1 2.1 Classification of Rolling Mills … following

32150-v_b_1503_fund_samara.ppt

- Количество слайдов: 19

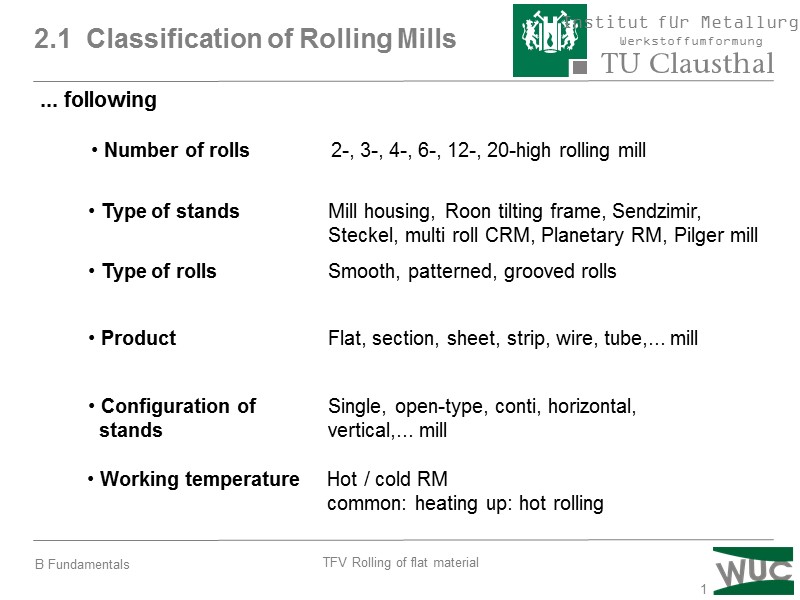

1 2.1 Classification of Rolling Mills ... following Number of rolls 2-, 3-, 4-, 6-, 12-, 20-high rolling mill Type of stands Mill housing, Roon tilting frame, Sendzimir, Steckel, multi roll CRM, Planetary RM, Pilger mill Type of rolls Smooth, patterned, grooved rolls Product Flat, section, sheet, strip, wire, tube,... mill Configuration of Single, open-type, conti, horizontal, stands vertical,... mill Working temperature Hot / cold RM common: heating up: hot rolling

1 2.1 Classification of Rolling Mills ... following Number of rolls 2-, 3-, 4-, 6-, 12-, 20-high rolling mill Type of stands Mill housing, Roon tilting frame, Sendzimir, Steckel, multi roll CRM, Planetary RM, Pilger mill Type of rolls Smooth, patterned, grooved rolls Product Flat, section, sheet, strip, wire, tube,... mill Configuration of Single, open-type, conti, horizontal, stands vertical,... mill Working temperature Hot / cold RM common: heating up: hot rolling

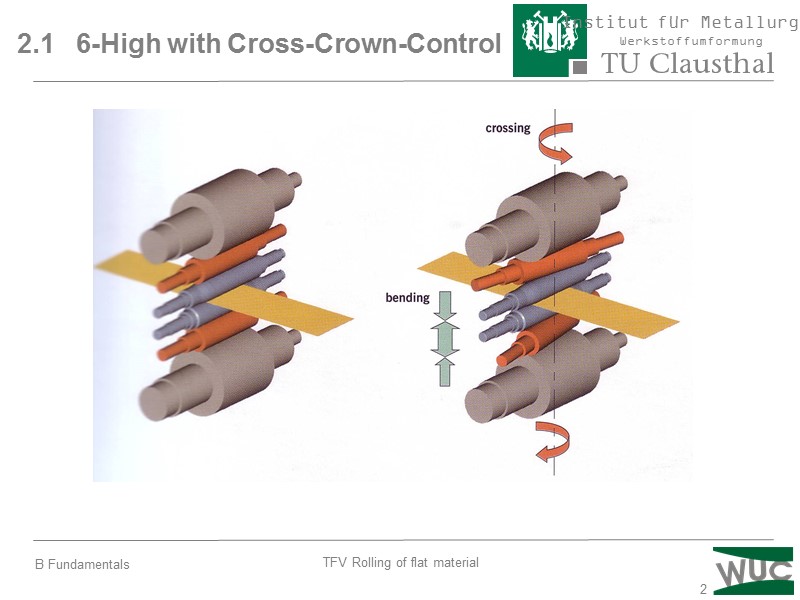

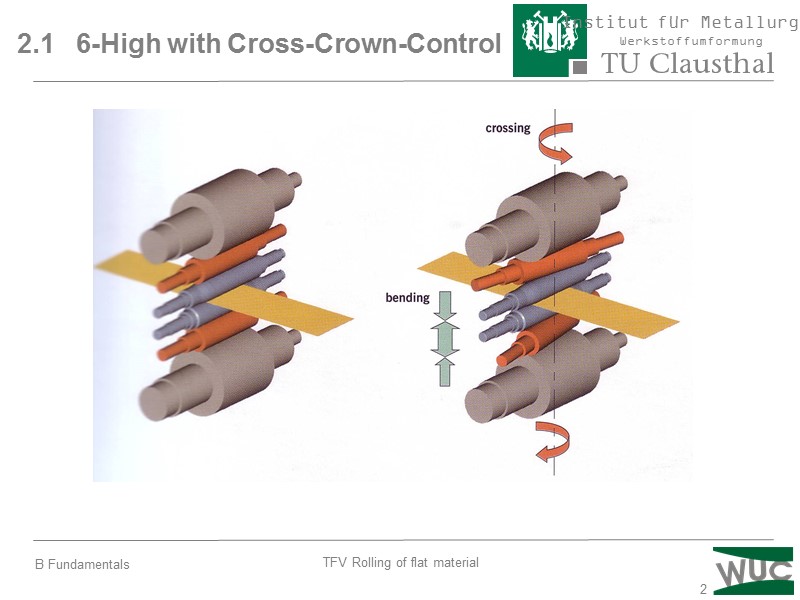

2 2.1 6-High with Cross-Crown-Control

2 2.1 6-High with Cross-Crown-Control

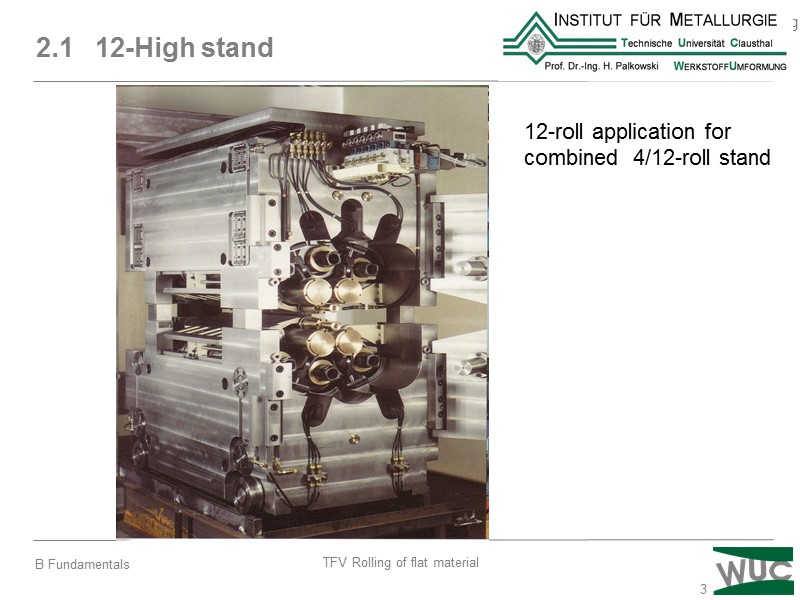

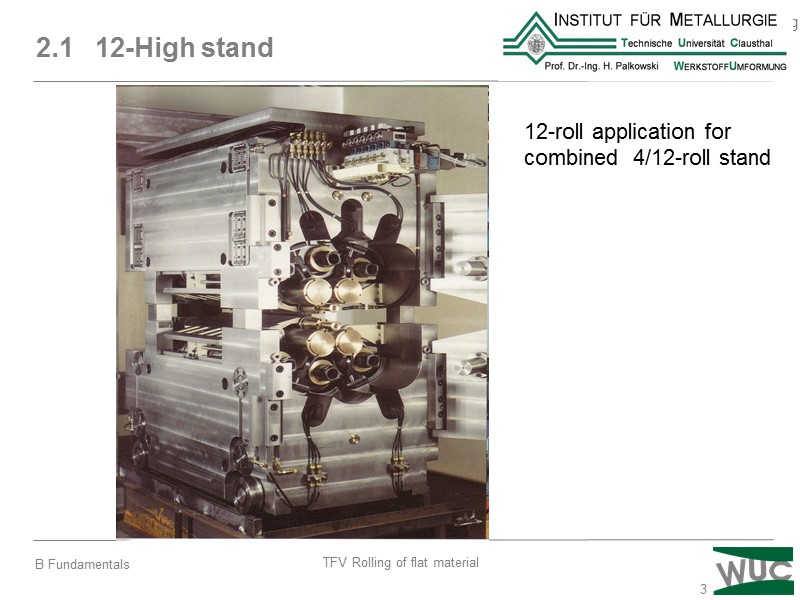

3 2.1 12-High stand 12-roll application for combined 4/12-roll stand

3 2.1 12-High stand 12-roll application for combined 4/12-roll stand

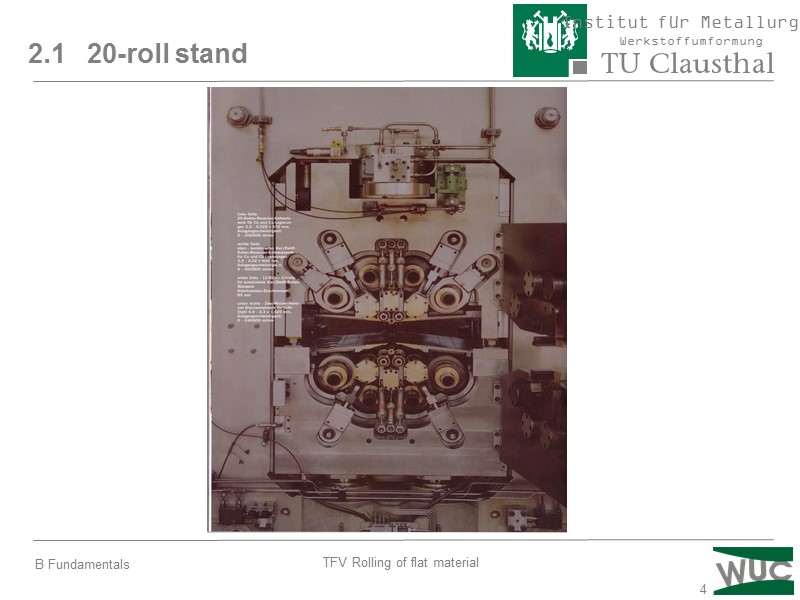

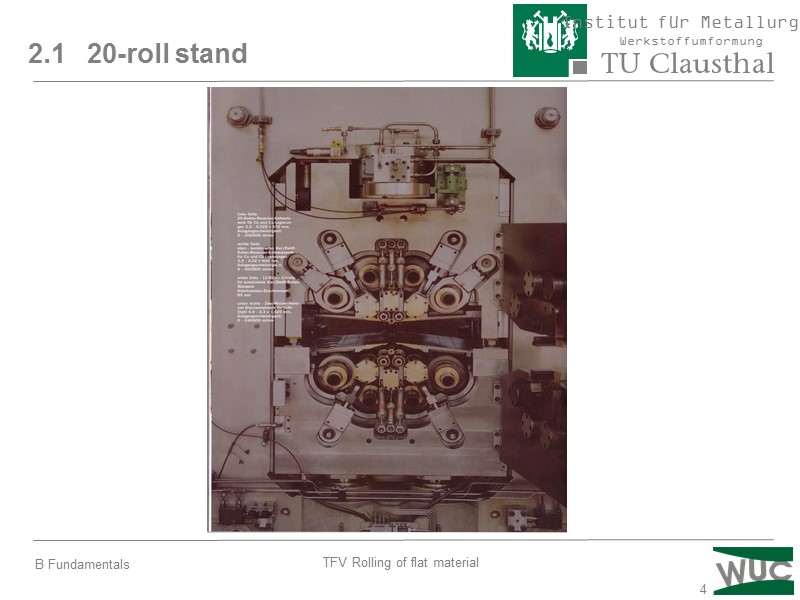

4 2.1 20-roll stand

4 2.1 20-roll stand

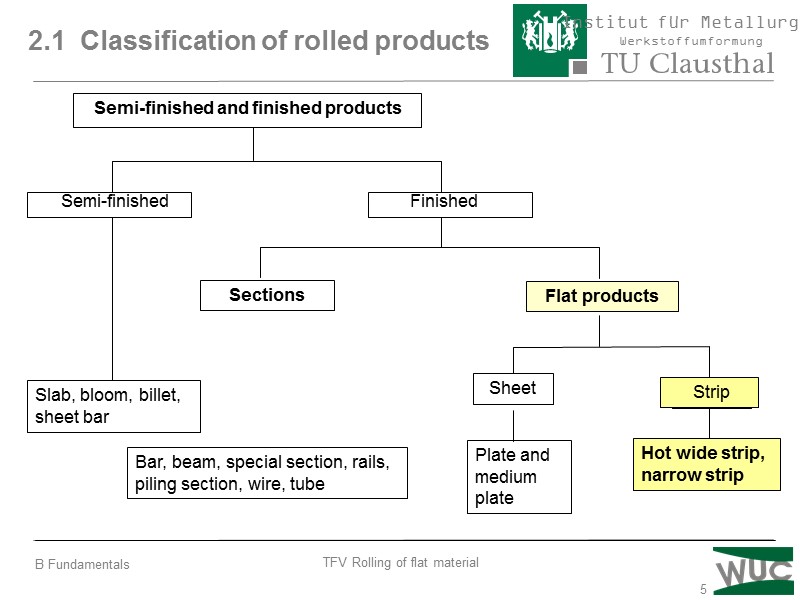

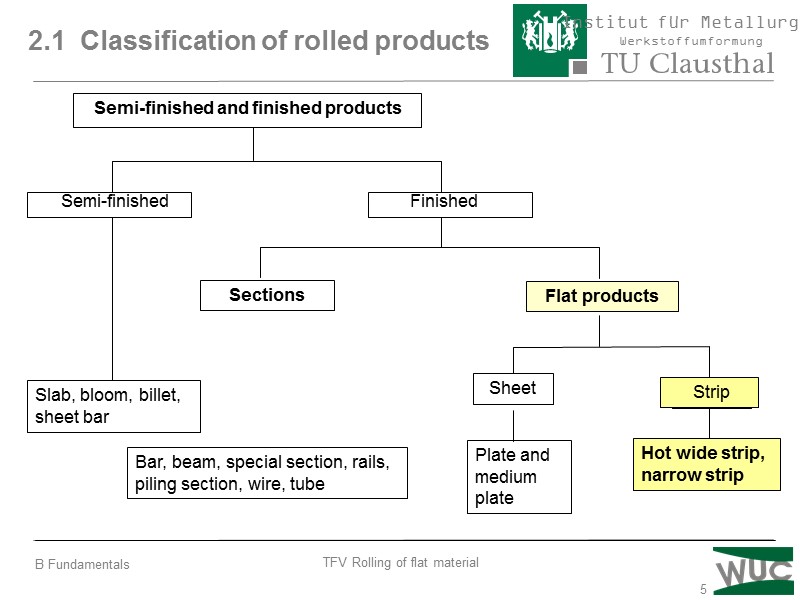

5 2.1 Classification of rolled products Semi-finished and finished products Semi-finished Slab, bloom, billet, sheet bar Finished Sections Flat products Sheet Strip Plate and medium plate Bar, beam, special section, rails, piling section, wire, tube Hot wide strip, narrow strip

5 2.1 Classification of rolled products Semi-finished and finished products Semi-finished Slab, bloom, billet, sheet bar Finished Sections Flat products Sheet Strip Plate and medium plate Bar, beam, special section, rails, piling section, wire, tube Hot wide strip, narrow strip

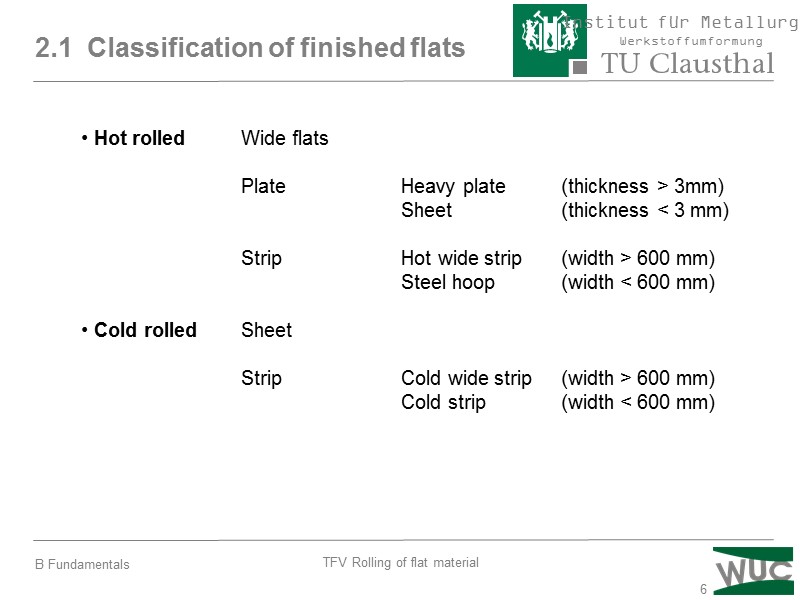

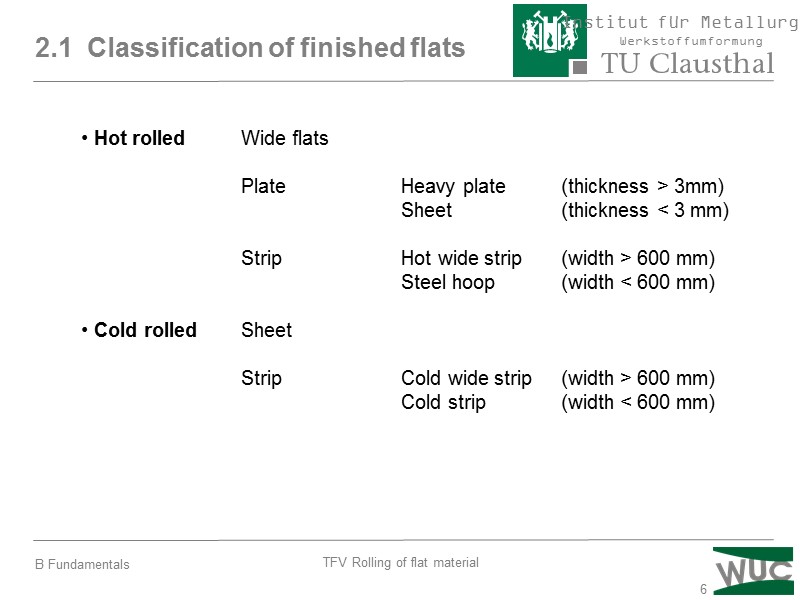

6 2.1 Classification of finished flats Hot rolled Wide flats Plate Heavy plate (thickness > 3mm) Sheet (thickness < 3 mm) Strip Hot wide strip (width > 600 mm) Steel hoop (width < 600 mm) Cold rolled Sheet Strip Cold wide strip (width > 600 mm) Cold strip (width < 600 mm)

6 2.1 Classification of finished flats Hot rolled Wide flats Plate Heavy plate (thickness > 3mm) Sheet (thickness < 3 mm) Strip Hot wide strip (width > 600 mm) Steel hoop (width < 600 mm) Cold rolled Sheet Strip Cold wide strip (width > 600 mm) Cold strip (width < 600 mm)

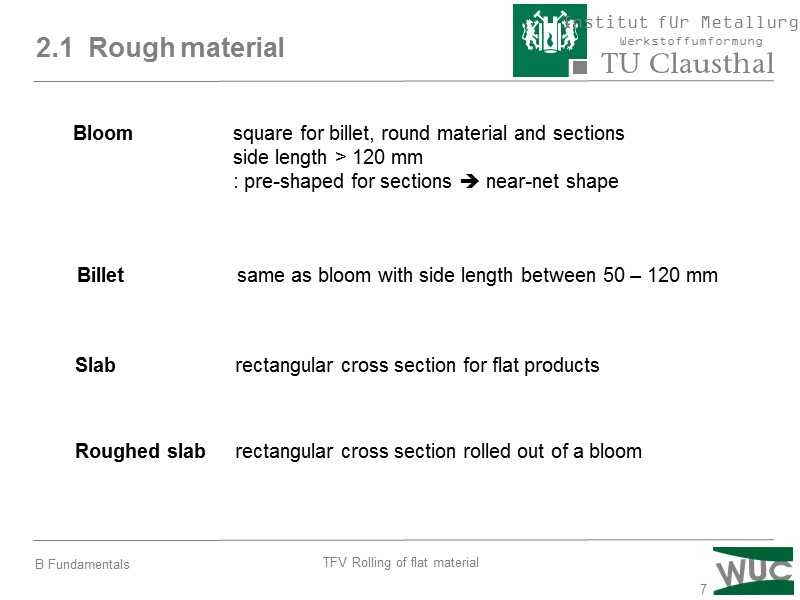

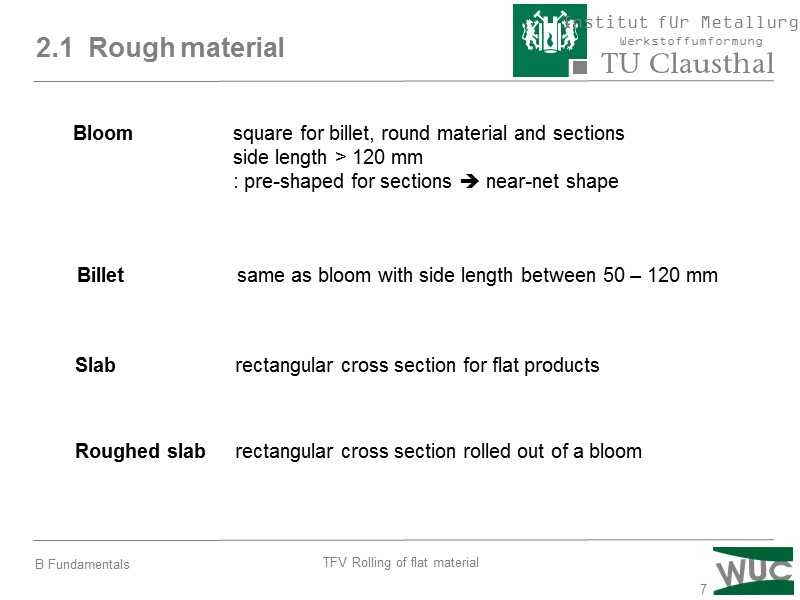

7 2.1 Rough material Bloom square for billet, round material and sections side length > 120 mm : pre-shaped for sections near-net shape Billet same as bloom with side length between 50 – 120 mm Slab rectangular cross section for flat products Roughed slab rectangular cross section rolled out of a bloom

7 2.1 Rough material Bloom square for billet, round material and sections side length > 120 mm : pre-shaped for sections near-net shape Billet same as bloom with side length between 50 – 120 mm Slab rectangular cross section for flat products Roughed slab rectangular cross section rolled out of a bloom

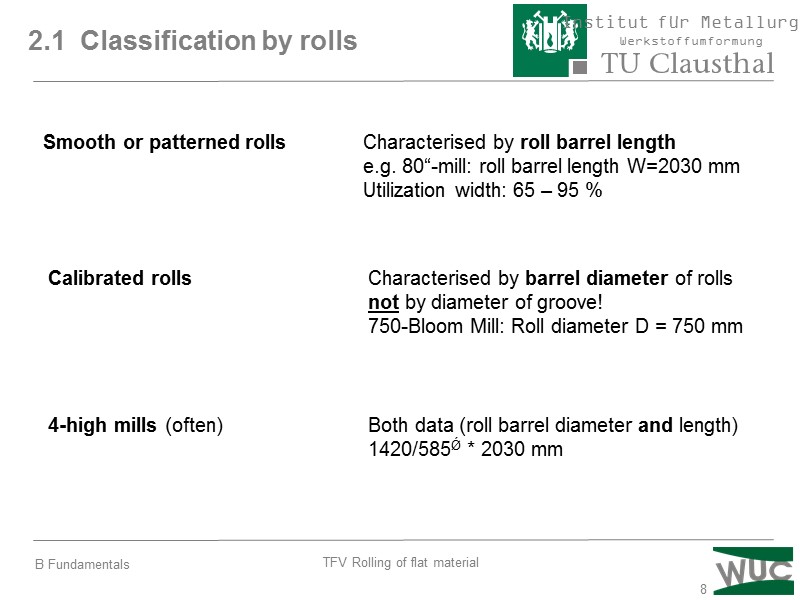

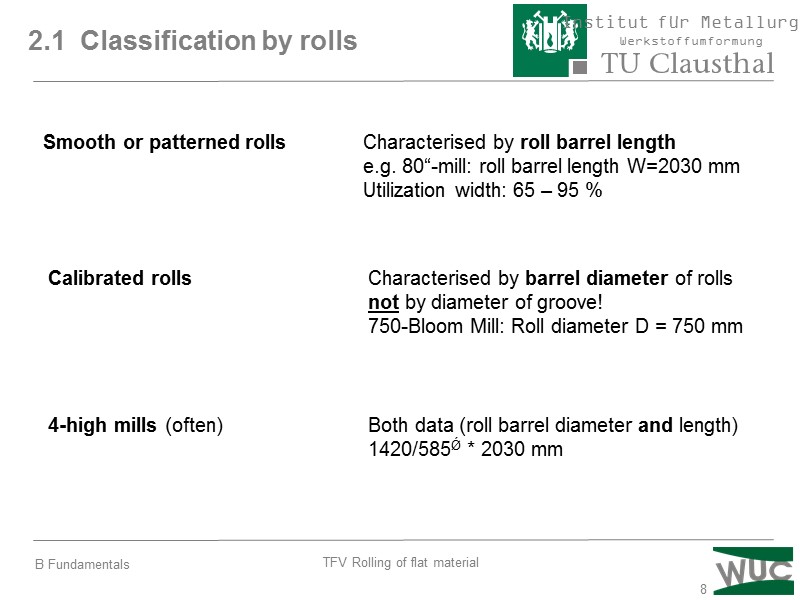

8 2.1 Classification by rolls Smooth or patterned rolls Characterised by roll barrel length e.g. 80“-mill: roll barrel length W=2030 mm Utilization width: 65 – 95 % Calibrated rolls Characterised by barrel diameter of rolls not by diameter of groove! 750-Bloom Mill: Roll diameter D = 750 mm 4-high mills (often) Both data (roll barrel diameter and length) 1420/585Ǿ * 2030 mm

8 2.1 Classification by rolls Smooth or patterned rolls Characterised by roll barrel length e.g. 80“-mill: roll barrel length W=2030 mm Utilization width: 65 – 95 % Calibrated rolls Characterised by barrel diameter of rolls not by diameter of groove! 750-Bloom Mill: Roll diameter D = 750 mm 4-high mills (often) Both data (roll barrel diameter and length) 1420/585Ǿ * 2030 mm

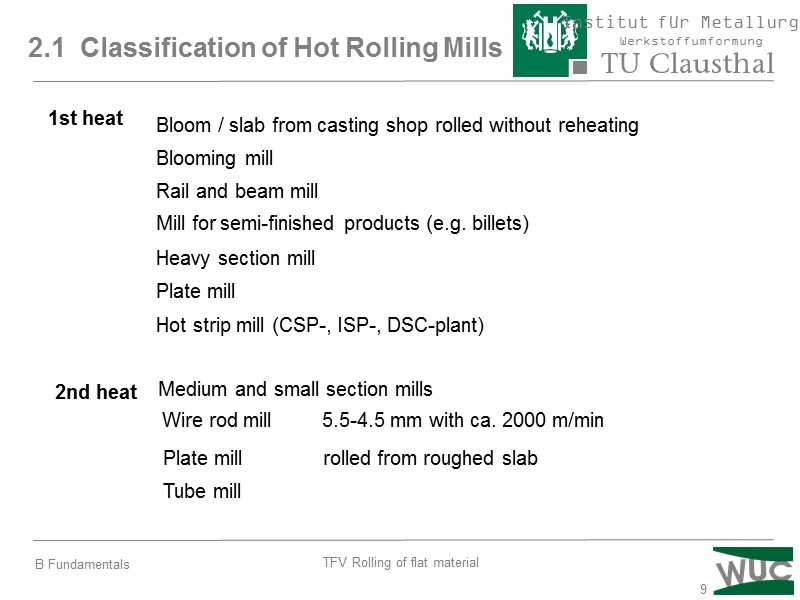

9 2.1 Classification of Hot Rolling Mills

9 2.1 Classification of Hot Rolling Mills

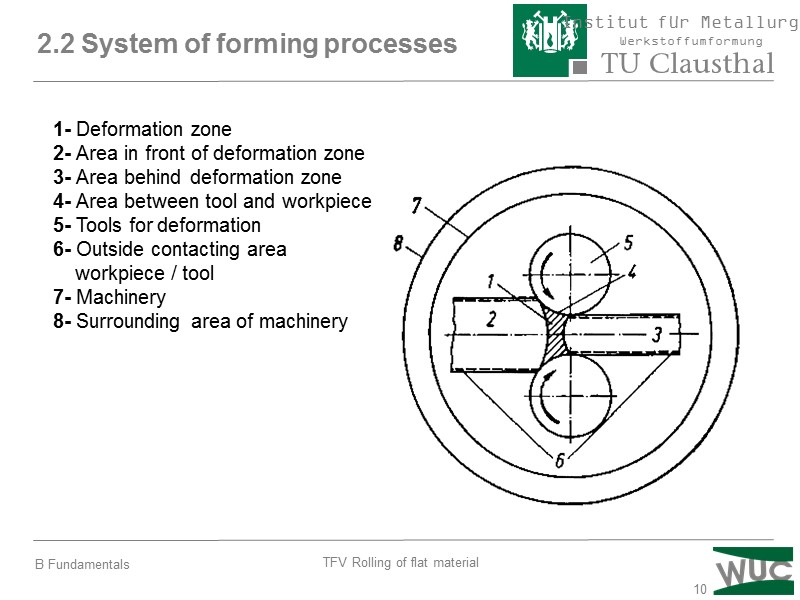

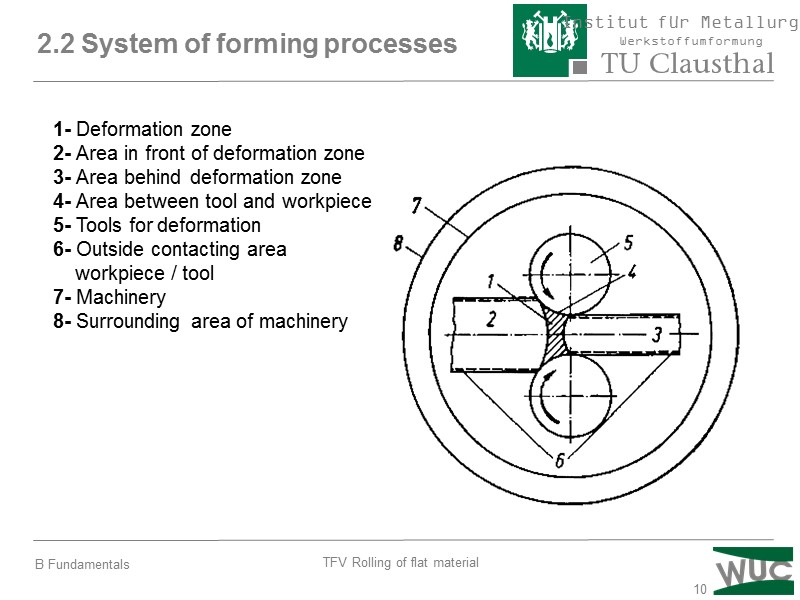

10 2.2 System of forming processes 1- Deformation zone 2- Area in front of deformation zone 3- Area behind deformation zone 4- Area between tool and workpiece 5- Tools for deformation 6- Outside contacting area workpiece / tool 7- Machinery 8- Surrounding area of machinery

10 2.2 System of forming processes 1- Deformation zone 2- Area in front of deformation zone 3- Area behind deformation zone 4- Area between tool and workpiece 5- Tools for deformation 6- Outside contacting area workpiece / tool 7- Machinery 8- Surrounding area of machinery

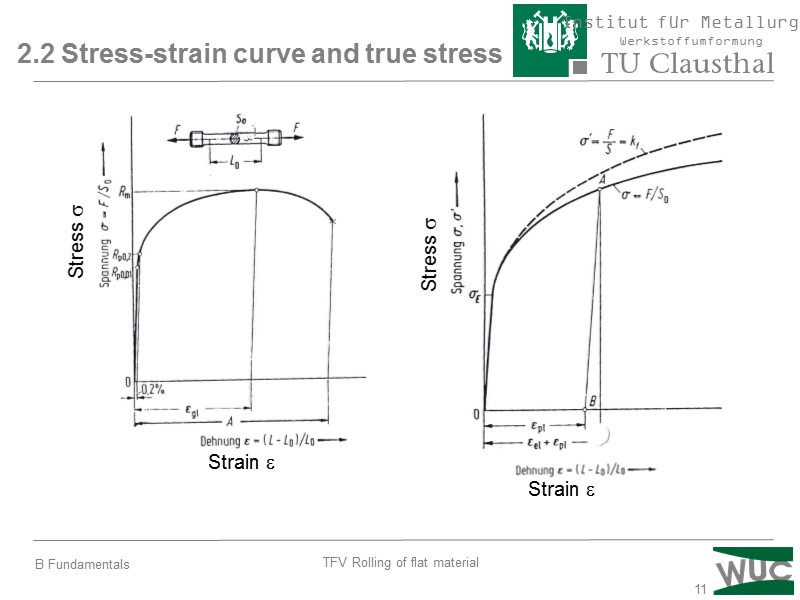

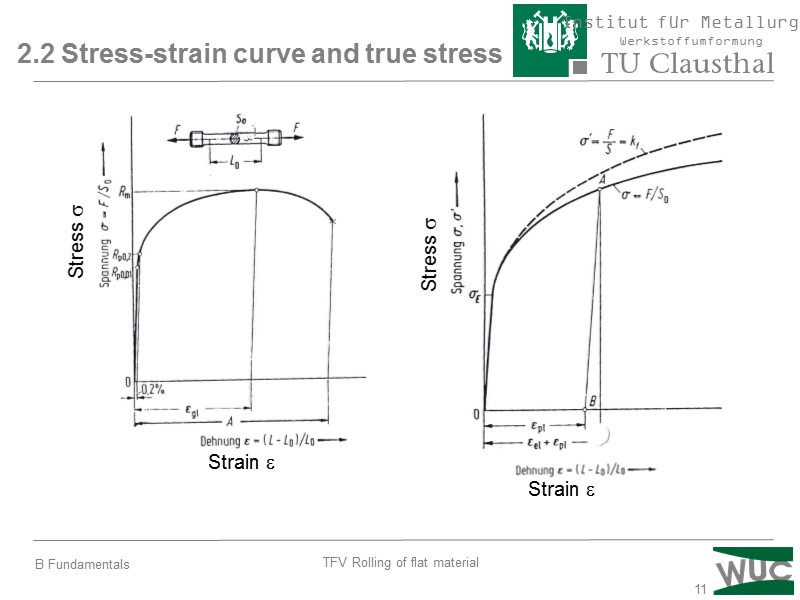

11 2.2 Stress-strain curve and true stress Strain Stress Stress Strain

11 2.2 Stress-strain curve and true stress Strain Stress Stress Strain

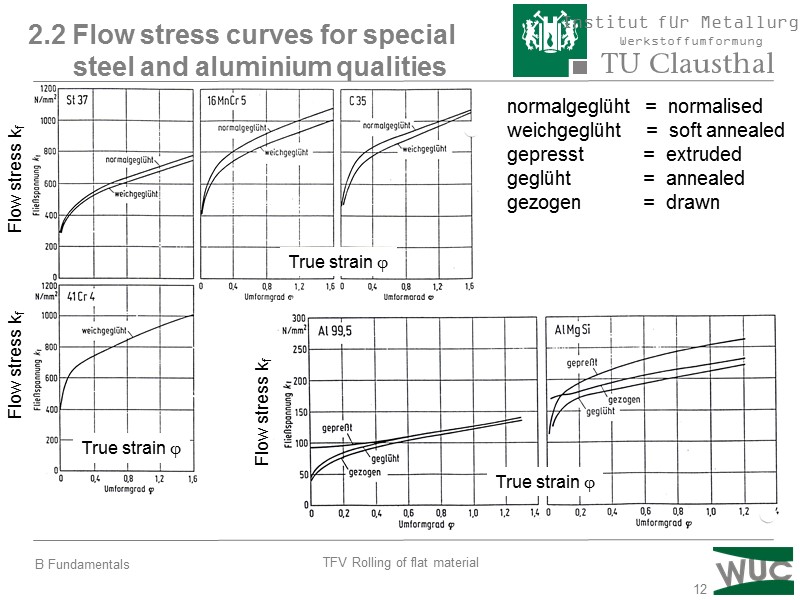

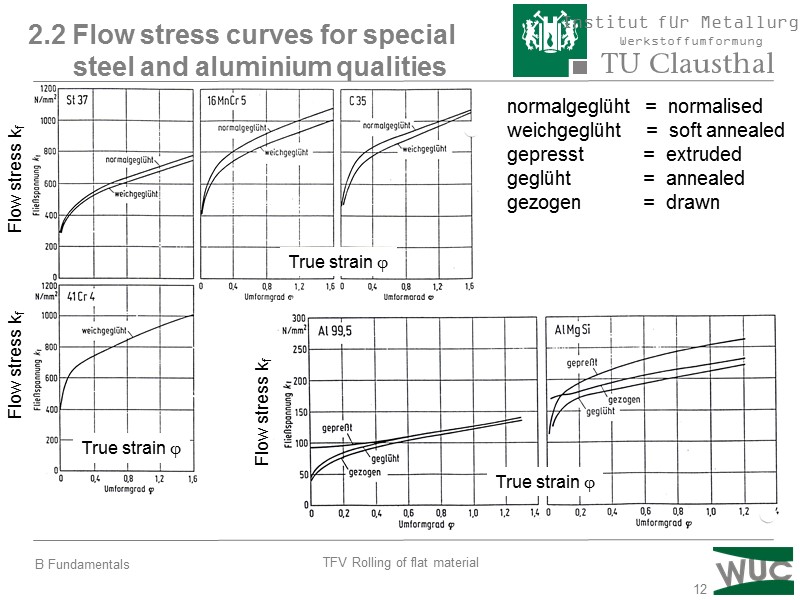

12 2.2 Flow stress curves for special steel and aluminium qualities normalgeglüht = normalised weichgeglüht = soft annealed gepresst = extruded geglüht = annealed gezogen = drawn Flow stress kf True strain Flow stress kf Flow stress kf True strain True strain

12 2.2 Flow stress curves for special steel and aluminium qualities normalgeglüht = normalised weichgeglüht = soft annealed gepresst = extruded geglüht = annealed gezogen = drawn Flow stress kf True strain Flow stress kf Flow stress kf True strain True strain

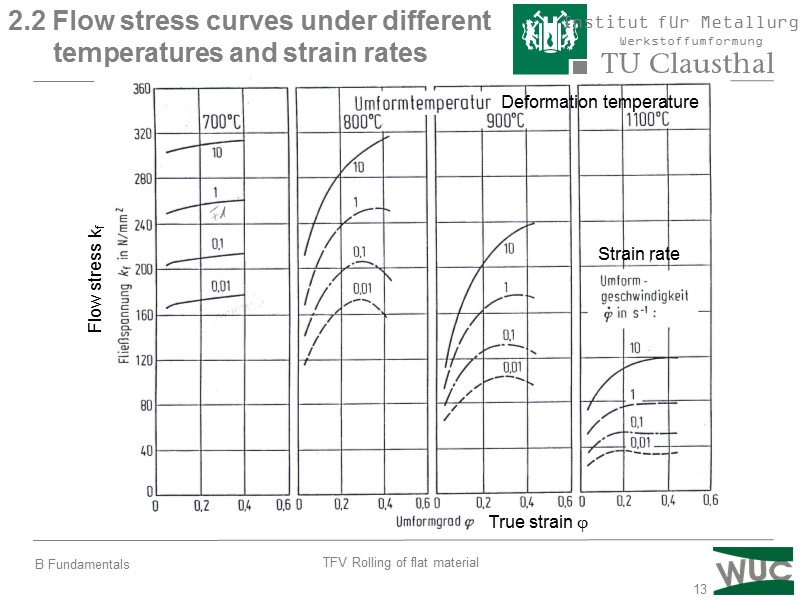

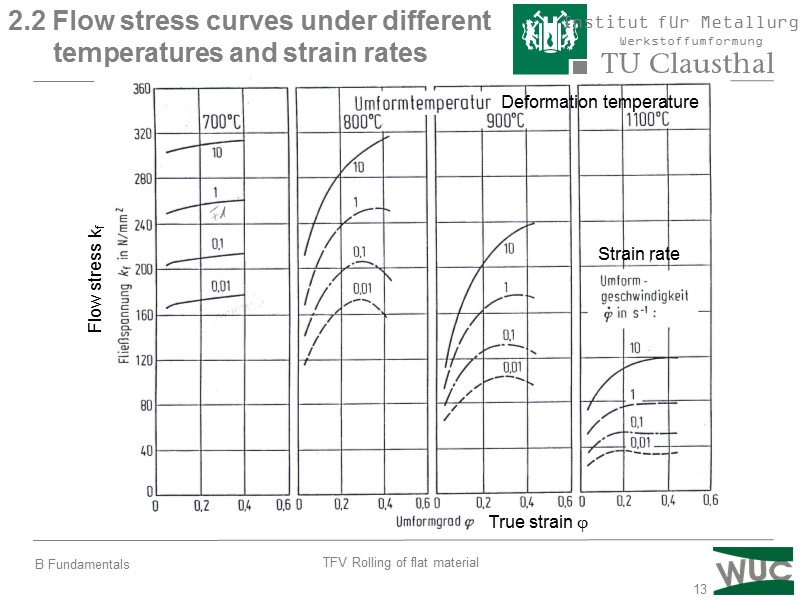

13 2.2 Flow stress curves under different temperatures and strain rates True strain Flow stress kf Strain rate Deformation temperature

13 2.2 Flow stress curves under different temperatures and strain rates True strain Flow stress kf Strain rate Deformation temperature

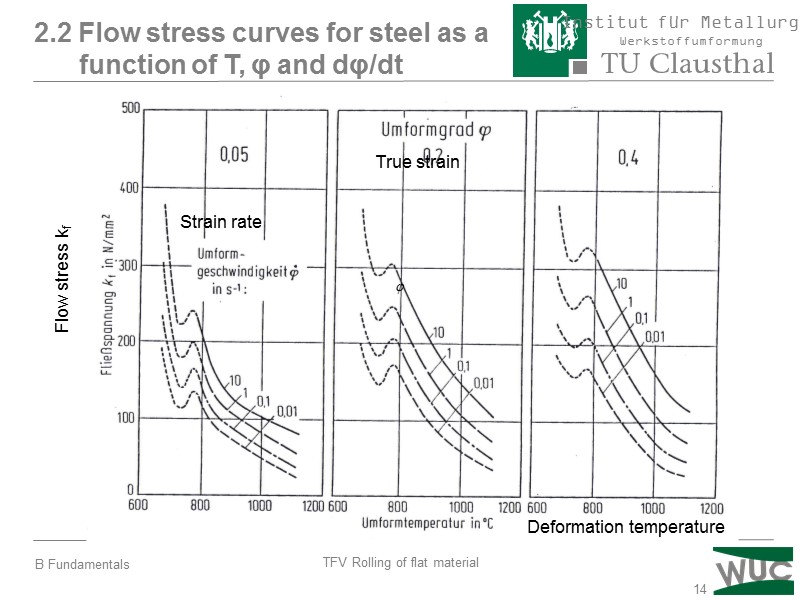

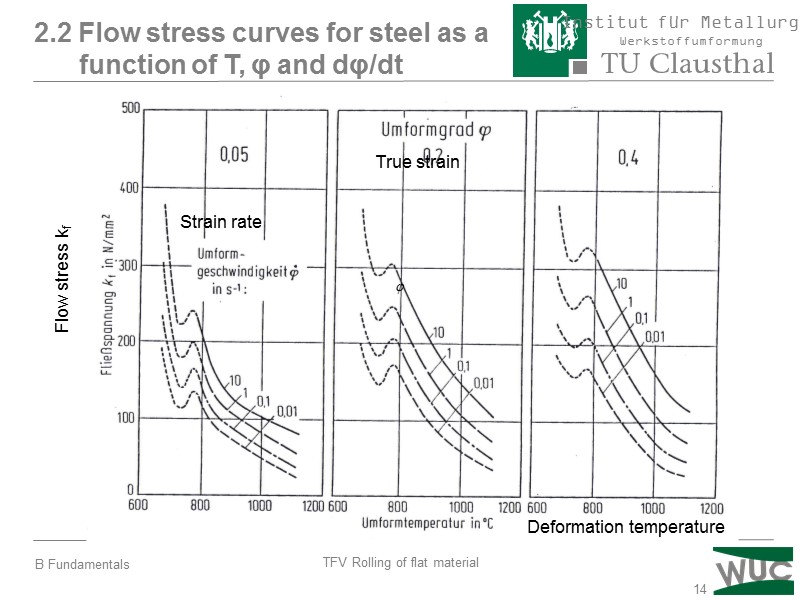

14 2.2 Flow stress curves for steel as a function of T, φ and dφ/dt Strain rate True strain Flow stress kf Deformation temperature

14 2.2 Flow stress curves for steel as a function of T, φ and dφ/dt Strain rate True strain Flow stress kf Deformation temperature

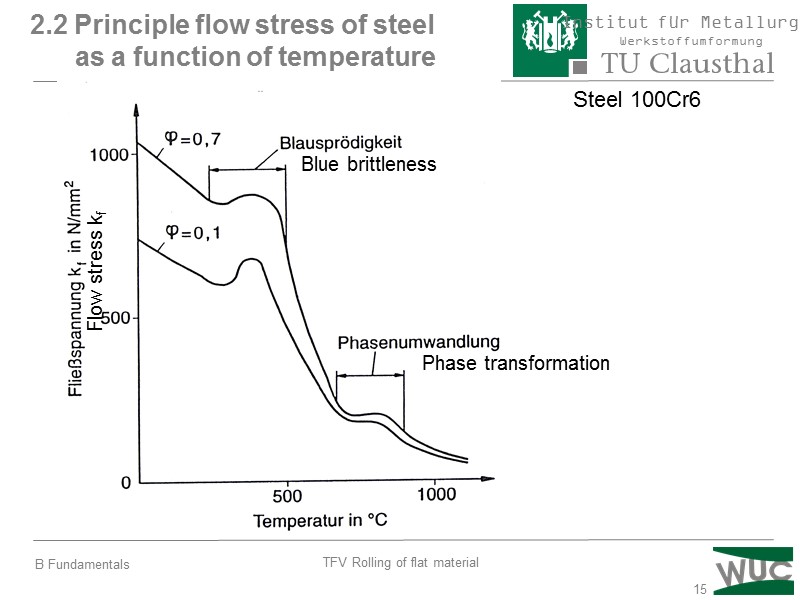

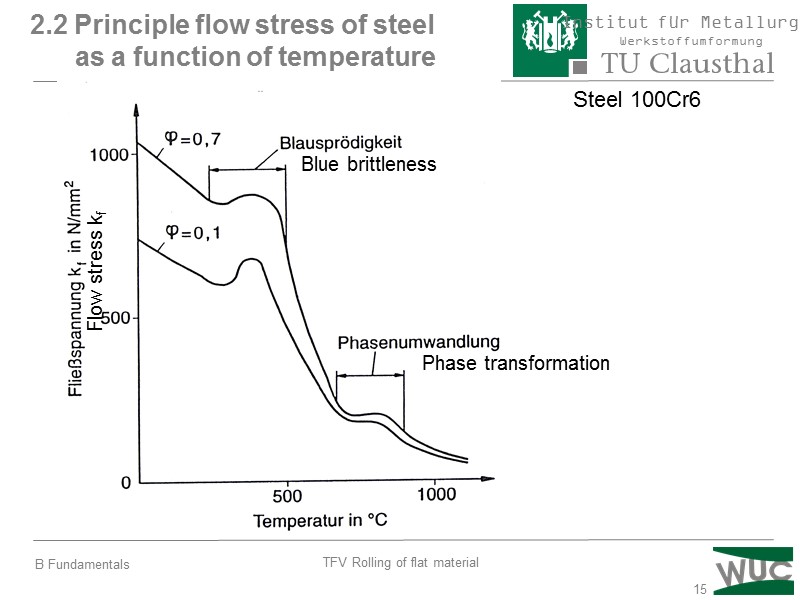

15 Flow stress kf Blue brittleness Phase transformation 2.2 Principle flow stress of steel as a function of temperature Steel 100Cr6

15 Flow stress kf Blue brittleness Phase transformation 2.2 Principle flow stress of steel as a function of temperature Steel 100Cr6

16 ... Constant mass: Volume constant! Formability of materials Metalle „without limits“ Regeneration Movability of atoms Movement of dislocations Recrystallisation 2.3 Fundamentals of Steel Properties

16 ... Constant mass: Volume constant! Formability of materials Metalle „without limits“ Regeneration Movability of atoms Movement of dislocations Recrystallisation 2.3 Fundamentals of Steel Properties

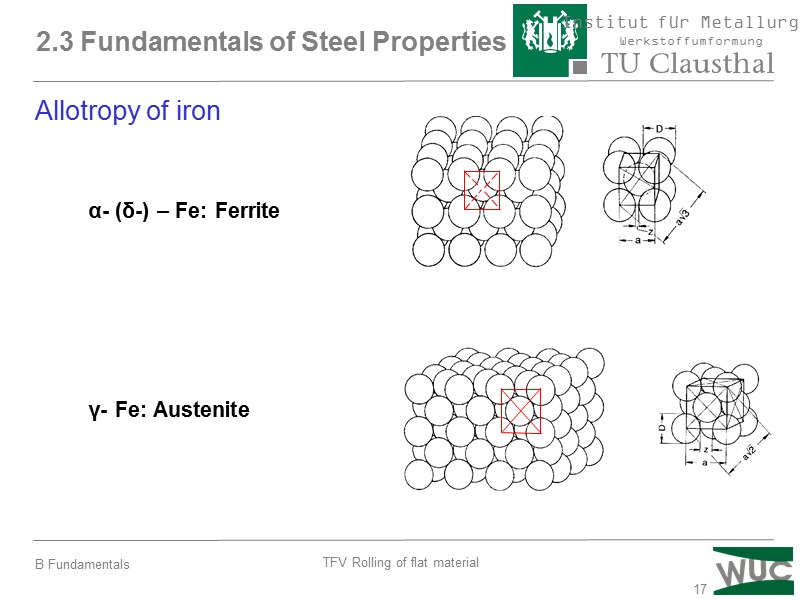

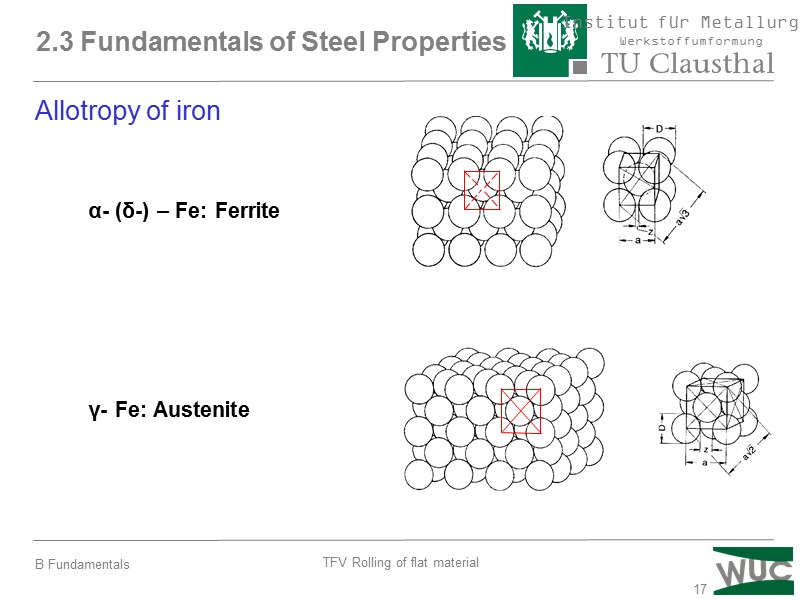

17 Allotropy of iron 2.3 Fundamentals of Steel Properties

17 Allotropy of iron 2.3 Fundamentals of Steel Properties

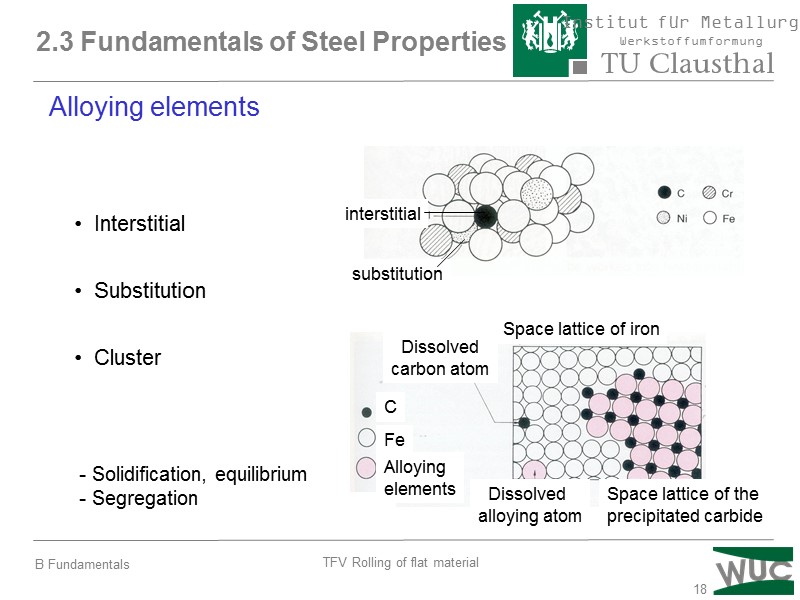

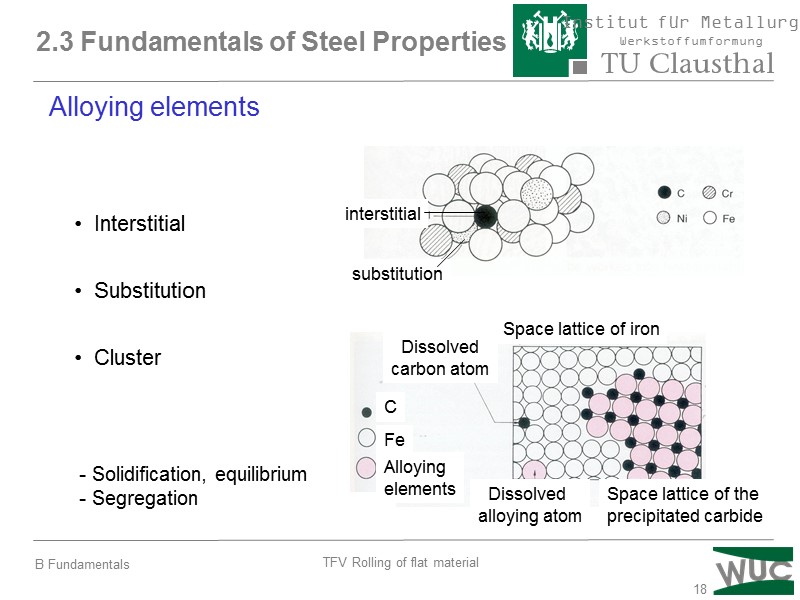

18 2.3 Fundamentals of Steel Properties Alloying elements Solidification, equilibrium Segregation

18 2.3 Fundamentals of Steel Properties Alloying elements Solidification, equilibrium Segregation

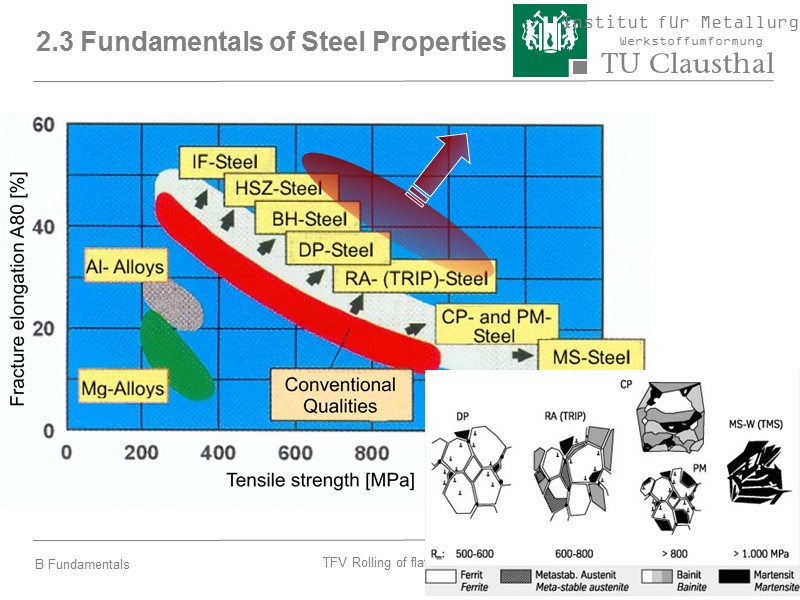

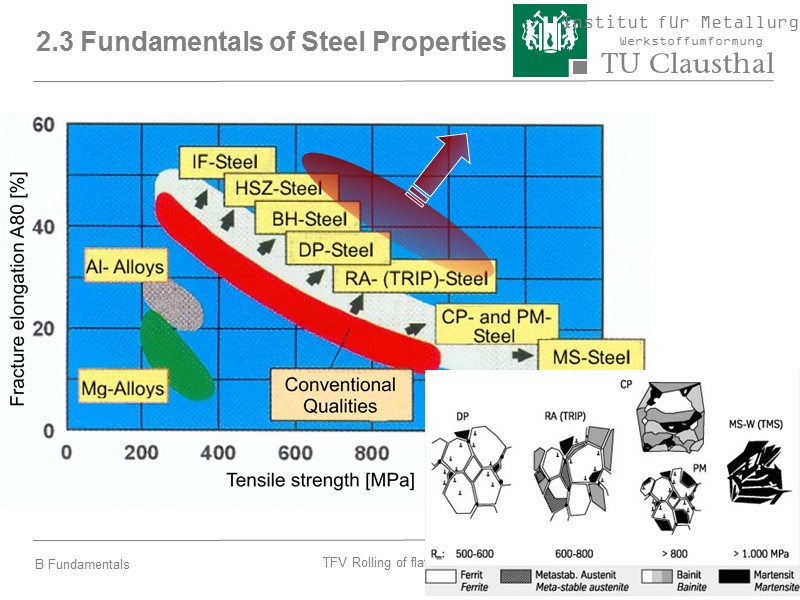

19 2.3 Fundamentals of Steel Properties

19 2.3 Fundamentals of Steel Properties