6128e0c0ef4120caeb6953146cd8b9ae.ppt

- Количество слайдов: 30

1 -1 ISE 360 Production Planning Asst. Prof. Dr. Arslan M. ÖRNEK Industrial Systems Engineering Textbook: Production and Operations Analysis Steven Nahmias, 5/e, Mc. Graw-Hill

1 -1 ISE 360 Production Planning Asst. Prof. Dr. Arslan M. ÖRNEK Industrial Systems Engineering Textbook: Production and Operations Analysis Steven Nahmias, 5/e, Mc. Graw-Hill

Chapter 1. Strategy and Competition Mc. Graw-Hill/Irwin Copyright © 2005 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

Chapter 1. Strategy and Competition Mc. Graw-Hill/Irwin Copyright © 2005 by The Mc. Graw-Hill Companies, Inc. All rights reserved.

Topic Areas in Operations Analysis n n n Forecasting Aggregate Planning Inventory Control: Deterministic Environments Inventory Control: Stochastic Environments Supply Chain Management Production Control Systems: MRP and JIT Operations Scheduling Project Scheduling Facilities Planning Quality and Assurance Maintenance and Reliability 1 -3

Topic Areas in Operations Analysis n n n Forecasting Aggregate Planning Inventory Control: Deterministic Environments Inventory Control: Stochastic Environments Supply Chain Management Production Control Systems: MRP and JIT Operations Scheduling Project Scheduling Facilities Planning Quality and Assurance Maintenance and Reliability 1 -3

1 -4 Marketing Operations Finance Functional Areas of the Firm

1 -4 Marketing Operations Finance Functional Areas of the Firm

Time Horizons for Strategic Decisions 1. Long Term Decisions q Locating and Sizing New Facilities q Finding New Markets for Products q Mission Statement: meeting quality objectives 2. Intermediate Term Decisions q Forecasting Product Demand q Determining Manpower Needs q Setting Channels of Distribution q Equipment Purchases and Maintenance 3. Short Term Decisions q Purchasing q Shift Scheduling q Inventory Control 1 -5

Time Horizons for Strategic Decisions 1. Long Term Decisions q Locating and Sizing New Facilities q Finding New Markets for Products q Mission Statement: meeting quality objectives 2. Intermediate Term Decisions q Forecasting Product Demand q Determining Manpower Needs q Setting Channels of Distribution q Equipment Purchases and Maintenance 3. Short Term Decisions q Purchasing q Shift Scheduling q Inventory Control 1 -5

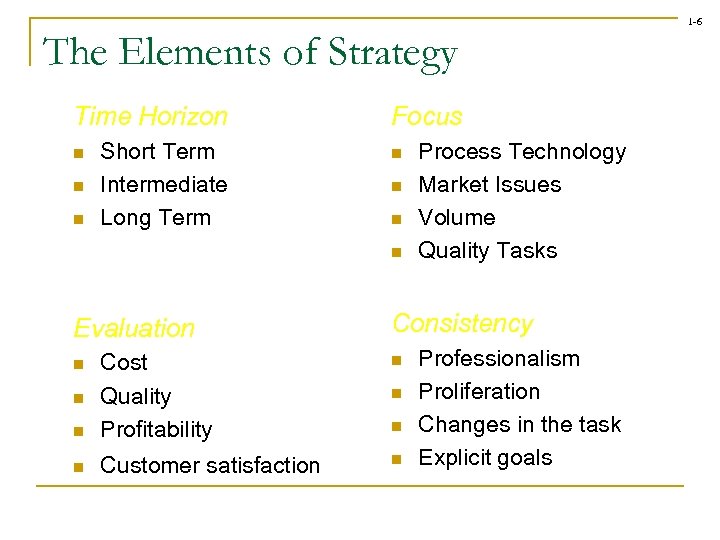

1 -6 The Elements of Strategy Time Horizon n Short Term Intermediate Long Term Focus n n Evaluation Consistency n n Cost Quality Profitability n Customer satisfaction n Process Technology Market Issues Volume Quality Tasks n n Professionalism Proliferation Changes in the task Explicit goals

1 -6 The Elements of Strategy Time Horizon n Short Term Intermediate Long Term Focus n n Evaluation Consistency n n Cost Quality Profitability n Customer satisfaction n Process Technology Market Issues Volume Quality Tasks n n Professionalism Proliferation Changes in the task Explicit goals

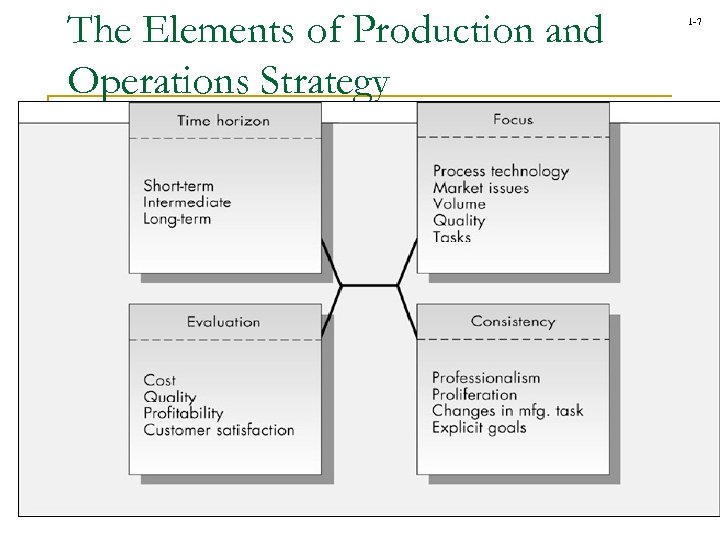

The Elements of Production and Operations Strategy 1 -7

The Elements of Production and Operations Strategy 1 -7

History of POM n Major Thrust of the Industrial Revolution 18501890. q n Production Manager Position. 1890 -1920. q n Factories tended to be small. Boss had total control. Little regard for workers safety or workers rights. Frederick Taylor champions the idea of “scientific management”. As complexity grows specializations take hold. q q Inventory Control Manager Purchasing Manager Scheduling Supervisor Quality Control Manager etc. 1 -8

History of POM n Major Thrust of the Industrial Revolution 18501890. q n Production Manager Position. 1890 -1920. q n Factories tended to be small. Boss had total control. Little regard for workers safety or workers rights. Frederick Taylor champions the idea of “scientific management”. As complexity grows specializations take hold. q q Inventory Control Manager Purchasing Manager Scheduling Supervisor Quality Control Manager etc. 1 -8

1 -9 Global Competition Global competition is heating up to an unprecedented degree. It appears that several factors favor the success of some industries in some countries: For example: ] ] ] Germany: printing presses, luxury cars, chemicals Switzerland: pharmaceuticals, chocolate Sweden: heavy trucks, mining equipment United States: personal computers, software, entertainment Japan: automobiles, consumer electronics

1 -9 Global Competition Global competition is heating up to an unprecedented degree. It appears that several factors favor the success of some industries in some countries: For example: ] ] ] Germany: printing presses, luxury cars, chemicals Switzerland: pharmaceuticals, chocolate Sweden: heavy trucks, mining equipment United States: personal computers, software, entertainment Japan: automobiles, consumer electronics

1 -10 Porter’s Thesis Famed management guru, Michael Porter, has developed a theory to explain the determinants of national competitive advantage. These include: n Factor Conditions (Land, Labor, Capital, etc. ) n Demand Conditions (local marketplace may be more sophisticated/demanding than world marketplace) n n Related and Supporting Industries Firm Strategy, structure, rivalry (e. g. : Germans are strong technically, Italian family structure, Japanese management methods)

1 -10 Porter’s Thesis Famed management guru, Michael Porter, has developed a theory to explain the determinants of national competitive advantage. These include: n Factor Conditions (Land, Labor, Capital, etc. ) n Demand Conditions (local marketplace may be more sophisticated/demanding than world marketplace) n n Related and Supporting Industries Firm Strategy, structure, rivalry (e. g. : Germans are strong technically, Italian family structure, Japanese management methods)

1 -11 Time-Based Competition “Time-based competitors focus on the bigger picture, on the entire value-delivery system. They attempt to transform an entire organization into one focused on the total time required to deliver a product or service. Their goal is not to devise the best way to perform a task, but to either eliminate the task altogether or perofrm it in parallel with other talks so that over -all system reponse time is reduced. Becoming a time-based competitor requires making revolutionary changes in the ways that processes are organized” (Blackburn(1991). Being not only the first to market but the first to volume production as well gives a firm a decided advantage. See Table on p. 15 of text.

1 -11 Time-Based Competition “Time-based competitors focus on the bigger picture, on the entire value-delivery system. They attempt to transform an entire organization into one focused on the total time required to deliver a product or service. Their goal is not to devise the best way to perform a task, but to either eliminate the task altogether or perofrm it in parallel with other talks so that over -all system reponse time is reduced. Becoming a time-based competitor requires making revolutionary changes in the ways that processes are organized” (Blackburn(1991). Being not only the first to market but the first to volume production as well gives a firm a decided advantage. See Table on p. 15 of text.

1 -12 How Do Firms Differentiate Themselves from Competitors? n Low Cost Leaders: Some examples include q q q n Wal. Mart and Costco in Retailing Korean automakers (Hyundai, Kia, etc. ) e machines personal computers High Quality (and price) Leaders. Ex: q q q Mercedes Benz automobiles Rolex Watches (some firms do both: Chevrolet and Cadillac)

1 -12 How Do Firms Differentiate Themselves from Competitors? n Low Cost Leaders: Some examples include q q q n Wal. Mart and Costco in Retailing Korean automakers (Hyundai, Kia, etc. ) e machines personal computers High Quality (and price) Leaders. Ex: q q q Mercedes Benz automobiles Rolex Watches (some firms do both: Chevrolet and Cadillac)

1 -13 Business Process Re-engineering The process of taking a cold hard look at the way that things are done. Term coined by Hammer and Champy in their 1993 book. Classic Example: IBM Credit Corporation. The process had been broken down to a series of multiple steps, each having substantial delays. Approval required from 6 days to 2 weeks. The process was re-engineered so that a single specialist would handle a request from beginning to end. The result was that turnaround time was slashed to an average of 4 hours!

1 -13 Business Process Re-engineering The process of taking a cold hard look at the way that things are done. Term coined by Hammer and Champy in their 1993 book. Classic Example: IBM Credit Corporation. The process had been broken down to a series of multiple steps, each having substantial delays. Approval required from 6 days to 2 weeks. The process was re-engineered so that a single specialist would handle a request from beginning to end. The result was that turnaround time was slashed to an average of 4 hours!

1 -14 Along What Other Dimensions Do Firms Compete? n Delivery Speed, Delivery Reliability q n Flexibility q n Federal Express, United Parcel Service Solectron: provides manufacturing services to many different companies. Service q Nordstrom bases its reputation on providing a high quality of service to customers

1 -14 Along What Other Dimensions Do Firms Compete? n Delivery Speed, Delivery Reliability q n Flexibility q n Federal Express, United Parcel Service Solectron: provides manufacturing services to many different companies. Service q Nordstrom bases its reputation on providing a high quality of service to customers

1 -15 Just-In-Time JIT is a production control system that grew out of Toyota’s kanban system. It is a philosophy of production control (also know as lean production) that attempts to reduce inventories to an absolute minimum. It has become pretty much a standard way of thinking in many industries (especially the automobile. ) We will discuss JIT and its relationship to MRP in Chapter 7.

1 -15 Just-In-Time JIT is a production control system that grew out of Toyota’s kanban system. It is a philosophy of production control (also know as lean production) that attempts to reduce inventories to an absolute minimum. It has become pretty much a standard way of thinking in many industries (especially the automobile. ) We will discuss JIT and its relationship to MRP in Chapter 7.

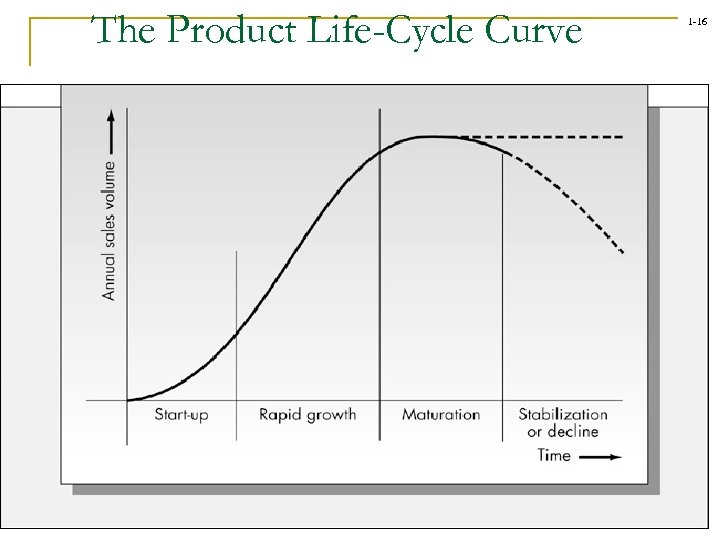

The Product Life-Cycle Curve 1 -16

The Product Life-Cycle Curve 1 -16

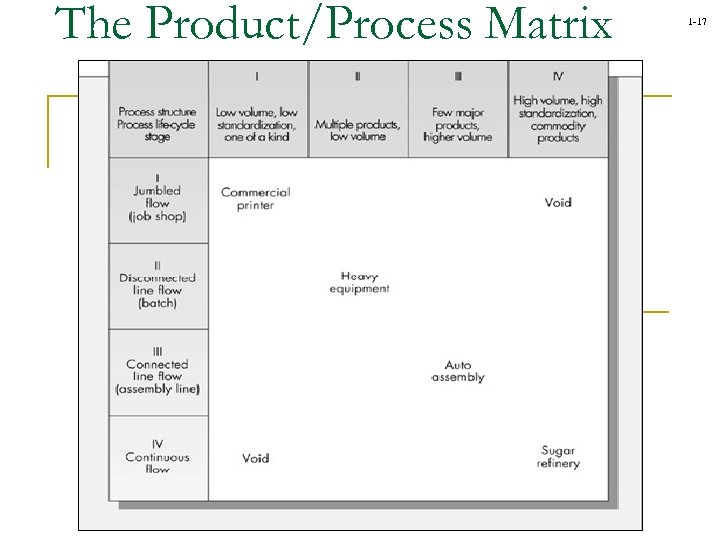

The Product/Process Matrix 1 -17

The Product/Process Matrix 1 -17

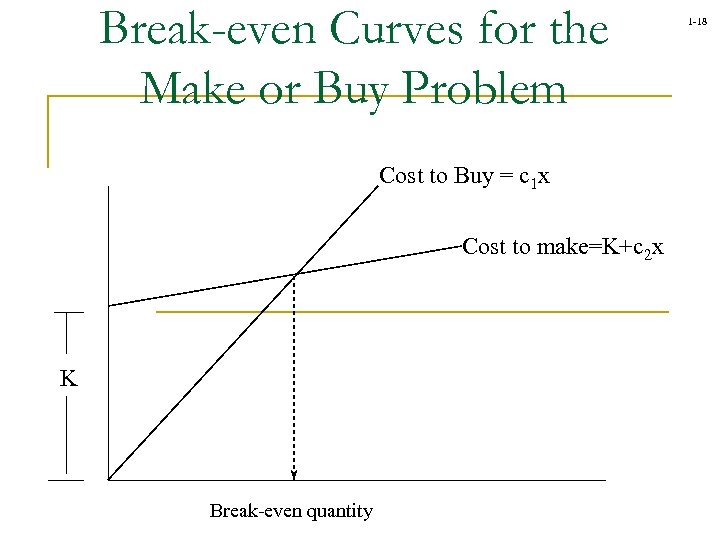

Break-even Curves for the Make or Buy Problem Cost to Buy = c 1 x Cost to make=K+c 2 x K Break-even quantity 1 -18

Break-even Curves for the Make or Buy Problem Cost to Buy = c 1 x Cost to make=K+c 2 x K Break-even quantity 1 -18

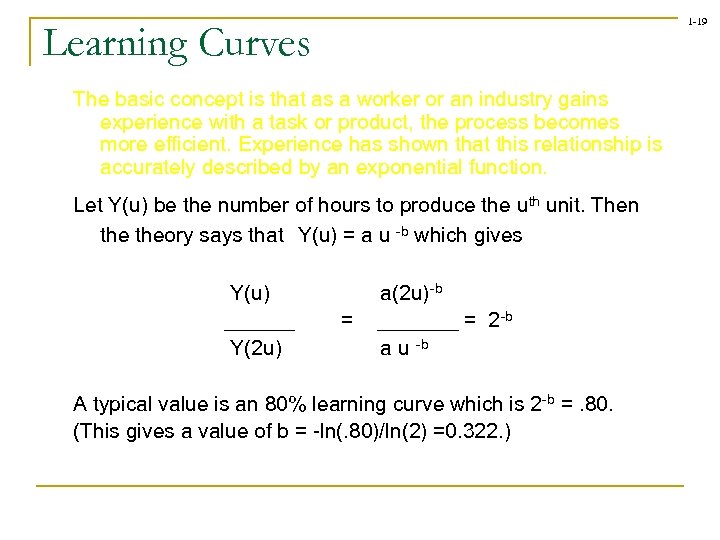

1 -19 Learning Curves The basic concept is that as a worker or an industry gains experience with a task or product, the process becomes more efficient. Experience has shown that this relationship is accurately described by an exponential function. Let Y(u) be the number of hours to produce the uth unit. Then theory says that Y(u) = a u -b which gives Y(u) ______ Y(2 u) = a(2 u) -b _______ = 2 -b a u -b A typical value is an 80% learning curve which is 2 -b =. 80. (This gives a value of b = -ln(. 80)/ln(2) =0. 322. )

1 -19 Learning Curves The basic concept is that as a worker or an industry gains experience with a task or product, the process becomes more efficient. Experience has shown that this relationship is accurately described by an exponential function. Let Y(u) be the number of hours to produce the uth unit. Then theory says that Y(u) = a u -b which gives Y(u) ______ Y(2 u) = a(2 u) -b _______ = 2 -b a u -b A typical value is an 80% learning curve which is 2 -b =. 80. (This gives a value of b = -ln(. 80)/ln(2) =0. 322. )

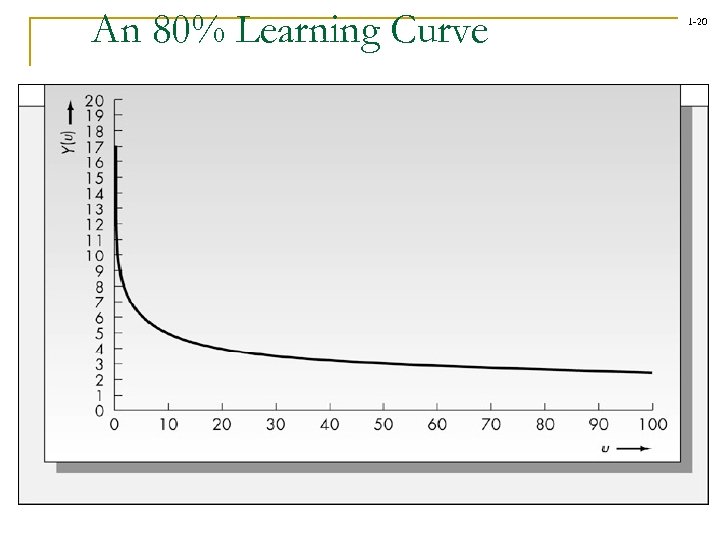

An 80% Learning Curve 1 -20

An 80% Learning Curve 1 -20

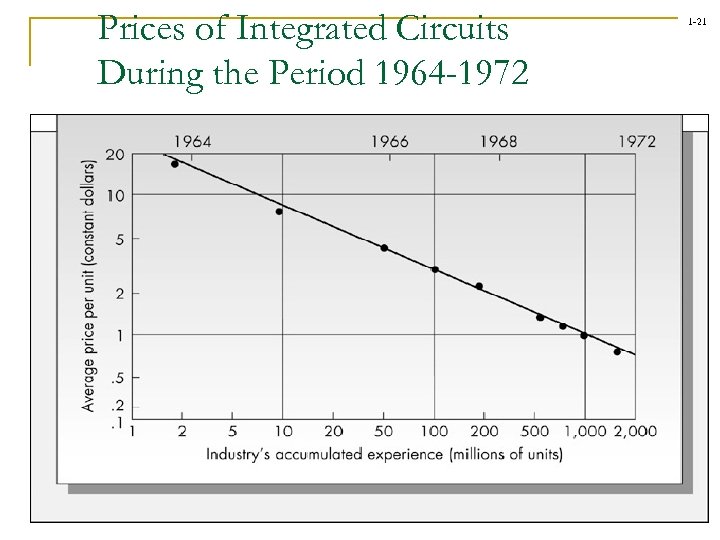

Prices of Integrated Circuits During the Period 1964 -1972 1 -21

Prices of Integrated Circuits During the Period 1964 -1972 1 -21

1 -22 Capacity Strategy Fundamental issues: q Amount. When adding capacity, what is the optimal amount to add? n n q q Too little means that more capacity will have to be added shortly afterwards. Too much means that capital will be wasted. Timing. What is the optimal time between adding new capacity? Type. Level of flexibility, automation, layout, process, level of customization, outsourcing, etc.

1 -22 Capacity Strategy Fundamental issues: q Amount. When adding capacity, what is the optimal amount to add? n n q q Too little means that more capacity will have to be added shortly afterwards. Too much means that capital will be wasted. Timing. What is the optimal time between adding new capacity? Type. Level of flexibility, automation, layout, process, level of customization, outsourcing, etc.

1 -23 Three Approaches to Capacity Strategy n Policy A: Try not to run short. Here capacity must lead demand, so on average there will be excess capacity. n Policy B: Build to forecast. Capacity additions should be timed so that the firm has excess capacity half the time and is short half the time. n Policy C: Maximize capacity utilization. Capacity additions lag demand, so that average demand is never met.

1 -23 Three Approaches to Capacity Strategy n Policy A: Try not to run short. Here capacity must lead demand, so on average there will be excess capacity. n Policy B: Build to forecast. Capacity additions should be timed so that the firm has excess capacity half the time and is short half the time. n Policy C: Maximize capacity utilization. Capacity additions lag demand, so that average demand is never met.

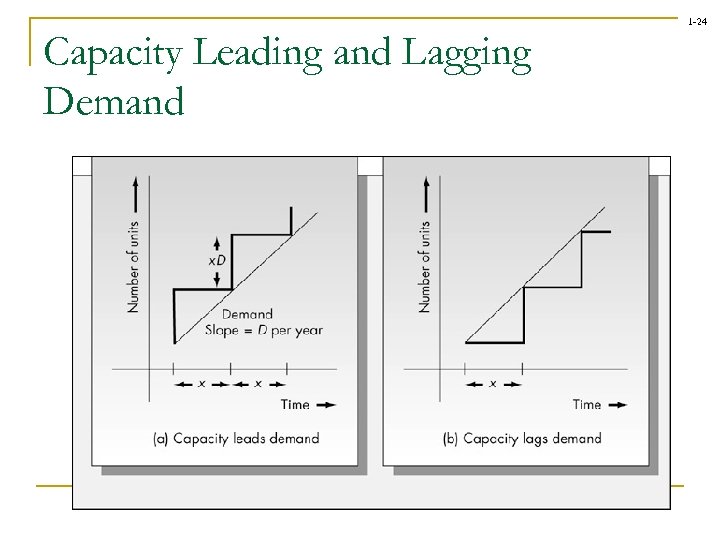

1 -24 Capacity Leading and Lagging Demand

1 -24 Capacity Leading and Lagging Demand

1 -25 Determinants of Capacity Strategy n n n Highly competitive industries (commodities, large number of suppliers, limited functional difference in products, time sensitive customers) – here shortages are very costly. Use Type A Policy. Monopolistic environment where manufacturer has power over the industry: Use Type C Policy. (Intel, Lockheed/Martin). Products that obsolete quickly, such as computer products. Want type C policy, but in competitive industry, such as computers, you will be gone if you cannot meet customer demand. Need best of both worlds: Dell Computer.

1 -25 Determinants of Capacity Strategy n n n Highly competitive industries (commodities, large number of suppliers, limited functional difference in products, time sensitive customers) – here shortages are very costly. Use Type A Policy. Monopolistic environment where manufacturer has power over the industry: Use Type C Policy. (Intel, Lockheed/Martin). Products that obsolete quickly, such as computer products. Want type C policy, but in competitive industry, such as computers, you will be gone if you cannot meet customer demand. Need best of both worlds: Dell Computer.

1 -26 Mathematical Model for Timing of Capacity Additions Let D = Annual Increase in Demand x = Time interval between adding capacity r = annual discount rate (compounded continuously) f(y) = Cost of operating a plant of capacity y Let C(x) be the total discounted cost of all capacity additions over an infinite horizon if new plants are built every x units of time. Then

1 -26 Mathematical Model for Timing of Capacity Additions Let D = Annual Increase in Demand x = Time interval between adding capacity r = annual discount rate (compounded continuously) f(y) = Cost of operating a plant of capacity y Let C(x) be the total discounted cost of all capacity additions over an infinite horizon if new plants are built every x units of time. Then

1 -27 Mathematical Model (continued n A typical form for the cost function f(y) is: Where k is a constant of proportionality, and a measures the ratio of incremental to average cost of a unit of plant capacity. A typical value is a=0. 6. Note that a<1 implies economies of scale in plant construction, since

1 -27 Mathematical Model (continued n A typical form for the cost function f(y) is: Where k is a constant of proportionality, and a measures the ratio of incremental to average cost of a unit of plant capacity. A typical value is a=0. 6. Note that a<1 implies economies of scale in plant construction, since

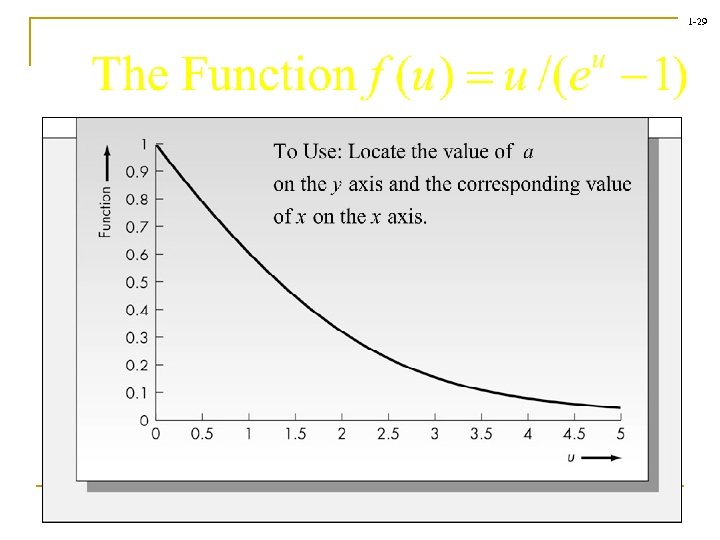

1 -28 Mathematical Model (continued) Hence, It can be shown that this function is minimized at x that satisfies the equation: This is known as a transcendental equation, and has no algebraic solution. However, using the graph on the next slide, one can find the optimal value of x or any value of a (0 < a < 1)

1 -28 Mathematical Model (continued) Hence, It can be shown that this function is minimized at x that satisfies the equation: This is known as a transcendental equation, and has no algebraic solution. However, using the graph on the next slide, one can find the optimal value of x or any value of a (0 < a < 1)

1 -29

1 -29

1 -30 Issues in Plant Location n n n n Size of the facility. Product lines. Process technology. Labor requirements. Utilities requirements Environmental issues. International considerations Tax Incentives.

1 -30 Issues in Plant Location n n n n Size of the facility. Product lines. Process technology. Labor requirements. Utilities requirements Environmental issues. International considerations Tax Incentives.