3e8a462a89833c13d23fdc579427c93c.ppt

- Количество слайдов: 8

03/21/2006 GLAST CU Beam Test Workshop Scanning Table <Oscar Ferreira / L. L. R Ecole Polytechnique> 1

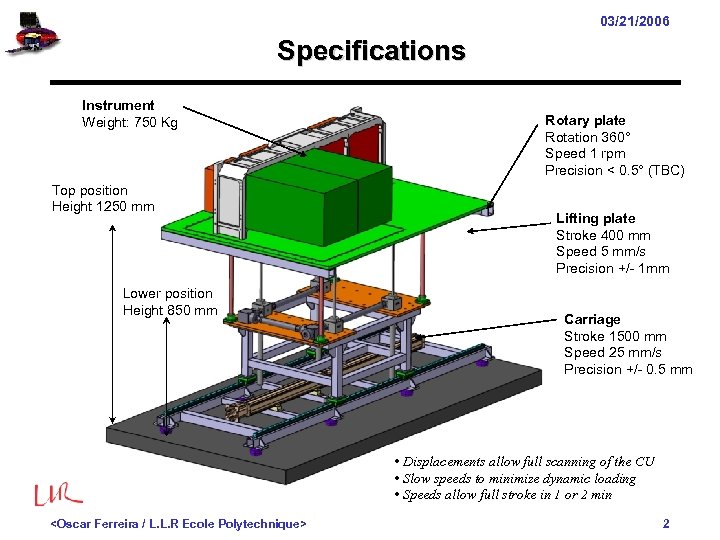

03/21/2006 Specifications Instrument Weight: 750 Kg Top position Height 1250 mm Lower position Height 850 mm Rotary plate Rotation 360° Speed 1 rpm Precision < 0. 5° (TBC) Lifting plate Stroke 400 mm Speed 5 mm/s Precision +/- 1 mm Carriage Stroke 1500 mm Speed 25 mm/s Precision +/- 0. 5 mm • Displacements allow full scanning of the CU • Slow speeds to minimize dynamic loading • Speeds allow full stroke in 1 or 2 min <Oscar Ferreira / L. L. R Ecole Polytechnique> 2

03/21/2006 Table control • All 3 axis motorized with stepper motors – Open loop control: no feedback on true position • 1 electronic board controlling 1 power module per axis – Modules mounted inside a control box attached to the carriage • PC connected to the control board to send move orders to the table – Local connection or cable from the control room – Serial link, optionally internet protocol (requires add-on bard) • Basic program language to communicate with the control board – “move to xx position” type of commands – Routines available to specific tasks: reference position • Development of simple GUI is planed for a more user-friendly control of the table • Reference position of the table defined by precision limit switches – Sensitivity +/- 1 motor step: negligible <Oscar Ferreira / L. L. R Ecole Polytechnique> 3

03/21/2006 Test Area Requirements • Space for to operate the table with CU mounted – 3 x 3 m² if 360° rotation of CU • Distance between ground and beam ~1300 mm – Ok for PS beam – Something needed at SPS to raise the table • Cement blocks? Additional removable structure? • Services – Power supply for the table control box • • Standard 220 AC, around 1 KW needed Handling of table – Plan is to have removable wheels to bring to table close to the test areas – Lifting equipment probably needed to position it in the beam (weight around 300 Kg) <Oscar Ferreira / L. L. R Ecole Polytechnique> 4

03/21/2006 Interfaces • Electrical: NA • Mechanical – Very simple due to CU mounted on large, stiff plate • Threaded holes for fasteners: already in the design based on current CAD model of the interface plate • Eventually additional holes for alignment pins • Cables – Only a few cables coming in and out of the CU but still a concern due to large strokes of the tables • Specific features need to be designed to deal with them <Oscar Ferreira / L. L. R Ecole Polytechnique> 5

03/21/2006 Security • Security features on table – Limit switches on 3 axis cabled on control board – Mechanical stops – Brake on motor lifting the table: won’t fall in case of power shutdown – General electrical shutdown • CERN Approval – Concern maybe not a problem: everything needs to be arranged before the table is sent to CERN – First contact with CERN security personnel but no feedback yet – Table should not fit in lifting equipment category but in machinery: needs to comply with European directive 98/37/CE • Certificate of Compliance required? => additional work, delay… <Oscar Ferreira / L. L. R Ecole Polytechnique> 6

03/21/2006 Resources - Planning • Budget: ok for 25 k€ – Money should be available by now at LLR: on time – Table more expensive than expected but most of the mechanical fabrication and assembly is done internally: compensates • Manpower: ok – Personnel from LLR available to deal with mechanical, electrical and software aspects • Planning: still on time – Mechanical design almost done: features to rotate the CU need to be reworked – First release of engineering drawings: allow fabrication work to start – Mechanical and electrical components chosen • Purchase order in early April, components available mid-May – 1 month for assembly and 2 weeks to test • Table ready in early July: safety margin is 2 weeks before shipping to CERN <Oscar Ferreira / L. L. R Ecole Polytechnique> 7

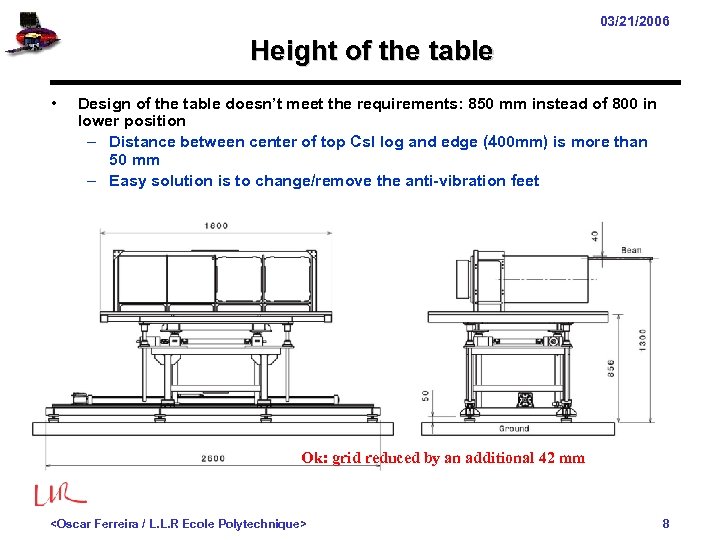

03/21/2006 Height of the table • Design of the table doesn’t meet the requirements: 850 mm instead of 800 in lower position – Distance between center of top Cs. I log and edge (400 mm) is more than 50 mm – Easy solution is to change/remove the anti-vibration feet Ok: grid reduced by an additional 42 mm <Oscar Ferreira / L. L. R Ecole Polytechnique> 8

3e8a462a89833c13d23fdc579427c93c.ppt