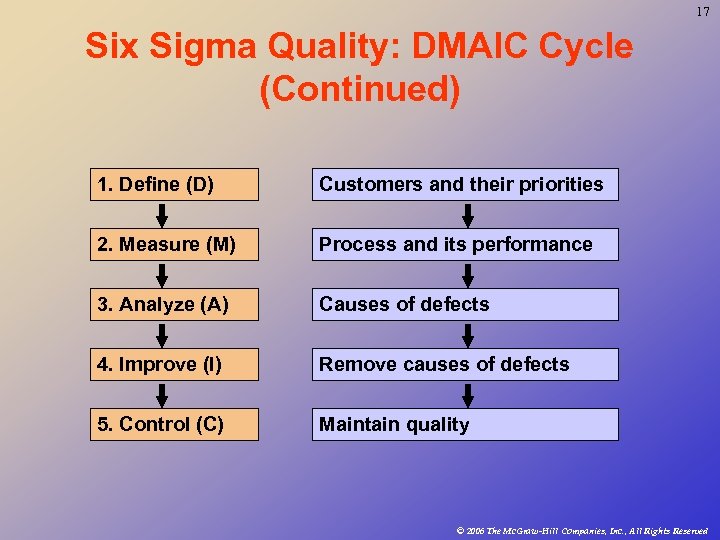

17 Six Sigma Quality: DMAIC Cycle (Continued) 1. Define (D) Customers and their priorities 2. Measure (M) Process and its performance 3. Analyze (A) Causes of defects 4. Improve (I) Remove causes of defects 5. Control (C) Maintain quality © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

17 Six Sigma Quality: DMAIC Cycle (Continued) 1. Define (D) Customers and their priorities 2. Measure (M) Process and its performance 3. Analyze (A) Causes of defects 4. Improve (I) Remove causes of defects 5. Control (C) Maintain quality © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

18 Example to illustrate the process… • We are the maker of this cereal. Consumer Reports has just published an article that shows that we frequently have less than 15 ounces of cereal in a box. • What should we do? © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

18 Example to illustrate the process… • We are the maker of this cereal. Consumer Reports has just published an article that shows that we frequently have less than 15 ounces of cereal in a box. • What should we do? © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

19 Step 1 - Define • What is the critical-to-quality characteristic? • The CTQ (critical-to-quality) characteristic in this case is the weight of the cereal in the box. © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

19 Step 1 - Define • What is the critical-to-quality characteristic? • The CTQ (critical-to-quality) characteristic in this case is the weight of the cereal in the box. © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

20 2 - Measure • How would we measure to evaluate the extent of the problem? • What are acceptable limits on this measure? © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

20 2 - Measure • How would we measure to evaluate the extent of the problem? • What are acceptable limits on this measure? © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

21 2 – Measure (continued) • Let’s assume that the government says that we must be within ± 5 percent of the weight advertised on the box. • Upper Tolerance Limit = 16 +. 05(16) = 16. 8 ounces • Lower Tolerance Limit = 16 –. 05(16) = 15. 2 ounces © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

21 2 – Measure (continued) • Let’s assume that the government says that we must be within ± 5 percent of the weight advertised on the box. • Upper Tolerance Limit = 16 +. 05(16) = 16. 8 ounces • Lower Tolerance Limit = 16 –. 05(16) = 15. 2 ounces © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

22 2. Measure (continued) • We go out and buy 1, 000 boxes of cereal and find that they weight an average of 15. 875 ounces with a standard deviation of. 529 ounces. • What percentage of boxes are outside the tolerance limits? © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

22 2. Measure (continued) • We go out and buy 1, 000 boxes of cereal and find that they weight an average of 15. 875 ounces with a standard deviation of. 529 ounces. • What percentage of boxes are outside the tolerance limits? © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

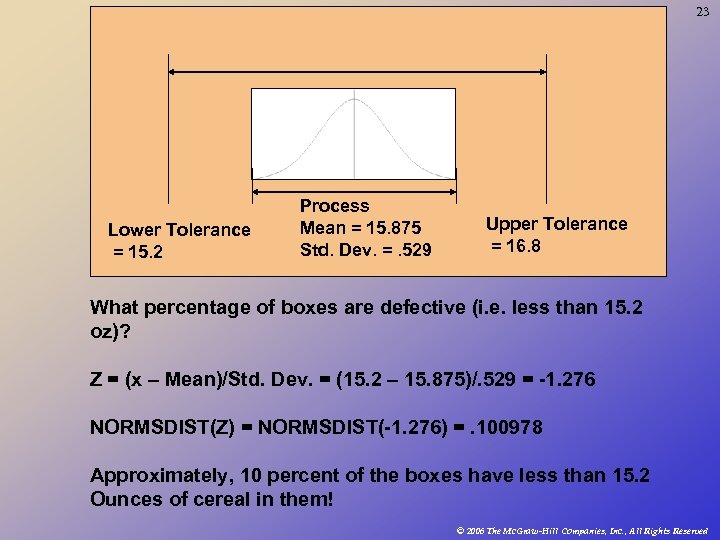

23 Lower Tolerance = 15. 2 Process Mean = 15. 875 Std. Dev. =. 529 Upper Tolerance = 16. 8 What percentage of boxes are defective (i. e. less than 15. 2 oz)? Z = (x – Mean)/Std. Dev. = (15. 2 – 15. 875)/. 529 = -1. 276 NORMSDIST(Z) = NORMSDIST(-1. 276) =. 100978 Approximately, 10 percent of the boxes have less than 15. 2 Ounces of cereal in them! © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

23 Lower Tolerance = 15. 2 Process Mean = 15. 875 Std. Dev. =. 529 Upper Tolerance = 16. 8 What percentage of boxes are defective (i. e. less than 15. 2 oz)? Z = (x – Mean)/Std. Dev. = (15. 2 – 15. 875)/. 529 = -1. 276 NORMSDIST(Z) = NORMSDIST(-1. 276) =. 100978 Approximately, 10 percent of the boxes have less than 15. 2 Ounces of cereal in them! © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

24 Step 3 - Analyze - How can we improve the capability of our cereal box filling process? – Decrease Variation – Center Process – Increase Specifications © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

24 Step 3 - Analyze - How can we improve the capability of our cereal box filling process? – Decrease Variation – Center Process – Increase Specifications © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

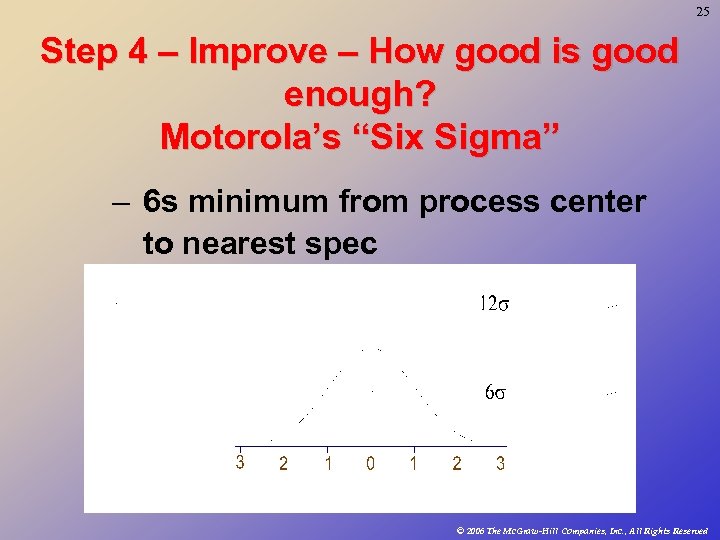

25 Step 4 – Improve – How good is good enough? Motorola’s “Six Sigma” – 6 s minimum from process center to nearest spec © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

25 Step 4 – Improve – How good is good enough? Motorola’s “Six Sigma” – 6 s minimum from process center to nearest spec © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

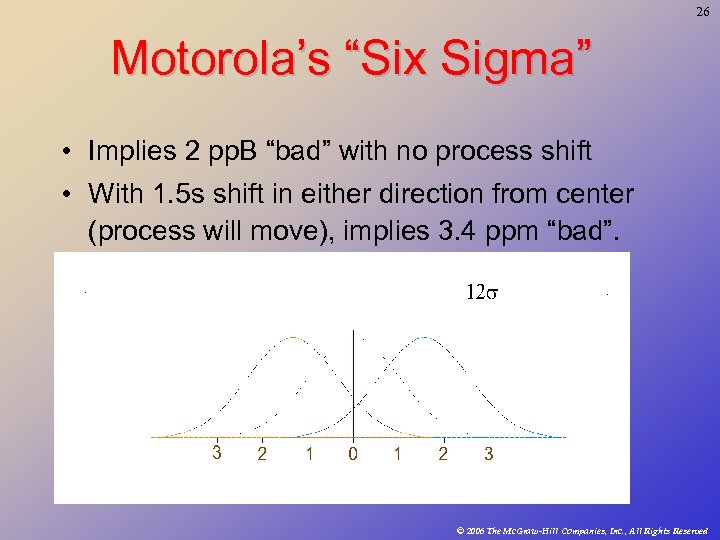

26 Motorola’s “Six Sigma” • Implies 2 pp. B “bad” with no process shift • With 1. 5 s shift in either direction from center (process will move), implies 3. 4 ppm “bad”. © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

26 Motorola’s “Six Sigma” • Implies 2 pp. B “bad” with no process shift • With 1. 5 s shift in either direction from center (process will move), implies 3. 4 ppm “bad”. © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

27 Step 5 – Control • Statistical Process Control (SPC) – Use data from the actual process – Estimate distributions – Look at capability - is good quality possible – Statistically monitor the process over time © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

27 Step 5 – Control • Statistical Process Control (SPC) – Use data from the actual process – Estimate distributions – Look at capability - is good quality possible – Statistically monitor the process over time © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

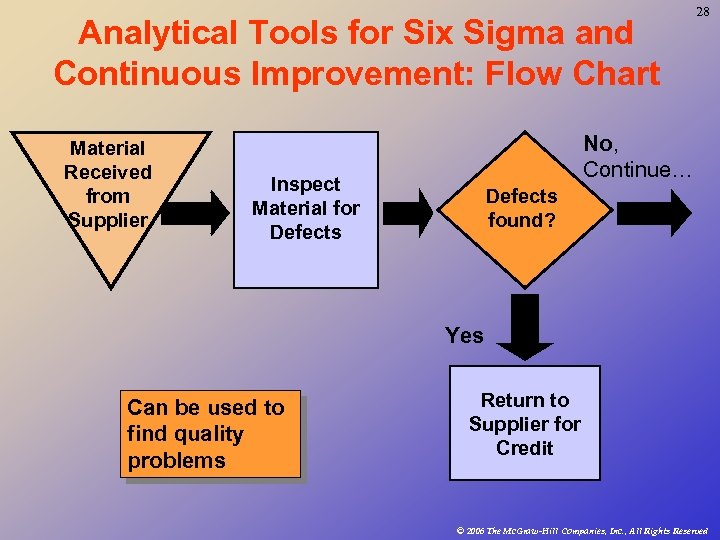

Analytical Tools for Six Sigma and Continuous Improvement: Flow Chart Material Received from Supplier 28 No, Continue… Inspect Material for Defects found? Yes Can be used to find quality problems Return to Supplier for Credit © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Analytical Tools for Six Sigma and Continuous Improvement: Flow Chart Material Received from Supplier 28 No, Continue… Inspect Material for Defects found? Yes Can be used to find quality problems Return to Supplier for Credit © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

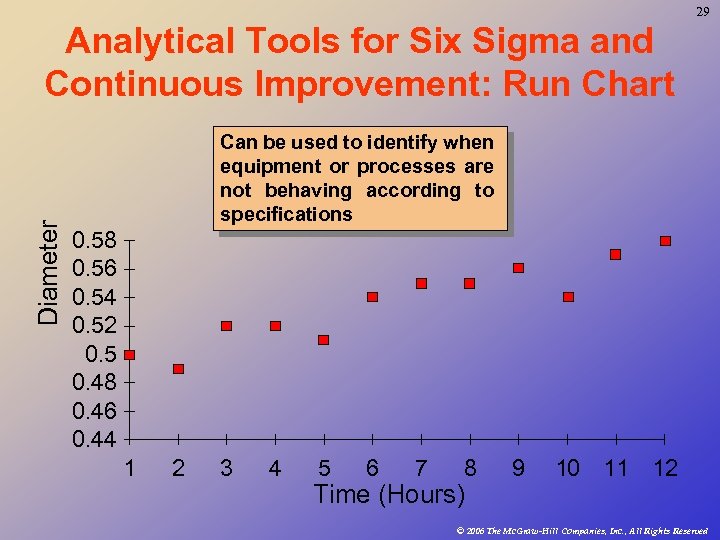

29 Diameter Analytical Tools for Six Sigma and Continuous Improvement: Run Chart Can be used to identify when equipment or processes are not behaving according to specifications 0. 58 0. 56 0. 54 0. 52 0. 5 0. 48 0. 46 0. 44 1 2 3 4 5 6 7 8 Time (Hours) 9 10 11 12 © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

29 Diameter Analytical Tools for Six Sigma and Continuous Improvement: Run Chart Can be used to identify when equipment or processes are not behaving according to specifications 0. 58 0. 56 0. 54 0. 52 0. 5 0. 48 0. 46 0. 44 1 2 3 4 5 6 7 8 Time (Hours) 9 10 11 12 © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

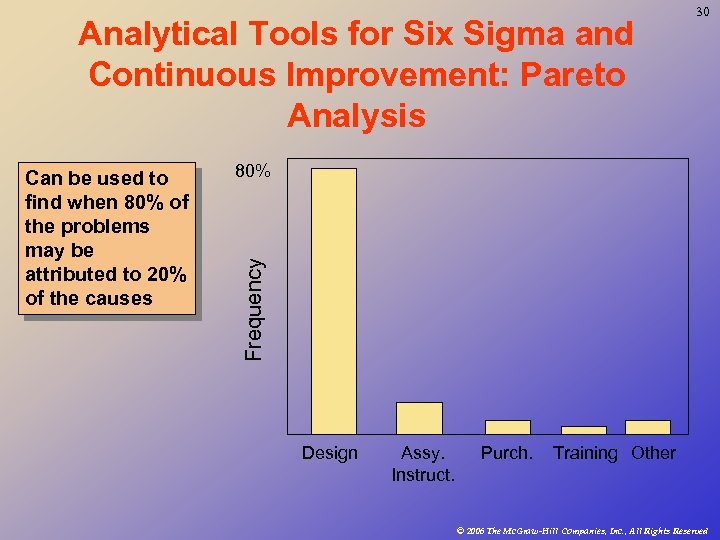

Analytical Tools for Six Sigma and Continuous Improvement: Pareto Analysis 80% Frequency Can be used to find when 80% of the problems may be attributed to 20% of the causes 30 Design Assy. Instruct. Purch. Training Other © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Analytical Tools for Six Sigma and Continuous Improvement: Pareto Analysis 80% Frequency Can be used to find when 80% of the problems may be attributed to 20% of the causes 30 Design Assy. Instruct. Purch. Training Other © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

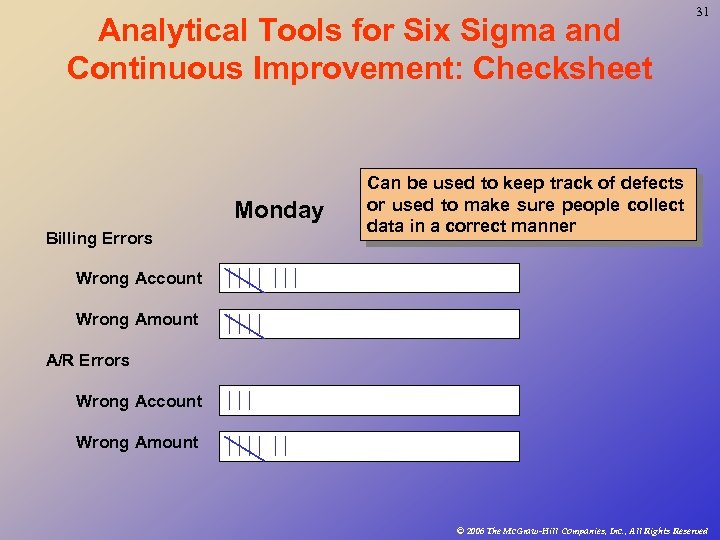

Analytical Tools for Six Sigma and Continuous Improvement: Checksheet Monday Billing Errors 31 Can be used to keep track of defects or used to make sure people collect data in a correct manner Wrong Account Wrong Amount A/R Errors Wrong Account Wrong Amount © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Analytical Tools for Six Sigma and Continuous Improvement: Checksheet Monday Billing Errors 31 Can be used to keep track of defects or used to make sure people collect data in a correct manner Wrong Account Wrong Amount A/R Errors Wrong Account Wrong Amount © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

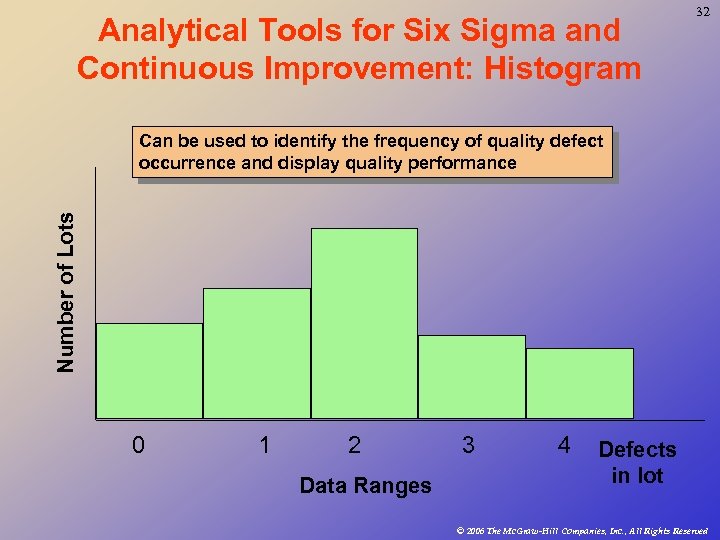

Analytical Tools for Six Sigma and Continuous Improvement: Histogram 32 Number of Lots Can be used to identify the frequency of quality defect occurrence and display quality performance 0 1 2 Data Ranges 3 4 Defects in lot © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Analytical Tools for Six Sigma and Continuous Improvement: Histogram 32 Number of Lots Can be used to identify the frequency of quality defect occurrence and display quality performance 0 1 2 Data Ranges 3 4 Defects in lot © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

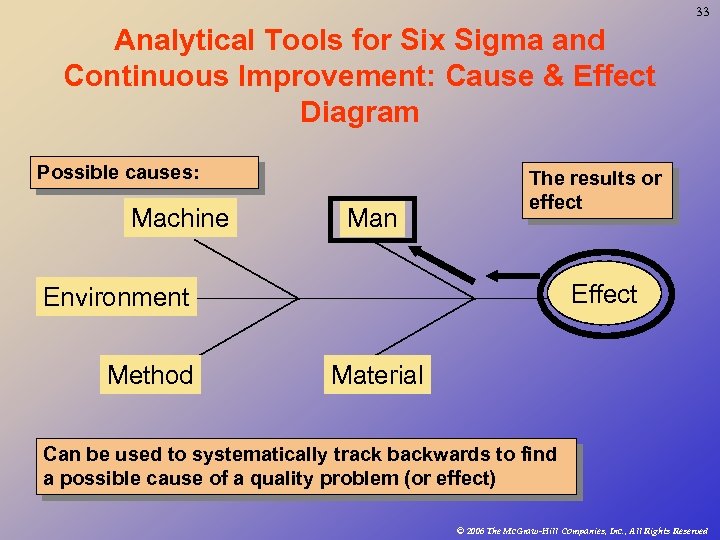

33 Analytical Tools for Six Sigma and Continuous Improvement: Cause & Effect Diagram Possible causes: Machine Man The results or effect Environment Method Material Can be used to systematically track backwards to find a possible cause of a quality problem (or effect) © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

33 Analytical Tools for Six Sigma and Continuous Improvement: Cause & Effect Diagram Possible causes: Machine Man The results or effect Environment Method Material Can be used to systematically track backwards to find a possible cause of a quality problem (or effect) © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

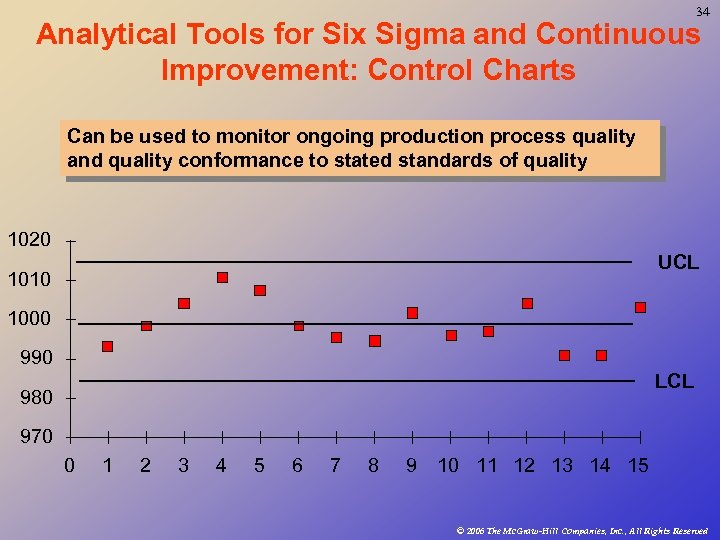

34 Analytical Tools for Six Sigma and Continuous Improvement: Control Charts Can be used to monitor ongoing production process quality and quality conformance to stated standards of quality 1020 UCL 1010 1000 990 LCL 980 970 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

34 Analytical Tools for Six Sigma and Continuous Improvement: Control Charts Can be used to monitor ongoing production process quality and quality conformance to stated standards of quality 1020 UCL 1010 1000 990 LCL 980 970 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

35 Other Six Sigma Tools • Opportunity Flow Diagram used to graphically show those activities that add value from those that are performed (and maybe could be reduced or removed) that do not add value to the finished product • Failure Mode and Effect Analysis (DMEA) is a structured approach to identify, estimate, prioritize, and evaluate risk of possible failures at each stage in the process • Design of Experiments (DOE) a statistical test to determine cause-and-effect relationships between process variables and output © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

35 Other Six Sigma Tools • Opportunity Flow Diagram used to graphically show those activities that add value from those that are performed (and maybe could be reduced or removed) that do not add value to the finished product • Failure Mode and Effect Analysis (DMEA) is a structured approach to identify, estimate, prioritize, and evaluate risk of possible failures at each stage in the process • Design of Experiments (DOE) a statistical test to determine cause-and-effect relationships between process variables and output © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

36 Six Sigma Roles and Responsibilities 1. Executive leaders must champion the process of improvement 2. Corporation-wide training in Six Sigma concepts and tools 3. Setting stretch objectives for improvement 4. Continuous reinforcement and rewards © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

36 Six Sigma Roles and Responsibilities 1. Executive leaders must champion the process of improvement 2. Corporation-wide training in Six Sigma concepts and tools 3. Setting stretch objectives for improvement 4. Continuous reinforcement and rewards © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

37 The Shingo System: Fail-Safe Design • Shingo’s argument: — SQC methods do not prevent defects — They provide information about defects but after the fact — Errors can best be prevented by strategic placement of controls within the process — Defects arise when people make errors — Defects can be prevented by providing workers with feedback on errors — Might require 100% inspection at all times © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

37 The Shingo System: Fail-Safe Design • Shingo’s argument: — SQC methods do not prevent defects — They provide information about defects but after the fact — Errors can best be prevented by strategic placement of controls within the process — Defects arise when people make errors — Defects can be prevented by providing workers with feedback on errors — Might require 100% inspection at all times © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

38 Poka-Yoke • Fail-safe procedures or devices that: — Include checklists — Prevent the worker from making an error that leads to a defect before starting a process, or — Give rapid feedback of abnormalities in the process to the worker in time to correct it © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

38 Poka-Yoke • Fail-safe procedures or devices that: — Include checklists — Prevent the worker from making an error that leads to a defect before starting a process, or — Give rapid feedback of abnormalities in the process to the worker in time to correct it © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

39 Six-Sigma In Practice 100 Rounds of Golf a Year • 2 < 6 missed putts per round • 3 1 missed putt per round • 4 1 missed putt every 9 th round • 5 1 missed putt in 2. 33 years • 6 1 missed putt in 163 years © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

39 Six-Sigma In Practice 100 Rounds of Golf a Year • 2 < 6 missed putts per round • 3 1 missed putt per round • 4 1 missed putt every 9 th round • 5 1 missed putt in 2. 33 years • 6 1 missed putt in 163 years © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

40 ISO 9000 • Series of standards agreed upon by the International Organization for Standardization (ISO) • Adopted in 1987 • More than 100 countries • A prerequisite for global competition? • ISO 9000 directs you to "document what you do and then do as you documented" © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

40 ISO 9000 • Series of standards agreed upon by the International Organization for Standardization (ISO) • Adopted in 1987 • More than 100 countries • A prerequisite for global competition? • ISO 9000 directs you to "document what you do and then do as you documented" © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

41 ISO 9000 Series • 9001 — Model for Quality Assurance in Design, Production Installation, and Servicing • 9002 — Model for Quality Assurance in Production and Installation • 9003 — Model for Quality Inspection and Test Assurance in Final © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

41 ISO 9000 Series • 9001 — Model for Quality Assurance in Design, Production Installation, and Servicing • 9002 — Model for Quality Assurance in Production and Installation • 9003 — Model for Quality Inspection and Test Assurance in Final © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

42 Guidelines for Use • 9000 — Quality Management and Quality Assurance Standards: Guidelines for Selection and Use • 9004 — Quality Management and Quality Systems Elements—Guidelines © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

42 Guidelines for Use • 9000 — Quality Management and Quality Assurance Standards: Guidelines for Selection and Use • 9004 — Quality Management and Quality Systems Elements—Guidelines © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

43 Three Forms of ISO Certification 1. First party: A firm audits itself against ISO 9000 standards 2. Second party: A customer audits supplier 3. Third party: A "qualified" national or international standards or certifying agency serves as auditor © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

43 Three Forms of ISO Certification 1. First party: A firm audits itself against ISO 9000 standards 2. Second party: A customer audits supplier 3. Third party: A "qualified" national or international standards or certifying agency serves as auditor © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

44 More About ISO 9000 • They are not award programs • They just provide criteria for measuring quality systems • They are quite flexible • Applies to all industries • It is a worldwide standard • Offers opportunity for global competition © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

44 More About ISO 9000 • They are not award programs • They just provide criteria for measuring quality systems • They are quite flexible • Applies to all industries • It is a worldwide standard • Offers opportunity for global competition © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

45 External Benchmarking Steps 1. Identify those processes needing improvement 2. Identify a firm that is the world leader in performing the process 3. Contact the managers of that company and make a personal visit to interview managers and workers 4. Analyze data © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

45 External Benchmarking Steps 1. Identify those processes needing improvement 2. Identify a firm that is the world leader in performing the process 3. Contact the managers of that company and make a personal visit to interview managers and workers 4. Analyze data © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

46 Steps to Benchmarking • Align benchmark goals to organizational goals • Develop methods of measuring performance • Undertake benchmark improvement activities • Measure performance • Repeat the process and continue to improve © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

46 Steps to Benchmarking • Align benchmark goals to organizational goals • Develop methods of measuring performance • Undertake benchmark improvement activities • Measure performance • Repeat the process and continue to improve © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

47 Benefits of Benchmarking • Cultural change — — Allows firm to set realistic goals Engenders cultural change: compare oneself • Performance improvement — — Forces firm to define and identify gaps Provides way for improvement • Human resource benefits — — Recognizes the importance of people Provides for training and make them part of problem-solving process © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

47 Benefits of Benchmarking • Cultural change — — Allows firm to set realistic goals Engenders cultural change: compare oneself • Performance improvement — — Forces firm to define and identify gaps Provides way for improvement • Human resource benefits — — Recognizes the importance of people Provides for training and make them part of problem-solving process © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

48 Pitfalls of Benchmarking • It is not a panacea — Will not work if the culture is lacking — Could be counterproductive • Potential pitfalls — Failure to involve/empower employees — Failure to define/understand own process first — Failure to take action on results — Failure to set realistic goals © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

48 Pitfalls of Benchmarking • It is not a panacea — Will not work if the culture is lacking — Could be counterproductive • Potential pitfalls — Failure to involve/empower employees — Failure to define/understand own process first — Failure to take action on results — Failure to set realistic goals © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

49 Service Quality Measurement: Servqual • A perceived service quality questionnaire survey methodology • Examines “Dimensions of Service Quality” including: Reliability, Responsiveness, Assurance, Empathy, and Tangibles (e. g. , appearance of physical facilities, equipment, etc. ) © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

49 Service Quality Measurement: Servqual • A perceived service quality questionnaire survey methodology • Examines “Dimensions of Service Quality” including: Reliability, Responsiveness, Assurance, Empathy, and Tangibles (e. g. , appearance of physical facilities, equipment, etc. ) © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Service Quality Measurement: Servqual (Continued) 50 • New version of this methodology is called “e -Service Quality” dealing service on the Internet • Dimensions of Service Quality on the e. Service methodology include: — Reliability, Responsiveness, Access, Flexibility, Ease of Navigation, Efficiency, Assurance/Trust, Security/Privacy, Price Knowledge, Site Aesthetics, and Customization/Personalization © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved

Service Quality Measurement: Servqual (Continued) 50 • New version of this methodology is called “e -Service Quality” dealing service on the Internet • Dimensions of Service Quality on the e. Service methodology include: — Reliability, Responsiveness, Access, Flexibility, Ease of Navigation, Efficiency, Assurance/Trust, Security/Privacy, Price Knowledge, Site Aesthetics, and Customization/Personalization © 2006 The Mc. Graw-Hill Companies, Inc. , All Rights Reserved