21202f8c2eca2c5b489503ca3a6b2ef1.ppt

- Количество слайдов: 15

1

2

MACHINES BAGGING MACHINES Flat reel bagging machines Tube reel bagging machines Open mouth bagging machines Bagging machines for pressed bales Valve Sack Bagging Machine JUMBO BAGGING MACHINES (500 Kgs - 2 Tons / bag) Big bag machines (10 - 15 bags / hr) High speed jumbo bagging machines (30 - 40 bags / hr) CAROUSAL JUMBO BAGGING MACHINES (500 Kgs - 2 Tons / bag) 3 Station bagging machines (40 - 50 bags / hr) 6 Station bagging machines (50 - 60 bags / hr) 3

ELOCOM BAGGING MACHINES Flat reel bagging machines Tube reel bagging machines Open mouth bagging machines Bagging machine for pressed bales Valve Sack Bagging machines 4

WEBSTER GRIFFIN JUMBO BAGGING MACHINES (500 Kgs - 2 Tons / bag) Big bag machines (10 - 15 bags / hr) High speed jumbo bagging machines (30 - 40 bags / hr) 5

THIMMON PALLET PROTECTION SYSTEMS Wrapping machines Stretch hooding systems 6

Elocom, Spain • • • Flat Reel Bagging System: - CV-3025, 3080, 3125. HYDRAULIC SYSTEM, CV-4025, 4080, 4125, 4150. BRUSHLESS SYSTEM ELOCOM Group is a reference company in the bagging sector. Its activity is developed in the industrial environment, by means of research and development suited to solutions required by each sector. Originally developed in external working environments, the ELOCOM laminated-sheet sack packers now specially target such sectors as the mining, chemical, substrate, biomass industries… Of sturdiest construction, these sack packers are most reliable because of their low failure rates/minimum maintenance requirements in addition to their capability of unmanned operation. Their components, as well as state -of-the-art welding systems, (ROPEX, etc. ) are all from leading brands in the market. Maximum outputs of up to 1700 25 kg sacks/hour and the number of machines produced each year explain why the CV series packer is the unquestionable number one worldwide. The dozing systems are specific for each type of product and are implemented to the CV bagging machine: Unique or double screw fed scale: Powder and fine powder products. Band fed scale: Big size granulated and (not fine powder) grinded products. Gravity fed scale: Products with good fluidity (up to 1. 600 bags per hour with unique scale). Volumetric dozing: Soils and arids with non extreme weight reliability requirements. Open Mouth Automatic Bagging Machines : - ELOCOM Group is a reference company in the bagging sector. Its activity is developed in the industrial environment, by means of research and development suited to solutions required by each sector. The more than 500 automatic bagging installations around the world, endorse Elocom’s commitment in nonstop improvement in security, quality and service, for all customers. • EP-400/600/1. 200/1. 500 The most advanced outcome of bagging technological evolution, fulfilling all needs of granulated and powder solids in open-mouth bags. Heavy duty conception and construction, with the most advanced technical materials for a fully automatic processing, with maximum reliability and minimum maintenance timing. Directed to solve high level productivity (EP-1. 200/1. 500), cleaning and accuracy (EP-400/600), automatism and high autonomy requirements. • Bag Palletisers : - ELOCOM is a reference company in the bagging sector. It’s activity is developed in the industrial environment, by means of reserch and development suited to solutions required by each sector. The more than 500 automatic bagging installations around the world, endorse Elocom’s commitment in nonstop improvement in security, quality and service, for all customers. In the manufacturing plants belonging to Elocom Group, all range of palletisers with the best technologic performances are covered. • Palletising Systems - ELOCOM is a reference company in the bagging sector. It’s activity is developed in the industrial environment, by means of reserch and development suited to solutions required by each sector. The more than 500 automatic bagging installations around the world, endorse Elocom’s commitment in nonstop improvement in security, quality and service, for all customers. In the manufacturing plants belonging to Elocom Group, all range of palletisers with the best technologic performances are covered. 7

Webster Griffin, UK • Semi automatic, Jumbo, FFS Bagging system • Form Fill Bagging Machine : - High speed fully automatic packing machine for small bags from 200 g to 4 kg. High speed fully automatic FFS Form Fill Seal - bag packing machine with cup dosing unit for crystals, grains & powders Up to 60 bags/minute, 3, 600 bags/hr. • Okura Technology : - Webster Griffin are one of the leading Okura distributors in Europe, having supplied systems for palletising everything from blocks of cheese to bags of chemicals, aggregates, cement and other food products. Okura robot palletizers have the flexibility to cope with everything a demanding environment can throw at it. With the application of Webster Griffin expertise, the Okura A 1600 provides a low cost, reliable method of dramatically improving efficiency. The Okura A 700 & A 1600 are capable of palletising form two separate packing lines—they are also able to pack bags, boxes, kegs & buckets. The application above shows an Okura robot palletising boxes, and, right, the mechanical drawing showing the same application. • Electronic Bagging Scales & Net Weighers : - The ultimate in speed and accuracy for companies who expect the very best results from their bag filling machinery Speeds - up to 30 bags per minute Accuracy of 0. 1% , 1 kg to 100 kg range, Fully automatic, Self optimizing Gravity / screw / belt feeder, Fully trade approved - UK cert. 2525, Heavy duty, built to highest quality standard giving long term reliability, For combination with fully & semi automatic bagging machines, Duplex versions for ultra high speed bagging, Designed and built for continuous round-the-clock, 24 hour/day operation • Bag Palletiser Model UPR : - Layer squaring – for symmetrical stacks, Layer pressing – for load stability, Perimeter alignment – for palletised stacks with flat straight sides, Ability to overlap ‘wedge’ shaped bags • Form Fill Seal Bagging Machine : - Stainless steel machine with net weigher for packing fertilizer, salt, chemicals and food ingredients 1200 x 25 kg bags/hour, 1500 x 10 kg bags/hour, Bag size range: 5 kg-25 kg & 10 kg-50 kg bags, Compact modular design, Minimum maintenance required Built-in reliability for 24 hours/day running, Totally automatic bagging, unattended operation. Form Fill Seal Bagging Machine : - Heavy duty machine with volumetric belt doser for high speed packing of sand, aggregates, soils & composts. 1200 x 25 kg bags/hour, 1500 x 10 kg bags/hour, Bag size range: 5 kg-25 kg & 10 kg-50 kg bags, Compact modular design, Minimum maintenance required, Built-in reliability for 24 hours/day running, Totally automatic bagging, unattended operation • • Universal Air Packer UAP-EFB : - Low pressure air blower with motor driven fan, 1. 0 - 2. 0 K W, Stainless steel product contact parts. • IBC - PF 4 Big Bag filling: - Product feeding and dosing, device to suit product Auto bag-on-spout ‘top-up’ Bag inflation fan 2. 5 -3. 5 kw Stainless steel product contacts parts Total stainless steel construction. • Filling spout with - Inflatable dust tight collar Internal venting/aspiration, Air blast, spout cleaning device, Aeration candle for heavy dense products and plastic pellets, Vibrator to consolidate fine powders • Automation - Sack placer, Filled sack discharge, Filled sack takeaway conveyor Valve closing/sealing system • Automatic palletising and pallet wrapping, Production reports – WDPS software, Intrinsically safe, explosion proof, Pre-set variable pressure settings 8

Thimon, France • COMBI-GLASS 2000 : - THIMON partner of the glass industry for many years, is the expert-manufacturer in overwrapping processes The hood preparing module. Transfer module. Machine frame. Hooding module, COVER-PAL 2000. Shrinking module HOT-PAL 2000 • COMBI-PAL 2000 : - The ergonomic association of the COVER-PAL 2000 and the HOT-PAL 2000 allows to get an efficient and compact system. Hood preparing module Transfer module. Machine frame. Hooding module, COVER-PAL 2000, . hrink module HOT-PAL 2000 • COVER-PAL 2000 : - The three main design objectives of the new generation automatic shrink hooding are: ergonomics of use and maintenance, working safety and high performance. The machine frame and the drive at floor level The hood preparing module. The film circuit is very simple and short The transfer module ensuring a positive grip of the hood The COVER-PAL 2000 hooding module which, relaying the transfer module, ensures accurate hooding and, depending on the applications: Multi-size film unwinding systems A rotating film gripping system • COVER-PAL 6000 : - At the origin of the concept, THIMON has always been way ahead in terms of stretching capacities. The machine frame and the drive at floor level The module that prepares the hood. in total safety conditions The transfer module that ensures a perfect gripping of the hood. The hooding module COVER-PAL 6000 stretch ensures the adaptation of the hood to the products, by relaying the transfer module • DEVIPAL : - A rigid mecanowelded iron frame, One or two film reels supports with their axle, Film guiding loose rollers. The operator selects the length of the hood to be cut thanks to a display located on the control box. He also can choose the film roll to be used. The operator goes on the platform and pushes on a pedal so that the machine starts paying film out. While the hood is going down, the operator guides it around the load. When the length programmed is reached, the machine stop paying film out, cut and seals the hood. • HOT - PAL 2000 : - Shrinkwrapping pallet loads is considered as the ideal process to answer the most severe transport constraints in many industries, namely hollow glass, bottling, chemicals, building, white goods. . . After 35 years’ experience, the HOT-PAL 2000 of THIMON sets the standard. The design of the hot air diffusors and of the concertina, that have always made the HOT- PAL unique, guarantee an even, constant temperature and the absence of thermal inertia. • WRA-PAL ORCAD PRO / TWIN : - very high speed high stretch rate perfect control of the lay-on force increased load retention • WRA-PAL SWING Pro : - 5 sides wrapping with only one machine perfect control of the lay-on force increased load retention easy film loading • ENDURANCE M 6000 : - This machine offers you an economical, fast, fully automatic method of wrapping palletized loads, it protects the pallet with a weatherproof cover made from a tube of plastic stretch film. 9

ACTIVITY SECTORS MINING – Sand / Rocks / Silica / Quartz / Dry mortar / Glue cement FERTILIZERS & SALT COMPOST – Organic fertilizers / Turf / Potting soil / Fibers BIOMASS – Pellet / Briquettes / Wood shavings ANIMAL FOOD – Seeds / Pet food / Dehydrated alfalfa / Compound food CHEMICAL PRODUCTS – Plastic siftings / Detergent / Ceramic additives FOOD – Rice / Sugar / Flour 10

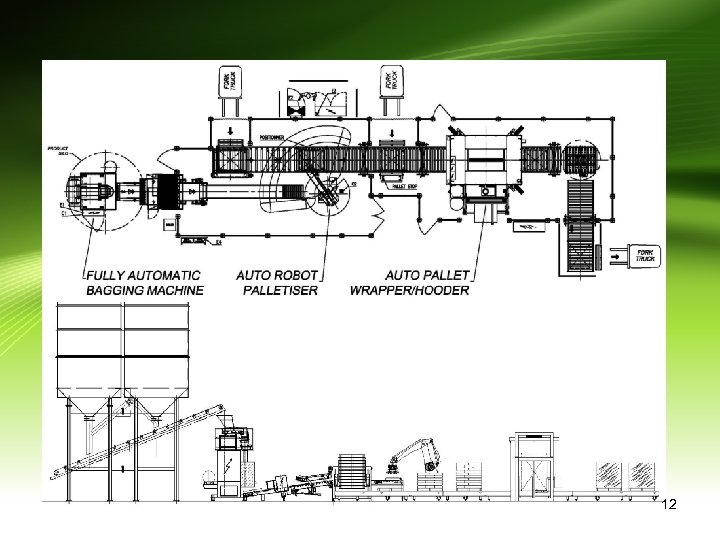

FULLY AUTOMATIC BAGGING LINE 11

12

Complete Bagging Plant Design 13

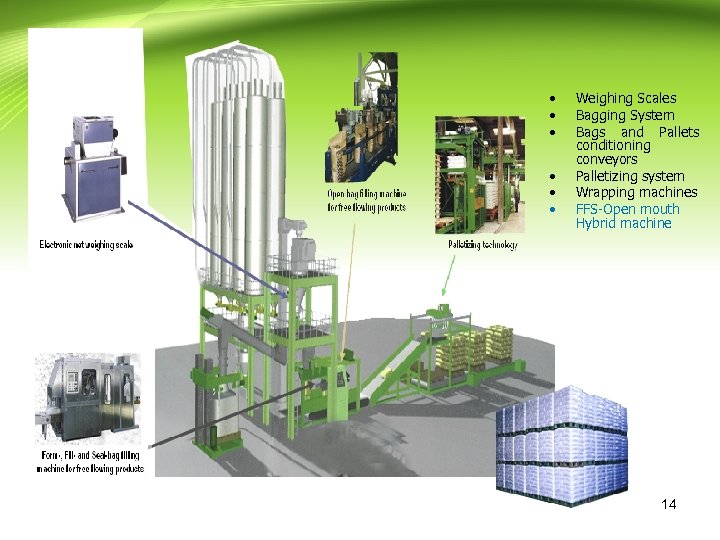

• • • Weighing Scales Bagging System Bags and Pallets conditioning conveyors Palletizing system Wrapping machines FFS-Open mouth Hybrid machine 14

15

21202f8c2eca2c5b489503ca3a6b2ef1.ppt